Role of Cu in Nanostructural Relationship Between Phase Separation and Deformation-Induced Twinning in Heavily Drawn Non-Equiatomic High-Entropy Alloy Wire

Abstract

1. Introduction

2. Experimental Procedures

2.1. Alloy Fabrication and Processing

2.2. Microstructural Characterization

2.3. Mechanical Testing

3. Results and Discussion

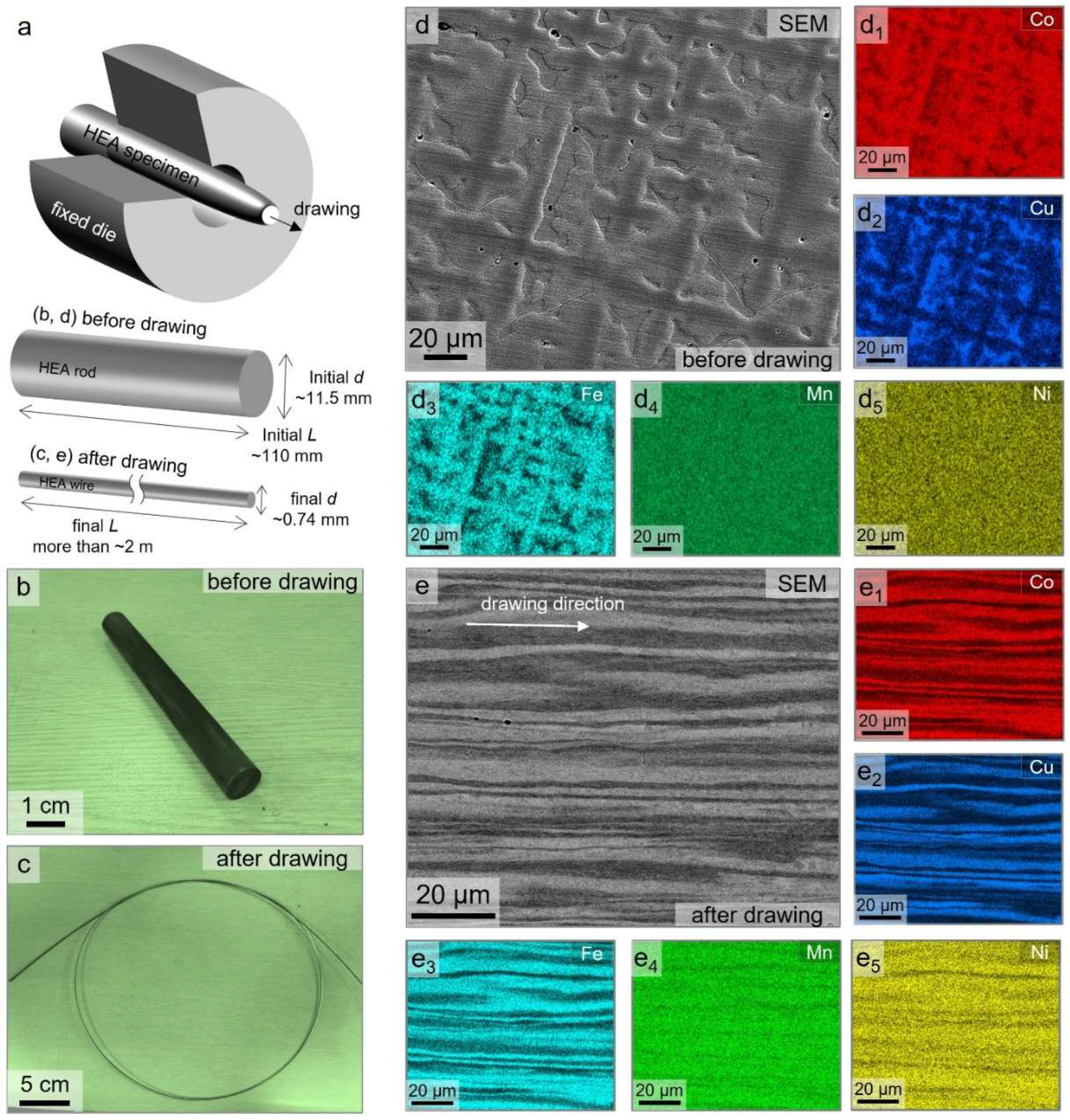

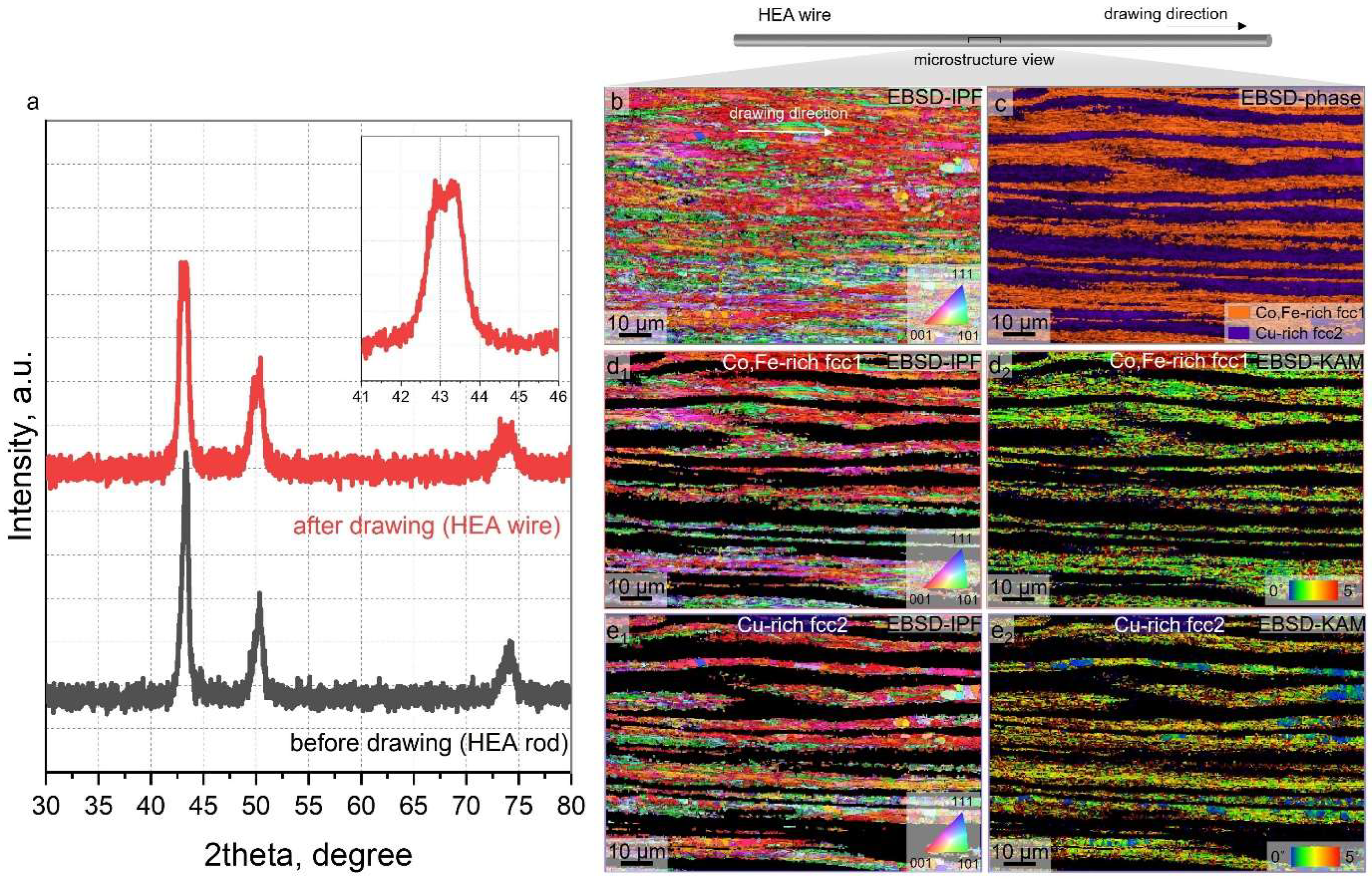

3.1. Microstructural Analysis

| Specimen | Phase | Co (at %) | Cu (at %) | Fe (at %) | Mn (at %) | Ni (at %) |

|---|---|---|---|---|---|---|

| HEA rod | Co-Fe-rich fcc1 | ~22.5 ± 2.5 | ~8.9 ± 1.7 | ~27.7 ± 1.8 | ~21.6 ± 1.7 | ~19.3 ± 2.4 |

