Glass-Based 4-in-1 High-Voltage Micro-LED Package for High-Brightness Mini-LED Backlight Applications

Abstract

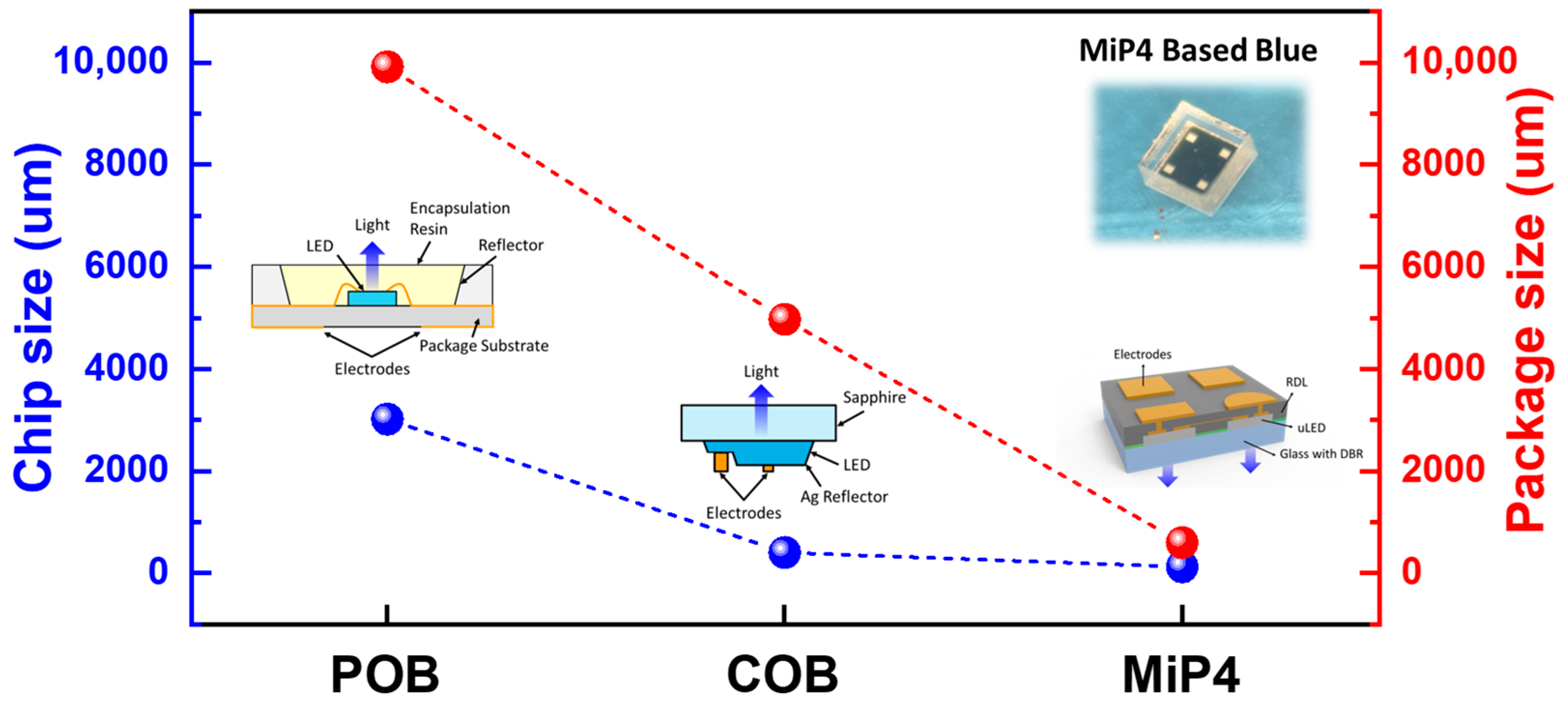

1. Introduction

2. Experiment and Fabrication Process

2.1. µ-LED Chip Transfer via Chemical Lift-Off Process

