The Influence of Initial Microstructure on the Microstructure and Mechanical Properties of Ductile Iron After Nanostructurisation Heat Treatment

Abstract

1. Introduction

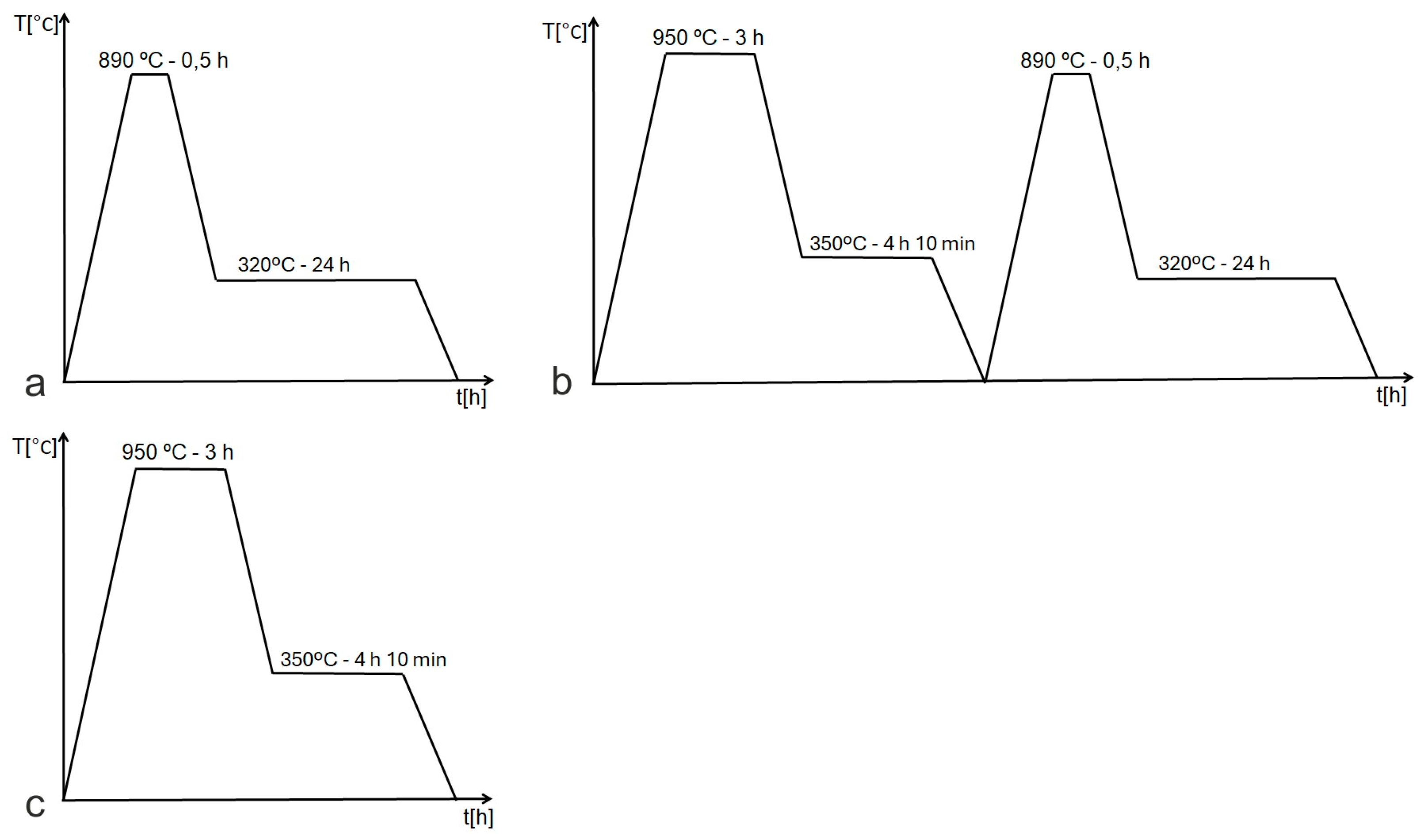

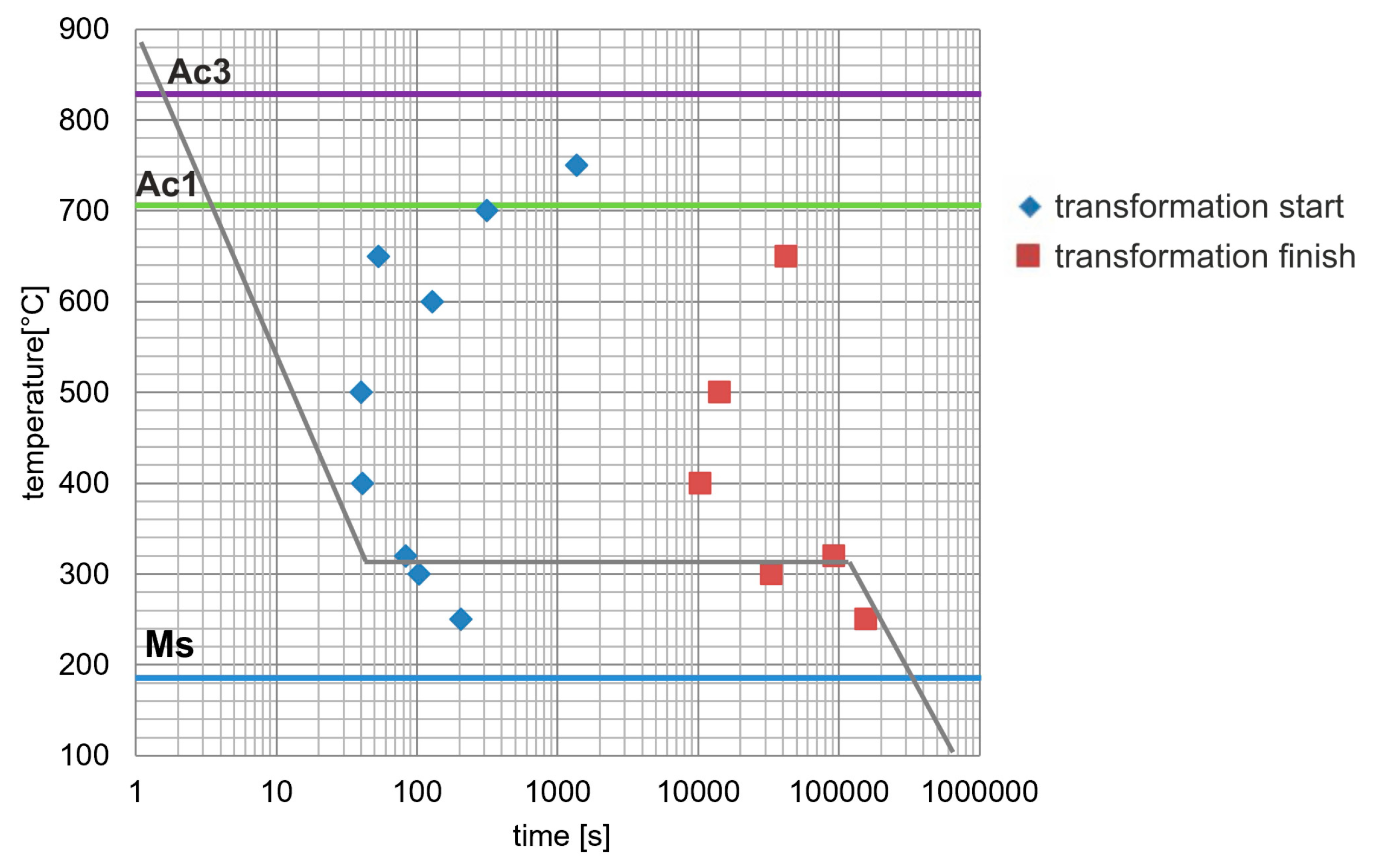

2. Materials and Methods

