Microstructure Evolution and Mechanical Properties of Fe-25Ni-15Cr Alloy During Cumulative Cold-Drawing Deformation Process

Abstract

1. Introduction

2. Materials and Methods

3. Results

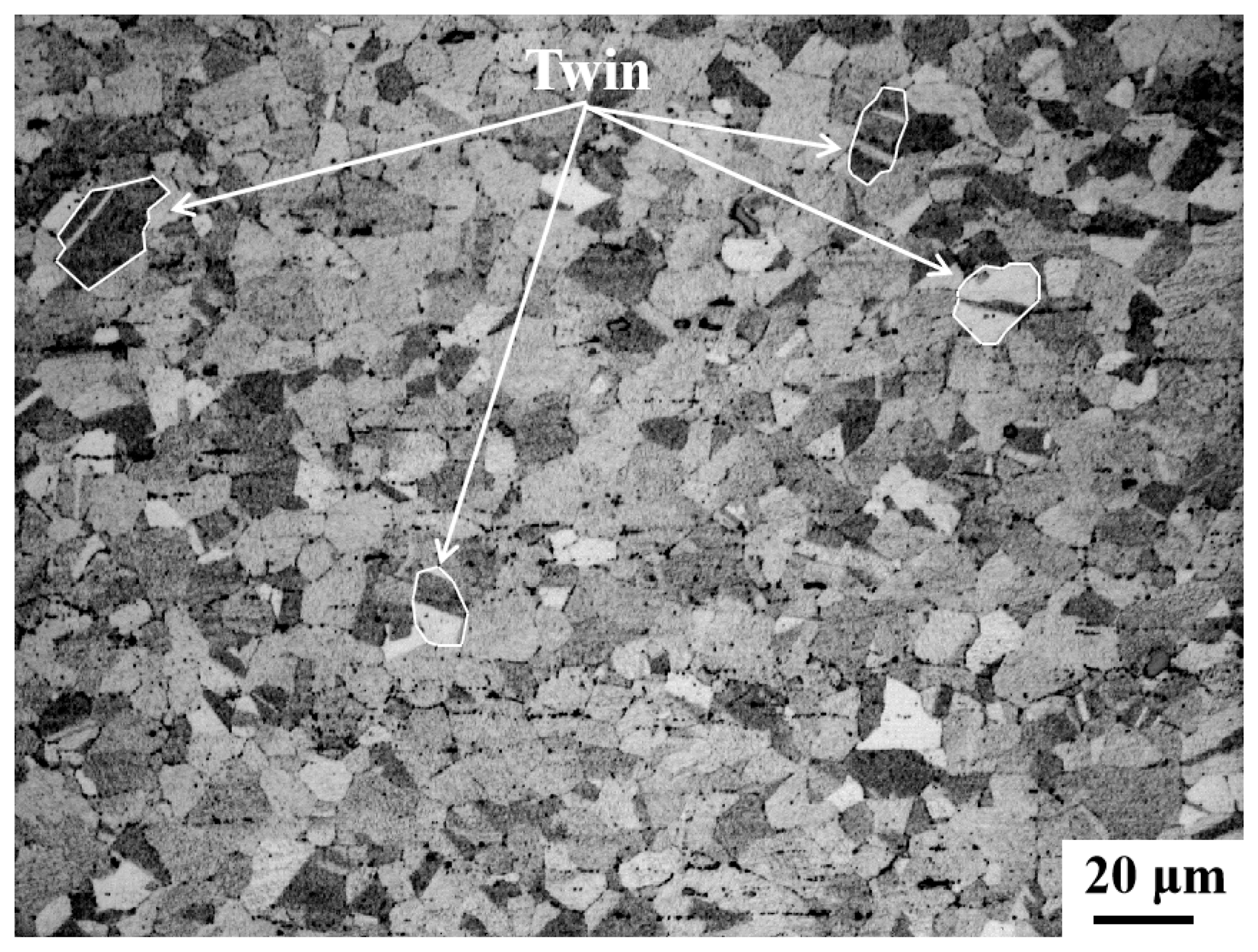

3.1. Cold-Drawn Billet

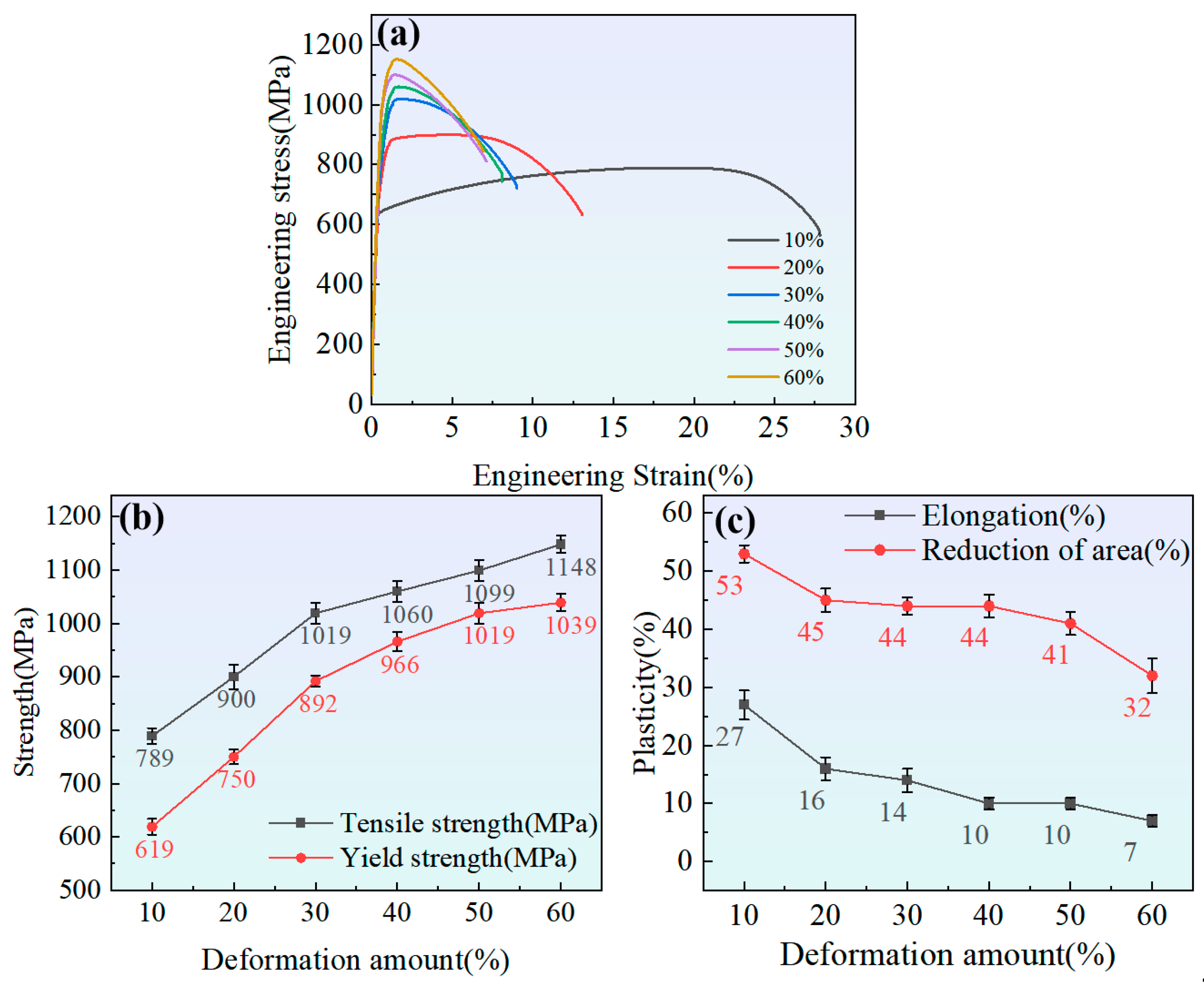

3.2. Room-Temperature Hardness and Tensile Change

