A Graphene/MXene-Modified Flexible Fabric for Infrared Camouflage, Electrothermal, and Electromagnetic Interference Shielding

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Sample Cloth

2.3. Preparation of Graphene Scratch Coating Paste

2.4. Preparation of Sample

2.5. Research Methods

3. Results and Discussion

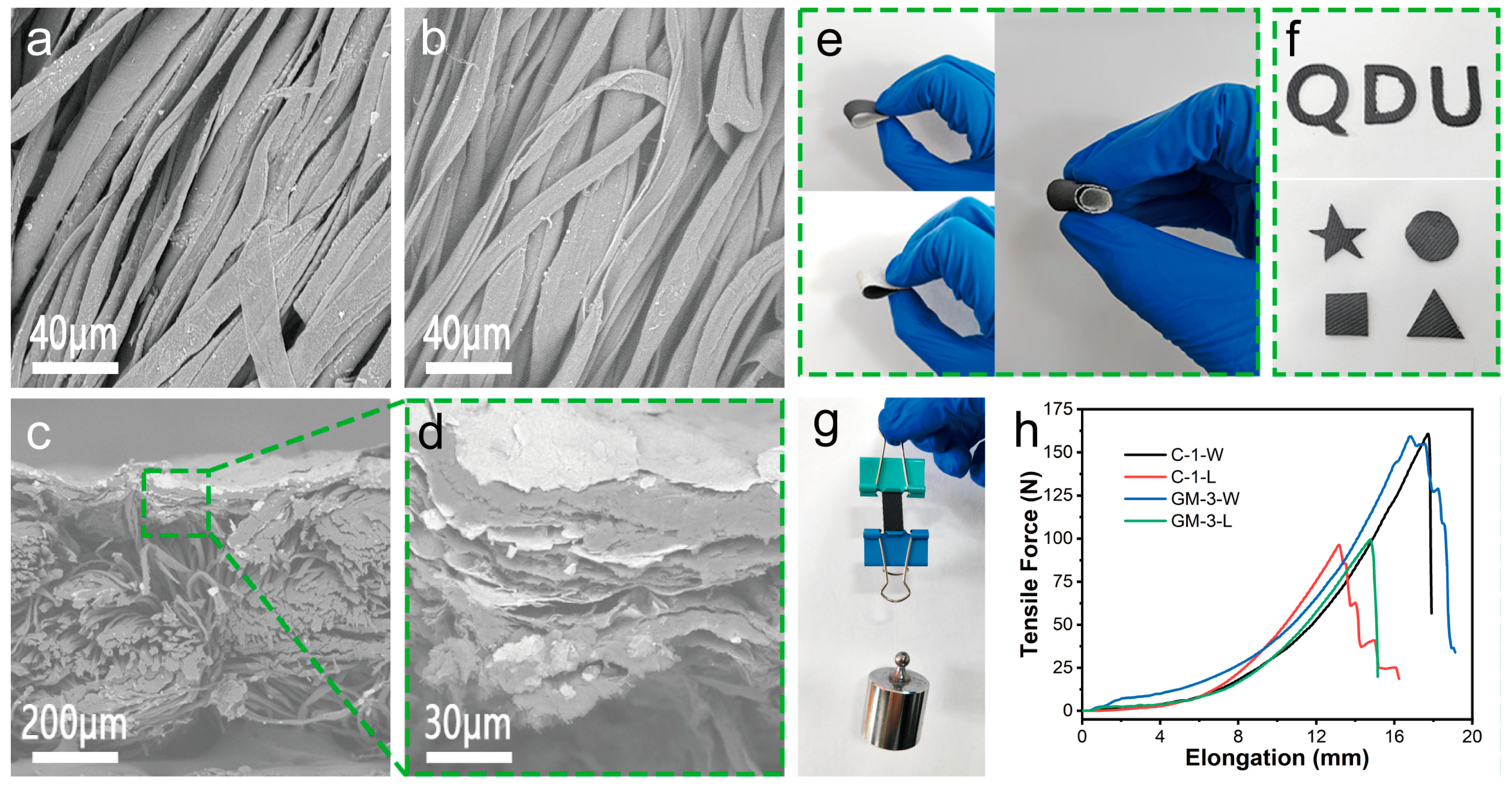

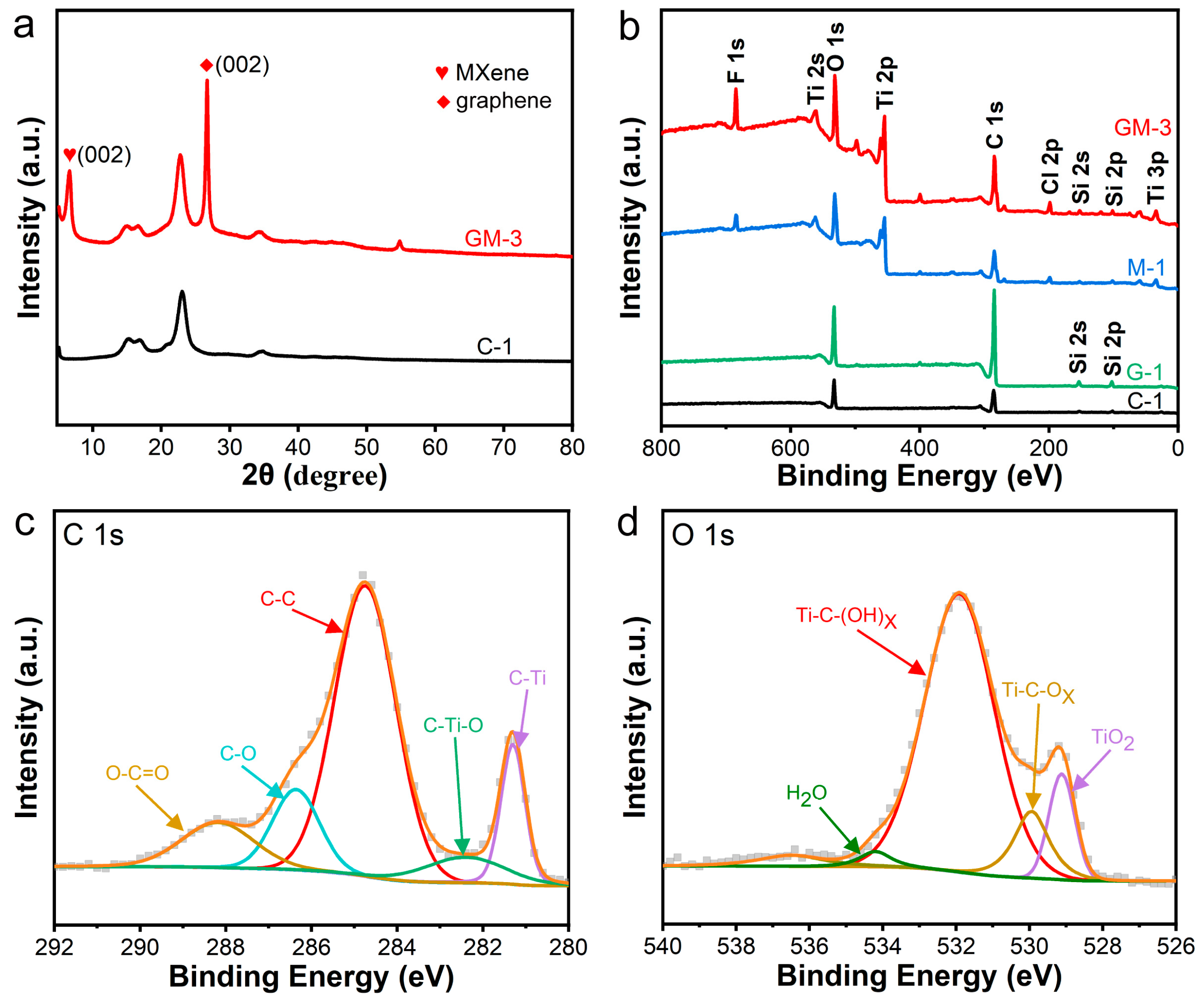

3.1. Characterization and Mechanical Properties of Graphene/MXene-Modified Fabrics

