The Research on Multi-Process Collaborative Manufacturing and Characterization Methods of Micro–Nano-Composite Layered Structures

Abstract

1. Introduction

2. Structure and Simulation

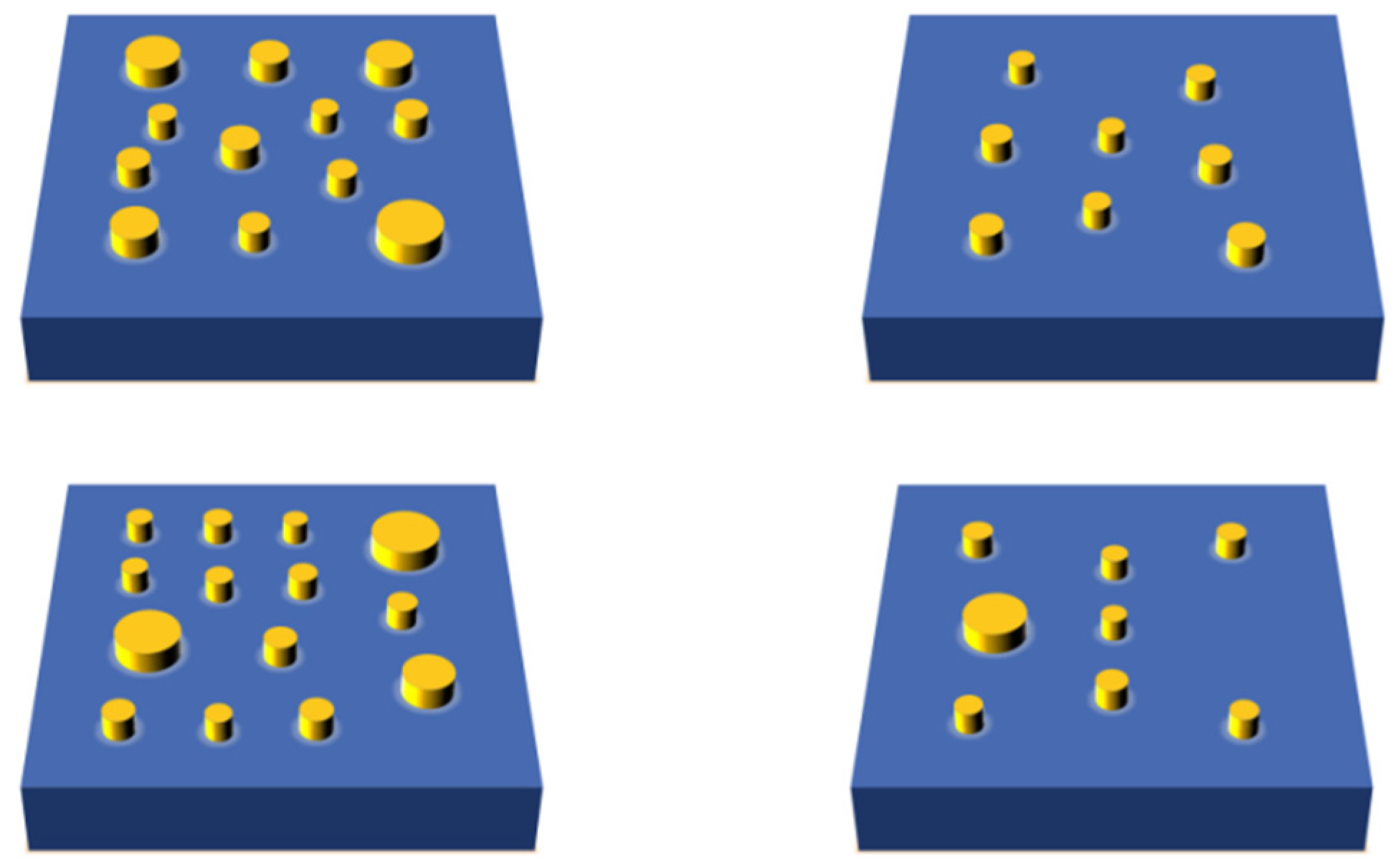

2.1. Micronano-Composite Layered Structures

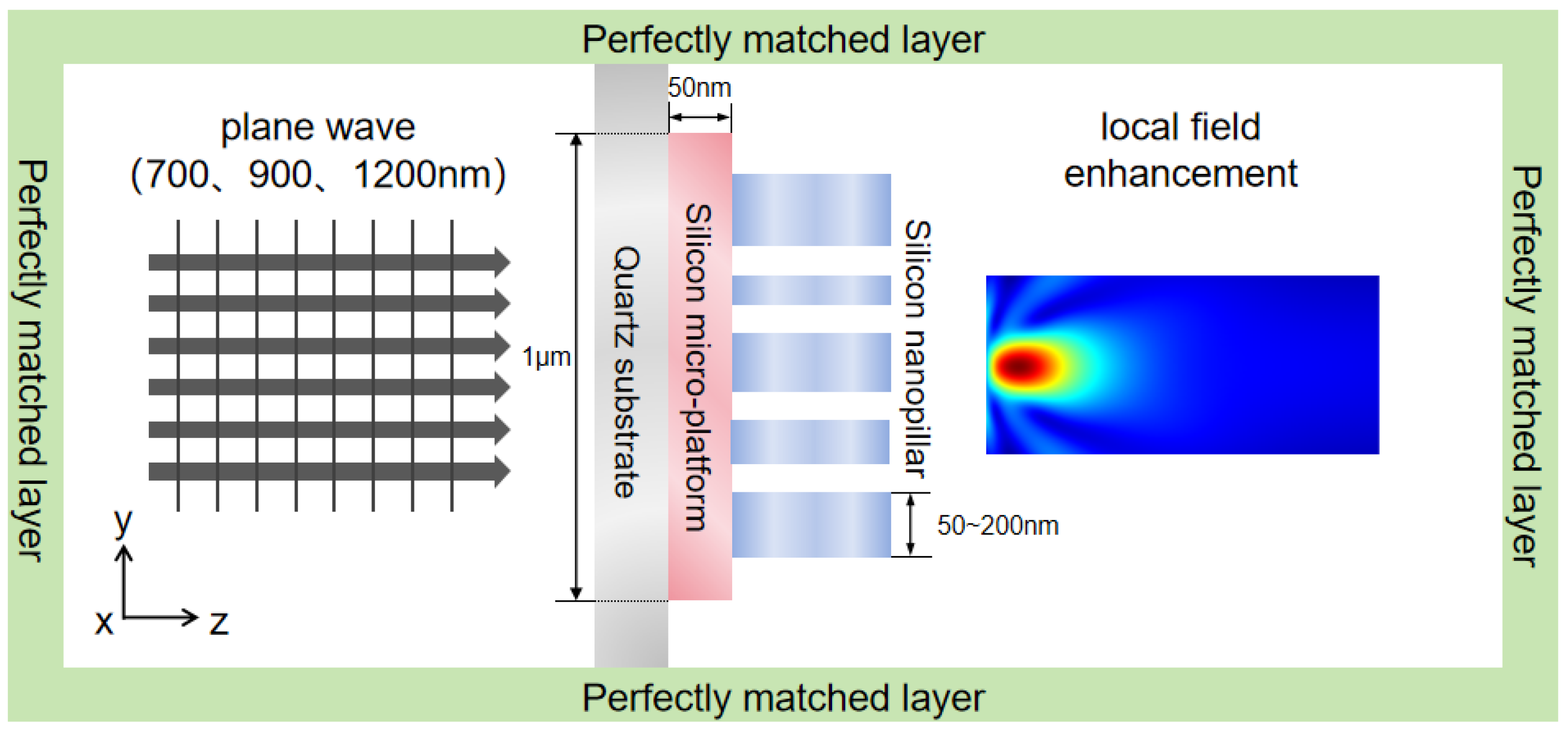

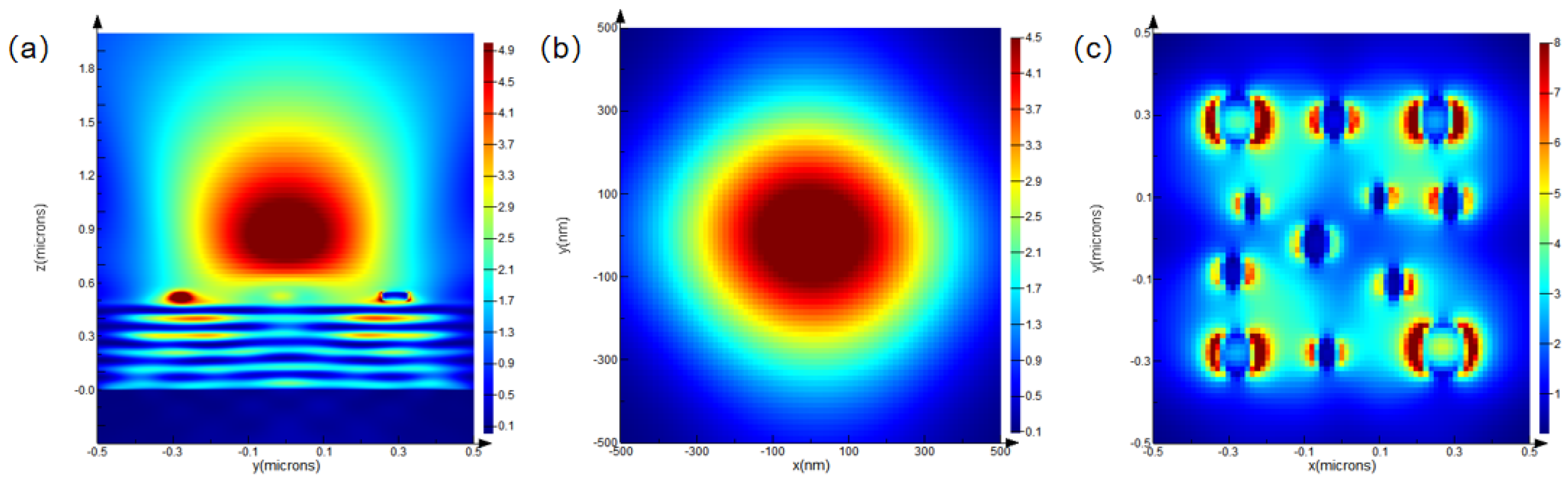

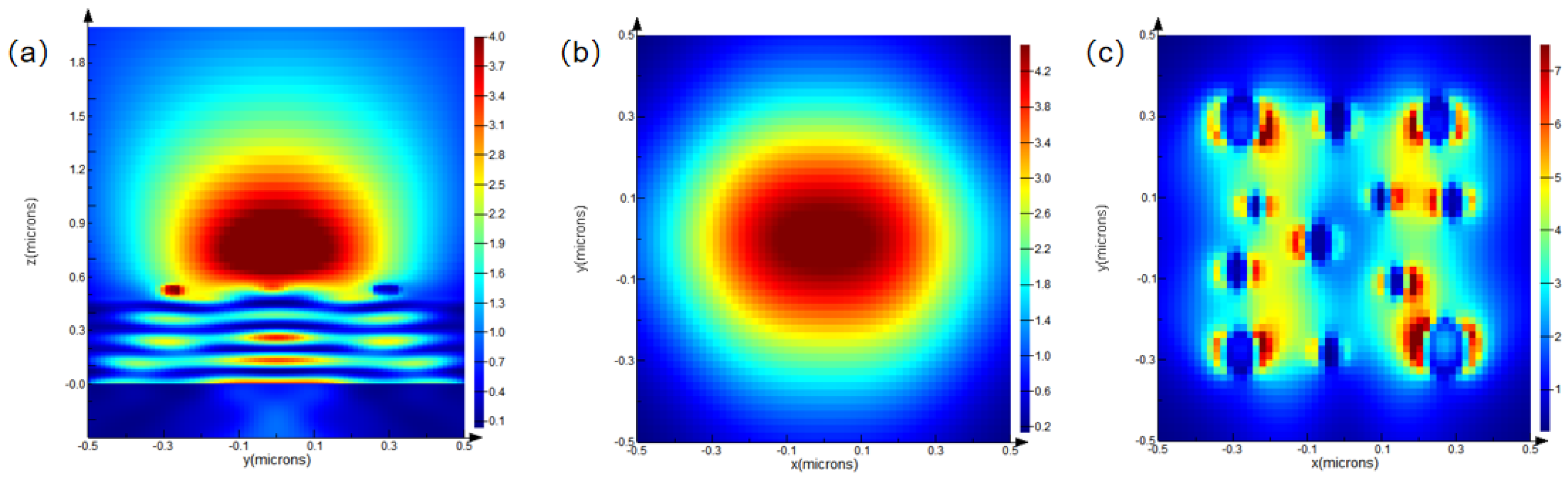

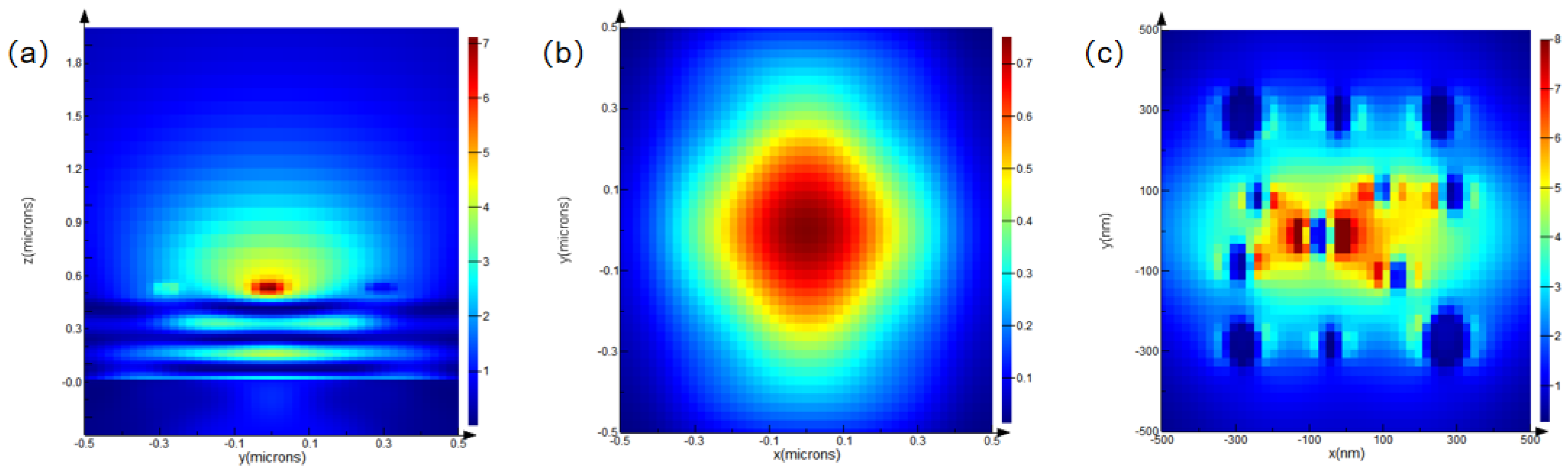

2.2. Structural Numerical Simulation

3. Methods