| Cu-rich fcc2 | ~6.3 ± 0.6 | ~50.0 ± 3.1 | ~8.4 ± 1.5 | ~22.4 ± 0.9 | ~12.9 ± 1.7 | |

| HEA wire | Co-Fe-rich fcc1 | ~24.1 ± 1.1 | ~10.7 ± 2.8 | ~26.4 ± 2.1 | ~18.7 ± 2.1 | ~20.1 ± 1.4 |

| Cu-rich fcc2 | ~7.4 ± 1.0 | ~47.5 ± 2.4 | ~10.3 ± 2.7 | ~19.6 ± 1.8 | ~15.2 ± 1.1 |

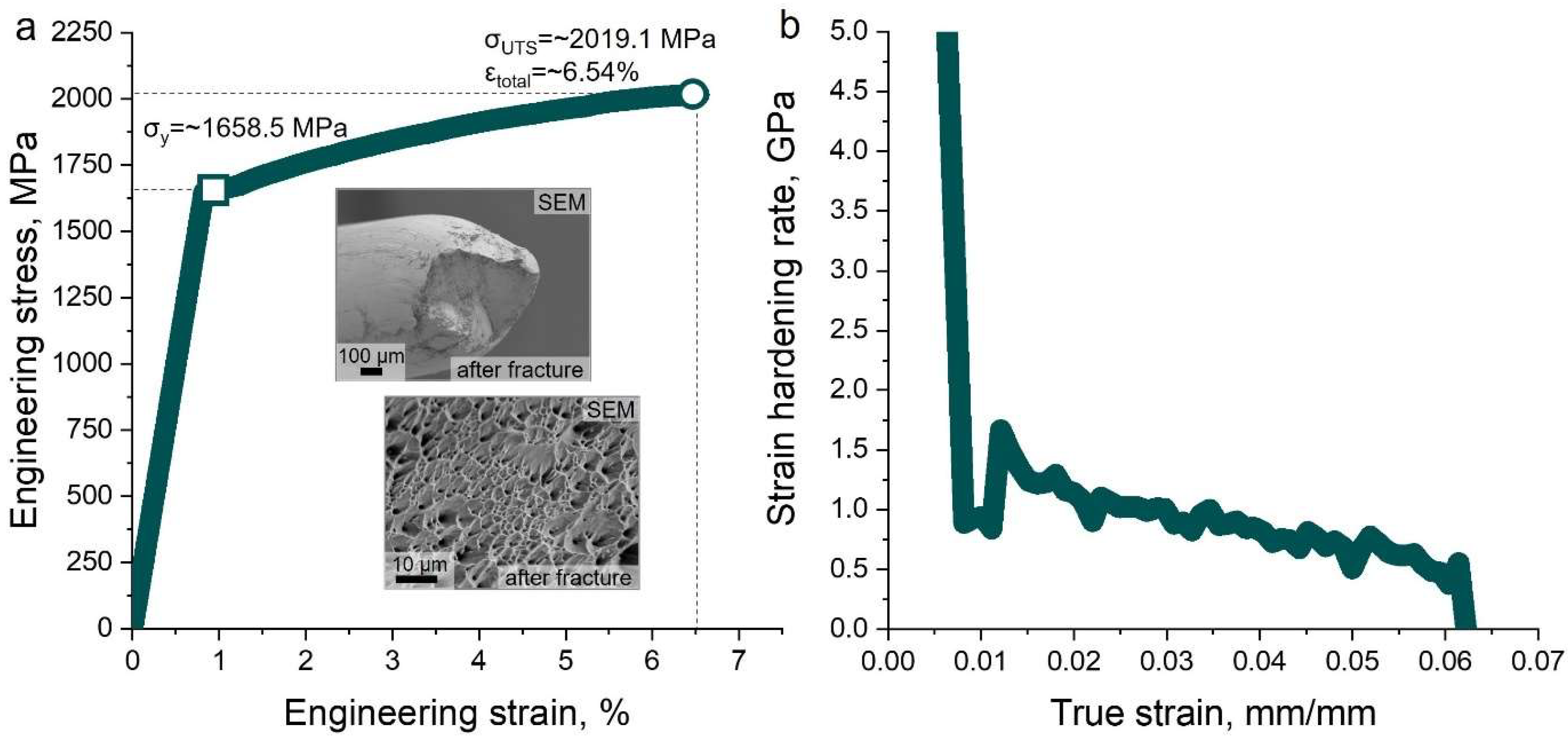

3.2. Mechanical Properties

