Enhancing Output Power of Textured Silicon Solar Cells by Embedding Indium Plasmonic Nanoparticles in Layers within Antireflective Coating

Abstract

1. Introduction

2. Experiments

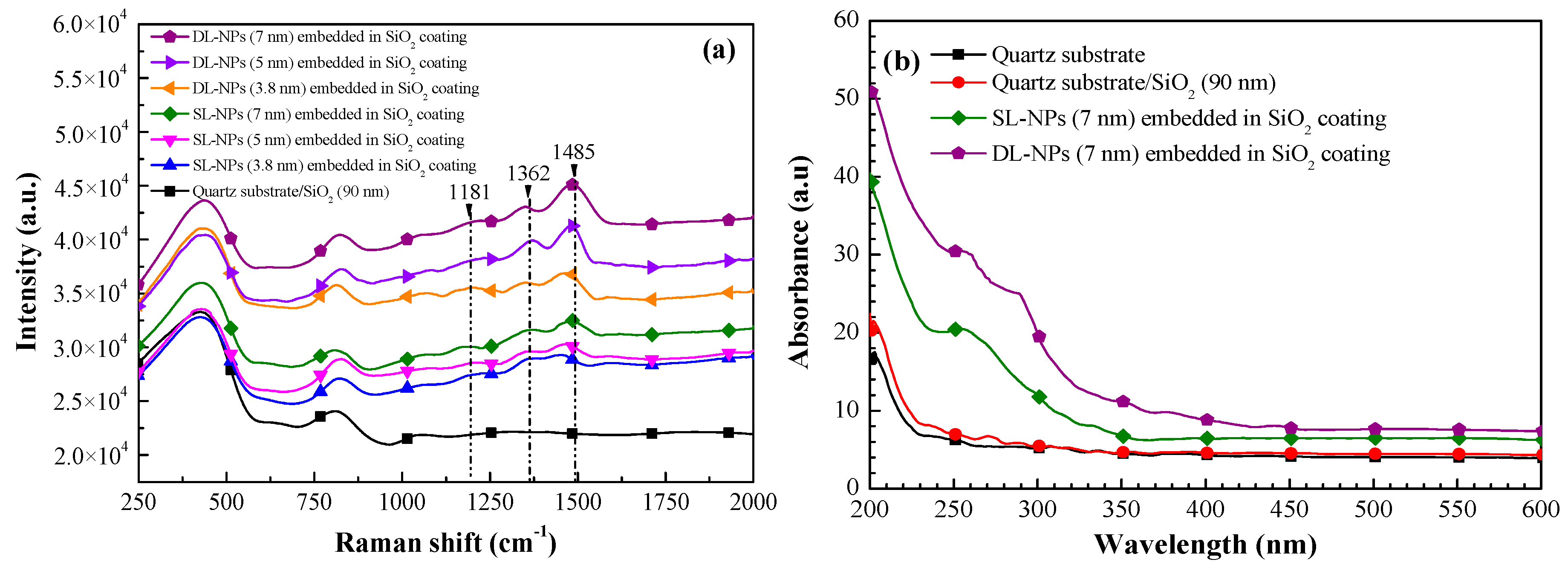

2.1. Characterization of Plasmonic Effects from Indium Nanoparticle Layers Embedded in SiO2 Coating

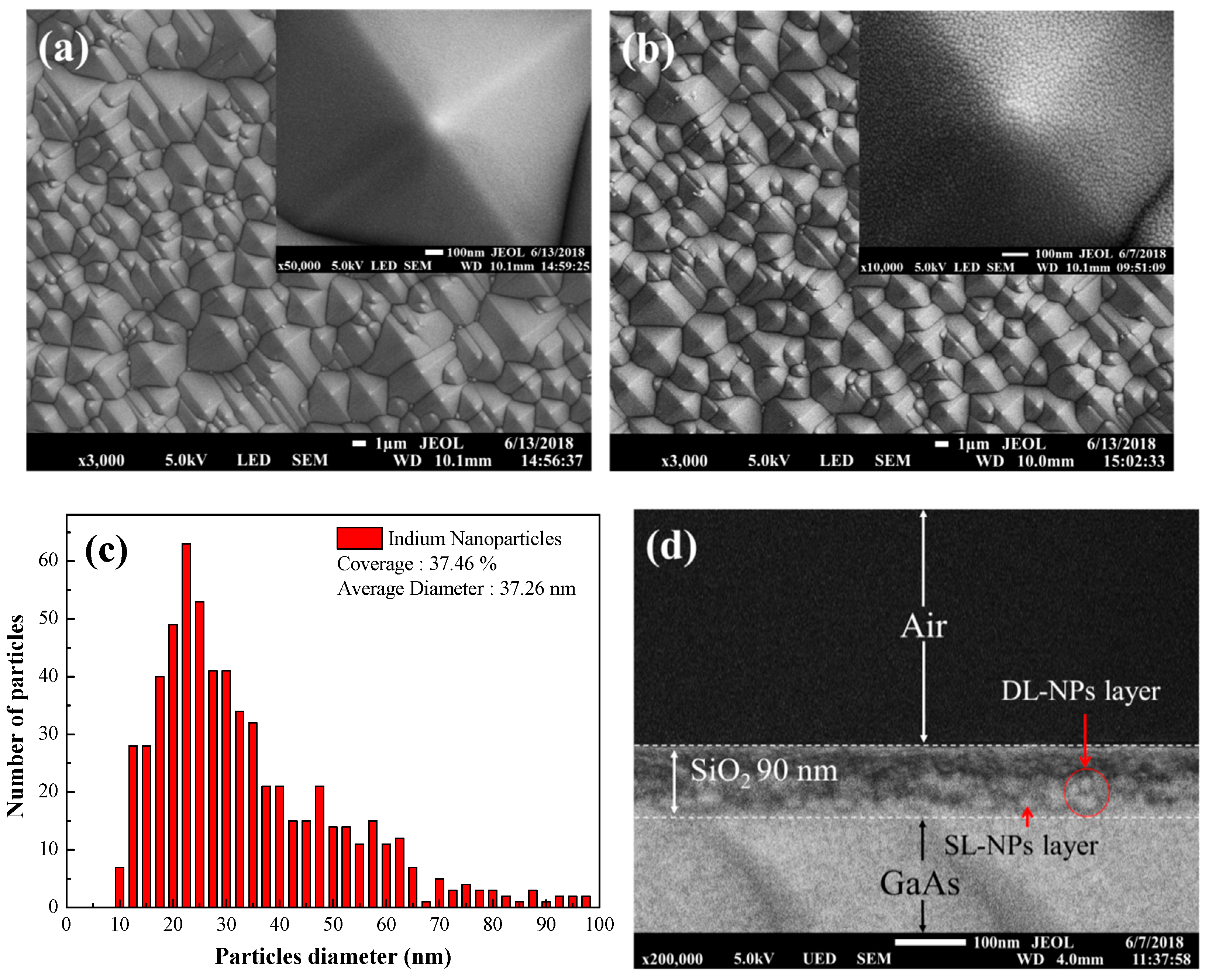

2.2. Fabrication and Characterization of Plasmonic Textured Silicon Solar Cells

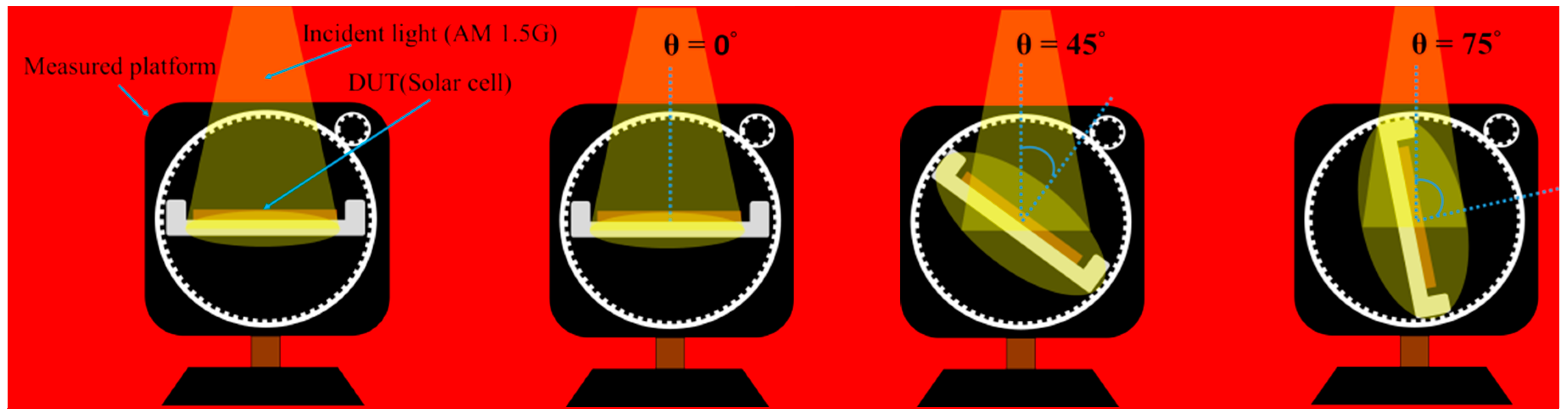

2.3. EQE and Photovoltaic Performance of Plasmonic Textured Silicon Solar Cells under Incident Light of Various Angles

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Blakers, A.; Zin, N.; McIntosh, K.R.; Fong, K. High efficiency silicon solar cells. Energy Procedia 2013, 33, 1–10. [Google Scholar] [CrossRef]

- Cho, C.; Oh, J.; Lee, B.; Kim, B. Combined effects of pyramid-like structures and antireflection coating on Si solar cell efficiency. J. Nanosci. Nanotechnol. 2015, 15, 7624–7631. [Google Scholar] [CrossRef] [PubMed]