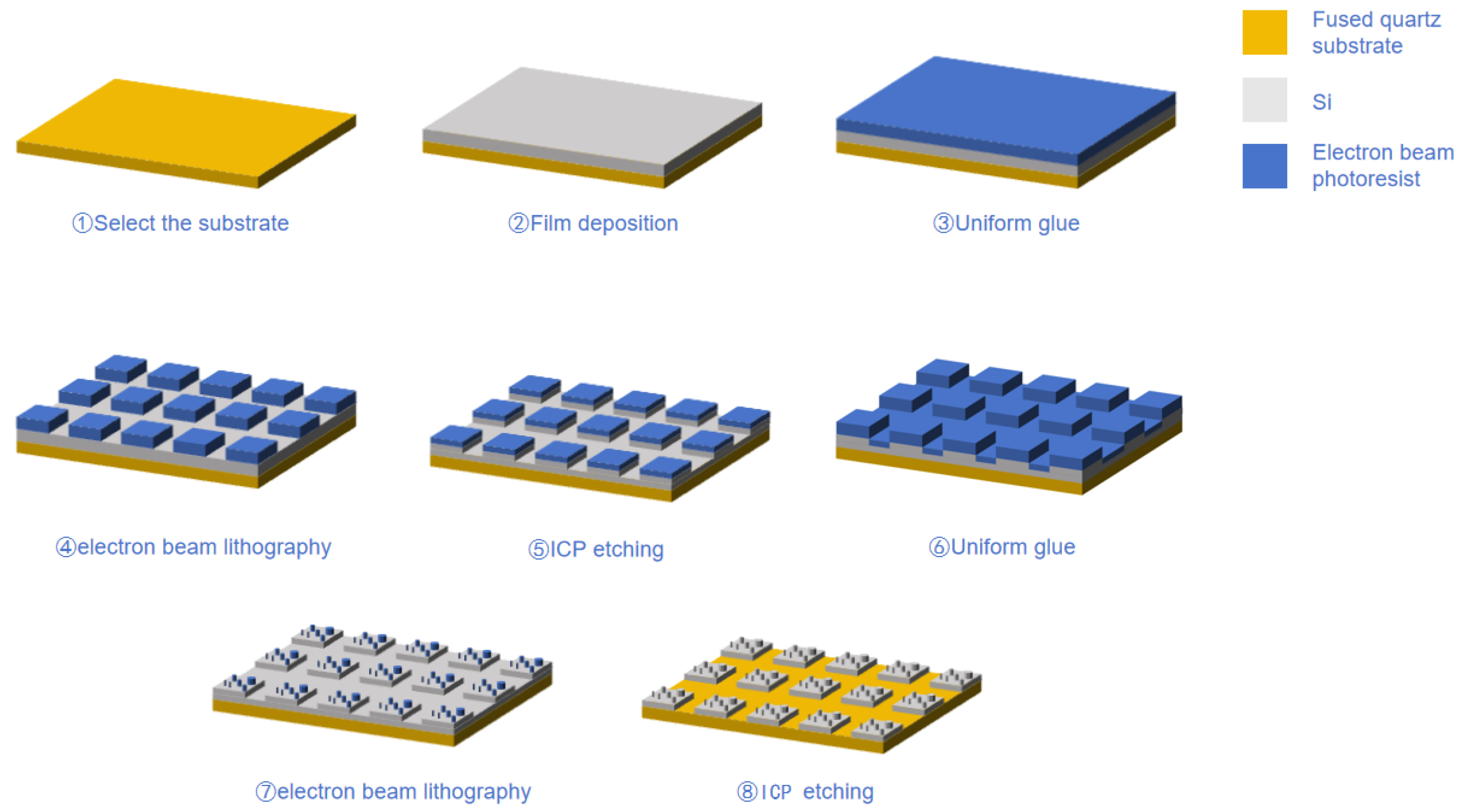

3.1. Stepwise Processes of EBL and ICP

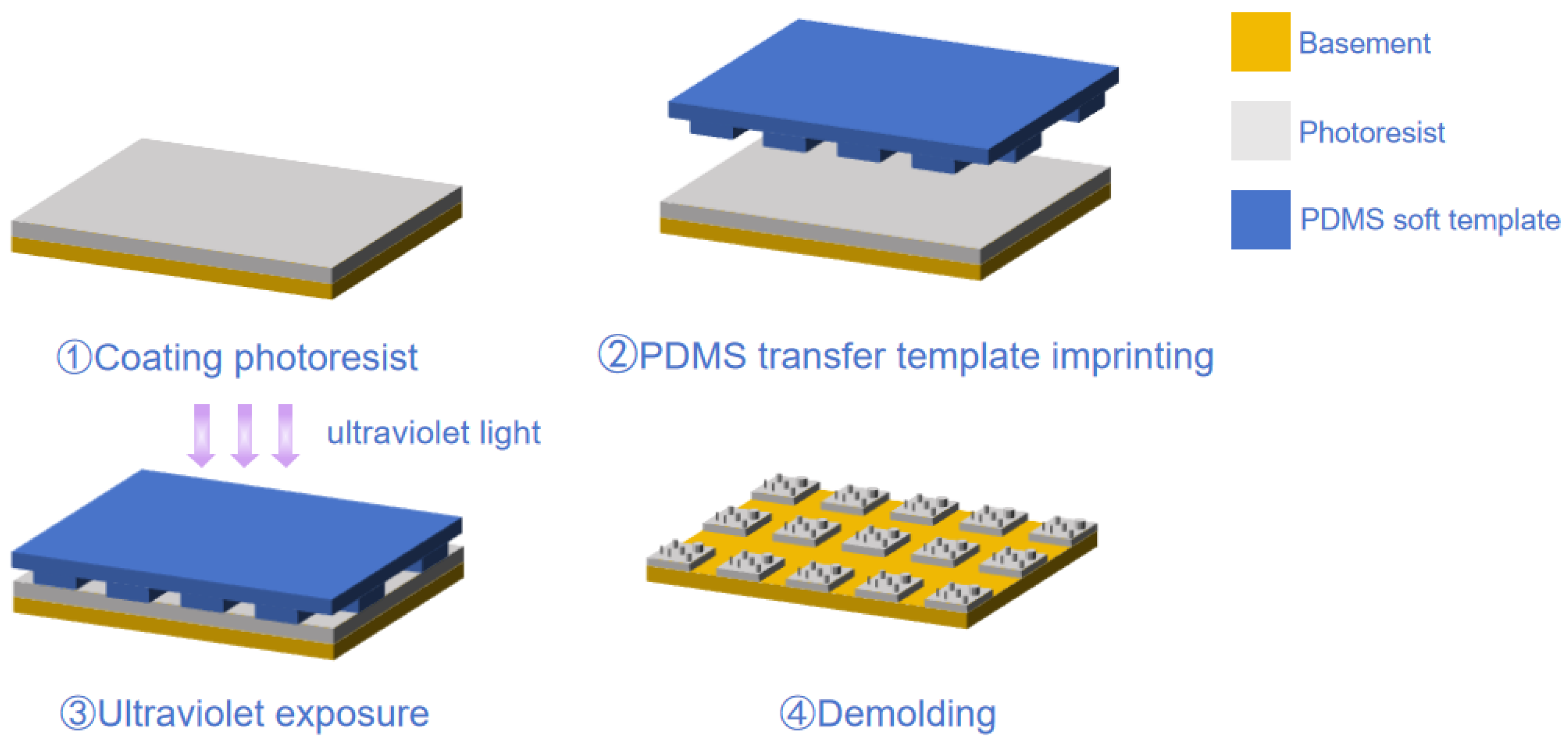

3.2. NIL Process

4. Results and Discussion

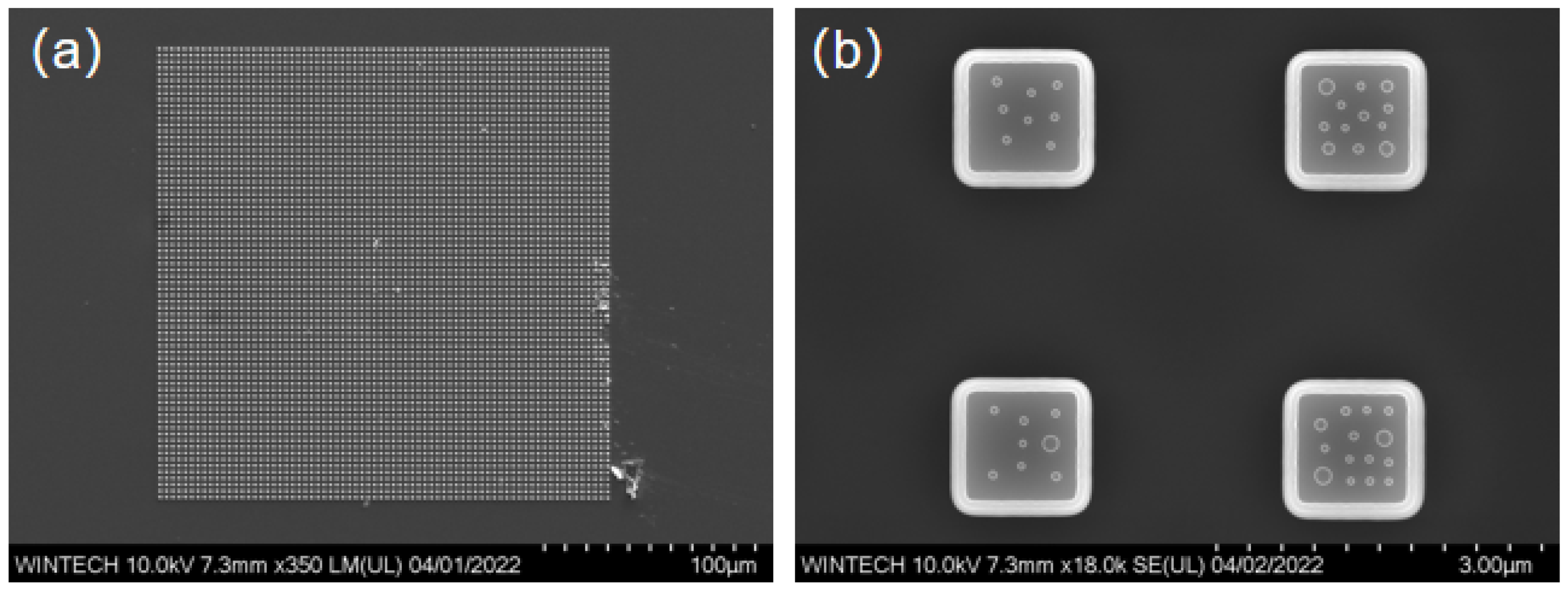

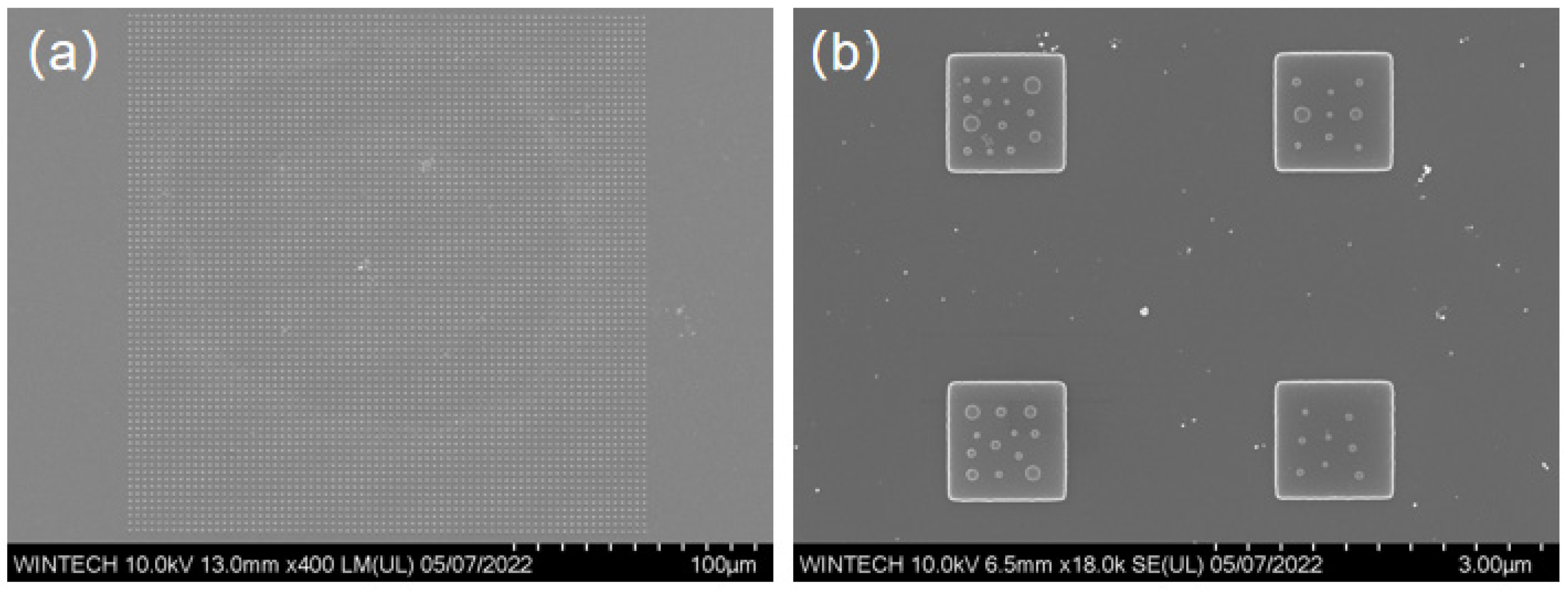

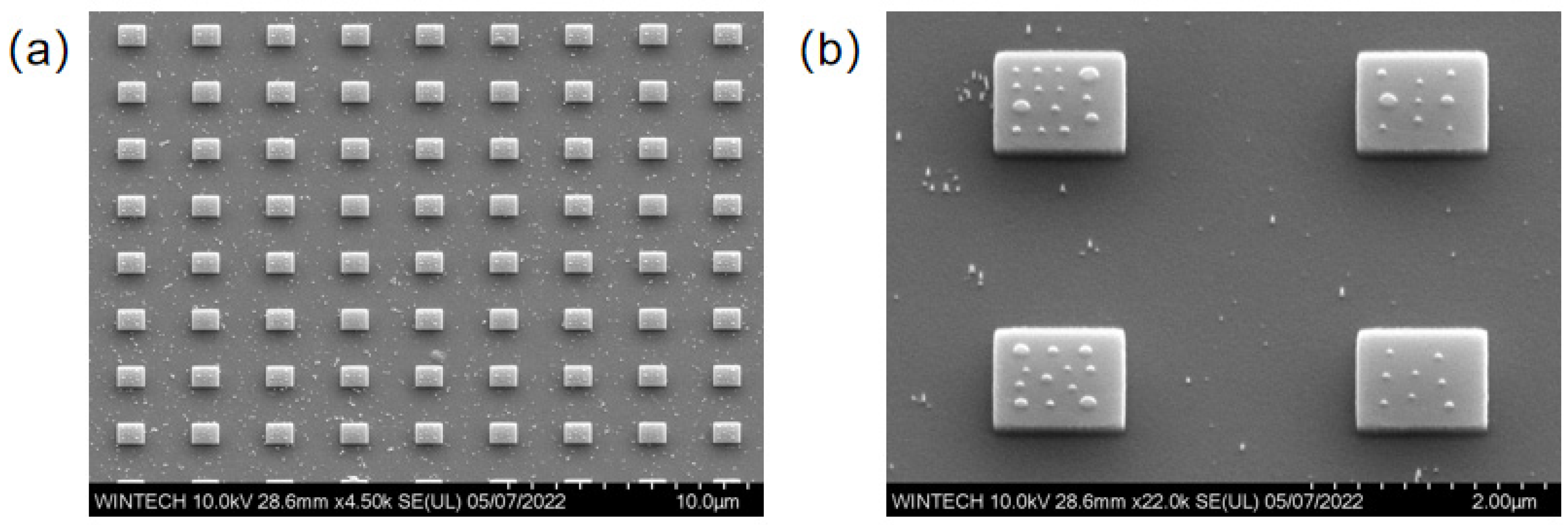

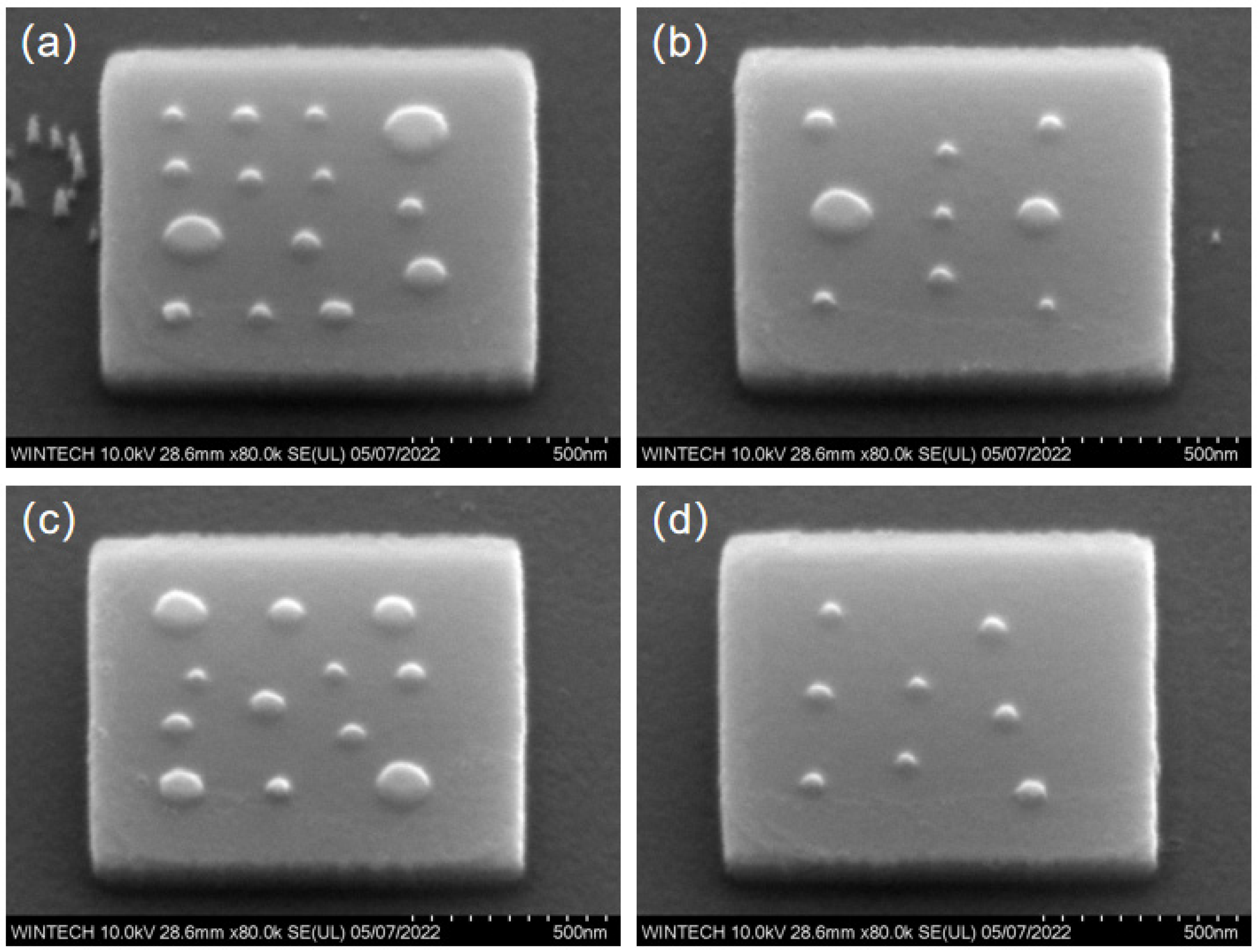

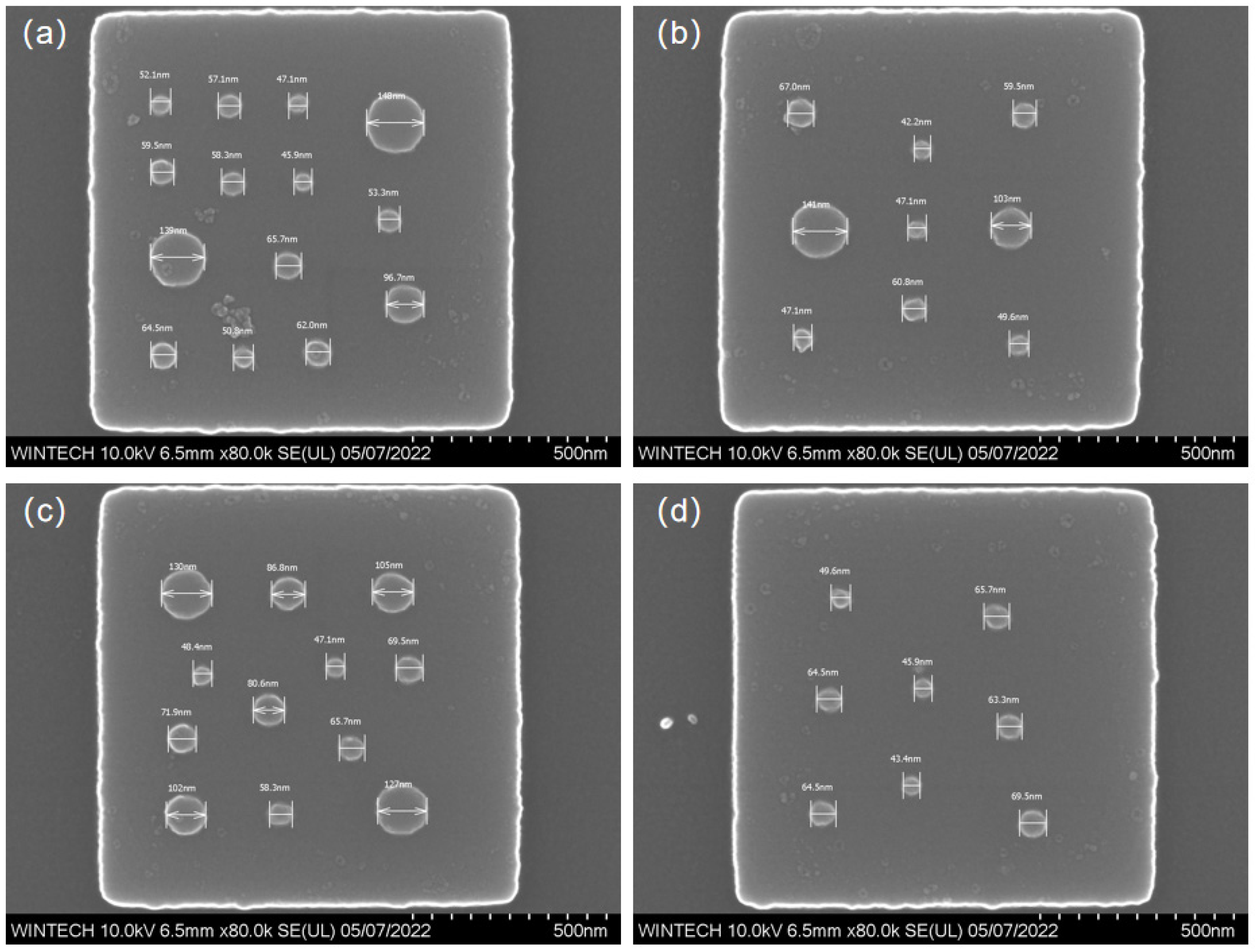

4.1. SEM Characterization Results of the Master Mold

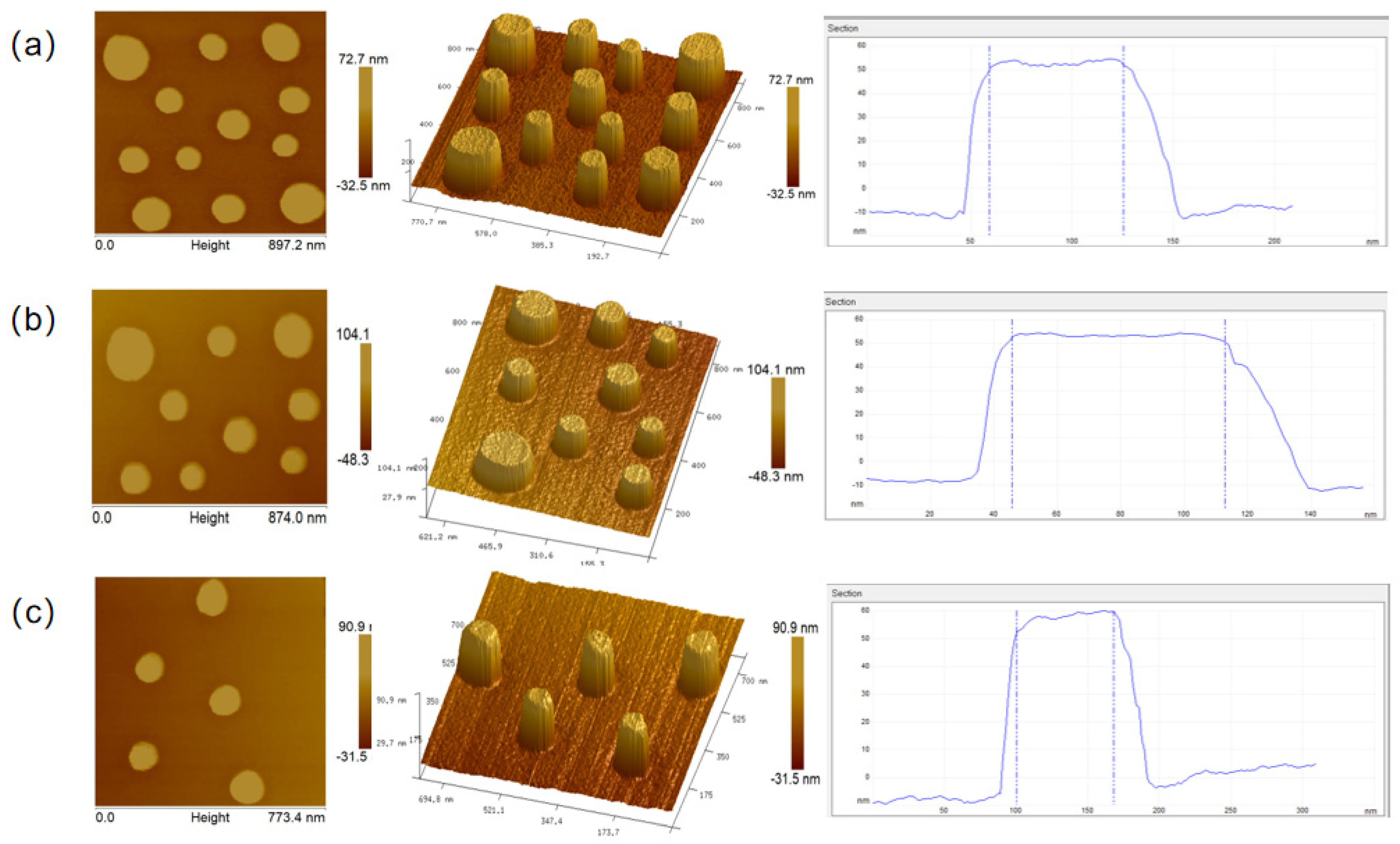

4.2. AFM Characterization Results of the Master Mold