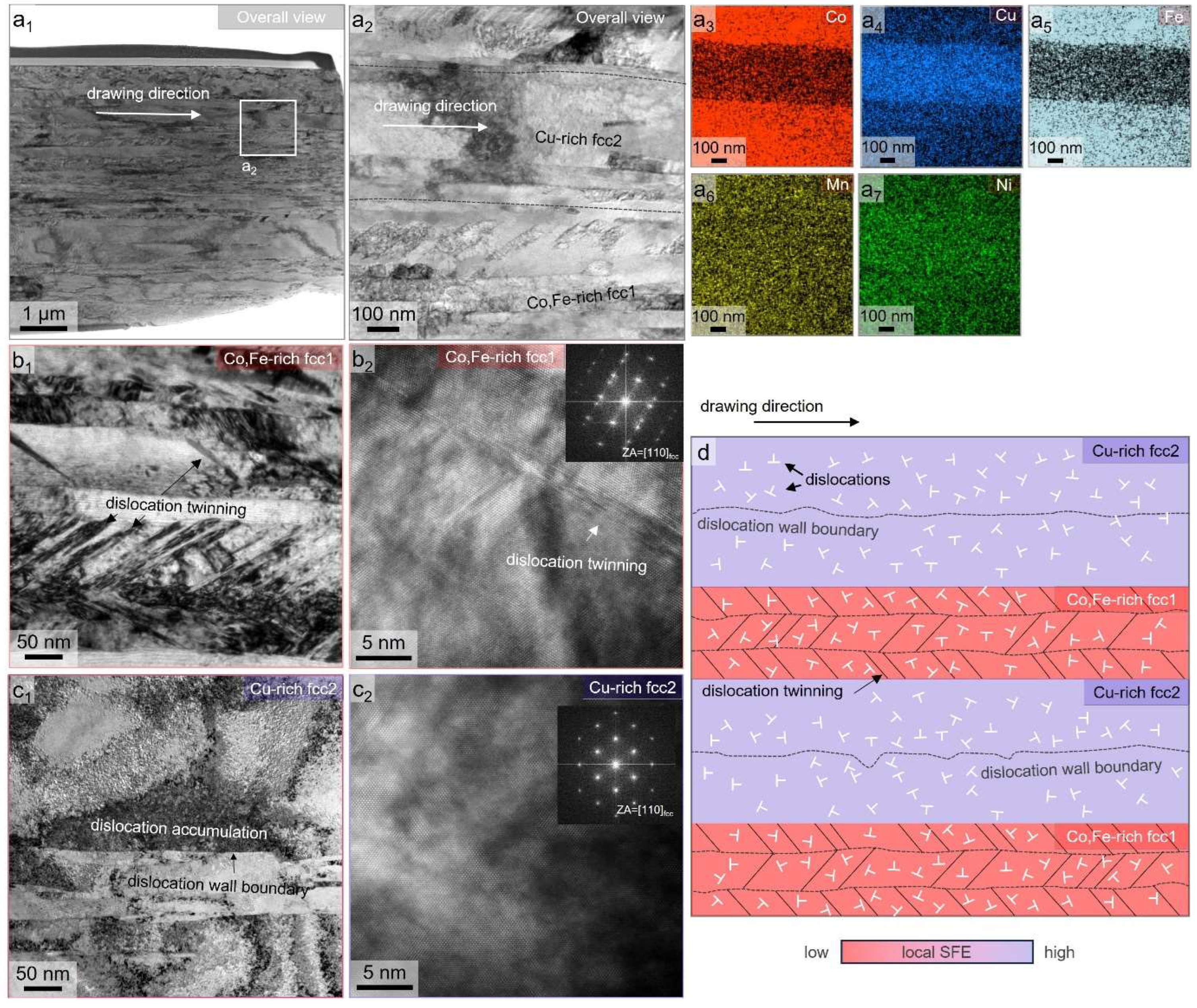

3.3. Deformation Mechanism

4. Conclusions

- Severe plastic deformation via cold drawing introduced a high true strain (~5.5), leading to significant microstructural refinement and spinodal-like phase separation into dual fcc phases, that is, Co-Fe-rich fcc1 and Cu-rich fcc2 phases—without heat treatment.

