Effects of the Combined Incorporation of ZnO and TiO2 Nanoparticles on the Mechanical, Rheological, Thermal, and Healing Properties of a Dense Polymeric Asphalt Mixture

Abstract

1. Introduction

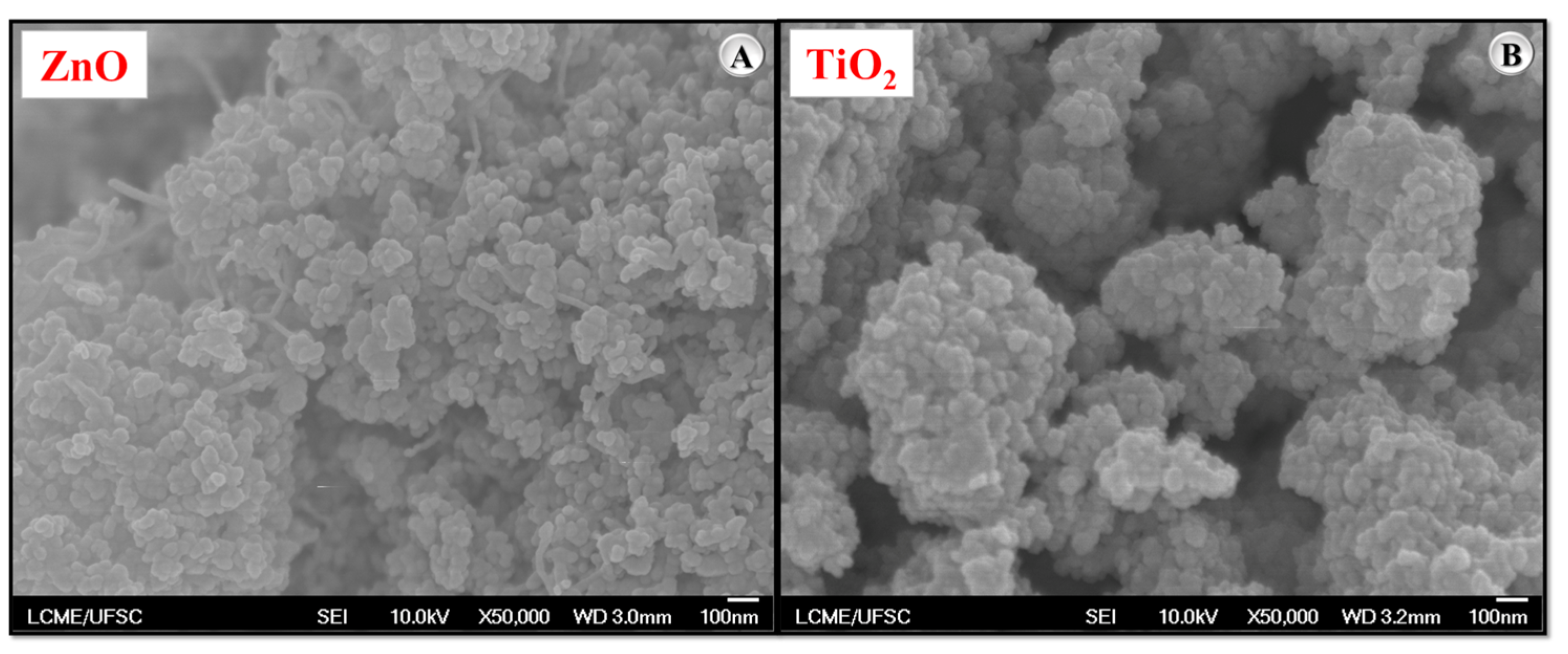

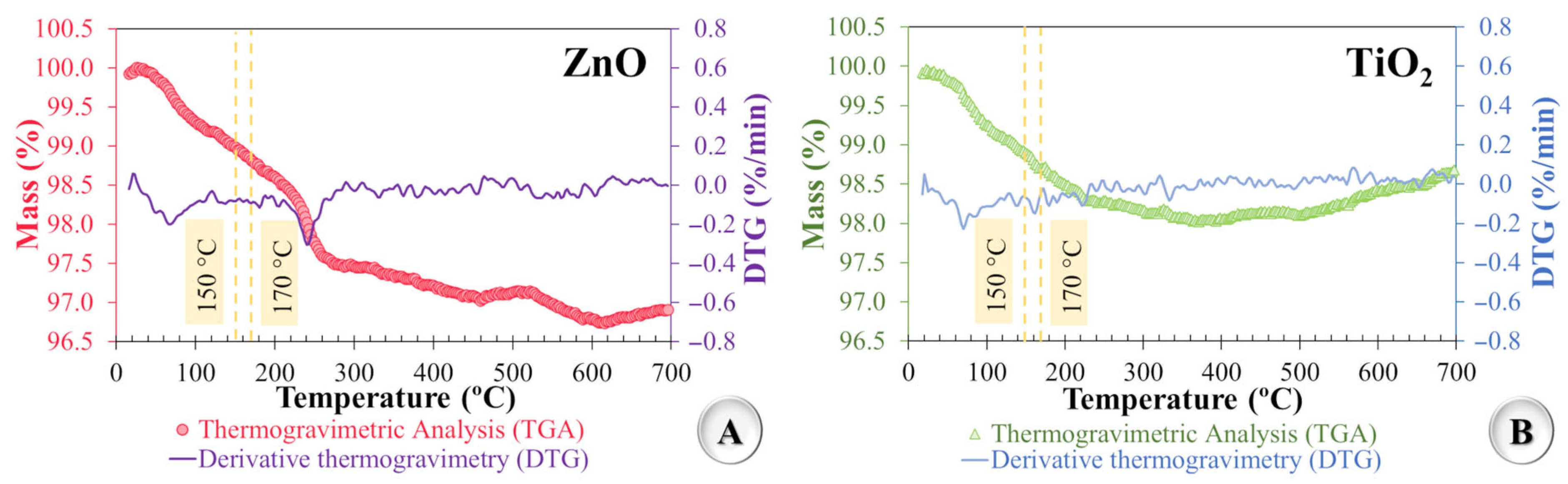

2. Materials

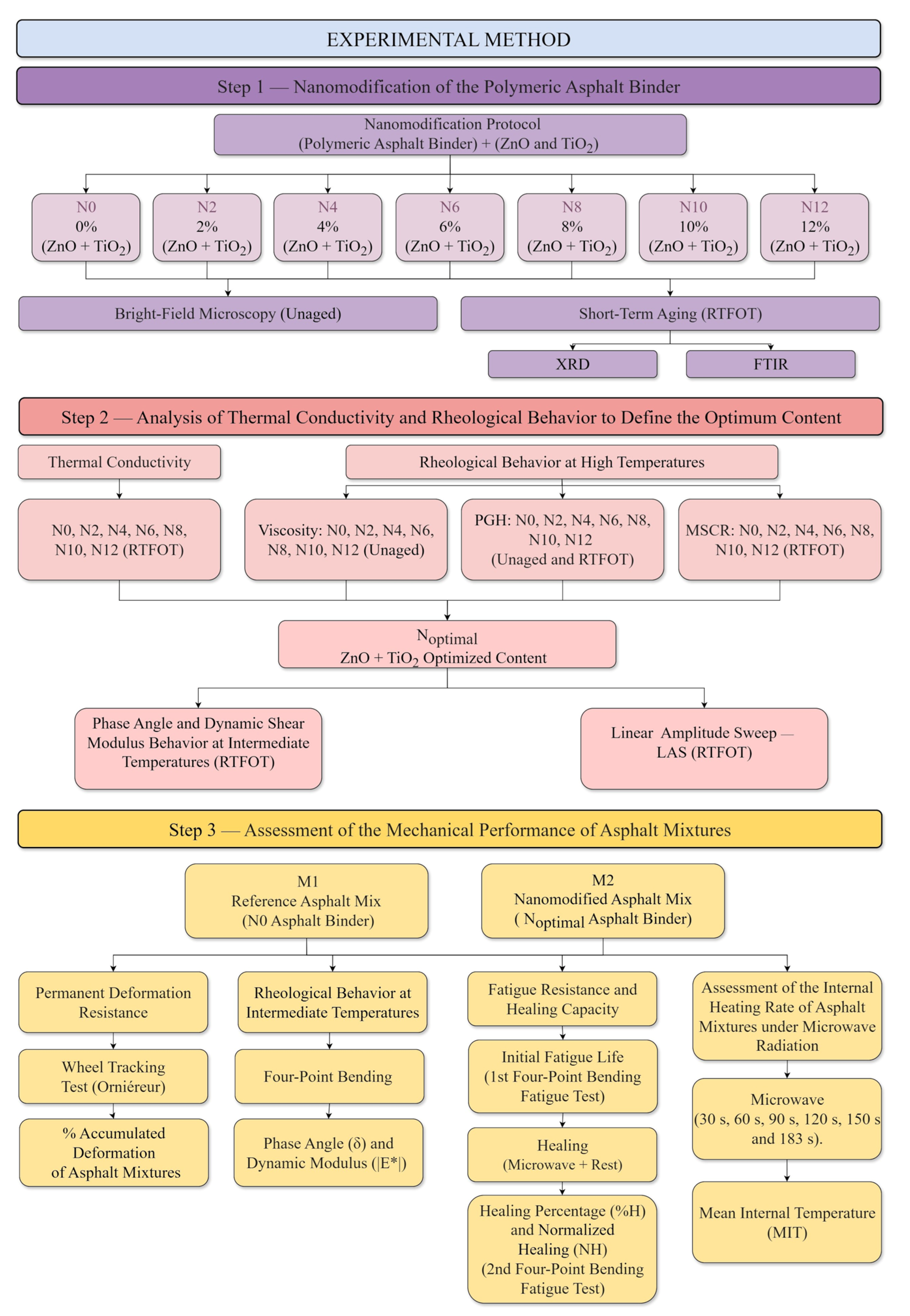

3. Methods

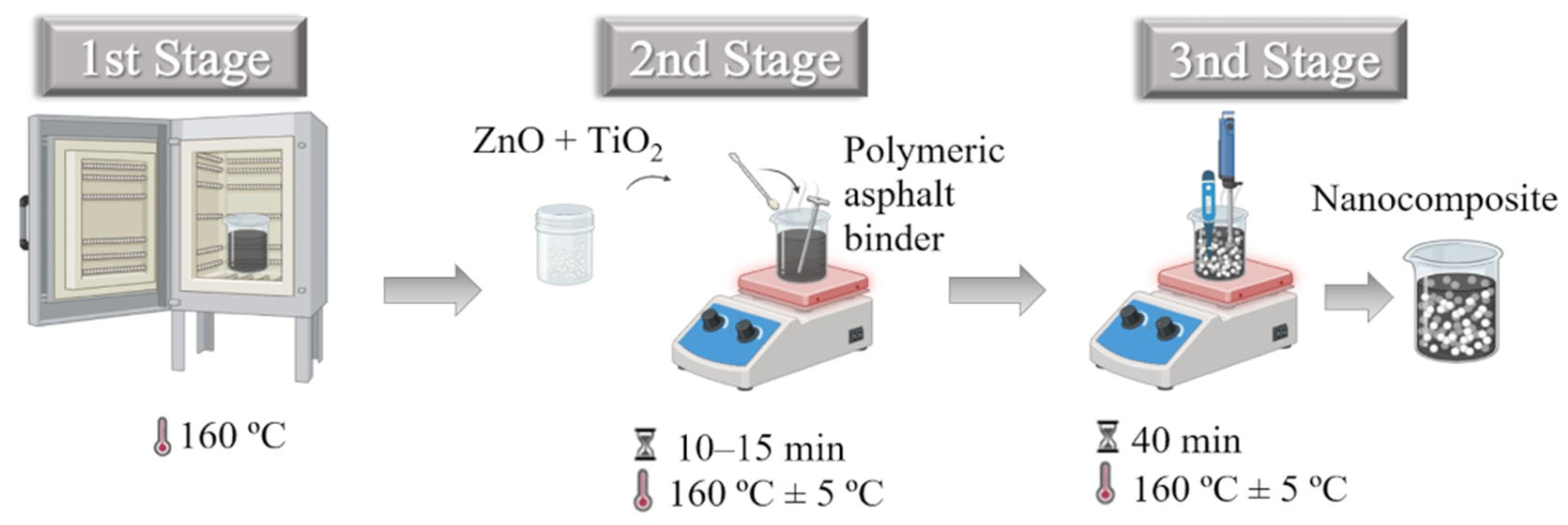

3.1. Nanomodification of the Polymeric Asphalt Binder

3.1.1. Bright-Field Microscopy

3.1.2. Short-Term Aging

3.1.3. X-Ray Diffraction

3.1.4. Fourier-Transform Infrared Spectroscopy

3.2. Analysis of Thermal Conductivity and Rheological Behavior to Define the Optimum Content

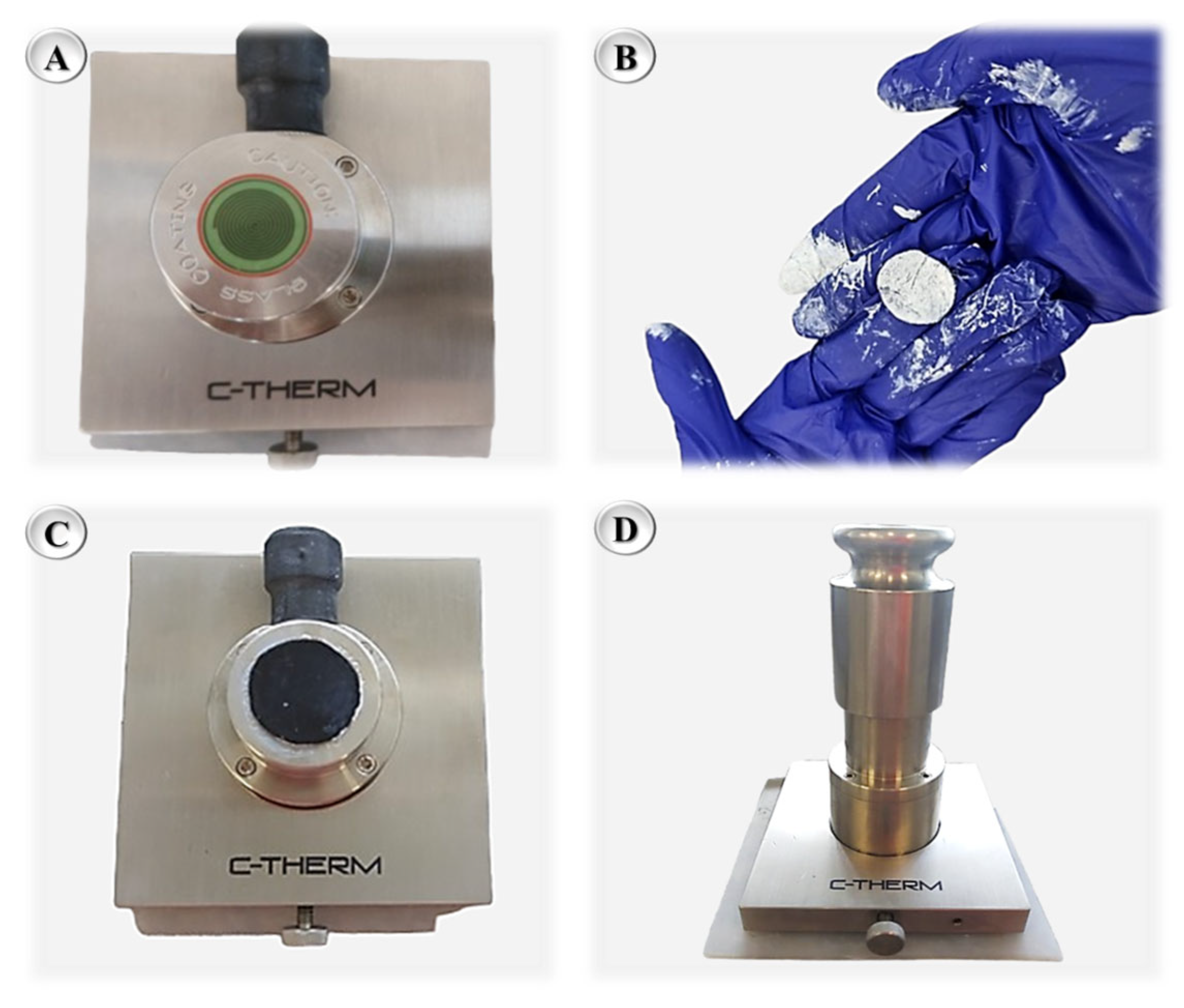

3.2.1. Thermal Conductivity

3.2.2. Rheological Behavior at High Temperatures

