Abstract

Polymer-based nanocomposites have demonstrated significant strategic value in dielectric energy storage systems due to their tunable high energy density and rapid charge–discharge efficiency. Poly(arylene ether nitrile) (PEN), owing to its superior thermal stability, high mechanical strength, chemical corrosion resistance, and outstanding dielectric properties, exhibits distinct advantages in the field of high-performance dielectric energy storage devices. This review focuses on key strategies for enhancing the dielectric energy storage performance of PEN-based composites, emphasizing molecular engineering approaches, microstructural design, the multiscale interface regulation mechanisms within composite systems, and the optimization of the dielectric constant (εr) and breakdown strength (Eb) through thermal stretching. Furthermore, the potential of PEN-based polymer composites in energy storage devices is highlighted, and future research directions are proposed, including the establishment of a dynamic balance mechanism between dielectric/insulating properties and the development of novel composite systems that offer both high energy storage density and stability. These advancements will provide the material foundation for the miniaturization and intellectualization of advanced pulse power equipment.

1. Introduction

The global transition towards cleaner and more efficient energy architectures has positioned the development of advanced energy storage technologies with both high power density and operational reliability as a pivotal driver for the energy revolution [1,2,3,4,5]. As one of the core components for next-generation energy storage devices, dielectric capacitors have demonstrated irreplaceable value in pulsed power applications including smart grid frequency regulation [6,7], electromagnetic weapon systems [8,9], and new energy electric vehicles owing to their ultra-fast charge–discharge characteristics (on the μs timescale) and exceptional power density (~108 W/kg) [10,11,12,13]. Among various dielectric materials for these capacitors, polymer-based composite systems have attracted significant attention due to their superior processability, high Eb, and excellent mechanical flexibility [14,15,16,17,18,19]. Notably, poly(arylene ether nitrile) (PEN), an emerging high-performance engineering plastic, has emerged as a research hotspot due to its unique aromatic ether-nitrile synergistic effects [20,21,22,23,24]. This molecular structure endows PEN with remarkable εr and superior solution/melt-processing capabilities [25,26,27,28], demonstrating potential to surpass the performance limitations of conventional poly(vinylidene fluoride) (PVDF)-based materials, particularly in high-temperature dielectric applications [29,30].

As a semi-crystalline polymer featuring aromatic ether linkages and strongly polar nitrile groups (–C≡N) in its structure [31], PEN exhibits exceptional comprehensive properties through molecular engineering: The rigid skeleton constructed by aromatic ether units ensures ultrahigh glass transition temperature (Tg > 150 °C), thermal decomposition temperature (Td > 450 °C) and melting point (Tm > 330 °C), guaranteeing thermal stability under extreme operating conditions [32]. Meanwhile, the high dipole moment from nitrile groups significantly enhances chain polarization capability, resulting in a higher εr (εr ≈ 3.8 at 1 kHz) than other polymers such as polyimide [33]. This unique ‘rigid-flexible balance’ characteristic renders PEN particularly promising for energy storage applications under high-temperature and high-electric-field conditions [34]. Furthermore, compared with other high-performance polymers such as polyimide (PI), polyetherimide (PEI), and polyetherketone (PEK), PEN demonstrates enhanced solution processability and melt-processing capabilities attributable to its pendant cyano groups [35,36]. However, current studies reveal that the energy storage density of pure PEN (Ue ≈ 0.78 J/cm3) remains inadequate for next-generation power systems’ demands on dielectric capacitors, resulting in an urgent need for performance breakthroughs through innovative material design and processing technologies [37].

Energy storage density serves as a key parameter for evaluating the energy storage performance of dielectric materials. When subjected to an external electric field, dielectric materials undergo polarization phenomena that generate induced charges on the electrode plates, enabling energy storage. The energy storage density of dielectric materials can be calculated using Equation (1) [38]:

where Ue denotes the storage density, E represents the applied field strength, and D corresponds to the electric displacement. D, characterizing the material’s response to electric fields, equals the surface charge density of parallel-plate capacitors. As governed by Maxwell’s equations describing fundamental electromagnetic principles, the relationship between electric displacement and applied field can be expressed as Equation (2) [39]:

Ue = ∫EdD

D = ε0εrE

For linear dielectrics such as PEN where εr remains field-independent, the energy density formula simplifies to Equation (3) [40]:

where ε0 is the vacuum permittivity (8.85 × 10−12 F/m). This formulation reveals that energy storage density is dependent on εr and quadratic Eb. Consequently, enhancing these two parameters constitutes the principal pathway for energy storage performance improvement. Current dielectric optimization strategies focus on two principal approaches: intrinsic molecular polarization enhancement and composite synergy of extrinsic polarization. Molecular engineering approaches that directionally introduce high-polarity functional groups (e.g., cyano and fluoro groups) into the PEN backbone can substantially enhance dipolar orientation capabilities while maintaining high insulation properties [7,12]. The extrinsic composite strategy involves introducing organic fillers, perovskite ceramic nanoparticles (e.g., barium titanate), or conductive fillers (e.g., graphene) into the PEN matrix to generate synergistic dielectric enhancement through interfacial polarization and micro-capacitance effects. Notably, surface functionalization techniques have emerged as critical approaches to enhance filler dispersion and optimize interfacial dielectric compatibility [15,20], which is essential for balancing dielectric response and loss characteristics in composite systems.

Ue = 0.5ε0εrEb2

Enhancement of Eb requires coordinated breakthroughs in intrinsic defect mitigation and electric field distribution regulation. Molecular design strategies, including co-polymerization modification for chain rigidity enhancement and cross-linked network construction, can effectively suppress charge carrier migration and space charge accumulation [3,22]. Concurrently, multilayered composite architecture design or incorporation of 2D insulating fillers (e.g., boron nitride, BN) can physically block electrical treeing propagation pathways and homogenize electric field distribution. The integration of these multi-scaled modification strategies provides new possibilities for achieving both high Eb and superior energy storage efficiency. The uniaxial hot-stretching technique leverages synergistic effects between molecular chain alignment and in-plane filler orientation, simultaneously enhancing crystallization (reducing defect density) and establishing anisotropic conductive pathways [6,27]. This innovative approach demonstrates unique advantages in the simultaneous optimization of εr and Eb, offering new pathways to overcome performance limitations of conventional modification methods.

This review systematically summarizes recent advancements in PEN-based dielectric materials, focusing on elucidating optimization mechanisms for εr and Eb. We firstly expound the intrinsic polarization enhancement through molecular engineering strategies, then discuss multi-scaled interface regulation mechanisms in filler composite systems, and conclusively analyze microstructure design principles for electric field optimization. Special emphasis is placed on emerging technologies like uniaxial hot-stretching, with detailed discussion on their dual-enhancement mechanism for εr and Eb via synergistic molecular chain orientation and filler alignment. Finally, we outline current challenges in PEN-based composites and propose multi-scaled structural design as a promising research direction, offering fundamental insights for developing high-performance PEN-based energy storage materials.

2. Strategic Framework for Enhancing Dielectric Constant of PEN

This section methodically elaborates three principal strategies to improve the dielectric constant of PEN for high energy storage performance: molecular structure design, composite system construction (organic/ceramic/conductive fillers in PEN matrix), and uniaxial orientation hot-stretching technology.

2.1. Polymer Molecular Structure Design

The molecular architecture of polymers critically governs their dielectric energy storage characteristics. Particularly, higher concentrations of polar functional groups (e.g., cyano (–CN), ether linkages (–O–), hydroxyl (–OH)) in polymer chains generally correlate with enhanced εr. However, excessive polar groups may compromise Eb [31], owing to localized polarization-induced electric field concentration effects under applied fields. Therefore, engineering PEN molecular structures with optimized polar group density is essential for achieving superior dielectric energy storage performance. Furthermore, the chain rigidity and crystallization of PEN also significantly influence its dielectric properties. Enhanced chain rigidity contributes to improved Eb, while controlled crystallization optimizes the εr-Eb trade-off. How to achieve a rational distribution of polar groups, control the rigidity of molecular chains, and optimize the crystallization in PEN through molecular design remains a key challenge in current research [9]. This section will explore strategies to enhance the dielectric performance of PEN through molecular structure design.

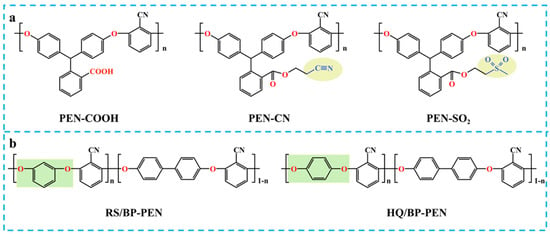

Recent advances in molecular structure design for PEN side-chain engineering have emerged as a research frontier for εr enhancement. As demonstrated by Huang et al., strategic incorporation of methanesulfonyl (–SO2CH3) and cyanoethyl (–CH2CH2CN) groups combined with phenolphthalin (PPL) non-planar structures enabled the successful synthesis of novel polar glass polymers (DGPs, Figure 1a) [22]. These materials exhibit high εr (4.3 for PEN-CN and 4.5 for PAEN-SO2) with low loss tangents (tanδ < 0.01), while maintaining high glass transition temperatures (Tg > 200 °C). This phenomenon originates from the strong polarity of cyano (–CN) and sulfonyl (–SO2–) groups, which were strategically incorporated into polymer side-chains, significantly amplifying molecular polarity and polarization capability through enhanced dipole moment interactions.

Figure 1.

The molecular structural formulas of (a) DGP [22] and (b) BP-PEN [20].

Complementary work by Chen et al. focused on main-chain optimization via bisphenol monomer engineering [20]. By modulating hydroquinone (HQ) and resorcinol (RS) ratios in 4,4′-biphenol (BP)-based PEN systems (Figure 1b), they achieved εr enhancement up to 4.1 at 1 kHz (2.8-RS/BP-PEN). This improvement stems from structural disorder induced by HQ/RS incorporation, which reduces crystallization while increasing chain polarity. Notably, RS-modified PEN demonstrated reduced Tg with preserved chain mobility at elevated temperatures, which is beneficial for high energy storage performance.

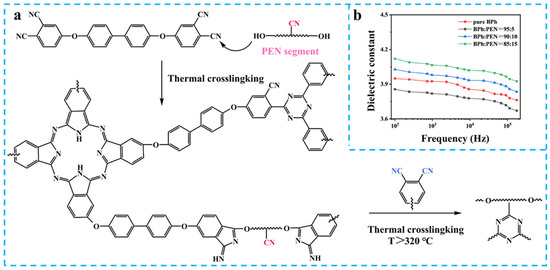

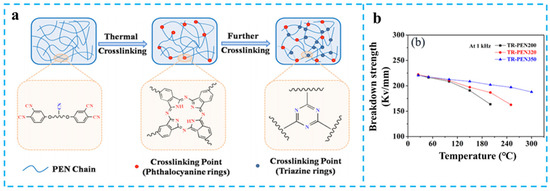

Pioneering work by Huang et al. introduced 4,4′-bis(3,4-dicyanophenoxy) biphenyl (BPh)/PEN-OH copolymers featuring dual crosslinking mechanisms: nitrile polymerization and triazine ring formation (Figure 2a) [23]. The resulting thermosetting networks exhibited stable εr (>4.1) across broad frequencies (100 Hz–200 kHz) with excellent thermal adaptability, attributed to optimized crosslinking density and hierarchical polarization behavior (Figure 2b). This molecular engineering approach establishes new paradigms for developing high-performance dielectric polymers through controlled chemical architecture design.