2.2. RDL Routing for MiP4 Structure

2.3. MiP4 Electrical Characterization

3. Results and Discussion

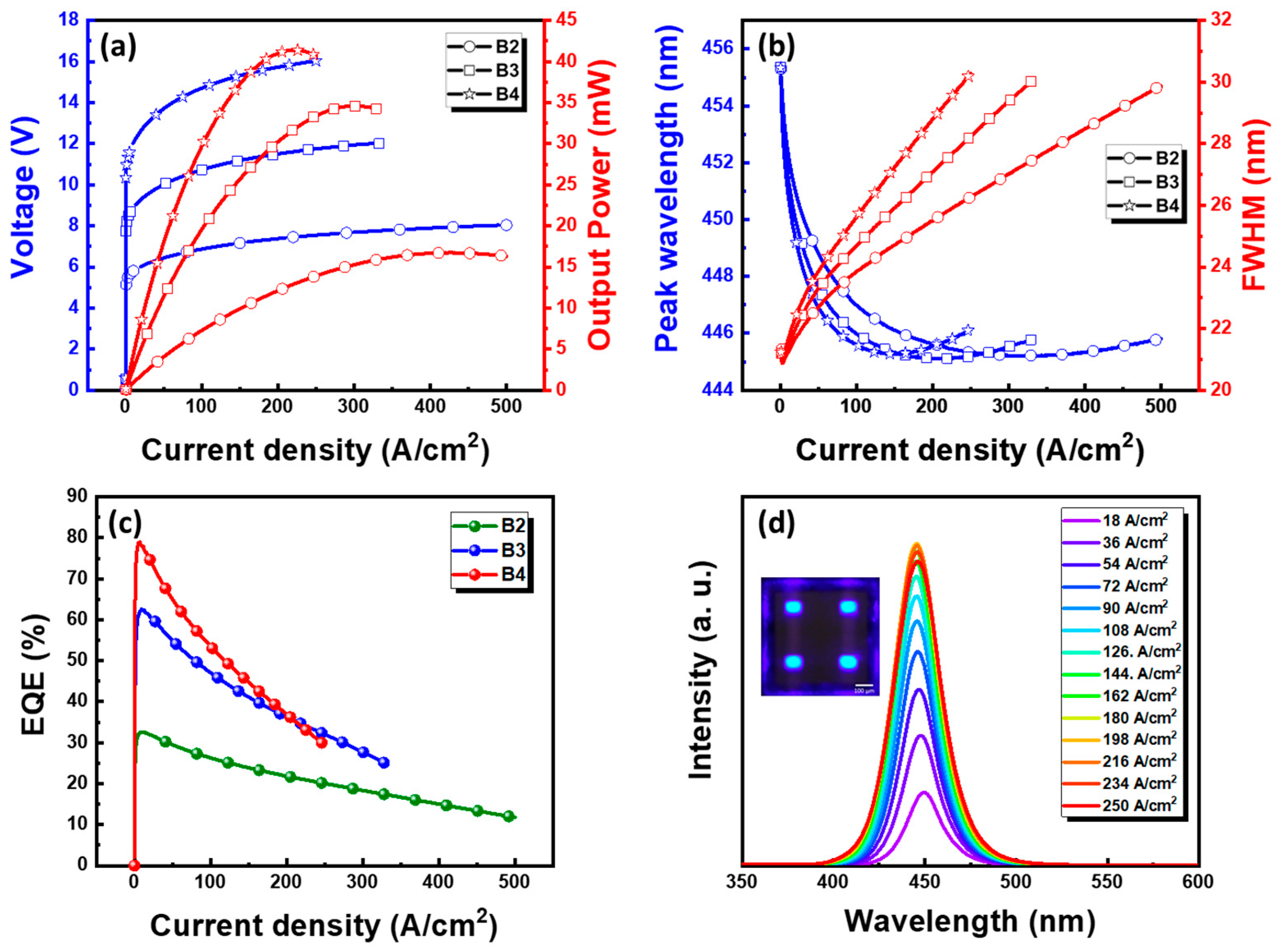

3.1. Electrical and Optical Performance of Blue MiP4 Devices

