Effects of N2 Partial Pressure on Growth, Structure, and Optical Properties of GaN Nanorods Deposited by Liquid-Target Reactive Magnetron Sputter Epitaxy

Abstract

1. Introduction

2. Materials and Methods

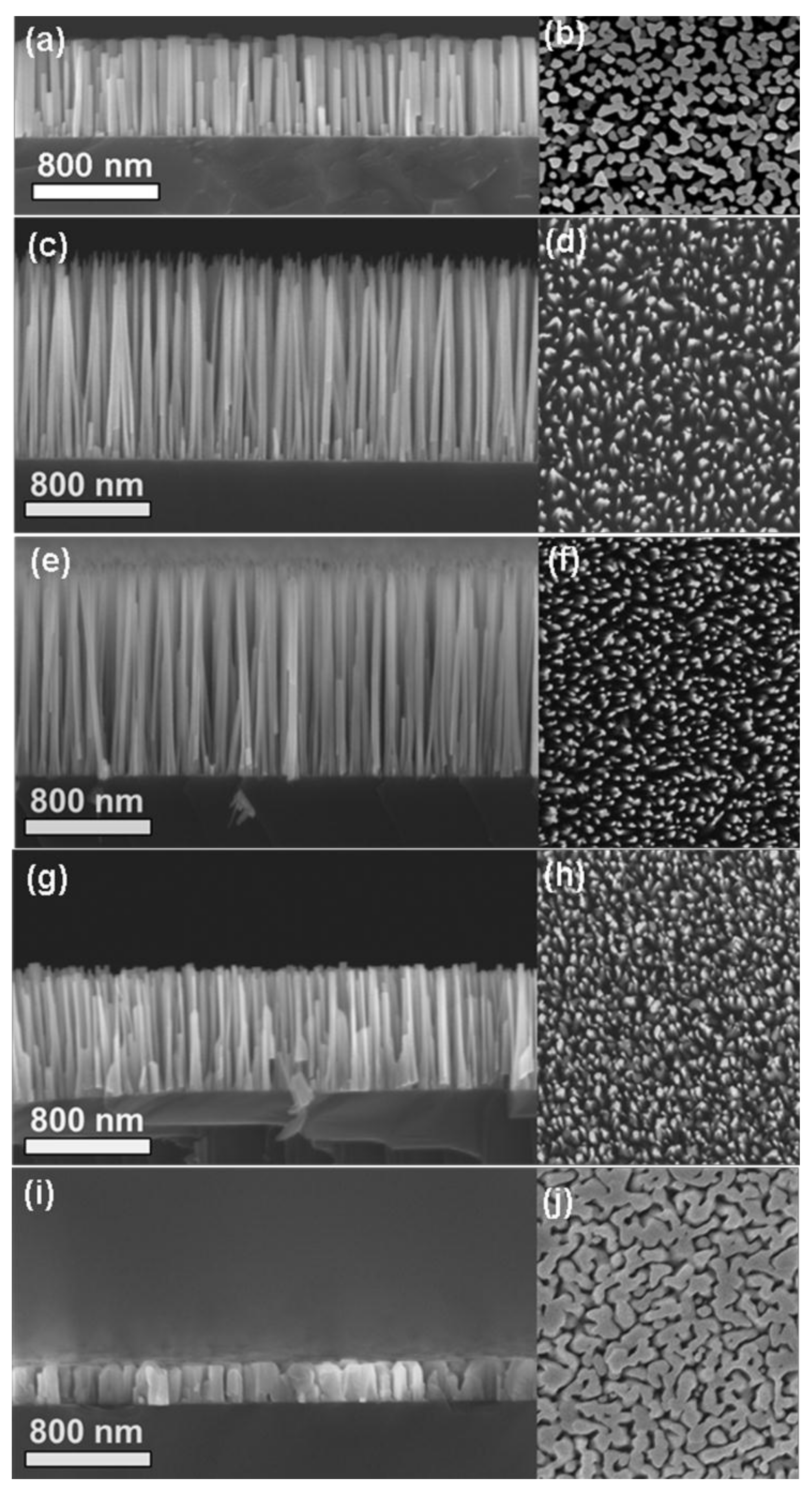

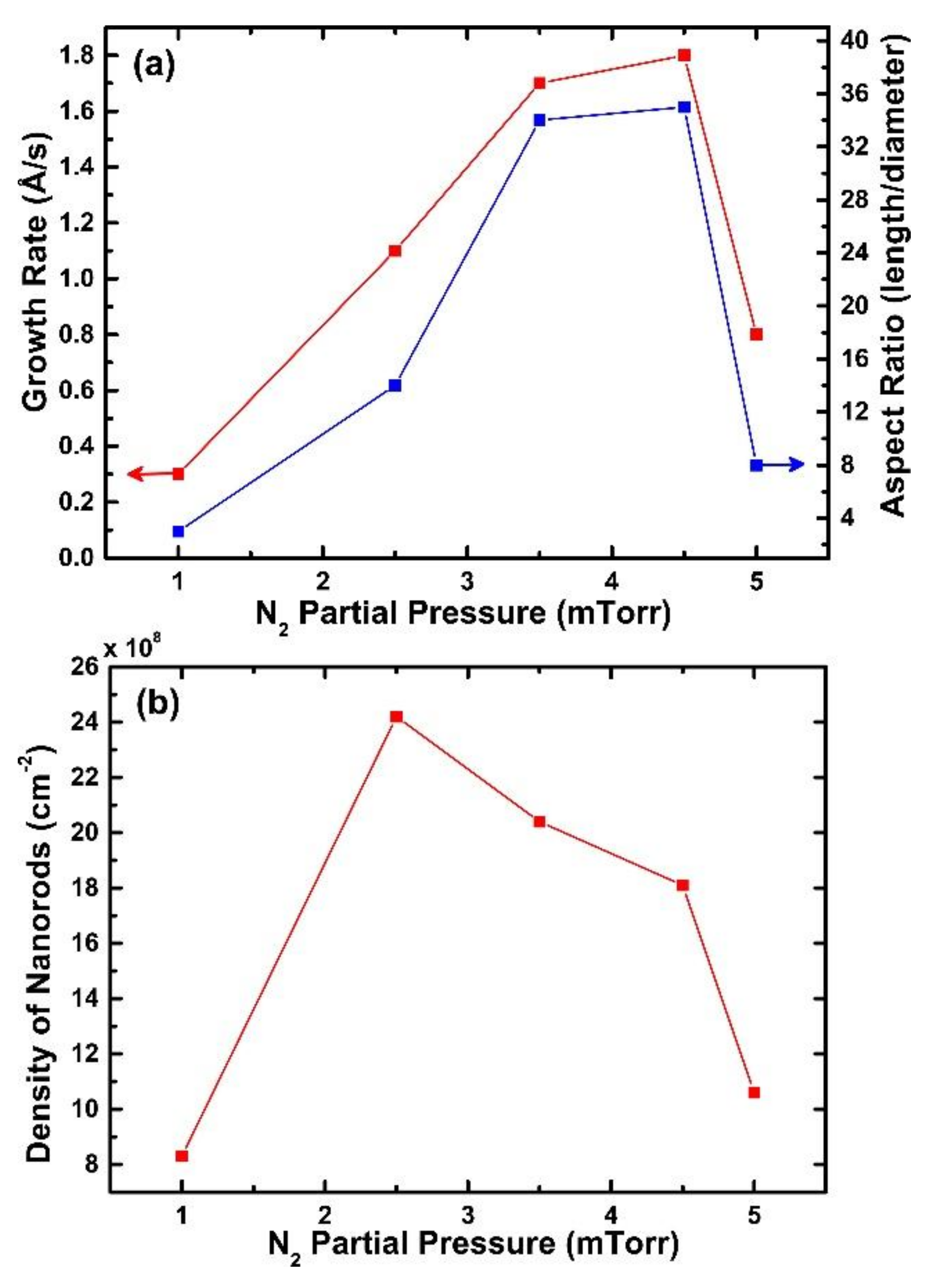

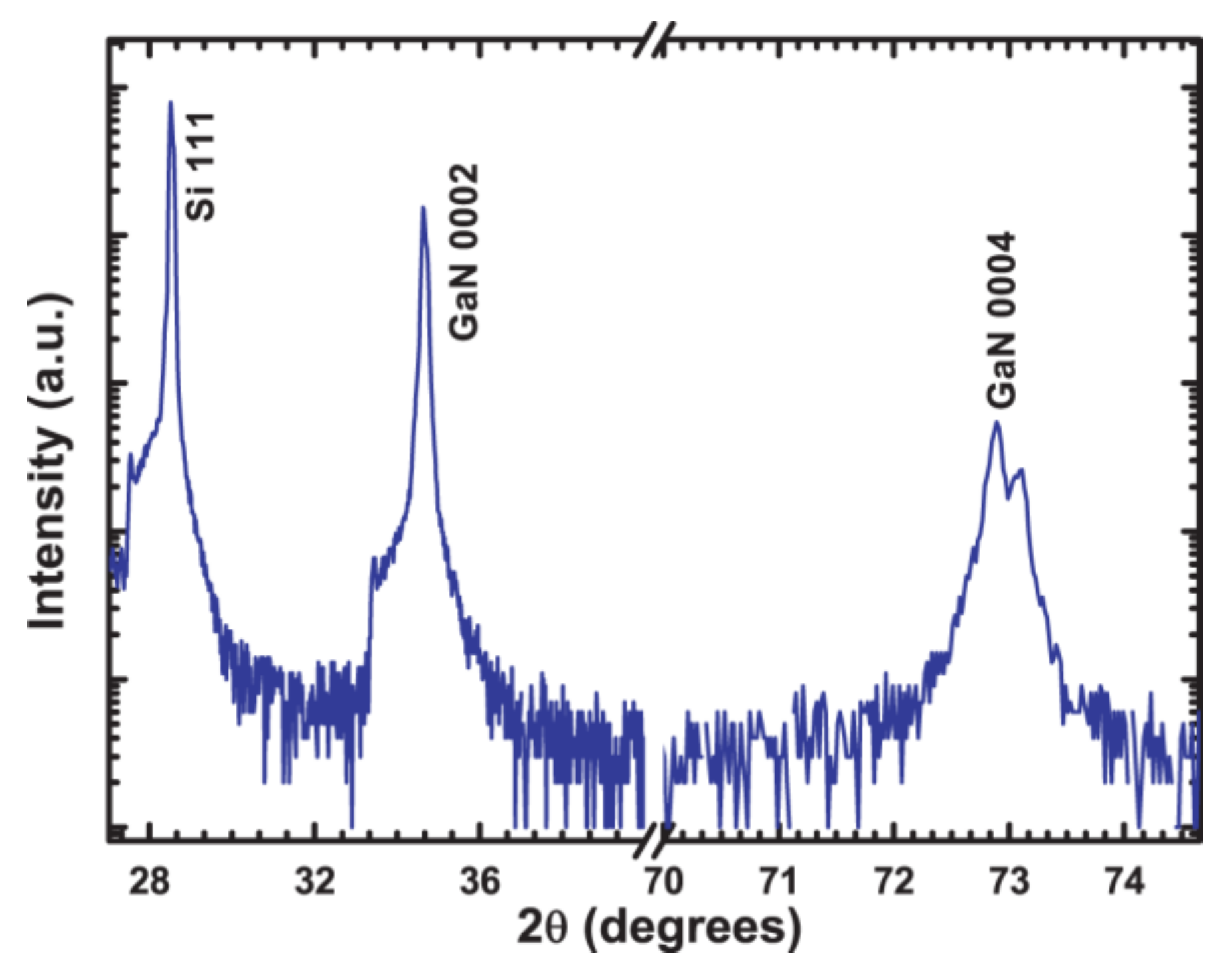