Apparent Viscosity

High-Temperature Performance Grade

Multiple Stress Creep and Recovery

3.2.3. Definition of the Optimized Content of ZnO + TiO2

Phase Angle and Dynamic Shear Modulus Behavior at Intermediate Temperatures

Linear Amplitude Sweep

3.3. Assessment of the Mechanical Performance of Asphalt Mixtures

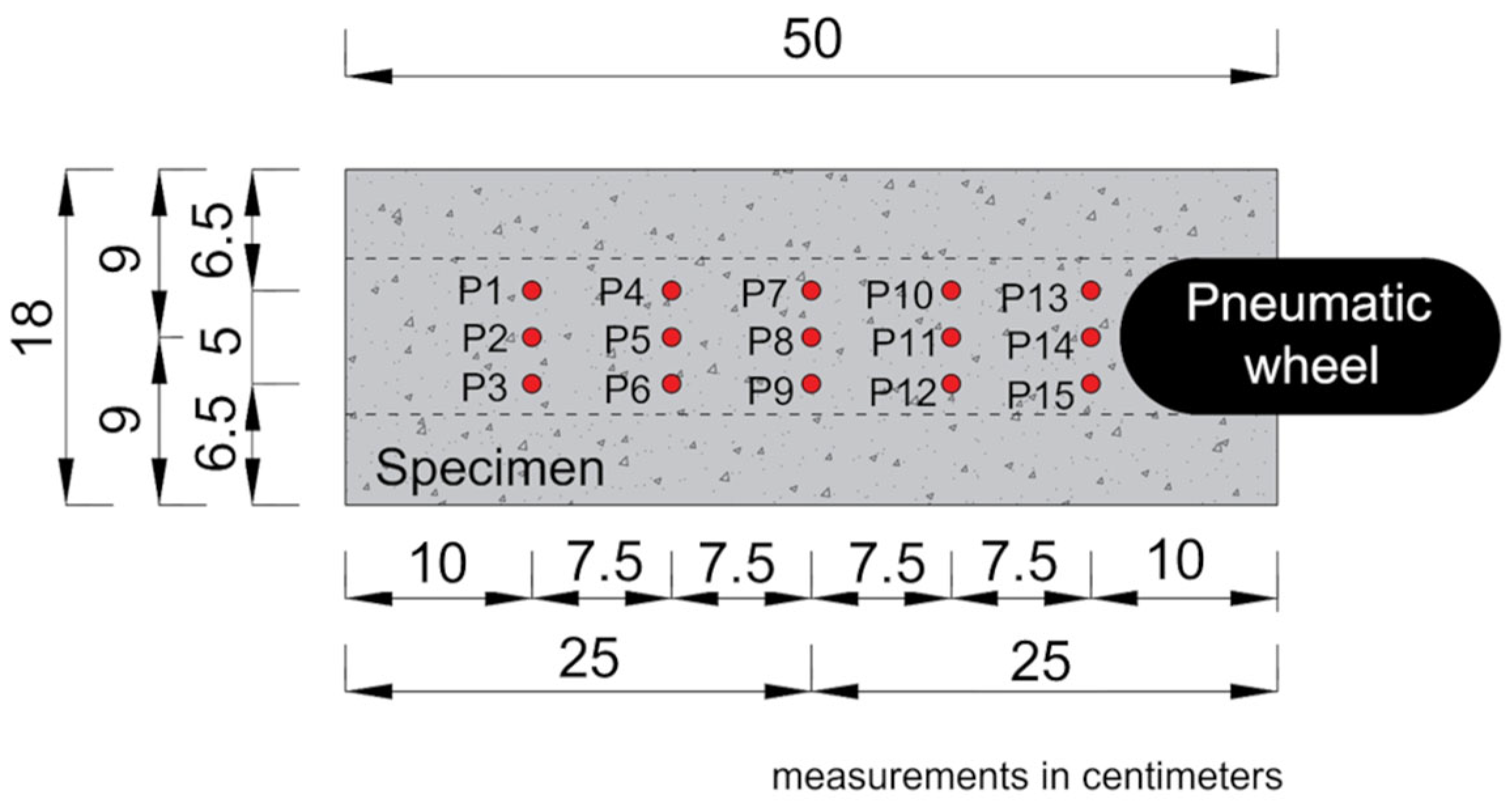

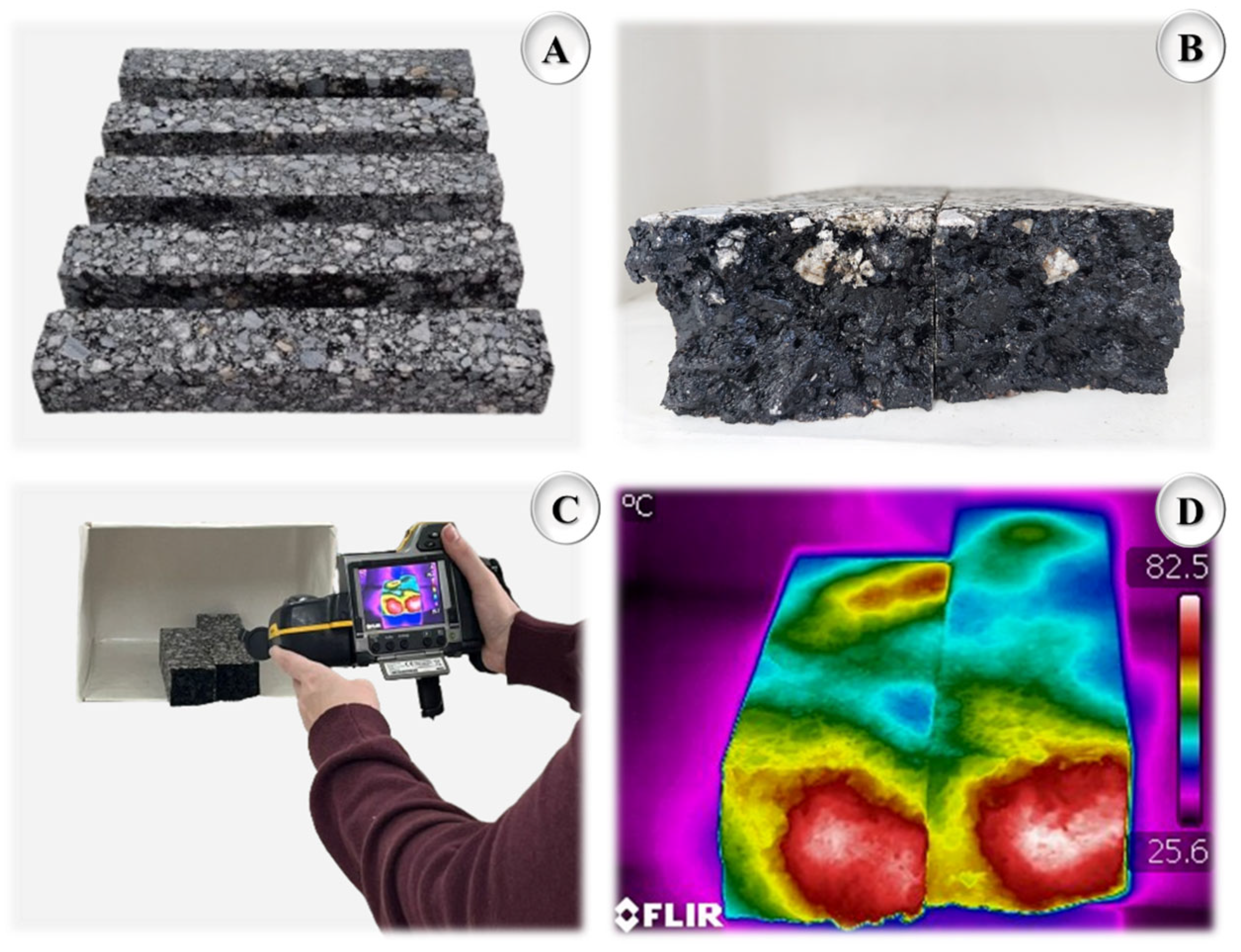

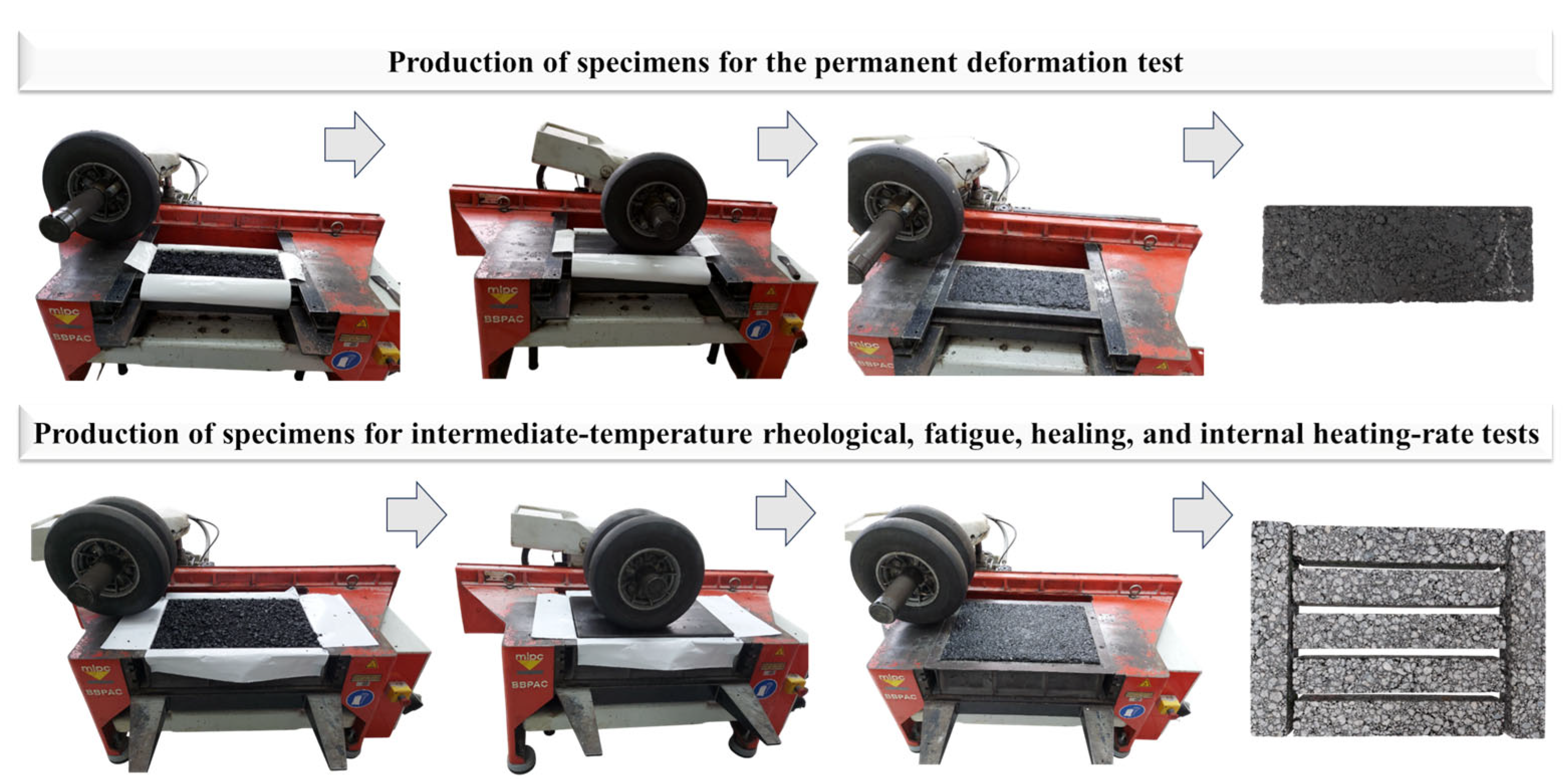

3.3.1. Permanent Deformation Resistance

3.3.2. Rheological Behavior at Intermediate Temperatures

3.3.3. Fatigue Resistance and Healing Capacity

3.3.4. Assessment of the Internal Heating Rate of Asphalt Mixtures Under Microwave Radiation

4. Results and Discussion

4.1. Nanomodification of the Polymeric Asphalt Binder