- Young, K.; Wen, Q.; Hanany, S.; Imada, H.; Koch, J.; Matsumura, T.; Suttmann, O.; Schütz, V. Broadband millimeter-wave anti-reflection coatings on silicon using pyramidal sub-wavelength structures. J. Appl. Phys. 2017, 121, 213103-1–213103-10. [Google Scholar] [CrossRef]

- Al-Husseini, A.M.; Lahlouh, B. Silicon pyramid structure as a reflectivity reduction mechanism. J. Appl. Sci. 2017, 17, 374–383. [Google Scholar] [CrossRef]

- Baker-Finch, S.C.; McIntosh, K.R. Reflection of normally incident light from silicon solar cells with pyramidal texture. Prog. Photovolt Res. Appl. 2011, 19, 406–416. [Google Scholar] [CrossRef]

- Chiao, S.C.; Zhou, J.L.; Macleod, H.A. Optimized design of an antireflection coating for textured silicon solar cells. Appl. Opt. 1993, 32, 5557–5560. [Google Scholar] [CrossRef]

- Bouhafs, D.; Moussi, A.; Chikouche, A.; Ruiz, J.M. Design and simulation of antireflection coating systems for optoelectronic devices: Application to silicon solar cells. Sol. Energy Mater. Sol. Cells 1998, 52, 79–93. [Google Scholar] [CrossRef]

- Ali, K.; Khan, S.A.; Mat Jafri, M.Z. Effect of double layer (SiO2/TiO2) anti-reflective coating on silicon solar cells. Int. J. Electrochem. Sci. 2014, 9, 7865–7874. [Google Scholar]

- Sanz, J.M.; Ortiz, D.; Alcaraz de la Osa, R.; Saiz, J.M.; González, F.; Brown, A.S.; Losurdo, M.; Everitt, H.O.; Moreno, F. UV plasmonic behavior of various metal nanoparticles in the near- and far-field regimes: Geometry and substrate effects. J. Phys. Chem. C 2013, 117, 19606–19615. [Google Scholar] [CrossRef]

- Deka, N.; Islam, M.; Sarswat, P.K.; Kumar, G. Enhancing solar cell efficiency with plasmonic behavior of double metal nanoparticle system. Vacuum 2018, 152, 285–290. [Google Scholar] [CrossRef]

- Kelly, K.L.; Coronado, E.; Zhao, L.L.; Schatz, G.C. The optical properties of metal nanoparticles: The influence of size, shape, and dielectric environment. J. Phys. Chem. B 2003, 107, 668–677. [Google Scholar] [CrossRef]

