Molecular Dynamics Simulation on Mechanical and Piezoelectric Properties of Boron Nitride Honeycomb Structures

Abstract

1. Introduction

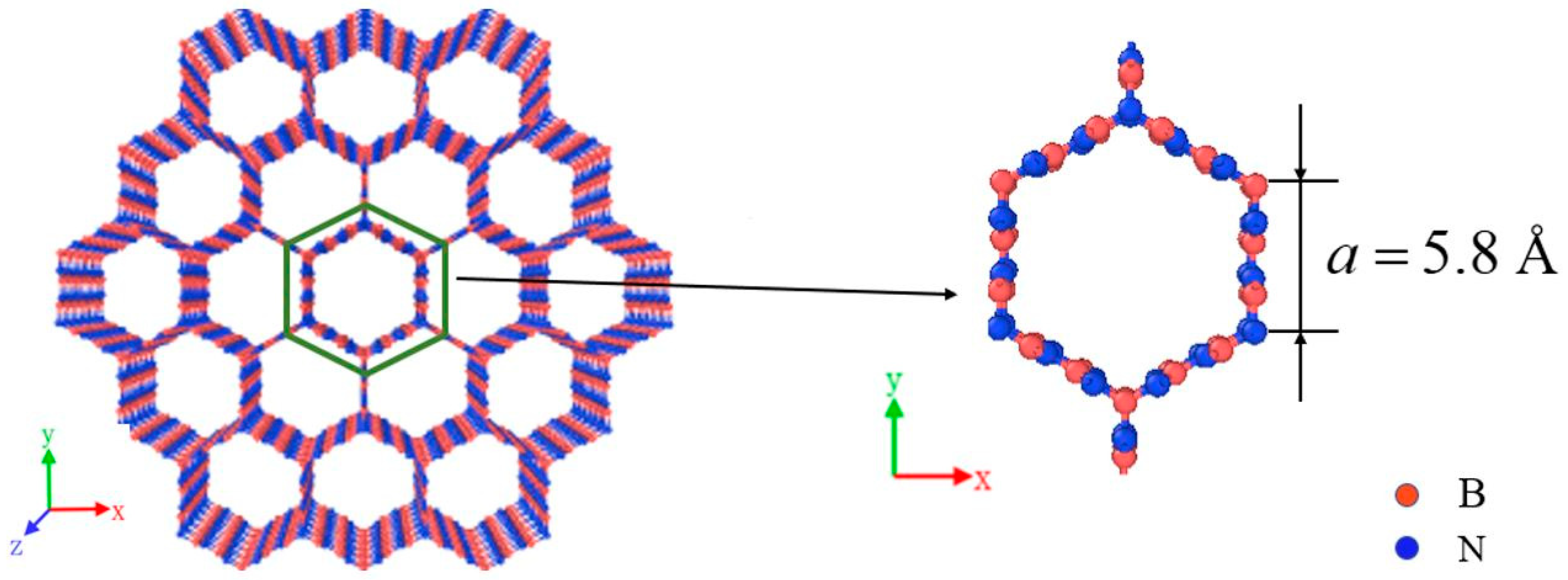

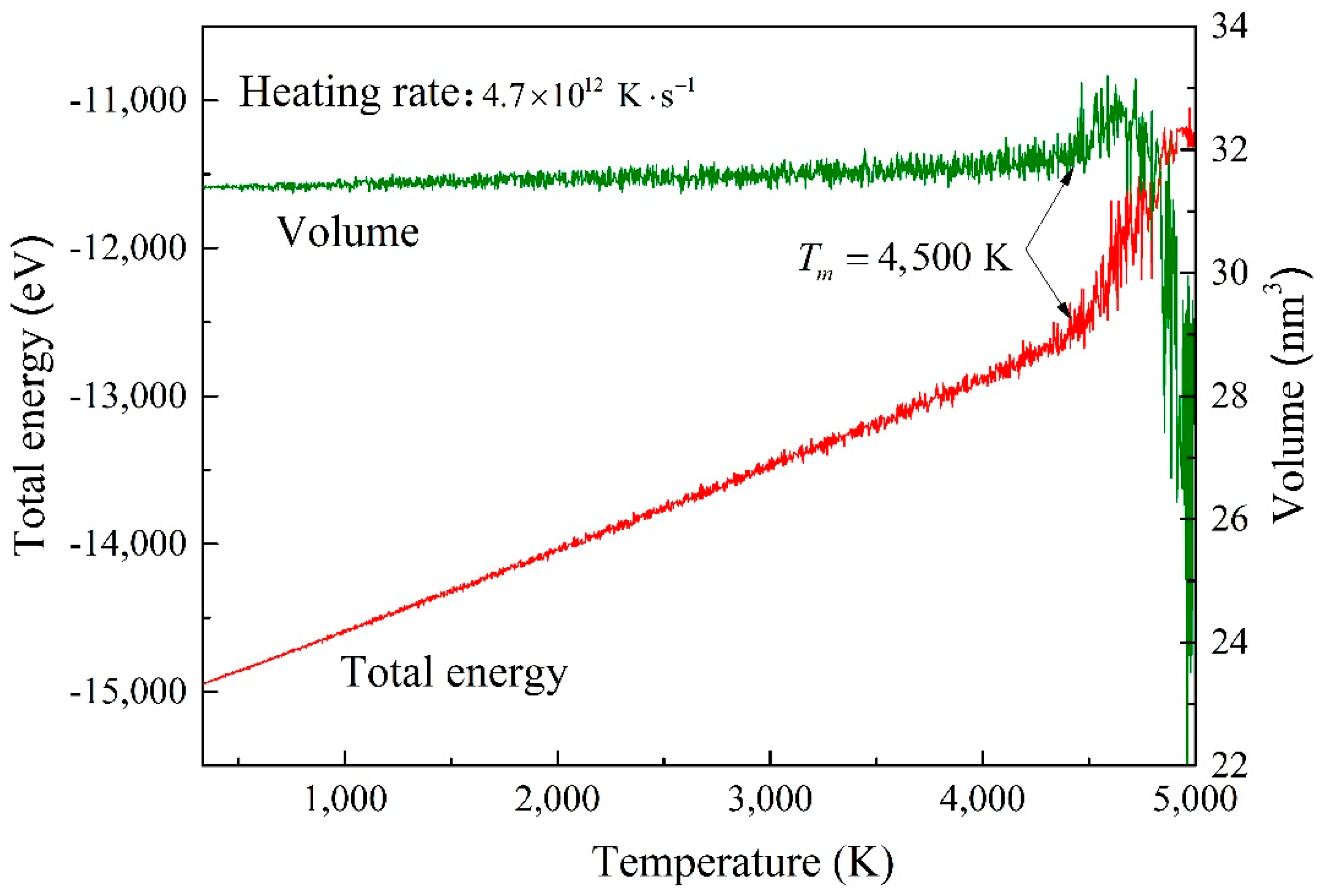

2. Materials and Methods

2.1. MD Simulations for Tensile Mechanical Properties of BNHCs

2.2. MD Simulations for Piezoelectric Properties of BNHCs

3. Results and Discussion

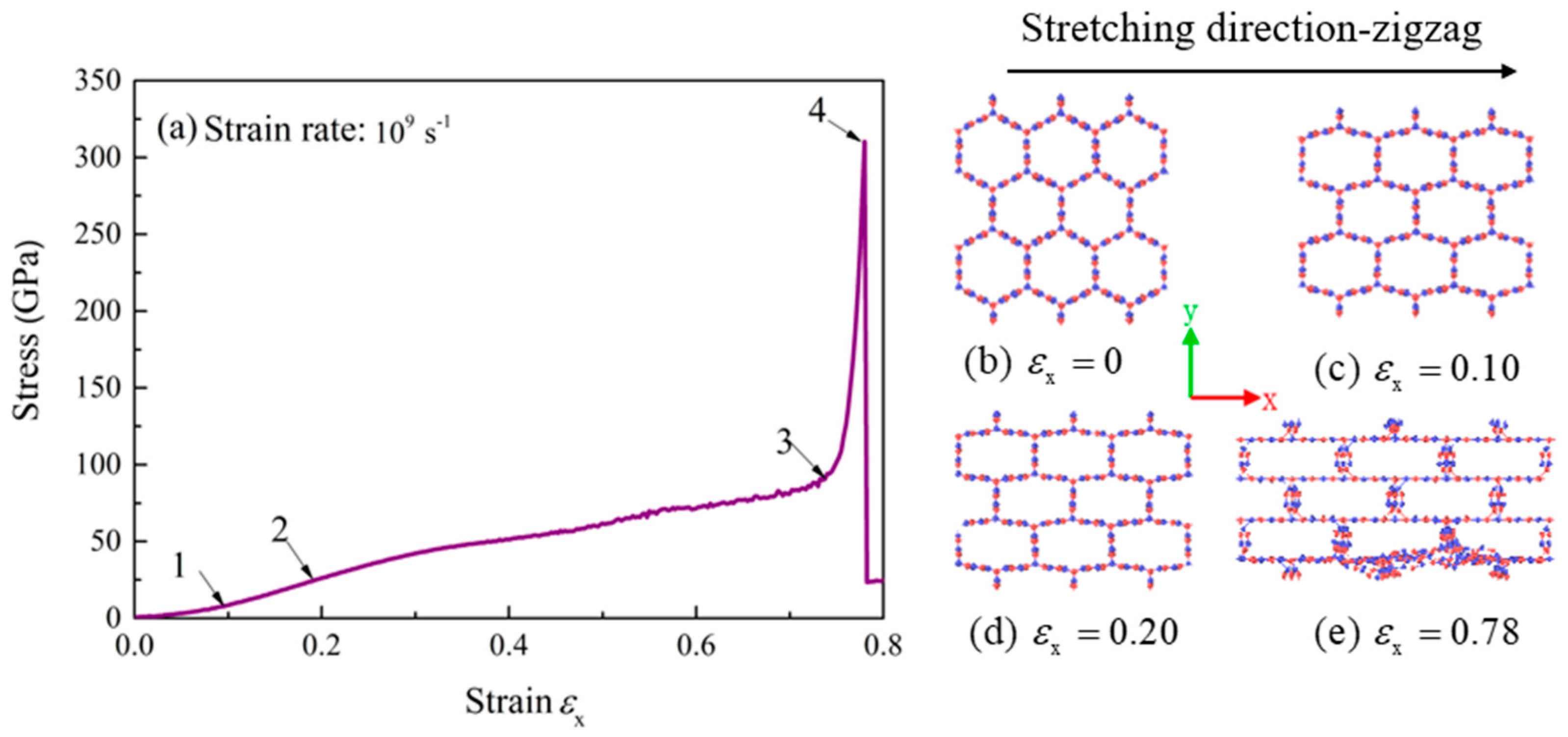

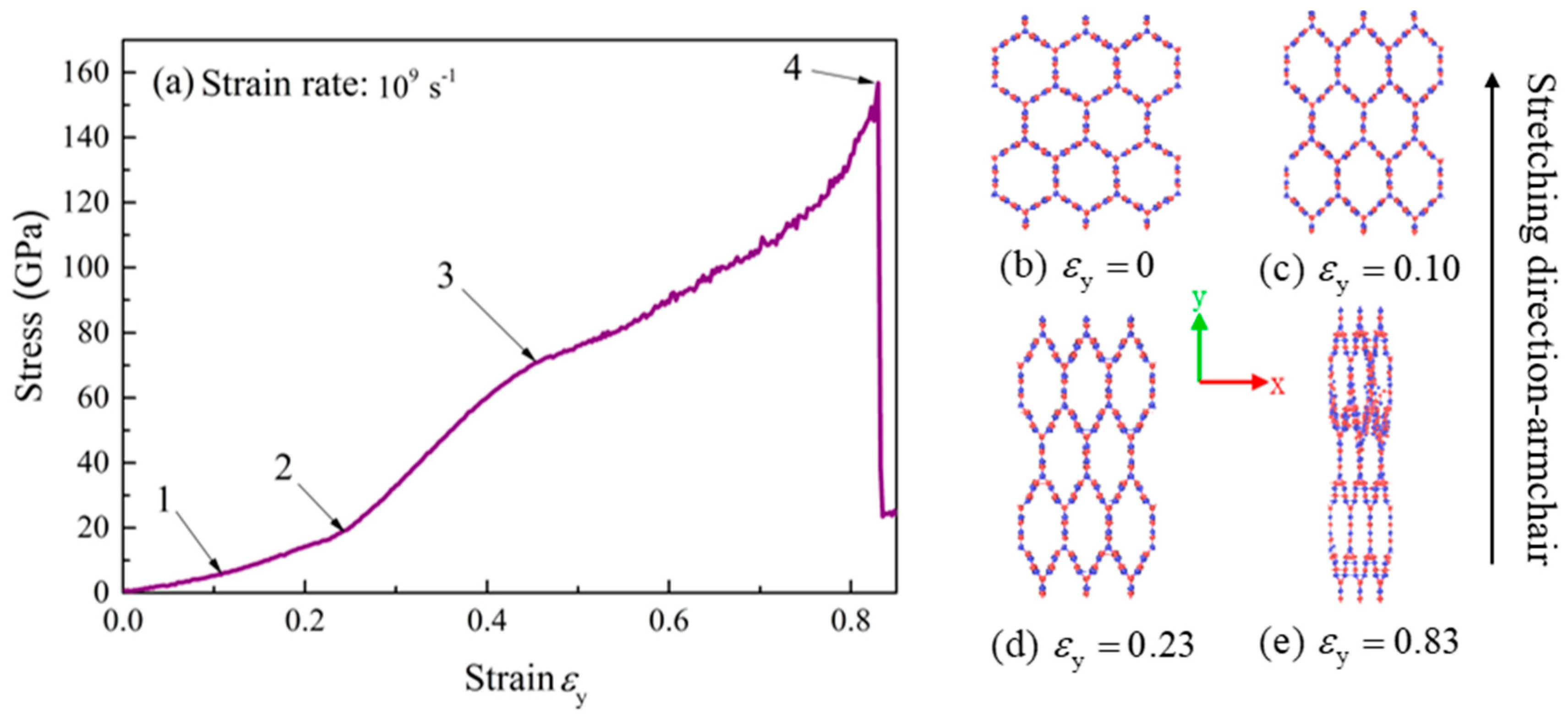

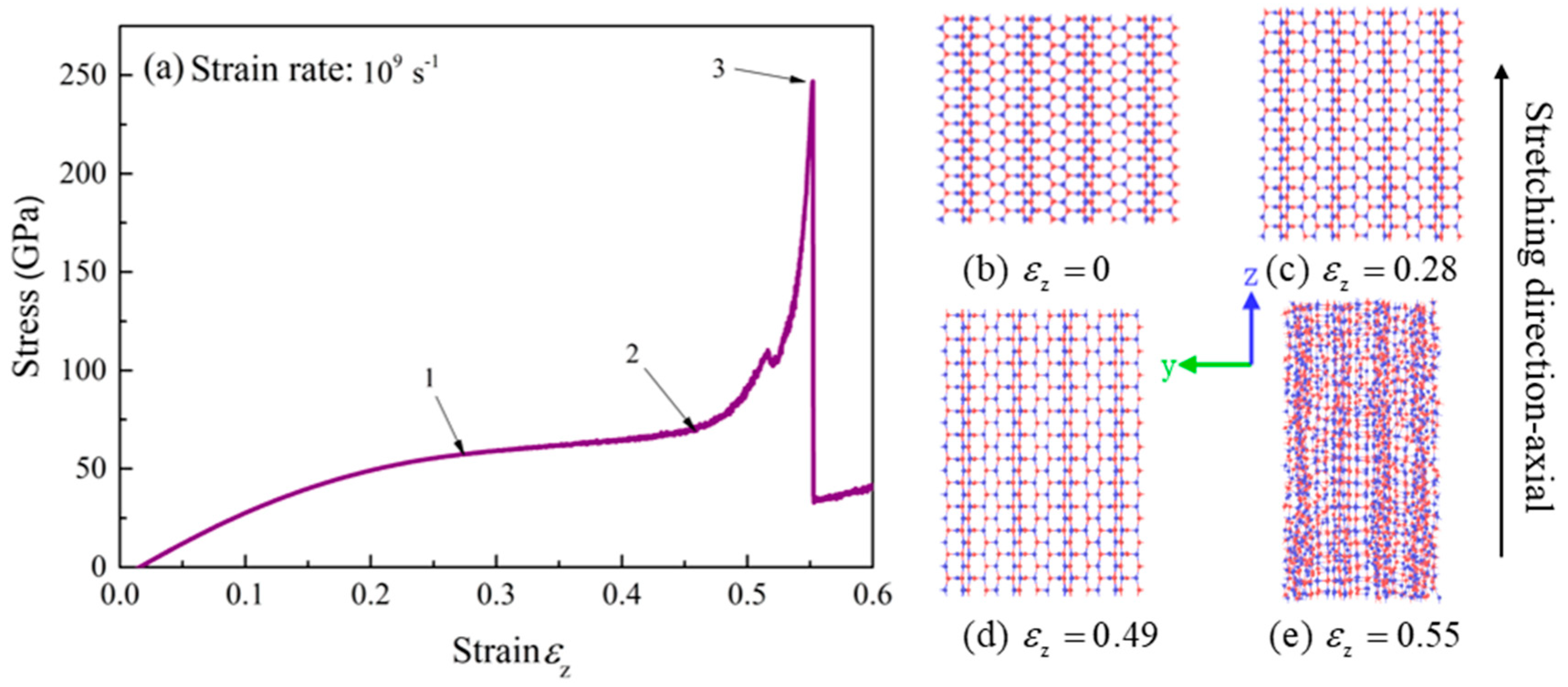

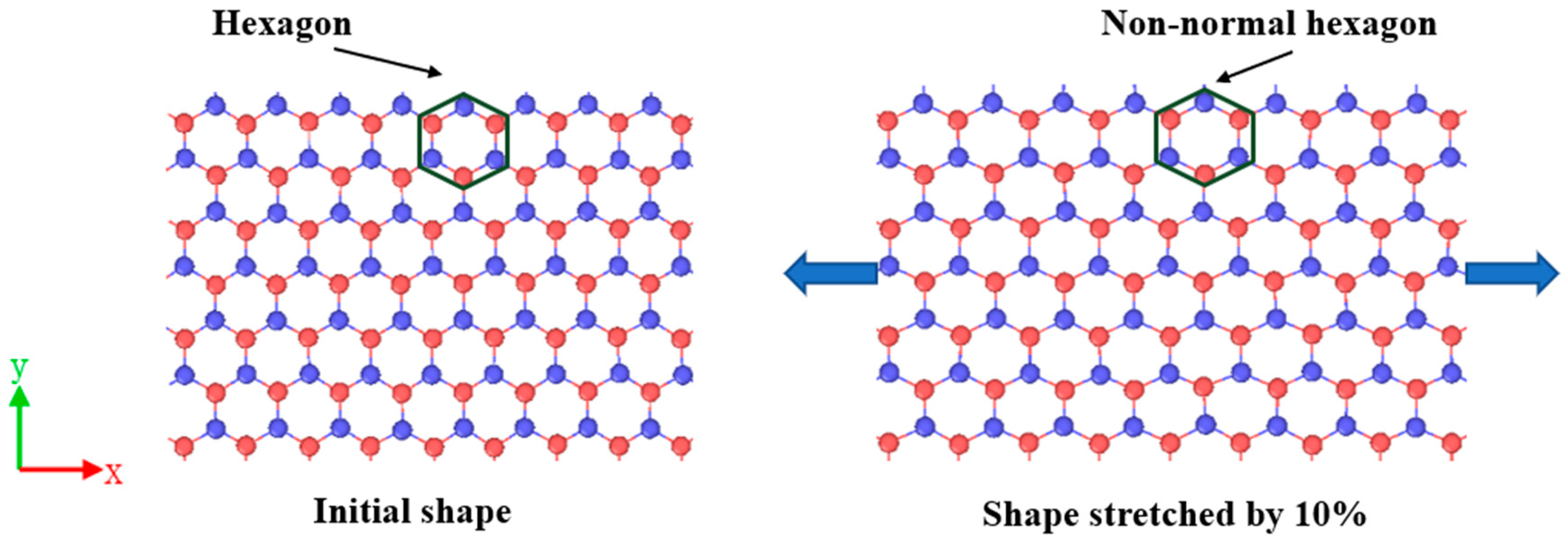

3.1. Tensile Mechanical Properties of BNHCs