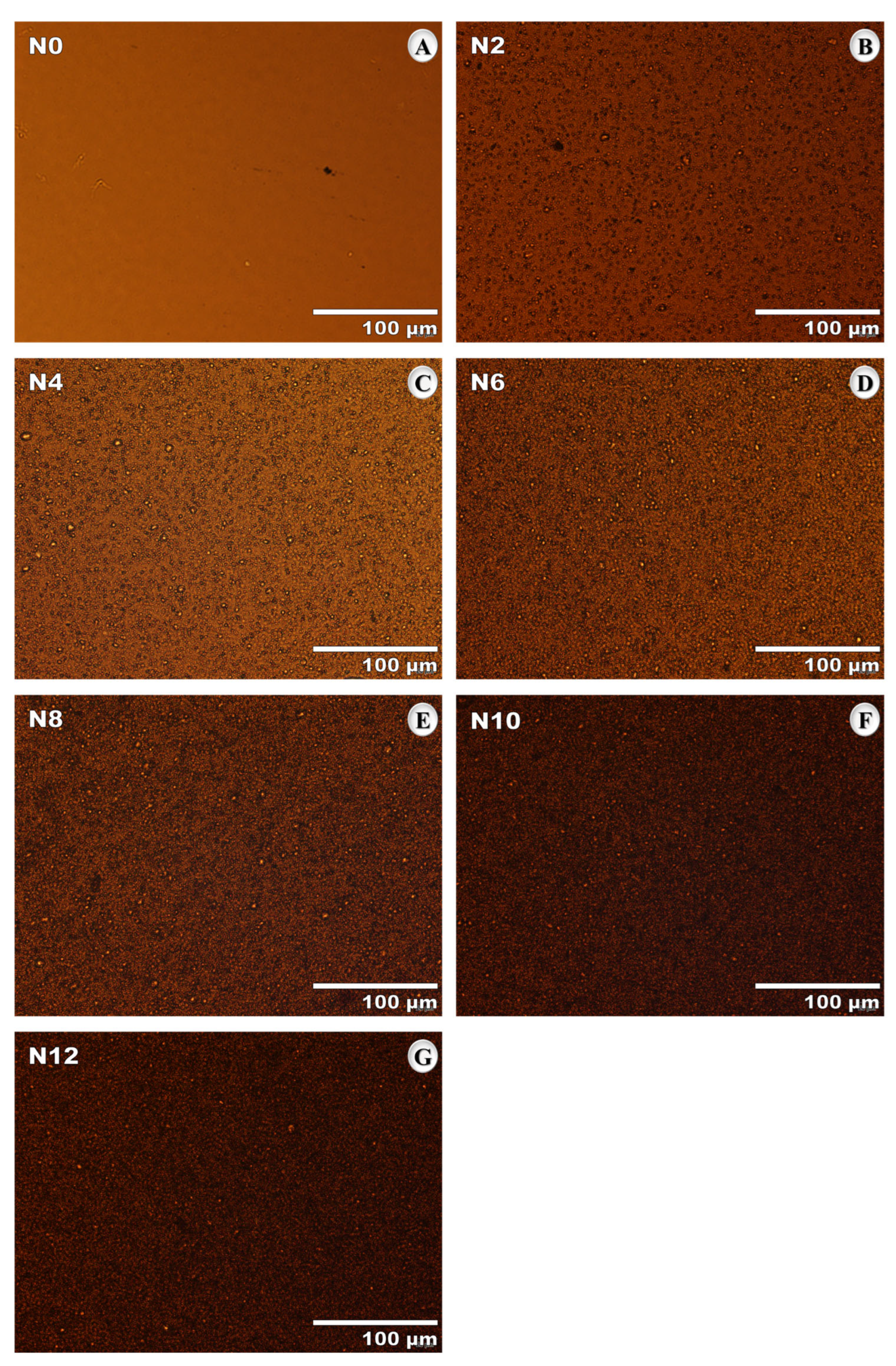

4.1.1. Bright-Field Microscopy

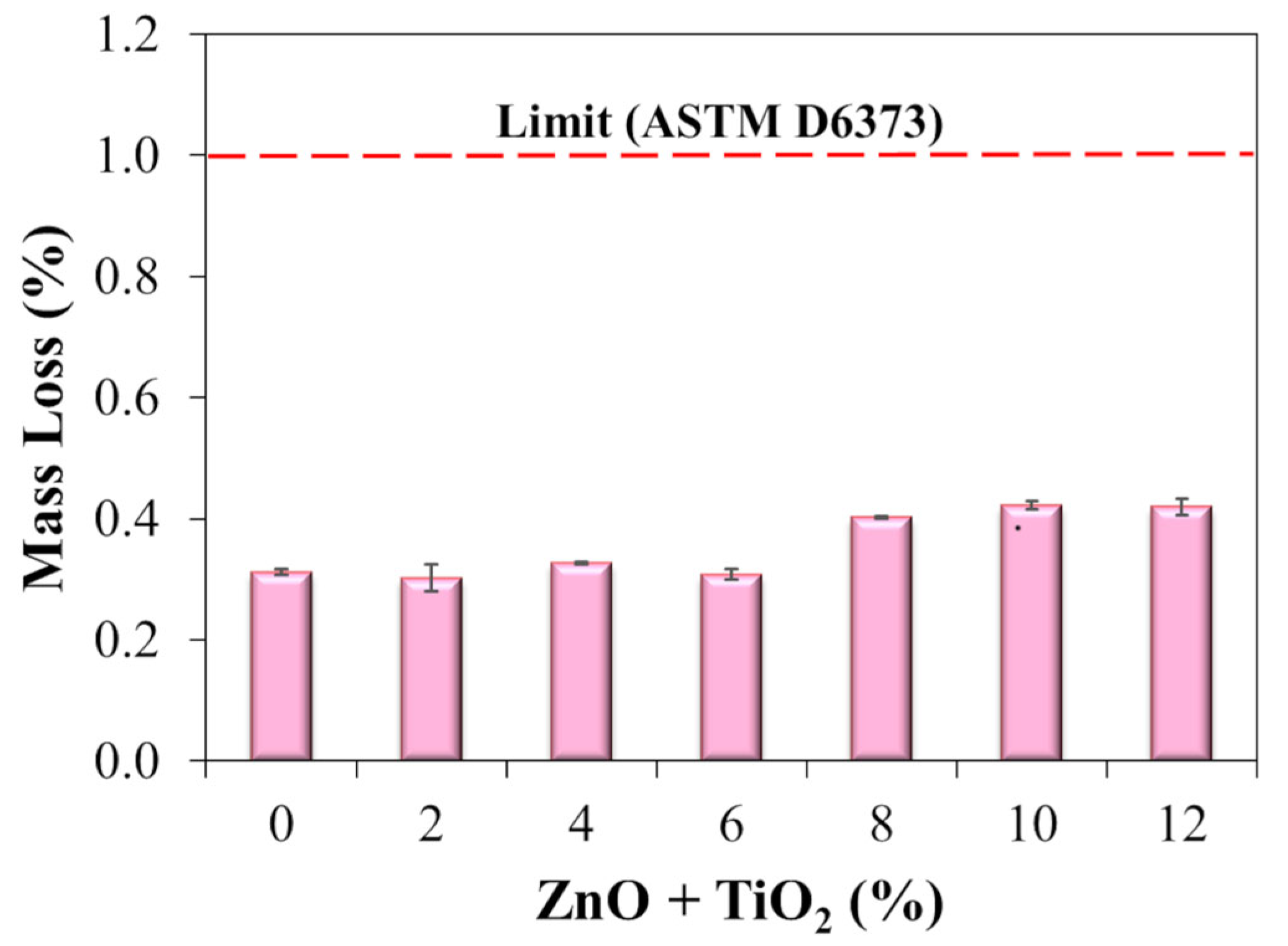

4.1.2. Short-Term Aging

4.1.3. X-Ray Diffraction

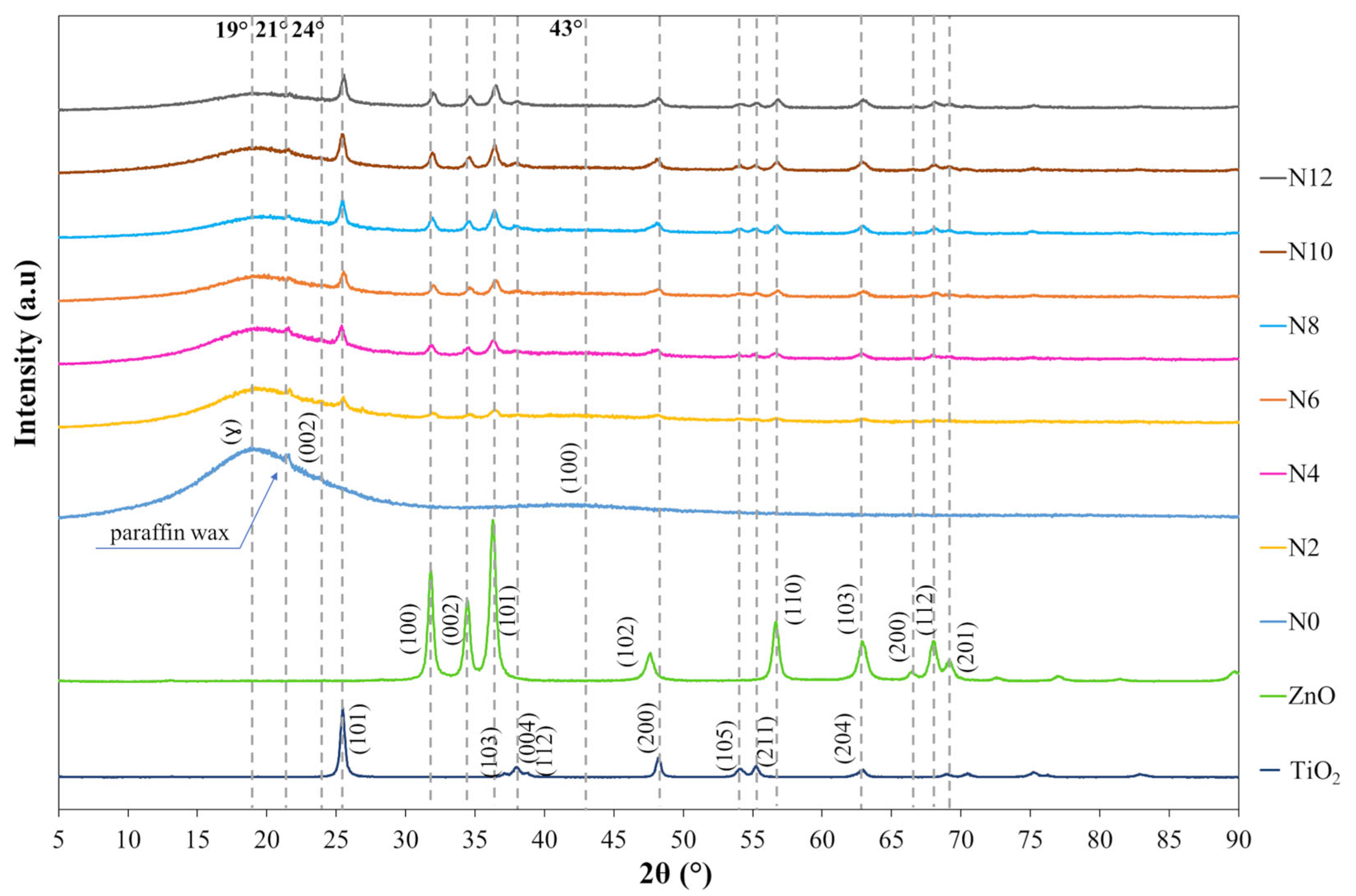

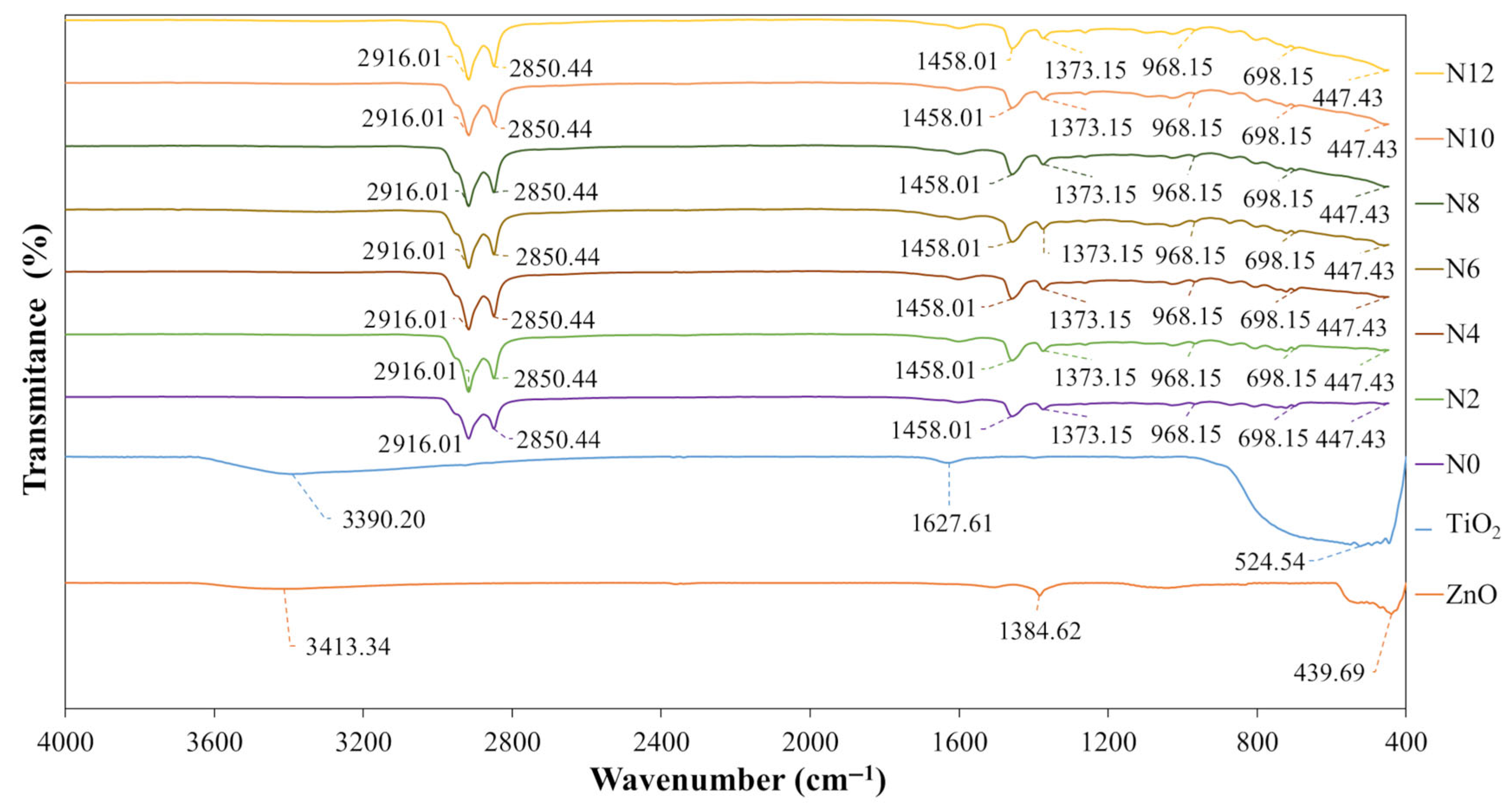

4.1.4. Fourier-Transform Infrared Spectroscopy

4.2. Analysis of Thermal Conductivity and Rheological Behavior to Define the Optimum Content

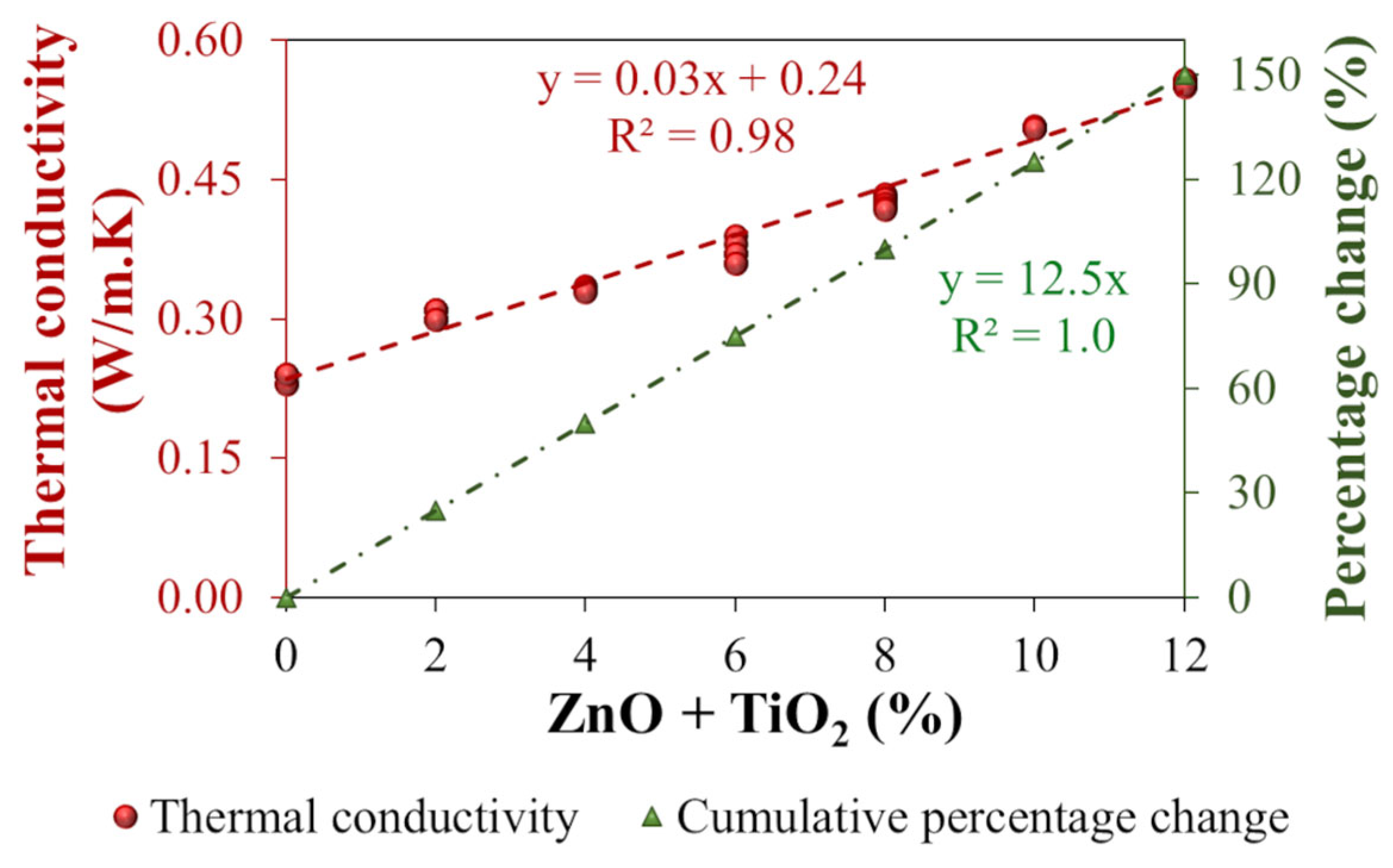

4.2.1. Thermal Conductivity

4.2.2. Rheological Behavior at High Temperatures

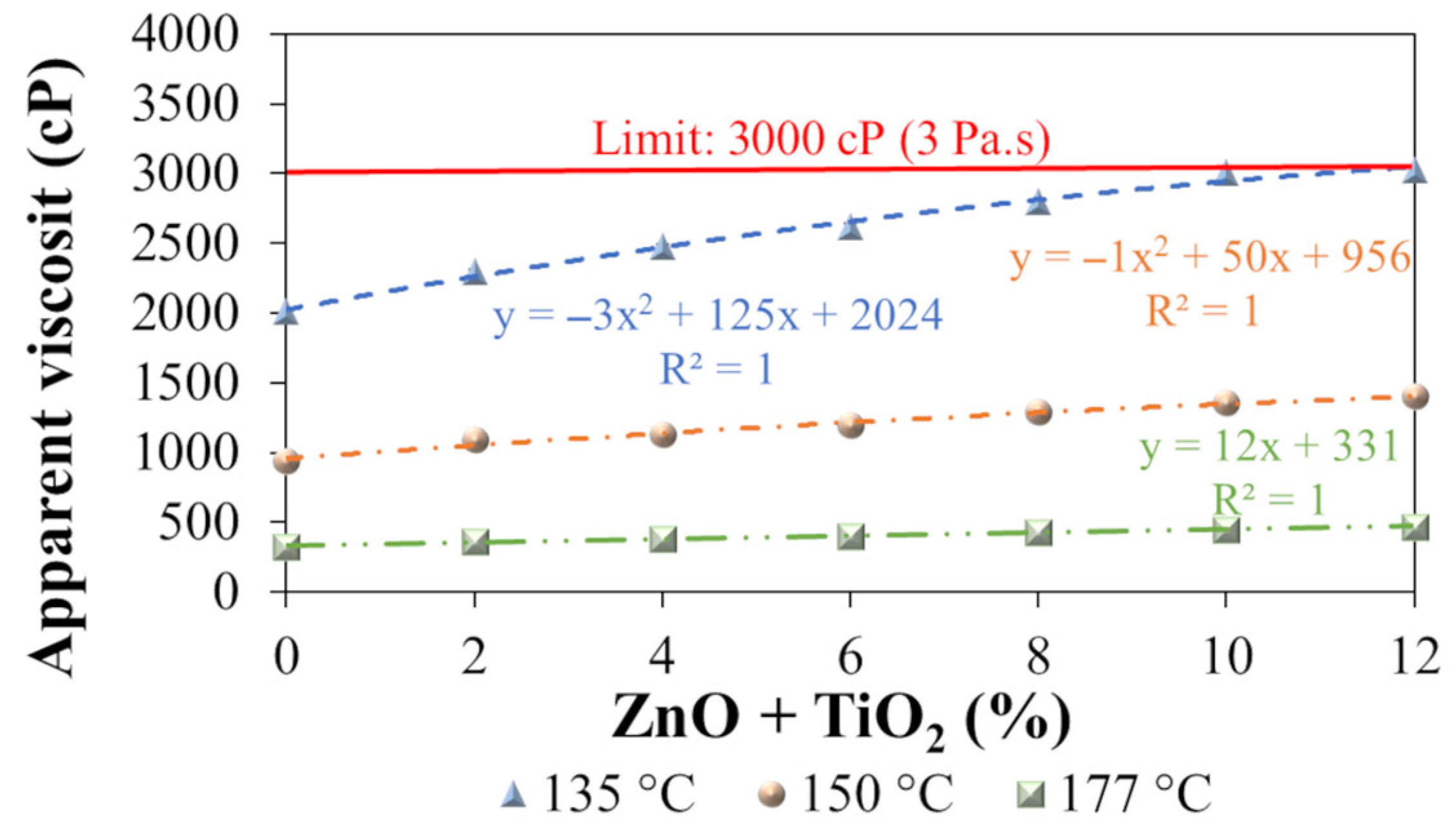

Apparent Viscosity

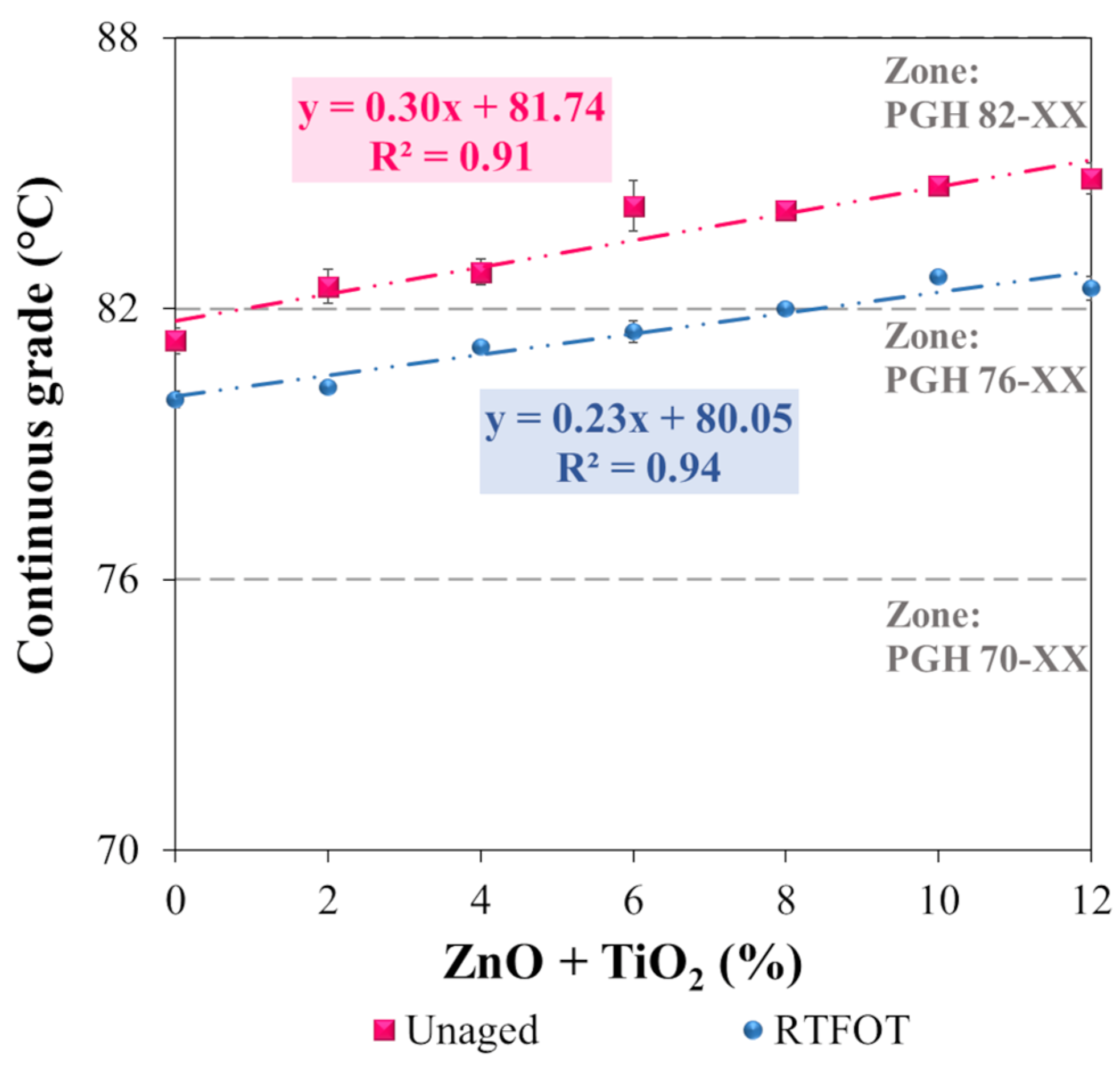

High-Temperature Performance Grade

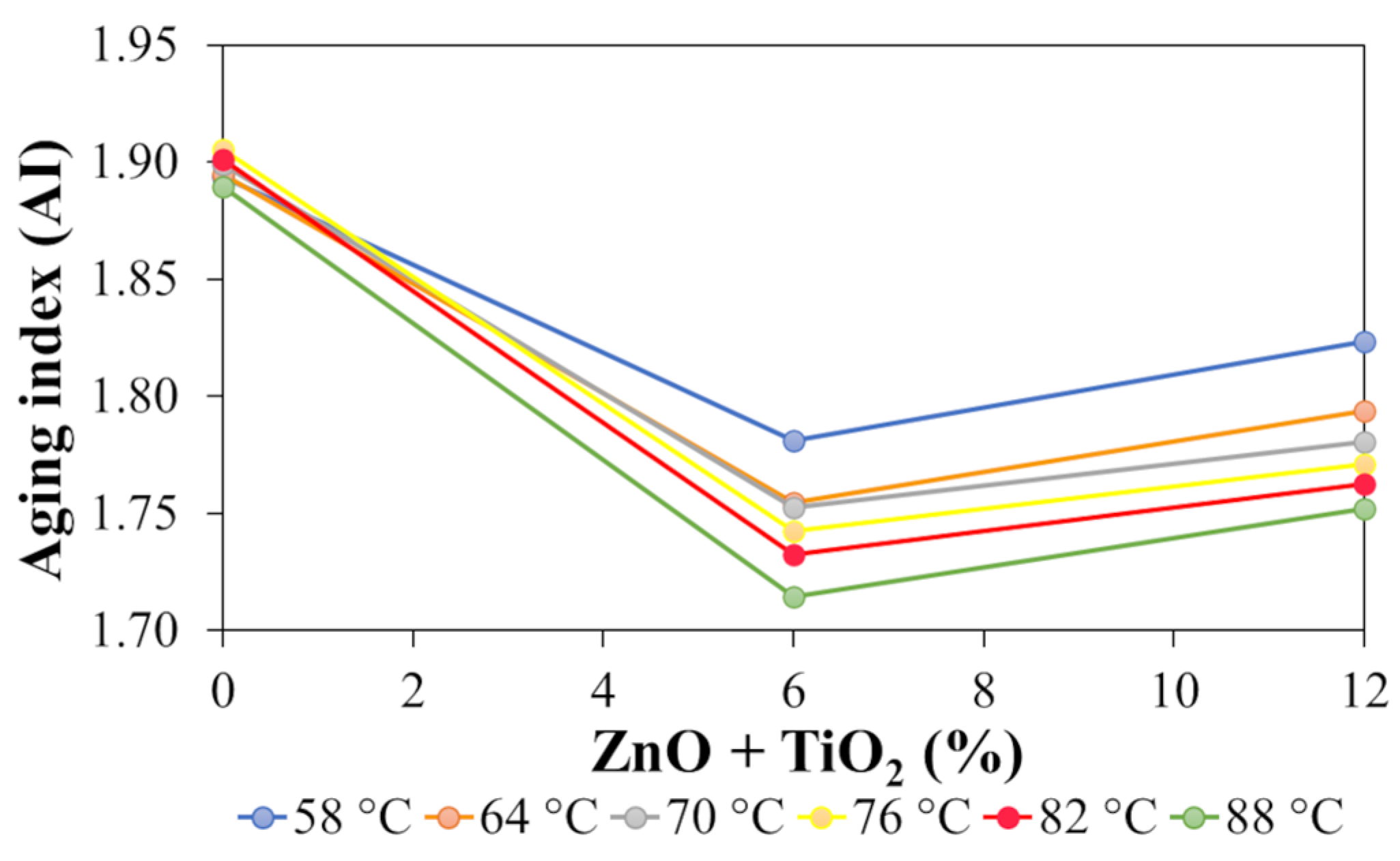

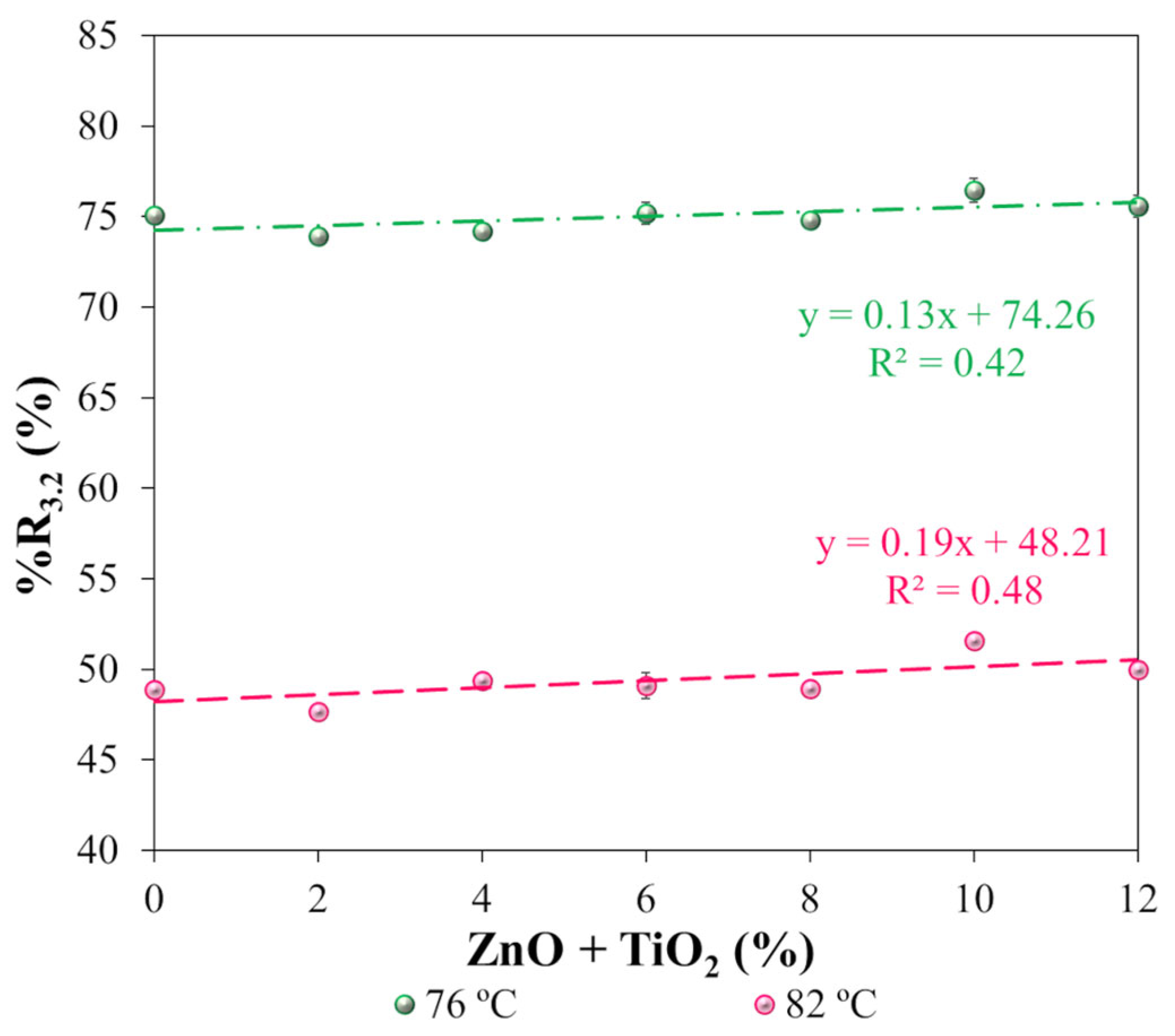

Multiple Stress Creep and Recovery

4.2.3. Definition of the Optimized Content of ZnO + TiO2

- Thermal conductivity of 0.5 W/m·K, representing a 106.3% increase compared with the reference polymeric asphalt binder;

- Increase in PGH from 76-XX to 82-XX for both unaged and short-term aged (RTFOT) conditions;

- Mean reduction of 7.2% in the aging index (AI), indicating higher resistance to oxidation;

- Reduction in non-recoverable creep compliance (Jnr3.2): at 82 °C, the value decreased to 1.29 kPa−1, corresponding to a 24.9% reduction; at 76 °C, the value was 0.41 kPa−1, reflecting a 17.3% reduction;

- Apparent viscosity of 2.870 Pa·s, which is 4.3% below the SUPERPAVE limit of 3.0 Pa·s (135 °C), ensuring that binder workability is maintained during mixing and application.