Figure 2.

(a) The synthetic route and (b) εr of BPh/PEN [23].

These findings establish that backbone engineering enables effective enhancement of PEN dielectric constant through three key strategies: (1) incorporating strong polar groups (e.g., cyano (–CN), sulfonyl (–SO2–)) to amplify molecular polarization [8]; (2) modulating monomer architecture and stoichiometry to optimize the chain polarity–crystallization balance [17]; (3) constructing crosslinked networks to enhance material stability and dielectric response. Crucially, these approaches not only elevate εr but also achieve suppressed dielectric loss tangent (tanδ) through controlled polar group dynamics.

2.2. Organic Filler/PEN Composites

Conventional homopolymer dielectrics are intrinsically limited by low εr (εr < 4.0), failing to meet the escalating energy density demands of advanced electronics. This challenge has driven the emergence of organic composite strategies as a new frontier for PEN-based dielectric optimization. By integrating high εr organic fillers, these systems synergistically optimize interfacial polarization and dielectric response characteristics through tailored phase interactions. This section critically reviews breakthroughs in PEN composites with archetypal organic fillers: PVDF, conductive polymers (e.g., polyaniline, PANI), metallic phthalocyanine (MPc) polymer, etc., with emphasis on filler–matrix interaction mechanisms.

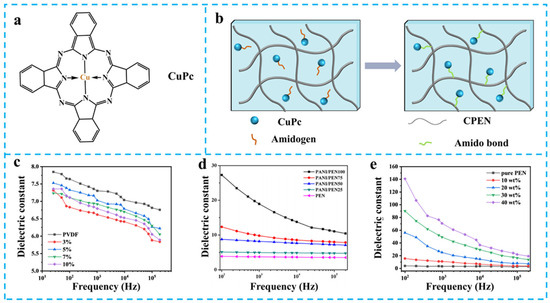

Pioneering work by Long et al. demonstrated PVDF/PEN blends prepared via solution casting [41]. With PVDF loading reaching 95 wt%, the composite exhibited exceptional dielectric stability (εr gradually decreasing from 7.2 to 6.0 across 25 Hz–1 MHz) (Figure 3c). This weak frequency dependence originates from micro-capacitor networks formed by alternating PVDF-rich domains (high εr phase) and PEN domains (low εr phase), effectively suppressing interfacial charge accumulation. Notably, the parallel-series capacitor analogy explains the inhibited dielectric relaxation phenomena. However, excess PVDF (>95 wt%) disrupts phase-separation periodicity, leading to escalated tanδ due to disordered charge transport pathways.

The strategic incorporation of conductive polymer fillers demonstrates superior dielectric enhancement compared to physical blending approaches, primarily through amplified interfacial polarization effects. Related work by Wei et al. employed in situ doping to integrate sulfuric acid-modified polyaniline (PANI) into the PEN matrix [42]. At 10 wt% PANI loading, the composite achieved a remarkable εr of 18.5 at 1 kHz (500% enhancement vs. pure PEN) (Figure 3d), governed by Maxwell–Wagner–Sillars (MWS) polarization. Percolating PANI networks create interfacial charge polarization zones due to dielectric mismatch with the PEN matrix. Notably, the composite maintained εr stability (<5% fluctuation) across 25–180 °C and survived in 10 thermal cycles without the obvious increment of tanδ (tanδ ≈ 0.25), attributed to the organic nature of PANI, which suppresses filler agglomeration and charge migration.

Phthalocyanines (Pc), particularly copper phthalocyanine (CuPc, Figure 3a), have emerged as promising dielectric fillers owing to their tunable 18-π-electron conjugated systems [43,44,45]. Yang et al. fabricated PEN-COOH/CuPc nanocomposites via solution casting, where –COOH/–NH2 hydrogen bonding and amide linkages ensured homogeneous dispersion (Figure 3b) [46]. At 40 wt% CuPc loading, the εr reached 45 at 1 kHz (1000% improvement) (Figure 3e), while chemical bonding effectively suppressed leakage currents through interfacial defect passivation [47,48,49].

Figure 3.

(a) The molecular structure of CuPc; (b) Schematic diagrams of the formation of chemical bond in the PEN/CuPc films [46]; The εr of (c) PVDF/PEN [41], (d) PANI/PEN, (e) CuPc/PEN [46]. Picture (d) was adapted with permission from Ref. [42]. Copyright 2016 Spring Nature.

These studies reveal synergistic dielectric regulation mechanisms: (1) insulator–insulator systems (e.g., PVDF/PEN): dielectric enhancement arises from dimensional confinement effects in phase-separated architectures, where micro-capacitor networks redistribute bound charges. (2) Insulator–conductive systems (e.g., PANI/PEN): MWS polarization dominates, with percolation threshold-dependent dielectric response. (3) Interfacial engineering: covalent/non-covalent interactions (hydrogen bonds, π–π stacking) minimize interfacial defects, enabling concurrent high-εr and low-tanδ performance.

2.3. Ceramic Filler/PEN Composites

Ceramic fillers such as barium titanate (BaTiO3, εr~2000) and copper calcium titanate (CuCa3Ti3O₁2, CCTO, εr~10⁴) demonstrate superior polarization enhancement capabilities in PEN composites due to their high εr [50,51]. However, these inorganic fillers suffer from intrinsic agglomeration tendencies and poor interfacial compatibility with the PEN matrix, often leading to interfacial defects and localized electric field distortions. Recent breakthroughs in filler morphology engineering and interfacial modification have addressed these critical challenges.

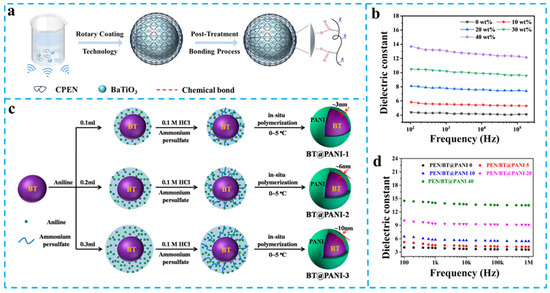

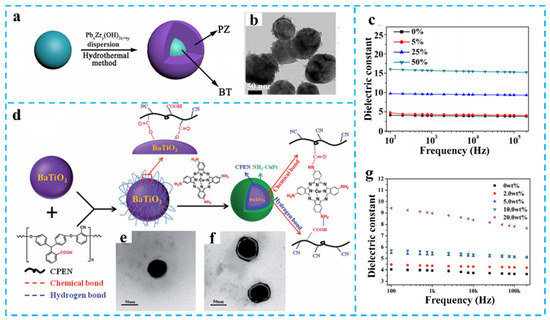

Early-stage investigations focused on physical dispersion methods for homogeneous filler distribution. As exemplified by Tang et al., continuous ultrasonication dispersion technology was employed to fabricate BaTiO3/PEN nanocomposite films [52]. At 40 wt% filler loading, the composite achieved εr = 12.5 (220% enhancement vs. pure PEN). Although ultrasonication effectively suppressed BaTiO3 agglomeration without using dispersant, it failed to resolve fundamental interfacial incompatibility issues. To overcome this limitation, advanced surface grafting techniques were developed. A breakthrough involved constructing CPEN@BaTiO3 core–shell architectures via spin-coating and post-treatment processes [53]. Carboxylated PEN (CPEN) formed 4–7 nm coating layers on BaTiO3 through monodentate coordination, improving dispersion and interfacial compatibility. This innovation elevated εr to 13.1 at 40 wt% loading (Figure 4a,b), while maintaining tanδ < 0.02 at 1 MHz through defect passivation effects.

Figure 4.

(a) Schematic diagram of the fabrication of core–shell structured CPEN@BaTiO3 nanoparticles [53]; (b) The εr of CPEN@BaTiO3/PEN [53]; (c) Schematic diagram of core–shell structured BT@PANI nanoparticles; (d) The εr of BT@PANI/PEN. Pictures (c,d) were adapted with permission from Ref. [54]. Open access under the terms of the Creative Commons Attribution License (CC BY 4.0).

Recent breakthroughs demonstrate enhanced interfacial polarization through conductive polymer coating strategies. Wei et al. developed BT@PANI core–shell architectures via in situ polymerization [54], achieving controlled PANI coating thickness (3–10 nm) on BaTiO3 (Figure 4c). At 40 wt% loading, the composite exhibited εr = 14.0 at 1 kHz (260% enhancement vs. pure PEN, Figure 4d), attributed to intensified interfacial polarization. A more advanced PZ@BT system with 20 nm PZ shells was synthesized through modified hydrothermal methods (Figure 5a,b) [55]. This ferroelectric/antiferroelectric hetero-structure demonstrated εr = 15.6 at 50 wt% loading (380% improvement, Figure 5c), resulting from ferroelectric-relaxor coupling that modulates band structures while suppressing charge migration, and enabled concurrent εr enhancement and loss reduction.

Figure 5.

(a) Scheme for the fabrication of PZ@BT nanoparticles; (b) TEM image of PZ@BT; (c) The εr of PZ@BT/PEN; (d) The preparation of the CPEN-f-BT@CuPc nanoparticles; TEM images of CPEN-f-BT (e) and CPEN-f-BT@CuPc (f); (g) The εr of CPEN-f-BT@CuPc/PEN. Picture (a–c) were adapted with permission from Ref. [55]. Copyright 2018 Spring Nature. Picture (d–g) were adapted with permission from Ref. [56]. Open access under the terms of the Creative Commons Attribution License (CC BY 4.0).

Building on the mono-layered structure, the team led by Liu et al. proposed a gradient dielectric design concept, successfully preparing core–shell–shell structured nanoparticles (CPEN-f-BT@CuPc, Figure 5d,f) by grafting amino copper phthalocyanine (NH2-CuPc) onto CPEN modified BaTiO3 [56]. The bi-layered interfacial system constructed using a combination of spin-coating and ultrasonic dispersion techniques enhanced the εr to 9.0 at a filler loading of 20 wt% (Figure 5g). The structure synergistically enhanced interfacial compatibility through the inner CPEN layer and formed a charge trap layer with the outer CuPc, effectively alleviating the dielectric mismatch between the filler and matrix, thereby enabling a linear increase in εr under low loss conditions.