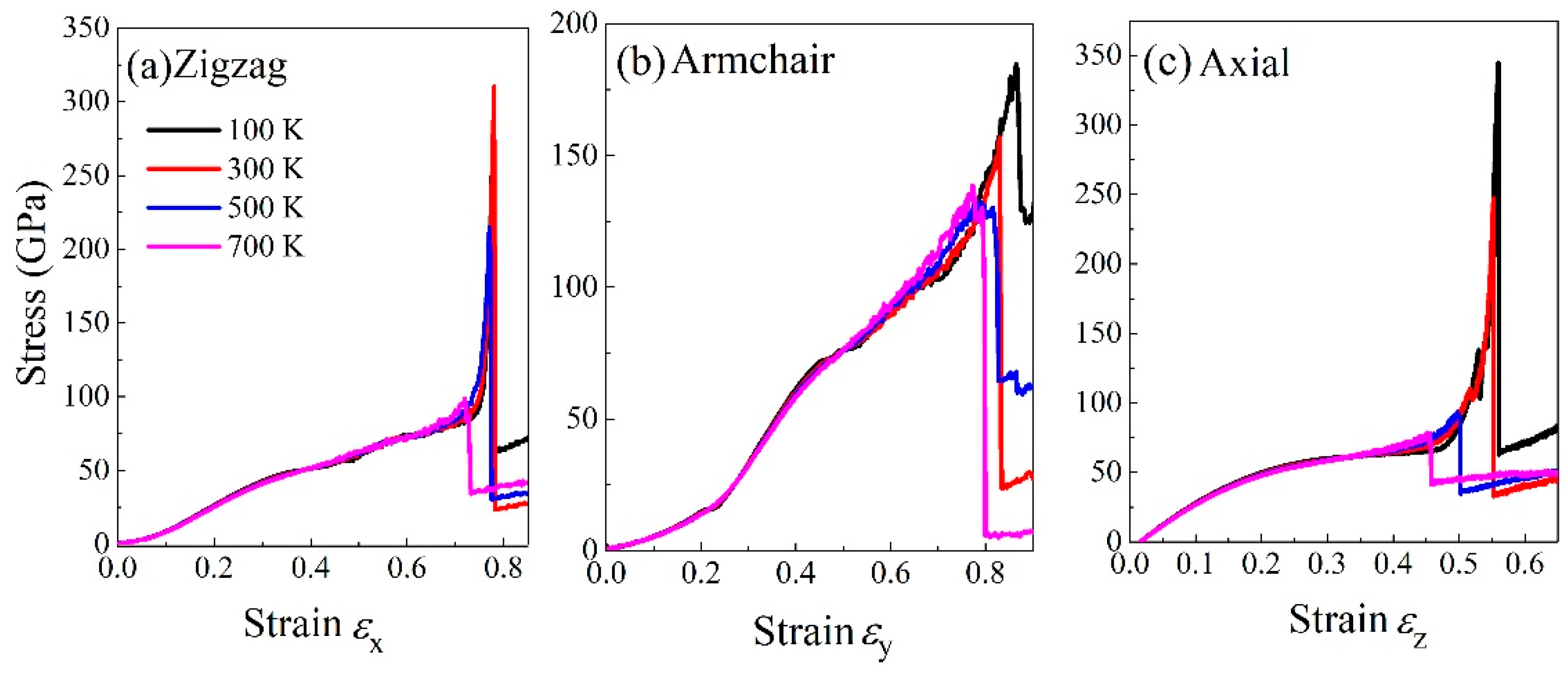

3.2. Effect of Temperature on the Tensile Mechanical Properties of BNHCs

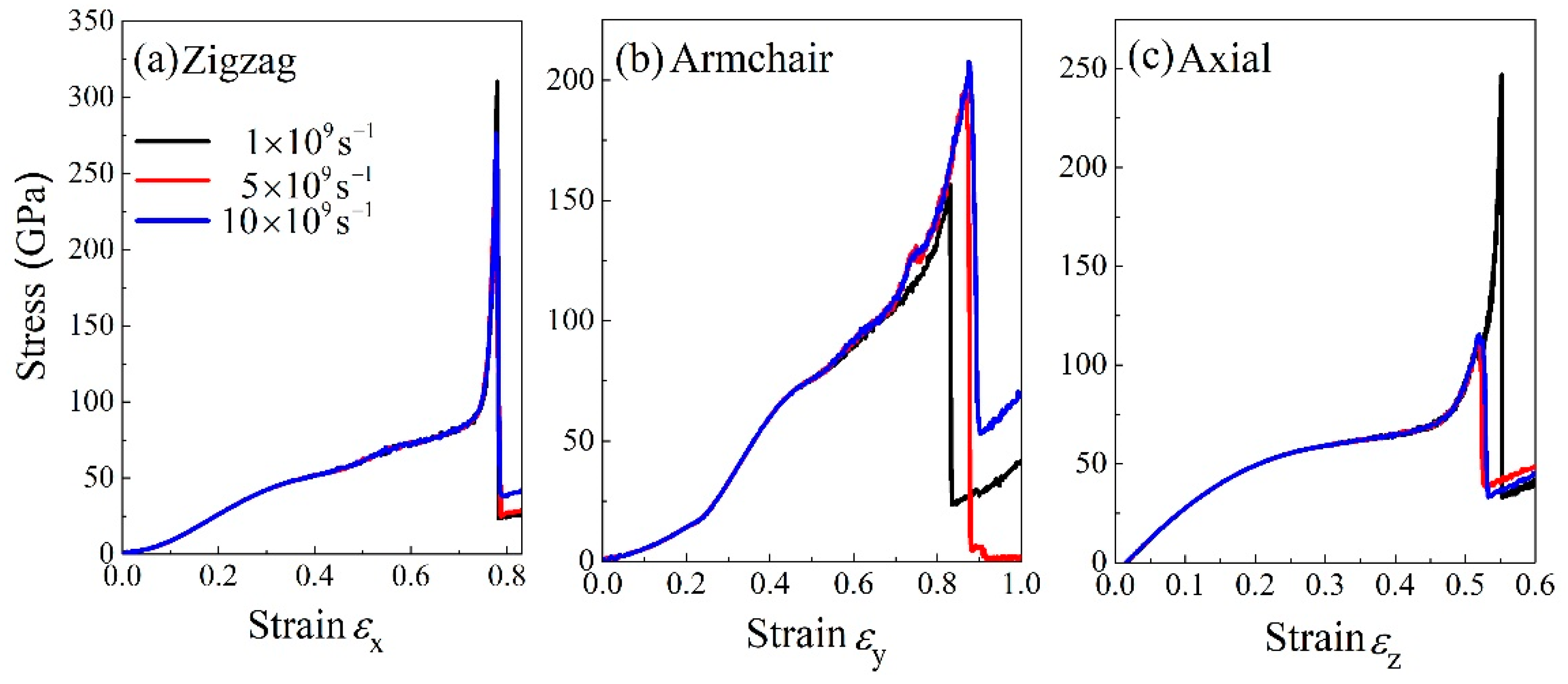

3.3. Effect of Strain Rate on the Tensile Mechanical Properties of BNHCs

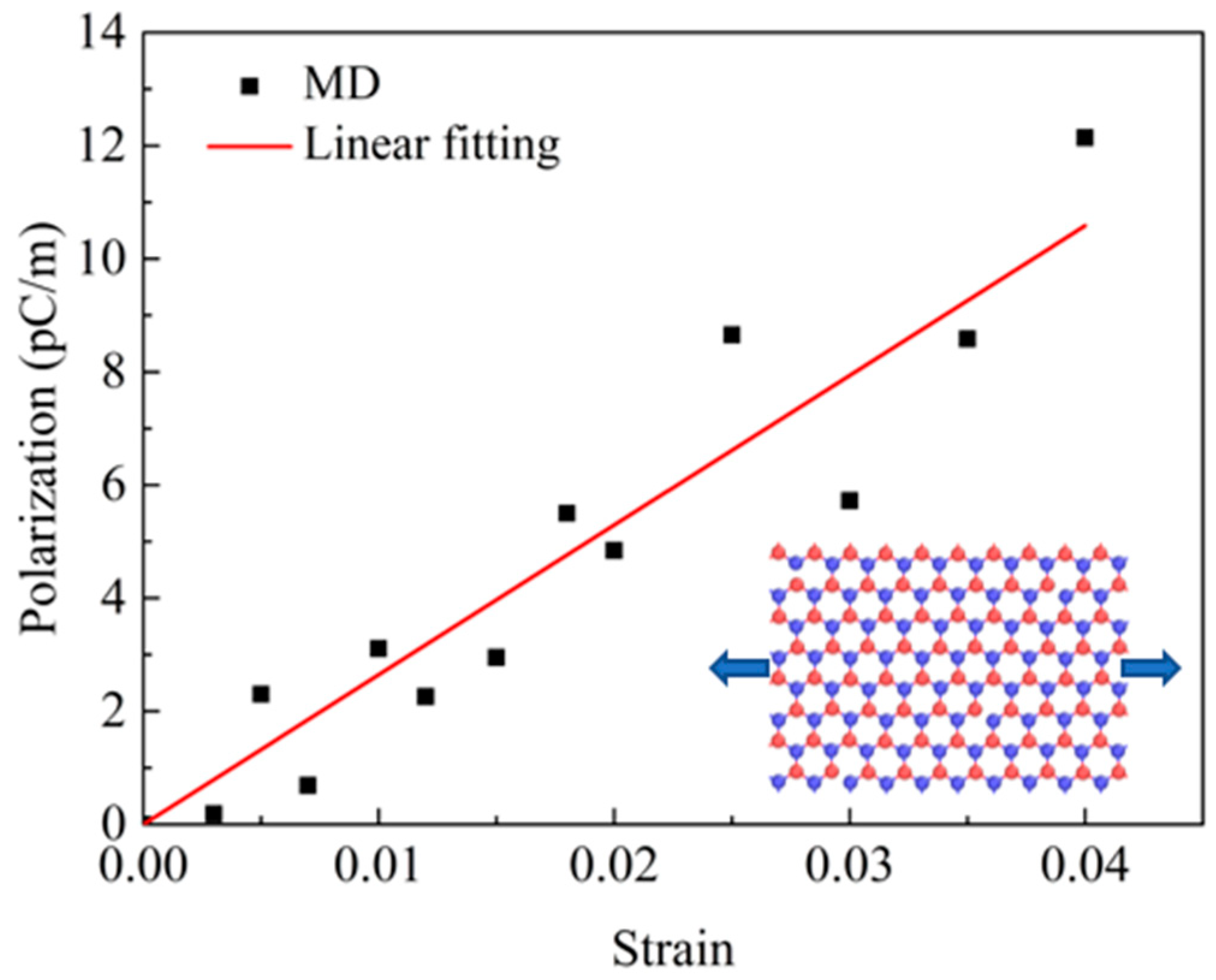

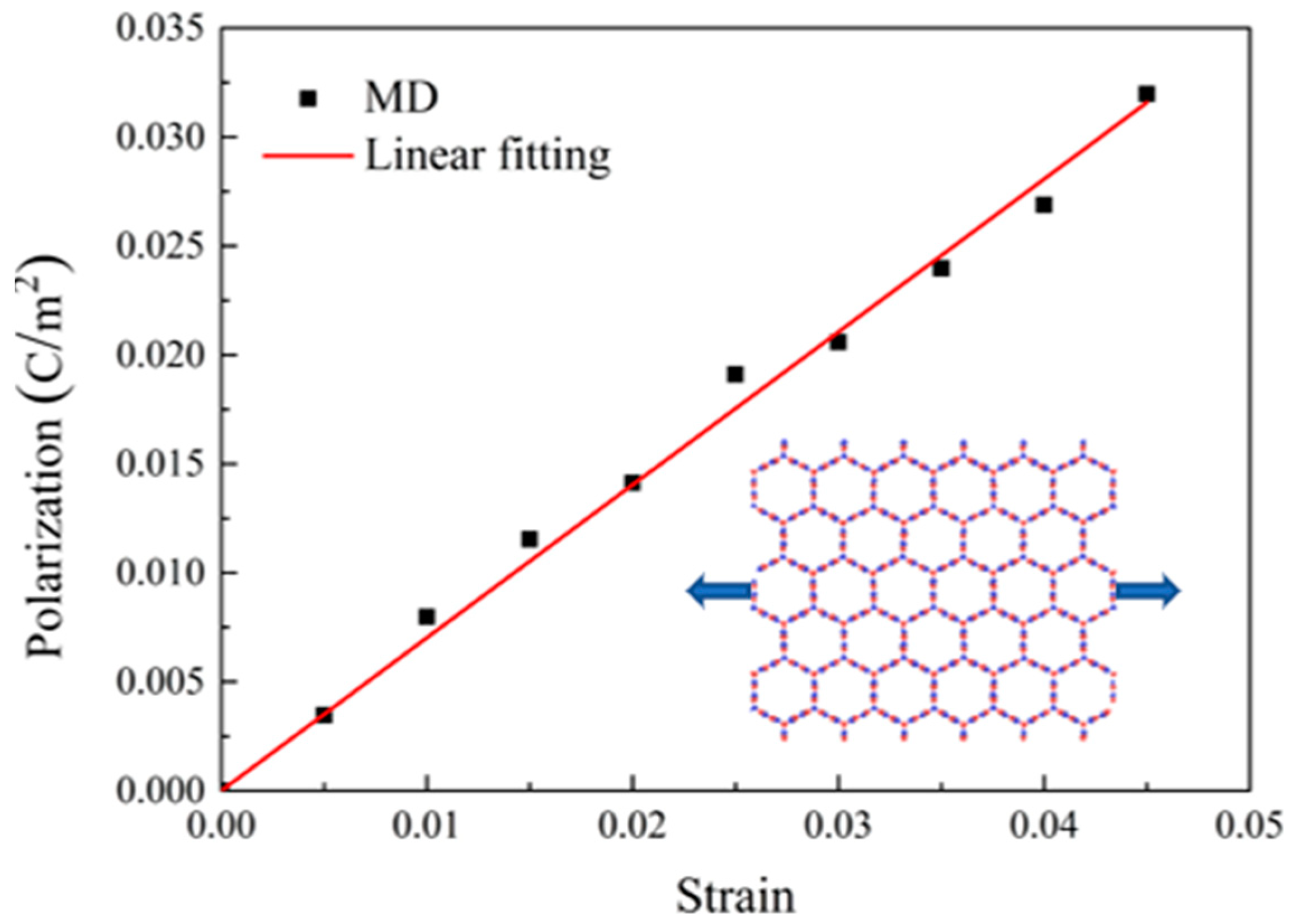

3.4. Piezoelectric Properties of BNHCs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Golberg, D.; Bando, Y.; Huang, Y.; Terao, T.; Mitome, M.; Tang, C.; Zhi, C. Boron Nitride Nanotubes and Nanosheets. ACS Nano 2010, 4, 2979–2993. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Connell, J.W. Advances in 2D boron nitride nanostructures: Nanosheets, nanoribbons, nanomeshes, and hybrids with graphene. Nanoscale 2012, 4, 6908–6939. [Google Scholar] [CrossRef] [PubMed]

- Pakdel, A.; Zhi, C.; Bando, Y.; Golberg, D. Low-dimensional boron nitride nanomaterials. Mater. Today 2012, 15, 256–265. [Google Scholar] [CrossRef]

- Duerloo, K.-A.N.; Ong, M.T.; Reed, E.J. Intrinsic Piezoelectricity in Two-Dimensional Materials. J. Phys. Chem. Lett. 2012, 3, 2871–2876. [Google Scholar] [CrossRef]

- Pakdel, A.; Bando, Y.; Golberg, D. Nano boron nitride flatland. Chem. Soc. Rev. 2014, 43, 934–959. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Jiang, D.; Schedin, F.; Booth, T.J.; Khotkevich, V.V.; Morozov, S.V.; Geim, A.K. Two-dimensional atomic crystals. Proc. Natl. Acad. Sci. USA 2005, 102, 10451–10453. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.-G.; Zou, J.; Liu, G.; Li, F.; Wang, Y.; Wang, L.; Yuan, X.-L.; Sekiguchi, T.; Cheng, H.-M.; Lu, G.Q. Novel Boron Nitride Hollow Nanoribbons. ACS Nano 2008, 2, 2183–2191. [Google Scholar] [CrossRef]