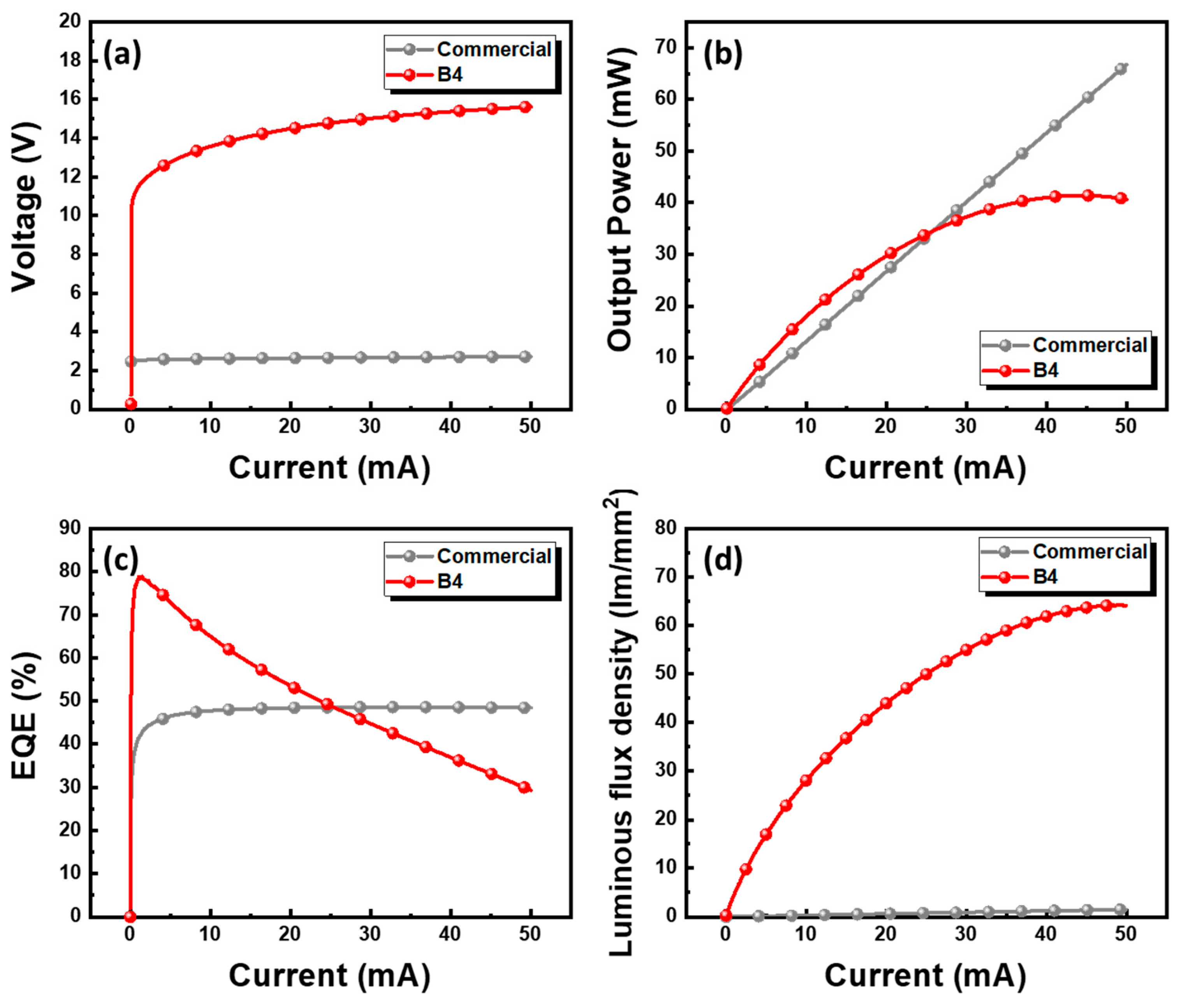

3.2. Comparison Between the Proposed MiP4 (B4) and a Commercial Blue LED

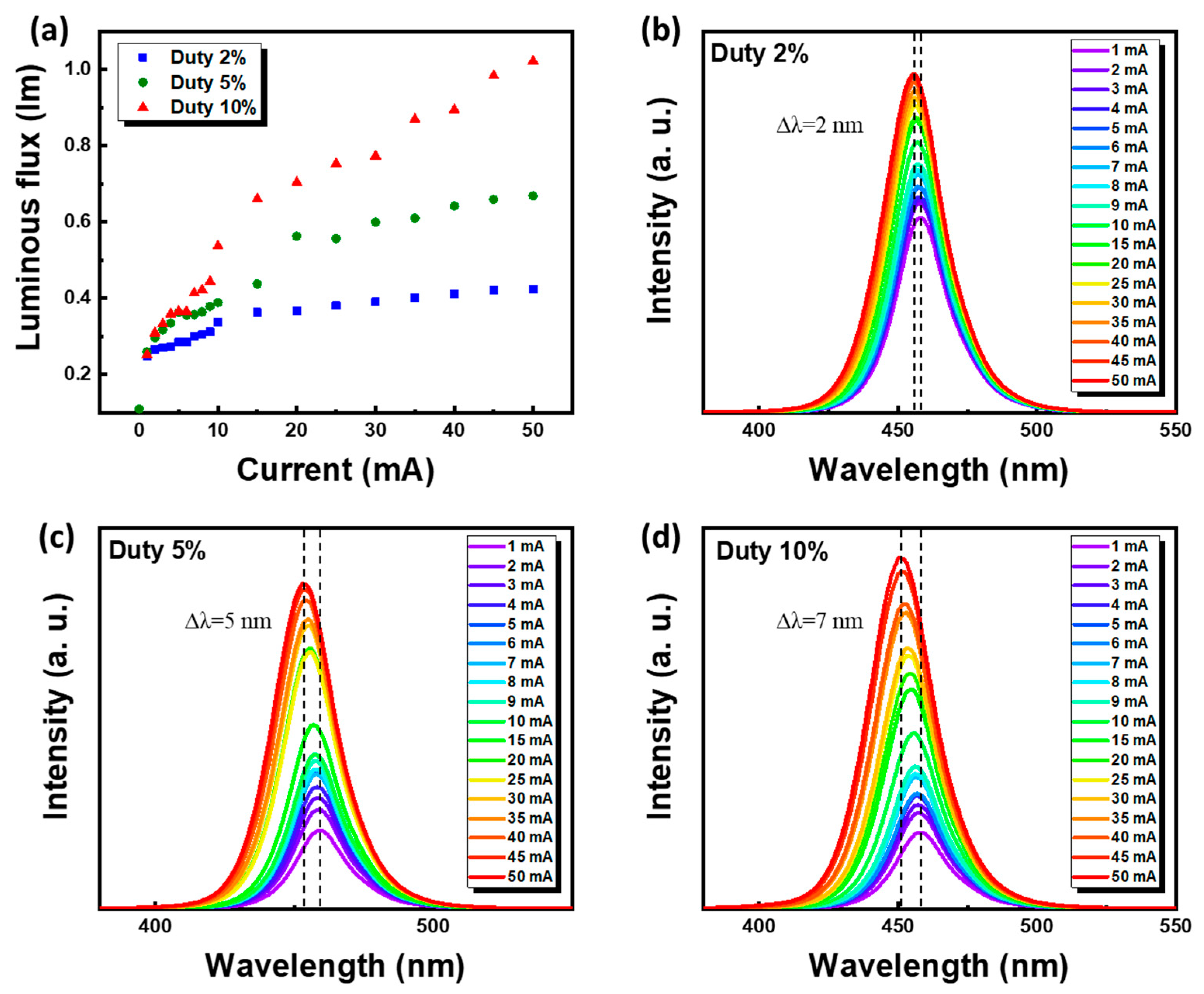

3.3. Pulse-Driven Performance Under Different Duty Cycles

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miao, W.C.; Hsiao, F.H.; Sheng, Y.; Lee, T.Y.; Hong, Y.H.; Tsai, C.W.; Chen, H.L.; Liu, Z.; Lin, C.L.; Chung, R.J. Microdisplays: Mini-LED, micro-OLED, and micro-LED. Adv. Opt. Mater. 2024, 12, 2300112. [Google Scholar] [CrossRef]