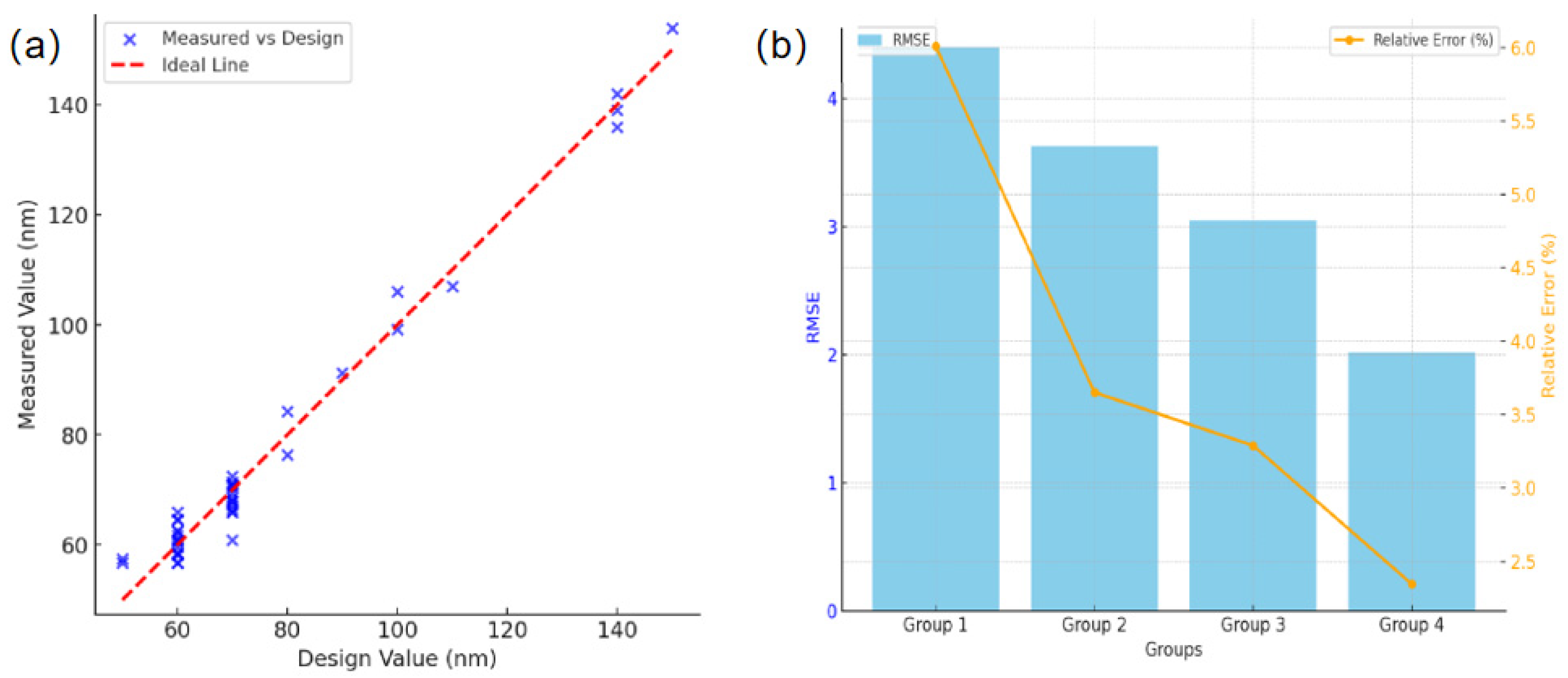

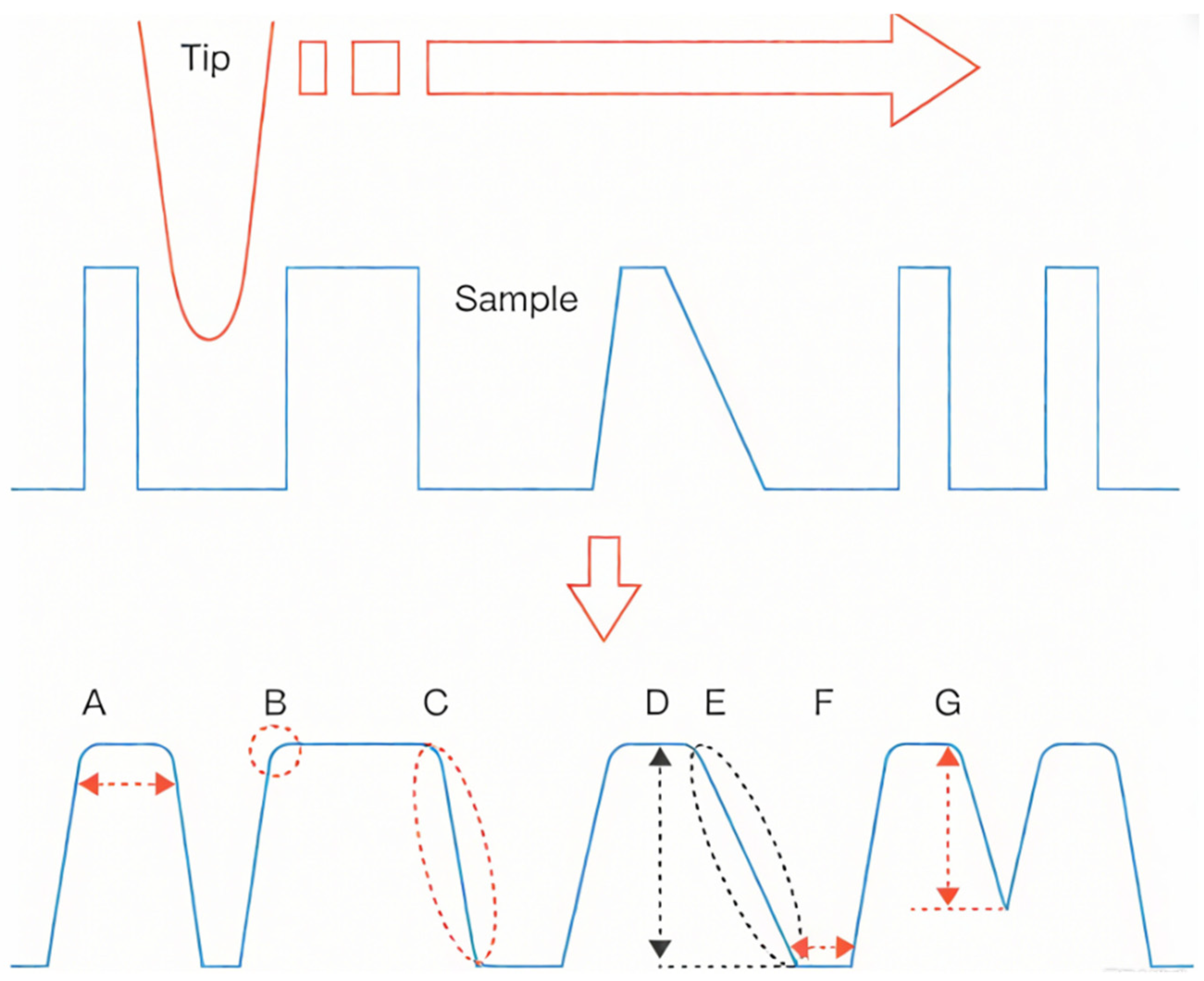

4.3. Probe Convolution Effect Correction Methods

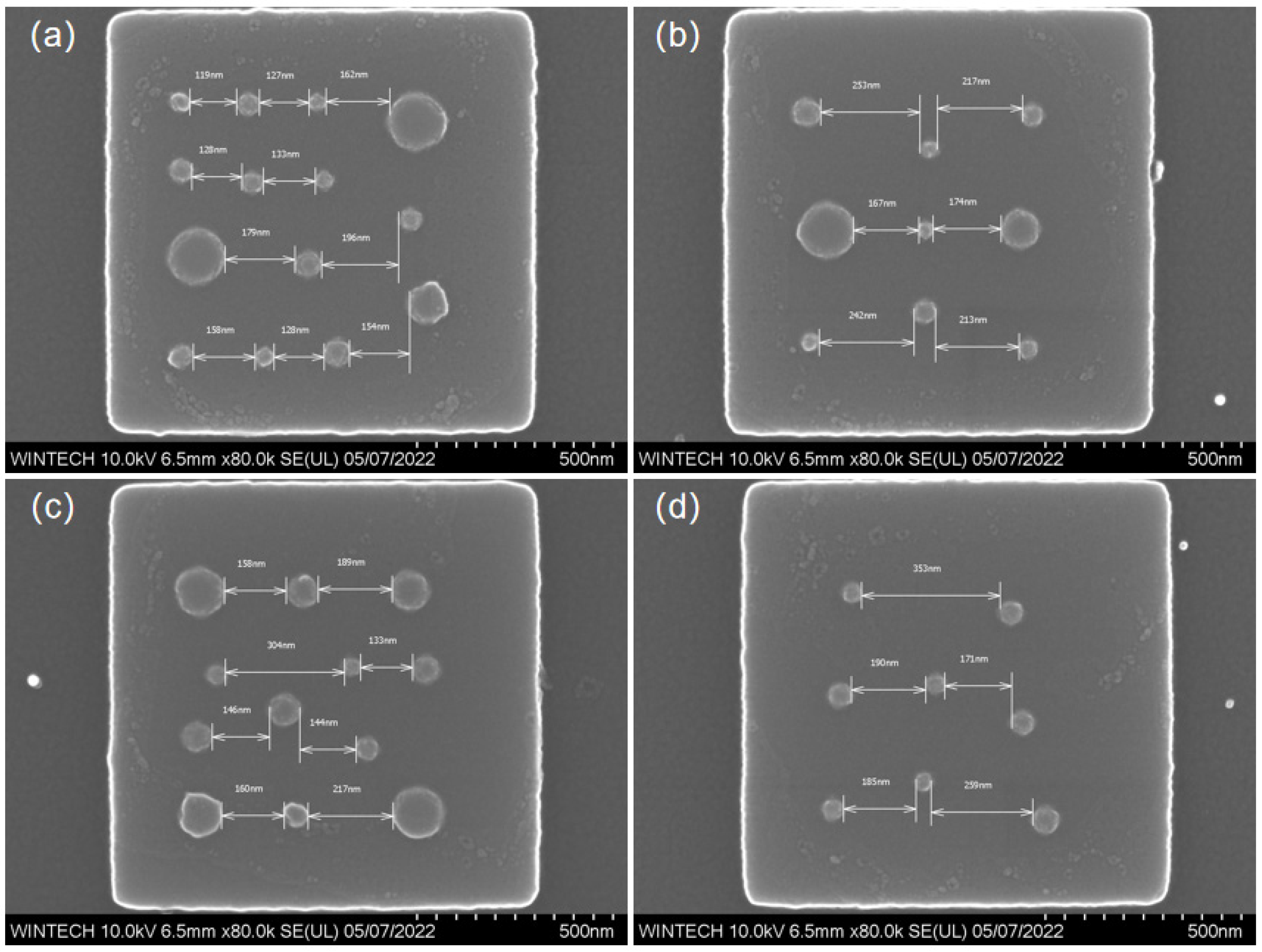

4.4. SEM Characterization Results of Nanoimprinted Structures

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EBL | Electron beam lithography |

| ICP | Inductively coupled plasma |

| NIL | Ultraviolet nanoimprint lithography |

| SEM | Scanning electron microscopy |

| AFM | Atomic force microscopy |