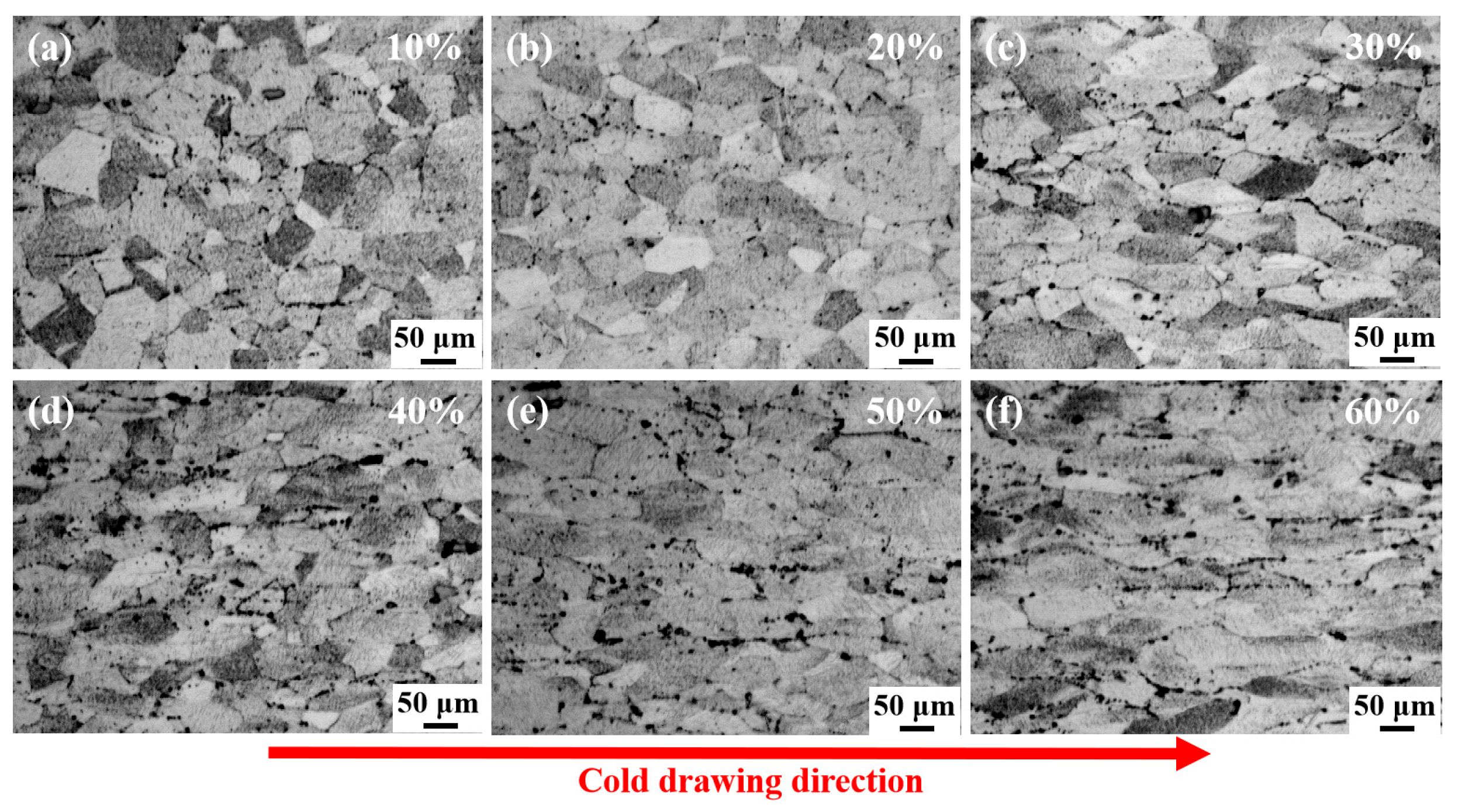

3.3. Microstructural Evolution

4. Discussion

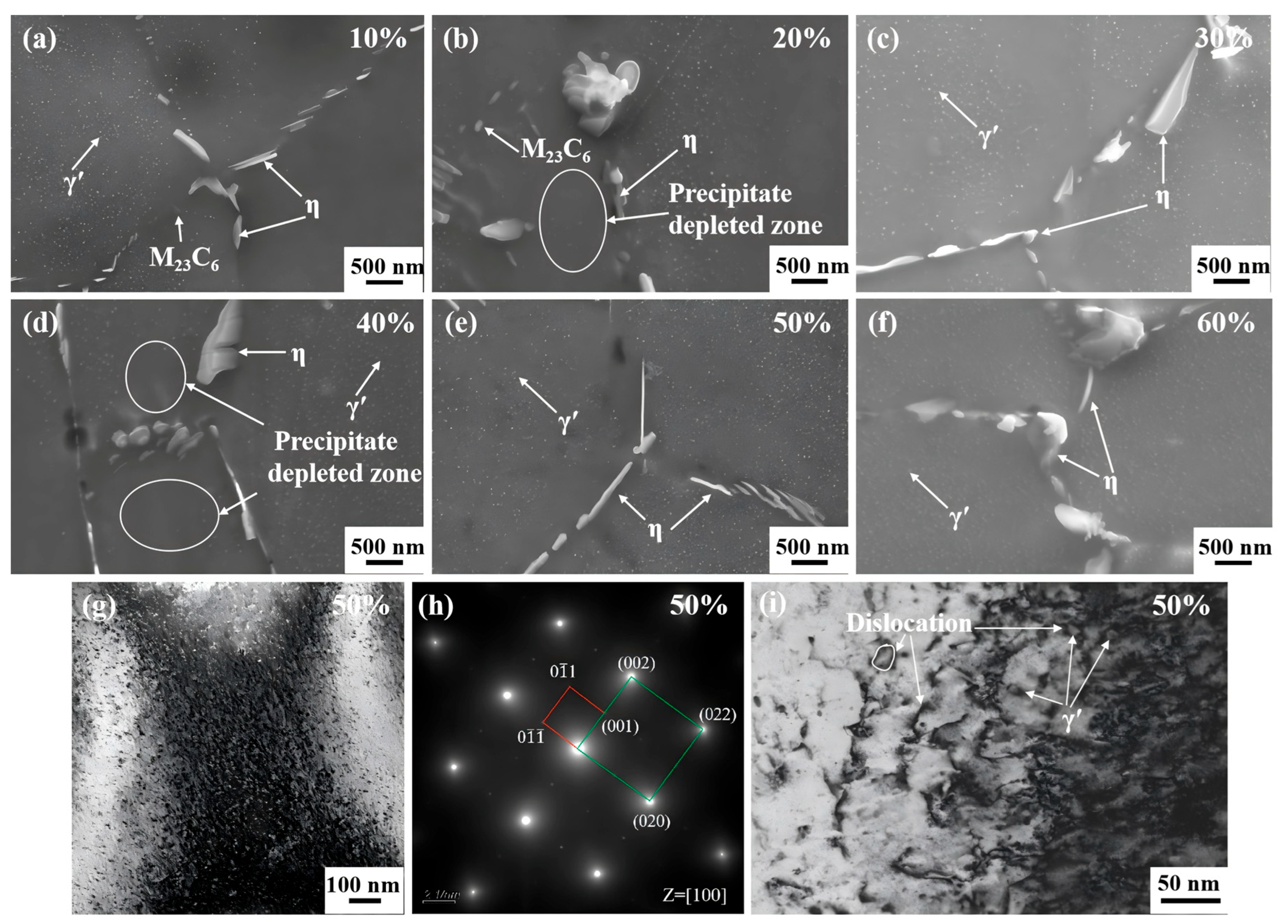

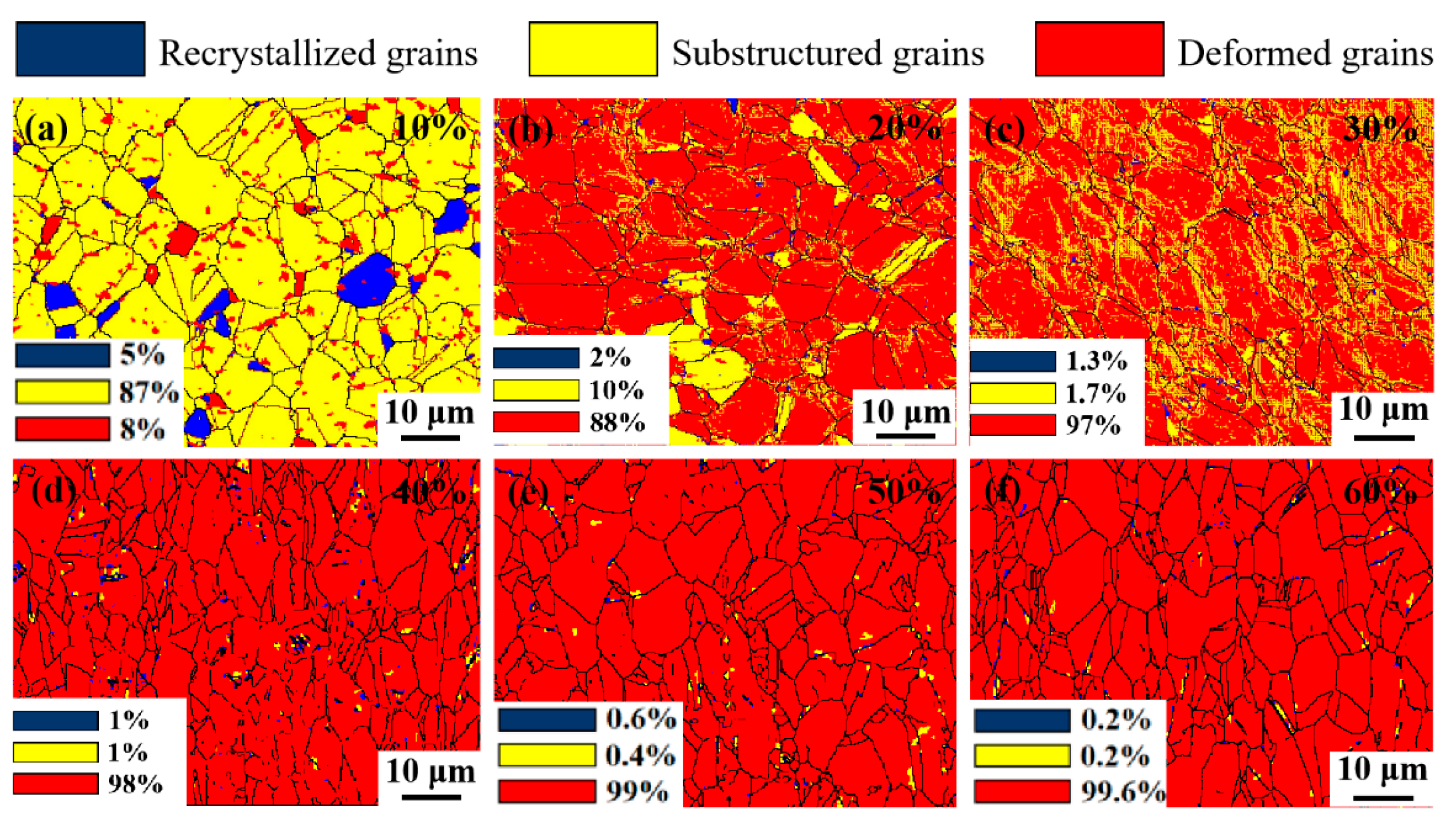