Phase Angle and Dynamic Shear Modulus Behavior at Intermediate Temperatures

Linear Amplitude Sweep

4.3. Assessment of the Mechanical Performance of Asphalt Mixtures

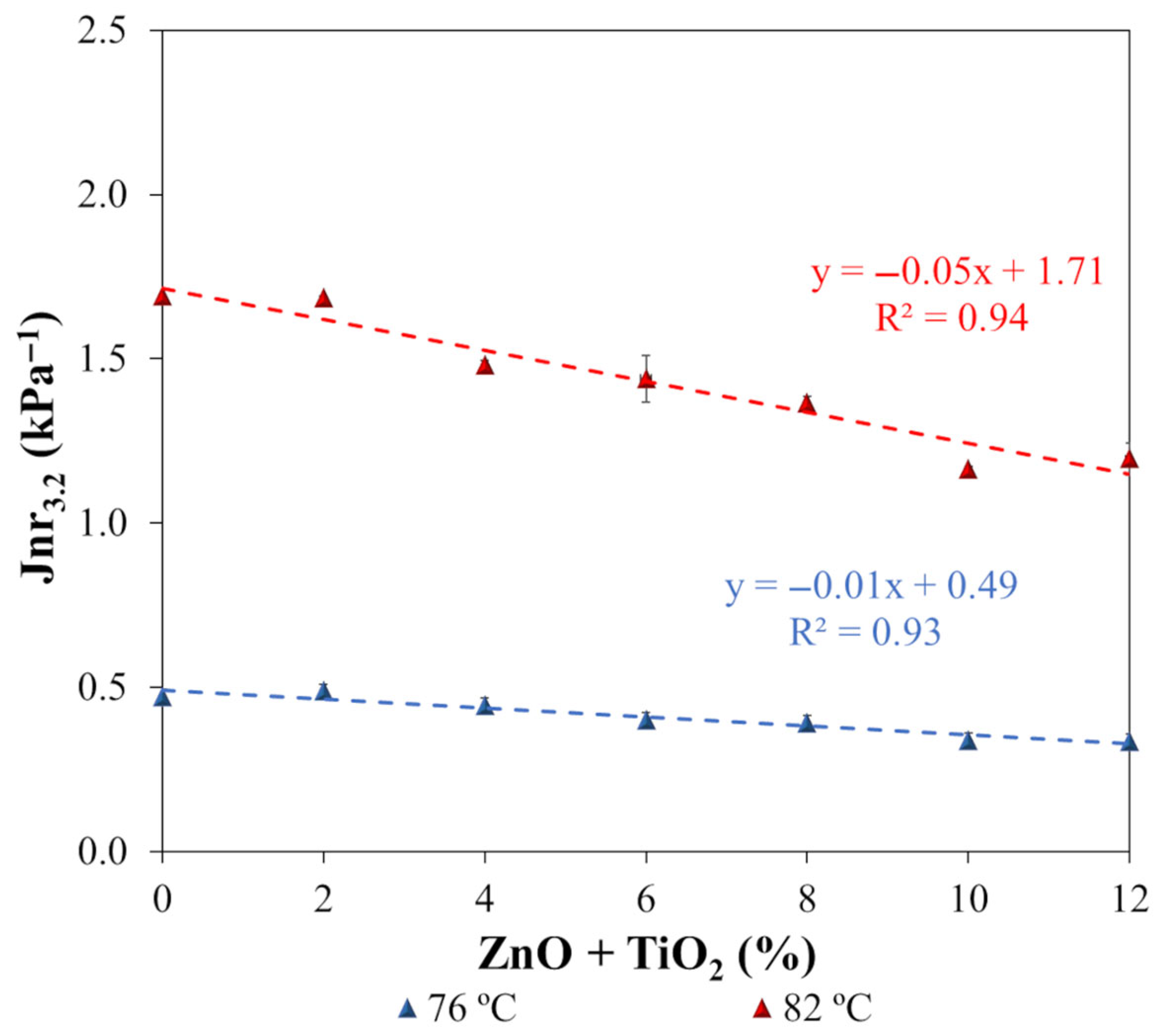

4.3.1. Permanent Deformation Resistance

4.3.2. Rheological Behavior at Intermediate Temperatures

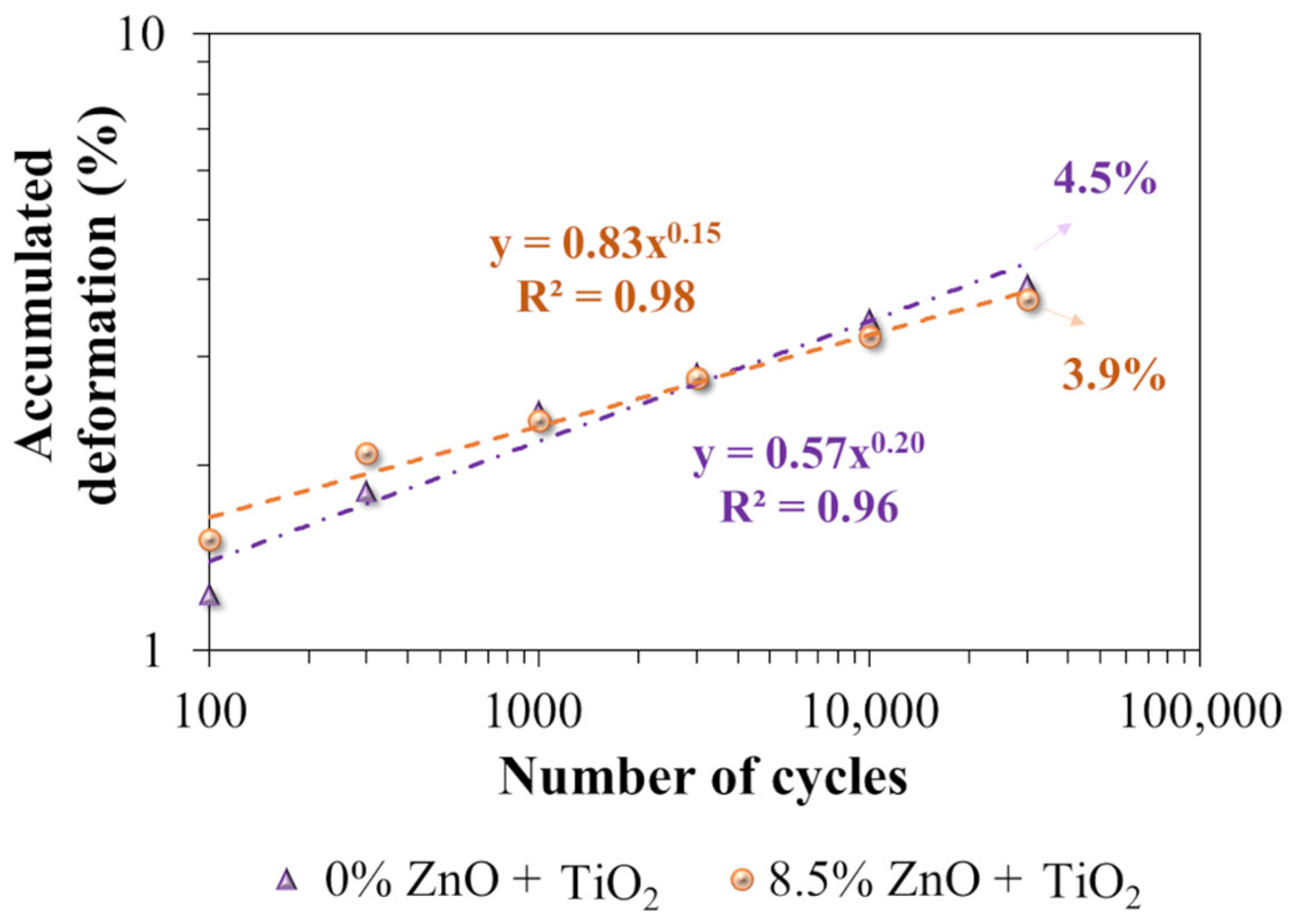

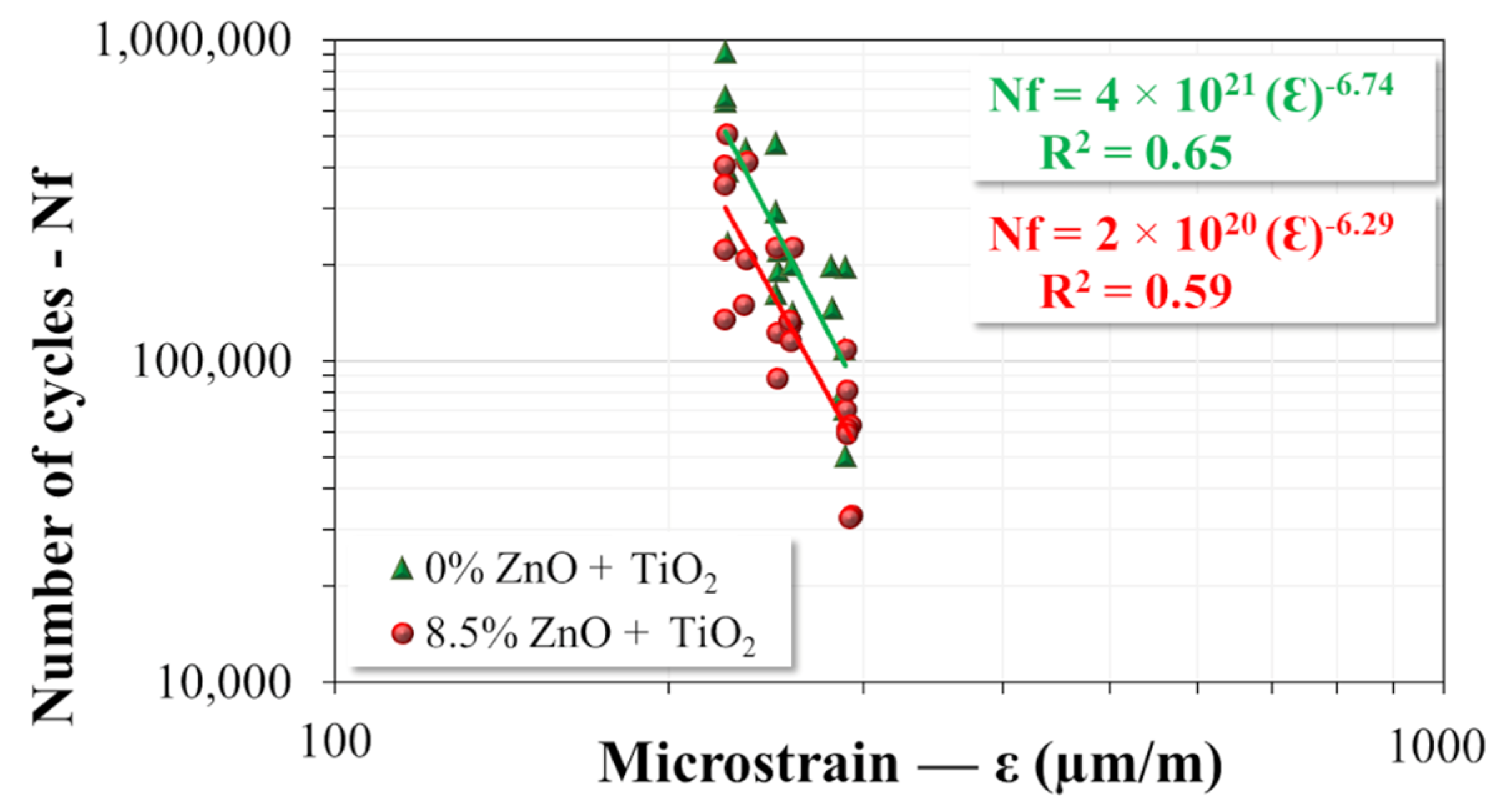

4.3.3. Fatigue Resistance and Healing Capacity

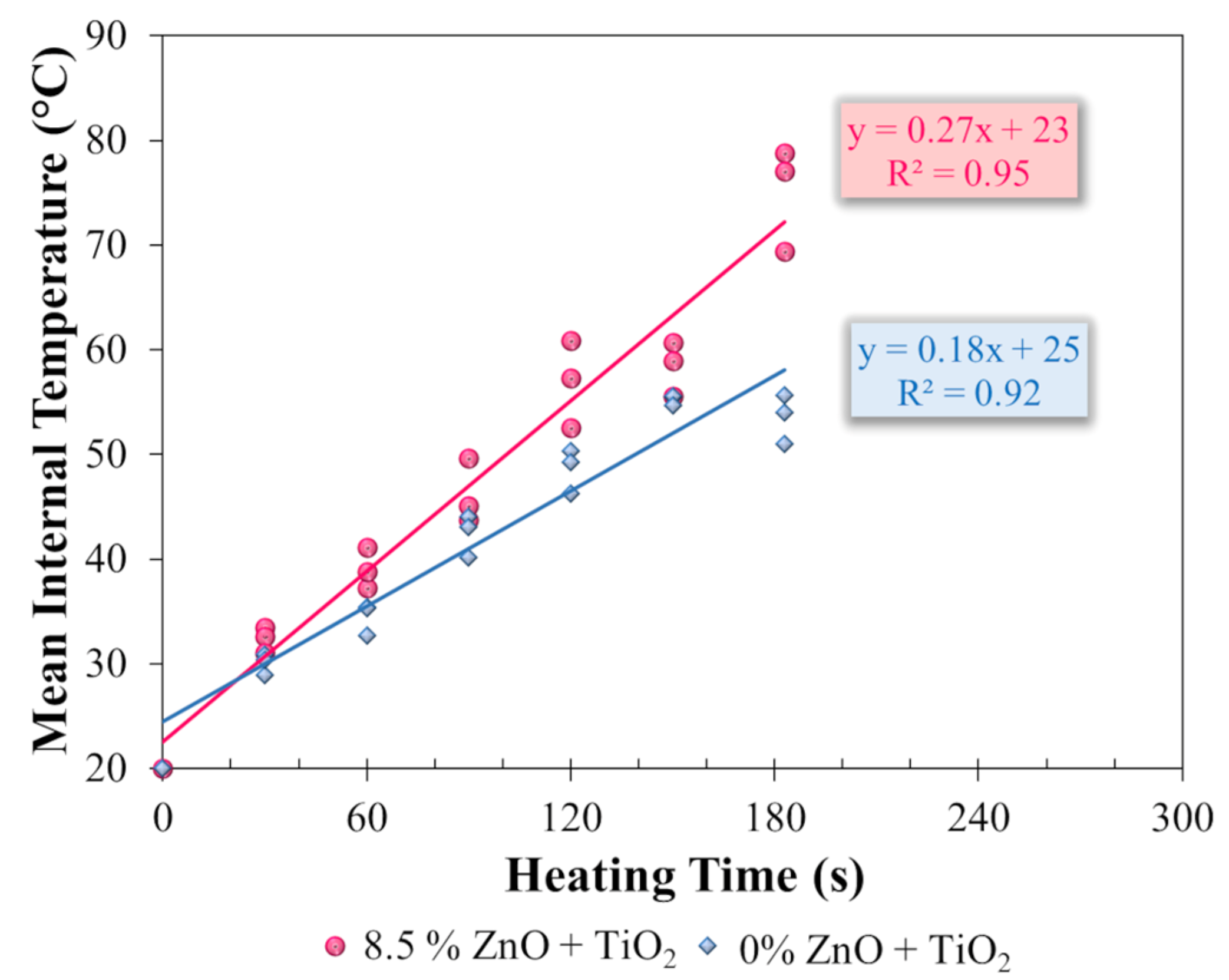

4.3.4. Assessment of the Internal Heating Rate of Asphalt Mixtures Under Microwave Radiation

5. Conclusions

- The combined addition of ZnO and TiO2 at contents ranging from 2 to 12 wt.% (in 2% increments) enhanced the high-temperature performance of the polymer-modified binder, increasing its thermal conductivity and resistance to permanent deformation.

- A dosage of 8.5 wt.% provided the most favorable combination of thermal and rheological properties, resulting in higher thermal conductivity, improved high-temperature stability, and reduced rutting susceptibility, while maintaining workability within the SUPERPAVE limit (≤3.0 Pa·s at 135 °C).

- The asphalt mixture produced with the binder modified with 8.5 wt.% ZnO + TiO2 exhibited higher stiffness at intermediate temperatures, a 50.7% increase in normalized healing efficiency, and 13.3% greater resistance to permanent deformation, demonstrating the contribution of the nanoparticles to mechanical reinforcement and structural recovery.

- The improvement in healing capacity was associated with a 50.0% increase in the internal heating rate, which accelerated binder mobilization, increased molecular mobility, and facilitated crack closure and the reconstruction of fatigue-damaged microstructures.

- Regarding fatigue performance under the same imposed microstrain levels, the incorporation of ZnO + TiO2 into the asphalt mixture resulted in a 4.4% reduction in the fatigue factor. This behavior is attributed to the increased stiffness provided by the nanomaterials, which reduces the ability of the mixture to deform under loading.

