Numerical Investigation on Electrothermal Performance of AlGaN/GaN HEMTs with Nanocrystalline Diamond/SiNx Trench Dual-Passivation Layers

Abstract

1. Introduction

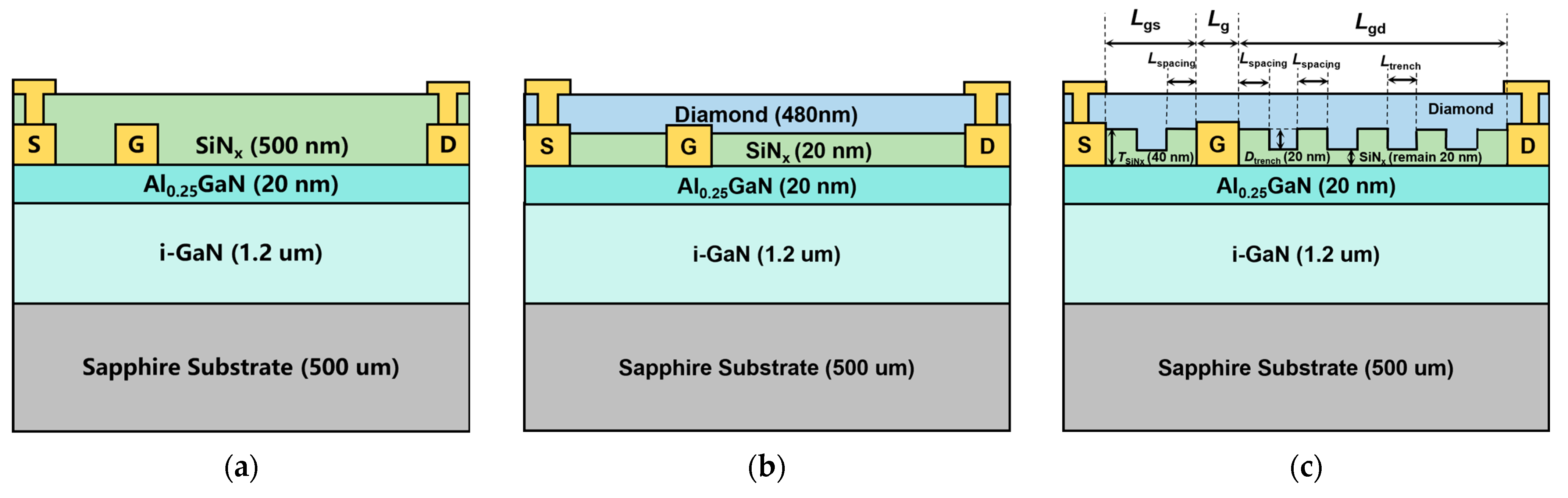

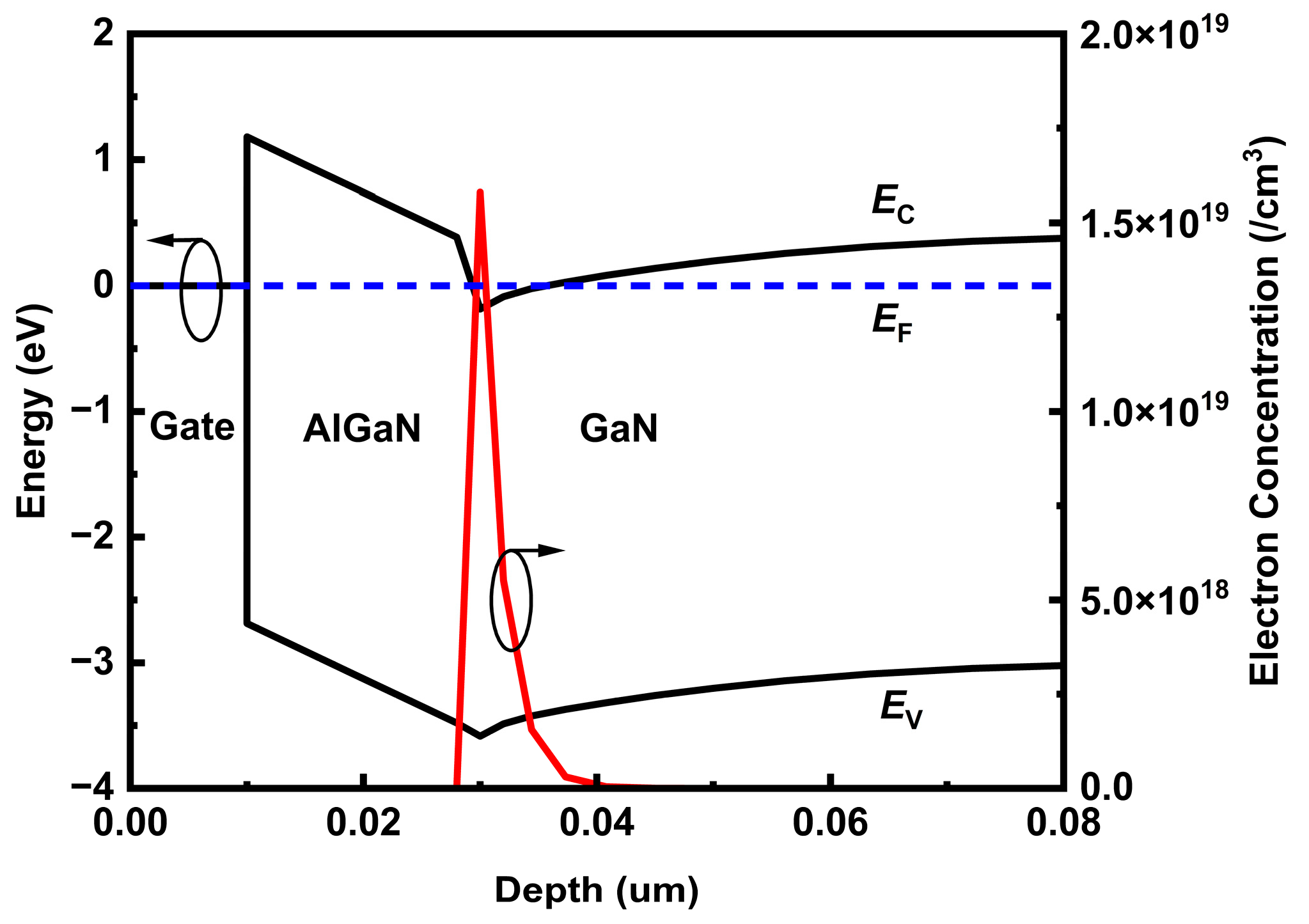

2. Device Structure Design and Simulation Setup

3. Results and Discussion

3.1. Junction Temperature Distributtion