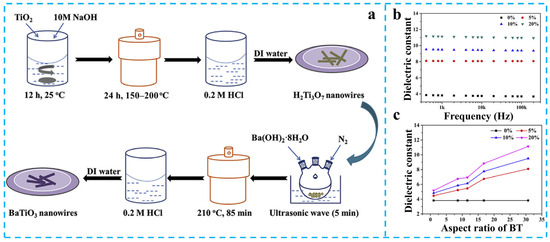

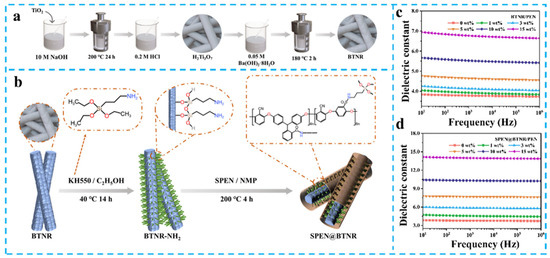

Although conventional particulate BaTiO3 offers facile processability due to its isotropic nature, its limited specific surface area and inherent agglomeration tendencies restrict dielectric enhancement in PEN composites. To address these problems, Tu et al. developed barium titanate nanowires (BT-NWs) with controlled aspect ratios (8.6, 11.6, 16.8, and 30.7) via a two-step hydrothermal method (Figure 6a) [57]. SEM characterization confirmed homogeneous BT-NWs dispersion in the PEN matrix without agglomeration. Dielectric measurements revealed progressive εr enhancement with increasing BT-NWs loading and aspect ratio, achieving εr = 11.1 at 1 kHz (300% vs. pure PEN, Figure 6b,c) with 20 wt% loading and aspect ratio 30.7. This originates from high-aspect-ratio BT-NWs establishing continuous polarization pathways through intensified interfacial polarization. Complementary work by Zhang et al. engineered surface-aminated BT nanorods (BTNR) using KH550, subsequently coated with sulfonated PEN (SPEN) to form SPEN@BTNR fillers (Figure 7a,b) [58,59]. The chemical similarity between SPEN and PEN matrix ensured excellent dispersion, yielding εr = 14.0 at 15 wt% loading (1 kHz, Figure 7c,d). This represents a 367% enhancement over pure PEN, attributed to optimized interfacial charge distribution and reduced leakage currents.

Figure 6.

(a) The procedure for the preparation of BT-NWs; (b) The εr of BT-NWs/PEN; (c) The εr of BT-NWs/PEN composites with variation of aspect ratio of BT at 1 kHz. Picture (a–c) were adapted with permission from Ref. [57]. Copyright 2019 Elsevier.

Figure 7.

(a) Scheme for synthesizing BTNR; (b) Synthesis route of SPEN@BTNR; The εr of (c) BTNR/PEN and (d) SPEN@BTNR/PEN. Picture (a–c) were adapted with permission from Ref. [59]. Copyright 2024 Springer Nature.

These studies demonstrate that 1D nanostructured engineering combined with interface modification can enhance contact area, dispersion of filler in the PEN matrix, thus increasing effective polarization interfaces, and prevent filler agglomeration-induced defects [60,61]. The synergistic effects enable simultaneous enhancement of εr (εr > 300%) and energy storage density [62,63,64].

2.4. Conductive Filler/PEN Composites

The advancement of conductive filler-modified PEN composites centers on two principal material systems: metallic fillers (Ag, Ni, Al) and carbon nanomaterials (carbon nanotubes, graphene derivatives, etc.) [65,66,67]. Metallic systems leverage intrinsic high conductivity to construct high εr architectures, while carbon-based counterparts exploit unique electron polarization and percolation effects. Notably, conductive fillers achieve 3–5 orders of magnitude εr enhancement at low loading (<5 wt%) through micro-capacitor formation and interfacial polarization, outperforming traditional ceramic fillers. However, persistent challenges include leakage currents near percolation thresholds and van der Waals force-induced charge accumulation at filler interfaces, necessitating advanced dispersion control strategies.

Pioneering work by Li et al. established Ag nanoparticle/PEN composite films via in situ reduction as a model system [68]. Systematic investigation revealed concentration-dependent morphological transitions: <1.0 wt% AgNO3 yields 80–110 nm Ag nanospheres, while >2.0 wt% AgNO3 results in nanorods longer than 300 nm. Remarkably, these unmodified Ag fillers achieved homogeneous dispersion through optimized reduction kinetics, enabling εr = 5.8 at 2.0 wt% loading (45% enhancement vs. pure PEN). This breakthrough provides critical insights into interface engineering for metal/polymer dielectric systems.

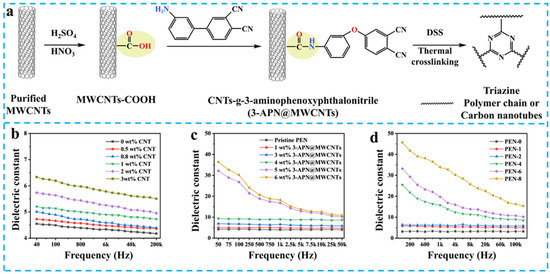

Carbon nanotubes (CNTs), as representative one-dimensional nanofillers, exhibit exceptional dielectric polarization responses due to their sp2-hybridized delocalized π-electron system. As demonstrated by Zheng et al. [69], incorporation of 3 wt% multi-walled carbon nanotubes (MWCNTs) enhanced the εr of biphenyl-typed PEN from 4.3 to 6.1 at 1 kHz (Figure 8b). However, the concomitant increase in loss factor from 0.010 to 0.026 revealed compatibility issues arising from filler aggregation in conventional blending methods. Jin et al. developed amino-functionalized MWCNTs (3-APN@MWCNT) through solvothermal grafting of 3-aminophenoxy phthalonitrile onto acid-treated carbon tubes (Figure 8a) [70]. This innovative approach achieved a remarkable 300% enhancement in εr (εr = 16.1) at 5.0 wt% loading (Figure 8c). Notably, Pu et al. engineered phthalonitrile-functionalized CNTs (CNT-CN) that react with nitrile groups on PEN backbones to form triazine-ring crosslinked structures [71]. After thermal treatment at 320 °C for 4 h, the composite achieved a record-high εr of 33.9 (Figure 8a,d) with exceptionally high-temperature stability.

Figure 8.

(a) Synthesis route for 3-APN@MWCNTs and the crosslinking of cyano groups [71]; The εr of CNTs/PEN (b) [69], 3-APN@MWCNTs/PEN (c) [70], and 3-APN@MWCNTs/PEN after crosslinking (d) [71].

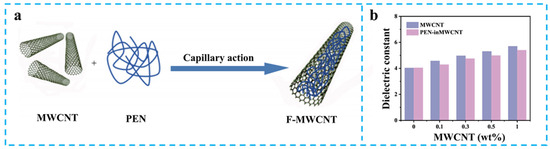

Structural innovation through core–shell hetero-structure design demonstrates remarkable synergistic effects. Huang et al. constructed MWCNT@BaTiO3 core–shell structured fillers that increased the εr of PEN composites to 14.2 at 1000 Hz with 50 wt% loading [72], representing a 200% enhancement over the pristine matrix [73]. Jin et al. developed a MWCNT@SiO2 hybrid filler system that achieved a balanced εr of 7.0 with a loss factor of 0.04, confirming the effectiveness of inorganic shells in suppressing conductive percolation. Particularly noteworthy is the filled MWCNT (F-MWCNT) developed by Xiao et al. [74], which leveraged capillary-induced nano-confinement effects by embedding PEN chains within the tubular cavities of MWCNT (Figure 9a). The 1.0 wt% composite system achieved a εr of 5.3 at 10 kHz with a low loss tangent of 0.011 (Figure 9b), establishing a new paradigm for resolving the dielectric loss paradox.

Figure 9.

(a) Synthesis route of F-MWCNT; (b) The εr of F-MWCNT/PEN. Picture (a,b) were adapted with permission from Ref. [74]. Open access under the terms of the Creative Commons Attribution License (CC BY 4.0).

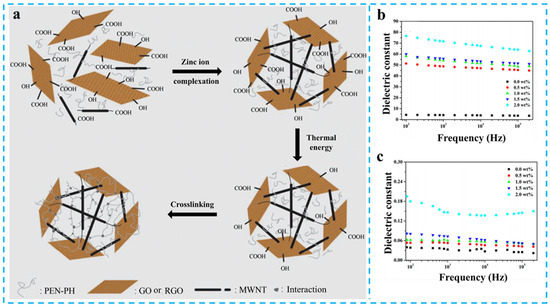

Research on graphene-based filler systems focused on interface optimization of two-dimensional structures and three-dimensional network construction [75]. Wang et al. developed reduced graphene oxide RGO/PEN composites via in situ thermal reduction of GO [76], achieving an extraordinary εr of 115.0 at 6.0 wt% loading (1000 Hz) with a remarkable 2300% enhancement. To address graphene aggregation issues, Li et al. functionalized GO with copper phthalocyanine (GO@CuPc), effectively suppressing the restacking of graphene sheets [77]. The 5 wt% composite exhibited a εr of 35. In three-dimensional architecture design, Wang et al. designed GN-Fe3O4 network, while Wei et al. constructed GS-Zn-CNT interpenetrating network demonstrating exceptional performance [78,79]. The 2 wt% GS-Zn-CNT/PEN system achieved a εr of 72.0 at 1000 Hz with a tanδ of 0.15 (Figure 10a–c), significantly lower than that of graphite/PEN nanocomposites (tanδ = 0.26) at equivalent 2 wt% graphene loading. This 2000% enhancement over the matrix originates from the three-dimensional network, which optimized the charge carrier migration pathways.

Figure 10.

(a) Fabrication route (a), εr (b) and tanδ (c) for GS-Zn-CNT/PEN. Picture (a–c) were adapted with permission from Ref. [79]. Open access under the terms of the Creative Commons Attribution License (CC BY 4.0).

2.5. Hot-Stretching of PEN Composites

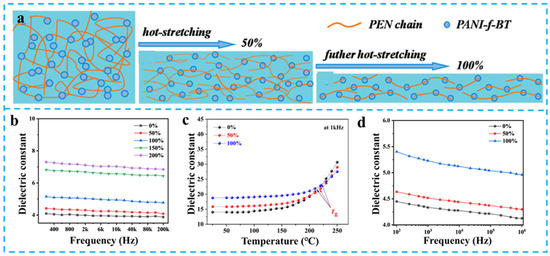

Hot-stretching, a high-efficiency polymer processing technique, remarkably enhances dielectric properties of PEN-based materials through molecular chain orientation engineering. The mechanism primarily involves three structural modulations: (1) crystallization behavior optimization via chain orientation, (2) enhanced dipolar polarization through ordered alignment of polar groups, and (3) conductive network construction via aligned nanofiller distribution. This multi-scaled synergistic effect establishes a new paradigm for designing high-performance dielectric materials.

You et al. achieved synergistic control of molecular chain alignment and crystalline domain reconstruction through high-temperature uniaxial hot-stretching [80]. Experimental results demonstrate that 200% stretching at 280 °C elevates crystallization from 4.9% to 19.2%, accompanied by εr enhancement from 4.0 to 6.7 at 1 kHz (Figure 11b). Systematic investigation reveals the performance enhancement originated from a synergistic tripartite mechanism: interfacial polarization amplification via increased crystallization, dipole orientation polarization intensification through -CN alignment, and polarization response efficiency improvement by molecular anisotropy. Notably, stretching temperature critically influences crystalline integrity. The 280 °C-treated sample demonstrates superior dielectric performance (εr = 6.7) with lower defect density, showing 52% enhancement over the 320 °C-processed counterpart (εr = 4.4), which elucidates the pivotal regulatory role of thermodynamic parameters in processing.