- Tsai, F.J.; Wang, J.Y.; Huang, J.J.; Kiang, Y.W.; Yang, C.C. Absorption enhancement of an amorphous Si solar cell through surface plasmon-induced scattering with metal nanoparticles. Opt. Express 2010, 18, A207–A220. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.C.; Lin, S.J.; Lin, C.H.; Tsai, C.S.; Lu, Y.J. Size effect of Ag nanoparticles on surface plasmon resonance. Surf. Coat. Technol. 2008, 202, 5339–5342. [Google Scholar] [CrossRef]

- Tan, H.; Santbergen, R.; Smets, A.H.M.; Zeman, M. Plasmonic light trapping in thin-film silicon solar cells with improved self-assembled silver nanoparticles. Nano Lett. 2012, 12, 4070–4076. [Google Scholar] [CrossRef] [PubMed]

- Pillai, S.; Catchpole, K.R.; Trupke, T.; Green, M.A. Surface plasmon enhanced silicon solar cells. J. Appl. Phys. 2007, 101, 093105. [Google Scholar] [CrossRef]

- Winans, J.D.; Hungerford, C.; Shome, K.; Rothberg, L.J.; Fauchet, P.M. Plasmonic effects in ultrathin amorphous silicon solar cells: Performance improvements with Ag nanoparticles on the front, the back, and both. Opt. Express 2015, 23, A92–A105. [Google Scholar] [CrossRef] [PubMed]

- Sardana, S.K.; Chava, V.S.N.; Thouti, E.; Chander, N.; Kumar, S.; Reddy, S.R.; Komarala, V.K. Influence of surface plasmon resonances of silver nanoparticles on optical and electrical properties of textured silicon solar cell. Appl. Phys. Lett. 2014, 104, 073903. [Google Scholar] [CrossRef]

- Wang, P.H.; Millard, M.; Brolo, A.G. Optimizing plasmonic silicon photovoltaics with Ag and Au nanoparticle mixtures. J. Phys. Chem. C 2014, 118, 5889–5895. [Google Scholar] [CrossRef]

- Yu, P.; Blondeau, J.P.; Andreazza, C.; Ntsoenzok, E.; Roussel, J.; Dutheil, P.; Thomann, A.L.; Caillard, A.; Mustapha, E.; Meot, J. Influence of gold nanoparticles (Au NPs) for performance improvement of a-Si:H photovoltaic cells. Plasmonics 2015, 10, 691–701. [Google Scholar] [CrossRef]

- Lim, S.H.; Mar, W.; Matheu, P.; Derkacs, D.; Yu, E.T. Photocurrent spectroscopy of optical absorption enhancement in silicon photodiodes via scattering from surface plasmon polaritons in gold nanoparticles. J. Appl. Phys. 2007, 101, 104309. [Google Scholar] [CrossRef]

- Temple, T.L.; Bagnall, D.M. Optical properties of gold and aluminium nanoparticles for silicon solar cell applications. J. Appl. Phys. 2011, 109, 084343-1–084343-13. [Google Scholar] [CrossRef]

- Parashar, P.K.; Sharma, R.P.; Komarala, V.K. Plasmonic silicon solar cell comprised of aluminum nanoparticles: Effect of nanoparticles’ self-limiting native oxide shell on optical and electrical properties. J. Appl. Phys. 2016, 120, 143104. [Google Scholar] [CrossRef]

- Parashar, P.K.; Sharma, R.P.; Komarala, V.K. Mediating broad band light trapping in silicon solar cell by aluminum nanoparticles with native oxide shell. Mater. Today Proc. 2017, 4, 12708–12715. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.; Ouyang, Z.; Lu, H.; Jia, B.; Shi, Z.; Gu, M. Improved multicrystalline Si solar cells by light trapping from Al nanoparticle enhanced antireflection coating. Opt. Mater. Express 2013, 3, 489–495. [Google Scholar] [CrossRef]

- Atwater, H.A.; Polman, A. Plasmonics for improved photovoltaic devices. Nat. Mater. 2010, 9, 205–213. [Google Scholar] [CrossRef] [PubMed]

- Olalla, S.S.; Manuel, J.M.; Sirazul, H.; Tiago, M.; Andreia, A.; Hugo, A.; Elvira, F.; Rodrigo, M. Colloidal-lithographed TiO2 photonic nanostructures for solar cell light trapping. J. Mater. Chem. C 2017, 5, 6852–6861. [Google Scholar] [CrossRef]