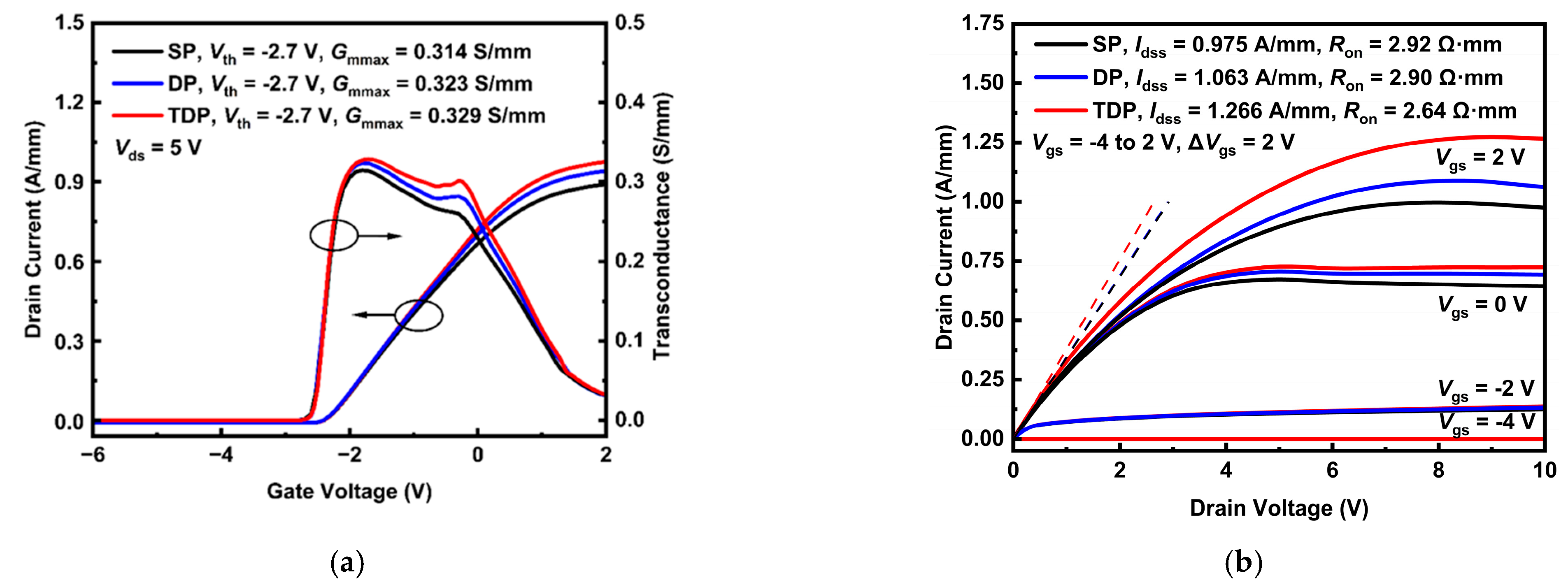

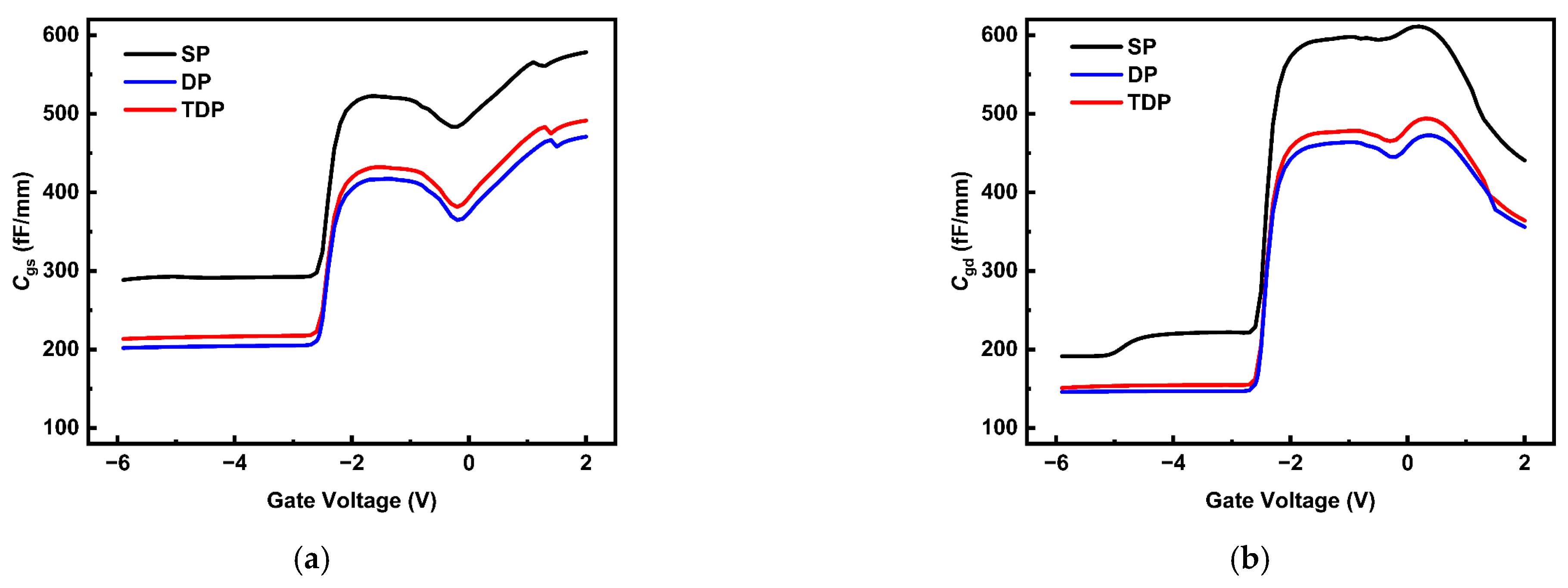

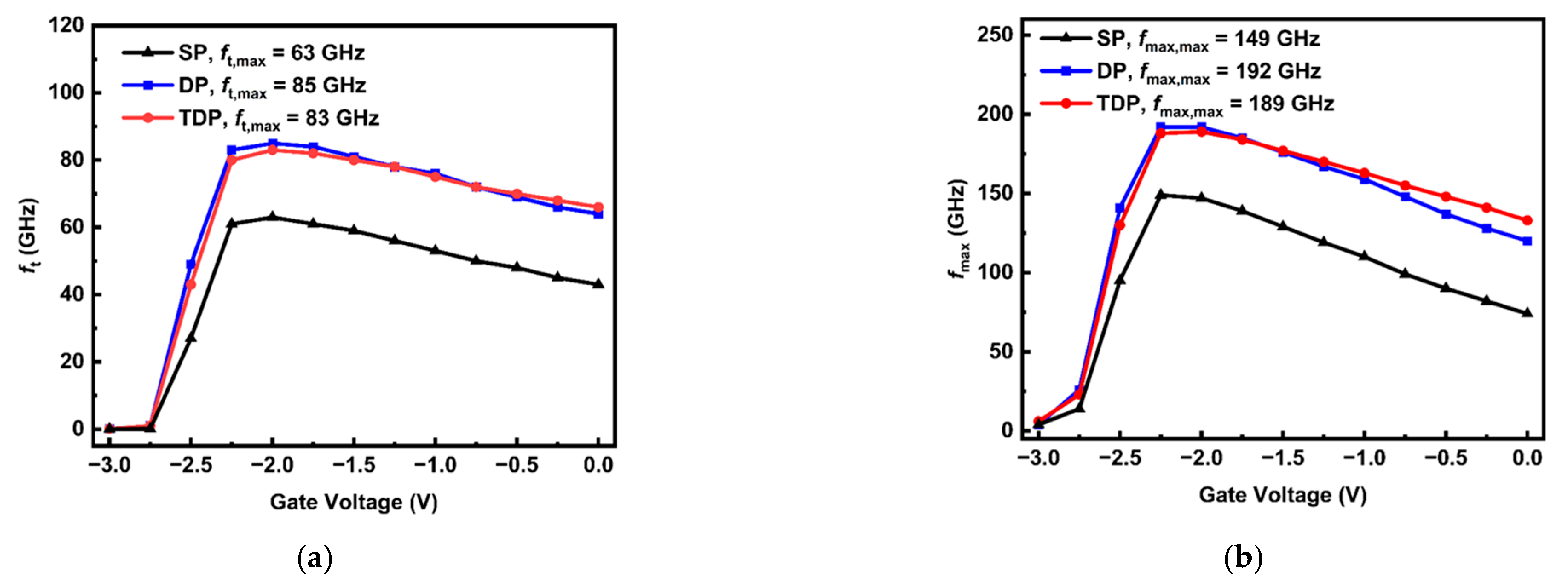

3.2. DC Characteristics and RF Small-Signal Characteristics