- Overall, the ZnO + TiO2 combination enhances the functional performance of asphalt materials, adding benefits in resistance to permanent deformation and healing capacity in addition to the well-known photocatalytic potential reported in the literature, making this nanocomposite a promising alternative for pavements subjected to high temperatures and heavy traffic.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lavudya, P.; Pant, H.; Srikanth, V.V.S.S.; Ammanabrolu, R. Mesoporous and Phase Pure Anatase TiO2 Nanospheres for Enhanced Photocatalysis. Inorg. Chem. Commun. 2023, 152, 110699. [Google Scholar] [CrossRef]

- Saini, R.; Kumar, P. Green Synthesis of TiO2 Nanoparticles Using Tinospora Cordifolia Plant Extract & Its Potential Application for Photocatalysis and Antibacterial Activity. Inorg. Chem. Commun. 2023, 156, 111221. [Google Scholar] [CrossRef]

- Chang, X.; Li, Z.; Zhai, X.; Sun, S.; Gu, D.; Dong, L.; Yin, Y.; Zhu, Y. Efficient Synthesis of Sunlight-Driven ZnO-Based Heterogeneous Photocatalysts. Mater. Des. 2016, 98, 324–332. [Google Scholar] [CrossRef]

- Ahmed, M.A.; Abou-Gamra, Z.M.; ALshakhanbeh, M.A.; Medien, H. Control Synthesis of Metallic Gold Nanoparticles Homogeneously Distributed on Hexagonal ZnO Nanoparticles for Photocatalytic Degradation of Methylene Blue Dye. Environ. Nanotechnol. Monit. Manag. 2019, 12, 100217. [Google Scholar] [CrossRef]

- De Melo, J.V.S.; Trichês, G.; Gleize, P.J.P.; Villena, J. Development and Evaluation of the Efficiency of Photocatalytic Pavement Blocks in the Laboratory and after One Year in the Field. Constr. Build. Mater. 2012, 37, 310–319. [Google Scholar] [CrossRef]

- Bica, B.O.; De Melo, J.V.S. Concrete Blocks Nano-Modified with Zinc Oxide (ZnO) for Photocatalytic Paving: Performance Comparison with Titanium Dioxide (TiO2). Constr. Build. Mater. 2020, 252, 119120. [Google Scholar] [CrossRef]

- Babagoli, R.; Nasr, D.; Ameli, A.; Moradi, M.R. Rutting and Fatigue Properties of Modified Binders with Polymer and Titanium Dioxide Nanoparticles. Constr. Build. Mater. 2022, 345, 128423. [Google Scholar] [CrossRef]

- Cadorin, N.D. Avaliação do Comportamento Reológico e da Eficiência Fotocatalítica de Nanocompósitos Asfálticos Produzidos com a Incorporação de nano-TiO2 e nano-ZnO. Bachelor’s Thesis, Civil Engineering, Federal University of Santa Catarina (UFSC), Florianópolis, Brazil, 2019. Available online: https://repositorio.ufsc.br/handle/123456789/202850 (accessed on 23 November 2025).

- Rocha Segundo, I.; Ferreira, C.; Freitas, E.F.; Carneiro, J.O.; Fernandes, F.; Júnior, S.L.; Costa, M.F. Assessment of Photocatalytic, Superhydrophobic and Self-Cleaning Properties on Hot Mix Asphalts Coated with TiO2 and/or ZnO Aqueous Solutions. Constr. Build. Mater. 2018, 166, 500–509. [Google Scholar] [CrossRef]

- Carneiro, J.O.; Azevedo, S.; Teixeira, V.; Fernandes, F.; Freitas, E.; Silva, H.; Oliveira, J. Development of Photocatalytic Asphalt Mixtures by the Deposition and Volumetric Incorporation of TiO2 Nanoparticles. Constr. Build. Mater. 2013, 38, 594–601. [Google Scholar] [CrossRef]

- Mousavi Rad, S.; Kamboozia, N.; Ameri, M.; Mirabdolazimi, S.M. Feasibility of Concurrent Improvement of Pollutants-Absorption Ability from Surface Runoff and Mechanical Performance of Asphalt Mixtures by Using Photocatalytic Nanomodified Porous Asphalt. J. Mater. Civ. Eng. 2023, 35, 04023248. [Google Scholar] [CrossRef]

- Qian, G.; Yu, H.; Gong, X.; Zhao, L. Impact of Nano-TiO2 on the NO2 Degradation and Rheological Performance of Asphalt Pavement. Constr. Build. Mater. 2019, 218, 53–63. [Google Scholar] [CrossRef]

- Hassan, M.M.; Dylla, H.; Asadi, S.; Mohammad, L.N.; Cooper, S. Laboratory Evaluation of Environmental Performance of Photocatalytic Titanium Dioxide Warm-Mix Asphalt Pavements. J. Mater. Civ. Eng. 2012, 24, 599–605. [Google Scholar] [CrossRef]

- Neto, V.F.D.S.; Lucena, L.C.D.F.L.; De Barros, A.G.; Lucena, A.E.D.F.L.; Filho, P.G.T.M. Rheological Evaluation of Asphalt Binder Modified with Zinc Oxide Nanoparticles. Case Stud. Constr. Mater. 2022, 17, e01224. [Google Scholar] [CrossRef]

- Babagoli, R.; Rezaei, M. Using Artificial Neural Network Methods for Modeling Moisture Susceptibility of Asphalt Mixture Modified by Nano TiO2. J. Mater. Civ. Eng. 2022, 34, 04022108. [Google Scholar] [CrossRef]

- Yunus, K.N.M.; Abdullah, M.E.; Ahmad, M.K.; Kamaruddin, N.H.M.; Tami, H. Physical and Rheological Properties of Nano Zinc Oxide Modified Asphalt Binder. MATEC Web Conf. 2018, 250, 02004. [Google Scholar] [CrossRef]

- He, Z.; Xie, T.; Li, Q.; Wang, P. Physical and Antiaging Properties of Rodlike Nano-ZnO–Modified Asphalt. J. Mater. Civ. Eng. 2021, 33, 04021316. [Google Scholar] [CrossRef]

- Xu, X.; Guo, H.; Wang, X.; Zhang, M.; Wang, Z.; Yang, B. Physical Properties and Anti-Aging Characteristics of Asphalt Modified with Nano-Zinc Oxide Powder. Constr. Build. Mater. 2019, 224, 732–742. [Google Scholar] [CrossRef]

- Shafabakhsh, G.H.; Ani, O.J. Experimental Investigation of Effect of Nano TiO2/SiO2 Modified Bitumen on the Rutting and Fatigue Performance of Asphalt Mixtures Containing Steel Slag Aggregates. Constr. Build. Mater. 2015, 98, 692–702. [Google Scholar] [CrossRef]

- Staub De Melo, J.V.; Manfro, A.L.; Barra, B.S.; Dell’Antonio Cadorin, N.; Borba Broering, W. Evaluation of the Rheological Behavior and the Development of Performance Equations of Asphalt Composites Produced with Titanium Dioxide and Zinc Oxide Nanoparticles. Nanomaterials 2023, 13, 288. [Google Scholar] [CrossRef] [PubMed]

- Sadeghnejad, M.; Shafabakhsh, G. Use of Nano SiO 2 and Nano TiO 2 to Improve the Mechanical Behaviour of Stone Mastic Asphalt Mixtures. Constr. Build. Mater. 2017, 157, 965–974. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Mirabdolazimi, S.M.; Sadeghnejad, M. Evaluation the Effect of Nano-TiO2 on the Rutting and Fatigue Behavior of Asphalt Mixtures. Constr. Build. Mater. 2014, 54, 566–571. [Google Scholar] [CrossRef]

- Mousavi Rad, S.; Kamboozia, N.; Anupam, K.; Saed, S.A. Experimental Evaluation of the Fatigue Performance and Self-Healing Behavior of Nanomodified Porous Asphalt Mixtures Containing RAP Materials under the Aging Condition and Freeze–Thaw Cycle. J. Mater. Civ. Eng. 2022, 34, 04022323. [Google Scholar] [CrossRef]

- Kamboozia, N.; Mousavi Rad, S.; Saed, S.A. Laboratory Investigation of the Effect of Nano-ZnO on the Fracture and Rutting Resistance of Porous Asphalt Mixture under the Aging Condition and Freeze–Thaw Cycle. J. Mater. Civ. Eng. 2022, 34, 04022052. [Google Scholar] [CrossRef]

- Fakhri, M.; Shahryari, E. The Effects of Nano Zinc Oxide (ZnO) and Nano Reduced Graphene Oxide (RGO) on Moisture Susceptibility Property of Stone Mastic Asphalt (SMA). Case Stud. Constr. Mater. 2021, 15, e00655. [Google Scholar] [CrossRef]

- Fu, Z.; Tang, Y.; Ma, F.; Wang, Y.; Shi, K.; Dai, J.; Hou, Y.; Li, J. Rheological Properties of Asphalt Binder Modified by Nano-TiO2/ZnO and Basalt Fiber. Constr. Build. Mater. 2022, 320, 126323. [Google Scholar] [CrossRef]

- Xie, X.; Hui, T.; Luo, Y.; Li, H.; Li, G.; Wang, Z. Research on the Properties of Low Temperature and Anti-UV of Asphalt with Nano-ZnO/Nano-TiO2/Copolymer SBS Composite Modified in High-Altitude Areas. Adv. Mater. Sci. Eng. 2020, 2020, 9078731. [Google Scholar] [CrossRef]

- Rocha Segundo, I.G.D.; Dias, E.A.L.; Fernandes, F.D.P.; Freitas, E.F.D.; Costa, M.F.; Carneiro, J.O. Photocatalytic Asphalt Pavement: The Physicochemical and Rheological Impact of TiO2 Nano/Microparticles and ZnO Microparticles onto the Bitumen. Road Mater. Pavement Des. 2019, 20, 1452–1467. [Google Scholar] [CrossRef]

- Zhang, H.; Su, M.; Zhao, S.; Zhang, Y.; Zhang, Z. High and Low Temperature Properties of Nano-Particles/Polymer Modified Asphalt. Constr. Build. Mater. 2016, 114, 323–332. [Google Scholar] [CrossRef]

- Janotti, A.; Van De Walle, C.G. Fundamentals of Zinc Oxide as a Semiconductor. Rep. Prog. Phys. 2009, 72, 126501. [Google Scholar] [CrossRef]

- Qumar, U.; Hassan, J.Z.; Bhatti, R.A.; Raza, A.; Nazir, G.; Nabgan, W.; Ikram, M. Photocatalysis vs Adsorption by Metal Oxide Nanoparticles. J. Mater. Sci. Technol. 2022, 131, 122–166. [Google Scholar] [CrossRef]

- Babu, U.J.R.; Hareesh, K.; Rondiya, S.R.; Nagaraju, D.H.; Mahendra, K. Synthesis and Characterization of Nitrogen and Phosphorus Co-Doped TiO2 Nanoparticle Anchored Graphitic Carbon Nitride Nanosheets: Photocatalytic Application on Dye Removal. Diam. Relat. Mater. 2023, 139, 110292. [Google Scholar] [CrossRef]

- Li, Y.; Fernández-Seara, J.; Du, K.; Pardiñas, Á.Á.; Latas, L.L.; Jiang, W. Experimental Investigation on Heat Transfer and Pressure Drop of ZnO/Ethylene Glycol-Water Nanofluids in Transition Flow. Appl. Therm. Eng. 2016, 93, 537–548. [Google Scholar] [CrossRef]

- Permanasari, A.A.; Kuncara, B.S.; Puspitasari, P.; Sukarni, S.; Ginta, T.L.; Irdianto, W. Convective Heat Transfer Characteristics of TiO2-EG Nanofluid as Coolant Fluid in Heat Exchanger. In Proceedings of the International Conference on Biology and Applied Science (ICOBAS), Malang, Indonesia, 13–14 March 2019; p. 050015. [Google Scholar]

- Broering, W.B.; De Melo, J.V.S.; Manfro, A.L. Incorporation of Nanoalumina into a Polymeric Asphalt Matrix: Reinforcement of the Nanostructure, Improvement of Phase Stability, and Amplification of Rheological Parameters. Constr. Build. Mater. 2022, 320, 126261. [Google Scholar] [CrossRef]

- Manfro, A.L.; Staub De Melo, J.V.; Villena Del Carpio, J.A.; Broering, W.B. Permanent Deformation Performance under Moisture Effect of an Asphalt Mixture Modified by Calcium Carbonate Nanoparticles. Constr. Build. Mater. 2022, 342, 128087. [Google Scholar] [CrossRef]

- Schuster, L. Avaliação da Contribuição da lã de aço Associada ao Nanotubo de Carbono na Reparação de Danos em Misturas Asfálticas Submetidas ao Aquecimento por Micro-Ondas. Master’s Thesis, Civil Engineering, Federal University of Santa Catarina (UFSC), Florianópolis, Brazil, 2020. Available online: https://tede.ufsc.br/teses/PECV1225-D.pdf (accessed on 23 November 2025).

- ASTM C131M; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D5821; Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C1252; Standard Test Methods for Uncompacted Void Content of Fine Aggregate (as Influenced by Particle Shape, Surface Texture, and Grading). ASTM International: West Conshohocken, PA, USA, 2023.

- AASHTO T 176; Plastic Fines in Graded Aggregates and Soils by Use of the Sand Equivalent Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO T 112; Standard Method of Test for Clay Lumps and Friable Particles in Aggregate. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2023.

- ASTM C88; Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. ASTM International: West Conshohocken, PA, USA, 2018.

- CBB Asfaltos. Certificado de Análise: Controle de Qualidade Número 54.421; CBB Asfaltos: Curitiba, Brazil, 2022. [Google Scholar]

- ABNT NBR 15166; Modified Asphalt—Test Method for Phase Separation. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2004.

- ABNT NBR 6296; Semi-Solid Bituminous Products—Determination of Density and Relative Density. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2012.

- ABNT NBR 6576; Betuminous Materials—Determination of Penetration. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2007.

- ABNT NBR 6560; Asphaltic Binders—Determination of the Softening Point—Ring-and-Ball Method. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2016.

- ABNT NBR 11341; Petroleum Products—Determination of the Flash and Fire Points by Cleveland Open Cup. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2015.

- ABNT NBR 15086; Bituminous Materials—Determination of the Elastic Recovery by Ductilometer of Elastomeric Polymer and Ground Tyre Rubber Modified Asphalt. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2022.

- ABNT NBR 14855; Asphalt Binder—Determination of Solubility in Trichloroethylene. Associação Brasileira De Normas Técnicas: Rio de Janeiro, Brazil, 2015.

- Kraton Polymers. KRATONTM D1101 A Polymer; Kraton Polymers: Houston, TX, USA, 2024. [Google Scholar]

- ISO 2781; Rubber, Vulcanized or Thermoplastic—Determination of Density. International Organization for Standardization: Geneva, Switzerland, 2018.

- ASTM D1895; Standard Test Methods for Apparent Density, Bulk Factor and Pourability of Plastic Materials. ASTM International: West Conshohocken, PA, USA, 2024.

- ISO 1133-1; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 37; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 868; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). International Organization for Standardization: Geneva, Switzerland, 2003.

- Nanostructured & Amorphous Materials Titanium Oxide Nanopowder (TiO2, Anatase, 99+%, 10 Nm). Available online: https://www.nanoamor.com/inc/sdetail/45710 (accessed on 30 March 2025).

- Nanostructured & Amorphous Materials Zinc Oxide Nanopowder (ZnO, 99%, 20 Nm). Available online: https://www.nanoamor.com/inc/sdetail/19983 (accessed on 30 March 2025).

- ASTM E2550; Standard Test Method for Thermal Stability by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2021.

- Dell’Antonio Cadorin, N.; Victor Staub De Melo, J.; Borba Broering, W.; Luiz Manfro, A.; Salgado Barra, B. Asphalt Nanocomposite with Titanium Dioxide: Mechanical, Rheological and Photoactivity Performance. Constr. Build. Mater. 2021, 289, 123178. [Google Scholar] [CrossRef]

- Zidi, Z.; Ltifi, M.; Ayadi, Z.B.; Mir, L.E.; Nóvoa, X.R. Effect of Nano-ZnO on Mechanical and Thermal Properties of Geopolymer. J. Asian Ceram. Soc. 2020, 8, 1–9. [Google Scholar] [CrossRef]

- Freitas, M.R. de Síntese e Caracterização de Nanopartículas de ZnO Dopado e Codopado com Metais de Transição. Master’s Thesis, Materials Science and Engineering, Federal University of Paraná (UFPR), Curitiba, Brazil, 2018. Available online: https://hdl.handle.net/1884/69956 (accessed on 23 November 2025).

- Song, Y.; Li, H.; Xiong, Z.; Cheng, L.; Du, M.; Liu, Z.; Li, J.; Li, D. TiO2/Carbon Composites from Waste Sawdust for Methylene Blue Photodegradation. Diam. Relat. Mater. 2023, 136, 109918. [Google Scholar] [CrossRef]

- Das, A.; Kumar, P.M.; Bhagavathiachari, M.; Nair, R.G. Hierarchical ZnO-TiO2 Nanoheterojunction: A Strategy Driven Approach to Boost the Photocatalytic Performance through the Synergy of Improved Surface Area and Interfacial Charge Transport. Appl. Surf. Sci. 2020, 534, 147321. [Google Scholar] [CrossRef]

- Munguti, L.; Dejene, F. Effects of Zn:Ti Molar Ratios on the Morphological, Optical and Photocatalytic Properties of ZnO-TiO2 Nanocomposites for Application in Dye Removal. Mater. Sci. Semicond. Process. 2021, 128, 105786. [Google Scholar] [CrossRef]

- Li, B.; Yuan, D.; Gao, C.; Zhang, H.; Li, Z. Synthesis and Characterization of TiO2/ZnO Heterostructural Composite for Ultraviolet Photocatalytic Degrading DOM in Landfill Leachate. Environ. Sci. Pollut. Res. 2022, 29, 85510–85524. [Google Scholar] [CrossRef]

- Spínola, J.R.; Staub De Melo, J.V.; Manfro, A.L.; Salgado Barra, B. Effects of the Addition of Industrial Graphene Nanoplatelets on the Permanent Deformation Susceptibility, Fatigue Resistance, and Healing Capacity of an Asphalt Mixture Modified with Styrene–Butadiene–Styrene Copolymer. J. Mater. Civ. Eng. 2025, 37, 04025048. [Google Scholar] [CrossRef]

- Saltan, M.; Terzi, S.; Karahancer, S. Mechanical Behavior of Bitumen and Hot-Mix Asphalt Modified with Zinc Oxide Nanoparticle. J. Mater. Civ. Eng. 2019, 31, 04018399. [Google Scholar] [CrossRef]

- ASTM D2872; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D6373; Standard Specification for Performance-Graded Asphalt Binder. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D4402 M; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D7405; Standard Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2024.