- Wu, M.; Wu, X.; Pei, Y.; Wang, Y.; Zeng, X.C. Three-dimensional network model of carbon containing only sp2-carbon bonds and boron nitride analogues. Chem. Commun. 2011, 47, 4406–4408. [Google Scholar] [CrossRef]

- Krainyukova, N.V.; Zubarev, E.N. Carbon Honeycomb High Capacity Storage for Gaseous and Liquid Species. Phys. Rev. Lett. 2016, 116, 055501. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Z.L. Piezotronics and piezo-phototronics for adaptive electronics and optoelectronics. Nat. Rev. Mater. 2016, 1, 16031. [Google Scholar] [CrossRef]

- Zhang, J.; Meguid, S.A. Piezoelectricity of 2D nanomaterials: Characterization, properties, and applications. Semicond. Sci. Technol. 2017, 32, 043006. [Google Scholar] [CrossRef]

- Espinosa, H.D.; Bernal, R.A.; Minary-Jolandan, M. A Review of Mechanical and Electromechanical Properties of Piezoelectric Nanowires. Adv. Mater. 2012, 24, 4656–4675. [Google Scholar] [CrossRef] [PubMed]

- Mele, E.J.; Král, P. Electric Polarization of Heteropolar Nanotubes as a Geometric Phase. Phys. Rev. Lett. 2002, 88, 056803. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L. Progress in Piezotronics and Piezo-Phototronics. Adv. Mater. 2012, 24, 4632–4646. [Google Scholar] [CrossRef] [PubMed]

- Qi, J.; Lan, Y.-W.; Stieg, A.Z.; Chen, J.-H.; Zhong, Y.-L.; Li, L.-J.; Chen, C.-D.; Zhang, Y.; Wang, K.L. Piezoelectric effect in chemical vapour deposition-grown atomic-monolayer triangular molybdenum disulfide piezotronics. Nat. Commun. 2015, 6, 7430. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.K.; Bhatia, R.; Kim, T.-H.; Seol, D.; Kim, J.H.; Kim, H.; Seung, W.; Kim, Y.; Lee, Y.H.; Kim, S.-W. Directional dependent piezoelectric effect in CVD grown monolayer MoS2 for flexible piezoelectric nanogenerators. Nano Energy 2016, 22, 483–489. [Google Scholar] [CrossRef]