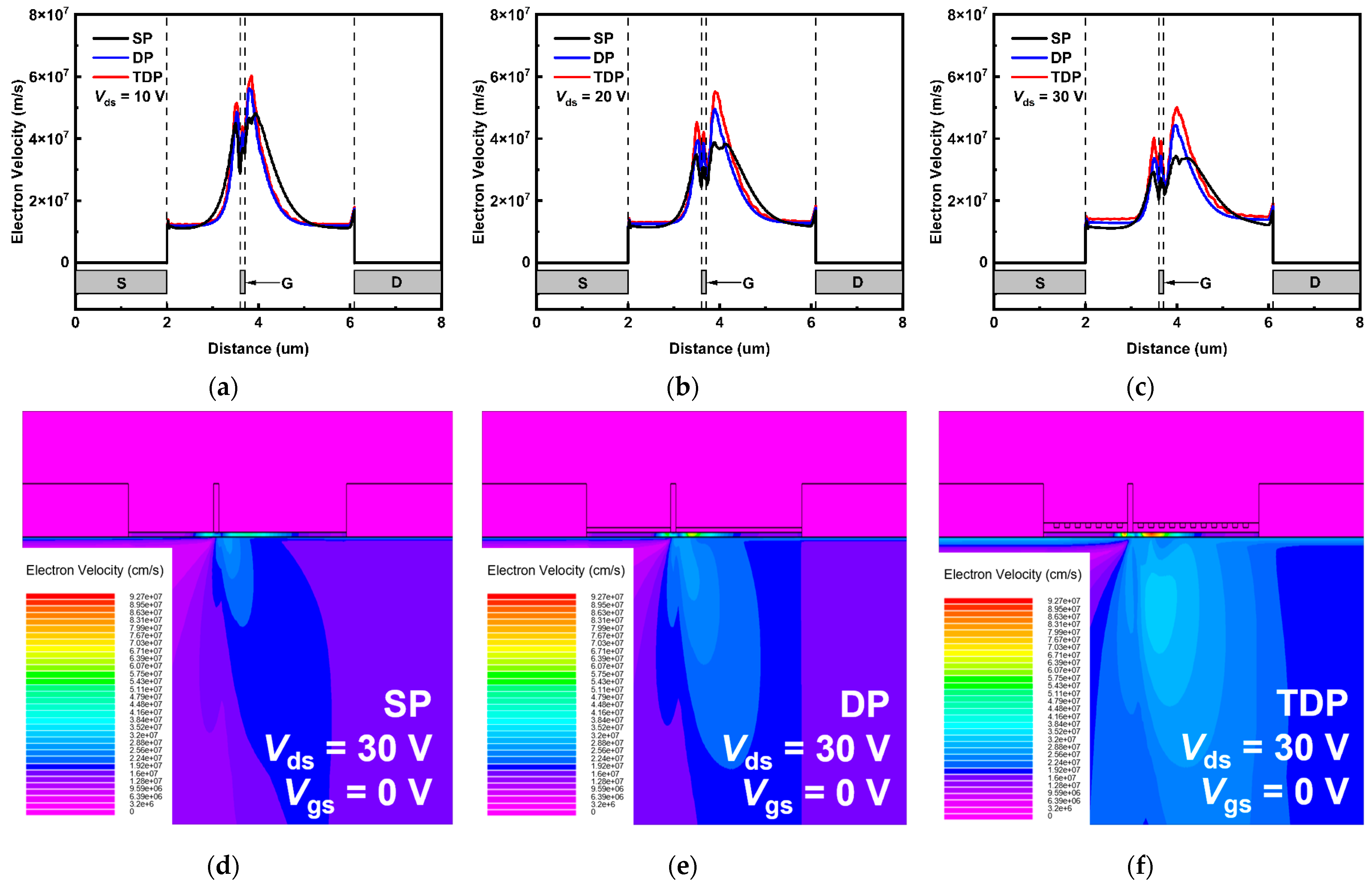

3.3. Electron Mobility and Electron Drift Velocity Distributtion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ikeda, N.; Niiyama, Y.; Kambayashi, H.; Sato, Y.; Nomura, T.; Kato, S.; Yoshida, S. GaN power transistors on Si substrates for switching applications. Proc. IEEE 2010, 98, 1151–1161. [Google Scholar] [CrossRef]