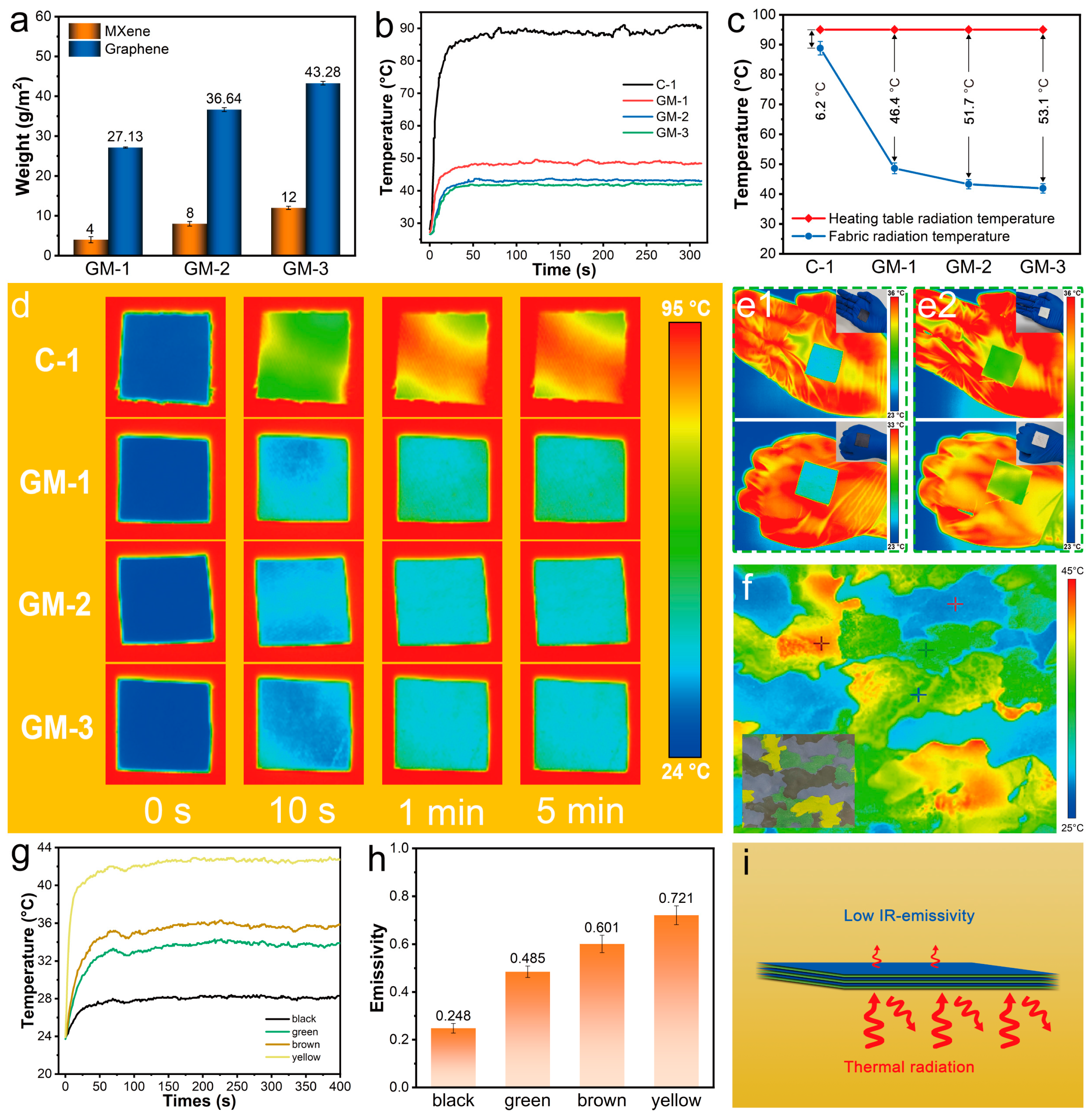

3.2. Infrared Camouflage Properties of Graphene/MXene-Modified Fabrics

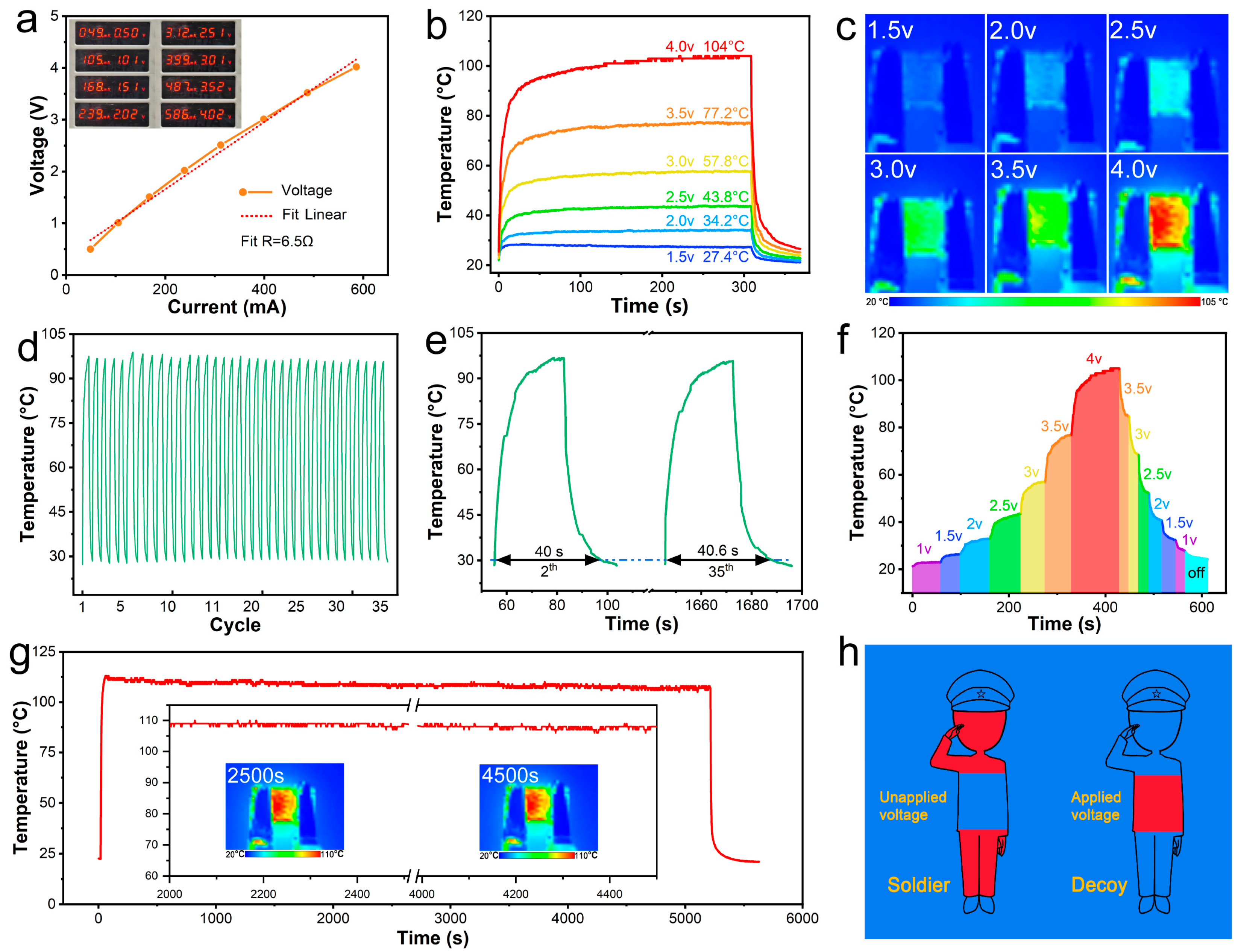

3.3. Electrothermal Properties of Graphene/MXene-Modified Fabrics

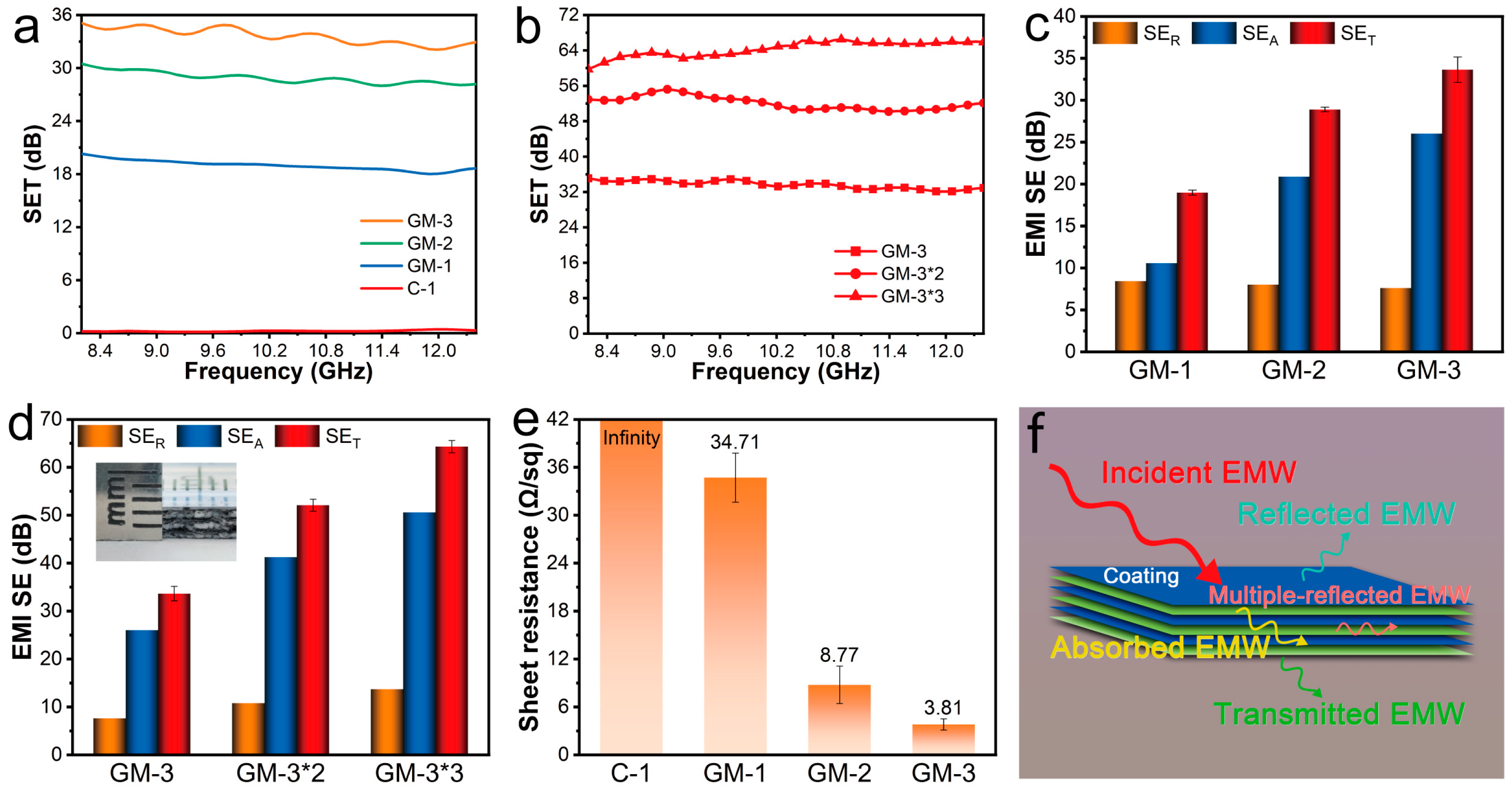

3.4. Electromagnetic Shielding Properties of Graphene/MXene-Modified Fabrics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jing, J.; Liu, H.; Wang, X. Long-Term Infrared Stealth by Sandwich-Like Phase-Change Composites at Elevated Temperatures via Synergistic Emissivity and Thermal Regulation. Adv. Funct. Mater. 