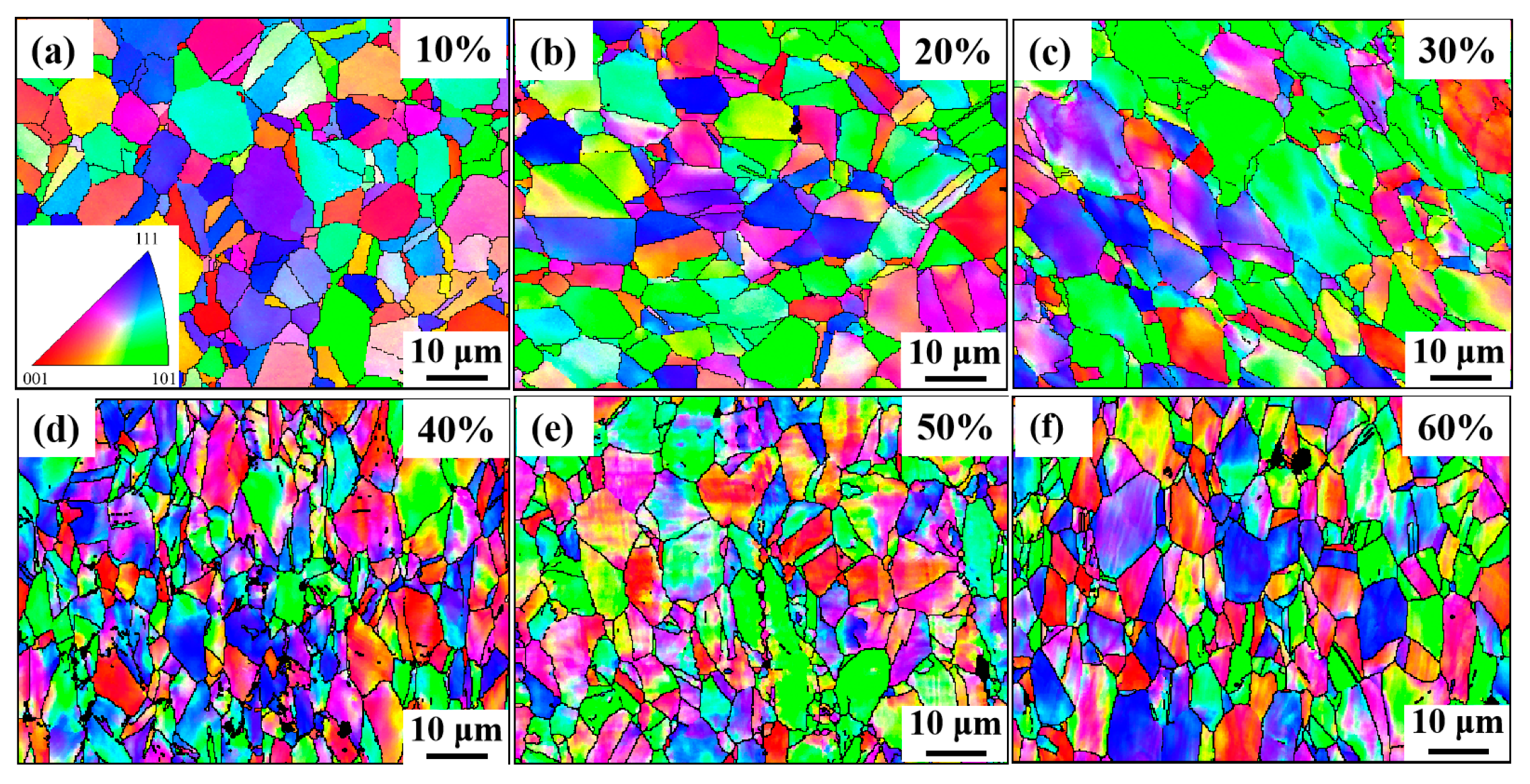

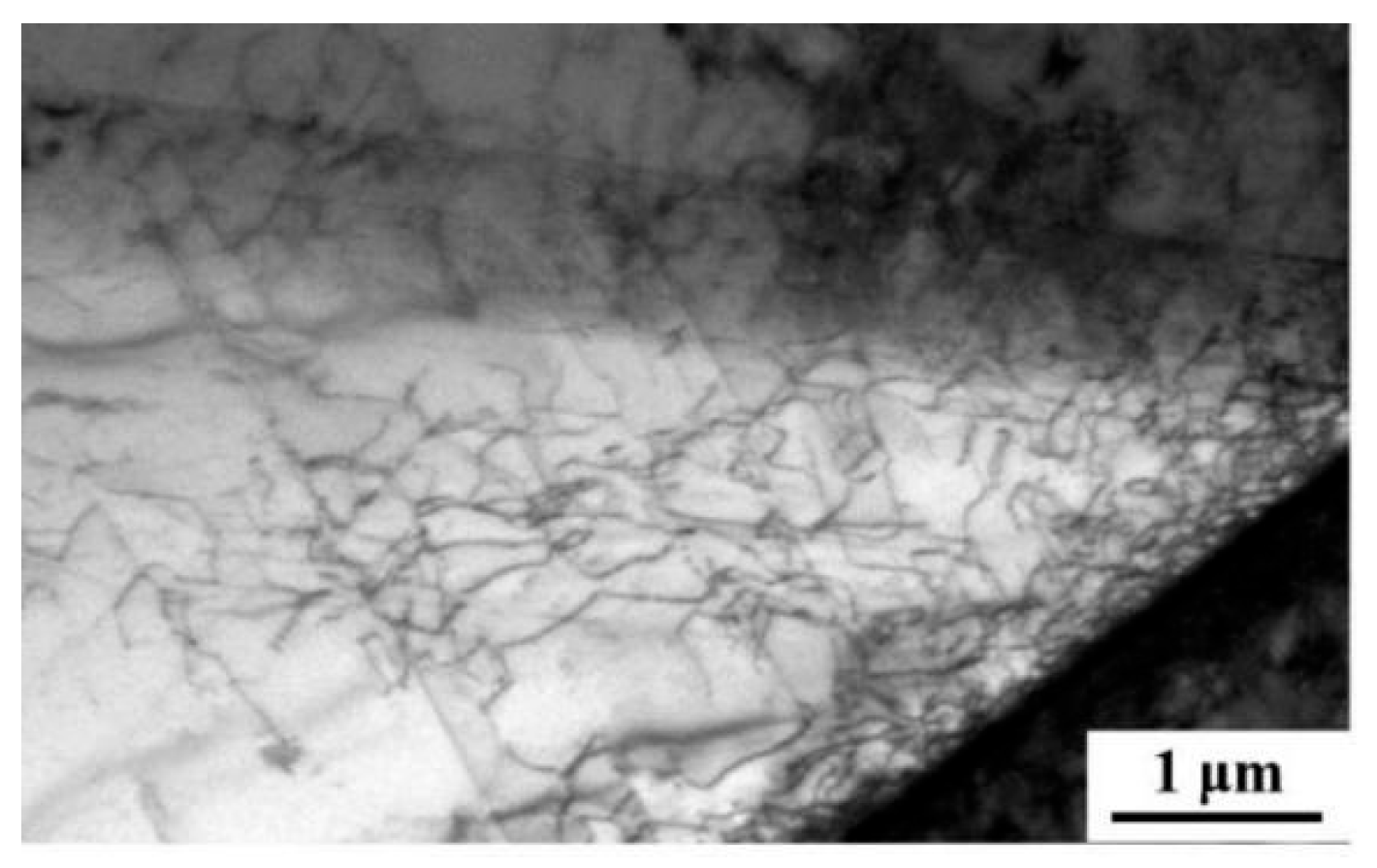

4.1. The Influence of Cold-Drawing Deformation on Microstructure

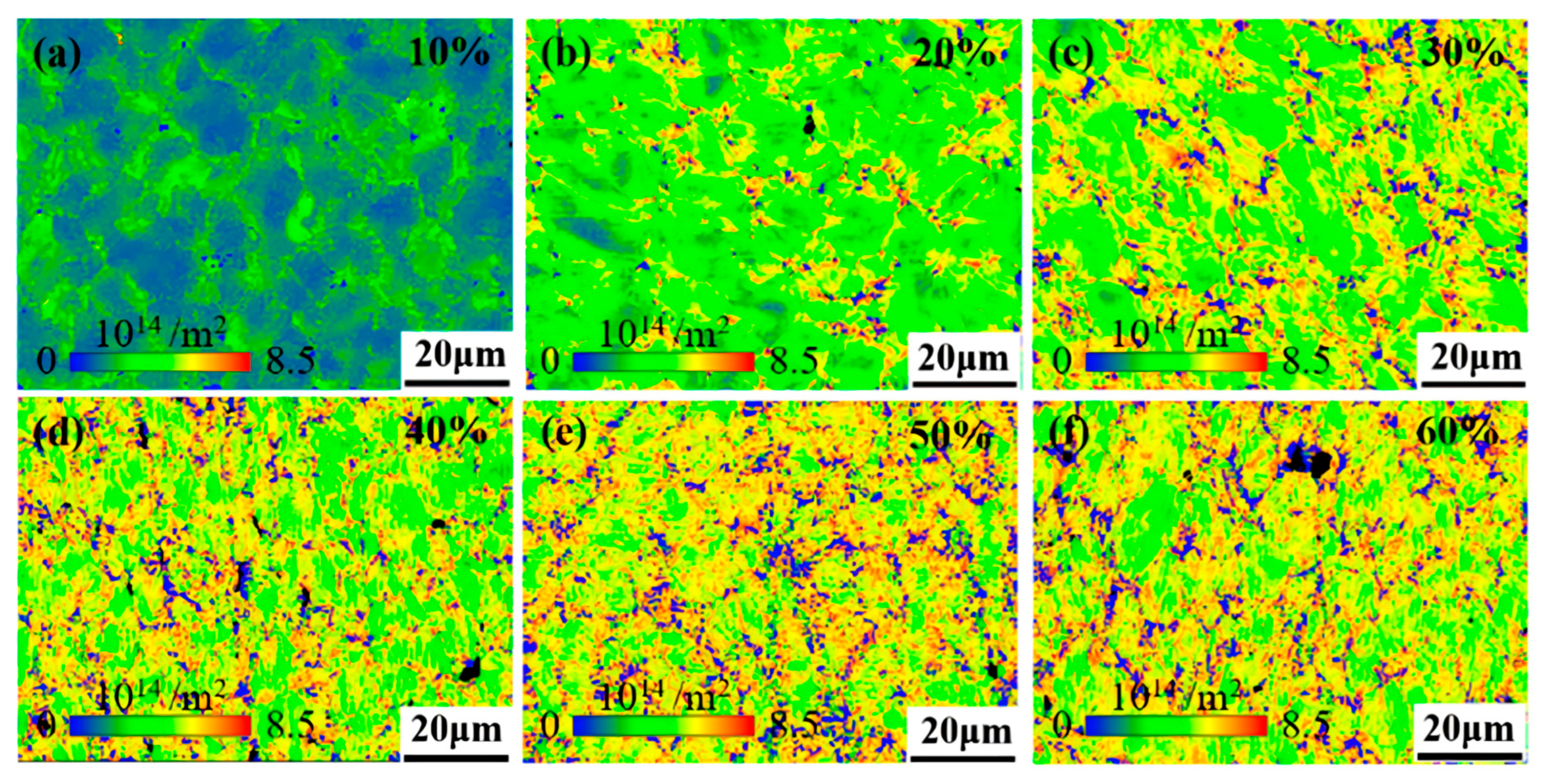

4.2. The Influence of Cold-Drawing Deformation on Dislocations

4.3. The Influence of Microstructure Evolution on Mechanical Properties

5. Conclusions

- (1)