| PECVD | Plasma-enhanced chemical vapor deposition |

| IPA | Isopropanol |

| MIBK | Methyl isobutyl ketone |

| RMSE | Root mean square error |

References

- Zhu, Y.; Feng, A.; Pan, X.; Yu, J.; Zhao, P. Research on the Preparation and Property of Superhydrophobic Surface with Micro-Nano Ripple Structure. J. Mater. Res. Pratt’s Guide Ventur. Cap. Sources 2023, 38, 3136–3150. [Google Scholar] [CrossRef]

- Tahir, U.; Kim, J.I.; Javeed, S.; Khaliq, A.; Kim, J.-H.; Kim, D.-I.; Jeong, M.Y. Process Optimization for Manufacturing Functional Nanosurfaces by Roll-To-Roll Nanoimprint Lithography. Nanomaterials 2022, 12, 480. [Google Scholar] [CrossRef]

- Park, T.W.; Kang, Y.L.; Kim, Y.N.; Park, W.I. High-Resolution Nanotransfer Printing of Porous Crossbar Array Using Patterned Metal Molds by Extreme-Pressure Imprint Lithography. Nanomaterials 2023, 13, 2335. [Google Scholar] [CrossRef]

- Hao, H.; Cai, Z.; Li, B.; Tang, P. Design of Double-Layer Circular Polarization Multiplex Focusing Metasurface Lens. Prog. Electromagn. Res. C 2024, 144, 169–180. [Google Scholar] [CrossRef]

- Sabirova, A.; Florica, C.F.; Pisig, F.; Syed, A.; Buttner, U.; Li, X.; Nunes, S.P. Nanoporous Membrane Fabrication by Nanoimprint Lithography for Nanoparticle Sieving. Nanoscale Adv. 2022, 4, 1119–1124. [Google Scholar] [CrossRef]

- Song, X.; Zhu, C.; Wu, Y.; Chen, L. Simulation Study on Enhancing Light Absorption of Photovoltaic Electrochemical Cells with Trapped-Light Structures. Acta Opt. Sin. 2024, 44, 227–233. [Google Scholar]