- Wu, T.; Sher, C.-W.; Lin, Y.; Lee, C.-F.; Liang, S.; Lu, Y.; Huang Chen, S.-W.; Guo, W.; Kuo, H.-C.; Chen, Z. Mini-LED and micro-LED: Promising candidates for the next generation display technology. Appl. Sci. 2018, 8, 1557. [Google Scholar] [CrossRef]

- Tsai, C.-H.; Wu, Y.-E.; Huang, C.-C.; Chen, L.-Y.; Chen, F.-C.; Kuo, H.-C. Digital Mini-LED Lighting Using Organic Thin-Film Transistors Reaching over 100,000 Nits of Luminance. Nanomaterials 2025, 15, 141. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.-Y.; Huang, C.-C.; Miao, W.-C.; Hsiao, F.-H.; Tsai, C.-H.; Hung, Y.-Y.; Chen, F.-C.; Lin, C.-L.; Ohkawa, K.; He, J.-H. Innovative Stacked Yellow and Blue Mini-LED Chip for White Lamp Applications. Micromachines 2024, 15, 796. [Google Scholar] [CrossRef]

- Huang, Y.; Tan, G.; Gou, F.; Li, M.C.; Lee, S.L.; Wu, S.T. Prospects and challenges of mini-LED and micro-LED displays. J. Soc. Inf. Disp. 2019, 27, 387–401. [Google Scholar] [CrossRef]

- Bandari, V.K.; Schmidt, O.G. A bright future for micro-LED displays. Light Sci. Appl. 2024, 13, 317. [Google Scholar] [CrossRef]

- Gao, Z.; Ning, H.; Yao, R.; Xu, W.; Zou, W.; Guo, C.; Luo, D.; Xu, H.; Xiao, J. Mini-LED backlight technology progress for liquid crystal display. Crystals 2022, 12, 313. [Google Scholar] [CrossRef]

- Lei, J.; Zhu, H.; Huang, X.; Lin, J.; Zheng, Y.; Lu, Y.; Chen, Z.; Guo, W. Mini-LED Backlight: Advances and Future Perspectives. Crystals 2024, 14, 922. [Google Scholar] [CrossRef]

- Hsiang, E.L.; Yang, Z.; Yang, Q.; Lan, Y.F.; Wu, S.T. Prospects and challenges of mini-LED, OLED, and micro-LED displays. J. Soc. Inf. Disp. 2021, 29, 446–465. [Google Scholar] [CrossRef]

- Deng, M.-Y.; Hsiang, E.-L.; Yang, Q.; Tsai, C.-L.; Chen, B.-S.; Wu, C.-E.; Lee, M.-H.; Wu, S.-T.; Lin, C.-L. Reducing power consumption of active-matrix mini-LED backlit LCDs by driving circuit. IEEE Trans. Electron Devices 2021, 68, 2347–2354. [Google Scholar] [CrossRef]

- Chen, Y.L.; Ye, Z.T.; Lai, W.; Chiu, C.C.; Lin, K.W.; Han, P. Application of mini-LEDs with microlens arrays and quantum dot film as extra-thin, large-area, and high-luminance backlight. Nanomaterials 2022, 12, 1032. [Google Scholar] [CrossRef]

- Xiao, J.; Fei, J.; Zheng, F.; Liu, Q.; Huo, W.; Li, J.; Mei, W.; Xu, H.; Zhang, S. Mini-LED backlight units on glass for 75-inch 8K resolution liquid crystal display. J. Soc. Inf. Disp. 2022, 30, 54–60. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y.; Cai, J.; Deng, L.; Xu, S.; Ye, Y.; Yan, Q.; Guo, T.; Chen, E. Uniformity improvement of a mini-LED backlight by a quantum-dot color conversion film with nonuniform thickness. Opt. Lett. 2023, 48, 5643–5646. [Google Scholar] [CrossRef]