- When the cumulative deformation amount reaches 50%, the grains transform from equiaxed to fibrous structures; dislocation density accumulates preferentially at the grain boundaries and forms cellular substructures, while the texture orientation gradually stabilizes from random distribution to the <111> direction.

- (2)

- Fe-25Ni-15Cr alloy bars fabricated via vacuum induction melting, electroslag remelting, forging, hot rolling, and annealing processes exhibit three strengthening mechanisms during cold drawing: grain refinement strengthening, second-phase precipitation strengthening, and work hardening.

- (3)

- When the deformation amount is less than 30%, the hardness, tensile strength, and yield strength increase significantly with the increase in deformation amount, while the plasticity and toughness continue to decline. This is mainly attributed to the increase in dislocation density, grain refinement, and the formation of cellular substructures. However, when the cumulative deformation amount exceeds 30%, the grain vibration and dislocation density tend to saturate, resulting in a weakened strengthening effect and a significant decrease in the rate of increase in hardness and strength.

- (4)

- The prediction model of the cold drawing and tensile strength cumulative deformation amount is obtained through experiments and theoretical calculations:

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, Y.L.; Feng, Z.G.; Tao, L.; Liu, Y. Mechanistic insights into twin fragmentation during plastic deformation of A286 superalloy. Eng. Fail. Anal. 2025, 170, 109334. [Google Scholar] [CrossRef]

- Huang, S.; Sun, R.K.; Wang, L.; Dong, D.Y.; Duan, R.; Song, X.; Liu, Y. Microstructure evolution and fracture mechanism of a Fe–Ni–Cr superalloy during various strain rates tensile deformation at elevated temperatures. J. Mater. Sci. 2023, 58, 5901–5920. [Google Scholar] [CrossRef]

- Seifollahi, M.; Razavi, S.; Kheirandish, S.; Abbasi, S. The mechanism of η phase precipitation in A286 superalloy during heat treatment. J. Mater. Eng. Perform. 2013, 22, 3063–3069. [Google Scholar] [CrossRef]

- Fukunaga, A. Effect of high-pressure hydrogen environment in elastic and plastic deformation regions on slow strain rate tensile tests for iron-based superalloy A286. Int. J. Hydrogen Energy 2023, 48, 18116–18128. [Google Scholar] [CrossRef]

- Günen, A.; Keddam, M.; Alkan, S.; Erdoğan, A.; Çetin, M. Microstructural characterization, boriding kinetics and tribo-wear behavior of borided Fe-based A286 superalloy. Mater. Charact. 2022, 186, 111778. [Google Scholar] [CrossRef]

- Hu, H.Y.; Zhao, T.J.; Ning, Z.H.; Wen, J.F.; Shen, T.D.; Wang, S.J.; Song, M. A novel age-hardenable austenitic stainless steel with superb printability. Acta Mater. 2025, 283, 120547. [Google Scholar] [CrossRef]

- Liu, G.L.; Huang, C.Z.; Zhu, H.T.; Liu, Z.Q.; Liu, Y.; Li, C.W. The modified surface properties and fatigue life of Incoloy A286 face-milled at different cutting parameters. Mater. Sci. Eng. A 2017, 704, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, Z.; Sun, Z.Y.; Zhao, Y.L.; Cui, Y.; Zhang, Z.W. Effects of Cold Deformation and Heat Treatments on the Microstructure and Properties of Fe-15Cr-25Ni Superalloy Cold-Drawn Bars. Nanomaterials 2024, 14, 1949. [Google Scholar] [CrossRef]

- Sreenu, B.; Sarkar, R.; Kumar, S.S.S.; Chatterjee, S.; Rao, G.A. Microstructure and mechanical behaviour of an advanced powder metallurgy nickel base superalloy processed through hot isostatic pressing route for aerospace applications. Mater. Sci. Eng. A 2020, 797, 140254. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Y.Y.; Hu, L.X.; Ke, Y.B.; Li, D.; Wei, S.H.; Zhang, C.T.F. Quantitative study on dynamic instantaneous dissolution of precipitated phases in 2195-T6 Al-Li alloy based on characterizations with SANS and TEM. Acta Mater. 2024, 266, 119689. [Google Scholar] [CrossRef]

- Müller, Y.L.; Natarajan, A.R. First-principles thermodynamics of precipitation in aluminum-containing refractory alloys. Acta Mater. 2024, 274, 119995. [Google Scholar] [CrossRef]

- Zhou, Z.F.; Li, R.G.; Wang, Y.K.; Li, S.L.; Song, C.; Xie, G.; Zhang, J.; Cheng, G.F.; Feng, Q.; Cormier, J.; et al. Heterogeneous fatigue damage in a nickel-based single-crystal superalloy unraveled using correlative 3D X-ray technology. Acta Mater. 2025, 297, 121326. [Google Scholar] [CrossRef]

- Rao, C.V.; Srinivas, N.C.S.; Sastry, G.V.S.; Singh, V. Dynamic strain aging, deformation and fracture behaviour of the nickel base superalloy Inconel 617. Mater. Sci. Eng. A 2019, 742, 44–60. [Google Scholar] [CrossRef]

- Li, P.F.; Wang, S.L.; Li, X.D.; Yin, J.; Gao, H.Z.; Xiang, X.J. Preparation of TC4-TA15 Bimetallic Materials by Laser Melting Deposition: Microstructure and Mechanical Properties at the Interfacial Union. JOM 2025, 77, 1873–1884. [Google Scholar] [CrossRef]