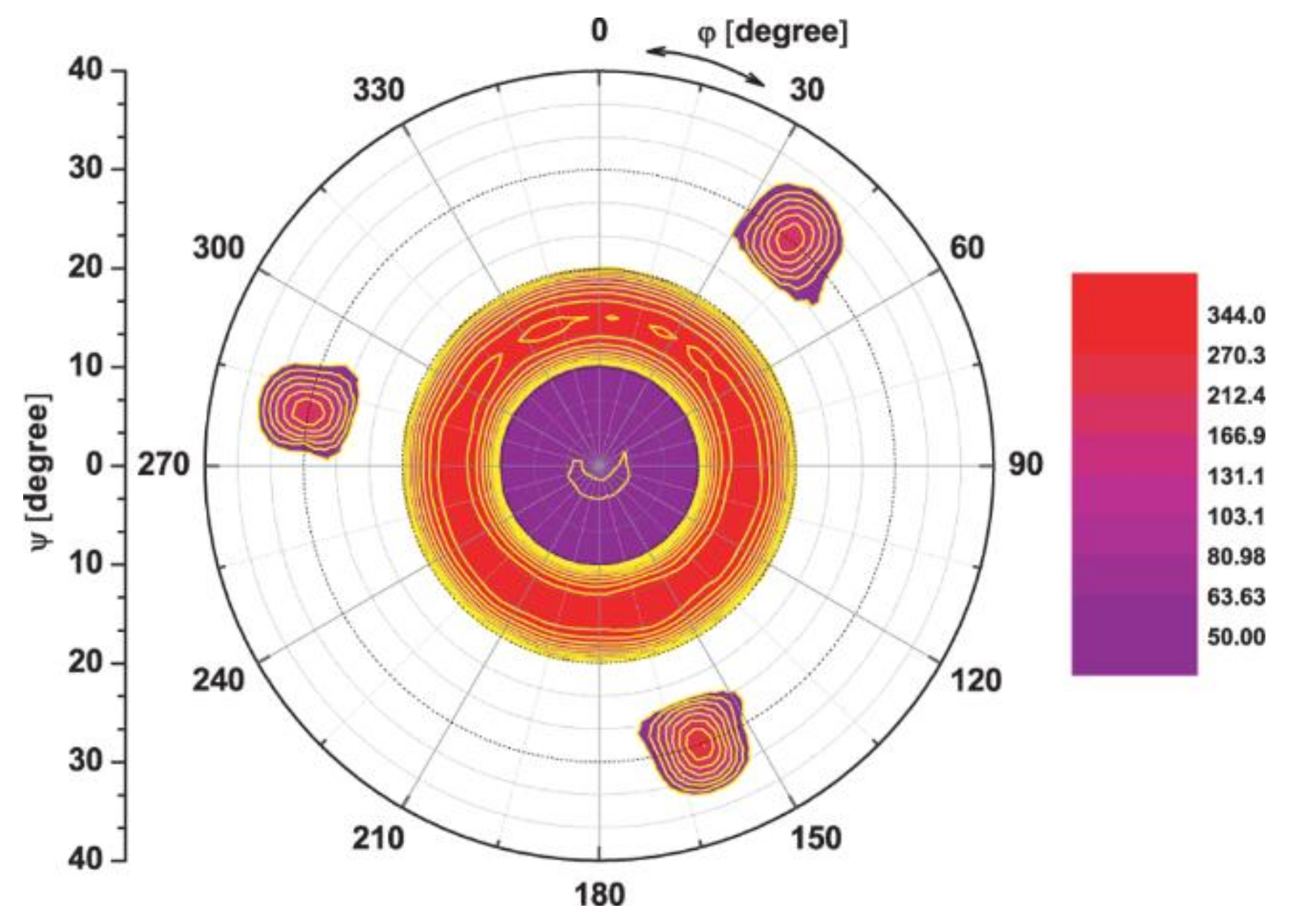

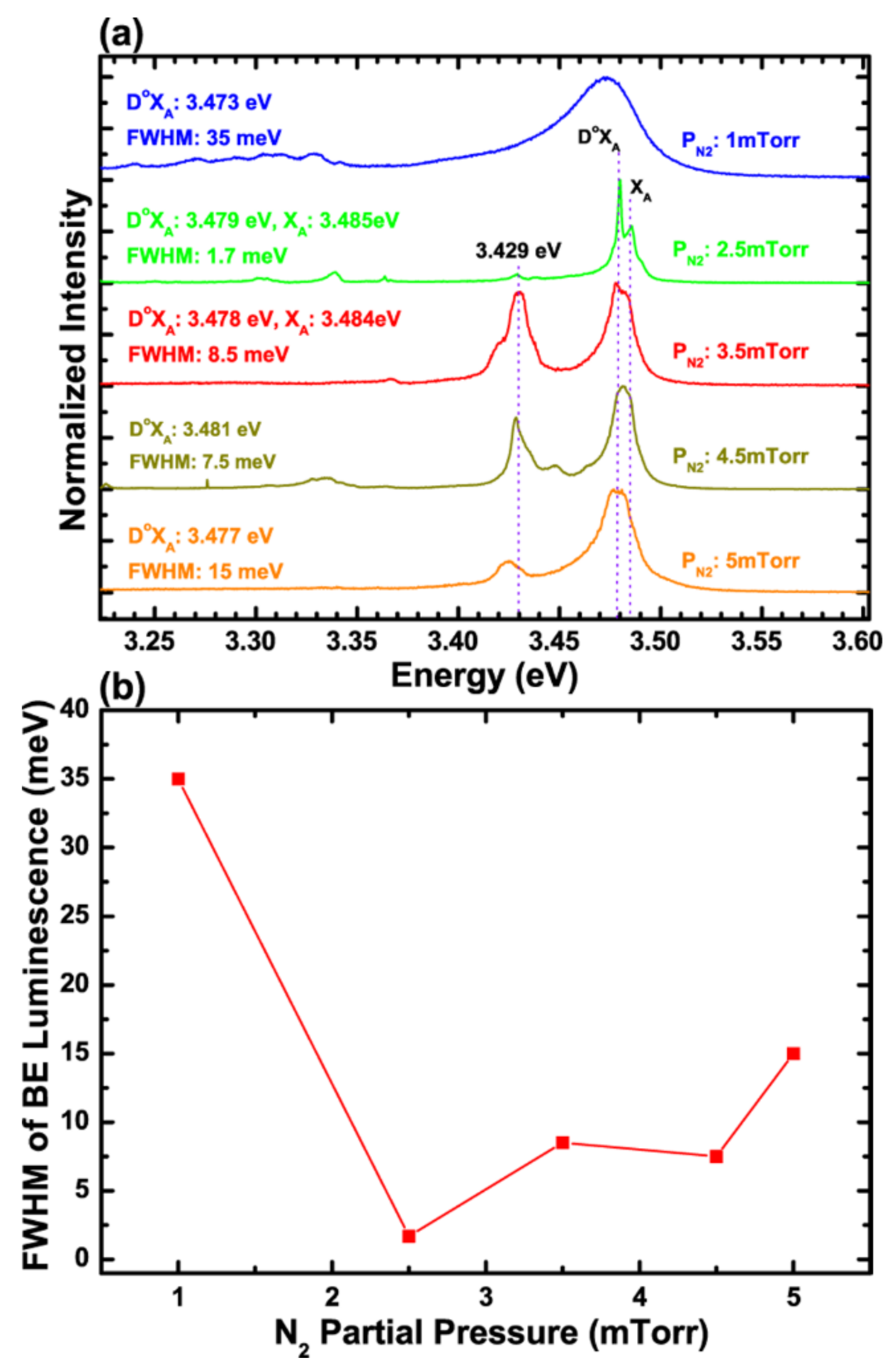

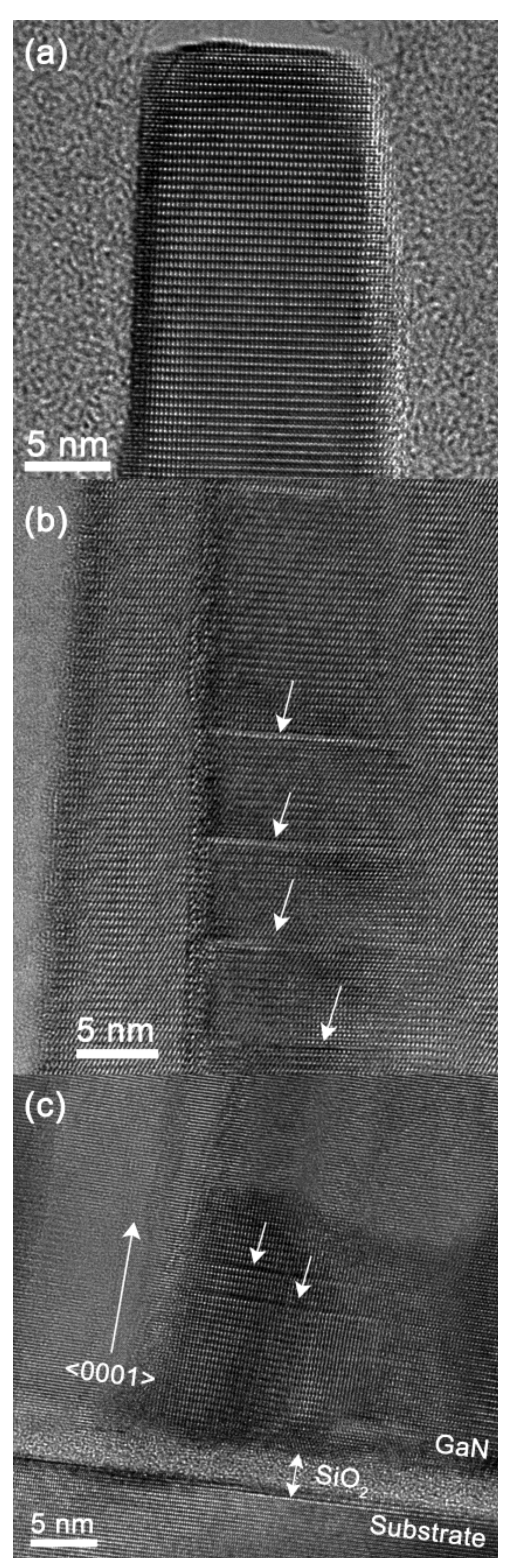

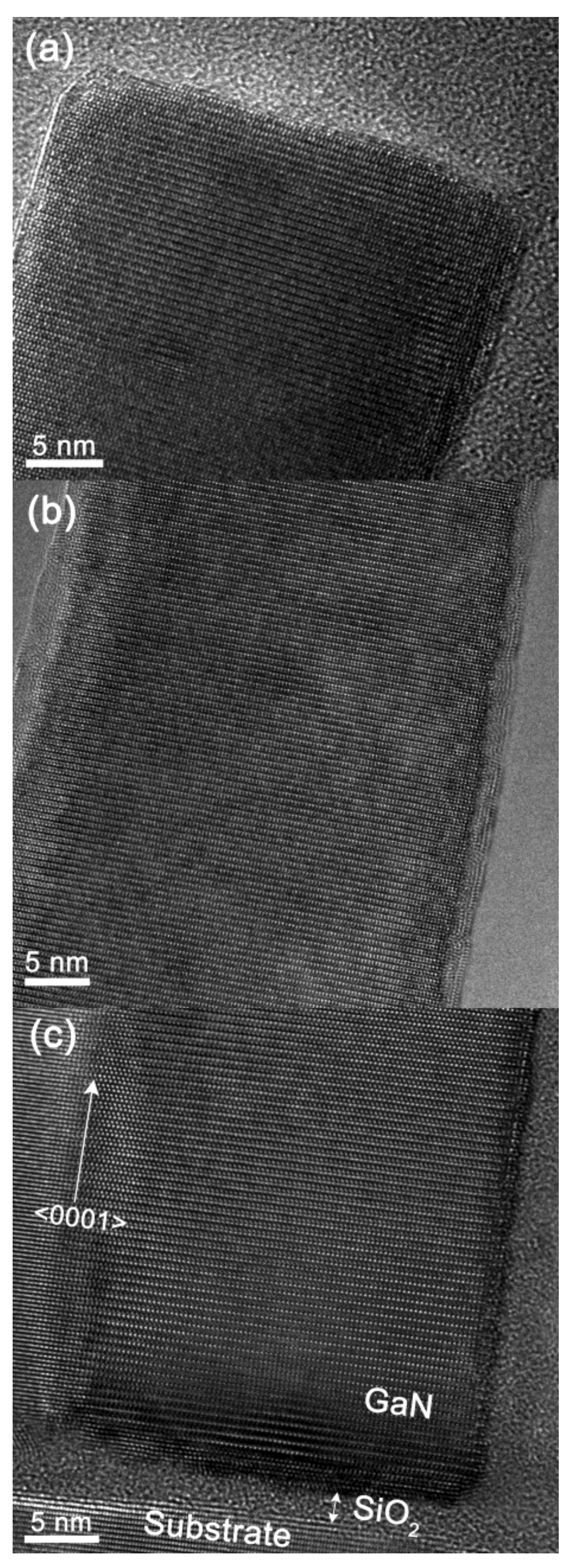

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Luryi, S.; Xu, J.; Zaslavsky, A. Future Trends in Microelectronics; From Nanophotonics to Sensor and Energy; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Lieber, C.M.; Wang, Z.L. Functional nanowires. MRS Bull. 2007, 32, 99–104. [Google Scholar] [CrossRef]