3. Results and Discussion

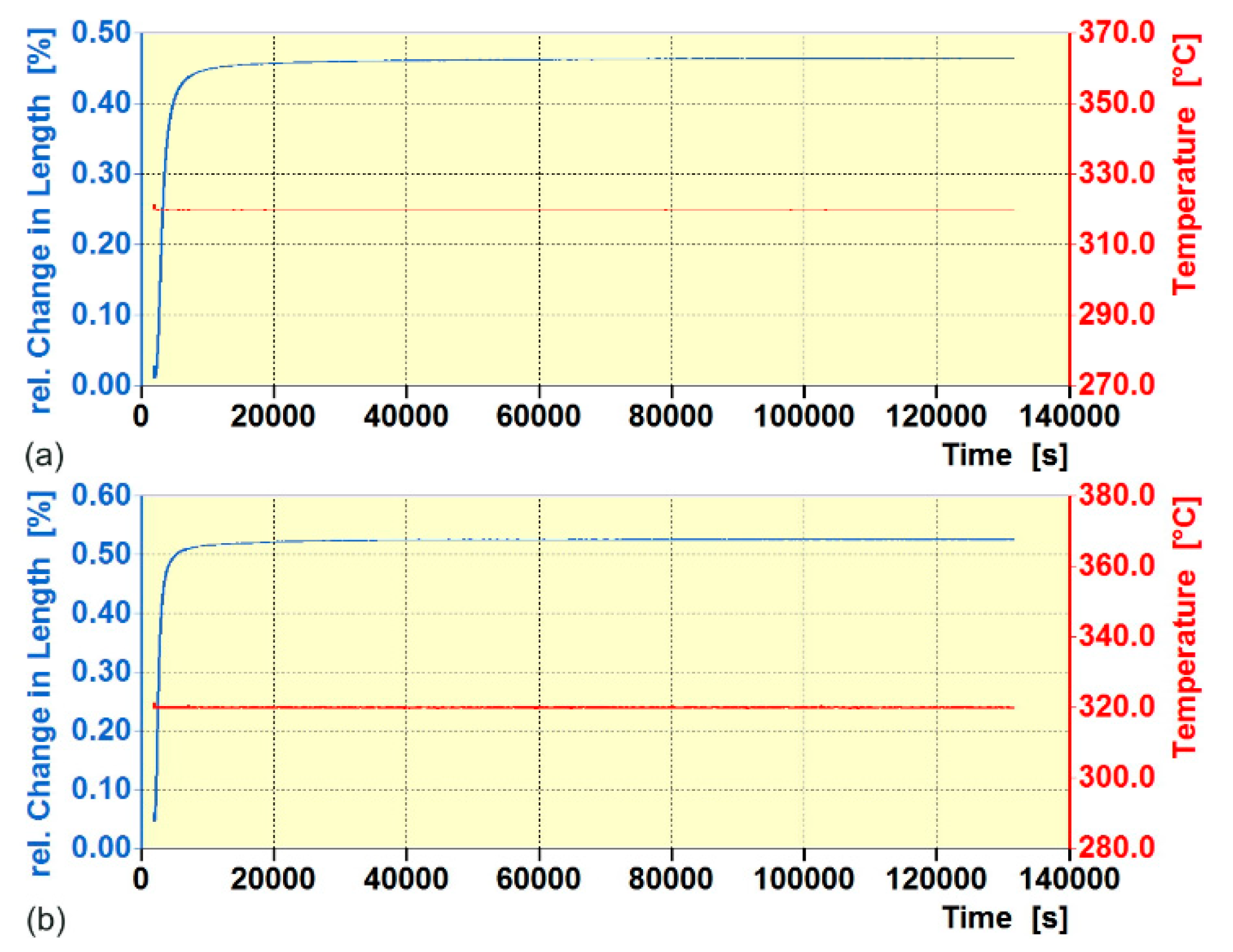

3.1. Dilatometric Analysis

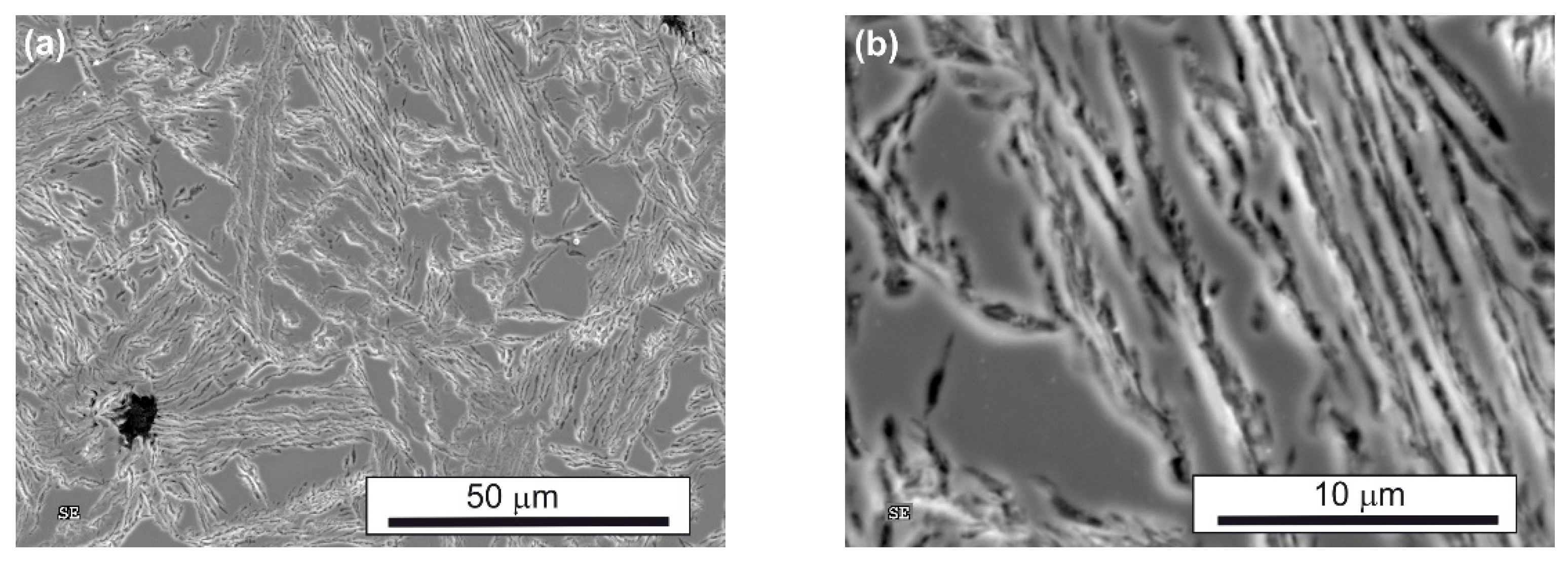

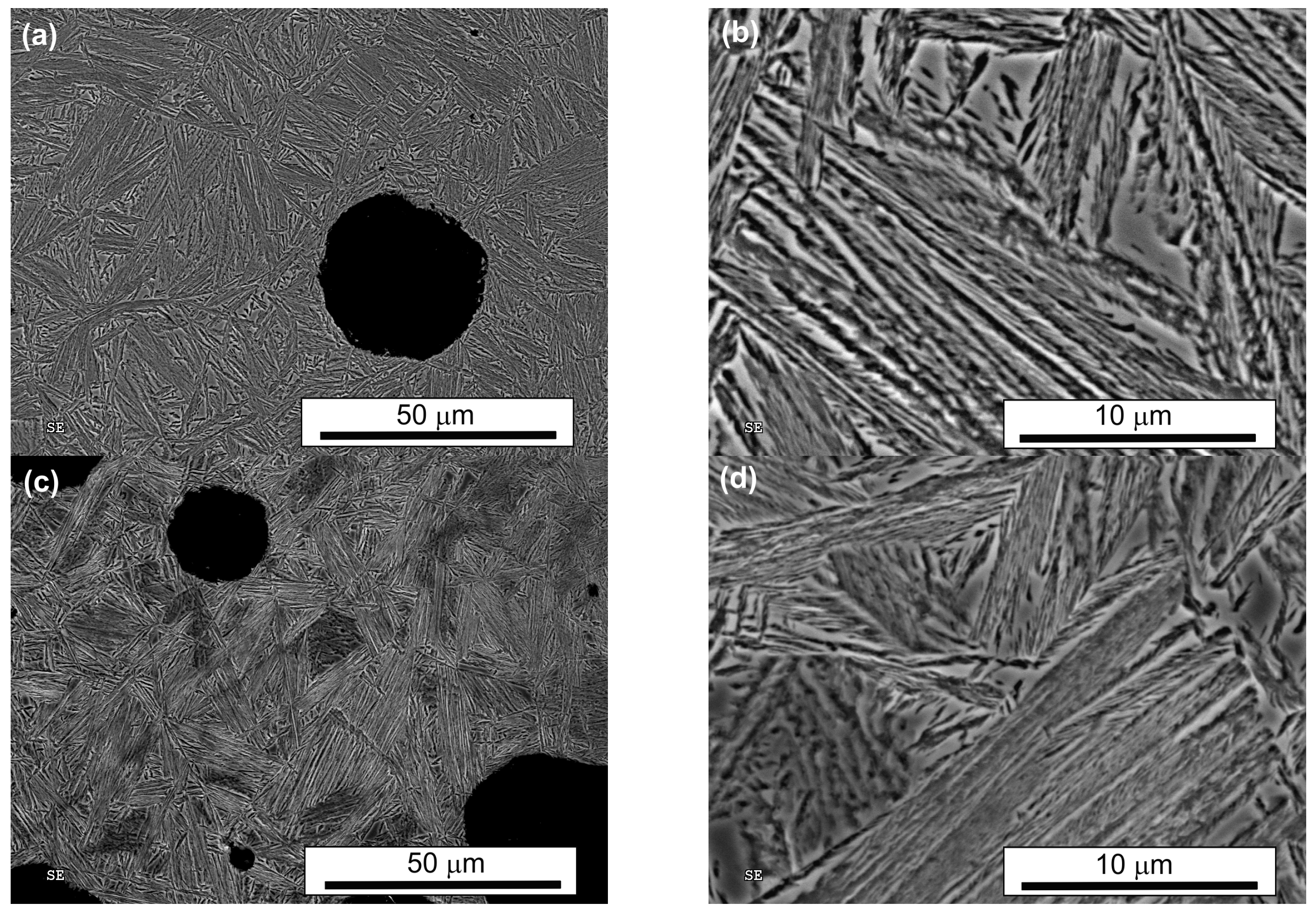

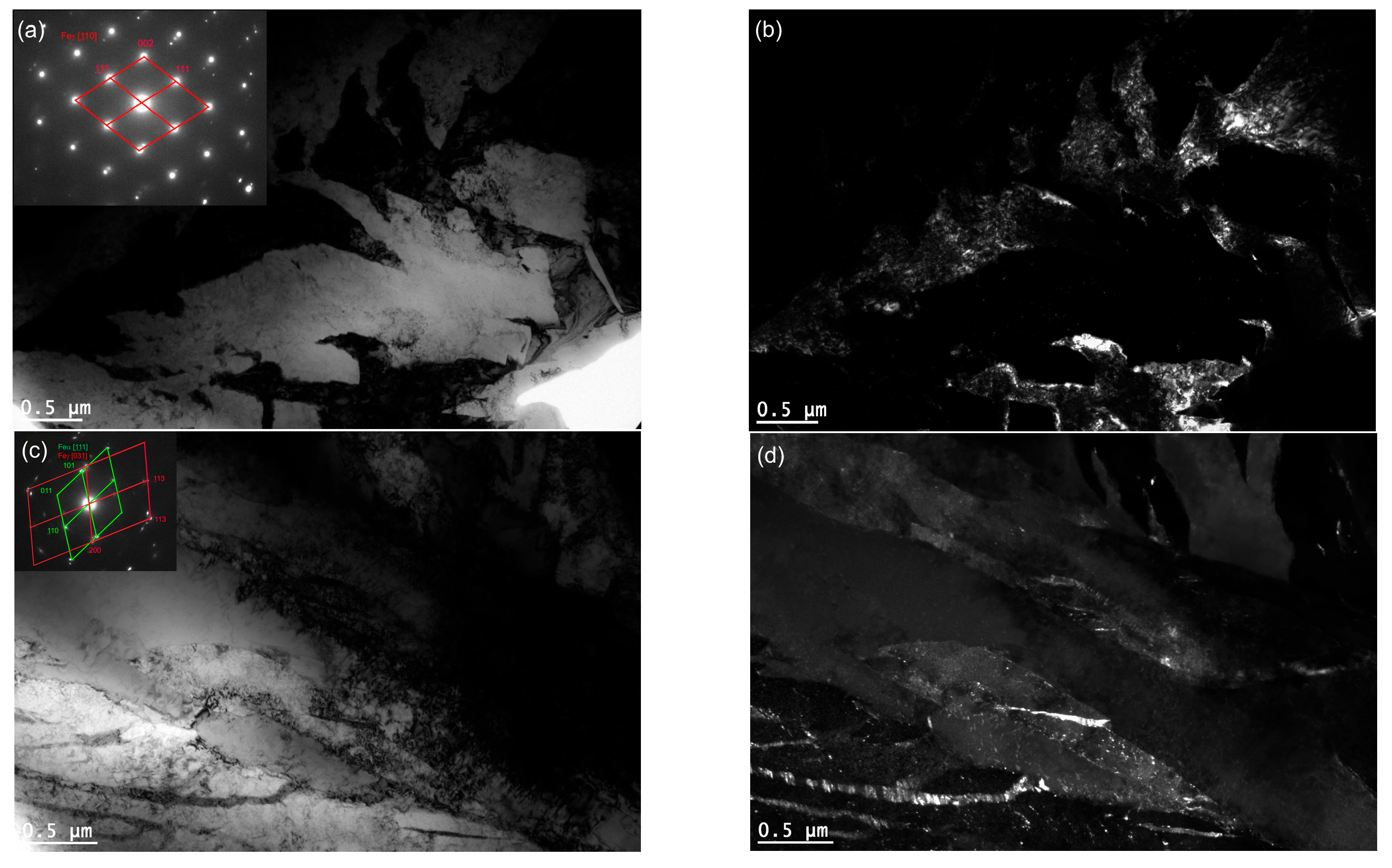

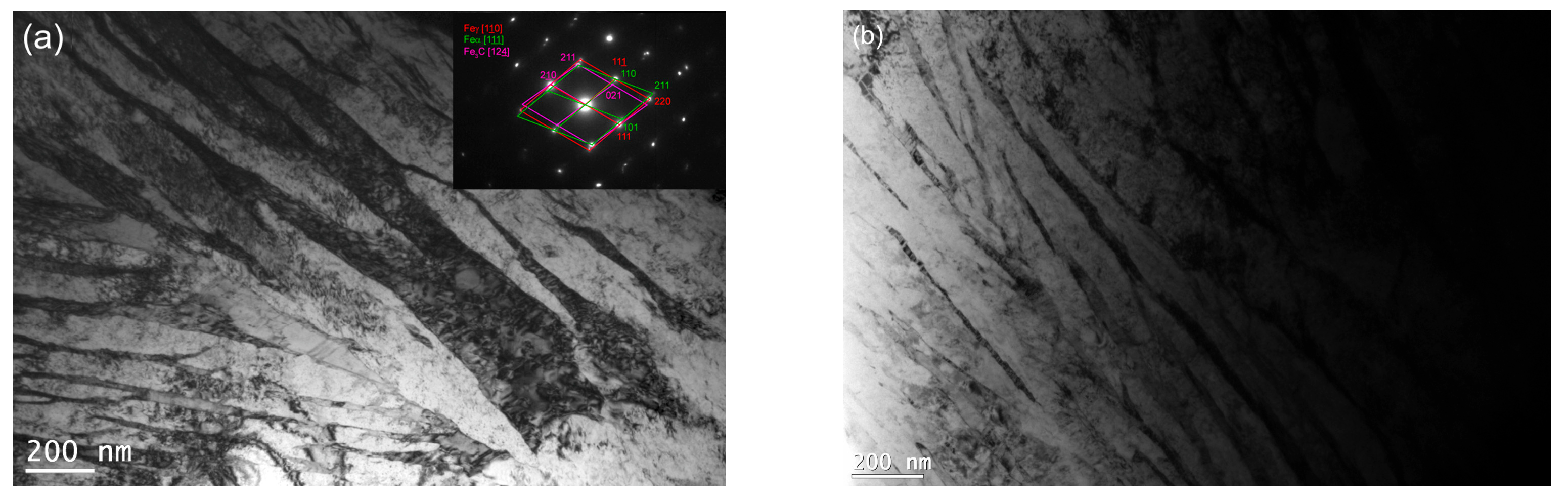

