Biocompatibility of Titania Nanotube Coatings Enriched with Silver Nanograins by Chemical Vapor Deposition

Abstract

1. Introduction

2. Results

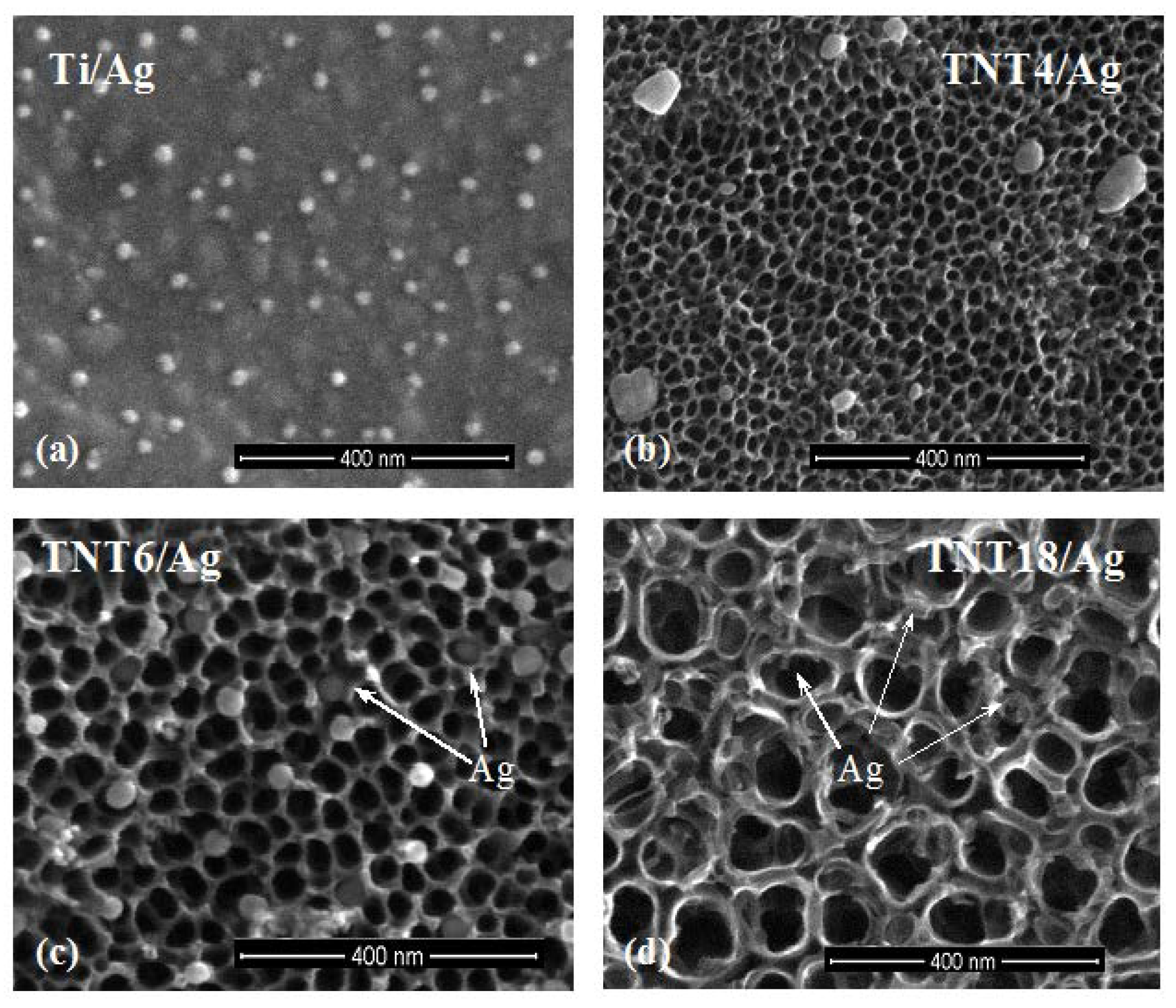

2.1. Fabrication and Characterization of TNT/Ag Nanocomposite Coatings

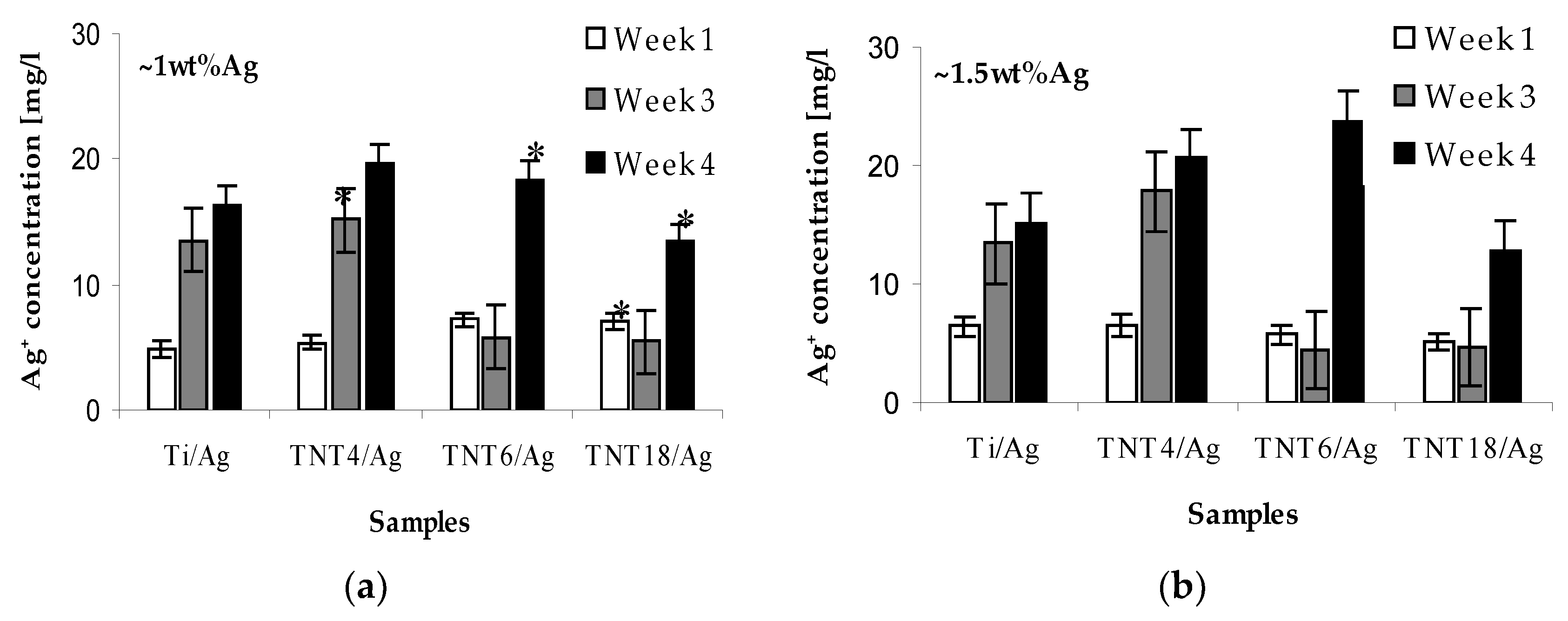

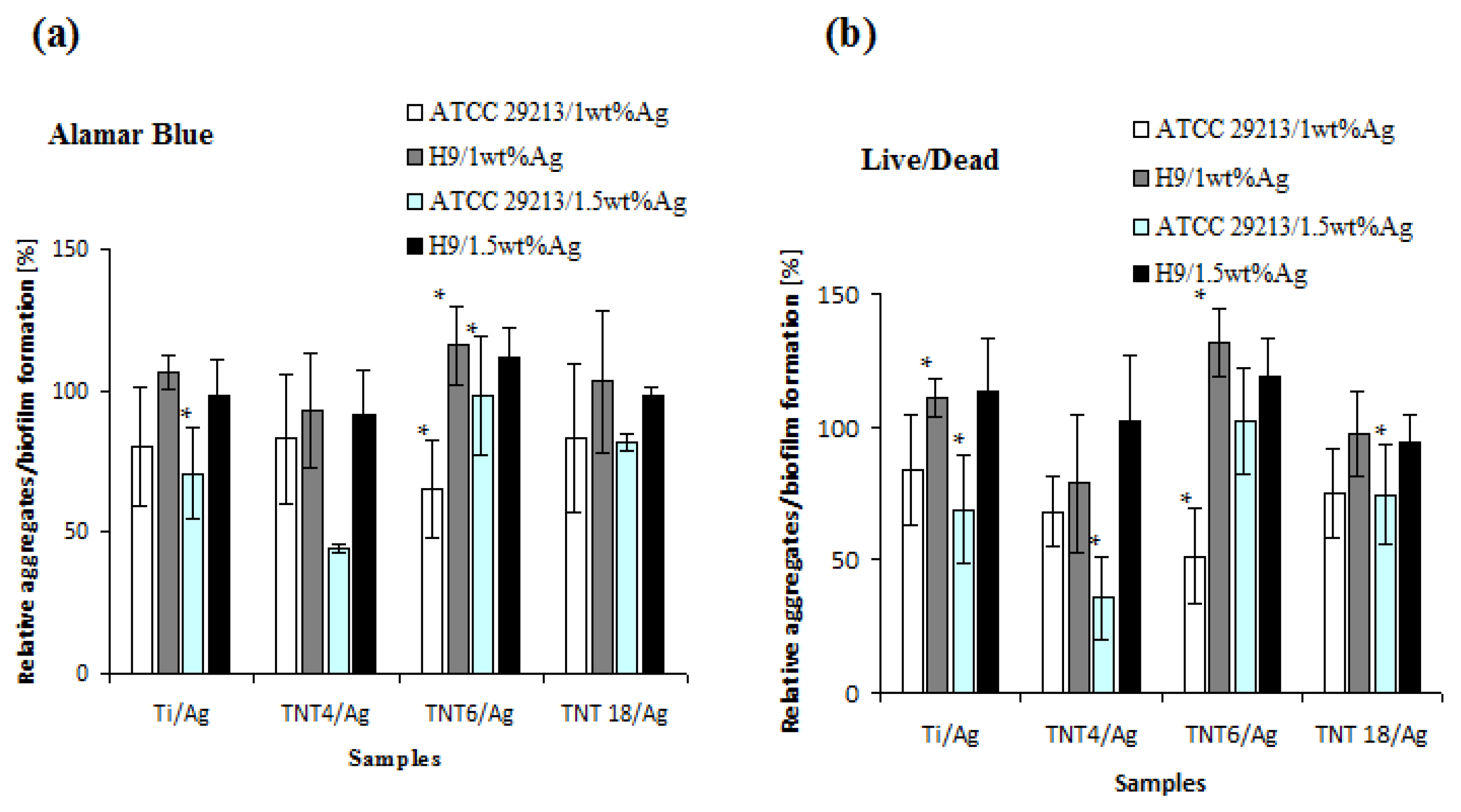

2.2. Antibacterial Activity of TNT/Ag Coatings

2.3. Fibroblasts Cells Adhesion and Proliferation

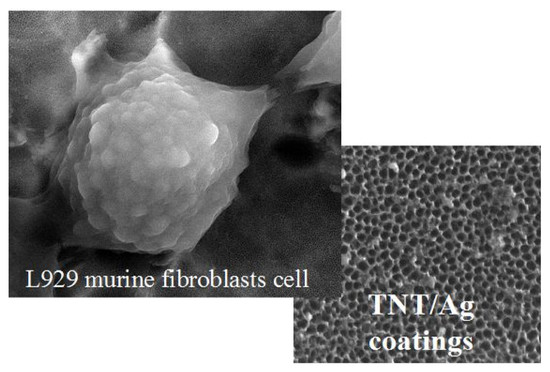

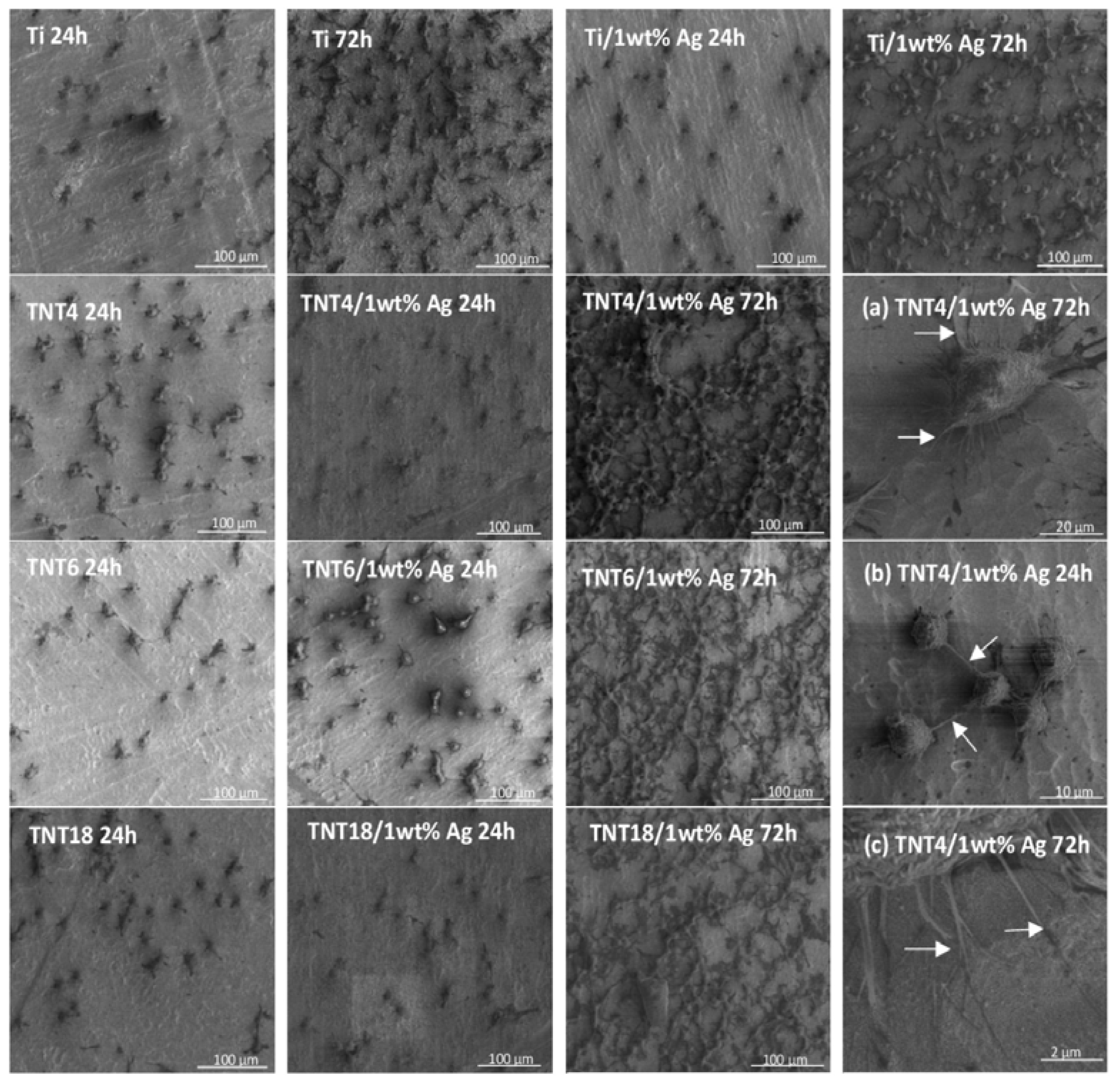

2.4. Morphology of Adherent Fibroblasts

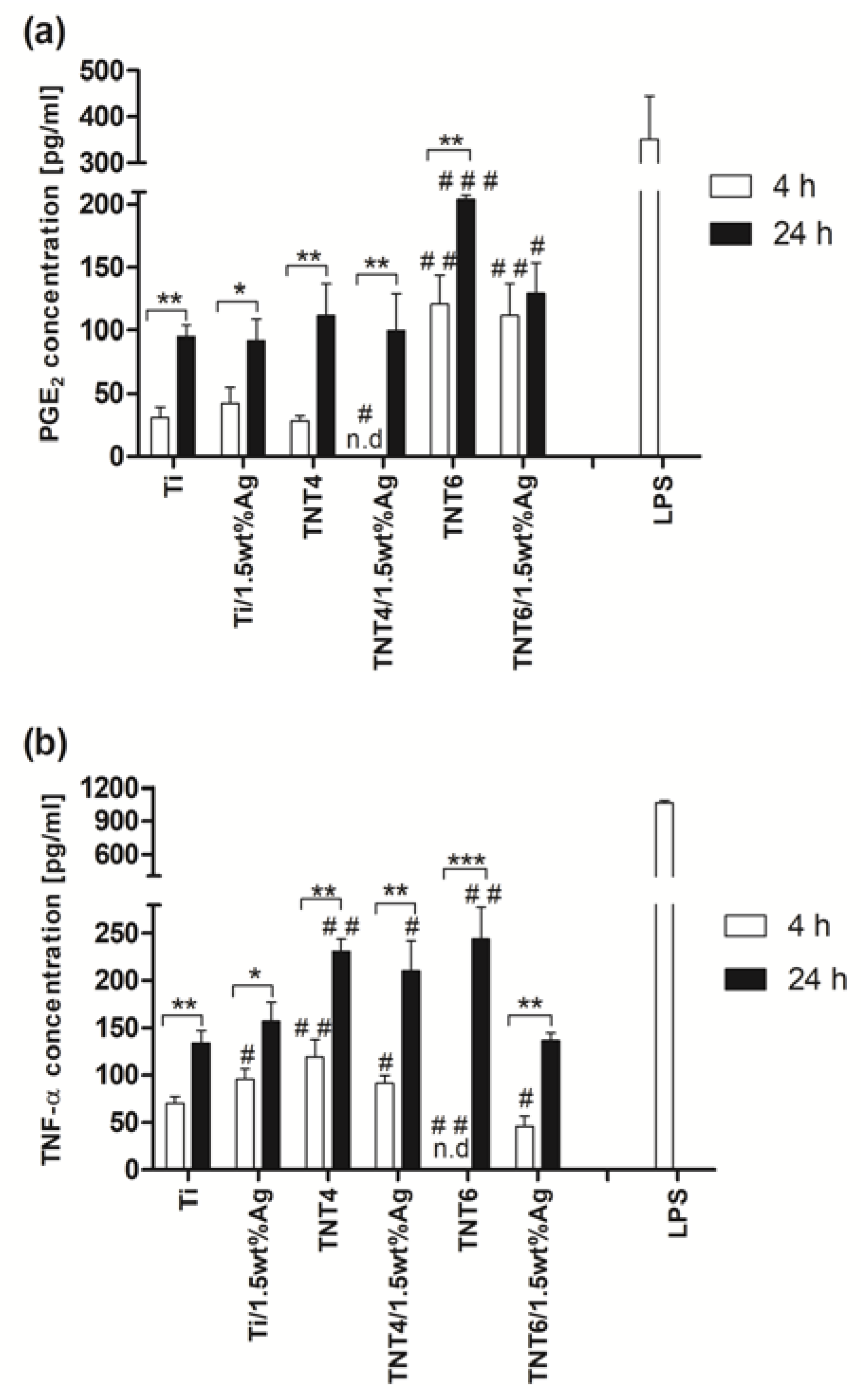