2023, 34, 2309269. [Google Scholar] [CrossRef]

- Zhang, X.A.; Yu, S.; Xu, B.; Li, M.; Peng, Z.; Wang, Y.; Deng, S.; Wu, X.; Wu, Z.; Ouyang, M.; et al. Dynamic gating of infrared radiation in a textile. Science 2019, 363, 619–623. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.; Gu, Y.; Seo, J.K.; Wang, J.; Liu, P.; Meng, Y.S.; Xu, S.; Chen, R. Wearable thermoelectrics for personalized thermoregulation. Sci. Adv. 2019, 5, eaaw0536. [Google Scholar] [CrossRef] [PubMed]

- Shi, T.; Liu, D.; Cheng, H.; Wang, X.; Tao, J. A personal thermal camouflage material based on nanofibrous polyamide membrane. Chem. Eng. J. 2024, 483, 149342. [Google Scholar] [CrossRef]

- Liu, H.; Li, L.; Tian, X.; Wang, X. Flexible phase-change composite films for infrared thermal camouflage and photothermal energy storage. J. Energy Storage 2023, 73, 109203. [Google Scholar] [CrossRef]

- Hsu, P.-C.; Liu, C.; Song, A.Y.; Zhang, Z.; Peng, Y.; Xie, J.; Liu, K.; Wu, C.-L.; Catrysse, P.B.; Cai, L.; et al. A dual-mode textile for human body radiative heating and cooling. Sci. Adv. 2017, 3, e1700895. [Google Scholar] [CrossRef] [PubMed]

- Raman, A.P.; Anoma, M.A.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef] [PubMed]

- Krishna, A.; Kim, J.M.; Leem, J.; Wang, M.C.; Nam, S.; Lee, J. Ultraviolet to Mid-Infrared Emissivity Control by Mechanically Reconfigurable Graphene. Nano Lett. 2019, 19, 5086–5092. [Google Scholar] [CrossRef] [PubMed]