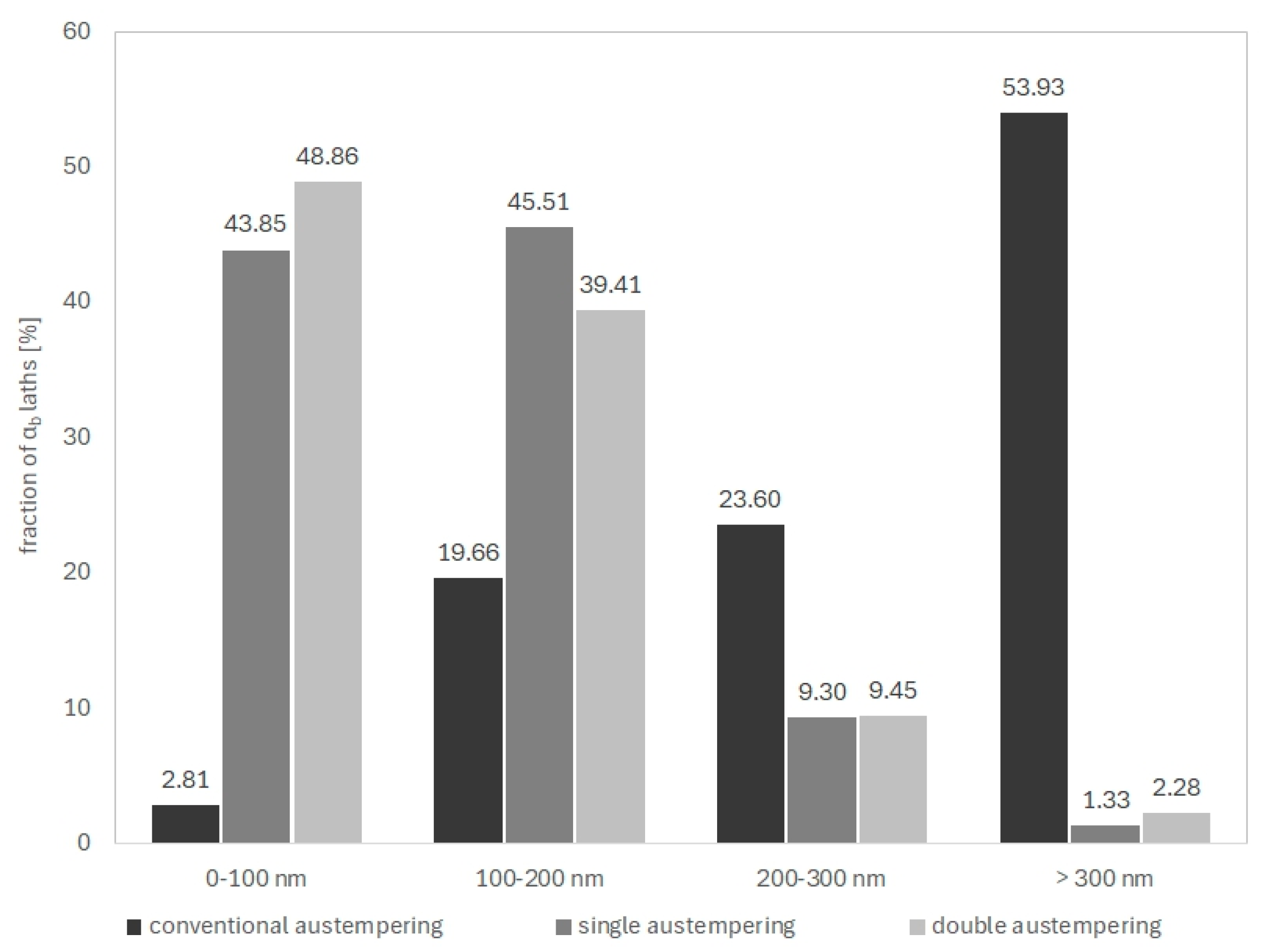

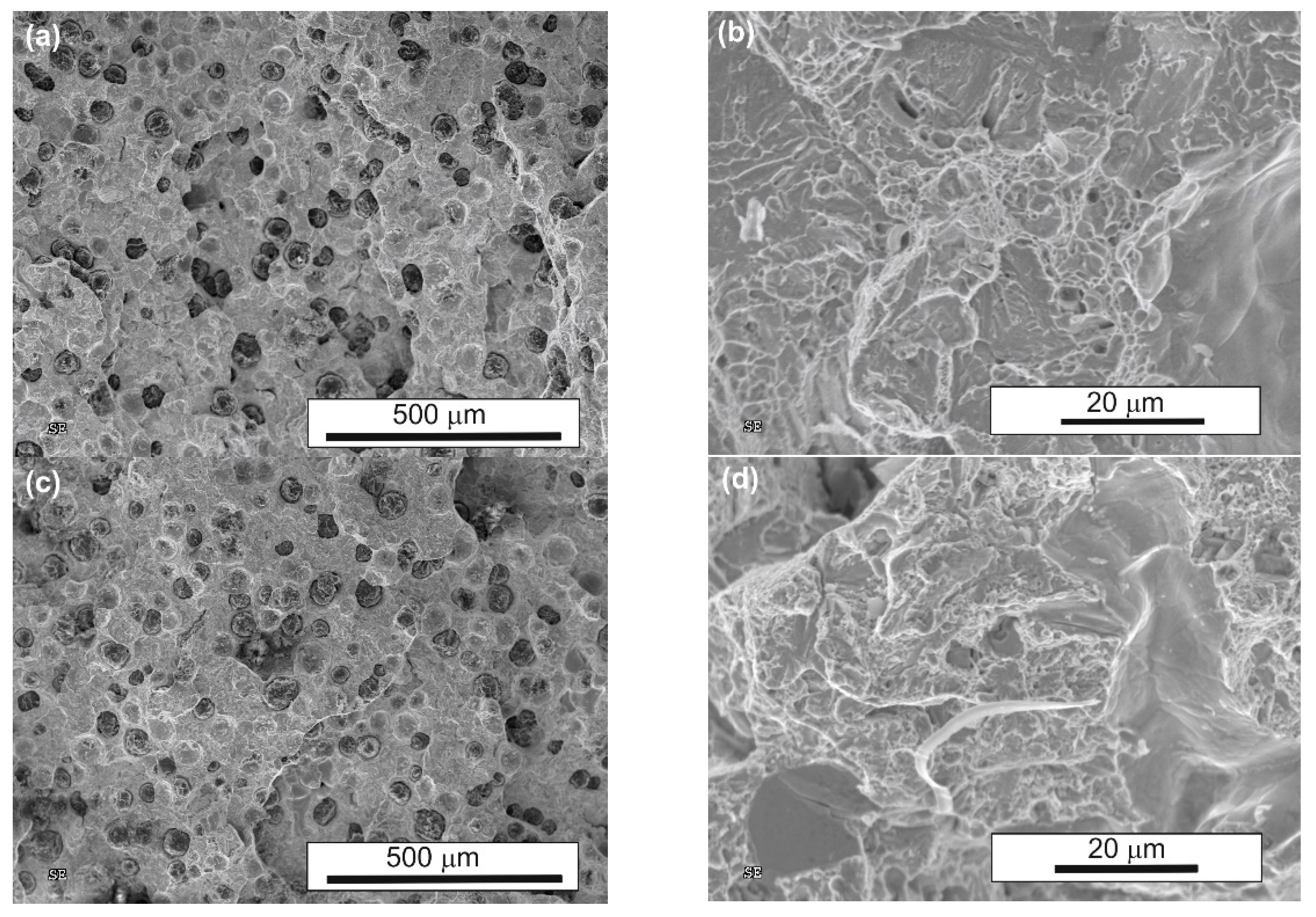

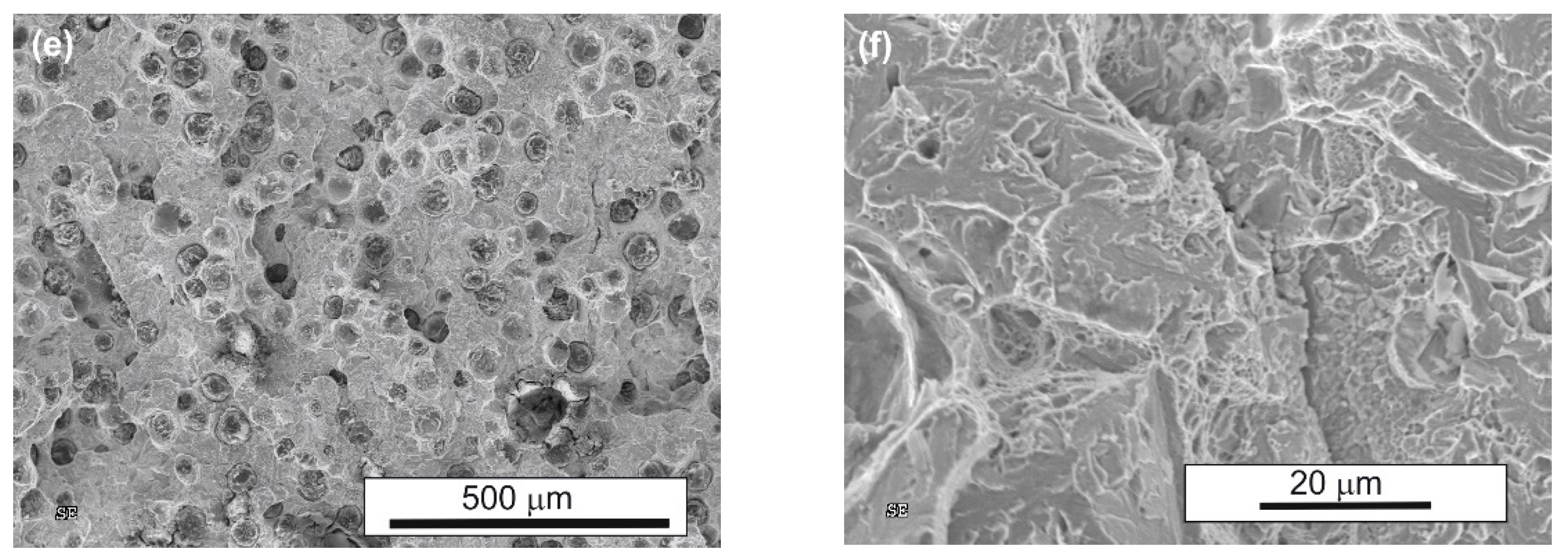

3.2. Microstructural Characterization

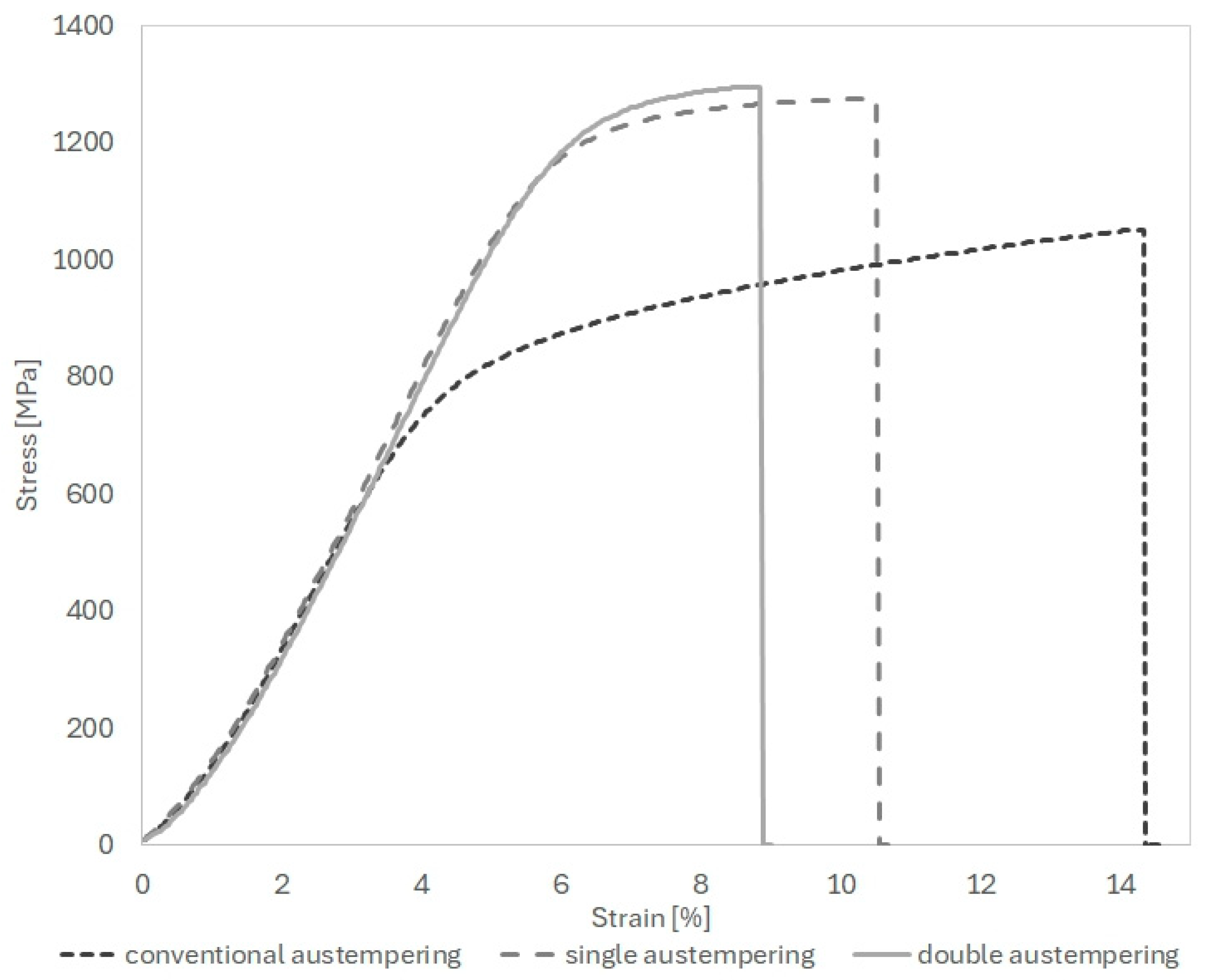

3.3. Mechanical Properties and Fracture Surface Analysis

4. Conclusions