2.5. Effect of TNT on the Synthesis of PGE2 and TNF-α by PBMCs

3. Discussion

4. Materials and Methods

4.1. The Fabrication of Ti/TNT Coatings and Their Characterization

4.2. Synthesis and Characterization of TNT/Ag Nanocomposite Coatings

4.3. Antibacterial Properties of TNT/Ag Coatings

4.4. L929 Cells Culture

4.5. L929 Cells Adhesion and Proliferation Assay on TNT

4.6. Peripheral Blood Mononuclear Cells Isolation and Culture

4.7. PBMCs Culture Condition for Enzyme-Linked Immunosorbent Assay (ELISA)

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jurczyk, M. Biomaterials for Dental Applications. Pan Stanford Publications Pte. Ltd.: Singapore, 2013; Volume 42, p. 251. [Google Scholar]

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Das, K.; Bose, S.; Bandyoppadhyay, A. TiO2 nanotubes on Ti: Influence of nanoscale morphology on bone cell-materials interaction. J. Biomed. Mater. Res. A 2009, 90, 225–237. [Google Scholar] [CrossRef] [PubMed]

- Goyal, N.; Priyanka, R.K. Effect of various implant surface treatments on osseointegration—A Literature Review. Indian J. Dent. Sci. 2012, 4, 154–157. [Google Scholar]

- Gulati, K.; Prideaux, M.; Kogawa, M.; Lima-Marques, L.; Atkins, G.J.; Findlay, D.M.; Losic, D. Anodized 3D-printed titanium implants with dual micro- and nano-scale topography promote interaction with human osteoblasts and osteocyte-like cells. J. Tissue Eng. Regen. Med. 2016. [Google Scholar] [CrossRef] [PubMed]

- Nakae, H.; Yoshida, M.; Yokota, M. Effects of roughness pitch of surfaces on their wettability. J. Mater. Sci. 2005, 40, 2287–2293. [Google Scholar] [CrossRef]

- Ponsonnet, L.; Reybier, K.; Jaffrezic, N.; Comte, V.; Lagneau, C.; Lissac, M.; Martelet, C. Relationship between surface properties (roughness, wettability) of titanium and titanium alloys and cell behavior. Mater. Sci. Eng. C 2003, 23, 551–560. [Google Scholar] [CrossRef]