- Yang, S.-H.; Wang, T.-Y.; Chen, W.-L.; Ho, C.-C. Light Extraction Efficiency of Nanostructures on OLED Prepared Using Nanoimprinting and Thermal Expansion. Appl. Surf. Sci. 2021, 579, 152143. [Google Scholar] [CrossRef]

- Li, J.; Hong, C.; Zhang, H.; Han, Y.; Li, X.; Sun, R.; Zhou, C. Fabrication of Self-Cross-Linking Silicified Polyvinylidene Chloride Emulsions with Core–Shell Structure and Its Film Properties. Polym. Bull. 2023, 81, 1651–1673. [Google Scholar] [CrossRef]

- Liu, B.; Chen, X.; Zhang, E.; Zhou, J.; Wu, H.; Chen, Y.; Yang, B.; Xu, B.; Jiang, W. Formation Mechanism and Luminescence Properties of Silicon Carbide Nanowires with Core-Shell Structure. Ceram. Int. 2024, 50, 48312–48322. [Google Scholar] [CrossRef]

- Chepkasov, I.V.; Radina, A.D.; Kvashnin, A.G. Structure-Driven Tuning of Catalytic Properties of Core-Shell Nanostructures. Nanoscale 2024, 16, 5870–5892. [Google Scholar] [CrossRef] [PubMed]

- Li, J.-R.; Li, J.; Tang, X.-M.; Chu, W.-X.; An, B.-L.; Zhang, J.-M.; Wang, X.-H.; Bai, Y.-L.; Xu, J. Synthesis and Luminescence Properties of Carbon Quantum Dots with Core@Shell Structures. Opt. Mater. 2024, 156, 115975. [Google Scholar] [CrossRef]

- Ko, T.; Kumar, S.; Shin, S.; Seo, D.; Seo, S. Colloidal Quantum Dot Nanolithography: Direct Patterning via Electron Beam Lithography. Nanomaterials 2023, 13, 2111. [Google Scholar] [CrossRef] [PubMed]

- Meinecke, C.R.; Heldt, G.; Blaudeck, T.; Lindberg, F.W.; van Delft, F.C.M.J.M.; Rahman, M.A.; Salhotra, A.; Månsson, A.; Linke, H.; Korten, T.; et al. Nanolithographic Fabrication Technologies for Network-Based Biocomputation Devices. Materials 2023, 16, 1046. [Google Scholar] [CrossRef]

- Andok, R.; Vutova, K.; Konecnikova, A.; Ritomsky, M.; Kostic, I. Study of Lithographic Parameters for the Trilayer Resist Systems in Electron Beam Lithography. AIP Conf. Proc. 2023, 2778, 030001. [Google Scholar] [CrossRef]

- Wang, X.; Dai, X.; Wang, H.; Wang, J.; Chen, Q.; Chen, F.; Yi, Q.; Tang, R.; Gao, L.; Ma, L.; et al. All-Water Etching-Free Electron Beam Lithography for On-Chip Nanomaterials. ACS Nano 2023, 17, 4933–4941. [Google Scholar] [CrossRef]

- Cho, S.I.; Park, H.K.; An, S.; Hong, S.J. Plasma Ion Bombardment Induced Heat Flux on the Wafer Surface in Inductively Coupled Plasma Reactive Ion Etch. Appl. Sci. 2023, 13, 9533. [Google Scholar] [CrossRef]

- Wang, Z.; Xia, Y.; Song, L.; Chen, J.; Wang, W. Fabrication of Bulk Tungsten Microstructure Arrays for Hydrophobic Metallic Surfaces Using Inductively Coupled Plasma Deep Etching. Micromachines 2024, 15, 807. [Google Scholar] [CrossRef]

- Gray, T.; Zhang, X.; Biswas, A.; Terlier, T.; Oliveira, E.F.; Puthirath, A.B.; Li, C.; Pieshkov, T.S.; Garratt, E.J.; Neupane, M.R.; et al. Benchmarking Diamond Surface Preparation and Fluorination via Inductively Coupled Plasma-Reactive Ion Etching. Carbon 2024, 228, 119366. [Google Scholar] [CrossRef]

- Ma, Z.; Ouyang, M.; Fu, Y.; Wu, J.; Zhou, J.; Ren, H.; Zhang, Z. Study on Mid-Infrared Bionic Composite Micro-Nano Structure Anti-Reflection Surfaces. Acta Opt. Sin. 2022, 42, 1031001. [Google Scholar]

- Feng, X.; Chen, Y.; Wu, R.; Yu, Z.; Ma, X.; Zhang, H.; Hou, L.; Wang, J.; Liu, W. Achieving Strength–Ductility Synergy in Graphene Nanoplatelets/Mg–14Li–1Al Composites through Constructing Micro-Nano Laminated Structure. J. Mater. Sci. Technol. 2025, 230, 244–257. [Google Scholar] [CrossRef]

- Yao, D.; Shi, G.; Zhang, J.; Meng, S. An Investigation on the Adhesion of Dual-Scale Micro-Nano Composite Structure on the Surface of Aluminum. Surf. Topogr. Metrol. Prop. 2023, 11, 025026. [Google Scholar] [CrossRef]

- Zhou, B.; Bu, X.; Li, J.; Gao, C.; Saitaer, X.; Guo, J. Electro–Centrifugal Spinning of Core–Sheath Composite Yarns with Micro/Nano Structures for Self–Powered Sensing. Compos. Commun. 2025, 53, 102141. [Google Scholar] [CrossRef]

- Bi, X.; Wang, Z.; Xu, M.; Li, X. Femtosecond Laser Fabricated Micro/Nano Interfacial Structures to Strengthen CFRPEEK/A6061-T6 FLJ Hybrid Joints. Compos. Part B Eng. 2021, 231, 109540. [Google Scholar] [CrossRef]

- Wang, H.; Xie, J.; Fan, T.; Sun, D.; Li, C. Improving the Thickness Uniformity of Micro Gear by Multi-Step, Self-Aligned Lithography and Electroforming. Micromachines 2023, 14, 775. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Chu, D.; Wang, Q.; Xu, X.; Yin, K.; Qu, S.; Yao, P.; Huang, C. A Porous Micro/Nano-Structured Polyethylene Film Prepared Using a Picosecond Laser for Agricultural Passive Cooling. Nanoscale 2024, 16, 5674–5684. [Google Scholar] [CrossRef]

- Lv, S.; Deng, J.; Feng, M.; Zhang, M.; Guo, Y.; Wu, Y.; Shi, G. A Simple Micro/Nano-Porous Structure with Day-Night Dynamic Thermal Control and High Thermal Conductivity for Enhanced Thermoelectric Power Generation. Adv. Mater. Technol. 2025, 10, 2401723. [Google Scholar] [CrossRef]

- Deng, S.; Zeng, Q.; Xiao, Z.; Zhang, J.; Yang, G.; Wu, X.; Li, J.; Zhang, D.; Zhou, J.; Liu, B. High-Performance Flexible Piezoresistive 3D Pressure Sensor Based on Wrinkled Structures and Porous Microstructures. Mater. Lett. 2025, 379, 137688. [Google Scholar] [CrossRef]

- Xing, L.; Zhang, Q.; Fu, Q.; Yu, J.; Huang, X. Preparation and Properties of Polytetrafluoroethylene Superhydrophobic Surface. Colloids Surf. A Physicochem. Eng. Asp. 2023, 670, 131574. [Google Scholar] [CrossRef]

- Kuang, M.; Yang, X.; Huang, Y.; Xu, K.; Ye, X. Preparation of Durable Superhydrophobic Composite Surface. Mater. Today Commun. 2023, 36, 106618. [Google Scholar] [CrossRef]

- Kuang, M.; Yang, X.; Huang, Y.; Xu, K.; Ye, X. Study on Nonfluorinated Preparation and Properties of Superhydrophobic Surface. NANO Brief Rep. Rev. 2023, 18, 2350086. [Google Scholar] [CrossRef]

- Pan, M.; Shao, H.; Fan, Y.; Yang, J.; Liu, J.; Deng, Z.; Liu, Z.; Chen, Z.; Zhang, J.; Yi, K.; et al. Superhydrophobic Surface-Assisted Preparation of Microspheres and Supraparticles and Their Applications. Nano-Micro Lett. 2024, 16, 68. [Google Scholar] [CrossRef] [PubMed]

- Yadav, P.; Dubey, D.P.; Rana, D.K.; Sharma, P.; Kumar, S. Core-Shell Structured BFO/CFO Nanocomposites for Efficient Microwave Absorption. Mater. Lett. 2025, 401, 139227. [Google Scholar] [CrossRef]

- Zhai, J.; Huang, Y.; Wei, Y. Core-Shell Structured SiO2@C-Sn/SnO2 Nanosphere as an Anode Material for High-Performance Lithium-Ion Batteries. Ionics 2023, 30, 689–695. [Google Scholar] [CrossRef]

- Yan, R.; Li, Y.; Yu, Q.; Zhong, F.; Chu, B.; Yang, T.; Huang, Z.; Shao, L.; Li, Y.; Yu, Z.; et al. Dual-Wavelength Superscattering in Plasmonic Core-Shell Nanostructures for Transparent Structural Color. Phys. Scr. 2024, 99, 095519. [Google Scholar] [CrossRef]

- Xuan, S.; Yin, H.; Li, G.; Yang, Y.; Wang, Y.; Liu, J.; Liu, S.; Li, X.; Song, Y.; Wu, T.; et al. Femtosecond Laser Composite Manufactured Double-Bionic Micro–Nano Structure for Efficient Photothermal Anti-Icing/Deicing. Mater. Horiz. 2024, 11, 3561–3572. [Google Scholar] [CrossRef]

