Dislocation Transformations at the Common 30°⟨0001⟩ Grain Boundaries During Plastic Deformation in Magnesium

Abstract

1. Introduction

2. Method

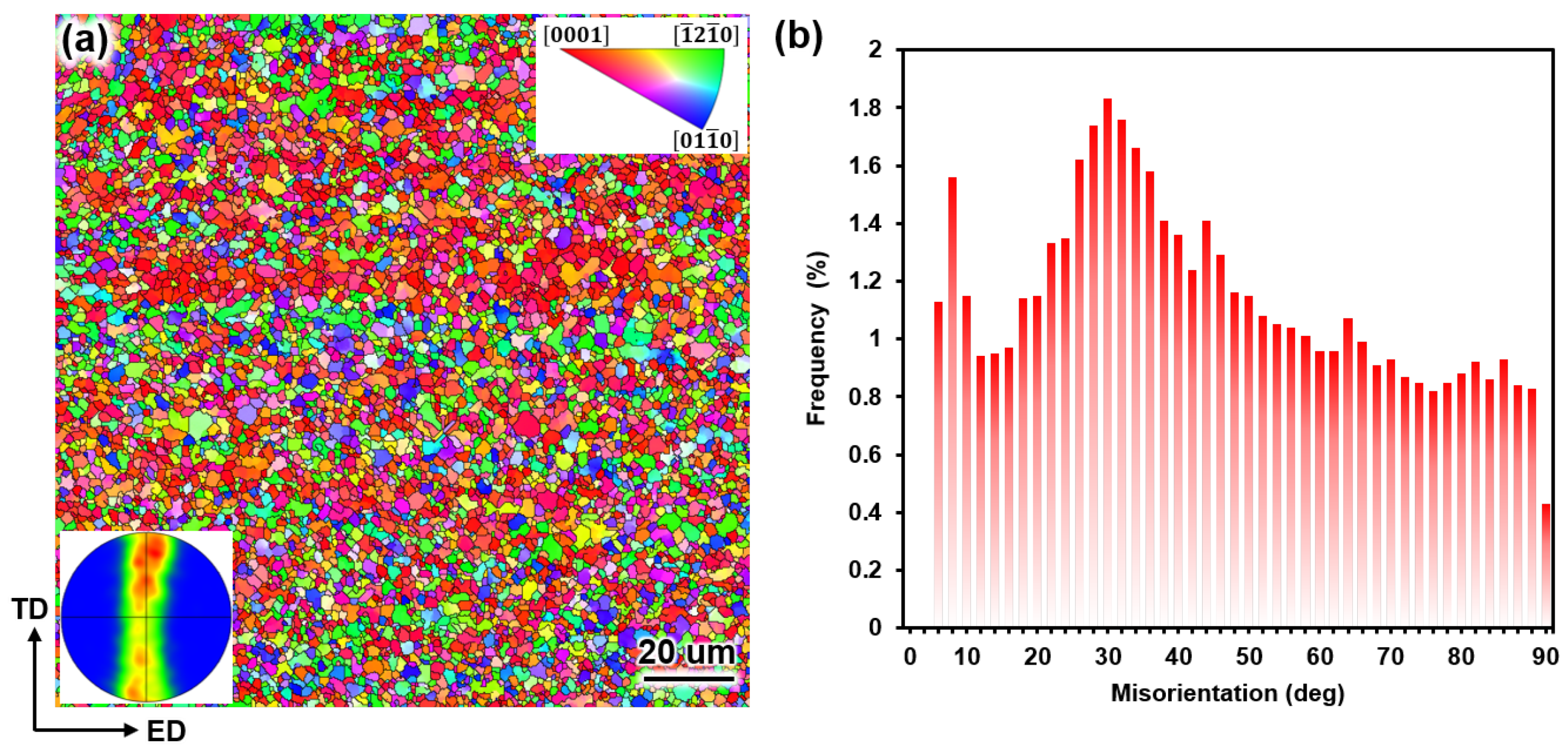

2.1. Experimental Details

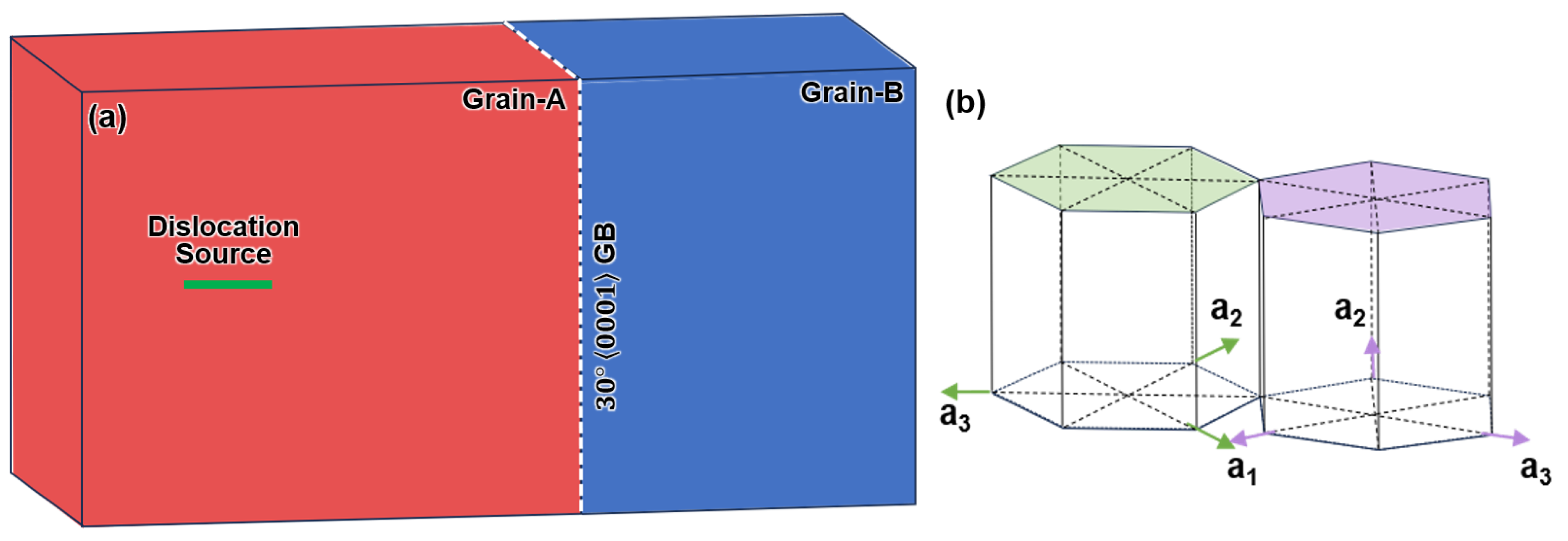

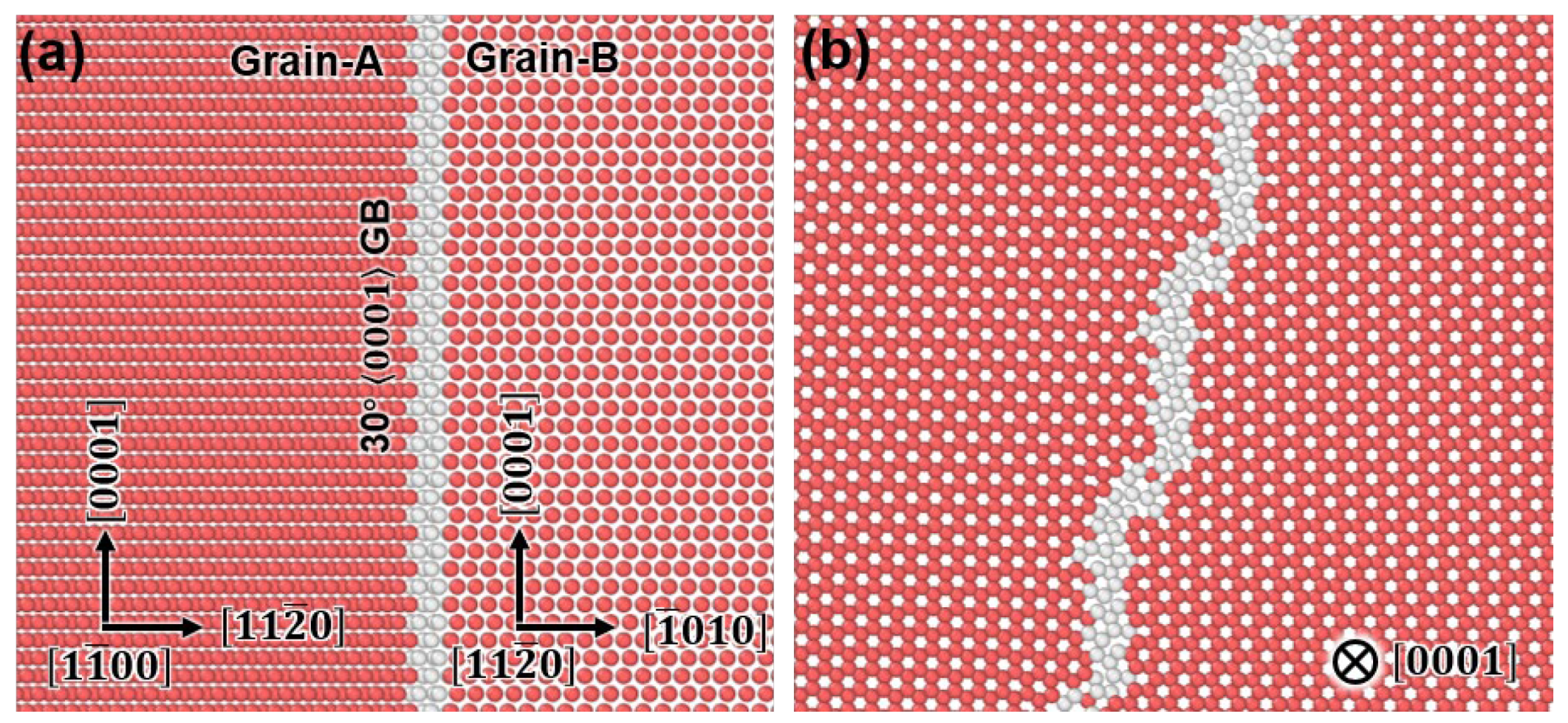

2.2. Molecular Dynamics Simulations

3. Results and Discussion

3.1. The 30° GB

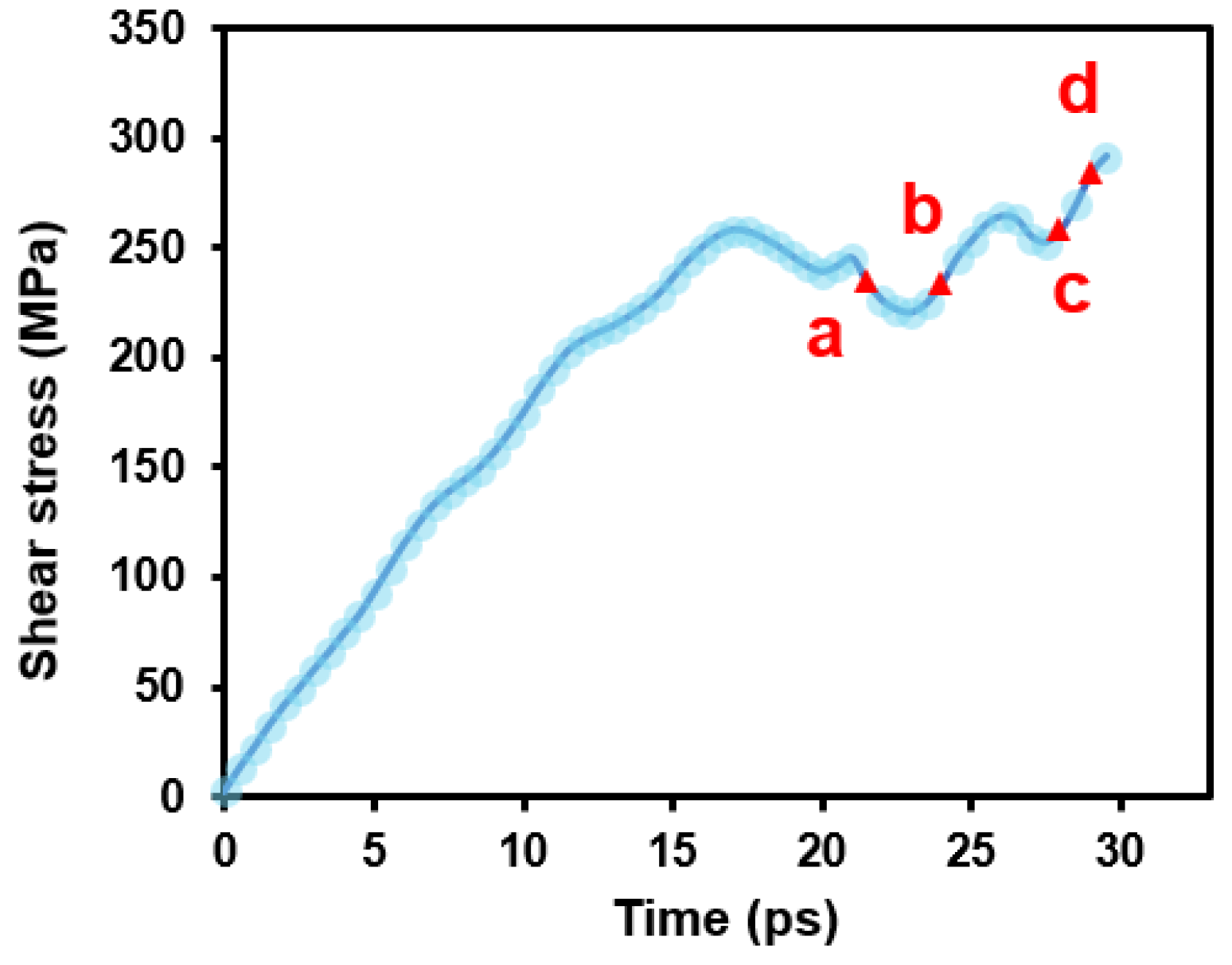