- Sollazzo, V.; Pezzetti, F.; Scarano, A.; Piattelli, A.; Bignozzi, C.A.; Massari, L.; Brunelli, G.; Carinci, F. Zirconium oxide coating improves implant osseointegration in vivo. Dent. Mater. 2008, 24, 357–361. [Google Scholar] [CrossRef] [PubMed]

- Steflik, D.E.; Sisk, A.L.; Parr, G.R.; Gardner, L.K.; Hanes, P.J.; Lake, F.T.; Berkery, D.J.; Brewer, P. Osteogenesis at the dental implant interface: High-voltage electron microscopic and conventional transmission electron microscopic observations. J. Biomed. Mater. Res. 1993, 27, 791–800. [Google Scholar] [CrossRef] [PubMed]

- Lewandowska, Ż.; Piszczek, P.; Radtke, A.; Jędrzejewski, T.; Kozak, W.; Sadowska, B. The evaluation of the impact of titania nanotube covers morphology and crystal phase on their biological properties. J. Mater. Sci. 2015, 26, 163. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Cui, Q.; Feng, B.; Wang, J.; Lu, X.; Weng, J. Antibacterial activity of TiO2 nanotubes: Influence of crystal phase, morphology and Ag deposition. J. Appl. Surf. Sci. 2013, 284, 179–183. [Google Scholar] [CrossRef]

- Fielding, G.A.; Roy, M.; Bandyopadhyay, A.; Bose, S. Antibacterial and biological characteristics of silver containing and strontium doped plasma sprayed hydroxyapatite coatings. Acta Biomater. 2012, 8, 3144–3152. [Google Scholar] [CrossRef] [PubMed]

- Wijnhoven, S.W.P.; Peijnenburg, W.J.G.M.; Herbersts, C.A.; Hagens, W.I.; Oomen, A.G.; Heugens, E.H.W.; Roszek, B.; Bisschops, J.; Gosens, I.; Van De Meent, D.; et al. Nano-silver—A review of available data and knowledge gaps in human and environmental risk assessment. Nanotoxicology 2009, 3, 109–138. [Google Scholar] [CrossRef]

- Piszczek, P.; Muchewicz, Ż.; Radtke, A.; Gryglas, M.; Dahm, H.; Różycki, H. CVD of TiO2 and TiO2/Ag antimicrobial layers: Deposition from the hexanuclear μ-oxo Ti (IV) complex as a precursor, and the characterization. Surf. Coat. Technol. 2013, 222, 38–43. [Google Scholar] [CrossRef]

- Cho, K.-H.; Park, J.-E.; Osaka, T.; Park, S.-G. The study of antimicrobial activity and preservative effects of nanosilver ingredient. Electrochim. Acta 2005, 51, 956–960. [Google Scholar] [CrossRef]

- Torres, N.; Oh, S.; Appleford, M.; Dean, D.D.; Jorgensen, J.H.; Ong, J.I.; Agrawal, C.M.; Mani, G. Stability of antibacterial self-assembled monolayers on hydroxyapatite. Acta Biomater. 2010, 6, 3242–3255. [Google Scholar] [CrossRef] [PubMed]

- Pisarek, M.; Rogulska, A.; Kudelski, A.; Andrzejczuk, M.; Janik-Czachor, M.; Kurzydłowski, K.J. The role of Ag particles deposited on TiO2 or Al2O3 self-organized nanoporous layers in their behavior as SERS-active and biomedical substrates. Mater. Chem. Phys. 2013, 139, 55–65. [Google Scholar] [CrossRef]

- Prabhu, S.; Poulose, E.K. Silver nanoparticles: Mechanism of antimicrobial action, synthesis, medical applications, and toxicity effects. Int. Nano Lett. 2012, 2, 3–10. [Google Scholar] [CrossRef]

- Hou, X.; Ma, H.; Liu, F.; Deng, J.; Ai, Y.; Zhao, X.; Mao, D.; Li, D.; Liao, B. Synthesis of Ag ion-implanted TiO2 thin films for antibacterial application and photocatalytic performance. J. Hazard. Mater. 2015, 299, 59–66. [Google Scholar] [CrossRef] [PubMed]

- Ewald, A.; Glückerman, S.K.; Thull, R.; Gbureck, U. Antimicrobial titanium/silver PVD coatings on titanium. Biomed. Eng. OnLine 2006, 5, 22. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Oh, S.; Ong, A.P.; Oh, N.; Liu, Y.; Courtney, H.S.; Appleford, M.; Ong, J.I. Antibacterial and osteogenic properties of silver-containing hydroxyapatite coatings produced using a sol gel process. J. Biomed. Mater. Res. A 2007, 82, 899–906. [Google Scholar] [CrossRef] [PubMed]

- Guzman, M.; Dille, J.; Godet, S. Synthesis and antibacterial activity of silver nanoparticles against gram-positive and gram-negative bacteria. Nanomedicine 2012, 8, 37–45. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Zhang, X.; Wang, X.; Qin, L. Review of Antibacterial Activity of Titanium-Based Implants’ Surfaces Fabricated by Micro-Arc Oxidation. Coatings 2017, 7, 45. [Google Scholar] [CrossRef]

- Bugla-Płoskońska, G.; Jasiorski, M.; Leszkiewicz, A.; Borak, B.; Drulis-Kawa, Z.; Baszczuk, A.; Maruszewski, K.; Doroszkiewicz, W. Silver nanoislands located on the silica spheres and its antimicrobial activity against Klebsiella pnaumoniae strain. Nano Sci. Nano Thechnol. Indian J. 2008, 2, 45–47. [Google Scholar]