For nanocomposite systems, hot-stretching demonstrates enhanced structural regulation advantages. In PANI-f-BT/PEN systems [81], hot-stretching treatment simultaneously aligns polymer matrix chains and induces ordered nanoparticle arrangement along the stretching direction (Figure 11a). Experimental data showed that 100% stretching elevates the εr from 14.0 to 18.7 at 40 wt% filler loading (Figure 11c), attributed to synergistic effects between enhanced filler–matrix interface polarization and optimized conductive pathways. You et al. further modified BaTiO3 nanoparticles (CPEN-f-BaTiO3@NH2-CuPc) for PEN composites [82]. After 100% hot-stretching, the system exhibited significant dielectric enhancement from 4.4 to 5.2 at 2 wt% loading (Figure 11d). This study confirms that filler surface functionalization effectively improves interfacial compatibility, while hot-stretching induced crystal nucleation strengthens filler-matrix synergism.

Figure 11.

(a) The theoretical model of PEN composite during hot-stretching; The εr of PEN (b) [80], PANI-f-BT/PEN (c), and CPEN-f-BaTiO3@NH2-CuPc/PEN (d) [82] under different stretching ratios. Picture (a,c) were adapted with permission from Ref. [81]. Open access under the terms of the Creative Commons Attribution License (CC BY 4.0).

In conductive filler systems, Huang et al. discovered unique percolation modulation phenomena in MWCNT/PEN composites [83]. Fifty percent hot-stretching dramatically increases the dielectric constant from 105.0 to 175.0 at 1000 Hz, originating from quasi-continuous conductive networks formed by MWCNT alignment. However, excessive stretching ratio (>200%) causes filler contacting disruption and performance degradation, elucidating the dynamic equilibrium between filler dispersion state and conductive network integrity.

In summary, hot-stretching significantly enhances dielectric properties of PEN-based materials through multi-scaled structural engineering, with core mechanisms including: (1) dipole polarization enhancement via chain orientation [43], (2) interfacial polarization optimization through crystallization control, and (3) conductive network construction by aligned filler arrangement. Current research demonstrates that precise control of hot-stretching temperature, ratio [51], and filler modification strategies enables tunable dielectric performance. Nevertheless, critical scientific challenges, including high-temperature induced crystal defect evolution mechanisms and dynamic response patterns of filler networks under large strains, require further investigation, which holds significant theoretical value for developing next-generation high-performance dielectric materials.

3. Strategic Framework for Enhancing Breakdown Strength of PEN

This section systematically presents some major strategies for improving the breakdown strength of PEN, focusing on molecular structure design (copolymerization and thermal crosslinking), composite system construction (high-insulation filler/PEN composites), and microstructure engineering (multilayer films and thermal stretching).

3.1. Copolymerization Strategy

PEN, while exhibiting excellent thermal resistance and mechanical strength as a high-performance engineering plastic, suffers from limited Eb due to disordered amorphous chain arrangements, which induce electric field distortion and charge accumulation. Co-polymerization enables precise regulation of chain conformation, polar group distribution, and crystallization behavior, effectively optimizing the structure-property synergy in dielectric materials [84]. This subsection focuses on co-polymer modification strategies, elucidating enhancement mechanisms through chain rigidification design and polar group functionalization [32,85], providing theoretical guidance for designing high-energy-density dielectric materials.

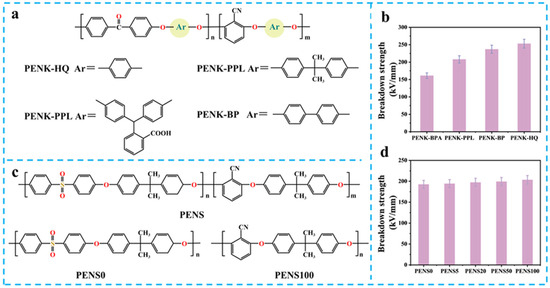

Chain rigidification and ordered alignment constitute the core strategy for Eb enhancement. Mao et al. synthesized poly(arylene ether nitrile ketone) (PENK) copolymers via nucleophilic aromatic substitution co-polymerization using 2,6-dichlorobenzonitrile (DCBN), 4,4′-difluorobenzophenone (DFBP), and various bisphenol monomers (HQ, BP, BPA, PPL) (Figure 12a) [86]. The study revealed that PENK-HQ and PENK-BP with rigid HQ/BP monomers form partially crystalline structures due to enhanced backbone regularity, achieving Eb of 253 kV/mm and 237 kV/mm significantly surpassing their amorphous counterparts (PENK-BPA: 161 kV/mm; PENK-PPL: 208 kV/mm) (Figure 12b). According to Tanaka’s charge injection theory, crystalline regions reduce trap density through ordered chain alignment, suppressing charge injection and space charge accumulation, thereby retarding electrical tree growth. DSC thermal analysis confirms this mechanism: PENK-HQ and PENK-BP exhibit melting enthalpies of 0.96 J/g and 1.50 J/g, respectively, where increased crystallization suppresses charge transport under high electric fields.

Figure 12.

(a) Structures of PENK copolymers [86]; (b) the Eb of the PENK copolymers [86]; (c) structures of PENS copolymers [87]; (d) the Eb of the PENS copolymers [87].

For polar groups synergistic modulation, Hu et al. constructed poly(arylene ether nitrile sulfone) (PENS) (Figure 12c) systems via ternary co-polymerization of DCBN, bisphenol A (BPA), and bis(4-chlorophenyl) sulfone (BCPS). As the PEN segment content increases from PENS0 to PENS100 [87], the gradual elevation of cyano group density progressively enhances Eb from 192 kV/mm to 203 kV/mm (Figure 12c). Mechanistic studies revealed that the high electronegativity of cyano groups enhances local polarization, while the rigid benzene-sulfone structure restricts chain segment mobility and reduces trap-state density. DSC analysis showed single glass transition temperatures (Tg ≈ 180–210 °C) for all PENS copolymers, confirming molecular chain homogeneity. This phase-separation-free microstructure minimizes internal defects, substantially reducing electric field distortion risks.

This subsection analyzes the enhancement mechanisms of co-polymerization strategies on PEN breakdown strength. Through chain rigidification design, polar group functionalization, and dynamic crosslinking network construction, researchers successfully increased PEN-based material Eb from 161 kV/mm to 253 kV/mm, achieving a 57% enhancement.

3.2. Thermal Crosslinking Strategy

Thermal crosslinking has garnered increasing attention due to its unique capability for constructing three-dimensional (3D) network architectures. This technique establishes 3D crosslinked networks through covalent bonding of molecular chains, which not only remarkably enhances thermal stability but more regulates charge carrier transport behavior and suppresses space charge accumulation, thereby synergistically optimizing Eb and Ue [88]. A pioneering design was developed by Wei et al. through blending phthalonitrile-functionalized titanium dioxide nanoparticles (TiO2-CN) with phthalonitrile-terminated PEN (PEN-Ph) [89]. Subsequent thermal crosslinking at 320 °C for 4 h successfully yielded TiO2-PEN hybrid materials. The resultant system demonstrated substantially improved thermostability with Tg elevated to 229 °C and 5% thermal decomposition temperature (T5%) exceeding 524 °C, establishing fundamental characteristics for high-temperature energy storage applications. The crosslinked network optimized dielectric properties through dual synergistic mechanisms: (1) The three-dimensional network effectively suppressed molecular chain relaxation, reducing tanδ to 0.008 at 1000 Hz; (2) physical confinement effects diminished free volume and restricted charge carrier migration pathways. The research team extended this strategy by incorporating functionalized boron nitride (BN-2CN) and carbon nanotubes (CNT-2CN) into the PEN matrix. High-temperature self-crosslinking produced CPEN-BN-CNT ternary hybrid materials, achieving a breakthrough Eb of 275 kV/mm [90], which experimentally validated the feasibility of multi-component synergistic enhancement.

Precise modulation of crosslinking density proves pivotal in optimizing high-temperature material performance. You et al. engineered crosslinking density gradients in the crosslinkable TR-PEN200 system via stepwise thermal processing (320 °C/350 °C) [91], fabricating TR-PEN320 and TR-PEN350 with distinct crosslinking densities (Figure 13a). Electrical characterization revealed a marginal difference in Eb at room temperature, while exhibiting a pronounced gradient at 180 °C: TR-PEN200 (165 kV/mm) < TR-PEN320 (191 kV/mm) < TR-PEN350 (208 kV/mm, Figure 13b). This temperature-dependent behavior originates from dual competing mechanisms: On one hand, elevated temperature intensifies chemical bond vibrations and migration of impurities within the polymeric matrix, thereby elevating electrical conductivity and thermal breakdown susceptibility; on the other hand, densely crosslinked networks effectively constrain molecular chain mobility and suppress long-range charge carrier migration under high temperature. Experimental evidence confirmed that beyond critical crosslinking density, the spatial confinement effect of network architectures dominates dielectric behavior, resulting in a 26% enhancement for Eb at high temperatures.

Figure 13.

(a) Scheme for the fabrication of the TR-PENs; (b) The Eb of the TR-PENs. Picture (a,b) were adapted with permission from Ref. [91]. Copyright 2019 American Chemical Society.

Thermal crosslinking offers multi-scaled optimization pathways for enhancing dielectric energy storage in PEN: (1) Significantly reinforced thermomechanical stability through 3D covalent network construction [92], (2) reduced dielectric loss via steric hindrance effects that impede charge carrier migration, (3) Optimized electric field distribution through free volume modulation [93].

3.3. High-Insulation Filler/PEN Composites

As a representative 2D wide-bandgap insulator (Eb > 800 kV/mm, bandgap ~6.0 eV), boron nitride nanosheets (BNNS) with a unique lamellar structure emerge as ideal candidates for optimizing breakdown strength of PEN [94,95,96]. Early-stage investigations primarily focused on single-filler reinforcement effects of BNNS. Pu et al. fabricated BNNS with lateral dimensions of ~1.5 μm via liquid-phase ultrasonic exfoliation [97]. At 12 wt% loading, the BNNS/PEN composite exhibited a breakthrough in Eb from 180 kV/mm (pristine matrix) to 240 kV/mm, representing a 33.3% enhancement. This remarkable improvement originates from triple synergistic mechanisms of BNNS: (1) formation of percolative 2D networks for electric field homogenization [98], (2) interlayer high potential barriers suppressing electron tunneling [99], (3) in-plane high thermal conductivity (~400 W/mK) facilitating rapid joule heat dissipation [100]. Based on this foundation, Lan et al. innovatively engineered h-BN/GO hybrid fillers, constructing hetero-interfaces through π-π stacking interactions. At 7.5 wt% h-BN-GO loading, the composite achieved 91.6% higher Eb than pure GO/PEN systems [101]. This originates from localized potential wells induced by space charge polarization at heterointerfaces, which effectively trap charge carriers and reduce leakage current density.