- Huang, Y.; Duan, X.; Lieber, C.M. Nanowires for integrated multi color nanophotonics. Small 2005, 1, 142. [Google Scholar] [CrossRef] [PubMed]

- Minot, E.D.; Kelkensberg, F.; van Kouwen, M.; van Dam, J.A.; Kouwenhoven, L.P.; Zwiller, V.; Borgström, M.T.; Wunnicke, O.; Verheijen, M.A.; Bakkers, E.P.A.M. Single quantum dot nanowire LEDs. Nano Lett. 2007, 7, 367–371. [Google Scholar] [CrossRef] [PubMed]

- Lekhal, K.; André, Y.; Trassoudaine, A.; Gil, E.; Avit, G.; Cellier, J.; Castelluci, D. Exceptional crystal-defined bunched and hyperbunched GaN nanorods grown by catalyst-free HVPE. Cryst. Growth Des. 2012, 12, 2251–2256. [Google Scholar] [CrossRef]

- Li, S.; Waag, A. GaN based nanorods for solid state lighting. J. Appl. Phys. 2012, 111, 071101. [Google Scholar] [CrossRef]

- Ko, S.-M.; Kim, J.-H.; Ko, Y.-H.; Chang, Y.H.; Kim, Y.-H.; Yoon, J.; Lee, J.Y.; Cho, Y.-H. Growth mechanism of catalyst-free and mask-free heteroepitaxial GaN submicrometer- and micrometer-sized rods under biaxial strain: Variation of surface energy and adatom kinetics. Cryst. Growth Des. 2012, 12, 3838. [Google Scholar] [CrossRef]

- Bertness, K.A.; Roshko, A.; Mansfield, L.M.; Harvey, T.E.; Sanford, N.A. Mechanism for spontaneous growth of GaN nanowires with molecular beam epitaxy. J. Cryst. Growth 2008, 310, 3154–3158. [Google Scholar] [CrossRef]

- Calarco, R.; Meijers, R.J.; Debnath, R.K.; Stoica, T.; Sutter, E.; Lüth, H. Nucleation and growth of GaN nanowires on Si (111) performed by molecular beam epitaxy. Nano Lett. 2007, 7, 2248–2251. [Google Scholar] [CrossRef] [PubMed]

- Landré, O.; Bougerol, C.; Renevier, H.; Daudin, B. Nucleation mechanism of GaN nanowires grown on (111) Si by molecular beam epitaxy. Nanotechnology 2009, 20, 415602. [Google Scholar] [CrossRef] [PubMed]

- Tu, L.W.; Hsiao, C.L.; Chi, T.W.; Lo, I.; Hsieh, K.Y. Self-assembled vertical GaN nanorods grown by molecular-beam epitaxy. Appl. Phys. Lett. 2003, 82, 1601–1603. [Google Scholar] [CrossRef]

- Junaid, M.; Chen, Y.-T.; Palisaitis, J.; Garbrecht, M.; Hsiao, C.-L.; Persson, P.O.Å.; Hultman, L.; Birch, J. Liquid-target reactive magnetron sputter epitaxy of high quality GaN (0001−) nanorods on Si (111). Mater. Sci. Semicond. Proc. 2015, 39, 702–710. [Google Scholar] [CrossRef]

- Serban, E.A.; Junaid, M.; Tengdelius, L.; Högberg, H.; Hultman, L.; Persson, P.O.Å.; Birch, J.; Hsiao, C.-L. Magnetron sputter epitaxy of single-crystal GaN nanorods on functional and cost-effective templates/substrates. Energies 2017, 10, 1322. [Google Scholar] [CrossRef]

- Serban, E.A.; Palisaitis, J.; Yeh, C.-C.; Hsu, H.-C.; Tsai, Y.-L.; Kuo, H.-C.; Junaid, M.; Hultman, L.; Persson, P.O.Å.; Birch, J.-L.; et al. Selective-area growth of single-crystal wurtzite GaN nanorods on SiOx/Si (001) substrates by magnetron sputter epitaxy exhibiting single-mode lasing. Sci. Rep. 2017, 7, 12701. [Google Scholar] [CrossRef] [PubMed]

- Serban, E.A.; Palisaitis, J.; Persson, P.O.Å.; Hultman, L.; Birch, J.; Hsiao, C.-L. Site-controlled growth of GaN nanorod arrays by magnetron sputter epitaxy. Thin Solid Films 2018. In press. [Google Scholar] [CrossRef]

- Junaid, M.; Hsiao, C.L.; Palisaitis, J.; Jensen, J.; Persson, P.O.Å.; Hultman, L.; Birch, J. Electronic-grade GaN(0001)/Al2O3(0001) grown by reactive dc-magnetron sputter epitaxy using a liquid Ga target. Appl. Phys. Lett. 2011, 98, 141915. [Google Scholar] [CrossRef]