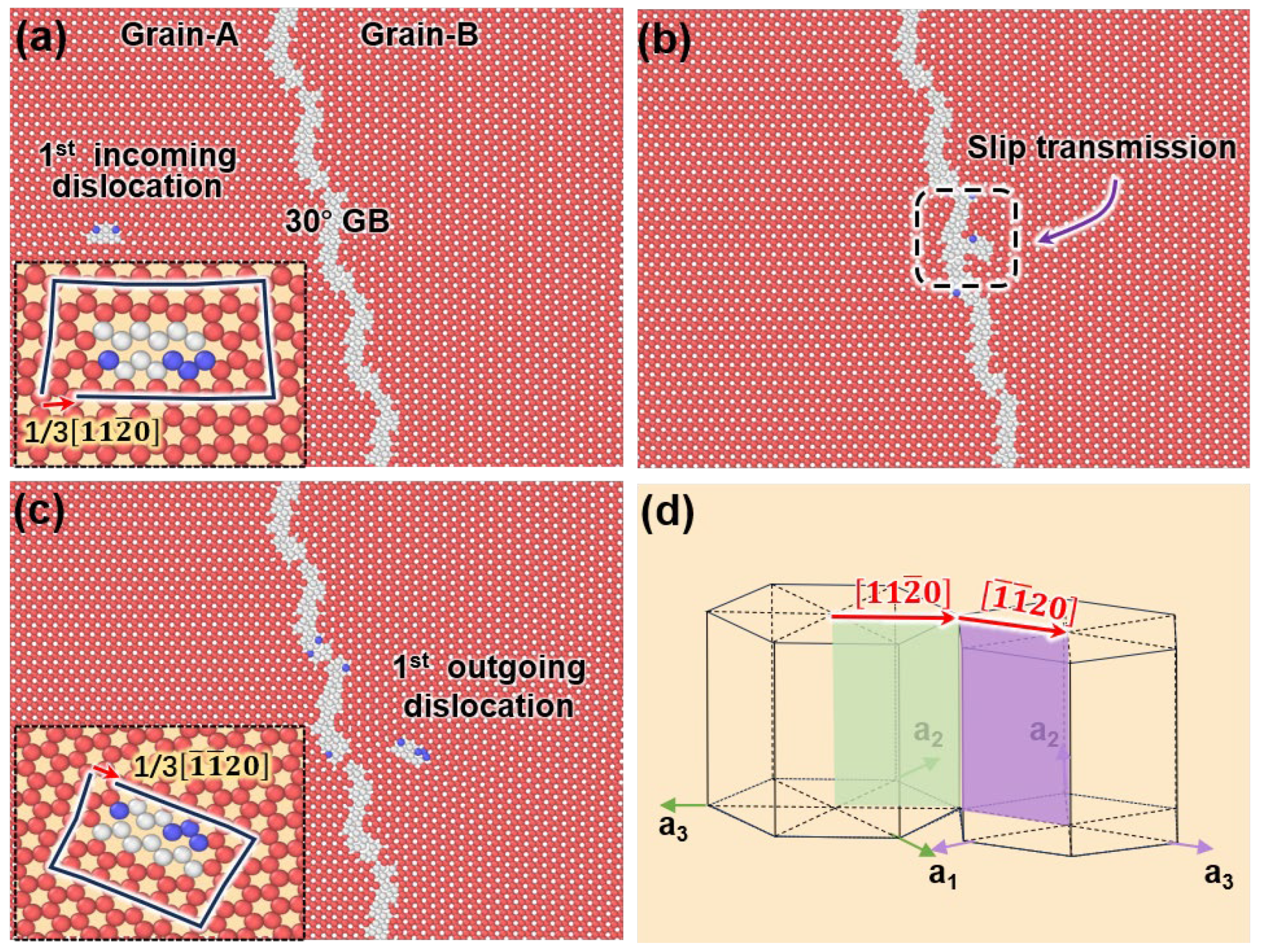

3.2. The Interaction Between Basal Dislocations and the 30° GB

3.3. The Interaction Between Prismatic Dislocations and the 30° GB

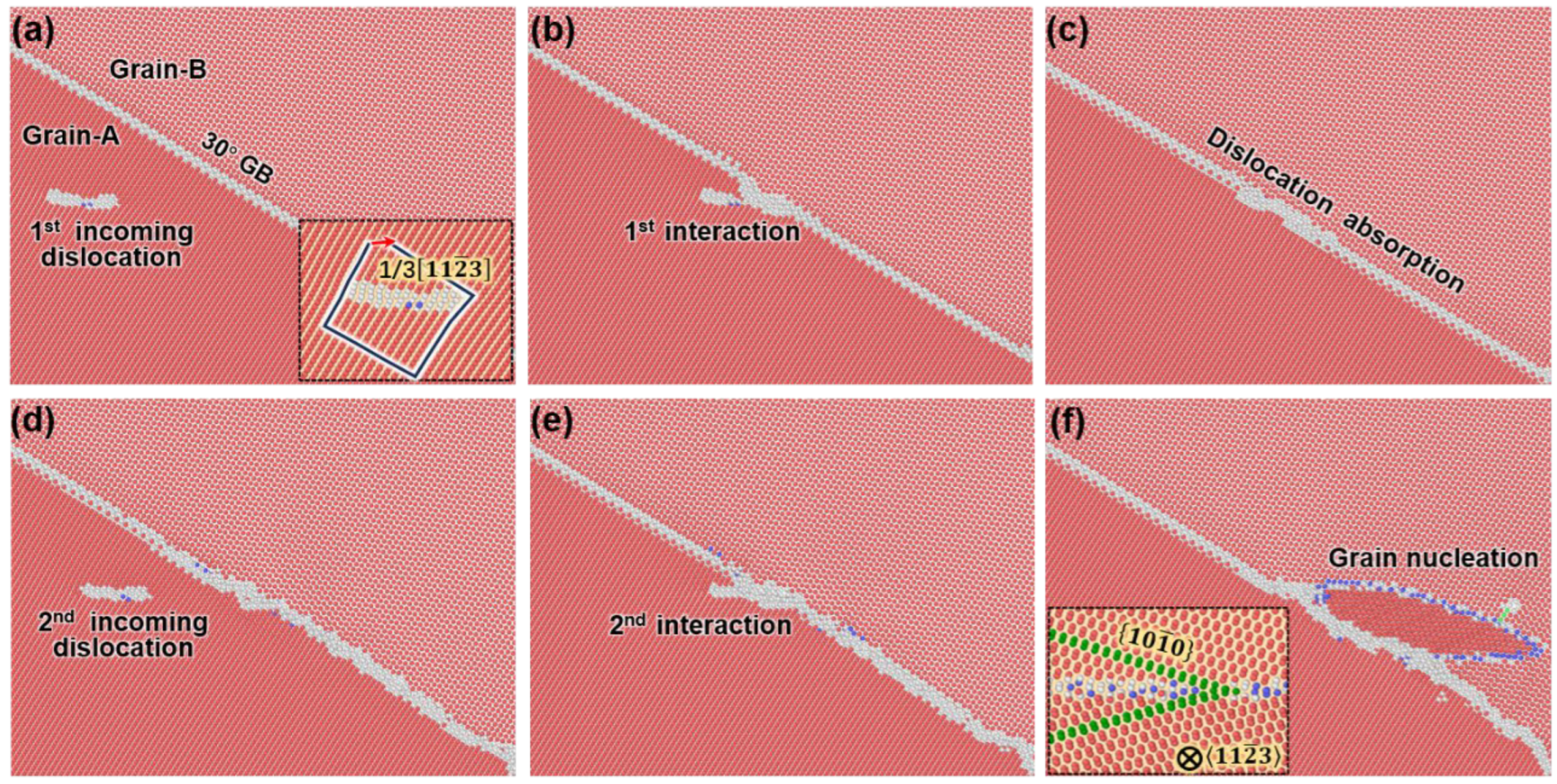

3.4. The Interaction Between Pyramidal Dislocation and 30° GB

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Q.; Yu, D.; Xu, B.; Hu, W.; Ma, Y.; Wang, Y.; Zhao, Z.; Wen, B.; He, J.; Liu, Z.; et al. Nanotwinned