Importance of Interface in the Coarse-Grained Model of CNT /Epoxy Nanocomposites

Abstract

1. Introduction

2. Simulation Methods

2.1. Potentials and Molecular Models

2.1.1. All-Atomic Model

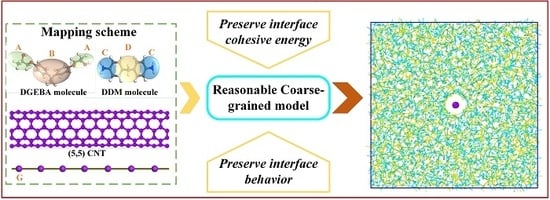

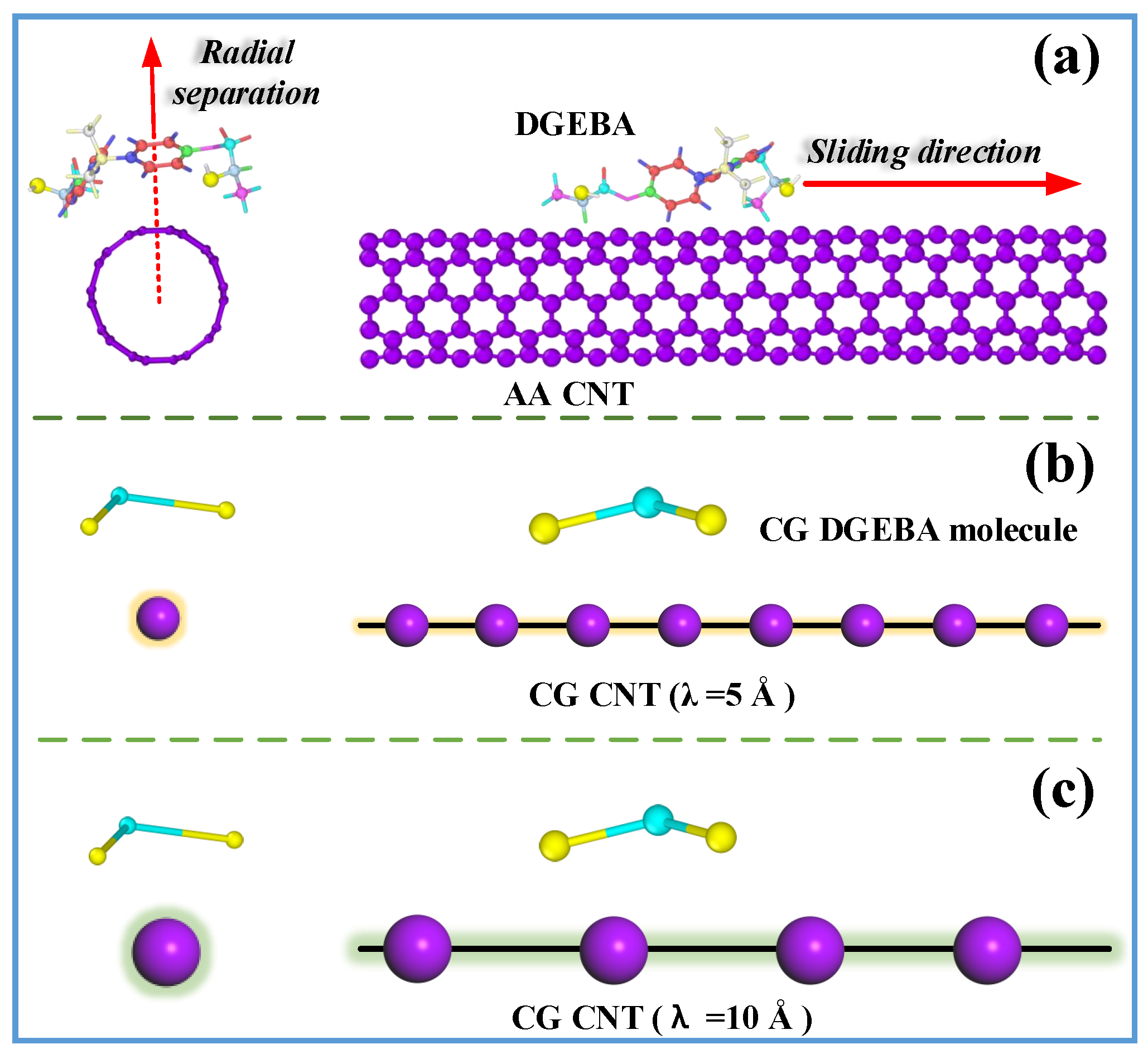

2.1.2. Coarse-Grained Model

2.2. Evaluation of the Interface Reasonability

2.2.1. Calculation of the Interfacial Cohesive Energy

2.2.2. Characterization of the Interface Load Transfer

3. Results And Discussion

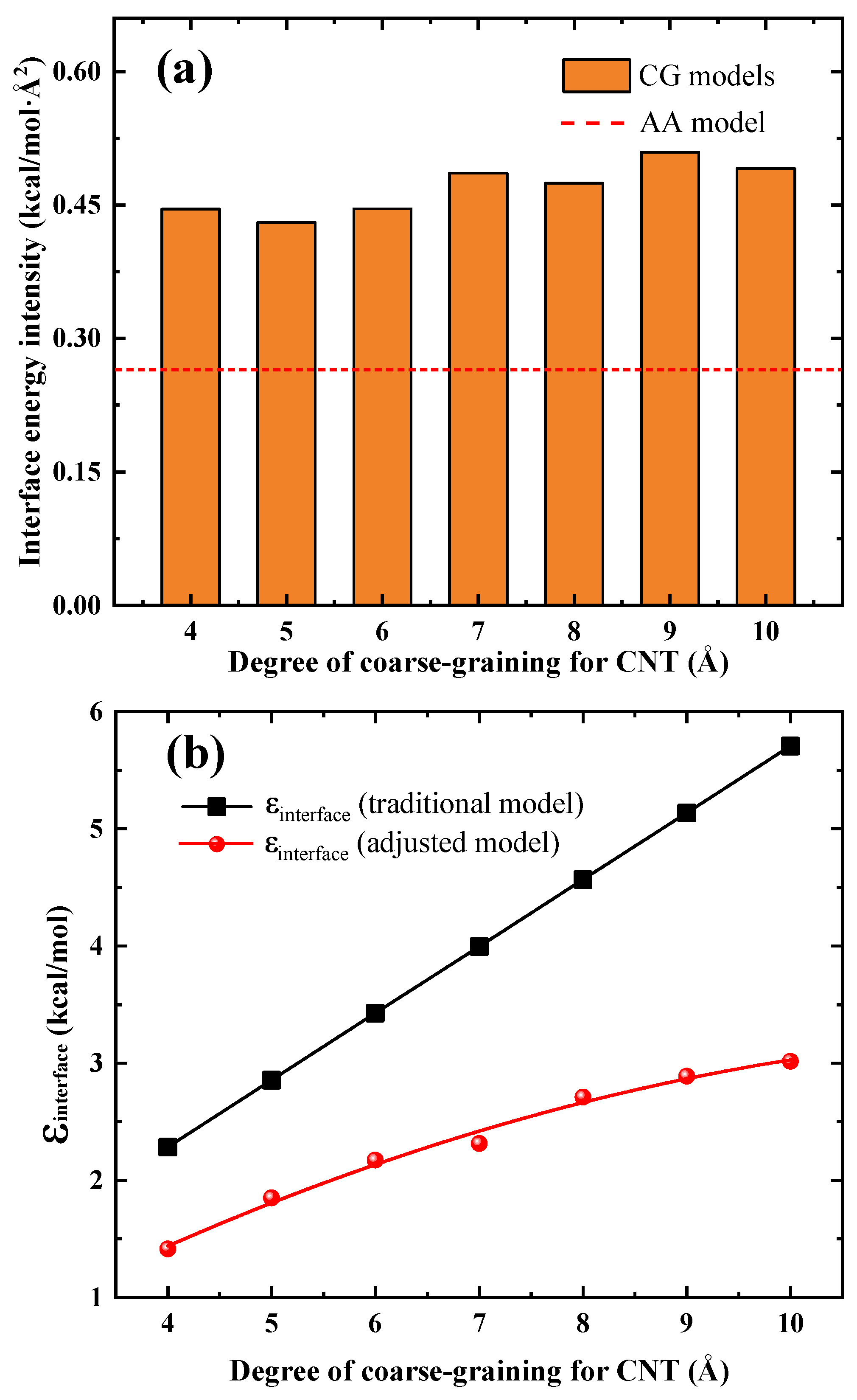

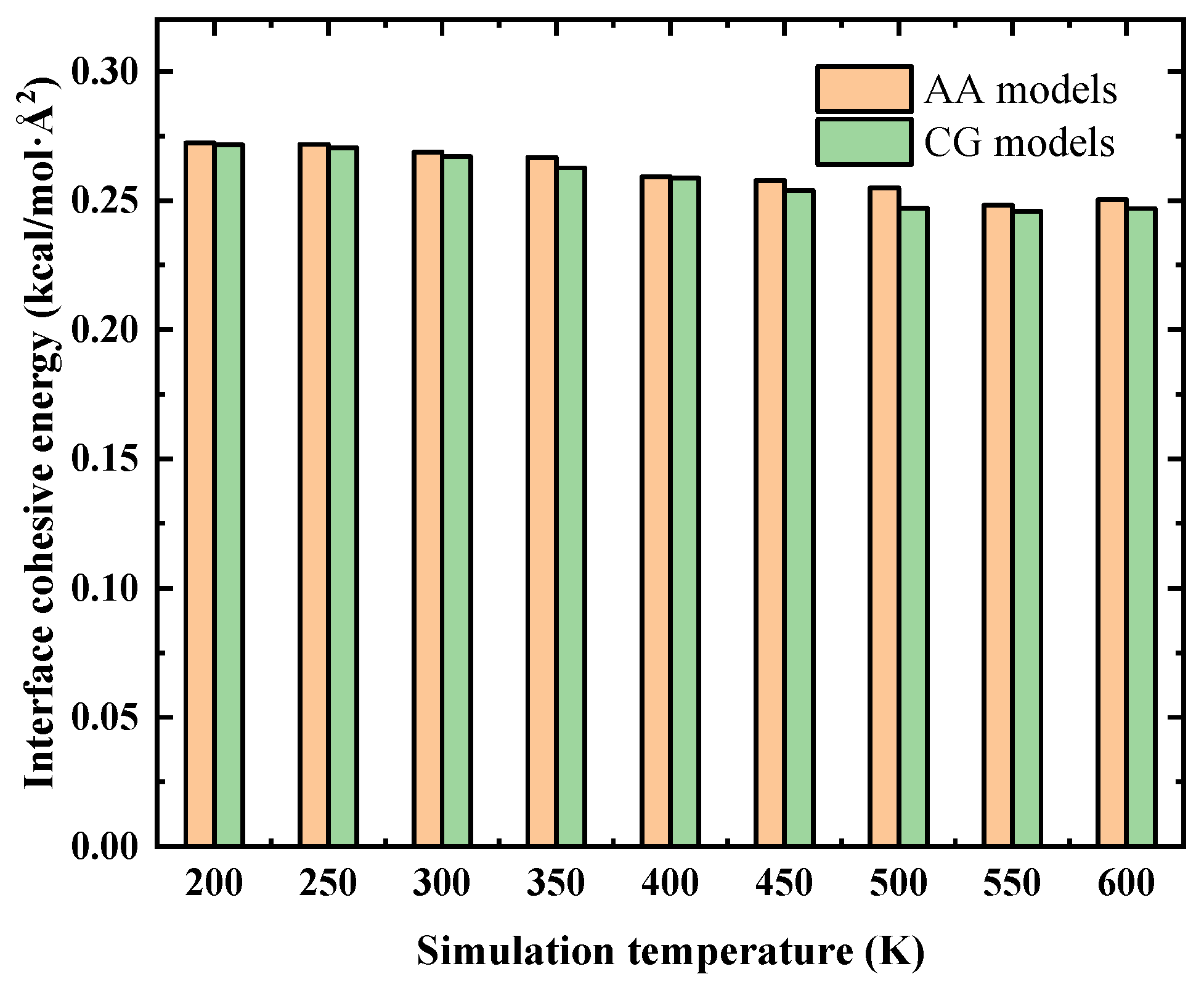

3.1. Preserve the Interface Cohesive Energies

3.2. Effects of on the Interfacial Load Transfer