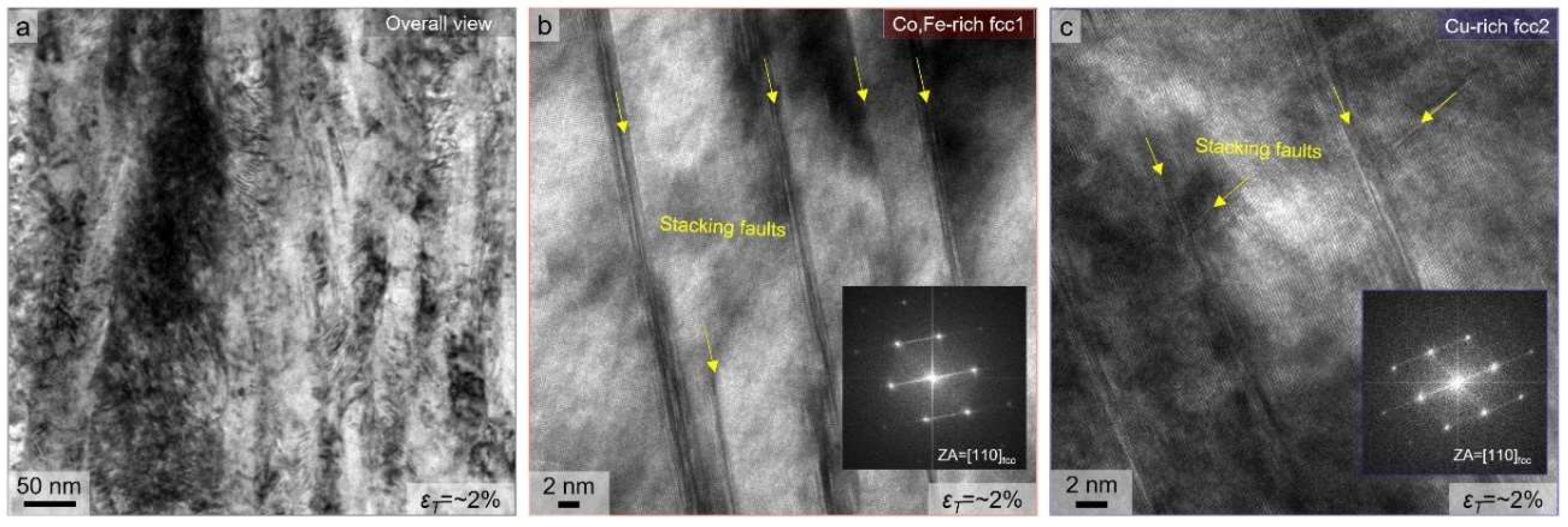

- Experimentally, different degrees of dislocation accumulation and distinct deformation structure appearances resulted in the dual-phase structure, which was caused by Cu-induced phase-separation-driven stacking fault energy (SFE) variations.

- The Co-Fe-rich fcc1 (Cu-depleted) phase, having a lower SFE, accommodated a higher dislocation density with a deformation twinning and stacking faults structure, while the Cu-rich fcc2 phase deformed mainly via dislocation glide. This complementary deformation response promoted strain partitioning and plastic compatibility across phase boundaries.

- The cold-drawn HEA wire exhibited an exceptional ultimate tensile strength of nearly ~2 GPa with a total elongation of ~6.5%, attributed to a synergistic combination of twinning-induced plasticity, dislocation hardening, and interface strengthening.