Diamond with Unprecedented Hardness and Stability. Nature 2014, 510, 250–253. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.X.; Liu, S.F.; Cao, B.X.; Luan, J.H.; Zhao, Y.L.; Chen, Z.; Zhang, Q.; Liu, X.J.; Liu, C.T.; Kai, J.J.; et al. Designing Nanoparticles-Strengthened High-Entropy Alloys with Simultaneously Enhanced Strength-Ductility Synergy at Both Room and Elevated Temperatures. Acta Mater. 2022, 238, 118216. [Google Scholar] [CrossRef]

- McMurtrey, M.D.; Was, G.S.; Patrick, L.; Farkas, D. Relationship between Localized Strain and Irradiation Assisted Stress Corrosion Cracking in an Austenitic Alloy. Mater. Sci. Eng. A 2011, 528, 3730–3740. [Google Scholar] [CrossRef]

- Jiao, Z.; Was, G.S. Impact of Localized Deformation on IASCC in Austenitic Stainless Steels. J. Nucl. Mater. 2011, 408, 246–256. [Google Scholar] [CrossRef]

- Hugo, R.C.; Kung, H.; Weertman, J.R.; Mitra, R.; Knapp, J.A.; Follstaedt, D.M. In-Situ TEM Tensile Testing of DC Magnetron Sputtered and Pulsed Laser Deposited Ni Thin Films. Acta Mater. 2003, 51, 1937–1943. [Google Scholar] [CrossRef]

- Kumar, K.S.; Suresh, S.; Chisholm, M.F.; Horton, J.A.; Wang, P. Deformation of Electrodeposited Nanocrystalline Nickel. Acta Mater. 2003, 51, 387–405. [Google Scholar] [CrossRef]