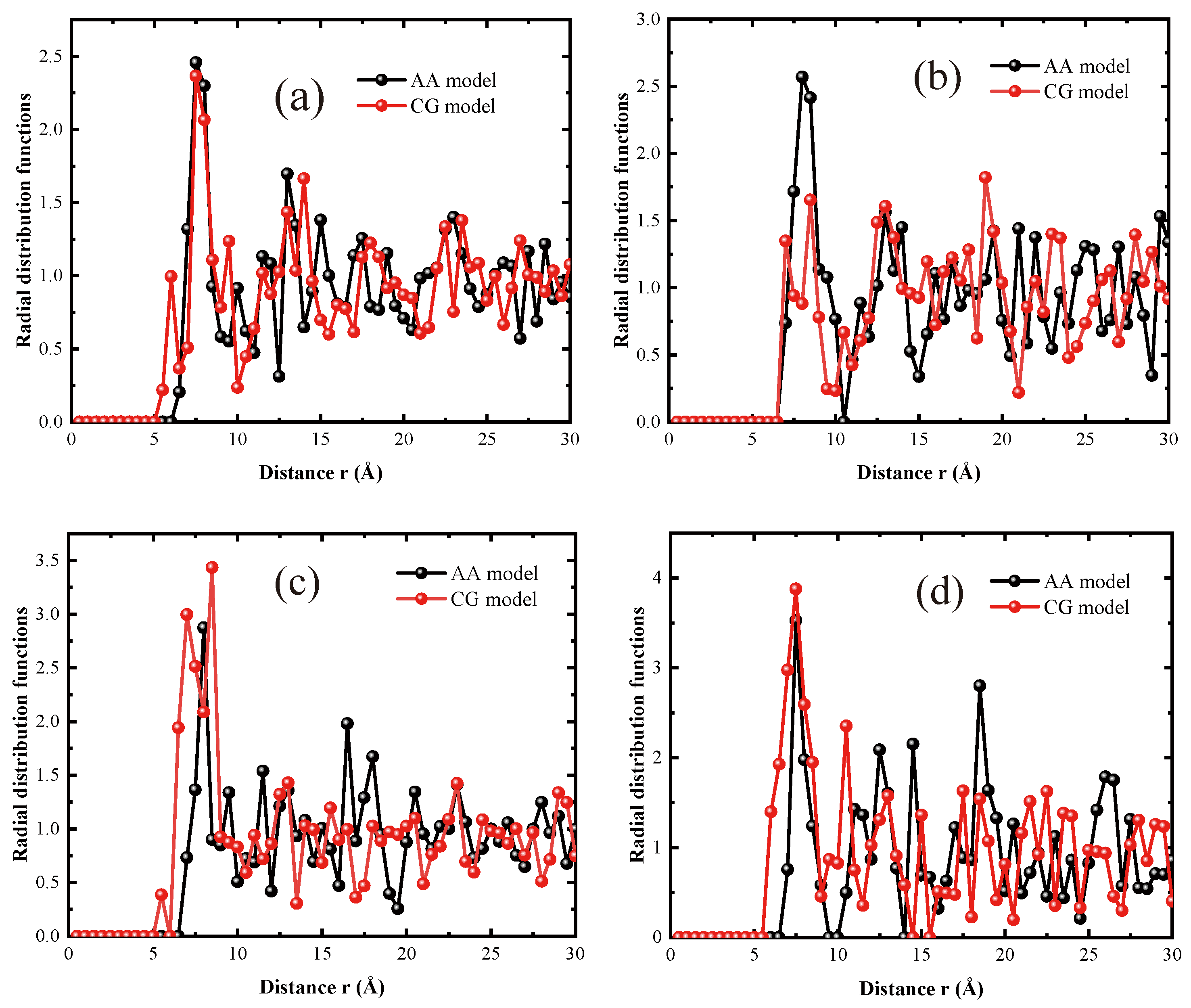

3.2.1. Separation Force Due to Radial Opening Mode

3.2.2. Sliding Force Due to Axial Sliding Mode

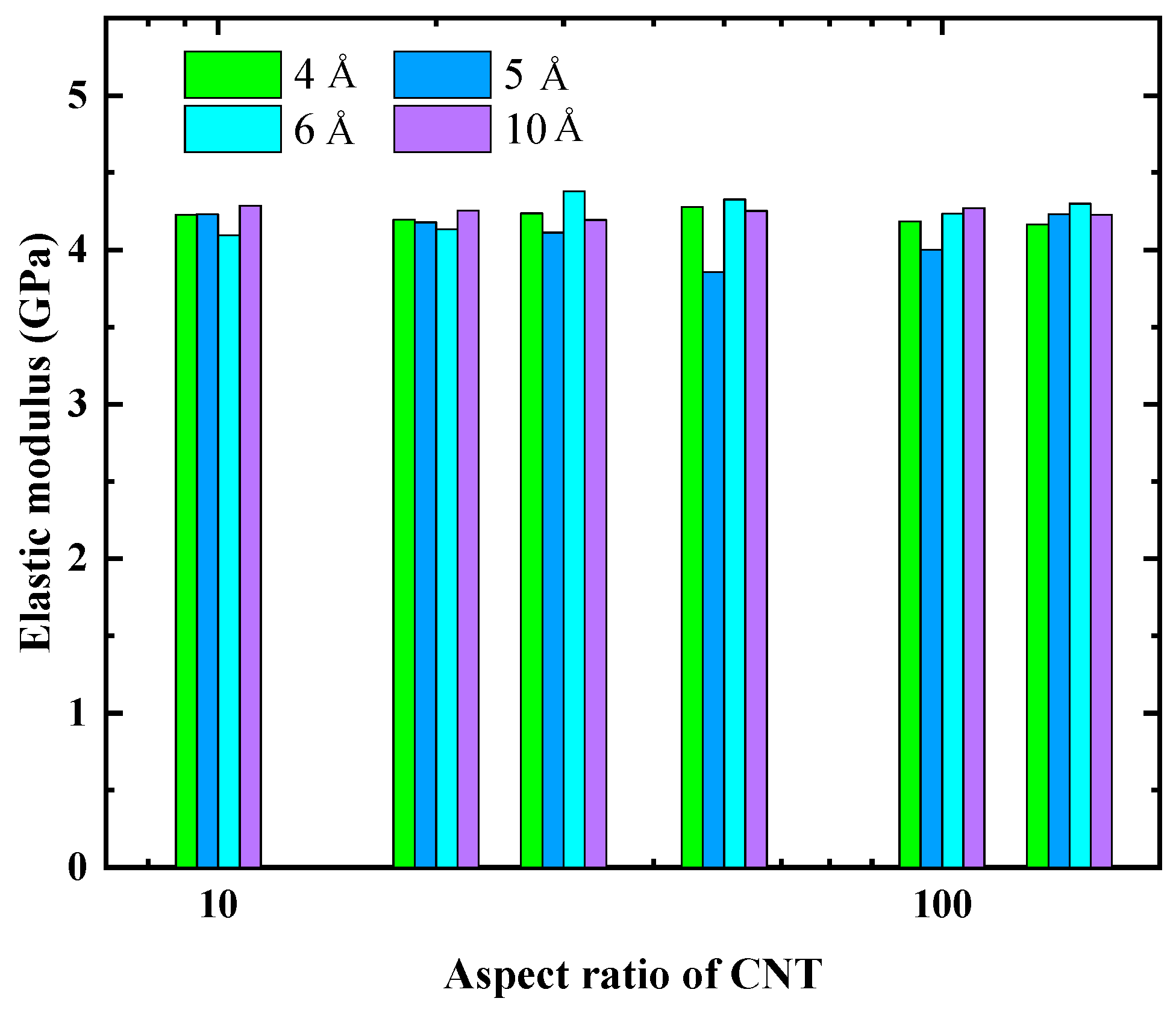

3.3. Effect of on Elastic Moduli

3.4. Determination of the Interface Force Fields

- For the reinforcement force fields, the selection of degree of coarse-graining for (5,5) CNT should be ∼5 Å, which provides a faithful approximation to the interface load transfer characteristics of the AA models (see potential parameters for CNT ( = 5 Å) in Supplementary Table S2).

- The cross-linked epoxy matrix force fields are based on our previous work and are shown in Supplementary Table S1 [23].