- Interrupted tensile tests revealed that the presence of stacking faults was activated at very early stages of deformation (interrupting strain of ~2%), confirming the onset of multi-mode plasticity from the beginning of loading.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schuh, B.; Mendez-Martin, F.; Völker, B.; George, E.P.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical Properties, Microstructure and Thermal Stability of a Nanocrystalline CoCrFeMnNi High-Entropy Alloy after Severe Plastic Deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef]

- Rizi, M.S.; Minouei, H.; Lee, B.J.; Pouraliakbar, H.; Toroghinejad, M.R.; Hong, S.I. Hierarchically Activated Deformation Mechanisms to Form Ultra-Fine Grain Microstructure in Carbon Containing FeMnCoCr Twinning Induced Plasticity High Entropy Alloy. Mater. Sci. Eng. A 2021, 824, 141803. [Google Scholar] [CrossRef]

- Minouei, H.; Rizi, M.S.; Kheradmandfard, M.; Shim, S.H.; Hong, S.I.; Park, N. NiNbTi(Al/Si) Medium-Entropy Amorphous Alloys with Enhanced Mechanical and Thermal Properties. Intermetallics 2025, 178, 108609. [Google Scholar] [CrossRef]

- Cantor, B. Multicomponent High-Entropy Cantor Alloys. Prog. Mater. Sci. 2021, 120, 100754. [Google Scholar] [CrossRef]

- Shim, S.H.; Oh, S.M.; Lee, J.; Hong, S.K.; Hong, S.I. Nanoscale Modulated Structures by Balanced Distribution of Atoms and Mechanical/Structural Stabilities in CoCuFeMnNi High Entropy Alloys. Mater. Sci. Eng. A 2019, 762, 138120. [Google Scholar] [CrossRef]

- Chen, J.X.; Li, T.; Chen, Y.; Cao, F.H.; Wang, H.Y.; Dai, L.H. Ultra-Strong Heavy-Drawn Eutectic High Entropy Alloy Wire. Acta Mater. 2023, 243, 118515. [Google Scholar] [CrossRef]

- Shi, P.; Zhong, Y.; Li, Y.; Ren, W.; Zheng, T.; Shen, Z.; Yang, B.; Peng, J.; Hu, P.; Zhang, Y.; et al. Multistage Work Hardening Assisted by Multi-Type Twinning in Ultrafine-Grained Heterostructural Eutectic High-Entropy Alloys. Mater. Today 2020, 41, 62–71. [Google Scholar] [CrossRef]

- Ma, X.; Chen, J.; Wang, X.; Xu, Y.; Xue, Y. Microstructure and Mechanical Properties of Cold Drawing CoCrFeMnNi High Entropy Alloy. J. Alloys Compd. 2019, 795, 45–53. [Google Scholar] [CrossRef]

- Liu, S.F.; Wu, Y.; Wang, H.T.; He, J.Y.; Liu, J.B.; Chen, C.X.; Liu, X.J.; Wang, H.; Lu, Z.P. Stacking Fault Energy of Face-Centered-Cubic High Entropy Alloys. Intermetallics 2018, 93, 269–273. [Google Scholar] [CrossRef]

- Shih, M.; Miao, J.; Mills, M.; GhazisaeidiI, M. Stacking Fault Energy in Concentrated Alloys. Nat. Commun. 2021, 12, 3590. [Google Scholar] [CrossRef]

- Tian, Y.Z.; Zhao, L.J.; Chen, S.; Shibata, A.; Zhang, Z.F.; Tsuji, N. Significant Contribution of Stacking Faults to the Strain Hardening Behavior of Cu-15%Al Alloy with Different Grain Sizes. Sci. Rep. 2015, 5, 16707. [Google Scholar] [CrossRef]

- Qin, G.; Yu, Q.; Yu, K.; Fang, Y.; Chen, R.; Liang, Z.; Huang, M. Strengthening complex concentrated alloy without ductility loss by 3D printed high-density coherent nanoparticles. Int. J. Plast. 2024, 177, 103987. [Google Scholar] [CrossRef]

- Fiocchi, J.; Mostaed, A.; Coduri, M.; Tuissi, A.; Casati, R. Development and Characterization of a Novel High Entropy Alloy Strengthened through Concurrent Spinodal Decomposition and Precipitation. J. Alloys Compd. 2023, 947, 169706. [Google Scholar] [CrossRef]

- MacDonald, B.E.; Fu, Z.; Wang, X.; Li, Z.; Chen, W.; Zhou, Y.; Raabe, D.; Schoenung, J.; Hahn, H.; Lavernia, E.J. Influence of Phase Decomposition on Mechanical Behavior of An Equiatomic CoCuFeMnNi High Entropy Alloy. Acta Mater. 2019, 181, 25–35. [Google Scholar] [CrossRef]