- Long-term austempering carried out at temperatures within the lower range of bainitic transformation resulted in pronounced microstructural refinement compared with conventional austempering. The applied process can be classified as a nanostructurisation heat treatment for ADI.

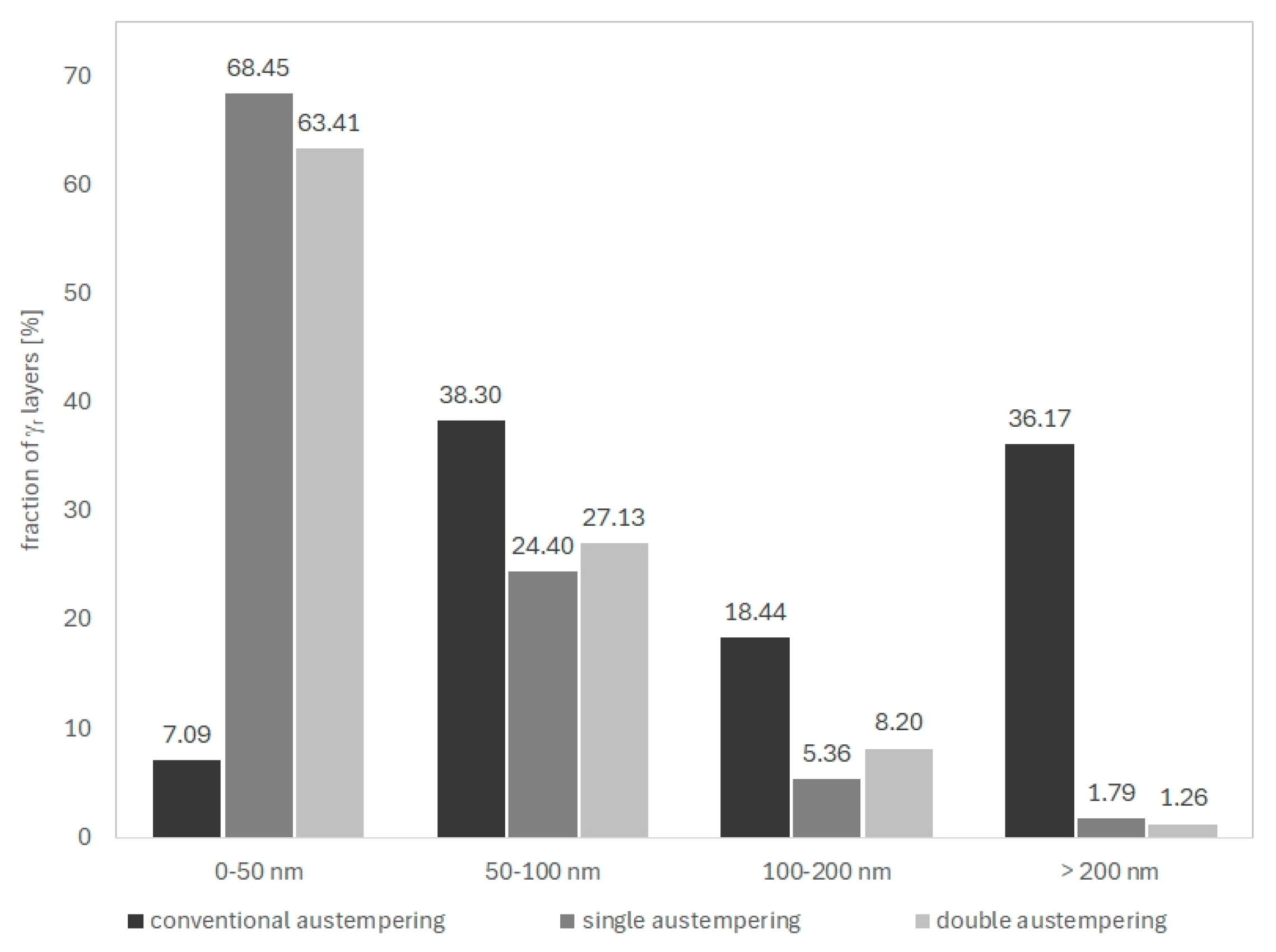

- Double-step austempering (AT-2) resulted in a finer and more homogeneous microstructure, characterized by extremely thin ferrite plates (<100 nm) and a reduced fraction of blocky austenite compared with the single-step treatment (AT-1).