- Al Bosta, M.M.S.; Ma, K.-J.; Chien, H.-H. The effect of MAO processing time on surface properties and low temperature infrared emissivity of ceramic coating on aluminium 6061 alloy. Infrared Phys. Technol. 2013, 60, 323–334. [Google Scholar] [CrossRef]

- Lu, F.; Tan, P.; Han, Y. Variable infrared emissivity based on polyaniline electrochromic device influenced by porous substrate. J. Appl. Polym. Sci. 2020, 138, e49622. [Google Scholar] [CrossRef]

- Lee, N.; Lim, J.S.; Chang, I.; Bae, H.M.; Nam, J.; Cho, H.H. Flexible Assembled Metamaterials for Infrared and Microwave Camouflage. Adv. Opt. Mater. 2022, 10, 2200448. [Google Scholar] [CrossRef]

- Kim, J.; Han, K.; Hahn, J.W. Selective dual-band metamaterial perfect absorber for infrared stealth technology. Sci. Rep. 2017, 7, 6740. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, J.; Zhao, D.; Zhang, J.; Li, Z.; Chen, Z.; Zeng, J.; Miao, L.; Shi, J. Investigation of terahertz waves propagating through far infrared/CO2 laser stealth-compatible coating based on one-dimensional photonic crystal. Infrared Phys. Technol. 2016, 79, 144–150. [Google Scholar] [CrossRef]

- Tang, K.; Dong, K.; Li, J.; Gordon, M.P.; Reichertz, F.G.; Kim, H.; Rho, Y.; Wang, Q.; Lin, C.-Y.; Grigoropoulos, C.P.; et al. Temperature-adaptive radiative coating for all-season household thermal regulation. Science 2021, 374, 1504–1509. [Google Scholar] [CrossRef] [PubMed]

- de Haan, L.T.; Gimenez-Pinto, V.; Konya, A.; Nguyen, T.S.; Verjans, J.M.N.; Sánchez-Somolinos, C.; Selinger, J.V.; Selinger, R.L.B.; Broer, D.J.; Schenning, A.P.H.J. Accordion-like Actuators of Multiple 3D Patterned Liquid Crystal Polymer Films. Adv. Funct. Mater. 2013, 24, 1251–1258. [Google Scholar] [CrossRef]

- Salihoglu, O.; Uzlu, H.B.; Yakar, O.; Aas, S.; Balci, O.; Kakenov, N.; Balci, S.; Olcum, S.; Süzer, S.; Kocabas, C. Graphene-Based Adaptive Thermal Camouflage. Nano Lett. 2018, 18, 4541–4548. [Google Scholar] [CrossRef] [PubMed]

- Li, E.; Bai, Y.; Dong, H.; Jia, R.; Zhao, X.; Wang, R.; Bao, M.; Ma, W. Infrared radiation and thermal properties of Al-doped SrZrO3 perovskites for potential infrared stealth coating materials in the high-temperature environment. Ceram. Int. 2021, 47, 23124–23133. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, S.; Liang, L.; Du, C.; Ye, Z.; Chen, G. PEDOT-based thermoelectric composites: Preparation, mechanism and applications. Chin. Chem. Lett. 2024, 35, 109804. [Google Scholar] [CrossRef]

- Wang, C.; Shi, J.; Zhang, L.; Fu, S. Asymmetric Janus Fibers with Bistable Thermochromic and Efficient Solar–Thermal Properties for Personal Thermal Management. Adv. Fiber Mater. 2024, 6, 264–277. [Google Scholar] [CrossRef]

- He, G.; Ning, F.; Liu, X.; Meng, Y.; Lei, Z.; Ma, X.; Tian, M.; Liu, X.; Zhang, X.; Zhang, X.; et al. High-Performance and Long-Term Stability of MXene/PEDOT:PSS-Decorated Cotton Yarn for Wearable Electronics Applications. Adv. Fiber Mater. 2023, 6, 367–386. [Google Scholar] [CrossRef]

- Wu, B.; Qi, Q.; Liu, L.; Liu, Y.; Wang, J. Wearable Aerogels for Personal Thermal Management and Smart Devices. ACS Nano 2024, 18, 9798–9822. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Li, M.; Xu, H.; Wang, X.; Jia, M.; Hou, X.; Gao, S.; Liu, Q.; Yang, Q.; Tian, M.; et al. MXene Sediment-Based Poly(vinyl alcohol)/Sodium Alginate Aerogel Evaporator with Vertically Aligned Channels for Highly Efficient Solar Steam Generation. Nano-Micro Lett. 2024, 16, 220. [Google Scholar] [CrossRef]