- Park, H.; Haftlang, F.; Heo, Y.; Seol, J.B.; Wang, Z.; Kim, H.S. Periodic Spinodal Decomposition in Double-Strengthened Medium–Entropy Alloy. Nat. Commun. 2024, 15, 5757. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Lin, D.; Tang, Z.; Song, X.; He, P.; Zhang, S.; Bian, H.; Fu, W.; Song, Y. Eutectic High-Entropy Alloys and Their Applications in Materials Processing Engineering: A Review. J. Mater. Sci. Technol. 2024, 189, 211–246. [Google Scholar] [CrossRef]

- Agrawal, P.; Gupta, S.; Shukla, S.; Nene, S.S.; Thapliyal, S.; Toll, M.P.; Mishra, R.S. Role of Cu Addition in Enhancing Strength-Ductility Synergy in Transforming High Entropy Alloy. Mater. Des. 2022, 215, 110487. [Google Scholar] [CrossRef]

- Minouei, H.; Akbari, G.H.; Enayati, M.H.; Hong, S.I. Amorphization and Nanocrystallization of Ni–Nb-Si Alloys. Mater. Sci. Eng. A 2017, 682, 396–401. [Google Scholar] [CrossRef]

- Lu, S.; Hu, Q.M.; Johansson, B.; Vitos, L. Stacking Fault Energies of Mn, Co and Nb Alloyed Austenitic Stainless Steels. Acta Mater. 2011, 59, 5728–5734. [Google Scholar] [CrossRef]

- Wei, D.; Li, X.; Heng, W.; Koizumi, Y.; He, F.; Choi, W.M.; Lee, B.J.; Kim, H.S.; Kato, H.; Chiba, A. Novel Co-Rich High Entropy Alloys with Superior Tensile Properties. Mater. Res. Lett. 2019, 7, 82–88. [Google Scholar] [CrossRef]

- Meiners, T.; Frolov, T.; Rudd, R.E.; Dehm, G.; Liebscher, C.H. Observations of Grain-Boundary Phase Transformations in an Elemental Metal. Nature 2020, 579, 375–378. [Google Scholar] [CrossRef]

- Shi, P.; Li, Y.; Li, Z.; Jiang, X.; Yan, J.; Zhou, R.; Qin, Y.; Lin, Y.; Huang, J.; Tan, B.; et al. Strong, Ductile, and Hierarchical Hetero-Lamellar-Structured Alloys through Microstructural Inheritance and Refinement. Proc. Natl. Acad. Sci. USA 2025, 122, e2409317121. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shim, S.H.; Saboktakin Rizi, M.; Minouei, H.; Hong, S.I. Role of Cu in Nanostructural Relationship Between Phase Separation and Deformation-Induced Twinning in Heavily Drawn Non-Equiatomic High-Entropy Alloy Wire. Nanomaterials 2025, 15, 1281. https://doi.org/10.3390/nano15161281

Shim SH, Saboktakin Rizi M, Minouei H, Hong SI. Role of Cu in Nanostructural Relationship Between Phase Separation and Deformation-Induced Twinning in Heavily Drawn Non-Equiatomic High-Entropy Alloy Wire. Nanomaterials. 2025; 15(16):1281. https://doi.org/10.3390/nano15161281

Chicago/Turabian StyleShim, Sang Hun, Mohsen Saboktakin Rizi, Hossein Minouei, and Sun Ig Hong. 2025. "Role of Cu in Nanostructural Relationship Between Phase Separation and Deformation-Induced Twinning in Heavily Drawn Non-Equiatomic High-Entropy Alloy Wire" Nanomaterials 15, no. 16: 1281. https://doi.org/10.3390/nano15161281

APA StyleShim, S. H., Saboktakin Rizi, M., Minouei, H., & Hong, S. I. (2025). Role of Cu in Nanostructural Relationship Between Phase Separation and Deformation-Induced Twinning in Heavily Drawn Non-Equiatomic High-Entropy Alloy Wire. Nanomaterials, 15(16), 1281. https://doi.org/10.3390/nano15161281