- Wang, L.; Jiao, Y.C.; Liu, R.F.; Wang, D.Y.; Yu, Z.G.; Xi, Y.T.; Zhang, K.R.; Xu, S.N.; Liu, H.T.; Wen, L.; et al. A Review of Mechanical Properties and Improvement Methods of Medium Entropy Alloys at High Temperature. JOM 2024, 76, 353–361. [Google Scholar] [CrossRef]

- Gao, Z.J. Study on Hot Drawing Behavior and Microstructure Characterization of Ti-6Al-4V Alloy Wire. Master’s Thesis, Yantai University, Yantai, China, 2025. [Google Scholar]

- Gilakjani, R.S.; Razavi, S.H.; Seifollahi, M. An investigation on thermodynamics and kinetics of η phase formation in Nb-modified iron-nickel base A286 superalloy. Metall. Res. Technol. 2021, 118, 105. [Google Scholar] [CrossRef]

- Ali, U.; Qurashi, M.S.; Lartey, P.O.; Jin, X.; Qiao, J.W. Influence of η-(Ni3Ti) and TiC phases on corrosion resistance and mechanical properties of A286 austenitic superalloy after heat treatment. Int. J. Electrochem. Sci. 2023, 18, 100208. [Google Scholar] [CrossRef]

- Wang, H.; Cai, Z.W.; Dong, H.; Liu, Y.Z.; Wang, W.Z. Mechanical-chemical-coupled peridynamic model for the corrosion fatigue behavior of a nickel-based alloy. Int. J. Fatigue 2023, 168, 107400. [Google Scholar] [CrossRef]

- Fukunaga, A. Differences between internal and external hydrogen effects on slow strain rate tensile test of iron-based superalloy A286. Int. J. Hydrogen Energy 2022, 47, 2723–2734. [Google Scholar] [CrossRef]

- Nakkalil, R.; Richards, N.L.; Chaturvedi, M.C. The influence of solidification mode on heat affected zone microfissuring in a nickel-iron base superalloy. Acta Metall. Et Mater. 1993, 41, 3381–3392. [Google Scholar] [CrossRef]

- Hu, H.L.; Zhao, M.J.; Rong, L.J. Retarding the precipitation of η phase in Fe-Ni based alloy through grain boundary engineering. J. Mater. Sci. Technol. 2020, 47, 152–161. [Google Scholar] [CrossRef]

- Qin, H.Y.; Pei, B.H.; Dong, J.; Zhang, M.C. Study on Cold Drawing Process of High-Strength Alloy GH2132. J. Iron Steel Res. 2010, 22, 48–52. [Google Scholar]

- Liu, S.C.; Gao, Y.; Lin, Z.L.; Guo, S.S.; Zhang, X.B.; Yin, X.J. Microstructure and properties after deformation and aging process of A286 superalloy. Rare Met. 2019, 38, 864–870. [Google Scholar] [CrossRef]

- Li, M.H.; Zhang, X.F.; Cao, M.M.; Zhou, Z.; Rao, J.S.; Yi, S.; Zhang, Y.X.; Fu, J.W.; Chen, L.M.; Ding, S.L. Wear resistance of molybdenum disulfide-based coatings on titanium alloys: A review. J. Mater. Sci. 2024, 59, 6662–6684. [Google Scholar] [CrossRef]

- Xiao, L.; Chen, D.L.; Chaturvedi, M.C. Shearing of γ″ precipitates and formation of planar slip bands in Inconel 718 during cyclic deformation. Scr. Mater. 2005, 52, 603–607. [Google Scholar] [CrossRef]

- Hou, G.C.; Xie, J.; Yu, J.J.; Sun, X.F.; Zhou, Y.Z. Room temperature tensile behaviour of K640S Co-based superalloy. Mater. Sci. Technol. 2019, 35, 530–535. [Google Scholar] [CrossRef]

- Huang, S.; Hu, J.; Li, X.Y.; Liu, J.M.; Liu, K.K.; Qin, H.Y.; Wang, H.C. Influence of deformation degree at cold drawing on structure-properties relationship of a Fe-Ni-Cr superalloy. J. Alloys Compd. 2023, 930, 167407. [Google Scholar] [CrossRef]

- Yan, F.K.; Liu, G.Z.; Tao, N.R.; Lu, K. Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 2012, 60, 1059–1071. [Google Scholar] [CrossRef]

- Ma, X.G.; Chen, J.; Wang, X.H.; Xu, Y.J.; Xue, Y.J. Microstructure and mechanical properties of cold drawing CoCrFeMnNi high entropy alloy. J. Alloys Compd. 2019, 795, 45–53. [Google Scholar] [CrossRef]

- Tian, Z.; Zhou, L.C.; Shi, C.J.; Li, R.G.; Yang, F.; Xia, Y.P.; Zhang, X.D.; Jiang, J.Q.; Fang, F. Achieving a saturated tensile strength of face-centered cubic Al2.5Ti2.5(CoCrFeNi)95 high-entropy alloy via severe cold drawing. J. Mater. Sci. Technol. 2026, 244, 173–179. [Google Scholar] [CrossRef]

- Luo, X.M.; Song, Z.M.; Li, M.L.; Wang, Q.; Zhang, G.P. Microstructural Evolution and Service Performance of Cold-drawn Pure Aluminum Conductor Wires. J. Mater. Sci. Technol. 2017, 33, 1039–1043. [Google Scholar] [CrossRef]

- Huo, W.Y.; Fang, F.; Zhou, H.; Xie, Z.H.; Shang, J.K.; Jiang, J.Q. Remarkable strength of CoCrFeNi high-entropy alloy wires at cryogenic and elevated temperatures. Scr. Mater. 2017, 141, 125–128. [Google Scholar] [CrossRef]

- GB/T 228.1-2010; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. AQSIQ: Beijing, China, 2010.