- Gao, Z.; Zhou, J.; Gu, Y.; Fei, P.; Hao, Y.; Bao, G.; Wang, Z.L. Effects of piezoelectric potential on the transport characteristics of metal-ZnO nanowire-metal field effect transistor. J. Appl. Phys. 2009, 105, 113707. [Google Scholar] [CrossRef]

- Zhang, J. Boron nitride honeycombs with superb and tunable piezopotential properties. Nano Energy 2017, 41, 460–468. [Google Scholar] [CrossRef]

- Chopra, N.G.; Zettl, A. Measurement of the elastic modulus of a multi-wall boron nitride nanotube. Solid State Commun. 1998, 105, 297–300. [Google Scholar] [CrossRef]

- Andrew, R.C.; Mapasha, R.E.; Ukpong, A.M.; Chetty, N. Mechanical properties of graphene and boronitrene. Phys. Rev. B 2012, 85, 125428. [Google Scholar] [CrossRef]

- Pang, Z.; Gu, X.; Wei, Y.; Yang, R.; Dresselhaus, M.S. Bottom-up Design of Three-Dimensional Carbon-Honeycomb with Superb Specific Strength and High Thermal Conductivity. Nano Lett. 2017, 17, 179–185. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO–The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Tersoff, J. Modeling solid-state chemistry: Interatomic potentials for multicomponent systems. Phys. Rev. B 1989, 39, 5566–5568. [Google Scholar] [CrossRef]

- Liao, M.-L.; Wang, Y.-C.; Ju, S.-P.; Lien, T.-W.; Huang, L.-F. Deformation behaviors of an armchair boron-nitride nanotube under axial tensile strains. J. Appl. Phys. 2011, 110, 054310. [Google Scholar] [CrossRef]

- Mortazavi, B.; Rémond, Y. Investigation of tensile response and thermal conductivity of boron-nitride nanosheets using molecular dynamics simulations. Phys. E Low Dimens. Syst. Nanostruct. 2012, 44, 1846–1852. [Google Scholar] [CrossRef]

- Zhang, J.; Meguid, S.A. Effect of number of layers upon piezoelectric behaviour of multi-walled boron nitride nanotubes. J. Phys. D Appl. Phys. 2015, 48, 495301. [Google Scholar] [CrossRef]

- Nosé, S. A unified formulation of the constant temperature molecular dynamics methods. J. Chem. Phys. 1984, 81, 511–519. [Google Scholar] [CrossRef]

- Arnau, A.; Soares, D. Fundamentals of Piezoelectricity. In Piezoelectric Transducers and Applications; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–38. [Google Scholar]

- Hu, J.; Wu, W.; Zhong, C.; Liu, N.; Ouyang, C.; Yang, H.Y.; Yang, S.A. Three-dimensional honeycomb carbon: Junction line distortion and novel emergent fermions. Carbon 2019, 141, 417–426. [Google Scholar] [CrossRef]

- Xie, L.; An, H.; He, C.; Qin, Q.; Peng, Q. Mechanical Properties of Vacancy Tuned Carbon Honeycomb. Nanomaterials 2019, 9, 156. [Google Scholar] [CrossRef]

- Jiang, J.-W. Parametrization of Stillinger–Weber potential based on valence force field model: Application to single-layer MoS2 and black phosphorus. Nanotechnology 2015, 26, 315706. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, C.; Adhikari, S. Fracture and buckling of piezoelectric nanowires subject to an electric field. J. Appl. Phys. 2013, 114, 174306. [Google Scholar] [CrossRef]

- Wang, J.; Kulkarni, A.J.; Ke, F.J.; Bai, Y.L.; Zhou, M. Novel mechanical behavior of ZnO nanorods. Comput. Methods Appl. Mech. Eng. 2008, 197, 3182–3189. [Google Scholar] [CrossRef]

| Stretching Direction | Young’s Modulus (GPa) | Failure Strain | Maximum Tensile Strength (GPa) |

|---|---|---|---|

| zigzag-x | 146 | 0.78 | 310 |

| armchair-y | 173 | 0.83 | 156 |

| axial-z | 334 | 0.55 | 247 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, L.; Wang, T.; He, C.; Sun, Z.; Peng, Q. Molecular Dynamics Simulation on Mechanical and Piezoelectric Properties of Boron Nitride Honeycomb Structures. Nanomaterials 2019, 9, 1044. https://doi.org/10.3390/nano9071044

Xie L, Wang T, He C, Sun Z, Peng Q. Molecular Dynamics Simulation on Mechanical and Piezoelectric Properties of Boron Nitride Honeycomb Structures. Nanomaterials. 2019; 9(7):1044. https://doi.org/10.3390/nano9071044

Chicago/Turabian StyleXie, Lu, Tianhua Wang, Chenwei He, Zhihui Sun, and Qing Peng. 2019. "Molecular Dynamics Simulation on Mechanical and Piezoelectric Properties of Boron Nitride Honeycomb Structures" Nanomaterials 9, no. 7: 1044. https://doi.org/10.3390/nano9071044

APA StyleXie, L., Wang, T., He, C., Sun, Z., & Peng, Q. (2019). Molecular Dynamics Simulation on Mechanical and Piezoelectric Properties of Boron Nitride Honeycomb Structures. Nanomaterials, 9(7), 1044. https://doi.org/10.3390/nano9071044