- Both long-term austempering treatments reduced the retained austenite content from approximately 42% to about 22%, increasing hardness from 27 HRC to 32–35 HRC, tensile strength from 1027 MPa to 1220–1296 MPa, and yield strength from 683 MPa to 1033–1054 MPa, while reducing total elongation from 11% to 4.3–4.9% and V-notched impact toughness from 13 J/cm2 to 8–9 J/cm2.

- Overall, both AT-1 and AT-2 treatments demonstrated clear advantages over conventional austempering by producing a finer and mechanically stronger nanoausferritic matrix.

- Long-term austempering is suitable for ADI components requiring high strength and low material costs, provided that they are not subjected to significant dynamic loading. This work demonstrates the effectiveness of controlling the initial microstructure and applying long-term, low-temperature austempering to enhance the mechanical properties of ADI, representing a novel pathway for optimizing its heat treatment.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADI | Austempered ductile iron |

| Q&P | Quenching and partitioning |

| Ms | Martensitic start temperature |

| Mf | Martensitic finish temperature |

| TQ | Quenching temperature |

| TP | Partitioning temperature |

| AT-1 | Single austempering |

| AT-2 | Double austempering |

| TTT | Time-temperature-transformation |

| Ac1 | Temperature at which austenitic transformiation starts (during heating) |

| Ac3 | Temperature at which austenitic transformiation ends (during heating) |

| SEM | Scanning electron microscope |

| TEM | Transmission electron microscope |

| BF | Bright-field observation |

| DF | Dark-field observation |

| SE | Secondary electron |

| XRD | X-ray diffraction |

| d | Thickness of a plate |

| L | Width of a plate |

| HB | Brinell hardness |

| HRC | Rockwell hardness |

| KVC | impact toughness |

| ∆L/L0 | Change in dilatometric sample length |

| R0.2 | Yield strength |

| Rm | Tensile strength |

| A5 | Total elongation |

References

- Concli, F. Austempered Ductile Iron (ADI) for Gears: Contact and Bending Fatigue Behavior. Procedia Struct. Integr. 2018, 8, 14–23. [Google Scholar] [CrossRef]

- Krzyńska, A.; Kaczorowski, M. The Studies of Mechanical Properties and Structure of ADI as Function of Austempering Parameters. Arch. Foundry Eng. 2010, 10, 41–44. [Google Scholar]

- Krzyńska, A.; Kochański, A. Properties and Structure of High-Silicone Austempered Ductile Iron. Arch. Foundry Eng. 2014, 14, 91–94. [Google Scholar] [CrossRef]

- Sckudlarek, W.; Krmasha, M.N.; Al-Rubaie, K.S.; Preti, O.; Milan, J.C.G.; Da Costa, C.E. Effect of Austempering Temperature on Microstructure and Mechanical Properties of Ductile Cast Iron Modified by Niobium. J. Mater. Res. Technol. 2021, 12, 2414–2425. [Google Scholar] [CrossRef]

- Sellamuthu, P.; Samuel, D.G.H.; Dinakaran, D.; Premkumar, V.P.; Li, Z.; Seetharaman, S. Austempered Ductile Iron (ADI): Influence of Austempering Temperature on Microstructure, Mechanical Andwear Properties and Energy Consumption. Metals 2018, 8, 53. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, B.; Cheng, C.; Misra, R.D.K.; Gao, G.; Bai, B.; Weng, Y. The Significance of Ultrafine Film-like Retained Austenite in Governing Very High Cycle Fatigue Behavior in an Ultrahigh-Strength MN-SI-Cr-C Steel. Mater. Sci. Eng. A 2015, 645, 116–121. [Google Scholar] [CrossRef]

- Kaczorowski, M.; Krzyńska, A. Mechanical Properties and Structure of Austempered Ductile Iron -ADI. Arch. Foundry Eng. 2007, 7, 161–166. [Google Scholar]

- Zhang, Y.; Guo, E.; Wang, L.; Zhao, S.; Liu, X.; Yi, P.; Li, Y.; Feng, Y.; Song, M. Insights into Effect of First-Step Austempering Temperature on the Microstructure and Properties of Austempered Ductile Iron. Mater. Res. Express 2021, 8, 086512. [Google Scholar] [CrossRef]

- ARanzabal, J.; Gutierrez, I.; Rodriguez-Ibabe, J.M.; Urcola, J.J. Influence of the Amount and Morphology of Retained Austenite on the Mechanical Properties of an Austempered Ductile Iron. Metall. Mater. Trans. A 1997, 28, 1143–1156. [Google Scholar] [CrossRef]

- Myszka, D.; Skołek, E.; Wieczorek, A. Manufacture of Toothed Elements in Nanoausferritic Ductile Iron. Arch. Metall. Mater. 2014, 59, 1217–1221. [Google Scholar] [CrossRef]

- Myszka, D.; Wieczorek, A. An Assessment of the Applicability of Austempered Ductile Iron Containing Mo and Ni for Mining Machines Parts. Arch. Metall. Mater. 2013, 58, 953–956. [Google Scholar] [CrossRef]

- Krawiec, H.; Lelito, J.; Mróz, M.; Radoń, M. Influence of Heat Treatment Parameters of Austempered Ductile Iron on the Microstructure, Corrosion and Tribological Properties. Materials 2023, 16, 4107. [Google Scholar] [CrossRef]

- Krawiec, H.; Vignal, V.; Lelito, J.; Krystianiak, A.; Tyrała, E. Influence of the Heat Treatment on the Microstructure and Corrosion Resistance of Austempered Ductile Iron (ADI). Arch. Metall. Mater. 2020, 65, 151–156. [Google Scholar] [CrossRef]

- Wang, X.; Du, Y.; Liu, C.; Hu, Z.; Li, P.; Gao, Z.; Guo, H.; Jiang, B. Relationship among Process Parameters, Microstructure, and Mechanical Properties of Austempered Ductile Iron (ADI). Mater. Sci. Eng. A 2022, 857, 144063. [Google Scholar] [CrossRef]

- Du, Y.; Gao, X.; Wang, X.; Wang, X.; Ge, Y.; Jiang, B. Tribological Behavior of Austempered Ductile Iron (ADI) Obtained at Different Austempering Temperatures. Wear 2020, 456–457, 203396. [Google Scholar] [CrossRef]

- Myszka, D.; Wasiluk, K.; Skołek, E.; Świątnicki, W. Nanoausferritic Matrix of Ductile Iron. Mater. Sci. Technol. 2015, 31, 829–834. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Zhang, Z.; Li, Y.; Lv, B.; Zheng, C.; Zhang, P.; Zhang, F. A Review of Heat Treatment Processes for Bainitic Steel. J. Mater. Res. Technol. 2025, 37, 279–307. [Google Scholar] [CrossRef]

- Chu, C.; Qin, Y.; Li, X.; Yang, Z.; Zhang, F.; Guo, C.; Long, X.; You, L. Effect of Two-Step Austempering Process on Transformation Kinetics of Nanostructured Bainitic Steel. Materials 2019, 12, 166. [Google Scholar] [CrossRef]

- Sun, D.; Feng, X.; Zhang, P.; Sun, X.; Yang, Z.; Long, X.; Zhang, F. Effects of Two-Step Austempering Processes on the Wear Resistance and Fatigue Lifetime of High-Carbon Nanostructured Bainitic Steel. J. Mater. Res. Technol. 2024, 30, 4739–4749. [Google Scholar] [CrossRef]