- De Koning, M.; Kurtz, R.J.; Bulatov, V.V.; Henager, C.H.; Hoagland, R.G.; Cai, W.; Nomura, M. Modeling of Dislocation–Grain Boundary Interactions in FCC Metals. J. Nucl. Mater. 2003, 323, 281–289. [Google Scholar] [CrossRef]

- Jang, H.; Farkas, D. Interaction of Lattice Dislocations with a Grain Boundary during Nanoindentation Simulation. Mater. Lett. 2007, 61, 868–871. [Google Scholar] [CrossRef]

- Yu, H.; Xin, Y.; Wang, M.; Liu, Q. Hall-Petch Relationship in Mg Alloys: A Review. J. Mater. Sci. Technol. 2018, 34, 248–256. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Knight, B.E.; Schuh, C.A. Six Decades of the Hall–Petch Effect—A Survey of Grain-Size Strengthening Studies on Pure Metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar] [CrossRef]

- Jin, Z.-H.; Gumbsch, P.; Albe, K.; Ma, E.; Lu, K.; Gleiter, H.; Hahn, H. Interactions between Non-Screw Lattice Dislocations and Coherent Twin Boundaries in Face-Centered Cubic Metals. Acta Mater. 2008, 56, 1126–1135. [Google Scholar] [CrossRef]

- Li, N.; Wang, J.; Huang, J.Y.; Misra, A.; Zhang, X. In Situ TEM Observations of Room Temperature Dislocation Climb at Interfaces in Nanolayered al/Nb Composites. Scr. Mater. 2010, 63, 363–366. [Google Scholar] [CrossRef]

- Chino, Y.; Sassa, K.; Kamiya, A.; Mabuchi, M. Enhanced Formability at Elevated Temperature of a Cross-Rolled Magnesium Alloy Sheet. Mater. Sci. Eng. A 2006, 441, 349–356. [Google Scholar] [CrossRef]

- Handbook, A.S. Magnesium and Magnesium Alloys. ASM international 1999, 106–118. [Google Scholar]

- Basu, I.; Pradeep, K.G.; Mießen, C.; Barrales-Mora, L.A.; Al-Samman, T. The Role of Atomic Scale Segregation in Designing Highly Ductile Magnesium Alloys. Acta Mater. 2016, 116, 77–94. [Google Scholar] [CrossRef]

- Steiner, M.A.; Bhattacharyya, J.J.; Agnew, S.R. The Origin and Enhancement of {0001} <> Texture during Heat Treatment of Rolled AZ31B Magnesium Alloys. Acta Mater. 2015, 95, 443–455. [Google Scholar] [CrossRef]

- Molodov, K.D.; Al-Samman, T.; Molodov, D.A.; Gottstein, G. Mechanisms of Exceptional Ductility of Magnesium Single Crystal during Deformation at Room Temperature: Multiple Twinning and Dynamic Recrystallization. Acta Mater. 2014, 76, 314–330. [Google Scholar] [CrossRef]

- Zhang, S.; Xie, Z.; Keuter, P.; Saood, S.; Abdellaoui, L.; Zhou, X.; Cautaerts, N.; Breitbach, B.; Aliramaji, S.; Korte-Kerzel, S.; et al. Atomistic Structures of <0001> Tilt Grain Boundaries in a Textured Mg Thin Film. Nanoscale 2022, 14, 18192–18199. [Google Scholar] [CrossRef]

- Huber, L.; Rottler, J.; Militzer, M. Atomistic Simulations of the Interaction of Alloying Elements with Grain Boundaries in Mg. Acta Mater. 2014, 80, 194–204. [Google Scholar] [CrossRef]

- Panigrahi, S.K.; Yuan, W.; Mishra, R.S.; DeLorme, R.; Davis, B.; Howell, R.A.; Cho, K. A Study on the Combined Effect of Forging and Aging in Mg–Y–RE Alloy. Mater. Sci. Eng. A 2011, 530, 28–35. [Google Scholar] [CrossRef]

- Bhattacharyya, J.J.; Agnew, S.R.; Muralidharan, G. Texture Enhancement during Grain Growth of Magnesium Alloy AZ31B. Acta Mater. 2015, 86, 80–94. [Google Scholar] [CrossRef]

- Barrett, C.D.; Imandoust, A.; Oppedal, A.L.; Inal, K.; Tschopp, M.A.; El Kadiri, H. Effect of Grain Boundaries on Texture Formation during Dynamic Recrystallization of Magnesium Alloys. Acta Mater. 2017, 128, 270–283. [Google Scholar] [CrossRef]

- Gottstein, G.; Al Samman, T. Texture Development in Pure Mg and Mg Alloy AZ31. MSF 2005, 495–497, 623–632. [Google Scholar] [CrossRef]