To overcome nanofiller agglomeration challenges, He et al. developed a core–shell architecture strategy [102], fabricating BPh-microsphere@BNNS composites via electrostatic self-assembly. The steric hindrance effect from the microsphere enabled uniform BNNS-OH dispersion, achieving 242 kV/mm Eb at merely 4.4 vol% loading, representing 34.2% improvement over pristine PEN. Three-dimensional tomography revealed graded dielectric interfaces within the matrix, generating multilevel trap states via Maxwell–Wagner polarization, thereby reducing charge carrier mobility. Wei et al. implemented molecular-scale engineering through cyano-functionalization to create BN-CN fillers [90]. At 8 wt% BN-CN content, Eb surged to 318 kV/mm (40.8% enhancement), setting the current record for PEN-based composites. The functionalization treatment elevated interfacial binding energy, effectively suppressing electrical treeing propagation.

The aforementioned studies demonstrate that multidimensional filler engineering design can significantly enhance Eb in PEN composites. This progression spans from electric field regulation via single BNNS fillers [103], through interfacial polarization enhancement with hybrid fillers [104], to molecular-level interface reinforcement through core–shell architectures and chemical functionalization, illustrating an evolutionary trajectory from macroscopic construction to in-depth microscopic mechanism exploration [105,106].

3.4. Multilayer Films

Among the PEN-based dielectric energy storage materials, pinhole defects pose critical challenges to Eb. Studies revealed nanoscale pinholes in solution-cast PEN films, present on both surfaces and cross-sections, arising from the high molecular weight characteristics of polymer chains during solvent evaporation and being inherently irremovable [107,108,109,110]. Air-filled pinholes with dielectric strength substantially lower than the polymer matrix severely degrade overall breakdown performance. To address this problem, Tang et al. proposed a bi-layered stacking strategy: laminating two 20 μm-thick PEN films using high-temperature silicone oil (0.3 μm-thick) as adhesive [111]. Experimental results demonstrated that the bi-layered structure achieves ‘pinhole shielding effect’ where defect-free regions in the upper layer physically mask pinholes in the lower layer, effectively mitigating electric field concentration and localized breakdown risks. Eventually, this architecture elevated Eb to 364 kV/mm. In contrast, biaxially stretched BOPP films inherently avoid pinhole defects due to their melt manufacturing process [112,113,114], rendering the bi-layered configuration less effective for Eb enhancement, thereby highlighting the unique advantage of multi-layered design in optimizing the breakdown strength of PEN.

3.5. Hot-Stretching of PEN Composites

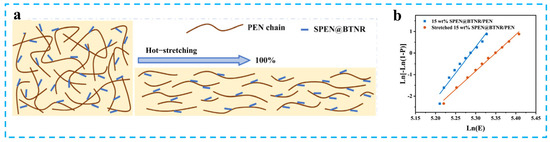

The efficacy of hot-stretching in enhancing Eb of PEN-based composites has been rigorously validated across multiple material systems. This technology’s fundamental breakthrough lies in achieving filler alignment through synergistic thermo-mechanical action, effectively mitigating localized electric field distortion [115,116,117]. Zhang et al. pioneered sulfonated PEN (SPEN)-functionalized barium titanate nanorods (SPEN@BTNR), which were aligned along the stretching direction within the PEN matrix via a hot-stretching process (stretching ratio 100%, 200 °C) [59], forming a nacre-like layered architecture (Figure 14a). This oriented structure enabled SPEN@BTNR/PEN composite to maintain an exceptional Eb of 210 kV/mm at 15 wt% high filler loading (Figure 14b). Gao et al. and Liu et al. further elucidated the strengthening mechanisms of hot-stretching on breakdown behavior via employing SPEN-modified calcium copper titanate nanorods (SPEN@CCTONR) and cyano-functionalized PEN (CPEN)-modified barium strontium titanate nanorods (CPEN@BSTNR), achieving high Eb of 199 kV/mm and 204 kV/mm at 15 wt% and 16 wt% filler loading after hot-stretching [118,119]. These findings collectively demonstrate that hot-stretching technology induces nanofiller alignment, effectively alleviating electric field distortion caused by high εr fillers [120,121], thereby providing an innovative solution for enhancing Eb in PEN-based composites.

Figure 14.

(a) Hot−stretching mechanism diagram; (b) Eb of 15 wt% SPEN@BTNR/PEN nanocomposite films before and after hot-stretching. Picture (a,b) were adapted with permission from Ref. [59]. Copyright 2024 Springer Nature.

4. Conclusions and Perspectives

This work systematically summarizes recent breakthroughs in multiscale structural regulation strategies for enhancing the energy storage performance of PEN-based dielectric composites. Building on the strong polarity and modifiable characteristics of cyano groups in PEN molecular chains, we innovatively propose a trinity synergistic strategy encompassing ‘molecular polarization regulation-dielectric synergy design-microstructure engineering’. Studies have demonstrated that the integration of organic/inorganic multiphase composite system design with uniaxial hot-stretching post-treatment enables synergistic optimization of relative εr and Eb. Despite breakthroughs in energy density, significant attenuation in energy conversion efficiency remains a critical barrier for practical applications in high-voltage power equipment. Therefore, developing PEN-based composites with concurrently high energy density and efficiency emerges as a pivotal challenge requiring urgent resolution.

Future research should focus on three strategic dimensions: First, in interfacial engineering, priority should be given to developing gradient core–shell fillers with self-adaptive dielectric properties. Compared with conventional SiO2@PEN systems, MXene-based hetero-junction structures may achieve local electric field redistribution through interfacial polarization regulation. Density functional theory (DFT) calculations enable precise prediction of dipole interaction intensity between filler surface functional groups and PEN cyano groups, providing theoretical guidance for constructing low-loss interfacial layers. Second, in terms of filler dimensional engineering, the construction of a multi-component topological structure incorporating 2D nanosheets and 3D nanoflowers can synergistically enhance both the polarization response efficiency and energy storage density of the PEN matrix. Finally, in device integration, adopting vapor deposition techniques from semiconductor packaging to develop all-organic composite dielectric films with 3D interpenetrating network structures is recommended. This biomimetic layered architecture can synergistically enhance mechanical flexibility and high-temperature energy storage stability.

Notably, recent breakthroughs in bio-based poly(ether nitrile) synthesis have opened new avenues for developing environmentally friendly dielectric materials. Covalent grafting of lignin derivatives with PEN molecular chains not only improves dielectric anisotropy but also substantially reduces raw material costs. We anticipate that the convergence of computational materials science, intelligent manufacturing technologies, and novel synthesis methods will propel PEN-based dielectric materials with superior energy density and cycling stability toward widespread applications in smart grids and new energy vehicles.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Agbabiaka, O.G.; Adegun, M.H.; Chan, K.-Y.; Zhang, H.; Shen, X.; Kim, J.-K. BN-PVDF/rGO-PVDF Laminate Nanocomposites for Energy Storage Applications. Nanomaterials 2022, 12, 4492. [Google Scholar] [CrossRef] [PubMed]

- Baivier, C.; Hammami, I.; Benzerga, R.; Graça, M.P.F.; Costa, L.C. Barium Titanate/Gadolinium Ferrite: A New Material Composite to Store Energy. Nanomaterials 2023, 13, 1955. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, Y.; Dang, Z.; Hou, Q.; Zhang, Z.; Feng, Z.; Yu, Y.; Hua, X.; Wei, R. Rational design of porous organic polymers for cycloaddition between CO2 and epoxides. Eng. Sci. 2025, 35, 1349. [Google Scholar]

- Feng, C.; Liu, T.; Bu, X.; Huang, S. Enhanced Ferroelectric, Dielectric Properties of Fe-Doped PMN-PT Thin Films. Nanomaterials 2021, 11, 3043. [Google Scholar] [CrossRef]

- Feng, Q.-K.; Dong, Q.; Zhang, D.-L.; Pei, J.-Y.; Dang, Z.-M. Enhancement of high-temperature dielectric energy storage performances of polyimide nanocomposites utilizing surface functionalized MAX nanosheets. Compos. Sci. Technol. 2022, 218, 109193. [Google Scholar] [CrossRef]

- Guo, D.; Tan, B.; Jiang, X.; Gao, G.; Lin, Y. Multifunctional polyimide/boron nitride nanosheet/Ti3C2Tx MXene composite film with three-dimensional conductive network for integrated thermal conductive, electromagnetic interference shielding, and Joule heating performances. Compos. Sci. Technol. 2024, 254, 110690. [Google Scholar] [CrossRef]

- Ji, M.; Min, D.; Li, Y.; Yang, L.; Wu, Q.; Liu, W.; Li, S. Improved energy storage performance of polyimide nanocomposites by constructing the meso- and macroscopic interfaces. Mater. Today Energy 2023, 31, 101200. [Google Scholar] [CrossRef]

- Li, D.; Meng, X.; Zhou, E.; Chen, X.; Shen, Z.; Guo, Q.; Yao, Z.; Cao, M.; Wu, J.; Zhang, S.; et al. Ultrahigh Energy Density of Antiferroelectric PbZrO3-Based Films at Low Electric Field. Adv. Funct. Mater. 2023, 33, 202302995. [Google Scholar] [CrossRef]

- Li, L.; Dong, J.; Hu, R.; Chen, X.; Niu, Y.; Wang, H. Wide-bandgap fluorides/polyimide composites with enhanced energy storage properties at high temperatures. Chem. Eng. J. 2022, 435, 135059. [Google Scholar] [CrossRef]

- Liang, X.; Li, Q.; Ren, Y.; Xie, W.; Tang, A.; Yang, H. Nanoclay Reinforced Polymer Composite Dielectrics for Ultra-Balanced Electrostatic Energy Storage. Adv. Funct. Mater. 2024, 34, 202408719. [Google Scholar] [CrossRef]

- Lv, Z.; Lu, T.; Liu, Z.; Hu, T.; Hong, Z.; Guo, S.; Xu, Z.; Song, Y.; Chen, Y.; Zhao, X.; et al. NaNbO3-Based Multilayer Ceramic Capacitors with Ultrahigh Energy Storage Performance. Adv. Energy Mater. 2024, 14, 202304291. [Google Scholar] [CrossRef]

- Palneedi, H.; Peddigari, M.; Hwang, G.T.; Jeong, D.Y.; Ryu, J. High-Performance Dielectric Ceramic Films for Energy Storage Capacitors: Progress and Outlook. Adv. Funct. Mater. 2018, 28, 201803665. [Google Scholar] [CrossRef]

- Peng, S.; Wang, R.; Liang, Z.; Du, X. Significantly enhanced energy storage performance in multi-layer polyimide films with nano dielectric layer. J. Energy Storage 2024, 99, 113381. [Google Scholar] [CrossRef]

- Qi, H.; Zuo, R.; Xie, A.; Tian, A.; Fu, J.; Zhang, Y.; Zhang, S. Ultrahigh Energy-Storage Density in NaNbO3-Based Lead-Free Relaxor Antiferroelectric Ceramics with Nanoscale Domains. Adv. Funct. Mater. 2019, 29, 201903877. [Google Scholar] [CrossRef]