- Skowronek, A.; Cordova-Tapia, E.; Tobajas-Balsera, P.; Garcia-Mateo, C.; Jiménez, J.A.; Petrov, R.; Grajcar, A. Bainite Plate Thickness Reduction and Microstructure Tailoring by Double Austempering of Al-Rich 3Mn Steel. Mater. Sci. Eng. A 2022, 853, 143743. [Google Scholar] [CrossRef]

- Hegde, A.; Sharma, S.; Hande, R.; Gurumurthy, B.M. Microstructure and Mechanical Properties of Manganese-Alloyed Austempered Ductile Iron Produced by Novel Modified Austempering Process. Cogent Eng. 2022, 9, 2046301. [Google Scholar] [CrossRef]

- Panneerselvam, S.; Putatunda, S.K. Processing of Nanostructured Austempered Ductile Cast Iron (ADI) by a Novel Method. Int. J. Metall. Met. Phys. 2018, 3, 11. [Google Scholar] [CrossRef]

- Du, Y.; Wang, X.; Zhang, D.; Wang, X.; Ju, C.; Jiang, B. A Superior Strength and Sliding-Wear Resistance Combination of Ductile Iron with Nanobainitic Matrix. J. Mater. Res. Technol. 2021, 11, 1175–1183. [Google Scholar] [CrossRef]

- Putatunda, S.K. Development of Austempered Ductile Cast Iron (ADI) with Simultaneous High Yield Strength and Fracture Toughness by a Novel Two-Step Austempering Process. Mater. Sci. Eng. A 2001, 315, 70–80. [Google Scholar] [CrossRef]

- Yang, J.; Putatunda, S.K. Effect of Microstructure on Abrasion Wear Behavior of Austempered Ductile Cast Iron (ADI) Processed by a Novel Two-Step Austempering Process. Mater. Sci. Eng. A 2005, 406, 217–228. [Google Scholar] [CrossRef]

- Putatunda, S.K. Comparison of the Mechanical Properties of Austempered Ductile Cast Iron (ADI) Processed by Conventional and Step-down Austempering Process. Mater. Manuf. Process. 2010, 25, 749–757. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chuang, T.L. Influence of Stepped Austempering Process on the Fracture Toughness of Austempered Ductile Iron. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2001, 32, 2509–2514. [Google Scholar] [CrossRef]

- Yang, J.; Putatunda, S.K. Improvement in Strength and Toughness of Austempered Ductile Cast Iron by a Novel Two-Step Austempering Process. Mater. Des. 2004, 25, 219–230. [Google Scholar] [CrossRef]

- Soliman, M.; Palkowski, H.; Nofal, A. Multiphase Ausformed Austempered Ductile Iron. Arch. Metall. Mater. 2017, 62, 1493–1498. [Google Scholar] [CrossRef][Green Version]

- Nofal, A.A.; El-din, H.N.; Ibrahim, M.M. Thermomechanical Treatment of Austempered Ductile Iron. Int. J. Cast Met. Res. 2007, 20, 47–52. [Google Scholar] [CrossRef]

- Ibrahim, K.M. Properties of Ausformed Austempered Ductile Iron (AADI) Containing Ni. Int. J. Cast Met. Res. 2005, 18, 309–314. [Google Scholar] [CrossRef]

- Nasr El-Din, H.; Nofal, A.A.; Ibrahim, K.M.; Ramadan, A.A. Ausforming of Austempered Ductile Iron Alloyed with Nickel. Int. J. Cast Met. Res. 2006, 19, 137–150. [Google Scholar] [CrossRef]

- Soliman, M.; Nofal, A.; Palkowski, H. Effect of Thermo-Mechanical Processing on Structure and Properties of Dual-Phase Matrix ADI with Different Si-Contents. Int. J. Met. 2020, 14, 853–860. [Google Scholar] [CrossRef]

- Melado, A.C.; Nishikawa, A.S.; Goldenstein, H.; Giles, M.A.; Reed, P.A.S. Effect of Microstructure on Fatigue Behaviour of Advanced High Strength Ductile Cast Iron Produced by Quenching and Partitioning Process. Int. J. Fatigue 2017, 104, 397–407. [Google Scholar] [CrossRef]

- Da Silva, A.J.S.T.; Goldenstein, H.; Guesser, W.L.; De Campos, M.F. Quenching and Partitioning Heat Treatment in Ductile Cast Irons. Mater. Res. 2014, 17, 1115–1123. [Google Scholar] [CrossRef]

- Wang, X.; Du, Y.; Liu, B.; Jiang, B. Enhanced Plasticity of Austempered Ductile Iron (ADI) by Partitioning Treatment. Mater. Sci. Eng. A 2021, 804, 140513. [Google Scholar] [CrossRef]

- Panneerselvam, S.; Martis, C.J.; Putatunda, S.K.; Boileau, J.M. An Investigation on the Stability of Austenite in Austempered Ductile Cast Iron (ADI). Mater. Sci. Eng. A 2015, 626, 237–246. [Google Scholar] [CrossRef]

- Myszka, D.; Wieczorek, A.N.; Skołek, E.; Borowski, T.; Kotwica, K.; Kalita, M.; Kruk, R.; Nuckowski, P.M. Abrasive Wear Resistance of Ultrafine Ausferritic Ductile Iron Intended for the Manufacture of Gears for Mining Machinery. Materials 2023, 16, 4311. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chen, M.L. Corrosion Behavior of Nickel Alloyed and Austempered Ductile Irons in 3.5% Sodium Chloride. Corros. Sci. 2010, 52, 2945–2949. [Google Scholar] [CrossRef]

- Joshi, D.; Putatunda, S.; Panneerselvam, S.; Boileau, J. Investigation of the Effect of Novel Two-Step Austenitization Process on the Microstructure and Mechanical Properties of ADI. Key Eng. Mater. 2025, 1011, 11–17. [Google Scholar] [CrossRef]

- Wadageri, C.S.; Kurahatti, R.V. Effect of Two-Step Austempering on Fatigue Behavior of Austempered Ductile Iron (ADI). SN Appl. Sci. 2019, 1, 300. [Google Scholar] [CrossRef]

- Parhad, P.; Likhite, A.; Bhatt, J.; Peshwe, D. Optimization of Isothermal Transformation Period for Austempered Ductile Iron. Metall. Foundry Eng. 2017, 43, 313. [Google Scholar] [CrossRef]

- Erić, O.; Jovanović, M.; Šidanin, L.; Rajnović, D.; Zec, S. The Austempering Study of Alloyed Ductile Iron. Mater. Des. 2006, 27, 617–622. [Google Scholar] [CrossRef]

- Felipe Dias, J.; Ribeiro, G.O.; Carmo, D.J.; Vilela, J.J. The Effect of Reducing the Austempering Time on the Fatigue Properties of Austempered Ductile Iron. Mater. Sci. Eng. A 2012, 556, 408–413. [Google Scholar] [CrossRef]

- Kovacs, B.V. Austempered Ductile Iron. Fact and Fiction. Mod. Cast. 1990, 80, 38–41. [Google Scholar]

- Karaca, B.; Şimşir, M.; Akkan, H. Effect of Heat Treatment on the Tensile Properties of Cam Shaft Made of Ductile Cast Iron. J. Achiev. Mater. Manuf. Eng. 2016, 76, 15–20. [Google Scholar] [CrossRef]

- Sharma, S.; Hegde, A. An Analysis of the Amount of Retained Austenite in Manganese Alloyed Austempered Ductile Iron. Mater. Res. 2021, 24, e20210301. [Google Scholar] [CrossRef]

- Górny, M.; Angella, G.; Tyrała, E.; Kawalec, M.; Paź, S.; Kmita, A. Role of Austenitization Temperature on Structure Homogeneity and Transformation Kinetics in Austempered Ductile Iron. Met. Mater. Int. 2019, 25, 956–965. [Google Scholar] [CrossRef]

- Tuan, H.A.; Hai, N.H.; Dung, N.H.; Nam, T.T.; Nam, N.D. Austenitization and Formation of Ausferrite Structure in Austempered Ductile Iron with Dual Matrix. Mater. Res. Express 2022, 9, 046520. [Google Scholar] [CrossRef]

- Bai, J.J.; Yu, F.; Wang, C.Y.; Wang, H.; Xu, Y.; Chen, X.P.; Cao, W. quan Effect of Cyclic Quenching Treatment on Microstructural Evolution and Properties of Ductile Cast Iron. J. Iron Steel Res. Int. 2023, 30, 126–136. [Google Scholar] [CrossRef]