- Mungkalasiri, J.; Bedel, L.; Emieux, F.; Renaud, F.N.R.; Sarantopoulos, C.; Maury, F. CVD Elaboration of Nanostructured TiO2-Ag Thin Films with Efficient Antibacterial Properties. Chem. Vap. Depos. 2010, 16, 35–41. [Google Scholar] [CrossRef]

- Plodinec, M.; Gajović, A.; Jakša, G.; Žagar, K.; Čeh, M. High-temperature hydrogenation of pure and silver-decorated titanate nanotubes to increase their solar absorbance for photocatalytic applications. J. Alloys Compd. 2014, 591, 147–155. [Google Scholar] [CrossRef]

- Lei, X.F.; Xue, X.X.; Yang, H. Preparation and characterization of Ag-doped TiO2 nanomaterials and their photocatalytic reduction of Cr (VI) under visible light. Appl. Surf. Sci. 2014, 321, 396–403. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, C.; Guo, Q.; Li, Y.; Zhang, L. Fabrication of silver-incorporated TiO2 nanotubes and evaluation on its antibacterial activity. Mater. Lett. 2014, 137, 464–467. [Google Scholar] [CrossRef]

- Xie, K.; Sun, L.; Wang, C.; Lai, Y.; Wang, M.; Chen, H.; Lin, C. Photoelectrocatalytic properties of Ag nanoparticles loaded TiO2 nanotube arrays prepared by pulse current deposition. Electrochemical 2010, 55, 7211–7218. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Y.; Tian, A.; Xue, X.X.; Wang, L.; Alquhali, A.; Bai, X. Improved antibacterial activity and biocompatibility on vancomycin-loaded TiO2 nanotubes: In vivo and in vitro studies. Int. J. Nanomed. 2013, 8, 4379–4389. [Google Scholar] [CrossRef] [PubMed]

- Radtke, A.; Piszczek, P.; Topolski, A.; Lewandowska, Ż.; Talik, E.; Andersen, I.H.; Nielsen, L.P.; Heikkilä, M.; Leskelä, M. The structure and the photocatalytic activity of titania based nanotube and nanofiber coatings. Appl. Surf. Sci. 2016, 368, 165–172. [Google Scholar] [CrossRef]

- Szłyk, E.; Piszczek, P.; Grodzicki, A.; Chaberski, M.; Goliński, A.; Szatkowski, J.; Błaszczyk, T. CVD of AgI complexes with tertiary phosphines and perfluorinated carboxylates—A new class of silver precursors. Chem. Vap. Depos. 2001, 7, 111–116. [Google Scholar] [CrossRef]

- Szłyk, E.; Piszczek, P.; Chaberski, M.; Goliński, A. Studies of thermal decomposition process of Ag(I) perfluorinated carboxylates with temperature variable IR and MS. Polyhedron 2001, 20, 2853–2861. [Google Scholar] [CrossRef]

- Piszczek, P.; Szłyk, E.; Chaberski, M.; Taeschner, C.; Leonhard, A.; Bała, W.; Bartkiewicz, K. Characterization of silver trimethylacetate complexes with tertiary phosphines as CVD precursors of thin silver films. Chem. Vap. Depos. 2005, 11, 53–59. [Google Scholar] [CrossRef]

- Szymańska, I.; Piszczek, P.; Szczęsny, R.; Szłyk, E. Thermal and MS studies of silver (I) 2, 2-dimethylbutyrate complexes with tertiary phosphines and their application for CVD of silver films. Polyhedron 2007, 26, 2440–2448. [Google Scholar] [CrossRef]

- Kumar, R.; Műnstedt, H. Silver release from antimicribial polyamide/silver composites. Biomaterials 2005, 6, 2081–2088. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Feng, B.; Li, Y.; Tan, J.; Lu, X.; Weng, J. Preparation and antibacterial activity of titanium nanotubes loaded with Ag nanoparticles in the dark and under the UV light. Appl. Surf. Sci. 2013, 280, 8–14. [Google Scholar] [CrossRef]

- Flemming, H.-C.; Wingender, J.; Szewzyk, U.; Steinberg, P.; Rice, S.A.; Kjelleberg, S. Biofilms: An emergent form of bacterial life. Nat. Rev. Microbiol. 2016, 14, 563–575. [Google Scholar] [CrossRef] [PubMed]

- Radtke, A.; Topolski, A.; Jędrzejewski, T.; Kozak, W.; Sadowska, B.; Więckowska-Szczakiel, M.; Szubka, M.; Talik, E.; Nielsen, L.P.; Piszczek, P. Biofilms: An emergent form of bacterial life. Nanomaterials 2017, 7, 197. [Google Scholar] [CrossRef]

- Lan, M.Y.; Liu, C.P.; Huang, H.H.; Lee, S.W. Both enhanced biocompatibility and antibacterial activity in Ag-decorated TiO2 nanotubes. PLoS ONE 2013, 8, e75364. [Google Scholar] [CrossRef] [PubMed]

- Braydich-Stolle, L.; Hussain, S.; Schlager, J.; Hofmann, M.C. In vitro cytotoxicity of nanoparticles in mammalian germline stem cells. Toxicol. Sci. 2005, 88, 412–419. [Google Scholar] [CrossRef] [PubMed]

- Alt, V.; Bechert, T.; Steinrucke, P.; Wagener, M.; Seidel, P. An in vitro assessment of the antibacterial properties and cytotoxicity of nanoparticulate silver bone cement. Biomaterials 2004, 25, 4383–4391. [Google Scholar] [CrossRef] [PubMed]