- AASHTO T 315; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- Manfro, A.L. Influência da Incorporação de Nanopartículas de Carbonato de Cálcio no Concreto Asfáltico Quanto à Resistência à Deformação Permanente e aos Efeitos Deletérios da Ação da Água. Master’s Thesis, Civil Engineering, Federal University of Santa Catarina (UFSC), Florianópolis, Brazil, 2022. Available online: https://tede.ufsc.br/teses/PECV1267-D.pdf (accessed on 23 November 2025).

- Broering, W.B. Efeitos da Incorporação de Nanopartículas de Óxido de Alumínio na Condutividade Térmica e nas Propriedades Reológicas de Ligantes Asfálticos. Master’s Thesis, Civil Engineering, Federal University of Santa Catarina (UFSC), Florianópolis, Brazil, 2020. Available online: https://tede.ufsc.br/teses/PECV1237-D.pdf (accessed on 23 November 2025).

- Spínola, J.R. Avaliação da Influência de Grafeno no Desempenho Mecânico e na Reparação aos Danos por Fadiga de uma Mistura Asfáltica com Incorporação de Polímero. Master’s Thesis, Civil Engineering, Federal University of Santa Catarina (UFSC), Florianópolis, Brazil, 2023. Available online: https://tede.ufsc.br/teses/PECV1312-D.pdf (accessed on 23 November 2025).

- AASHTO T 391; Standard Method of Test for Estimating Fatigue Resistance of Asphalt Binders Using the Linear Amplitude Sweep. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2020.

- DNIT 439 ME; Pavimentação—Ligante Asfáltico—Avaliação Da Resistência à Fadiga de Ligantes Asfálticos Usando Varredura de Amplitude Linear (LAS—Linear Amplitude Sweep)—Método de Ensaio. Departamento Nacional de Infraestrutura de Transportes: Brasilia, Brazil, 2022. Available online: https://www.gov.br/dnit/pt-br/assuntos/planejamento-e-pesquisa/ipr/coletanea-de-normas/coletanea-de-normas/metodo-de-ensaio-me/dnit_439_2022_me.pdf (accessed on 23 November 2025).

- Melo, J.V.S. de Desenvolvimento e Estudo do Comportamento Reológico e Desempenho Mecânico de Concretos Asfálticos Modificados com Nanocompósitos. Ph.D. Thesis, Civil Engineering, Federal University of Santa Catarina (UFSC), Florianópolis, Brazil, 2014. Available online: https://tede.ufsc.br/teses/PECV0931-T.pdf (accessed on 23 November 2025).

- AASHTO M 323; Standard Specification for Superpave Volumetric Mix Design. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO R 35; Standard Practice for Superpave Volumetric Design for Asphalt Mixtures. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO R 30; Standard Practice for Mixture Conditioning of Hot Mix Asphalt (HMA). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- EN 12697-33; Bituminous Mixtures. Test Methods—Part 33: Specimen Prepared by Roller Compactor. European Committee for Standardization (CEN): Brussels, Belgium, 2022.

- EN 12697-22; Bituminous Mixtures. Test Methods—Part 22: Wheel Tracking. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- EN 12697-26; Bituminous Mixtures—Test Methods—Part 26: Stiffness. European Committee for Standardization (CEN): Brussels, Belgium, 2022.

- De Melo, J.V.S.; Trichês, G. Evaluation of Properties and Fatigue Life Estimation of Asphalt Mixture Modified by Organophilic Nanoclay. Constr. Build. Mater. 2017, 140, 364–373. [Google Scholar] [CrossRef]

- EN 12697-24; Bituminous Mixtures. Test Methods—Part 24: Resistance to Fatigue. European Committee for Standardization (CEN): Brussels, Belgium, 2018.

- Instituto de Pesquisas Rodoviárias (IPR); Departamento Nacional de Infraestrutura de Transportes (DNIT); Instituto Alberto Luiz Coimbra de Pós-Graduação e Pesquisa de Engenharia, Universidade Federal do Rio de Janeiro (COPPE/UFRJ). Execução de Estudos e Pesquisa para Elaboração de Método Mecanístico–Empírico de Dimensionamento de Pavimento Asfáltico: Manual de Utilização do Programa MeDiNa; DNIT/IPR: Rio de Janeiro, Brazil, 2020.

- Gómez-Rodríguez, P.; Van Grieken, R.; López-Muñoz, M.J. Influence of the TiO2 Crystalline Phase on the Performance of UVA/Brookite/Persulfate and UVA/Anatase/Persulfate Systems for the Degradation of Isothiazolinones in Aqueous Matrices. J. Environ. Chem. Eng. 2024, 12, 113110. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, W.; Li, X.; Yin, X.; Liu, Y.; Su, S.; Wang, Q.; Zhang, L. Enhanced Photocatalytic Activity of Sn3O4/TiO2 Heterostructures for Cr(VI) Reduction and Isoniazid Degradation. Mater. Sci. Semicond. Process. 2025, 192, 109441. [Google Scholar] [CrossRef]

- Kahandal, A.; Chaudhary, S.; Methe, S.; Nagwade, P.; Sivaram, A.; Tagad, C.K. Galactomannan Polysaccharide as a Biotemplate for the Synthesis of Zinc Oxide Nanoparticles with Photocatalytic, Antimicrobial and Anticancer Applications. Int. J. Biol. Macromol. 2023, 253, 126787. [Google Scholar] [CrossRef]

- Jakhrani, M.A.; Bhatti, M.A.; Tahira, A.; Shah, A.A.; Dawi, E.A.; Vigolo, B.; Nafady, A.; Saleem, L.M.; Haj Ismail, A.A.K.; Ibupoto, Z.H. Biogenic Preparation of ZnO Nanostructures Using Leafy Spinach Extract for High-Performance Photodegradation of Methylene Blue under the Illumination of Natural Sunlight. Molecules 2023, 28, 2773. [Google Scholar] [CrossRef]

- Han, Z.; Cong, P. Understanding Relationships between Aging Induced Variation of Asphaltene Aggregation Morphology and Asphalt Properties through Molecular Dynamics Simulation. Constr. Build. Mater. 2024, 420, 135610. [Google Scholar] [CrossRef]

- Jin, J.; Liu, S.; Chen, H.; Wen, Z.; Xiao, M.; Rao, R.; Zheng, J. Evaluation of Compatibility in Bio-Oil and Zinc Oxide Modified Asphalt to Facilitate Waste Recycling. J. Clean. Prod. 2024, 476, 143710. [Google Scholar] [CrossRef]

- Gebresellasie, K.; Lewis, J.C.; Shirokoff, J. X-Ray Spectral Line Shape Analysis of Asphalt Binders. Energy Fuels 2013, 27, 2018–2024. [Google Scholar] [CrossRef]

- Nagaraju, G.; Udayabhanu; Shivaraj; Prashanth, S.A.; Shastri, M.; Yathish, K.V.; Anupama, C.; Rangappa, D. Electrochemical Heavy Metal Detection, Photocatalytic, Photoluminescence, Biodiesel Production and Antibacterial Activities of Ag–ZnO Nanomaterial. Mater. Res. Bull. 2017, 94, 54–63. [Google Scholar] [CrossRef]

- Rajith Kumar, C.R.; Betageri, V.S.; Nagaraju, G.; Pujar, G.H.; Onkarappa, H.S.; Latha, M.S. Synthesis of Core/Shell (ZnO/Ag) Nanoparticles Using Calotropis Gigantea and Their Applications in Photocatalytic and Antibacterial Studies. J. Inorg. Organomet. Polym. Mater. 2020, 30, 3410–3417. [Google Scholar] [CrossRef]

- Worku, A.K.; Ayele, D.W.; Habtu, N.G.; Melas, G.A.; Yemata, T.A.; Mekonnen, N.Y.; Teshager, M.A. Structural and Thermal Properties of Pure and Chromium Doped Zinc Oxide Nanoparticles. SN Appl. Sci. 2021, 3, 699. [Google Scholar] [CrossRef]

- Xiong, G.; Pal, U.; Serrano, J.G. Correlations among Size, Defects, and Photoluminescence in ZnO Nanoparticles. J. Appl. Phys. 2007, 101, 024317. [Google Scholar] [CrossRef]

- Wahab, R.; Ansari, S.G.; Kim, Y.S.; Seo, H.K.; Kim, G.S.; Khang, G.; Shin, H.-S. Low Temperature Solution Synthesis and Characterization of ZnO Nano-Flowers. Mater. Res. Bull. 2007, 42, 1640–1648. [Google Scholar] [CrossRef]

- Facin, F.; Staub De Melo, J.V.; Costa Puerari, R.; Matias, W.G. Toxicological Effects of Leachates Extracted from Photocatalytic Concrete Blocks with Nano-TiO2 on Daphnia Magna. Nanomaterials 2024, 14, 1447. [Google Scholar] [CrossRef]

- Islam, T.; Roni, N.P.; Ali, Y.; Islam, R.; Hossan, S.; Rahman, M.H.; Zahid, A.A.S.M.; E Alam, N.; Hanif, A.; Akhtar, M.S. Selectivity of Sol-Gel and Hydrothermal TiO2 Nanoparticles towards Photocatalytic Degradation of Cationic and Anionic Dyes. Molecules 2023, 28, 6834. [Google Scholar] [CrossRef]

- Chawraba, K.; Medlej, H.; Noun, A.; Sakr, M.; Toufaily, J.; Lalevee, J.; Hamieh, T. Photocatalytic Epoxy Paint Based on TiO2 for the Decontamination of Water under Visible LED and Sunlight Irradiation. ChemistrySelect 2024, 9, e202303055. [Google Scholar] [CrossRef]

- Hesami, S.; Mahzari, M.; Sobhi, S.; Bay, M.A. Investigating the Rheological Properties and Microstructural Analysis of Nano-Expanded Perlite Modified Asphalt Binder. Case Stud. Constr. Mater. 2025, 22, e04208. [Google Scholar] [CrossRef]

- Filho, P.G.T.M.; Rodrigues Dos Santos, A.T.; Lucena, L.C.D.F.L.; De Sousa Neto, V.F. Rheological Evaluation of Asphalt Binder 50/70 Incorporated with Titanium Dioxide Nanoparticles. J. Mater. Civ. Eng. 2019, 31, 04019235. [Google Scholar] [CrossRef]

- Yan, C.; Xiao, F.; Huang, W.; Lv, Q. Critical Matters in Using Attenuated Total Reflectance Fourier Transform Infrared to Characterize the Polymer Degradation in Styrene–Butadiene–Styrene-Modified Asphalt Binders. Polym. Test. 2018, 70, 289–296. [Google Scholar] [CrossRef]

- Yu, J.; Vaidya, M.; Su, G.; Adhikari, S.; Korolev, E.; Shekhovtsova, S. Experimental Study of Soda Lignin Powder as an Asphalt Modifier for a Sustainable Pavement Material. Constr. Build. Mater. 2021, 298, 123884. [Google Scholar] [CrossRef]

- Wu, S.; Pang, L.; Mo, L.; Chen, Y.; Zhu, G. Influence of Aging on the Evolution of Structure, Morphology and Rheology of Base and SBS Modified Bitumen. Constr. Build. Mater. 2009, 23, 1005–1010. [Google Scholar] [CrossRef]

- Neto, V.F.D.S.; Minervina Silva, I.; Lucena, L.C.D.F.L.; Lucena, A.E.D.F.L.; De Medeiros Melo Neto, O.; Lima, R.K.B.D. Effect of Superficially Modified Zinc Oxide Nanoparticles as an Additive on the Rheological Performance of Asphalt Binder. Road Mater. Pavement Des. 2024, 25, 1211–1228. [Google Scholar] [CrossRef]

- Broering, W.B.; De Melo, J.V.S.; Manfro, A.L. Modification of the Asphalt Binder with Nano-Aluminum Oxide: An Alternative to Improve the Thermal Conductivity and the Rheological Properties of the Asphalt Matrix. J. Test. Eval. 2024, 52, 1109–1128. [Google Scholar] [CrossRef]

- Asphalt Institute. Asphalt Institute Asphalt Binder Testing. Manual Series N° 25 (MS-25); Asphalt Institute: Lexington, KY, USA, 2012. [Google Scholar]

- Günay, T.; Ahmedzade, P. Physical and Rheological Properties of Nano- TiO 2 and Nanocomposite Modified Bitumens. Constr. Build. Mater. 2020, 243, 118208. [Google Scholar] [CrossRef]

- Nascimento, L.A.H. Do Implementation and Validation of the Viscoelastic Continuum Damage Theory for Asphalt Mixture and Pavement Analysis in Brazil. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2015. [Google Scholar]

- Horikoshi, S.; Matsubara, A.; Takayama, S.; Sato, M.; Sakai, F.; Kajitani, M.; Abe, M.; Serpone, N. Characterization of Microwave Effects on Metal-Oxide Materials: Zinc Oxide and Titanium Dioxide. Appl. Catal. B Environ. 2010, 99, 490–495. [Google Scholar] [CrossRef]

- Yang, Z.; Luo, F.; Hu, Y.; Duan, S.; Zhu, D.; Zhou, W. Dielectric and Microwave Absorption Properties of TiO2/Al2O3 Coatings and Improved Microwave Absorption by FSS Incorporation. J. Alloys Compd. 2016, 678, 527–532. [Google Scholar] [CrossRef]

- Ahmad, P.; Venkateswara Rao, A.; Suresh Babu, K.; Narsinga Rao, G. Particle Size Effect on the Dielectric Properties of ZnO Nanoparticles. Mater. Chem. Phys. 2019, 224, 79–84. [Google Scholar] [CrossRef]