- Liu, X.; Yu, W.; Che, H.; Zhang, J.; Zhu, J.; Jiang, Q.; Zhang, C.; Wang, M. The Effect of Cyclic Heat Treatment on the Microstructure and Mechanical Properties of 18CrNiMo7-6 Gear Steel. Materials 2024, 17, 5855. [Google Scholar] [CrossRef]

- Zhou, X.; Jia, C.; Mi, P.; Zhang, H.; Yan, W.; Wang, W.; Sun, M.; van der Zwaag, S.; Rong, L. Cyclic Quenching Treatment Doubles the Charpy V-Notch Impact Energy of a 2.3 GPa Maraging Steel. J. Mater. Sci. Technol. 2025, 209, 311–328. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, X.; Pan, H. Cyclic Quenching Treatment to Improve Strength–Ductility Combinations in 18CrNiMo7-6 Steel. J. Mater. Eng. Perform. 2023, 33, 10446–10454. [Google Scholar] [CrossRef]

- Chang, L.C.; Bhadeshia, H.K.D.H. Austenite Films in Bainitic Microstructures. Mater. Sci. Technol. 2014, 11, 874–882. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Spychalski, W.L.; Rózniatowski, K.; Kurzydłowski, K.J. Image Based Analysis of Complex Microstructures of Engineering Materials. Int. J. Appl. Math. Comput. Sci. 2008, 18, 33–39. [Google Scholar] [CrossRef]

- Skołek, E.; Giętka, T.; Świątnicki, W.A.; Myszka, D. The Comparative Study of the Microstructure and Phase Composition of Nanoausferritic Ductile Iron Alloy Using SEM, TEM, Magnetometer, and X-Ray Diffraction Methods. Acta Phys. Pol. A 2017, 131, 1319–1324. [Google Scholar] [CrossRef]

- ISO 6892-1:2019; Matallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- DIN EN 10045-1:1991-04; Charpy Impact Test on Metallic Materials; Part 1: Test Method. NSAI: Dublin, Ireland, 1991.

- Landesberger, M.; Koos, R.; Hofmann, M.; Li, X.; Boll, T.; Petry, W.; Volk, W. Phase Transition Kinetics in Austempered Ductile Iron (ADI) with Regard to MO Content. Materials 2020, 13, 5266. [Google Scholar] [CrossRef]

- Rajnovic, D.; Eric, O.; Sidjanin, L. The Standard Processing Window of Alloyed ADI Mate. Kov. Mater. 2012, 50, 199–208. [Google Scholar] [CrossRef]

- Caballero, F.G.; Garcia-Mateo, C.; Santofimia, M.J.; Miller, M.K.; García de Andrés, C. New Experimental Evidence on the Incomplete Transformation Phenomenon in Steel. Acta Mater. 2009, 57, 8–17. [Google Scholar] [CrossRef]

- Putatunda, S.K.; Gadicherla, P.K. Effect of Austempering Time on Mechanical Properties of a Low Manganese Austempered Ductile Iron. J. Mater. Eng. Perform. 2000, 9, 193–203. [Google Scholar] [CrossRef]

- Grahovac, N.; Rade, Đ. Determination of Processing Window for ADI; Association of Metallurgical Engineers of Serbia: Belgrade, Serbia, 2010. [Google Scholar]

- De Godoi Pereira, L.N.; de Castro Medeiros, R.G.; de Freitas, P.G.M.; da Silva, C.F.; da Silva, L.M.; Leal, R.H. Microstructural Evaluation of an Austempered Cast Iron Alloy. Mater. Res. 2022, 25, e20210256. [Google Scholar] [CrossRef]

- Benam, A.S. Effect of Alloying Elements on Austempered Ductile Iron (ADI) Properties and Its Process: Review. China Foundry 2015, 12, 54–70. [Google Scholar]

- Kejzlar, P.; Andrsova, Z.; Petrzilkova, M.; Skrbek, B.; Duchac, A.; Myszka, D. Highly Accurate Structural Analysis of Austempered Ductile Iron Using EBSD Technique. Mater. Sci. Forum 2023, 1081, 125–130. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, Z.; Wang, P.; Li, D. Effect of Austenitizing Temperature on Isothermal Quenching Microstructure and Mechanical Properties of 52100 Bearing Steel. Mater. Sci. Eng. A 2024, 892, 146051. [Google Scholar] [CrossRef]

- Yang, J.; Putatunda, S.K. Influence of a Novel Two-Step Austempering Process on the Strain-Hardening Behavior of Austempered Ductile Cast Iron (ADI). Mater. Sci. Eng. A 2004, 382, 265–279. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Mg | Ni | Mo | Cu | Cr | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. % | 3.5 | 2.54 | 0.16 | 0.047 | 1.4 | 0.24 | 0.5 | 0.03 | 0.04 | 0.013 | balance |

| ADI After Conventional Austempering | ADI After Single Austempering (AT-1) | ADI After Double Austempering (AT-2) | |||

|---|---|---|---|---|---|

| average | core | edge | core | edge | |

| Minimum [µm2] | 1 | 0.02 | 0.44 | 0.4 | 0.74 |

| Maximum [µm2] | 143 | 22 | 43.47 | 13 | 24.54 |

| Average [µm2] | 14 ± 5 | 3.9 ± 0.9 | 3.81 ± 0.96 | 3.1 ± 0.9 | 4.16 ± 0.98 |

| Thickness of Structural Element | ADI After Conventional Austempering | ADI After Single Austempering (AT-1) | ADI After Double Austempering (AT-2) | |||

|---|---|---|---|---|---|---|

| Ferrite | Austenite | Ferrite | Austenite | Ferrite | Austenite | |

| Minimum [nm] | 70 | 30 | 24 | 9 | 15 | 8 |

| Maximum [nm] | 977 | 1192 | 686 | 420 | 434 | 268 |

| Average [nm] | 351 ± 28 | 225 ± 13 | 124 ± 8 | 47 ± 5 | 117 ± 8 | 52 ± 4 |

| ADI After Conventional Austempering | ADI After Single Austempering (AT-1) | ADI After Double Austempering (AT-2) | |

|---|---|---|---|

| The amount of blocky residual austenite [%] (micrometer) | 28.9 ± 5.5 | 17.4 ± 3.3 | 12.8 ± 2.3 |

| Total amount of residual austenite (XRD) [%] | 41.7 | 21.7 | 22.4 |

| ADI After Conventional Austempering | ADI After Single Austempering (AT-1) | ADI After Double Austempering (AT-2) | |

|---|---|---|---|

| HRC | 27 ± 4 | 37 ± 4 | 35 ± 5 |

| HB | 266 ± 12 | 349 ± 38 | 331 ± 45 |

| R0.2 [MPa] | 683 ± 7 | 1033 ± 28 | 1054 ± 22 |

| Rm [MPa] | 1027 ± 28 | 1220 ± 30 | 1296 ± 2 |

| A5 [%] | 11 ± 0.3 | 4.3 ± 2.9 | 4.9 ± 0.2 |

| KVC [J/cm2] | 13.3 ± 1.2 | 9 ± 0 | 8.3 ± 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skołek, E.; Skoczylas, P.; Wasiluk, K.; Świątnicki, W.A.; Wieczorek, A.N.; Myszka, D. The Influence of Initial Microstructure on the Microstructure and Mechanical Properties of Ductile Iron After Nanostructurisation Heat Treatment. Nanomaterials 2025, 15, 1710. https://doi.org/10.3390/nano15221710

Skołek E, Skoczylas P, Wasiluk K, Świątnicki WA, Wieczorek AN, Myszka D. The Influence of Initial Microstructure on the Microstructure and Mechanical Properties of Ductile Iron After Nanostructurisation Heat Treatment. Nanomaterials. 2025; 15(22):1710. https://doi.org/10.3390/nano15221710

Chicago/Turabian StyleSkołek, Emilia, Paweł Skoczylas, Kamil Wasiluk, Wiesław A. Świątnicki, Andrzej N. Wieczorek, and Dawid Myszka. 2025. "The Influence of Initial Microstructure on the Microstructure and Mechanical Properties of Ductile Iron After Nanostructurisation Heat Treatment" Nanomaterials 15, no. 22: 1710. https://doi.org/10.3390/nano15221710

APA StyleSkołek, E., Skoczylas, P., Wasiluk, K., Świątnicki, W. A., Wieczorek, A. N., & Myszka, D. (2025). The Influence of Initial Microstructure on the Microstructure and Mechanical Properties of Ductile Iron After Nanostructurisation Heat Treatment. Nanomaterials, 15(22), 1710. https://doi.org/10.3390/nano15221710