- He, Y.-J.; Shao, Y.-W.; Xiao, Y.-Y.; Yang, J.-H.; Qi, X.-D.; Wang, Y. Multifunctional Phase Change Composites Based on Elastic MXene/Silver Nanowire Sponges for Excellent Thermal/Solar/Electric Energy Storage, Shape Memory, and Adjustable Electromagnetic Interference Shielding Functions. ACS Appl. Mater. Interfaces 2022, 14, 6057–6070. [Google Scholar] [CrossRef] [PubMed]

- Yan, B.; Bao, X.; Gao, Y.; Zhou, M.; Yu, Y.; Xu, B.; Cui, L.; Wang, Q.; Wang, P. Antioxidative MXene@GA-Decorated Textile Assisted by Metal Ion for Efficient Electromagnetic Interference Shielding, Dual-Driven Heating, and Infrared Thermal Camouflage. Adv. Fiber Mater. 2023, 5, 2080–2098. [Google Scholar] [CrossRef]

- Zhu, Z.; Tian, Z.; Liu, Y.; Yue, S.; Li, Y.; Wang, Z.L.; Yu, Z.Z.; Yang, D. Human Nervous System Inspired Modified Graphene Nanoplatelets/Cellulose Nanofibers-Based Wearable Sensors with Superior Thermal Management and Electromagnetic Interference Shielding. Adv. Funct. Mater. 2024, 34, 2315851. [Google Scholar] [CrossRef]

- Shen, Y.; Li, G.; Cheng, Y.; Li, Y.; Alhadhrami, A.; Fallatah, A.M.; Alshammari, D.A.; Zhou, B.; Feng, Y.; Liu, C. Lightweight double-layer structured ANF/MXene aerogel film with electromagnetic interference shielding and dynamic infrared camouflage. Adv. Compos. Hybrid Mater. 2024, 7, 175. [Google Scholar] [CrossRef]

- Peng, J.; Cheng, H.; Liu, J.; Han, W.; Wu, T.; Yin, Y.; Wang, C. Superhydrophobic MXene-Based Fabric with Electromagnetic Interference Shielding and Thermal Management Ability for Flexible Sensors. Adv. Fiber Mater. 2023, 5, 2099–2113. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Dong, J.; Li, X.; Zhao, X.; Zhang, Q. Continuous Surface Metallization of Polyimide Fibers for Textile-Substrate Electromagnetic Shielding Applications. Adv. Fiber Mater. 2023, 5, 1892–1904. [Google Scholar] [CrossRef]

- Wang, S.; Li, D.; Jiang, L.; Fang, D. Flexible and mechanically strong MXene/FeCo@C decorated carbon cloth: A multifunctional electromagnetic interference shielding material. Compos. Sci. Technol. 2022, 221, 109337. [Google Scholar] [CrossRef]

- He, G.; Wang, L.; Bao, X.; Lei, Z.; Ning, F.; Li, M.; Zhang, X.; Qu, L. Synergistic flame retardant weft-knitted alginate/viscose fabrics with MXene coating for multifunctional wearable heaters. Compos. Part B 2022, 232, 109618. [Google Scholar] [CrossRef]

- Zong, J.-Y.; Cao, M.-S. Graphene-like MXene-based microwave absorbers and shields: Latest progress and perspectives. Materials Today Physics 2024, 43, 101400. [Google Scholar] [CrossRef]

- Li, Z.-Y.; Zhao, W.-J.; Sun, Y.; Zhou, B.; Feng, Y.-Z.; Liu, C.-T. Comparative enhancement of H+ and OH− treatment on electromagnetic interference shielding in aligned and compact Ti3C2Tx MXene film. Rare Met. 2024. [Google Scholar] [CrossRef]

- Hassan, T.; Iqbal, A.; Yoo, B.; Jo, J.Y.; Cakmakci, N.; Naqvi, S.M.; Kim, H.; Jung, S.; Hussain, N.; Zafar, U.; et al. Multifunctional MXene/Carbon Nanotube Janus Film for Electromagnetic Shielding and Infrared Shielding/Detection in Harsh Environments. Nano-Micro Lett. 2024, 16, 216. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Zhang, X.; Zhang, X.; Wang, L.; Feng, W.; Li, Q. Beyond the Visible: Bioinspired Infrared Adaptive Materials. Adv. Mater. 2021, 33, 2004754. [Google Scholar] [CrossRef] [PubMed]