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Data Availability

References

- Andropova, U.; Tebeneva, N.; Serenko, O.; Tarasenkov, A.; Buzin, M.; Shaposhnikova, V.; Muzafarov, A. Nanocomposites based on polyarylene ether ketones from sol–gel process: Characterizations and prospect applications. Mater. Des. 2018, 160, 1052–1058. [Google Scholar] [CrossRef]

- Duan, K.; Li, Y.; Li, L.; Hu, Y.; Wang, X. Pillared graphene as excellent reinforcement for polymer-based nanocomposites. Mater. Des. 2018, 147, 11–18. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, H.P.; Li, X.; Tang, Y.; Yang, G. Crosslinked carbon nanofiber films with hierarchical pores as flexible electrodes for high performance supercapacitors. Mater. Des. 2018, 141, 17–25. [Google Scholar] [CrossRef]

- Martin-Gallego, M.; Yuste-Sanchez, V.; Sanchez-Hidalgo, R.; Verdejo, R.; Lopez-Manchado, M.A. Epoxy nanocomposites filled with carbon nanoparticles. Chem. Rec. 2018, 18, 928–939. [Google Scholar] [CrossRef]

- Kumar, S.K.; Benicewicz, B.C.; Vaia, R.A.; Winey, K.I. 50th anniversary perspective: Are polymer nanocomposites practical for applications? Macromolecules 2017, 50, 714–731. [Google Scholar] [CrossRef]

- Zhang, Z.; Luo, S.; Yu, S.; Guan, Z.; Sun, R.; Wong, C.P. Significantly enhanced dielectric and energy storage performance of blend polymer-based composites containing inorganic 3D–network. Mater. Des. 2018, 142, 106–113. [Google Scholar] [CrossRef]

- Moon, J.; Kim, B.; Choi, J.; Cho, M. Multiscale Study of the Relationship between Photoisomerization and Mechanical Behavior of Azo-Polymer Based on the Coarse-Grained Molecular Dynamics Simulation. Macromolecules 2019, 52, 2033–2049. [Google Scholar] [CrossRef]

- Yang, S.; Kwon, S.; Lee, M.Y.; Cho, M. Molecular dynamics and micromechanics study of hygroelastic behavior in graphene oxide-epoxy nanocomposites. Compos. Part B Eng. 2019, 164, 425–436. [Google Scholar] [CrossRef]