- Ostapovets, A.; Šedá, P.; Jäger, A.; Lejček, P. Characteristics of Coincident Site Lattice Grain Boundaries Developed during Equal Channel Angular Pressing of Magnesium Single Crystals. Scr. Mater. 2011, 64, 470–473. [Google Scholar] [CrossRef]

- Li, B.; Liao, M.; Ma, Q.; McClelland, Z. Structure of Grain Boundaries with 30°[0001] Misorientation in Dynamically Recrystallized Magnesium Alloys. Comput. Mater. Sci. 2015, 101, 175–180. [Google Scholar] [CrossRef]

- Wu, B.L.; Wan, G.; Zhang, Y.D.; Du, X.H.; Wagner, F.; Esling, C. Fragmentation of Large Grains in AZ31 Magnesium Alloy during ECAE via Route a. Mater. Sci. Eng. A 2010, 527, 3365–3372. [Google Scholar] [CrossRef]

- Liu, X.; Wang, J. Low-Energy, Mobile Grain Boundaries in Magnesium. Sci. Rep. 2016, 6, 21393. [Google Scholar] [CrossRef]

- Wang, W.; Han, P.; Peng, P.; Zhang, T.; Liu, Q.; Yuan, S.-N.; Huang, L.-Y.; Yu, H.-L.; Qiao, K.; Wang, K.-S. Friction Stir Processing of Magnesium Alloys: A Review. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 43–57. [Google Scholar] [CrossRef]

- Bitzek, E.; Koskinen, P.; Gähler, F.; Moseler, M.; Gumbsch, P. Structural Relaxation Made Simple. Phys. Rev. Lett. 2006, 97, 170201. [Google Scholar] [CrossRef]

- Garg, P.; Rupert, T.J. Local Structural Ordering Determines the Mechanical Damage Tolerance of Amorphous Grain Boundary Complexions. Scr. Mater. 2023, 237, 115712. [Google Scholar] [CrossRef]

- Pan, Z.; Rupert, T.J. Damage Nucleation from Repeated Dislocation Absorption at a Grain Boundary. Comput. Mater. Sci. 2014, 93, 206–209. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short- Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Baskes, M.I.; Nelson, J.S.; Wright, A.F. Semiempirical Modified Embedded-Atom Potentials for Silicon and Germanium. Phys. Rev. B Condens. Matter 1989, 40, 6085–6100. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.Y.; Adams, J.B.; Ercolessi, F.; Moriarty, J.A. EAM Potential for Magnesium from Quantum Mechanical Forces. Model. Simul. Mater. Sci. Eng. 1996, 4, 293–303. [Google Scholar] [CrossRef]

- Wang, F.X.; Li, B. Origin of Deflection of Precipitates during Interaction with a Migrating Twin Boundary in Magnesium Alloys. Comput. Mater. Sci. 2018, 154, 472–480. [Google Scholar] [CrossRef]

- Li, B.; En, M. Zonal Dislocations Mediating {} <> Twinning in Magnesium. Acta Mater. 2009, 57, 1734–1743. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and Analysis of Atomistic Simulation Data with OVITO-the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Honeycutt, J.D.; Andersen, H.C. Molecular Dynamics Study of Melting and Freezing of Small Lennard-Jones Clusters. J. Phys. Chem. 1987, 91, 4950–4963. [Google Scholar] [CrossRef]

- Stukowski, A. Dislocation Analysis Tool for Atomistic Simulations. In Handbook of Materials Modeling: Methods: Theory and Modeling; Springer: Cham, Switzerland, 2020; pp. 1545–1558. [Google Scholar]

- Khater, H.A.; Serra, A.; Pond, R.C.; Hirth, J.P. The Disconnection Mechanism of Coupled Migration and Shear at Grain Boundaries. Acta Mater. 2012, 60, 2007–2020. [Google Scholar] [CrossRef]

- Sato, Y.; Roh, J.-Y.; Ikuhara, Y. Grain-Boundary Structural Transformation Induced by Geometry and Chemistry. Phys. Rev. B 2013, 87, 140101. [Google Scholar] [CrossRef]

- Chen, P.; Wang, F.; Li, B. Dislocation Absorption and Transmutation at {} Twin Boundaries in Deformation of Magnesium. Acta Mater. 2019, 164, 440–453. [Google Scholar] [CrossRef]

- Chen, P.; Ombogo, J.; Li, B. Dislocation ↔ Twin Transmutations during Interaction between Prismatic Slip and {} Twin in Magnesium. Acta Mater. 2020, 186, 291–307. [Google Scholar] [CrossRef]

- Ma, A.; Roters, F.; Raabe, D. Studying the Effect of Grain Boundaries in Dislocation Density Based Crystal-Plasticity Finite Element Simulations. Int. J. Solids Struct. 2006, 43, 7287–7303. [Google Scholar] [CrossRef]