- Pu, S.; Zan, G.; Zhou, H.; Dong, K.; Mao, X.; Wu, Q.; Wu, T. Sustaining 500,000 Folding Cycles Through Bioinspired Stress Dispersion Design in Sodium-Ion Batteries. Angew. Chem. Int. Ed. 2024, e202417589. [Google Scholar] [CrossRef]

- Meng, Y.; Zhang, Z.; Hou, X.; Wang, T.; Guo, X.; Liu, X.; Tian, M.; Qu, L.; Zhang, X. Flexible and ultra-thin graphene@MXene@Fe3O4 composites with excellent microwave absorption performance. Ceram. Int. 2024, 50, 6624–6633. [Google Scholar] [CrossRef]

- Zan, G.; Jiang, W.; Kim, H.; Zhao, K.; Li, S.; Lee, K.; Jang, J.; Kim, G.; Shin, E.; Kim, W.; et al. A core–shell fiber moisture-driven electric generator enabled by synergetic complex coacervation and built-in potential. Nat. Commun. 2024, 15, 10056. [Google Scholar] [CrossRef] [PubMed]

- Natu, V.; Benchakar, M.; Canaff, C.; Habrioux, A.; Célérier, S.; Barsoum, M.W. A critical analysis of the X-ray photoelectron spectra of Ti3C2Tz MXenes. Matter 2021, 4, 1224–1251. [Google Scholar] [CrossRef]

- Zong, J.-Y.; Zhou, X.-J.; Hu, Y.-F.; Yang, T.-B.; Yan, D.-X.; Lin, H.; Lei, J.; Li, Z.-M. A wearable multifunctional fabric with excellent electromagnetic interference shielding and passive radiation heating performance. Compos. Part B 2021, 225, 109299. [Google Scholar] [CrossRef]

- Wang, X.; Lei, Z.; Ma, X.; He, G.; Xu, T.; Tan, J.; Wang, L.; Zhang, X.; Qu, L.; Zhang, X. A lightweight MXene-Coated nonwoven fabric with excellent flame Retardancy, EMI Shielding, and Electrothermal/Photothermal conversion for wearable heater. Chem. Eng. J. 2022, 430, 132605. [Google Scholar] [CrossRef]

| Samples | Preparation Method |

|---|---|

| C-1 | Pre-treated cotton twill fabric |

| G-1 | Scrape graphene paste onto C-1 fabric |

| M-1 | Spray MXene aqueous suspension on C-1 fabric |

| GM-1 | The C-1 fabric is scraped with graphene paste and then sprayed with MXene water-based suspension |

| GM-2 | The GM-1 fabric is scraped with graphene paste and then sprayed with MXene water-based suspension |

| GM-3 | The GM-2 fabric is scraped with graphene paste and then sprayed with MXene water-based suspension |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, X.; Zang, Z.; Meng, Y.; Wang, T.; Gao, S.; Liu, Q.; Qu, L.; Zhang, X. A Graphene/MXene-Modified Flexible Fabric for Infrared Camouflage, Electrothermal, and Electromagnetic Interference Shielding. Nanomaterials 2025, 15, 98. https://doi.org/10.3390/nano15020098

Hou X, Zang Z, Meng Y, Wang T, Gao S, Liu Q, Qu L, Zhang X. A Graphene/MXene-Modified Flexible Fabric for Infrared Camouflage, Electrothermal, and Electromagnetic Interference Shielding. Nanomaterials. 2025; 15(2):98. https://doi.org/10.3390/nano15020098

Chicago/Turabian StyleHou, Xianguang, Ziyi Zang, Yaxin Meng, Tian Wang, Shuai Gao, Qingman Liu, Lijun Qu, and Xiansheng Zhang. 2025. "A Graphene/MXene-Modified Flexible Fabric for Infrared Camouflage, Electrothermal, and Electromagnetic Interference Shielding" Nanomaterials 15, no. 2: 98. https://doi.org/10.3390/nano15020098

APA StyleHou, X., Zang, Z., Meng, Y., Wang, T., Gao, S., Liu, Q., Qu, L., & Zhang, X. (2025). A Graphene/MXene-Modified Flexible Fabric for Infrared Camouflage, Electrothermal, and Electromagnetic Interference Shielding. Nanomaterials, 15(2), 98. https://doi.org/10.3390/nano15020098