- Li, M.; Zhou, H.; Zhang, Y.; Liao, Y.; Zhou, H. Effect of defects on thermal conductivity of graphene/epoxy nanocomposites. Carbon 2018, 130, 295–303. [Google Scholar] [CrossRef]

- Guan, L.; Zhao, L.; Wan, Y.J.; Tang, L.C. Three-dimensional graphene-based polymer nanocomposites: Preparation, properties and applications. Nanoscale 2018, 10, 14788–14811. [Google Scholar] [CrossRef]

- Kausar, A.; Rafique, I.; Muhammad, B. Review of Applications of Polymer/Carbon Nanotubes and Epoxy/CNT Composites. Polym.-Plast. Technol. Eng. 2016, 55, 1167–1191. [Google Scholar] [CrossRef]

- Park, H.; Choi, J.; Kim, B.; Yang, S.; Shin, H.; Cho, M. Toward the constitutive modeling of epoxy matrix: Temperature-accelerated quasi-static molecular simulations consistent with the experimental test. Compos. Part B Eng. 2018, 142, 131–141. [Google Scholar] [CrossRef]

- Shin, H.; Choi, J.; Cho, M. An efficient multiscale homogenization modeling approach to describe hyperelastic behavior of polymer nanocomposites. Compos. Sci. Technol. 2019, 175, 128–134. [Google Scholar] [CrossRef]

- Bao, S.; Tjong, S. Mechanical behaviors of polypropylene/carbon nanotube nanocomposites: The effects of loading rate and temperature. Mater. Sci. Eng. A 2008, 485, 508–516. [Google Scholar] [CrossRef]

- Alian, A.R.; Meguid, S. Large-scale atomistic simulations of CNT-reinforced thermoplastic polymers. Compos. Struct. 2018, 191, 221–230. [Google Scholar] [CrossRef]

- Alian, A.; El-Borgi, S.; Meguid, S. Multiscale modeling of the effect of waviness and agglomeration of CNTs on the elastic properties of nanocomposites. Comput. Mater. Sci. 2016, 117, 195–204. [Google Scholar] [CrossRef]

- Zhang, W.; Deng, X.; Sui, G.; Yang, X. Improving interfacial and mechanical properties of carbon nanotube-sized carbon fiber/epoxy composites. Carbon 2019, 145, 629–639. [Google Scholar] [CrossRef]

- Zeng, Q.; Yu, A.; Lu, G. Multiscale modeling and simulation of polymer nanocomposites. Prog. Polym. Sci. 2008, 33, 191–269. [Google Scholar] [CrossRef]

- Paran, S.M.R.; Abdorahimi, M.; Shekarabi, A.; Khonakdar, H.A.; Jafari, S.H.; Saeb, M.R. Modeling and analysis of nonlinear elastoplastic behavior of compatibilized polyolefin/polyester/clay nanocomposites with emphasis on interfacial interaction exploration. Compos. Sci. Technol. 2018, 154, 92–103. [Google Scholar] [CrossRef]

- Zhang, X.; Nguyen, H.; Daly, M.; Nguyen, S.T.; Espinosa, H.D. Nanoscale toughening of ultrathin graphene oxide-polymer composites: Mechanochemical insights into hydrogen-bonding/van der Waals interactions, polymer chain alignment, and steric parameters. Nanoscale 2019, 11, 12305–12316. [Google Scholar] [CrossRef]

- Arash, B.; Park, H.S.; Rabczuk, T. Mechanical properties of carbon nanotube reinforced polymer nanocomposites: A coarse-grained model. Compos. Part B Eng. 2015, 80, 92–100. [Google Scholar] [CrossRef]

- Xia, W.; Hansoge, N.K.; Xu, W.S.; Phelan, F.R.; Keten, S.; Douglas, J.F. Energy renormalization for coarse-graining polymers having different segmental structures. Sci. Adv. 2019, 5, eaav4683. [Google Scholar] [CrossRef] [PubMed]

- Duan, K.; He, Y.; Li, Y.; Liu, J.; Zhang, J.; Hu, Y.; Lin, R.; Wang, X.; Deng, W.; Li, L. Machine-learning assisted coarse-grained model for epoxies over wide ranges of temperatures and cross-linking degrees. Mater. Des. 2019, 183, 108130. [Google Scholar] [CrossRef]

- Noid, W.G. Perspective: Coarse-grained models for biomolecular systems. J. Chem. Phys. 2013, 139, 090901. [Google Scholar] [CrossRef]