- Yang, J.; Yang, J.; Fu, Y.; Wu, J.; Ouyang, M.; Dong, L.; Kou, S. Design and Manufacturing of Mid-Infrared Ultra-Wide-Angle Antireflective Composite Micro-Nano Structure Film. Opt. Mater. 2024, 230, 244–257. [Google Scholar] [CrossRef]

- Wu, J.; Huang, H.; Li, X.; Zheng, K.; Xiao, X.; Yuan, D.; Zhang, J.; Yang, B. A Novel Cu-Sn-Zr Alloy with Core-Shell Structure. Mater. Sci. Eng. A 2024, 895, 146230. [Google Scholar] [CrossRef]

- Munir, R.; Khan, B.; Dastagir, G.; Uza, N.U. Implication of Scanning Electron Microscopy and Light Microscopy for Morphology of Some Selected Seed Drugs: As a Tool for Authentication. J. Microsc. Ultrastruct. 2023, 11, 60–67. [Google Scholar] [CrossRef]

- Wang, K.; Wang, D.; Sun, J.; Shi, J.; Yu, P.; Su, C.; Liu, L. Multiscale Profile Characterization Based on Atomic Force Microscopy. IEEE Trans. Instrum. Meas. 2025, 74, 1–9. [Google Scholar] [CrossRef]

- Yeo, R.J.; Yeo, J.C.C.; Yu Tan, S.; Sng, A.; Tomczak, N.; Muiruri, J.K.; Wang, S.; Wang, P.; Thitsartarn, W.; Wang, F.; et al. Core-Shell Micro-and Nano-Structures for the Modification of Light—Surface Interactions. Adv. Opt. Mater. 2023, 12, 2301955. [Google Scholar] [CrossRef]

- Pan, A.; Mei, X.; Wang, W.; Xia, Y.; Su, Y.; Zhao, S.; Chen, T. In-Situ Deposition of Oxidized Porous Metal Nanoparticles on the Surface of Picosecond Laser-Induced Micro/Nano Structures: A New Kind of Meta-Surface Equipped with Both Super-Hydrophobicity and Anti-Reflectivity. Chem. Eng. J. 2023, 460, 141582. [Google Scholar] [CrossRef]

- Ji, X.; Lu, Z.; Wang, J.; Ye, N.; Zhang, H.; Zhou, L.; Li, J.; Lu, Y. Construction of Micro-Nano Hybrid Structure Based on Carbon Nanotube Whisker and Alumina for Thermally Conductive yet Electrically Insulating Silicone Rubber Composites. Compos. Sci. Technol. 2024, 249, 110495. [Google Scholar] [CrossRef]

- Yin, L.; Zhang, K.; Qin, T.; Ma, W.; Ding, Y.; Xu, Y. Enhanced Flow Boiling Heat Transfer of HFE-7100 in Open Microchannels Using Micro-Nano Composite Structures. Front. Heat Mass Transf. 2025, 23, 751–764. [Google Scholar] [CrossRef]

- Lou, Z.; Yan, Y.; Wang, J.; Zhang, A.; Cui, H.; Li, C.; Geng, Y. Exploring the Structural Color of Micro-Nano Composite Gratings with FDTD Simulation and Experimental Validation. Opt. Express 2024, 32, 2432–2451. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Shen, W.; Yang, S.; Wu, Y.; Zhao, D.; Leng, Z.; Tang, Y.; Zhu, H.; Liu, S.; Zhang, Z. Laser-Enhanced Electrodeposition Preparation Technology of Superhydrophobic Micro-Nano Structure Coating. Colloids Surf. A Physicochem. Eng. Asp. 2022, 657, 130507. [Google Scholar] [CrossRef]

- Zhang, K.; Bai, Y.; Zhang, Z. Compensation Method for Correcting the Topography Convolution of the 3D AFM Profile Image of a Diffraction Grating. Machines 2024, 12, 126. [Google Scholar] [CrossRef]

- Liu, C.; Feng, Y.; Liu, X.; Yuan, Y.; Li, Y.; Shen, T. Multiparameter Sensor Based on Micro/Nano-Structured Optical Fiber and Composites. Heliyon 2022, 8, e10941. [Google Scholar] [CrossRef]

- Li, Y.; Yang, W.; Zhang, J.; Hou, Y.; Wen, G.; Xin, G.; Jiang, M.; Ma, Y. Precursor-Derived Mo2C/SiC Composites with a Two-Dimensional Sheet Structure for Electromagnetic Wave Absorption. Materials 2025, 18, 1573. [Google Scholar] [CrossRef]

- Tian, D.; Zhang, K.; Sun, L.; Rong, Z.; Zhang, D.; Liu, L.; Wu, Y.; Gao, C.; Kan, Z.; Liu, Y. Renewable Superhydrophobic Antifouling Composite Silicone Based on Micro-Nano Structure. Compos. Sci. Technol. 2025, 264, 111111. [Google Scholar] [CrossRef]

- Su, D.; Zhang, H.; Xiao, H.; Song, W.; Xiong, H.; Xiao, D.; Wang, X. A Double-Layer Metal-Only Huygens’ Metasurface Transmitarray. IEEE Antennas Wirel. Propag. Lett. 2023, 22, 1897–1901. [Google Scholar] [CrossRef]

- Miao, H.; Cao, X.; Fu, M. Double-Layer Metasurface for Blocking the Fundamental SH Wave. Smart Mater. Struct. 2024, 33, 095044. [Google Scholar] [CrossRef]

- Kim, Y.H.; Song, I.H.; Jeon, S.T.; Kim, S.J. Double-Layered Metasurfaces Fabricated by Single-Step Lithography for Efficient Phase Control. IEEE Access 2024, 12, 84622–84631. [Google Scholar] [CrossRef]

- Tan, P.; Liu, Y.; Hao, J.; Wang, J.; Wang, R.; Han, Q.; Xu, Z. Near-Infrared Double-Layer Cascaded Metasurface for Beam Shaping. Opt. Mater. Express 2024, 14, 2844. [Google Scholar] [CrossRef]

- Ding, Z.; Su, W.; Lu, H.; Wu, H.; Yao, H. Terahertz Absorber Based on Double-Layer Graphene Metasurface with Tunable Absorption Window and Intensity. Opt. Laser Technol. 2023, 163, 109446. [Google Scholar] [CrossRef]

- Guo, K.; Li, X.; Kang, Q.; Guo, Z. Tunable Full-Space Light Field Manipulation Based on Double-Layer Ge2Sb2Te5 Metasurfaces. Phys. Scr. 2023, 98, 115528. [Google Scholar] [CrossRef]

| Processing Step | Parameter | Value |

|---|---|---|

| Resist Coating | Low-speed RPM | 500 rpm |

| High-speed RPM | 4000 rpm | |

| Bake Temperature | 180 °C | |

| Bottom Layer Exposure (EBL) | Voltage | 20 kV |

| Beam Current | 50 pA | |

| Exposure Dose | 250 μC/cm2 | |

| Top Layer Exposure (EBL) | Beam Current | 30 pA |

| Exposure Dose | 150 μC/cm2 | |

| ICP Etching (Bottom Layer) | SF6 Flow Rate | 50 sccm |

| C4F8 Flow Rate | 30 sccm | |

| Chamber Pressure | 20 mTorr | |

| ICP Etching (Top Layer) | SF6 Flow Rate | 30 sccm |

| C4F8 Flow Rate | 10 sccm | |

| Chamber Pressure | 15 mTorr |

| Test Item | Test Result Description | ||||

|---|---|---|---|---|---|

| AFM | Lateral Feature Size Measurement of Nanostructures (nm) | Probe Tip Curvature Radius (nm) | Corrected Nanopillar Dimensions (nm) | Average Corrected Dimension (nm) | |

| Position a | 65.884 | 15 | 51.884 | 52.541 | |

| Position b | 65.893 | 51.893 | |||

| Position c | 67.845 | 53.845 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Ge, S.; Sun, Z.; Li, J.; Shi, R.; Shen, L.; Zhang, J.; Xi, Y. The Research on Multi-Process Collaborative Manufacturing and Characterization Methods of Micro–Nano-Composite Layered Structures. Nanomaterials 2025, 15, 1716. https://doi.org/10.3390/nano15221716

Xu S, Ge S, Sun Z, Li J, Shi R, Shen L, Zhang J, Xi Y. The Research on Multi-Process Collaborative Manufacturing and Characterization Methods of Micro–Nano-Composite Layered Structures. Nanomaterials. 2025; 15(22):1716. https://doi.org/10.3390/nano15221716

Chicago/Turabian StyleXu, Shibo, Shaobo Ge, Zehua Sun, Junyan Li, Ronghua Shi, Lujun Shen, Jin Zhang, and Yingxue Xi. 2025. "The Research on Multi-Process Collaborative Manufacturing and Characterization Methods of Micro–Nano-Composite Layered Structures" Nanomaterials 15, no. 22: 1716. https://doi.org/10.3390/nano15221716

APA StyleXu, S., Ge, S., Sun, Z., Li, J., Shi, R., Shen, L., Zhang, J., & Xi, Y. (2025). The Research on Multi-Process Collaborative Manufacturing and Characterization Methods of Micro–Nano-Composite Layered Structures. Nanomaterials, 15(22), 1716. https://doi.org/10.3390/nano15221716