- Li, Z.; Hou, C.; Huang, M.; Ouyang, C. Strengthening Mechanism in Micro-Polycrystals with Penetrable Grain Boundaries by Discrete Dislocation Dynamics Simulation and Hall–Petch Effect. Comput. Mater. Sci. 2009, 46, 1124–1134. [Google Scholar] [CrossRef]

- Han, J.; Thomas, S.L.; Srolovitz, D.J. Grain-Boundary Kinetics: A Unified Approach. Prog. Mater. Sci. 2018, 98, 386–476. [Google Scholar] [CrossRef]

- Bieler, T.R.; Eisenlohr, P.; Zhang, C.; Phukan, H.J.; Crimp, M.A. Grain Boundaries and Interfaces in Slip Transfer. Curr. Opin. Solid. State Mater. Sci. 2014, 18, 212–226. [Google Scholar] [CrossRef]

- Clark, W.A.T.; Wagoner, R.H.; Shen, Z.Y.; Lee, T.C.; Robertson, I.M.; Birnbaum, H.K. On the Criteria for Slip Transmission across Interfaces in Polycrystals. Scr. Metall. Mater. 1992, 26, 203–206. [Google Scholar] [CrossRef]

- Thomas, T.Y. Combined Elastic and von Mises Stress-Strain Relations. Proc. Natl. Acad. Sci. USA 1955, 41, 908–910. [Google Scholar] [CrossRef]

- McCabe, R.J.; Kumar, M.A.; Liu, W.; Tomé, C.N.; Capolungo, L. Revealing the Effect of Local Stresses on Twin Growth Mechanisms in Titanium Using Synchrotron X-Ray Diffraction. Acta Mater. 2021, 221, 117359. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Capolungo, L.; Marshall, P.E.; McCabe, R.J.; Tomé, C.N. Statistical Analyses of Deformation Twinning in Magnesium. Philos. Mag. 2010, 90, 2161–2190. [Google Scholar] [CrossRef]

- Wang, J.; Beyerlein, I.J.; Tomé, C.N. An Atomic and Probabilistic Perspective on Twin Nucleation in Mg. Scr. Mater. 2010, 63, 741–746. [Google Scholar] [CrossRef]

- Wu, Z.; Curtin, W.A. The Origins of High Hardening and Low Ductility in Magnesium. Nature 2015, 526, 62–67. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.-Y.; Liu, F.; Yang, N.; Zhai, X.-B.; Zhang, L.; Yang, Y.; Li, B.; Li, J.; Ma, E.; Nie, J.-F.; et al. Large Plasticity in Magnesium Mediated by Pyramidal Dislocations. Science 2019, 365, 73–75. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Gong, M.; Wang, J.; Pan, Z.; Wang, X.; Zhang, D.; Wang, Y.M.; Ciston, J.; Minor, A.M.; Xu, M.; et al. Visualization and Validation of Twin Nucleation and Early-Stage Growth in Magnesium. Nat. Commun. 2022, 13, 20. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; El-Awady, J.A. Formation and Slip of Pyramidal Dislocations in Hexagonal Close-Packed Magnesium Single Crystals. Acta Mater. 2014, 71, 319–332. [Google Scholar] [CrossRef]

- Wu, J.; Lu, S.; Tian, J.; Chiu, Y. In-Situ TEM Study of Dislocations in Mg–Y Alloys. Mater. Sci. Eng. A 2024, 897, 146320. [Google Scholar] [CrossRef]

- Gaillard, Y.; Tromas, C.; Woirgard, J. Quantitative Analysis of Dislocation Pile-Ups Nucleated during Nanoindentation in MgO. Acta Mater. 2006, 54, 1409–1417. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Sun, Y.; Huang, A.; Wang, F.; Chen, P. Dislocation Transformations at the Common 30°⟨0001⟩ Grain Boundaries During Plastic Deformation in Magnesium. Nanomaterials 2025, 15, 232. https://doi.org/10.3390/nano15030232

Zhu Y, Sun Y, Huang A, Wang F, Chen P. Dislocation Transformations at the Common 30°⟨0001⟩ Grain Boundaries During Plastic Deformation in Magnesium. Nanomaterials. 2025; 15(3):232. https://doi.org/10.3390/nano15030232

Chicago/Turabian StyleZhu, Yulong, Yaowu Sun, An Huang, Fangxi Wang, and Peng Chen. 2025. "Dislocation Transformations at the Common 30°⟨0001⟩ Grain Boundaries During Plastic Deformation in Magnesium" Nanomaterials 15, no. 3: 232. https://doi.org/10.3390/nano15030232

APA StyleZhu, Y., Sun, Y., Huang, A., Wang, F., & Chen, P. (2025). Dislocation Transformations at the Common 30°⟨0001⟩ Grain Boundaries During Plastic Deformation in Magnesium. Nanomaterials, 15(3), 232. https://doi.org/10.3390/nano15030232