- Heller, E.R.; Crespo, A. Electro-thermal modeling of multifinger AlGaN/GaN HEMT device operation including thermal substrate effects. Microelectron. Reliab. 2008, 48, 45–50. [Google Scholar] [CrossRef]

- Sozzi, G.; Menozzi, R. A review of the use of electro-thermal simulations for the analysis of heterostructure FETs. Microelectron. Reliab. 2007, 47, 65–73. [Google Scholar] [CrossRef]

- Hirama, K.; Taniyasu, Y.; Kasu, M. AlGaN/GaN high-electron mobility transistors with low thermal resistance grown on single-crystal diamond (111) substrates by metalorganic vapor-phase epitaxy. Appl. Phys. Lett. 2011, 98, 162112. [Google Scholar] [CrossRef]

- Ji, H.; Kuball, M.; Sarua, A.; Das, J.; Ruythooren, W.; Germain, M.; Borghs, G. Three-dimensional thermal analysis of a flip-chip mounted AlGaN/GaN HFET using confocal micro-Raman spectroscopy. IEEE Trans. Electron Devices 2006, 53, 2658–2661. [Google Scholar]

- Zhang, R.; Zhao, W.S.; Yin, W.Y.; Zhao, Z.G.; Zhou, H.J. Impacts of diamond heat spreader on the thermo-mechanical characteristics of high-power AlGaN/GaN HEMTs. Diam. Relat. Mater. 2015, 52, 25–31. [Google Scholar] [CrossRef]

- Tadjer, M.J.; Anderson, T.J.; Ancona, M.G.; Raad, P.E.; Komarov, P.; Bai, T.; Gallagher, J.C.; Koehler, A.D.; Goorsky, M.S.; Francis, D.A.; et al. GaN-on-diamond HEMT technology with TAVG= 176 C at PDC,max = 56 W/mm measured by transient thermoreflectance imaging. IEEE Electron Device Lett. 2019, 40, 881–884. [Google Scholar] [CrossRef]

- Ejeckam, F.; Francis, D.; Faili, F.; Twitchen, D.; Bolliger, B.; Babic, D.; Felbinger, J. S2-T1: GaN-on-diamond: A brief history. In Proceedings of the 2014 Lester Eastman Conference on High Performance Devices (LEC), Ithaca, NY, USA, 5–7 August 2014; IEEE: New York, NY, USA, 2014; pp. 1–5. [Google Scholar]

- Dussaigne, A.; Gonschorek, M.; Malinverni, M.; Py, M.A.; Martin, D.; Mouti, A.; Stadelmann, P.; Grandjean, N. High-mobility AlGaN/GaN two-dimensional electron gas heterostructure grown on (111) single crystal diamond substrate. Jpn. J. Appl. Phys. 2010, 49, 061001. [Google Scholar] [CrossRef]

- Tijent, F.Z.; Faqir, M.; Chouiyakh, H.; Essadiqi, E.H. integration methods of GaN and diamond for thermal management optimization. ECS J. Solid State Sci. Technol. 2021, 10, 074003. [Google Scholar] [CrossRef]

- Schwander, M.; Partes, K. A review of diamond synthesis by CVD processes. Diam. Relat. Mater. 2011, 20, 1287–1301. [Google Scholar] [CrossRef]

- Angus, J.C.; Will, H.A.; Stanko, W.S. Growth of diamond seed crystals by vapor deposition. J. Appl. Phys. 1968, 39, 2915–2922. [Google Scholar] [CrossRef]