- Ren, Z.; Shi, Z.; Tang, Q.; Xia, S.; Sun, L.; Fan, R.; Cui, H.; Wang, H. Core-shell TiO2@Au Nanofibers Derived from a Unique Physical Coating Strategy for Excellent Capacitive Energy Storage Nanocomposites. Adv. Funct. Mater. 2024, 34, 202401907. [Google Scholar] [CrossRef]

- Song, J.; Qin, H.; Qin, S.; Liu, M.; Zhang, S.; Chen, J.; Zhang, Y.; Wang, S.; Li, Q.; Dong, L.; et al. Alicyclic polyimides with large band gaps exhibit superior high-temperature capacitive energy storage. Mater. Horiz. 2023, 10, 2139–2148. [Google Scholar] [CrossRef]

- Sun, L.; Shi, Z.; He, B.; Wang, H.; Liu, S.; Huang, M.; Shi, J.; Dastan, D.; Wang, H. Asymmetric Trilayer All-Polymer Dielectric Composites with Simultaneous High Efficiency and High Energy Density: A Novel Design Targeting Advanced Energy Storage Capacitors. Adv. Funct. Mater. 2021, 31, 202100280. [Google Scholar] [CrossRef]

- Sun, W.; Liu, J.; Pan, J.; Wang, Y.; Wei, C.; Li, X.; Ma, T.; He, N.; Dong, J.; Nan, D. In-situ amino-functionalized and reduced graphene oxide/polyimide composite films for high-performance triboelectric nanogenerator. J. Colloid Interface Sci. 2024, 675, 488–495. [Google Scholar] [CrossRef]

- Tsyganov, A.; Vikulova, M.; Artyukhov, D.; Zheleznov, D.; Gorokhovsky, A.; Gorshkov, N. Intercalation Effects on the Dielectric Properties of PVDF/Ti3C2Tx MXene Nanocomposites. Nanomaterials 2023, 13, 1337. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, J.; Zhang, T.; Nie, M.; Liu, S.; Liu, X. Design and properties of high-performance polyaryl ether nitrile dielectric polymer materials for enhanced energy storage via tailored bisphenol monomers. Mater. Today Commun. 2025, 43, 111714. [Google Scholar] [CrossRef]

- Guo, N.; Liu, J.; Xin, S.; Du, C.; Liu, J.; Zhang, Y.; Xi, Y.; Wei, R.; Wang, L.; Li, D. Petal-Shaped Graphene Porous Films with Enhanced Absorption-Dominated Electromagnetic Shielding Performance and Mechanical Properties. ACS Appl. Mater. Interfaces 2024, 16, 36923–36934. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Ju, T.; Li, R.; Duan, Y.; Duan, Y.; Wei, J.; Zhu, L. High-κ and High-Temperature Dipolar Glass Polymers Based on Sulfonylated and Cyanolated Poly(Arylene Ether)s for Capacitive Energy Storage. Adv. Electron. Mater. 2022, 9, 202200414. [Google Scholar] [CrossRef]

- Huang, Y.; Luo, Y.; Xu, M.; Lei, Y.; Liu, X. Studied on mechanical, thermal and dielectric properties of BPh/PEN-OH copolymer. Compos. Part B Eng. 2016, 106, 294–299. [Google Scholar] [CrossRef]

- Huo, Y.; He, Z.; Wang, C.; Zhang, L.; Xuan, Q.; Wei, S.; Wang, Y.; Pan, D.; Dong, B.; Wei, R.; et al. The recent progress of synergistic supramolecular polymers: Preparation, properties and applications. Chem. Commun. 2021, 57, 1413–1429. [Google Scholar] [CrossRef] [PubMed]

- Song, D.; Yang, C.; Lei, X.; Hua, X.; Wang, L.; Wei, R. Sandwich-structured dielectrics constructed from carbon nanotube and polyarylene ether nitrile composite layers demonstrating positive and negative permittivity. Polym. Compos. 2024, 45, 14644–14657. [Google Scholar] [CrossRef]

- Tong, L.; Wang, Y.; You, Y.; Tu, L.; Wei, R.; Liu, X. Effect of Plasticizer and Shearing Field on the Properties of Poly(arylene ether nitrile) Composites. ACS Omega 2020, 5, 1870–1878. [Google Scholar] [CrossRef]

- Wang, L.; Bai, Z.; Liu, C.; Wei, R.; Liu, X. Porous fluorinated polyarylene ether nitrile as ultralow permittivity dielectrics used under humid environment. J. Mater. Chem. C. 2021, 9, 860–868. [Google Scholar] [CrossRef]

- Wang, L.; Liu, X.; Liu, C.; Zhou, X.; Liu, C.; Cheng, M.; Wei, R.; Liu, X. Ultralow dielectric constant polyarylene ether nitrile foam with excellent mechanical properties. Chem. Eng. J. 2020, 384, 123231. [Google Scholar] [CrossRef]

- Wang, M.; Li, W.L.; Feng, Y.; Hou, Y.F.; Zhang, T.D.; Fei, W.D.; Yin, J.H. Effect of BaTiO3 nanowires on dielectric properties and energy storage density of polyimide composite films. Ceram. Int. 2015, 41, 13582–13588. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, J.; Jiang, W.; Jiang, Z.; Jiang, L.; Zhou, Y.; Zhang, Y. Roll-to-Roll Production of High-Performance All-Organic Polymer Nanocomposites for High-Temperature Capacitive Energy Storage. Adv. Funct. Mater. 2024, 35, 202414616. [Google Scholar] [CrossRef]

- Wang, L.; Wei, R.; Luo, Y.; Liu, C.; Liu, X.; Li, D. Construction of alternating multilayer films with stable absorption-dominated electromagnetic shielding performance and reinforced mechanical properties via interface engineering. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107862. [Google Scholar] [CrossRef]

- Tu, L.; You, Y.; Tong, L.; Wang, Y.; Hu, W.; Wei, R.; Liu, X. Crystallinity of poly(arylene ether nitrile) copolymers containing hydroquinone and bisphenol A segments. J. Appl. Polym. Sci. 2018, 135, 46412. [Google Scholar] [CrossRef]

- Wei, R.; Liu, K.; Liu, Y.; Wang, Z.; Jiao, Y.; Huo, Q.; Hua, X.; Wang, L.; Wang, X. Controlled Distribution of MXene on the Pore Walls of Polyarylene Ether Nitrile Porous Films for Absorption-Dominated Electromagnetic Interference Shielding Materials. Small 2024, 21, 202407142. [Google Scholar] [CrossRef] [PubMed]

- Wu, N.; Bai, X.; Pan, D.; Dong, B.; Wei, R.; Naik, N.; Patil, R.R.; Guo, Z. Recent Advances of Asymmetric Supercapacitors. Adv. Mater. Interfaces 2020, 8, 202001710. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Z.; Liu, J.; Liu, C.; Li, X.; Zhang, Y.; Wang, W.; Ma, J.; Sun, Z. Selective ozone catalyzation modulated by surface and bulk oxygen vacancies over MnO2 for superior water purification. Appl. Catal. B Environ. 2024, 343, 123526. [Google Scholar] [CrossRef]

- Yue, W.; Cai, Y.; Zhao, H.; Guo, Q.; Wang, D.; Jia, T. Enhanced energy storage density of Bi3.25La0.75Ti3O12 thin films by preferred orientation and interface engineering. Ceram. Int. 2024, 50, 13644–13651. [Google Scholar] [CrossRef]

- Zhang, X.; Wen, Z.; Zhang, H.; Han, W.; Ma, J.; Wei, R.; Hua, X. Dielectric Properties of Azo Polymers: Effect of the Push-Pull Azo Chromophores. Int. J. Polym. Sci. 2018, 10, 4541937. [Google Scholar] [CrossRef]

- Zeng, J.; Yan, J.; Li, B.-W.; Zhang, X. Improved breakdown strength and energy storage performances of PEI-based nanocomposite with core-shell structured PI@BaTiO3 nanofillers. Ceram. Int. 2022, 48, 20526–20533. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Jiang, G.; Wei, H.; Zhang, Z.; Ren, J. Enhanced Thermal Conductivity and Dielectric Properties of Epoxy Composites with Fluorinated Graphene Nanofillers. Nanomaterials 2023, 13, 2322. [Google Scholar] [CrossRef]

- Zhang, K.; Ma, Z.; Deng, H.; Fu, Q. Improving high-temperature energy storage performance of PI dielectric capacitor films through boron nitride interlayer. Adv. Compos. Hybrid Mater. 2021, 5, 238–249. [Google Scholar] [CrossRef]

- Long, C.; Wei, R.; Huang, X.; Feng, M.; Jia, K.; Liu, X. Mechanical, dielectric, and rheological properties of poly(arylene ether nitrile)–reinforced poly(vinylidene fluoride). High Perform. Polym. 2016, 29, 178–186. [Google Scholar] [CrossRef]

- Wei, R.; Li, K.; Ma, J.; Zhang, H.; Liu, X. Improving dielectric properties of polyarylene ether nitrile with conducting polyaniline. J. Mater. Sci. Mater. Electron. 2016, 27, 9565–9571. [Google Scholar] [CrossRef]

- Feng, Z.; Tang, B.; Liu, K.; Hou, Q.; Dang, Z.; Yang, C.; Hua, X.; Yu, Q.; Wang, L.; Wei, R. One-pot synthesis of copper phthalocyanine polymer: An efficient CO2 fixation catalyst. Mater. Today Commun. 2024, 41, 110875. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, R.; Liu, X. Facile fabrication of multilayer films of graphene oxide/copper phthalocyanine with high dielectric properties. RSC Adv. 2015, 5, 88306–88310. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, R.; Liu, X. Preparation and dielectric properties of copper phthalocyanine/graphene oxide nanohybrids via in situ polymerization. J. Mater. Sci. 2016, 51, 4682–4690. [Google Scholar] [CrossRef]

- Yang, J.; Yang, X.; Pu, Z.; Chen, L.; Liu, X. Controllable high dielectric permittivity of poly(arylene ether nitriles)/copper phthalocyanine functional nanohybrid films via chemical interaction. Mater. Lett. 2013, 93, 199–202. [Google Scholar] [CrossRef]

- Wang, Z.; Wei, R.; Liu, X. Dielectric properties of copper phthalocyanine nanocomposites incorporated with graphene oxide. J. Mater. Sci. Mater. Electron. 2017, 28, 7437–7448. [Google Scholar] [CrossRef]

- Yan, L.; Pu, Z.; Xu, M.; Wei, R.; Liu, X. Fabrication and Electromagnetic Properties of Conjugated NH2-CuPc@Fe3O4. J. Electron. Mater. 2017, 46, 5608–5618. [Google Scholar] [CrossRef]

- Yang, R.; Li, K.; Tong, L.; Jia, K.; Liu, X. The relationship between processing and performances of polyarylene ether nitriles terminated with phthalonitrile/trifunctional phthalonitrile composites. J. Polym. Res. 2015, 22, 0860. [Google Scholar] [CrossRef]