- Dirk, R.; Mathias, P.; Florian, M.P. Deriving effective mesoscale potentials from atomistic simulations. J. Comput. Chem. 2003, 24, 1624–1636. [Google Scholar]

- Izvekov, S.; Roth, G.A. A multiscale coarse-graining method for biomolecular systems. J. Phys. Chem. B 2005, 109, 2469–2473. [Google Scholar] [CrossRef]

- Noid, W.G.; Chu, J.W.; Ayton, G.S.; Krishna, V.; Izvekov, S.; Voth, G.A.; Das, A.; Andersen, H.C. The multiscale coarse-graining method. I. A rigorous bridge between atomistic and coarse-grained models. J. Chem. Phys. 2008, 128, 244114. [Google Scholar] [CrossRef]

- Lyubartsev, A.P.; Laaksonen, A. Calculation of effective interaction potentials from radial distribution functions: A reverse Monte Carlo approach. Phys. Rev. E 2008, 52, 3730. [Google Scholar] [CrossRef]

- Buehler, J.M. Mesoscale modeling of mechanics of carbon nanotubes: Self-assembly, self-folding, and fracture. J. Mater. Res. 2006, 21, 2855–2869. [Google Scholar] [CrossRef]

- Li, Y.; Abberton, B.C.; Kroger, M.; Liu, W.K. Challenges in Multiscale Modeling of Polymer Dynamics. Polymers 2013, 5, 751–832. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, J.W.; Wang, L.; Guo, W.; Rabczuk, T. Coarse-grained potentials of single-walled carbon nanotubes. J. Mech. Phys. Solids 2014, 71, 197–218. [Google Scholar] [CrossRef]

- Arash, B.; Park, H.S.; Rabczuk, T. Coarse-grained model of the J-integral of carbon nanotube reinforced polymer composites. Carbon 2016, 96, 1084–1092. [Google Scholar] [CrossRef]

- Mayo, S.L.; Olafson, B.D.; Goddard, W.A. DREIDING: A generic force field for molecular simulations. J. Phys. Chem. 1990, 94, 8897–8909. [Google Scholar] [CrossRef]

- Dauber-Osguthorpe, P.; Roberts, V.A.; Osguthorpe, D.J.; Wolff, J.; Genest, M.; Hagler, A.T. Structure and energetics of ligand binding to proteins: Escherichia coli dihydrofolate reductase-trimethoprim, a drug-receptor system. Proteins 1988, 4, 31–47. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Mumby, S.J.; Maple, J.R.; Hagler, A.T. An ab initio CFF93 all-atom force field for polycarbonates. J. Am. Chem. Soc. 1994, 116, 2978–2987. [Google Scholar] [CrossRef]

- Rappe, A.K.; Goddard, W.A., III. Charge equilibration for molecular dynamics simulations. J. Phys. Chem. 1991, 95, 3358–3363. [Google Scholar] [CrossRef]

- Duan, K.; Zhang, J.; Li, L.; Hu, Y.; Zhu, W.; Wang, X. Diamond nanothreads as novel nanofillers for cross-linked epoxy nanocomposites. Compos. Sci. Technol. 2019, 174, 84–93. [Google Scholar] [CrossRef]

- Li, Y.; Kröger, M. Viscoelasticity of carbon nanotube buckypaper: Zipping–unzipping mechanism and entanglement effects. Soft Matter 2012, 8, 7822–7830. [Google Scholar] [CrossRef]

- Liu, X.; Lu, W.; Ayala, O.M.; Wang, L.P.; Karlsson, A.M.; Yang, Q.; Chou, T.W. Microstructural evolution of carbon nanotube fibers: Deformation and strength mechanism. Nanoscale 2013, 5, 2002–2008. [Google Scholar] [CrossRef]

- Shen, Z.; Röding, M.; Kröger, M.; Li, Y. Carbon nanotube length governs the viscoelasticity and permeability of buckypaper. Polymers 2017, 9, 115. [Google Scholar] [CrossRef]

- Sengab, A.; Picu, R.C. Mechanical behavior of carbon nanotube yarns with stochastic microstructure obtained by stretching buckypaper. Compos. Sci. Technol. 2018, 166, 54–65. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Choi, J.; Shin, H.; Cho, M. A multiscale mechanical model for the effective interphase of SWNT/epoxy nanocomposite. Polymer 2016, 89, 159–171. [Google Scholar] [CrossRef]

- Awasthi, A.P.; Lagoudas, D.C.; Hammerand, D.C. Modeling of graphene–polymer interfacial mechanical behavior using molecular dynamics. Model. Simul. Mater. Sci. Eng. 2008, 17, 015002. [Google Scholar] [CrossRef]