- Arivazhagan, L.; Jarndal, A.; Nirmal, D. GaN HEMT on Si substrate with diamond heat spreader for high power applications. J. Comput. Electron. 2021, 20, 873–882. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, Z.; Lu, Y. Enhancement of hot spot cooling by capped diamond layer deposition for multifinger AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2019, 67, 47–52. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, Z. Thickness dependence and anisotropy of capped diamond thermal conductivity on cooling of pulse-operated GaN HEMTs. IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 233–240. [Google Scholar] [CrossRef]

- Zhou, Y.; Ramaneti, R.; Anaya, J.; Korneychuk, S.; Derluyn, J.; Sun, H.; Pomeroy, J.; Verbeeck, J.; Haenen, K.; Kuball, M. Thermal characterization of polycrystalline diamond thin film heat spreaders grown on GaN HEMTs. Appl. Phys. Lett. 2017, 111, 041901. [Google Scholar] [CrossRef]

- Wang, A.; Tadjer, M.J.; Anderson, T.J.; Baranyai, R.; Pomeroy, J.W.; Feygelson, T.I.; Hobart, K.D.; Pate, B.B.; Calle, F.; Kuball, M. Impact of intrinsic stress in diamond capping layers on the electrical behavior of AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2013, 60, 3149–3156. [Google Scholar] [CrossRef]

- Anderson, T.J.; Koehler, A.D.; Hobart, K.D.; Tadjer, M.J.; Feygelson, T.I.; Hite, J.K.; Pate, B.B.; Kub, F.J.; Eddy, C.R. Nanocrystalline Diamond-Gated AlGaN/GaN HEMT. IEEE Electron Device Lett. 2013, 34, 1382–1384. [Google Scholar] [CrossRef]

- Anderson, T.J.; Hobart, K.D.; Tadjer, M.J.; Koehler, A.D.; Imhoff, E.A.; Hite, J.K.; Feygelson, T.I.; Pate, B.B.; Eddy, C.R.; Kub, F.J. Nanocrystalline diamond integration with III-nitride HEMTs. ECS J. Solid State Sci. Technol. 2016, 6, Q3036. [Google Scholar] [CrossRef]

- Guggenheim, R.; Rothschild, J.A.; Rodes, L.; Hoffman, A. Thermal characteristics of diamond film coatings for GaN HEMT devices. In Proceedings of the 2015 IEEE International Conference on Microwaves, Communications, Antennas and Electronic Systems (COMCAS), Tel Aviv, Israel, 2–4 November 2015; IEEE: New York, NY, USA, 2015; pp. 1–3. [Google Scholar]

- Alomari, M.; Dipalo, M.; Rossi, S.; Diforte-Poisson, M.A.; Delage, S.; Carlin, J.F.; Grandjean, N.; Gaquiere, C.; Toth, L.; Pecz, B.; et al. Diamond overgrown InAlN/GaN HEMT. Diam. Relat. Mater. 2011, 20, 604–608. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.; Yu, X.; Zhou, J.; Kong, Y. Thermal performance improvement of AlGaN/GaN HEMTs using nanocrystalline diamond capping layers. Micromachines 2022, 13, 1486. [Google Scholar] [CrossRef]

- Karmalkar, S.; Mishra, U.K. Enhancement of breakdown voltage in AlGaN/GaN high electron mobility transistors using a field plate. IEEE Trans. Electron Devices 2001, 48, 1515–1521. [Google Scholar] [CrossRef]

- Zhang, Y.; Teo, K.H.; Palacios, T. Beyond thermal management: Incorporating p-diamond back-barriers and cap layers into AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2016, 63, 2340–2345. [Google Scholar] [CrossRef]

- Smith, K.V.; Haller, J.; Guerrero, J.; Smith, R.P.; Lal, R.; Wu, Y.F. Lifetime tests of 600-V GaN-on-Si power switches and HEMTs. Microelectron. Reliab. 2016, 58, 197–203. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, Q.; Zhang, Q.M.; Zhang, S. Dielectric behavior of bilayer films of P(VDF-CTFE) and low temperature PECVD fabricated Si3N4. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 463–470. [Google Scholar] [CrossRef]