- Gao, F.; Wei, R.; Zhou, L.; Luo, W.; Li, Z.; Pang, L.; Li, S.; Hua, X.; Wang, L. Improved dielectric properties of poly(arylene ether nitrile) with sulfonated poly(arylene ether nitrile) modified CaCu3Ti4O12. Polym. Compos. 2023, 44, 8658–8668. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; Liu, C.; Tu, L.; You, Y.; Wei, R.; Liu, X. Polyarylene Ether Nitrile and Barium Titanate Nanocomposite Plasticized by Carboxylated Zinc Phthalocyanine Buffer. Polymers 2019, 11, 418. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Zhong, J.; Yang, J.; Ma, Z.; Liu, X. Flexible Polyarylene Ether Nitrile/BaTiO3 Nanocomposites with High Energy Density for Film Capacitor Applications. J. Electron. Mater. 2010, 40, 141–148. [Google Scholar] [CrossRef]

- Tang, H.; Wang, P.; Zheng, P.; Liu, X. Core-shell structured BaTiO3@polymer hybrid nanofiller for poly(arylene ether nitrile) nanocomposites with enhanced dielectric properties and high thermal stability. Compos. Sci. Technol. 2016, 123, 134–142. [Google Scholar] [CrossRef]

- You, Y.; Wang, Y.; Tu, L.; Tong, L.; Wei, R.; Liu, X. Interface Modulation of Core-Shell Structured BaTiO3@polyaniline for Novel Dielectric Materials from Its Nanocomposite with Polyarylene Ether Nitrile. Polymers 2018, 10, 1378. [Google Scholar] [CrossRef]

- Wei, R.; Yang, R.; Xiong, Z.; Xiao, Q.; Li, K.; Liu, X. Enhanced Dielectric Properties of Polyarylene Ether Nitriles Filled with Core–Shell Structured PbZrO3 Around BaTiO3 Nanoparticles. J. Electron. Mater. 2018, 47, 6177–6184. [Google Scholar] [CrossRef]

- You, Y.; Han, W.; Tu, L.; Wang, Y.; Wei, R.; Liu, X. Double-layer core/shell-structured nanoparticles in polyarylene ether nitrile-based nanocomposites as flexible dielectric materials. RSC Adv. 2017, 7, 29306–29311. [Google Scholar] [CrossRef]

- Tu, L.; You, Y.; Liu, C.; Zhan, C.; Wang, Y.; Cheng, M.; Wei, R.; Liu, X. Enhanced dielectric and energy storage properties of polyarylene ether nitrile composites incorporated with barium titanate nanowires. Ceram. Int. 2019, 45, 22841–22848. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, P.; Feng, M.; Wei, R.; Liu, X. Cross-linked sulfonated poly(arylene ether nitrile)s with low swelling and high proton conductivity. Macromol. Res. 2017, 25, 1199–1204. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, L.; Wang, L.; Hao, Q.; Hua, X.; Wei, R. Enhancing energy storage density of poly(arylene ether nitrile) via incorporating modified barium titanate nanorods and hot-stretching. Nano Res. 2024, 17, 7574–7584. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; You, Y.; Wang, Y.; Wei, R.; Liu, X. Fabrication of BaTiO3-Loaded Graphene Nanosheets-Based Polyarylene Ether Nitrile Nanocomposites with Enhanced Dielectric and Crystallization Properties. Nanomaterials 2019, 9, 1667. [Google Scholar] [CrossRef]

- Tang, H.; Ma, Z.; Zhong, J.; Yang, J.; Zhao, R.; Liu, X. Effect of surface modification on the dielectric properties of PEN nanocomposites based on double-layer core/shell-structured BaTiO3 nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2011, 384, 311–317. [Google Scholar] [CrossRef]

- Wei, H.; Wang, H.; Xia, Y.; Cui, D.; Shi, Y.; Dong, M.; Liu, C.; Ding, T.; Zhang, J.; Ma, Y.; et al. An overview of lead-free piezoelectric materials and devices. J. Mater. Chem. C. 2018, 6, 12446–12467. [Google Scholar] [CrossRef]

- Yang, R.; Xiao, Q.; You, Y.; Wei, R.; Liu, X. In situ catalyzed and reinforced high-temperature flexible crosslinked ZnO nano-whisker/polyarylene ether nitriles composite dielectric films. Polym. Compos. 2016, 39, 2801–2811. [Google Scholar] [CrossRef]

- You, Y.; Zhan, C.; Tu, L.; Wang, Y.; Hu, W.; Wei, R.; Liu, X. Polyarylene Ether Nitrile-Based High-k Composites for Dielectric Applications. Int. J. Polym. Sci. 2018, 10, 5161908. [Google Scholar] [CrossRef]

- Gu, H.; Xu, X.; Dong, M.; Xie, P.; Shao, Q.; Fan, R.; Liu, C.; Wu, S.; Wei, R.; Guo, Z. Carbon nanospheres induced high negative permittivity in nanosilver-polydopamine metacomposites. Carbon 2019, 147, 550–558. [Google Scholar] [CrossRef]

- Gu, H.; Zhang, H.; Ma, C.; Xu, X.; Wang, Y.; Wang, Z.; Wei, R.; Liu, H.; Liu, C.; Shao, Q.; et al. Trace electrosprayed nanopolystyrene facilitated dispersion of multiwalled carbon nanotubes: Simultaneously strengthening and toughening epoxy. Carbon 2019, 142, 131–140. [Google Scholar] [CrossRef]

- Han, W.; Gao, F.; Zhou, L.; Wang, L.; Hua, X.; Xue, X.; Li, Z.; Luo, W.; Pang, L.; Wei, R. Flexible fluorinated multi-walled carbon nanotube/polyarylene ether nitrile metacomposites with negative permittivity. J. Mater. Chem. C 2022, 10, 171–179. [Google Scholar] [CrossRef]

- Li, K.; Tong, L.; Yang, R.; Wei, R.; Liu, X. In-situ preparation and dielectric properties of silver-polyarylene ether nitrile nanocomposite films. J. Mater. Sci. Mater. Electron. 2016, 27, 4559–4565. [Google Scholar] [CrossRef]

- Zheng, P.; Pu, Z.; Yang, W.; Shen, S.; Jia, K.; Liu, X. Effect of multiwalled carbon nanotubes on the crystallization and dielectric properties of BP-PEN nanocomposites. J. Mater. Sci. Mater. Electron. 2014, 25, 3833–3839. [Google Scholar] [CrossRef]

- Jin, F.; Feng, M.; Jia, K.; Liu, X. Aminophenoxyphthalonitrile modified MWCNTs/polyarylene ether nitriles composite films with excellent mechanical, thermal, dielectric properties. J. Mater. Sci. Mater. Electron. 2015, 26, 5152–5160. [Google Scholar] [CrossRef]

- Pu, Z.; Huang, X.; Chen, L.; Yang, J.; Tang, H.; Liu, X. Effect of nitrile-functionalization and thermal cross-linking on the dielectric and mechanical properties of PEN/CNTs–CN composites. J. Mater. Sci. Mater. Electron. 2013, 24, 2913–2922. [Google Scholar] [CrossRef]

- Huang, X.; Feng, M.; Liu, X. Synergistic enhancement of dielectric constant of novel core/shell BaTiO3@MWCNTs/PEN nanocomposites with high thermal stability. J. Mater. Sci. Mater. Electron. 2013, 25, 97–102. [Google Scholar] [CrossRef]

- Huang, X.; Wang, K.; Jia, K.; Liu, X. Preparation of TiO2–MWCNT core/shell heterostructures containing a single MWCNT and their electromagnetic properties. Compos. Interfaces 2015, 22, 343–351. [Google Scholar] [CrossRef]

- Xiao, Q.; Yang, R.; You, Y.; Zhang, H.; Wei, R.; Liu, X. Crystalline, Mechanical and Dielectric Properties of Polyarylene Ether Nitrile with Multi-Walled Carbon Nanotube Filled with Polyarylene Ether Nitrile. J. Nanosci. Nanotechno. 2018, 18, 4311–4317. [Google Scholar] [CrossRef]

- Wang, L.; Feng, Z.; Hou, Q.; Dang, Z.; Yu, Y.; Yang, C.; Tang, B.; Zhou, Q.; Hua, X.; Wei, R.; et al. Quaternary ammonium salt functionalized copper phthalocyanine-graphene oxide hybrids for cocatalyst-free carbon dioxide cycloaddition. Adv. Compos. Hybrid Mater. 2024, 8, 40. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, W.; Liu, X. Electrical properties of poly(arylene ether nitrile)/graphene nanocomposites prepared by in situ thermal reduction route. J. Polym. Res. 2014, 21, 358. [Google Scholar] [CrossRef]

- Li, J.; Pu, Z.; Wang, Z.; Long, Y.; Jia, K.; Liu, X. High Dielectric Constants of Composites of Fiber-Like Copper Phthalocyanine-Coated Graphene Oxide Embedded in Poly(arylene Ether Nitriles). J. Electron. Mater. 2015, 44, 2378–2386. [Google Scholar] [CrossRef]

- Wang, J.; Wei, R.; Tong, L.; Liu, X. Effect of magnetite bridged carbon nanotube/graphene networks on the properties of polyarylene ether nitrile. J. Mater. Sci. Mater. Electron. 2016, 28, 3978–3986. [Google Scholar] [CrossRef]

- Wei, R.; Wang, J.; Zhang, H.; Han, W.; Liu, X. Crosslinked Polyarylene Ether Nitrile Interpenetrating with Zinc Ion Bridged Graphene Sheet and Carbon Nanotube Network. Polymers 2017, 9, 342. [Google Scholar] [CrossRef]

- You, Y.; Huang, X.; Pu, Z.; Jia, K.; Liu, X. Enhanced crystallinity, mechanical and dielectric properties of biphenyl polyarylene ether nitriles by unidirectional hot-stretching. J. Polym. Res. 2015, 22, 211. [Google Scholar] [CrossRef]

- You, Y.; Tu, L.; Wang, Y.; Tong, L.; Wei, R.; Liu, X. Achieving Secondary Dispersion of Modified Nanoparticles by Hot-Stretching to Enhance Dielectric and Mechanical Properties of Polyarylene Ether Nitrile Composites. Nanomaterials 2019, 9, 1006. [Google Scholar] [CrossRef] [PubMed]

- You, Y.; Du, X.; Mao, H.; Tang, X.; Wei, R.; Liu, X. Synergistic enhancement of mechanical, crystalline and dielectric properties of polyarylene ether nitrile-based nanocomposites by unidirectional hot stretching–quenching. Polym. Int. 2017, 66, 1151–1158. [Google Scholar] [CrossRef]

- Huang, X.; Wang, K.; Jia, K.; Liu, X. Polymer-based composites with improved energy density and dielectric constants by monoaxial hot-stretching for organic film capacitor applications. RSC Adv. 2015, 5, 51975–51982. [Google Scholar] [CrossRef]

- Mao, H.; You, Y.; Tong, L.; Tang, X.; Wei, R.; Liu, X. Dielectric properties of diblock copolymers containing a polyarylene ether nitrile block and a polyarylene ether ketone block. J. Mater. Sci. Mater. Electron. 2017, 29, 3127–3134. [Google Scholar] [CrossRef]