- Li, Y.; Seidel, G.D. Multiscale modeling of the effects of nanoscale load transfer on the effective elastic properties of unfunctionalized carbon nanotube–polyethylene nanocomposites. Model. Simul. Mater. Sci. Eng. 2014, 22, 025023. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhuang, X.; Muthu, J.; Mabrouki, T.; Fontaine, M.; Gong, Y.; Rabczuk, T. Load transfer of graphene/carbon nanotube/polyethylene hybrid nanocomposite by molecular dynamics simulation. Compos. Part B Eng. 2014, 63, 27–33. [Google Scholar] [CrossRef]

- Wang, T.; Dalton, A.B.; Keddie, J.L. Importance of Molecular Friction in a Soft Polymer-Nanotube Nanocomposite. Macromolecules 2008, 41, 7656–7661. [Google Scholar] [CrossRef]

- Lordi, V.; Yao, N. Molecular mechanics of binding in carbon-nanotube–polymer composites. J. Mater. Res. 2000, 15, 2770–2779. [Google Scholar] [CrossRef]

- Lebold, K.M.; Noid, W.G. Dual approach for effective potentials that accurately model structure and energies. J. Chem. Phys. 2019, 150, 234107. [Google Scholar] [CrossRef]

- Lebold, K.M.; Noid, W.G. Systematic study of temperature and density variations in effective potentials for coarse-grained models of molecular liquids. J. Chem. Phys. 2019, 150, 014104. [Google Scholar] [CrossRef] [PubMed]

- DeLyser, M.R.; Noid, W.G. Extending pressure-matching to inhomogeneous systems via local-density potentials. J. Chem. Phys. 2017, 147, 134111. [Google Scholar] [CrossRef] [PubMed]

- Dwaikat, M.; Spitas, C.; Spitas, V. Predicting nonlinear stress-strain curves of unidirectional fibrous composites in consideration of stick-slip. Compos. Part B Eng. 2013, 44, 501–507. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Rafiee, R. Investigation of nanotube length effect on the reinforcement efficiency in carbon nanotube based composites. Compos. Struct. 2010, 92, 2415–2420. [Google Scholar] [CrossRef]

- Karimi, M.; Montazeri, A.; Ghajar, R. On the elasto-plastic behavior of CNT-polymer nanocomposites. Compos. Struct. 2017, 160, 782–791. [Google Scholar] [CrossRef]

- Vu-Bac, N.; Rafiee, R.; Zhuang, X.; Lahmer, T.; Rabczuk, T. Uncertainty quantification for multiscale modeling of polymer nanocomposites with correlated parameters. Compos. Part B Eng. 2015, 68, 446–464. [Google Scholar] [CrossRef]

- Gao, X.L.; Li, K. A shear-lag model for carbon nanotube-reinforced polymer composites. Int. J. Solids Struct. 2005, 42, 1649–1667. [Google Scholar] [CrossRef]

- Li, X.; Gao, H.; Scrivens, W.A.; Fei, D.; Xu, X.; Sutton, M.A.; Reynolds, A.P.; Myrick, M.L. Nanomechanical characterization of single-walled carbon nanotube reinforced epoxy composites. Nanotechnology 2004, 15, 1416–1423. [Google Scholar] [CrossRef]

| DOC-60 | DOC-70 | DOC-80 | DOC-90 | |

|---|---|---|---|---|

| AA models | 0.272 | 0.271 | 0.270 | 0.269 |

| CG models | 0.219 | 0.229 | 0.242 | 0.269 |

| CG-adjusted | 0.272 | 0.271 | 0.270 | 0.269 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, K.; Li, L.; Wang, F.; Meng, W.; Hu, Y.; Wang, X. Importance of Interface in the Coarse-Grained Model of CNT /Epoxy Nanocomposites. Nanomaterials 2019, 9, 1479. https://doi.org/10.3390/nano9101479

Duan K, Li L, Wang F, Meng W, Hu Y, Wang X. Importance of Interface in the Coarse-Grained Model of CNT /Epoxy Nanocomposites. Nanomaterials. 2019; 9(10):1479. https://doi.org/10.3390/nano9101479

Chicago/Turabian StyleDuan, Ke, Li Li, Fei Wang, Weishuang Meng, Yujin Hu, and Xuelin Wang. 2019. "Importance of Interface in the Coarse-Grained Model of CNT /Epoxy Nanocomposites" Nanomaterials 9, no. 10: 1479. https://doi.org/10.3390/nano9101479

APA StyleDuan, K., Li, L., Wang, F., Meng, W., Hu, Y., & Wang, X. (2019). Importance of Interface in the Coarse-Grained Model of CNT /Epoxy Nanocomposites. Nanomaterials, 9(10), 1479. https://doi.org/10.3390/nano9101479