- Junaid, M.; Lundin, D.; Palisaitis, J.; Hsiao, C.-L.; Darakchieva, V.; Jensen, J.; Persson, P.O.Å.; Sandström, P.; Helmersson, U.; Hultman, L.; et al. Two-domain formation during the epitaxial growth of GaN (0001) on c-plane Al2O3 (0001) by high power impulse magnetron sputtering. J. Appl. Phys. 2011, 110, 123519. [Google Scholar] [CrossRef]

- Greczynski, G.; Lu, J.; Jensen, J.; Petrov, I.; Greene, J.E.; Bolz, S.; Kölker, W.; Schiffers, C.; Lemmer, O.; Hultman, L. Metal vs. Rare-gas Ion Irradiation during Ti1 xAlxN Film Growth by Hybrid HIPIMS/DCMS Co-sputtering using Synchronized Pulsed Substrate Bias. J. Vac. Sci. Technol. A 2012, 30, 061504. [Google Scholar] [CrossRef]

- Greczynski, G.; Petrov, I.; Greene, J.E.; Hultman, L. Strategy for tuning the average charge state of metal ions incident at the growing film during HIPIMS deposition. Vacuum 2015, 116, 36–41. [Google Scholar] [CrossRef]

- Ivanov, I.; Kazansky, P.; Hultman, L.; Petrov, I.; Sundgren, J.-E. Influence of an external axial magnetic field on the plasma characteristics and deposition conditions during direct current planar magnetron sputtering. J. Vac. Sci. Technol. A 1994, 12, 314. [Google Scholar] [CrossRef]

- Li, B.-S.; Wang, T.-G.; Ding, J.; Cai, Y.; Shi, J.; Zhang, X. Influence of N2/Ar flow ratio on microstructure and properties of the AlCrSiN coatings deposited by high-power impulse magnetron sputtering. Coatings 2018, 8, 3. [Google Scholar] [CrossRef]

- Amloy, S.; Chen, Y.T.; Karlsson, K.F.; Chen, K.H.; Hsu, H.C.; Hsiao, C.L.; Chen, L.C.; Holtz, P.O. Polarization resolved fine structure splitting of zero-dimensional InGaN excitons. Phys. Rev. B 2011, 83, 201307. [Google Scholar] [CrossRef]

- Chen, Y.T.; Tsai, W.C.; Chen, W.Y.; Hsiao, C.L.; Hsu, H.C.; Chang, W.H.; Hsu, T.M.; Chen, K.H.; Chen, L.C. Growth of sparse arrays of narrow GaN nanorods hosting spectrally stable InGaN quantum disks. Opt. Express 2012, 20, 16166. [Google Scholar] [CrossRef]

- Debnath, R.K.; Meijers, R.; Richter, T.; Stoica, T.; Calarco, R.; Lüth, H. Mechanism of molecular beam epitaxy growth of GaN nanowires on Si (111). Appl. Phys. Lett. 2007, 90, 123117. [Google Scholar] [CrossRef]

- Bertness, K.A.; Sanford, N.A.; Davydov, A.V. GaN nanowires grown by molecular beam epitaxy. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 847–858. [Google Scholar] [CrossRef]

- Stoica, T.; Sutter, E.; Meijers, R.J.; Debnath, R.K.; Calarco, R.; Lüth, H.; Grützmacher, D. Interface and wetting layer effect on the catalyst-free nucleation and growth of GaN nanowires. Small 2008, 4, 751–754. [Google Scholar] [CrossRef] [PubMed]

- Geelhaar, L.; Chèze, C.; Jenichen, B.; Brandt, O.; Pfüller, C.; Münch, S.; Rothemund, R.; Reitzenstein, S.; Forchel, A.; Kehagias, T.; et al. Properties of GaN Nanowires Grown by Molecular Beam Epitaxy. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 878–888. [Google Scholar] [CrossRef]

- Yoshizawa, M.; Kikuchi, A.; Mori, M.; Fujita, N.; Kishino, K. Growth of self-organized GaN nanostructures on Al2O3 (0001) by RF-radical source molecular beam epitaxy. Jpn. J. Appl. Phys. 1997, 36, L459–L462. [Google Scholar] [CrossRef]

- Calleja, E.; Sánchez-García, M.A.; Sánchez, F.J.; Calle, F.; Naranjo, F.B.; Muñoz, E.; Jahn, U.; Ploog, K. Luminescence properties and defects in GaN nanocolumns grown by molecular beam epitaxy. Phys. Rev. B 2000, 62, 16826–16834. [Google Scholar] [CrossRef]

- Consonni, V. Self-induced growth of GaN nanowires by molecular beam epitaxy: A critical review of the formation mechanisms. Phys. Status Solidi RRL 2013, 7, 699–712. [Google Scholar] [CrossRef]

- Foxon, C.T.; Novikov, S.V.; Hall, J.L.; Campion, R.P.; Cherns, D.; Griffiths, I.; Khongphetsak, S. A complementary geometric model for the growth of GaN nanocolumns prepared by plasma-assisted molecular beam epitaxy. J. Cryst. Growth 2009, 311, 3423–3427. [Google Scholar] [CrossRef]