- Wei, R.; Huo, Q.; Liu, K.; Elnaggar, A.Y.; El-Bahy, S.M.; El-Bahy, Z.M.; Ren, J.; Wang, L.; Wu, Z. Distributing fluorinated carbon nanotube on pore walls of polyarylene ether nitrile porous films for advanced electromagnetic interference shielding. Adv. Compos. Hybrid Mater. 2024, 7, 196. [Google Scholar] [CrossRef]

- Mao, H.; You, Y.; Tong, L.; Tang, X.; Wei, R.; Liu, X. Dielectric properties of poly(arylene ether nitrile ketone) copolymers. High Perform. Polym. 2018, 31, 901–908. [Google Scholar] [CrossRef]

- Hu, W.; You, Y.; Tong, L.; Tu, L.; Wang, Y.; Wei, R.; Liu, X. Preparation and physical properties of polyarylene ether nitrile and polyarylene ether sulfone random copolymers. High Perform. Polym. 2018, 31, 686–693. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, Z.; Feng, Y.; Gao, F.; Luo, Y.; Li, S.; Wei, R.; Wang, L. Covalently cross-linked CaCu3Ti4O12 and poly(arylene ether nitrile) hybrids with enhanced high temperature energy storage properties. Mater. Today Commun. 2024, 38, 108544. [Google Scholar] [CrossRef]

- Wei, R.-B.; Zhan, C.-H.; Yang, Y.; He, P.-L.; Liu, X.-B. Polyarylene Ether Nitrile and Titanium Dioxide Hybrids as Thermal Resistant Dielectrics. Chin. J. Polym. Sci. 2020, 39, 211–218. [Google Scholar] [CrossRef]

- Wei, R.; Liu, Y.; Gao, F.; Feng, Z.; Huo, Q.; Liu, K.; Zhang, Z.; Lei, X.; Wang, L. Enhancing high-temperature energy storage performance of poly(arylene ether nitrile) hybrids synergistically via phthalonitrile modified boron nitride and carbon nanotube. Adv. Compos. Hybrid Mater. 2024, 7, 50. [Google Scholar] [CrossRef]

- You, Y.; Liu, S.; Tu, L.; Wang, Y.; Zhan, C.; Du, X.; Wei, R.; Liu, X. Controllable Fabrication of Poly(Arylene Ether Nitrile) Dielectrics for Thermal-Resistant Film Capacitors. Macromolecules 2019, 52, 5850–5859. [Google Scholar] [CrossRef]

- Yang, R.; Wei, R.; Li, K.; Tong, L.; Jia, K.; Liu, X. Crosslinked polyarylene ether nitrile film as flexible dielectric materials with ultrahigh thermal stability. Sci. Rep. 2016, 6, 36434. [Google Scholar] [CrossRef] [PubMed]

- Wei, R.; Tu, L.; You, Y.; Zhan, C.; Wang, Y.; Liu, X. Fabrication of crosslinked single-component polyarylene ether nitrile composite with enhanced dielectric properties. Polymer 2019, 161, 162–169. [Google Scholar] [CrossRef]

- Liu, S.; Liu, C.; Feng, X.; Lin, G.; Bai, Z.; Liu, X. Dielectric properties of polyarylene ether nitrile composites based on modified boron nitride. J. Phys. Conf. Ser. 2022, 2338, 012035. [Google Scholar] [CrossRef]

- Nomura, K.; Terwilliger, P. Self-dual Leonard pairs. Spec. Matrices 2019, 7, 1–19. [Google Scholar] [CrossRef]

- Tu, L.; Xiao, Q.; Wei, R.; Liu, X. Fabrication and Enhanced Thermal Conductivity of Boron Nitride and Polyarylene Ether Nitrile Hybrids. Polymers 2019, 11, 1340. [Google Scholar] [CrossRef]

- Pu, L.; Zeng, J.; Long, Y.; Zhang, H.; Huang, X.; Liu, J. Ultra-high power density in poly(arylene ether nitrile)-based composites containing barium titanate and boron nitride nanosheets. Polym. Compos. 2023, 44, 8141–8152. [Google Scholar] [CrossRef]

- Xiao, Q.; Han, W.; Yang, R.; You, Y.; Wei, R.; Liu, X. Mechanical, dielectric, and thermal properties of polyarylene ether nitrile and boron nitride nanosheets composites. Polym. Compos. 2017, 39, 24518. [Google Scholar] [CrossRef]

- Xiao, Q.; Zhan, C.; You, Y.; Tong, L.; Wei, R.; Liu, X. Preparation and thermal conductivity of copper phthalocyanine grafted boron nitride nanosheets. Mater. Lett. 2018, 227, 33–36. [Google Scholar] [CrossRef]

- You, Y.; Chen, S.; Yang, S.; Li, L.; Wang, P. Enhanced Thermal and Dielectric Properties of Polyarylene Ether Nitrile Nanocomposites Incorporated with BN/TiO2-Based Hybrids for Flexible Dielectrics. Polymers 2023, 15, 4279. [Google Scholar] [CrossRef]

- Lan, T.; Zhang, W.; Wang, Y.; Liu, S.; Liu, C.; Tong, L.; Liu, X. Dielectric films with good dielectric breakdown strength based on poly(arylene ether nitrile) enhanced by nano boron nitride and graphene oxide via noncovalent interaction. J. Phys. Chem. Solids 2021, 151, 109906. [Google Scholar] [CrossRef]

- He, L.; Zheng, Y.; Xu, X.; Liu, X.; Tong, L. Highly efficient thermal conductivity of polyarylene ether nitrile composites via the introduction of hybrid fillers and tailored cross-linked structure. Polymer 2024, 307, 127245. [Google Scholar] [CrossRef]

- Tang, X.; You, Y.; Mao, H.; Li, K.; Wei, R.; Liu, X. Energy Storage of Polyarylene Ether Nitriles at High Temperature. Electron. Mater. Lett. 2018, 14, 440–445. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, J.; Zhu, H.; Luo, H.; Zhai, X.; Huan, Y.; Yan, J.; Wang, K.; Liu, C.; Cheng, H.; et al. Synergically improved energy storage performance and stability in sol–gel processed BaTiO3/(Pb,La,Ca)TiO3/BaTiO3 tri-layer films with a crystalline engineered sandwich structure. J. Adv. Ceram. 2023, 12, 2300–2314. [Google Scholar]

- Wang, Z.; Wei, R.; Liu, X. Fluffy and Ordered Graphene Multilayer Films with Improved Electromagnetic Interference Shielding over X-Band. ACS Appl. Mater. Interfaces 2017, 9, 22408–22419. [Google Scholar] [CrossRef]

- Zhang, T.; Yin, C.; Zhang, C.; Feng, Y.; Li, W.; Chi, Q.; Chen, Q.; Fei, W. Self-polarization and energy storage performance in antiferroelectric-insulator multilayer thin films. Compos. Part B-Eng. 2021, 221, 109027. [Google Scholar] [CrossRef]

- Chen, Y.; Xue, Y.; Shi, J.; Zhou, J.; Bai, K.; Li, Y.; Ma, R.; Liu, J.; Dastan, D.; Liu, X.; et al. Sandwich-structured relaxor ferroelectric nanocomposite incorporated with core-shell fillers for outstanding-energy-storage capacitor application. J. Alloys Compd. 2024, 1003, 175642. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, H.; Xin, S.; Pan, Z.; Ding, X.; Li, Z.; Fan, X.; Liu, J.; Li, P.; Yu, J. Polyimide-Based Composite Films with Largely Enhanced Energy Storage Performances toward High-Temperature Electrostatic Capacitor Applications. ACS Appl. Energy Mater. 2022, 5, 10297–10306. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Wang, J.; Zhen, X.; Lei, C.; Shen, Z.; Zhang, X.; Nan, C.W. Ultrahigh Capacitive Energy Storage in a Heterogeneous Nanolayered Composite. Adv. Funct. Mater. 2024, 34, 202410823. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Y.; Li, W.; Song, R.; Zhang, Y.; Zhao, W.; Wang, Z.; Peng, Y.; Fei, W. Enhanced energy storage properties of amorphous BiFeO3/Al2O3 multilayers. J. Mater. Res. Technol. 2021, 11, 1852–1858. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, X.-m.; Wu, W.-w.; Khesro, A.; Liu, P.; Mao, M.; Song, K.; Sun, R.; Wang, D. Outstanding discharge energy density and efficiency of the bilayer nanocomposite films with BaTiO3-dispersed PVDF polymer and polyetherimide layer. Chem. Eng. J. 2022, 446, 136926. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Birkhölzer, Y.A.; Houwman, E.P.; Koster, G.; Rijnders, G. Enhancing the Energy-Storage Density and Breakdown Strength in PbZrO3/Pb0.9La0.1Zr0.52Ti0.48O3-Derived Antiferroelectric/Relaxor-Ferroelectric Multilayers. Adv. Energy Mater. 2022, 12, 202200517. [Google Scholar] [CrossRef]

- Ren, S.; Yuan, S.; Huang, M.; Pang, L.; Li, W.; Wang, X.; Zhou, D.; Zhao, Y. Cost-effective strategy for high-temperature energy storage performance of polyimide nanocomposite films. J. Energy Storage 2024, 95, 112524. [Google Scholar] [CrossRef]

- Sun, Z.; Houwman, E.P.; Wang, S.; Nguyen, M.D.; Koster, G.; Rijnders, G. Revealing the effect of the Schottky barrier on the energy storage performance of ferroelectric multilayers. J. Alloys Compd. 2024, 981, 173758. [Google Scholar] [CrossRef]

- Li, D.-L.; Liu, C.-Y.; Lan, K.-Y.; Li, Y.; Xu, L.; Zhong, G.-J.; Huang, H.-D.; Li, Z.-M. Scalable In-situ Microfibrillar dielectric films: Achieving exceptional energy density and efficiency. Energy Storage Mater. 2024, 72, 103717. [Google Scholar] [CrossRef]

- Li, D.-L.; Liu, C.-Y.; Li, Y.; Xu, L.; Lei, J.; Zhong, G.-J.; Huang, H.-D.; Li, Z.-M. In Situ Well-Aligned Microfibrils and Mother–Daughter Crystals as Promising Blocks to Suppress Carrier Transport in Polypropylene Dielectric Films. Macromolecules 2024, 57, 10208–10218. [Google Scholar] [CrossRef]

- Zheng, M.-S.; Zheng, Y.-T.; Zha, J.-W.; Yang, Y.; Han, P.; Wen, Y.-Q.; Dang, Z.-M. Improved dielectric, tensile and energy storage properties of surface rubberized BaTiO3/polypropylene nanocomposites. Nano Energy 2018, 48, 144–151. [Google Scholar] [CrossRef]

- Gao, F.; Zhou, L.; Liu, K.; Feng, Z.; Huo, Q.; Yang, C.; Zhang, T.; Mao, Y.; Li, D.; Wang, L.; et al. Improving energy storage properties of polyarylene ether nitrile with coral-like CaCu3Ti4O12 nanorods. Chem. Eng. J. 2024, 493, 152830. [Google Scholar] [CrossRef]