- Li, L.L.; Ding, Q.Q.; Zhang, Z.Q.; Li, Y.K.; Wei, X.; Zhang, Z.; Bei, H.B. The effect of Al and Ti on the microstructure, mechanical properties and oxidation resistance of γ′-Ni3(Al, Ti) strengthened austenitic stainless steels. J. Mater. Res. Technol. 2023, 24, 4650–4660. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.X.; Wang, A.D. Microstructural evolution and recrystallization of GH4698 superalloy during cold drawing. Trans. Mater. Heat Treat. 2025, 46, 140–151. [Google Scholar]

- Shahedi, R.; Kheirandish, S.; Shirazi, F.; Seifollahi, M. The effect of solid solution treatment parameters on the microstructure and mechanical properties of A286 superalloy. Metall. Res. Technol. 2021, 118, 517. [Google Scholar] [CrossRef]

- Schayes, C.; Bouquerel, J.; Vogt, J.B.; Palleschi, F.; Zaefferer, S. A comparison of EBSD based strain indicators for the study of Fe-3Si steel subjected to cyclic loading. Mater. Charact. 2016, 115, 61–70. [Google Scholar] [CrossRef]

- An, Z.B.; Mao, S.C.; Liu, Y.N.; Zhou, H.; Zhai, Y.D.; Tian, Z.Y.; Liu, C.X.; Zhang, Z.; Han, X.D. Hierarchical grain size and nanotwin gradient microstructure for improved mechanical properties of a non-equiatomic CoCrFeMnNi high-entropy alloy. J. Mater. Sci. Technol. 2021, 92, 195–207. [Google Scholar] [CrossRef]

- Yang, C.L.; Shen, H.J.; Wang, G.D.; Wang, Z.X. Microstructure evolution behavior of GH4169 alloy during solution and cold drawing process. Heat Treat. Met. 2023, 48, 231–238. [Google Scholar]

- Mei, Y.P.; Liu, Y.C.; Liu, C.X.; Li, C.; Yu, L.M.; Guo, Q.Y.; Li, H.J. Effects of cold rolling on the precipitation kinetics and the morphology evolution of intermediate phases in Inconel 718 alloy. J. Alloys Compd. 2015, 649, 949–960. [Google Scholar] [CrossRef]

- Wang, Z.G.; Yang, Y.J.; TIan, S.X.; Yang, X.L.; Zhang, P.; Ren, H. Influence of Cold Drawing Process on Microstructures and Tensile Properties of Alloy GH3625. J. Iron Steel Res. 2011, 23, 92–95. [Google Scholar]

- Jiang, S.Y.; Hu, L.; Zhang, Y.Q.; Liang, Y.L. Nanocrystallization and amorphization of NiTi shape memory alloy under severe plastic deformation based on local canning compression. J. Non-Cryst. Solids 2013, 367, 23–29. [Google Scholar] [CrossRef]

- Zhu, Q.; Sun, Y.Y.; Liu, K.; Zhang, L.F.; Fan, G.H.; Zhang, P. Synergistic improvement of micro-tensile strength and ductility in CoCrNiMo medium-entropy alloys: Dynamic Hall-Petch effect dependent on deformation twinning. J. Alloys Compd. 2025, 1037, 182629. [Google Scholar] [CrossRef]

- Keerti, S.; Yang, X.L.; Babu, N.H. A generic Hall-Petch relationship in metallic materials with varied grain morphology. Mater. Sci. Eng. A 2025, 943, 148764. [Google Scholar] [CrossRef]

| Elements | C | Fe | Ni | Cr | Mo | Co | Ti | Al | V |

|---|---|---|---|---|---|---|---|---|---|

| Content | 0.05 | 53.90 | 24.56 | 15.12 | 1.26 | 0.20 | 1.79 | 0.19 | 0.32 |

| Elements (at%) | C | Fe | Ni | Cr | Mo | Ti | Al |

|---|---|---|---|---|---|---|---|

| 10% deformation amount | 20.66 ± 3 | 41.20 ± 2 | 17.50 ± 1 | 11.12 ± 0.5 | 0.62 ± 0.1 | 1.91 ± 0.1 | 0.64 ± 0.1 |

| 20% deformation amount | 20.80 ± 3 | 40.50 ± 2 | 18.90 ± 1 | 12.30 ± 0.5 | 0.60 ± 0.1 | 2.04 ± 0.1 | 0.60 ± 0.1 |

| ε | Actual Value (MPa) | Model Predicted Value (MPa) | Error (%) |

|---|---|---|---|

| 0.1 | 789 | 968 | 22.6 |

| 0.2 | 900 | 1012 | 12.4 |

| 0.3 | 1019 | 1048 | 2.8 |

| 0.4 | 1060 | 1080 | 1.8 |

| 0.5 | 1099 | 1109 | 0.9 |

| 0.6 | 1148 | 1136 | 1.0 |

| Average error | 6.9 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, Z.; Chen, W.; Tian, Z.; An, X.; Zhang, Y.; Zhang, Z. Microstructure Evolution and Mechanical Properties of Fe-25Ni-15Cr Alloy During Cumulative Cold-Drawing Deformation Process. Nanomaterials 2025, 15, 1717. https://doi.org/10.3390/nano15221717

Zhang Y, Zhang Z, Chen W, Tian Z, An X, Zhang Y, Zhang Z. Microstructure Evolution and Mechanical Properties of Fe-25Ni-15Cr Alloy During Cumulative Cold-Drawing Deformation Process. Nanomaterials. 2025; 15(22):1717. https://doi.org/10.3390/nano15221717

Chicago/Turabian StyleZhang, Yunfei, Zhen Zhang, Wei Chen, Zhongjie Tian, Xueliang An, Yang Zhang, and Zhongwu Zhang. 2025. "Microstructure Evolution and Mechanical Properties of Fe-25Ni-15Cr Alloy During Cumulative Cold-Drawing Deformation Process" Nanomaterials 15, no. 22: 1717. https://doi.org/10.3390/nano15221717

APA StyleZhang, Y., Zhang, Z., Chen, W., Tian, Z., An, X., Zhang, Y., & Zhang, Z. (2025). Microstructure Evolution and Mechanical Properties of Fe-25Ni-15Cr Alloy During Cumulative Cold-Drawing Deformation Process. Nanomaterials, 15(22), 1717. https://doi.org/10.3390/nano15221717