- Magnan, F.; Gagnon, J.; Fontaine, F.G.; Boudreau, D. Indium@silica core-shell nanoparticles as plasmonic enhancers of molecular luminescence in the UV region. Chem. Commun. 2013, 49, 9299–9301. [Google Scholar] [CrossRef]

- Das, R.; Soni, R.K. Indium nanoparticles for ultraviolet surface-enhanced Raman spectroscopy. AIP Conf. Proc. 2018, 1953, 030123. [Google Scholar] [CrossRef]

- Haynes, C.L.; Duyne, R.P.V. Plasmon-sampled surface-enhanced Raman excitation spectroscopy. J. Phys. Chem. B 2003, 107, 7426–7433. [Google Scholar] [CrossRef]

- Lee, Y.Y.; Ho, W.J.; Liu, J.J.; Lin, C.H. Light-trapping performance of silicon thin-film plasmonics solar cells based on indium nanoparticles and various TiO2 space layer thicknesses. Jpn. J. Appl. Phys. 2014, 53, 06JE11. [Google Scholar] [CrossRef]

- Ho, W.J.; Lin, J.C.; Liu, J.J.; Yeh, C.W.; Syu, H.J.; Lin, C.F. Plasmonic light scattering in textured silicon solar cells with indium nanoparticles from normal to non-normal light incidence. Materials 2017, 10, 737. [Google Scholar] [CrossRef] [PubMed]

- Ho, W.J.; Su, S.Y.; Lee, Y.Y.; Syu, H.J.; Lin, C.F. Performance-enhanced textured silicon solar cells based on plasmonic light scattering using silver and indium nanoparticles. Materials 2015, 25, 6668–6676. [Google Scholar] [CrossRef] [PubMed]

- Ho, W.J.; Lee, Y.Y.; Lin, C.H.; Yeh, C.W. Performance enhancement of plasmonics silicon solar cells using Al2O3/In NPs/TiO2 antireflective surface coating. Appl. Sur. Sci. 2015, 354, 100–105. [Google Scholar] [CrossRef]