- Gao, X.-W.; Zhao, Z.-W.; He, Y.; Fan, S.-F.; Jiao, K.-R.; Lou, S.-Y.; Han, X.-Y.; Song, P.-F.; Cai, R.; Hu, Z.; et al. Nanodiamond: A promising metal-free nanoscale material in photocatalysis and electrocatalysis. Rare Met. 2024, 43, 3501–3552. [Google Scholar] [CrossRef]

- Bhat, A.M.; Shafi, N.; Sahu, C.; Periasamy, C. Analysis of AlGaN/GaN HEMT and its operational improvement using a grated gate field plate. J. Electron. Mater. 2021, 50, 6218–6227. [Google Scholar] [CrossRef]

- Neamen, D.A. Semiconductor Physics and Devices: Basic Principles, 4th ed.; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- ATLAS User’s Manual; Silvaco Int.: Santa Clara, CA, USA, 2010.

- Tan, L.T.; Chen, P.; Chua, S.J. Impact of V/III flux ratio and Si-doping concentration on GaN grown by metalorganic chemical-vapor deposition on sapphire substrate. In Proceedings of the ICONIP’02, the 9th International Conference on Neural Information Processing, Computational Intelligence for the E-Age (IEEE Cat. No. 02EX575), Penang, Malaysia, 19–21 December 2002; IEEE: New York, NY, USA, 2002; pp. 172–176. [Google Scholar]

| Parameters | GaN | AlGaN |

|---|---|---|

| Eg300 (eV) | 3.4 | 3.96 |

| Affinity (eV) | - | 3.82 |

| Align | 0.8 | 0.8 |

| Permittivity | 9.5 | 9.5 |

| Mun (cm2/V-s) | 900 | 600 |

| Mup (cm2/V-s) | 10 | 10 |

| Vsatn (cm/s) | 2 × 107 | - |

| Nc300 (/cm3) | 1.07 × 1018 | 2.07 × 1018 |

| Nv300 (/cm3) | 1.16 × 1018 | 1.16 × 1018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Deng, C.; Tang, C.; Tang, X.; Tao, W.; Wang, Z.; Tao, N.; Wang, Q.; Wang, Q.; Yu, H. Numerical Investigation on Electrothermal Performance of AlGaN/GaN HEMTs with Nanocrystalline Diamond/SiNx Trench Dual-Passivation Layers. Nanomaterials 2025, 15, 574. https://doi.org/10.3390/nano15080574

Wang P, Deng C, Tang C, Tang X, Tao W, Wang Z, Tao N, Wang Q, Wang Q, Yu H. Numerical Investigation on Electrothermal Performance of AlGaN/GaN HEMTs with Nanocrystalline Diamond/SiNx Trench Dual-Passivation Layers. Nanomaterials. 2025; 15(8):574. https://doi.org/10.3390/nano15080574

Chicago/Turabian StyleWang, Peiran, Chenkai Deng, Chuying Tang, Xinyi Tang, Wenchuan Tao, Ziyang Wang, Nick Tao, Qi Wang, Qing Wang, and Hongyu Yu. 2025. "Numerical Investigation on Electrothermal Performance of AlGaN/GaN HEMTs with Nanocrystalline Diamond/SiNx Trench Dual-Passivation Layers" Nanomaterials 15, no. 8: 574. https://doi.org/10.3390/nano15080574

APA StyleWang, P., Deng, C., Tang, C., Tang, X., Tao, W., Wang, Z., Tao, N., Wang, Q., Wang, Q., & Yu, H. (2025). Numerical Investigation on Electrothermal Performance of AlGaN/GaN HEMTs with Nanocrystalline Diamond/SiNx Trench Dual-Passivation Layers. Nanomaterials, 15(8), 574. https://doi.org/10.3390/nano15080574