- Liao, J.; Anchun, M.; Zhu, Z.; Quan, Y. Antibacterial titanium plate deposited by silver nanoparticles exhibits cell compatibility. Int. J. Nanomed. 2010, 5, 337–342. [Google Scholar]

- Chang, Y.Y.; Lai, C.H.; Hsu, J.T.; Tang, C.H.; Liao, W.C.; Huang, H.L. Antibacterial properties and human gingival fibroblast cell compatibility of TiO2/Ag compound coatings and ZnO films on titanium-based material. Clin. Oral Investig. 2012, 16, 95–100. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.L.; Chang, Y.Y.; Lai, M.C.; Lin, C.R.; Lai, C.H.; Shieh, T.M. Antibacterial TaN-Ag coatings on titanium dental implants. Surf. Coat. Technol. 2010, 205, 1636–1641. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, B.; Wang, Y.; Zhou, X.; Weng, J.; Qu, S.; Feng, B.; Watari, F.; Ding, Y.; Leng, Y. Nano-Ag-loaded hydroxyapatite coatings on titanium surfaces by electrochemical deposition. J. R. Soc. Interface 2011, 8, 529–539. [Google Scholar] [CrossRef] [PubMed]

- Swan, E.E.; Popat, K.C.; Grimes, C.A.; Desai, T.A. Fabrication and evaluation of nanoporous alumina membranes for osteoblast culture. J. Biomed. Mater. Res. A 2005, 72, 288–295. [Google Scholar] [CrossRef] [PubMed]

- Dalby, M.J.; Riehle, M.O.; Johnstone, H.; Affrossman, S.; Curtis, A.S. Investigating the limits of filopodial sensing: A brief report using SEM to image the interaction between 10 nm high nano-topography and fibroblast filopodia. Cell. Biol. Int. 2004, 28, 229–236. [Google Scholar] [CrossRef] [PubMed]

- Silverwood, R.K.; Fairhurst, P.G.; Sjöström, T.; Welsh, F.; Sun, Y.; Li, G.; Yu, B.; Young, P.S.; Su, B.; Meek, R.M.D.; et al. Analysis of osteoclastogenesis/osteoblastogenesis on nanotopographical titania surfaces. Adv. Healthc. Mater. 2016, 5, 947–955. [Google Scholar] [CrossRef] [PubMed]

- Brammer, K.S.; Frandsen, C.J.; Jin, S. TiO2 nanotubes for bone regeneration. Trends Biotechnol. 2012, 30, 315–322. [Google Scholar] [CrossRef] [PubMed]

- Furuhashi, A.; Ayukawa, Y.; Atsuta, I.; Okawachi, H.; Koyano, K. The difference of fibroblast behavior on titanium substrata with different surface characteristics. Odontology 2012, 100, 199–205. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Cai, Z.; Wang, W.; Ge, F. Preparation of superhydrophobic cotton fabrics based on SiO2 nanoparticles and ZnO nanorod arrays with subsequent hydrophobic modification. Surf. Coat. Technol. 2010, 204, 1556–1561. [Google Scholar] [CrossRef]

- Higgins, D.M.; Basaraba, R.J.; Hohnbaum, A.C.; Lee, E.J.; Grainger, D.W.; Gonzalez-Juarrero, M. Localized immunosuppressive environment in the foreign body response to implanted biomaterials. Am. J. Pathol. 2009, 175, 161–170. [Google Scholar] [CrossRef] [PubMed]

- Gschwind, A.; Zwick, E.; Prenzel, N.; Leserer, M.; Ullrich, A. Cell communication networks: Epidermal growth factor receptor transactivation as the paradigm for interreceptor signal transmission. Oncogene 2001, 20, 1594–1600. [Google Scholar] [CrossRef] [PubMed]

- Dinarello, C.A. Role of pro-and anti-inflammatory cytokines during inflammation: Experimental and clinical findings. J. Biol. Regul. Homeost. Agents 1997, 11, 91–103. [Google Scholar] [PubMed]

- Kalinski, P. Regulation of immune responses by prostaglandin E2. J. Immunol. 2012, 188, 21–28. [Google Scholar] [CrossRef] [PubMed]

- Kieswetter, K.; Schwartz, Z.; Hummert, T.W.; Cochran, D.L.; Simpson, J.; Dean, D.D.; Boyan, B.D. Surface roughness modulates the local production of growth factors and cytokines by osteoblast-like MG-63 cells. J. Biomed. Mater. Res. 1996, 32, 55–63. [Google Scholar] [CrossRef]

- Kaji, H.; Sugimoto, T.; Kanatani, M.; Fukase, M.; Kumegawa, M.; Chihara, K. Prostaglandin E2 stimulates osteoclast-like cell formation and bone-resorbing activity via osteoblasts: Role of cAMP-dependent protein kinase. J. Bone Miner. Res. 1996, 11, 62–71. [Google Scholar] [CrossRef] [PubMed]

- Lincks, J.; Boyan, B.D.; Blanchard, C.R.; Lohmann, C.H.; Liu, Y.; Cochran, D.L.; Dean, D.D.; Schwartz, Z. Response of MG63 osteoblast-like cells to titanium and titanium alloy is dependent on surface roughness and composition. Biomaterials 1998, 19, 2219–2232. [Google Scholar] [CrossRef]

- Yang, J.S.; Vang, M.S.; Uhm, S.W.; Chung, Y.S.; Lee, K.K.; Lee, D.J.; Chung, H.J.; Kim, Y.J. Response of fetal rat calvarial cells to nanotubular titanium oxide surface. J. Nanosci. Nanotechnol. 2011, 11, 1807–1810. [Google Scholar] [CrossRef] [PubMed]