- Feng, Q.; Xiao, H.; Yang, L.; Zhu, B.; Yuan, Y.; Wang, Z.; Lv, G. Ultrathin miniLED backlight system using optical film with microstructures. Appl. Opt. 2021, 60, 9497–9503. [Google Scholar] [CrossRef]

- Zou, J.; Zhan, T.; Hsiang, E.-L.; Du, X.; Yu, X.; Li, K.; Wu, S.-T. Doubling the optical efficiency of VR systems with a directional backlight and a diffractive deflection film. Opt. Express 2021, 29, 20673–20686. [Google Scholar] [CrossRef] [PubMed]

- Tan, G.; Huang, Y.; Li, M.-C.; Lee, S.-L.; Wu, S.-T. High dynamic range liquid crystal displays with a mini-LED backlight. Opt. Express 2018, 26, 16572–16584. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Hsiang, E.-L.; Deng, M.-Y.; Wu, S.-T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef]

- Chang, S.-H.; Huang, C.-H.; Langpoklakpam, C.; James Singh, K.; Lin, C.-C.; Kuo, H.-C. Improving Mini-LED Pattern Quality by Using Distributed Bragg Reflector and Digital Twin Technology. Crystals 2022, 12, 529. [Google Scholar] [CrossRef]

- Esteki, M.; Khajehoddin, S.A.; Safaee, A.; Li, Y. LED systems applications and LED driver topologies: A review. IEEE Access 2023, 11, 38324–38358. [Google Scholar] [CrossRef]

- Lin, C.-C.; Wu, Y.-R.; Kuo, H.-C.; Wong, M.S.; DenBaars, S.P.; Nakamura, S.; Pandey, A.; Mi, Z.; Tian, P.; Ohkawa, K. The micro-LED roadmap: Status quo and prospects. J. Phys. Photonics 2023, 5, 042502. [Google Scholar] [CrossRef]

- Parbrook, P.J.; Corbett, B.; Han, J.; Seong, T.Y.; Amano, H. Micro-light emitting diode: From chips to applications. Laser Photonics Rev. 2021, 15, 2000133. [Google Scholar] [CrossRef]

- Xu, X.; Zhuo, Q.; Jiang, C.; Zhou, Z.; Tang, J.; Zou, W. An Adaptive High-Efficiency LED Backlight Driver. Electronics 2024, 13, 3057. [Google Scholar] [CrossRef]

- Wang, Y.; Alonso, J.M.; Ruan, X. A review of LED drivers and related technologies. IEEE Trans. Ind. Electron. 2017, 64, 5754–5765. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-C.; Lee, T.-Y.; Tsai, C.-H.; Chen, F.-C.; Chen, L.-Y.; Kuo, H.-C. Glass-Based 4-in-1 High-Voltage Micro-LED Package for High-Brightness Mini-LED Backlight Applications. Nanomaterials 2025, 15, 1818. https://doi.org/10.3390/nano15231818

Huang C-C, Lee T-Y, Tsai C-H, Chen F-C, Chen L-Y, Kuo H-C. Glass-Based 4-in-1 High-Voltage Micro-LED Package for High-Brightness Mini-LED Backlight Applications. Nanomaterials. 2025; 15(23):1818. https://doi.org/10.3390/nano15231818

Chicago/Turabian StyleHuang, Chien-Chi, Tzu-Yi Lee, Chia-Hung Tsai, Fang-Chung Chen, Li-Yin Chen, and Hao-Chung Kuo. 2025. "Glass-Based 4-in-1 High-Voltage Micro-LED Package for High-Brightness Mini-LED Backlight Applications" Nanomaterials 15, no. 23: 1818. https://doi.org/10.3390/nano15231818

APA StyleHuang, C.-C., Lee, T.-Y., Tsai, C.-H., Chen, F.-C., Chen, L.-Y., & Kuo, H.-C. (2025). Glass-Based 4-in-1 High-Voltage Micro-LED Package for High-Brightness Mini-LED Backlight Applications. Nanomaterials, 15(23), 1818. https://doi.org/10.3390/nano15231818