- Chèze, C.; Geelhaar, L.; Trampert, A.; Riechert, H. In situ investigation of self-induced GaN nanowire nucleation on Si. Appl. Phys. Lett. 2010, 97, 043101. [Google Scholar] [CrossRef]

- Ababneh, A.; Schmid, U.; Hernando, J.; Sánchez-Rojas, J.L.; Seidel, H. The influence of sputter deposition parameters on piezoelectric and mechanical properties of AlN thin films. Mater. Sci. Eng. B 2010, 172, 253–258. [Google Scholar] [CrossRef]

- Venkataraj, S.; Severin, D.; Drese, R.; Koerfer, F.; Wuttig, M. Structural, optical and mechanical properties of aluminium nitride films prepared by reactive DC magnetron sputtering. Thin Solid Films 2006, 502, 235–239. [Google Scholar] [CrossRef]

- Zywietz, T.; Neugebauer, J.; Scheffler, M. Adatom diffusion at GaN (0001) and (0001−) surfaces. Appl. Phys. Lett. 1998, 73, 487–489. [Google Scholar] [CrossRef]

- Paskov, P.P.; Paskova, T.; Holtz, P.O.; Monemar, B. Spin-exchange splitting of excitons in GaN. Phys. Rev. B 2001, 64, 115201. [Google Scholar] [CrossRef]

- Paskov, P.P.; Schifano, R.; Paskova, T.; Figge, S.; Hommel, D.; Monemar, B. Emission properties of a -plane GaN grown by metal-organic chemical-vapor deposition. J. Appl. Phys. 2005, 98, 093519. [Google Scholar] [CrossRef]

- Forsberg, M.; Serban, E.A.; Poenaru, I.; Hsiao, C.L.; Junaid, M.; Birch, J.; Pozina, G. Stacking fault related luminescence in GaN nanorods. Nanotechnology 2015, 26, 355203. [Google Scholar] [CrossRef] [PubMed]

- Pozina, G.; Forsberg, M.; Serban, E.A.; Hsiao, C.-L.; Junaid, M.; Birch, J.; Kaliteevski, M.A. Polarization of stacking fault related luminescence in GaN nanorods. AIP Adv. 2017, 7, 015303. [Google Scholar] [CrossRef]

- Ito, S.; Nakagita, T.; Sawaki, N.; Ahn, H.S.; Irie, M.; Hikosaka, T.; Honda, Y.; Yamaguchi, M.; Amano, H. Nature of yellow luminescence band in GaN grown on Si substrate. Jpn. J. Appl. Phys. 2014, 53, 11RC02. [Google Scholar] [CrossRef]

- Dıaz-Guerra, C.; Piqueras, J. Time-resolved cathodoluminescence and photocurrent study of the yellow band in Si-doped GaN. J. Appl. Phys. 2003, 94, 2341–2343. [Google Scholar] [CrossRef]

- Liu, B.; Yuan, F.; Dierre, B.; Sekiguchi, T.; Zhang, S.; Xu, Y.; Jiang, X. Origin of yellow-band emission in epitaxially grown GaN nanowire arrays. ACS Appl. Mater. Interfaces 2014, 6, 14159–14166. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Junaid, M.; Hsiao, C.-L.; Chen, Y.-T.; Lu, J.; Palisaitis, J.; Persson, P.O.Å.; Hultman, L.; Birch, J. Effects of N2 Partial Pressure on Growth, Structure, and Optical Properties of GaN Nanorods Deposited by Liquid-Target Reactive Magnetron Sputter Epitaxy. Nanomaterials 2018, 8, 223. https://doi.org/10.3390/nano8040223

Junaid M, Hsiao C-L, Chen Y-T, Lu J, Palisaitis J, Persson POÅ, Hultman L, Birch J. Effects of N2 Partial Pressure on Growth, Structure, and Optical Properties of GaN Nanorods Deposited by Liquid-Target Reactive Magnetron Sputter Epitaxy. Nanomaterials. 2018; 8(4):223. https://doi.org/10.3390/nano8040223

Chicago/Turabian StyleJunaid, Muhammad, Ching-Lien Hsiao, Yen-Ting Chen, Jun Lu, Justinas Palisaitis, Per Ola Åke Persson, Lars Hultman, and Jens Birch. 2018. "Effects of N2 Partial Pressure on Growth, Structure, and Optical Properties of GaN Nanorods Deposited by Liquid-Target Reactive Magnetron Sputter Epitaxy" Nanomaterials 8, no. 4: 223. https://doi.org/10.3390/nano8040223

APA StyleJunaid, M., Hsiao, C.-L., Chen, Y.-T., Lu, J., Palisaitis, J., Persson, P. O. Å., Hultman, L., & Birch, J. (2018). Effects of N2 Partial Pressure on Growth, Structure, and Optical Properties of GaN Nanorods Deposited by Liquid-Target Reactive Magnetron Sputter Epitaxy. Nanomaterials, 8(4), 223. https://doi.org/10.3390/nano8040223