- Batzer, R.; Liu, Y.; Cochran, D.L.; Szmuckler-Moncler, S.; Dean, D.D.; Boyan, B.D.; Schwartz, Z. Prostaglandins mediate the effects of titanium surface roughness on MG63 osteoblast-like cells and alter cell responsiveness to 1α, 25-(OH)2D3. J. Biomed. Mater. Res. 1998, 41, 489–496. [Google Scholar] [CrossRef]

- Li, M.; Thompson, D.D.; Paralkar, V.M. Prostaglandin E2 receptors in bone formation. Int. Orthop. 2007, 31, 767–772. [Google Scholar] [CrossRef] [PubMed]

- Esfahanizadeh, N.; Motalebi, S.; Daneshparvar, N.; Akhoundi, N.; Bonakdar, S. Morphology, proliferation, and gene expression of gingival fibroblasts on Laser-Lok, titanium, and zirconia surfaces. Lasers Med. Sci. 2016, 31, 863–873. [Google Scholar] [CrossRef] [PubMed]

- Barrientos, S.; Stojadinovic, O.; Golinko, M.S.; Brem, H.; Tomic-Canic, M. Growth factors and cytokines in wound healing. Wound Repair Regen. 2008, 16, 585–601. [Google Scholar] [CrossRef] [PubMed]

- Szłyk, E.; Łakomska, I.; Grodzicki, A. Studies of Ag(I) complexes with triphenylphosphine and fluorinated carboxylates. Pol. J. Chem. 1994, 68, 1529–1534. [Google Scholar]

- Szłyk, E.; Łakomska, I.; Grodzicki, A. Studies of Au(I) complexes with triphenylphosphine and perfluorinated carboxylates. Pol. J. Chem. 1995, 69, 1103–1108. [Google Scholar]

- Jędrzejewski, T.; Pawlikowska, M.; Piotrowski, J.; Kozak, W. Protein-bound polysaccharides from Coriolus versicolor attenuate LPS-induced synthesis of pro-inflammatory cytokines and stimulate PBMCs proliferation. Immunol. Lett. 2016, 178, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Jedrzejewski, T.; Wrotek, S.; Piotrowski, J.; Kozak, W. Silver nanoparticles augment releasing of pyrogenic factors by blood cells stimulated with LPS. Cent. Eur. J. Biol. 2014, 9, 1058–1067. [Google Scholar] [CrossRef]

| Sample | Ti4+ | O2− | OH− | H2O | Ag | ||

|---|---|---|---|---|---|---|---|

| Ti (2p3/2) (eV) | Ti (2p1/2) (eV) | O (1s) (eV) | O (1s) (eV) | O (1s) (eV) | Ag (3d5/2) (eV) | Ag (3d5/2) (eV) | |

| TNT4/Ag | 458.9 | 464.7 | 530.5 (58%) | 532.0 (29%) | 533.2 (13%) | 368.5 | 374.5 |

| TNT6/Ag | 459.3 | 465.1 | 530.1 (71%) | 531.8 (22%) | 533.0 (7%) | 368.8 | 374.9 |

| TNT18/Ag | 459.5 | 465.3 | 530.3 (54%) | 531.7 (13%) | 532.7 (33%) | 368.0 | 373.9 |

| Sample | dTNT (nm) | dAg (nm) |

|---|---|---|

| Ti/Ag | - | 35–40 |

| TNT4/Ag | 20–30 | 45–65 |

| TNT6/Ag | 35–45 | 30–45 |

| TNT18/Ag | 100–150 | ≥15 |

| Precursor | Ag(OOCC2F5) |

|---|---|

| Precursor weight (mg) | 5 and 10 |

| Vaporization temperature (TV) (K) | 513 |

| Carrier gas | Ar |

| Total reactor pressure (p) (mbar) | 3.0 |

| Substrate temperature (TD) (K) | 553 |

| Substrates | Ti/TNT |

| Deposition time (min) | 30 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piszczek, P.; Lewandowska, Ż.; Radtke, A.; Jędrzejewski, T.; Kozak, W.; Sadowska, B.; Szubka, M.; Talik, E.; Fiori, F. Biocompatibility of Titania Nanotube Coatings Enriched with Silver Nanograins by Chemical Vapor Deposition. Nanomaterials 2017, 7, 274. https://doi.org/10.3390/nano7090274

Piszczek P, Lewandowska Ż, Radtke A, Jędrzejewski T, Kozak W, Sadowska B, Szubka M, Talik E, Fiori F. Biocompatibility of Titania Nanotube Coatings Enriched with Silver Nanograins by Chemical Vapor Deposition. Nanomaterials. 2017; 7(9):274. https://doi.org/10.3390/nano7090274

Chicago/Turabian StylePiszczek, Piotr, Żaneta Lewandowska, Aleksandra Radtke, Tomasz Jędrzejewski, Wiesław Kozak, Beata Sadowska, Magdalena Szubka, Ewa Talik, and Fabrizio Fiori. 2017. "Biocompatibility of Titania Nanotube Coatings Enriched with Silver Nanograins by Chemical Vapor Deposition" Nanomaterials 7, no. 9: 274. https://doi.org/10.3390/nano7090274

APA StylePiszczek, P., Lewandowska, Ż., Radtke, A., Jędrzejewski, T., Kozak, W., Sadowska, B., Szubka, M., Talik, E., & Fiori, F. (2017). Biocompatibility of Titania Nanotube Coatings Enriched with Silver Nanograins by Chemical Vapor Deposition. Nanomaterials, 7(9), 274. https://doi.org/10.3390/nano7090274