| Silicon Solar Cell | RW (%) @ 380–1000 nm | EQEW (%) @ 380–1000 nm |

|---|---|---|

| Ref. Cell | 4.58 | 88.82 |

| DL-ARC | 4.15 | 89.87 |

| SL-In NPs (3.8 nm) Cell | 3.78 | 90.13 |

| SL-In NPs (5 nm) Cell | 3.54 | 90.45 |

| SL-In NPs (7 nm) Cell | 3.34 | 91.35 |

| DL-In NPs (7 nm) Cell | 2.32 | 92.74 |

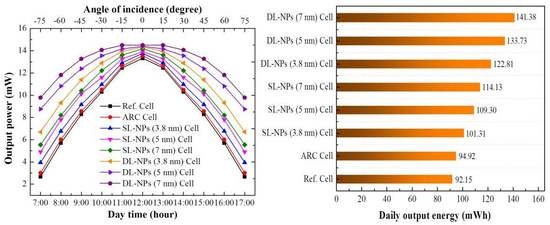

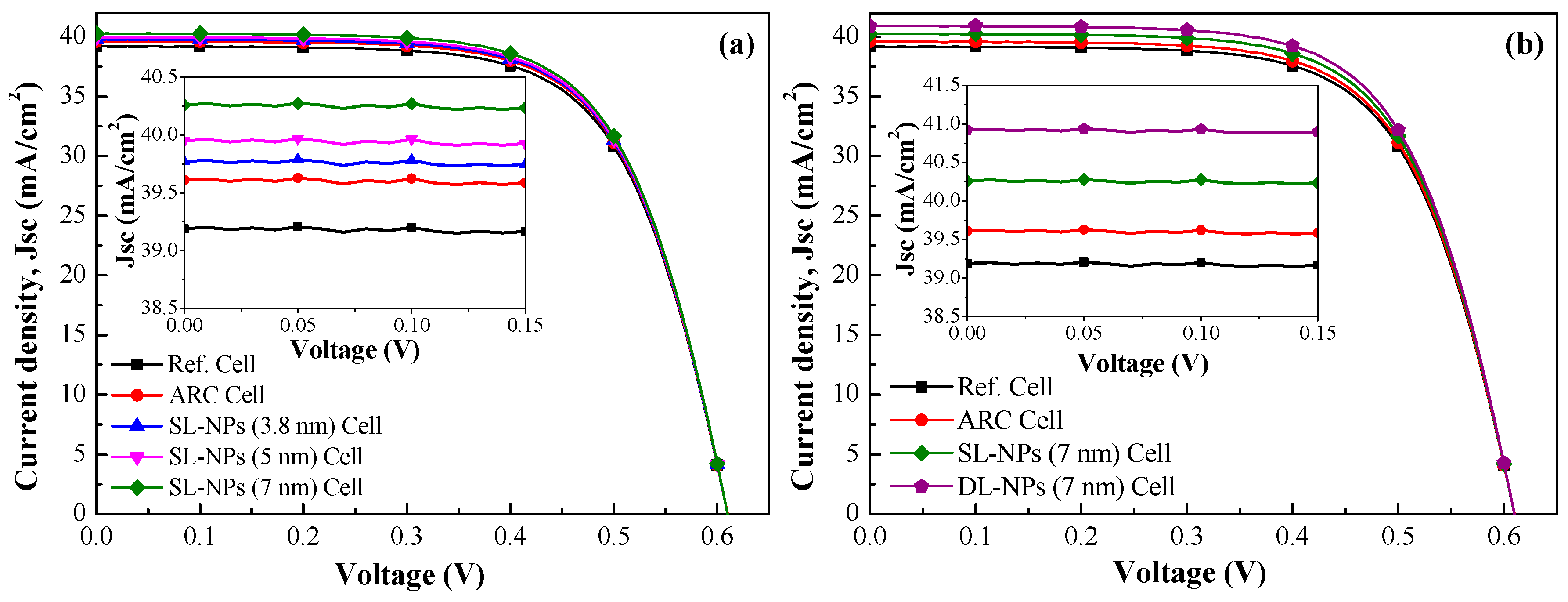

| Silicon Solar Cell | Jsc (mA/cm2) | Voc (mV) | Fill Factor (%) | η (%) | ΔJsc (%) | Δη (%) |

|---|---|---|---|---|---|---|

| Ref. Cell | 39.19 | 609.40 | 67.68 | 16.16 | --- | --- |

| ARC Cell | 39.61 | 609.50 | 67.70 | 16.34 | 1.07 | 1.11 |

| SL-In NPs (3.8 nm) Cell | 39.77 | 609.51 | 67.85 | 16.44 | 1.47 | 1.73 |

| SL-In NPs (5 nm) Cell | 39.95 | 609.52 | 67.84 | 16.51 | 1.93 | 2.16 |

| SL-In NPs (7 nm) Cell | 40.26 | 609.53 | 67.72 | 16.61 | 2.73 | 2.78 |

| DL-In NPs (7 nm) Cell | 40.92 | 609.50 | 68.05 | 16.97 | 4.41 | 5.01 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ho, W.-J.; Liu, J.-J.; Yang, Y.-C.; Ho, C.-H. Enhancing Output Power of Textured Silicon Solar Cells by Embedding Indium Plasmonic Nanoparticles in Layers within Antireflective Coating. Nanomaterials 2018, 8, 1003. https://doi.org/10.3390/nano8121003

Ho W-J, Liu J-J, Yang Y-C, Ho C-H. Enhancing Output Power of Textured Silicon Solar Cells by Embedding Indium Plasmonic Nanoparticles in Layers within Antireflective Coating. Nanomaterials. 2018; 8(12):1003. https://doi.org/10.3390/nano8121003

Chicago/Turabian StyleHo, Wen-Jeng, Jheng-Jie Liu, Yun-Chieh Yang, and Chun-Hung Ho. 2018. "Enhancing Output Power of Textured Silicon Solar Cells by Embedding Indium Plasmonic Nanoparticles in Layers within Antireflective Coating" Nanomaterials 8, no. 12: 1003. https://doi.org/10.3390/nano8121003

APA StyleHo, W.-J., Liu, J.-J., Yang, Y.-C., & Ho, C.-H. (2018). Enhancing Output Power of Textured Silicon Solar Cells by Embedding Indium Plasmonic Nanoparticles in Layers within Antireflective Coating. Nanomaterials, 8(12), 1003. https://doi.org/10.3390/nano8121003