- Sun, J.; Wang, W.; Yue, Q. Review on Microwave-Matter Interaction Fundamentals and Efficient Microwave-Associated Heating Strategies. Materials 2016, 9, 231. [Google Scholar] [CrossRef]

| Properties | Test Method | Results |

|---|---|---|

| Hardness (Los Angeles abrasion) | ASTM C131 [38] | 18.64% |

| Absorption of coarse aggregate | ASTM C127 [39] | 1.43% |

| Angularity of coarse aggregate | ASTM D5821 [40] | 100% |

| Angularity of fine aggregate | ASTM C1252 [41] | 52.36% |

| Clay content (sand equivalent) | AASHTO T 176 [42] | 71.95% |

| Bulk specific gravity (Gsb) of coarse aggregate | ASTM C127 [39] | 2.592 g/cm3 |

| Apparent specific gravity (Gsa) of coarse aggregate | ASTM C127 [39] | 2.648 g/cm3 |

| Deleterious material | AASHTO T 112 [43] | 0.00% |

| Soundness | ASTM C88 [44] | 1.59% |

| Properties | Test Method | Results |

|---|---|---|

| Phase separation (∆PA) | NBR 15166 [46] | 0.3 °C |

| Density, 25 °C | NBR 6296 [47] | 1.009 |

| Penetration, 100 g, 5 s, 25 °C | NBR 6576 [48] | 48 (0.1 mm) |

| Softening point | NBR 6560 [49] | 68 °C |

| Flash and fire points | NBR 11341 [50] | 254 °C |

| Elastic recovery, 20 cm, 25 °C | NBR 15086 [51] | 90.0% |

| Solubility in trichloroethylene | NBR 14855 [52] | 99.9% (mass) |

| Property | Test Method | Typical Value |

|---|---|---|

| Specific gravity | ISO 2781 [54] | 0.94 |

| Bulk density | ASTM D1895 method B [55] | 0.4 kg/dm3 |

| Melt flow rate, 200 °C/5 kg | ISO 1133 [56] | <1 g/10 min |

| Tensile strength | ISO 37 [57] | 33 MPa |

| 300% modulus | ISO 37 [57] | 2.9 MPa |

| Elongation at break | ISO 37 [57] | 880% |

| Hardness, shore A (30 s) | ISO 868 [58] | 72 |

| Properties | ZnO | TiO2 |

|---|---|---|

| Purity | >99% | >99% |

| Mean particle size | 20 nm | 10 nm |

| Morphology of particles | Spherical | Ellipsoidal/spherical |

| Specific surface area | ≥40 m2/g | ≥60 m2/g |

| Bulk density | 0.1–0.2 g/cm3 | 0.2–0.3 g/cm3 |

| pH value | 6.5–7.5 | 5.5–7.0 |

| Loss on drying (110 °C/2 h) | ≤1.0 wt.% | ≤2.0 wt.% |

| Loss on calcination (850 °C/2 h) | ≤3.0 wt.% | ≤5.0 wt.% |

| Number of Produced Nanocomposites | Incorporation (by Binder Weight) | Produced Nanocomposite | |

|---|---|---|---|

| Nanomaterial | |||

| ZnO | TiO2 | ||

| N0 (reference) | 0% | 0% | 0% (ZnO + TiO2) |

| N2 | 1% | 1% | 1% (ZnO + TiO2) |

| N4 | 2% | 2% | 2% (ZnO + TiO2) |

| N6 | 3% | 3% | 3% (ZnO + TiO2) |

| N8 | 4% | 4% | 4% (ZnO + TiO2) |

| N10 | 5% | 5% | 5% (ZnO + TiO2) |

| N12 | 6% | 6% | 6% (ZnO + TiO2) |

| Aggregate Fraction | Sieves (ASTM Series) | % Retained |

|---|---|---|

| Coarse aggregates | 1/2 in. | 22.5 |

| 3/8 in. | 16.2 | |

| No. 4 | 18.0 | |

| Fine aggregates | No. 10 | 19.0 |

| No. 16 | 6.9 | |

| No. 30 | 4.8 | |

| No. 50 | 2.8 | |

| No. 100 | 2.2 | |

| No. 200 | 2.2 | |

| Filler | Filler | 5.4 |

| N0 | N2 | N4 | N6 | N8 | N10 | N12 | ||

| N0 | Mean difference | - | −0.0683 | −0.0955 | −0.135 | −0.1895 | −0.2698 | −0.3163 |

| p-value | - | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | |

| N2 | Mean difference | - | −0.0272 | −0.0667 | −0.1212 | −0.2015 | −0.248 | |

| p-value | - | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | ||

| N4 | Mean difference | - | −0.0395 | −0.094 | −0.1743 | −0.2208 | ||

| p-value | - | 0.003 | <0.001 | <0.001 | <0.001 | |||

| N6 | Mean difference | - | −0.0545 | −0.1348 | −0.1813 | |||

| p-value | - | <0.001 | <0.001 | <0.001 | ||||

| N8 | Mean difference | - | −0.0803 | −0.1268 | ||||

| p-value | - | <0.001 | <0.001 | |||||

| N10 | Mean difference | - | −0.0465 | |||||

| p-value | - | <0.001 | ||||||

| N12 | Mean difference | - | ||||||

| p-value | - |

| Temperature | Parameter | Mean (0.1 Hz–30 Hz) | % Variation | |

|---|---|---|---|---|

| 0% ZnO + TiO2 (N0) | 8.5% ZnO + TiO2 (Noptimal) | |||

| 35 °C | |G*| (kPa) | 394 | 802 | 103.4% |

| δ (°) | 64.1 | 64.2 | 0.1% | |

| G′ (kPa) | 178 | 362 | 103.1% | |

| G″ (kPa) | 352 | 715 | 103.3% | |

| 30 °C | |G*| (kPa) | 985 | 2019 | 105.0% |

| δ (°) | 61.6 | 61.3 | −0.4% | |

| G′ (kPa) | 512 | 1054 | 106.0% | |

| G″ (kPa) | 840 | 1717 | 104.3% | |

| 25 °C | |G*| (kPa) | 2645 | 5419 | 104.9% |

| δ (°) | 55.9 | 55.5 | −0.8% | |

| G′ (kPa) | 1630 | 3377 | 107.2% | |

| G″ (kPa) | 2075 | 4225 | 103.6% | |

| 20 °C | |G*| (kPa) | 6332 | 12,846 | 102.9% |

| δ (°) | 49.2 | 48.6 | −1.2% | |

| G′ (kPa) | 4463 | 9116 | 104.2% | |

| G″ (kPa) | 4467 | 9001 | 101.5% | |

| 15 °C | |G*| (kPa) | 13,510 | 27,091 | 100.5% |

| δ (°) | 42.5 | 41.9 | −1.3% | |

| G′ (kPa) | 10,470 | 21,075 | 101.3% | |

| G″ (kPa) | 8482 | 16,915 | 99.4% | |

| 10 °C | |G*| (kPa) | 26,630 | 55,413 | 108.1% |

| δ (°) | 35.8 | 35.1 | −2.1% | |

| G′ (kPa) | 22,303 | 46,685 | 109.3% | |

| G″ (kPa) | 14,425 | 29,615 | 105.3% | |

| 5 °C | |G*| (kPa) | 48,232 | 99,115 | 105.5% |

| δ (°) | 30.4 | 29.9 | −1.7% | |

| G′ (kPa) | 42,462 | 87,556 | 106.2% | |

| G″ (kPa) | 22,644 | 46,015 | 103.2% | |

| Parameter | N0 (0% ZnO + TiO2) | Noptimal (8.5% ZnO + TiO2) | % Variation | ||||

|---|---|---|---|---|---|---|---|

| Mean | SD | CV | Mean | SD | CV | ||

| A | 10,350,246 | 1,753,858 | 17.0% | 9,226,490 | 1,399,268 | 15.2% | −10.9% |

| B | 5.21 | 0.01 | 0.1% | 5.24 | 0.02 | 0.4% | 0.6% |

| Nf (γ: 1.25%) | 3,236,134 | 544,325 | 16.8% | 2,865,510 | 436,161 | 15.2% | −11.5% |

| Nf (γ: 2.50%) | 87,417 | 14 | 16.4% | 75,817 | 11,720 | 15.5% | −13.3% |

| Nf (γ: 5.00%) | 2361 | 379 | 16.1% | 2006 | 317 | 15.8% | −15.0% |

| Nf (γ: 7.50%) | 286 | 45 | 15.9% | 240 | 38 | 16.0% | −16.1% |

| Nf (γ: 10.00%) | 64 | 10 | 15.7% | 53 | 9 | 16.2% | −16.8% |

| Nf (γ: 12.50%) | 20 | 3 | 15.6% | 16 | 3 | 16.4% | −17.3% |

| Nf (γ: 15.00%) | 8 | 1 | 15.5% | 6 | 1 | 16.5% | −17.8% |

| FF (γ: 1.25–2.50%) | 1.72 | 0.02 | 1.3% | 1.71 | 0.02 | 1.1% | −1.0% |

| Temperature | Parameter | Mean (0.1 Hz–20 Hz) | % Variation | |

|---|---|---|---|---|

| 0% ZnO + TiO2 (M1) | 8.5% ZnO + TiO2 (M2) | |||

| 30 °C | |E*| (kPa) | 1,536,667 | 2,012,889 | 31.0% |

| δ (°) | 42.1 | 40.1 | −4.6% | |

| E2 (kPa) | 1,004,944 | 1,230,108 | 22.4% | |

| E1 (kPa) | 1,160,868 | 1,588,547 | 36.8% | |

| 25 °C | |E*| (kPa) | 2,774,778 | 3,359,333 | 21.1% |

| δ (°) | 36.6 | 34.5 | −5.9% | |

| E2 (kPa) | 1,531,254 | 1,711,363 | 11.8% | |

| E1 (kPa) | 2,304,012 | 2,873,802 | 24.7% | |

| 20 °C | |E*| (kPa) | 5,293,667 | 5,975,778 | 12.9% |

| δ (°) | 27.4 | 25.2 | −7.9% | |

| E2 (kPa) | 2,171,383 | 2,280,832 | 5.0% | |

| E1 (kPa) | 4,802,030 | 5,495,797 | 14.5% | |

| 15 °C | |E*| (kPa) | 8,268,111 | 9,056,778 | 9.5% |

| δ (°) | 19.7 | 17.9 | −9.2% | |

| E2 (kPa) | 2,488,840 | 2,502,437 | 0.6% | |

| E1 (kPa) | 7,852,371 | 8,673,551 | 10.5% | |

| 10 °C | |E*| (kPa) | 11,605,000 | 12,281,333 | 5.8% |

| δ (°) | 14.0 | 12.5 | −10.3% | |

| E2 (kPa) | 2,580,523 | 2,463,172 | −4.6% | |

| E1 (kPa) | 11,291,725 | 12,008,692 | 6.4% | |

| 5 °C | |E*| (kPa) | 15,103,444 | 15,672,778 | 3.8% |

| δ (°) | 9.6 | 8.7 | −8.8% | |

| E2 (kPa) | 2,350,058 | 2,240,258 | −4.7% | |

| E1 (kPa) | 14,903,350 | 15,498,457 | 4.0% | |

| 0 °C | |E*| (kPa) | 18,560,556 | 19,388,889 | 4.5% |

| δ (°) | 6.4 | 5.9 | −9.0% | |

| E2 (kPa) | 1,970,855 | 1,901,843 | −3.5% | |

| E1 (kPa) | 18,444,338 | 19,288,878 | 4.6% | |

| Reference Asphalt Mixture (M1) | Nanomodified Asphalt Mixture (M2) | ||||

|---|---|---|---|---|---|

| ε (µm/m) | |E*| Initial (MPa) | Nf | ε (µm/m) | |E*| Initial (MPa) | Nf |

| 281 | 7741 | 145,611 | 289 | 7401 | 108,932 |

| 288 | 7983 | 71,034 | 289 | 7236 | 70,574 |

| 289 | 7163 | 50,745 | 292 | 7142 | 63,355 |

| 288 | 7980 | 109,200 | 293 | 7252 | 32,980 |

| 289 | 7585 | 196,106 | 290 | 7774 | 80,782 |

| 280 | 6893 | 197,173 | 290 | 8163 | 61,364 |

| 287 | 7933 | 79,516 | 291 | 7236 | 32,584 |

| 251 | 6226 | 191,576 | 290 | 7716 | 59,148 |

| 251 | 6610 | 220,823 | 251 | 6270 | 122,997 |

| 250 | 7318 | 290,632 | 250 | 6285 | 226,283 |

| 250 | 6209 | 476,063 | 251 | 7115 | 88,356 |

| 250 | 6375 | 161,744 | 258 | 7987 | 128,532 |

| 258 | 6769 | 199,664 | 257 | 6836 | 133,059 |

| 259 | 6911 | 141,592 | 258 | 8212 | 115,448 |

| 225 | 7257 | 641,263 | 259 | 7043 | 224,878 |

| 225 | 6444 | 914,578 | 225 | 7171 | 405,659 |

| 225 | 6568 | 665,988 | 225 | 6526 | 134,329 |

| 226 | 6769 | 233,245 | 226 | 7647 | 505,834 |

| 226 | 6613 | 391,755 | 225 | 7328 | 222,345 |

| 235 | 7503 | 455,050 | 235 | 7647 | 206,528 |

| 225 | 7804 | 354,816 | |||

| 236 | 7571 | 414,825 | |||

| 234 | 7181 | 149,794 | |||

| Mean | 7043 | Mean | 7328 | ||

| SD | 591 | SD | 526 | ||

| Asphalt Mixture | 0% ZnO + TiO2 (M1) | 8.5% ZnO + TiO2 (M2) |

|---|---|---|

| Equation | Nf = 4 × 1021 (ε)−6.74 | Nf = 2 × 1020 (ε)−6.29 |

| Nf100 | 123,448,265 | 49,674,175 |

| Nf250 | 256,667 | 155,987 |

| FFM | 2.70 | 2.58 |

| Reference Asphalt Mixture (M1) | Nanomodified Asphalt Mixture (M2) | ||||||

|---|---|---|---|---|---|---|---|

| ε (µm/m) | Number of Cycles (Nf) | %H | ε (µm/m) | Number of Cycles (Nf) | %H | ||

| 1st Fatigue Test | 2st Fatigue Test | 1st Fatigue Test | 2st Fatigue Test | ||||

| 281 | 145,611 | 31,636 | 21.7 | 289 | 108,932 | 20,946 | 19.2 |

| 288 | 71,034 | 12,749 | 18.0 | 289 | 70,574 | 11,536 | 16.4 |

| 289 | 50,745 | 12,627 | 24.9 | 292 | 63,355 | 23,495 | 37.1 |

| 288 | 109,200 | 23,657 | 21.7 | 293 | 32,980 | 8849 | 26.8 |

| 289 | 196,106 | 50,030 | 25.5 | 290 | 80,782 | 14,265 | 17.7 |

| 280 | 197,173 | 32,651 | 16.6 | 290 | 61,364 | 11,400 | 18.6 |

| 287 | 79,516 | 22,042 | 27.7 | 291 | 32,584 | 10,497 | 32.2 |

| 251 | 191,576 | 18,107 | 9.5 | 290 | 59,148 | 18,761 | 31.7 |

| 251 | 220,823 | 57,319 | 26.0 | 251 | 122,997 | 29,199 | 23.7 |

| 250 | 290,632 | 53,256 | 18.3 | 250 | 226,283 | 52,831 | 23.4 |

| 250 | 476,063 | 69,435 | 14.6 | 251 | 88,356 | 26,902 | 30.5 |

| 250 | 161,744 | 8323 | 5.2 | 258 | 128,532 | 21,427 | 16.7 |

| 258 | 199,664 | 58,945 | 29.5 | 257 | 133,059 | 43,623 | 32.8 |

| 259 | 141,592 | 25,928 | 18.3 | 258 | 115,448 | 24,221 | 21.0 |

| 225 | 641,263 | 18,993 | 3.0 | 259 | 224,878 | 42,732 | 19.0 |

| 225 | 914,578 | 11,938 | 1.3 | 225 | 405,659 | 97,278 | 24.0 |

| 225 | 665,988 | 30,185 | 4.5 | 225 | 134,329 | 37,328 | 27.8 |

| 226 | 233,245 | 16,008 | 6.9 | 226 | 505,834 | 115,000 | 22.7 |

| 226 | 391,755 | 31,750 | 8.1 | 225 | 222,345 | 44,690 | 20.1 |

| 235 | 455,050 | 42,625 | 9.4 | 235 | 206,528 | 35,318 | 17.1 |

| 225 | 354,816 | 50,815 | 14.3 | ||||

| 236 | 414,825 | 103,724 | 25.0 | ||||

| 234 | 149,794 | 33,563 | 22.4 | ||||

| %H Mean | 15.5 | %H Mean | 23.5 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolfart, J.; Staub de Melo, J.V.; Manfro, A.L.; Barra, B.S.; Barbosa, R.C. Effects of the Combined Incorporation of ZnO and TiO2 Nanoparticles on the Mechanical, Rheological, Thermal, and Healing Properties of a Dense Polymeric Asphalt Mixture. Nanomaterials 2025, 15, 1779. https://doi.org/10.3390/nano15231779

Wolfart J, Staub de Melo JV, Manfro AL, Barra BS, Barbosa RC. Effects of the Combined Incorporation of ZnO and TiO2 Nanoparticles on the Mechanical, Rheological, Thermal, and Healing Properties of a Dense Polymeric Asphalt Mixture. Nanomaterials. 2025; 15(23):1779. https://doi.org/10.3390/nano15231779

Chicago/Turabian StyleWolfart, Jaqueline, João Victor Staub de Melo, Alexandre Luiz Manfro, Breno Salgado Barra, and Rafael Cassimiro Barbosa. 2025. "Effects of the Combined Incorporation of ZnO and TiO2 Nanoparticles on the Mechanical, Rheological, Thermal, and Healing Properties of a Dense Polymeric Asphalt Mixture" Nanomaterials 15, no. 23: 1779. https://doi.org/10.3390/nano15231779

APA StyleWolfart, J., Staub de Melo, J. V., Manfro, A. L., Barra, B. S., & Barbosa, R. C. (2025). Effects of the Combined Incorporation of ZnO and TiO2 Nanoparticles on the Mechanical, Rheological, Thermal, and Healing Properties of a Dense Polymeric Asphalt Mixture. Nanomaterials, 15(23), 1779. https://doi.org/10.3390/nano15231779