Architecting Durability: Synergies in Assembly, Self-Repair, and Advanced Characterization of Carbon Nanotube Materials

Abstract

1. Introduction

1.1. The Durability Imperative in Advanced Carbon Materials

1.2. State of the Art

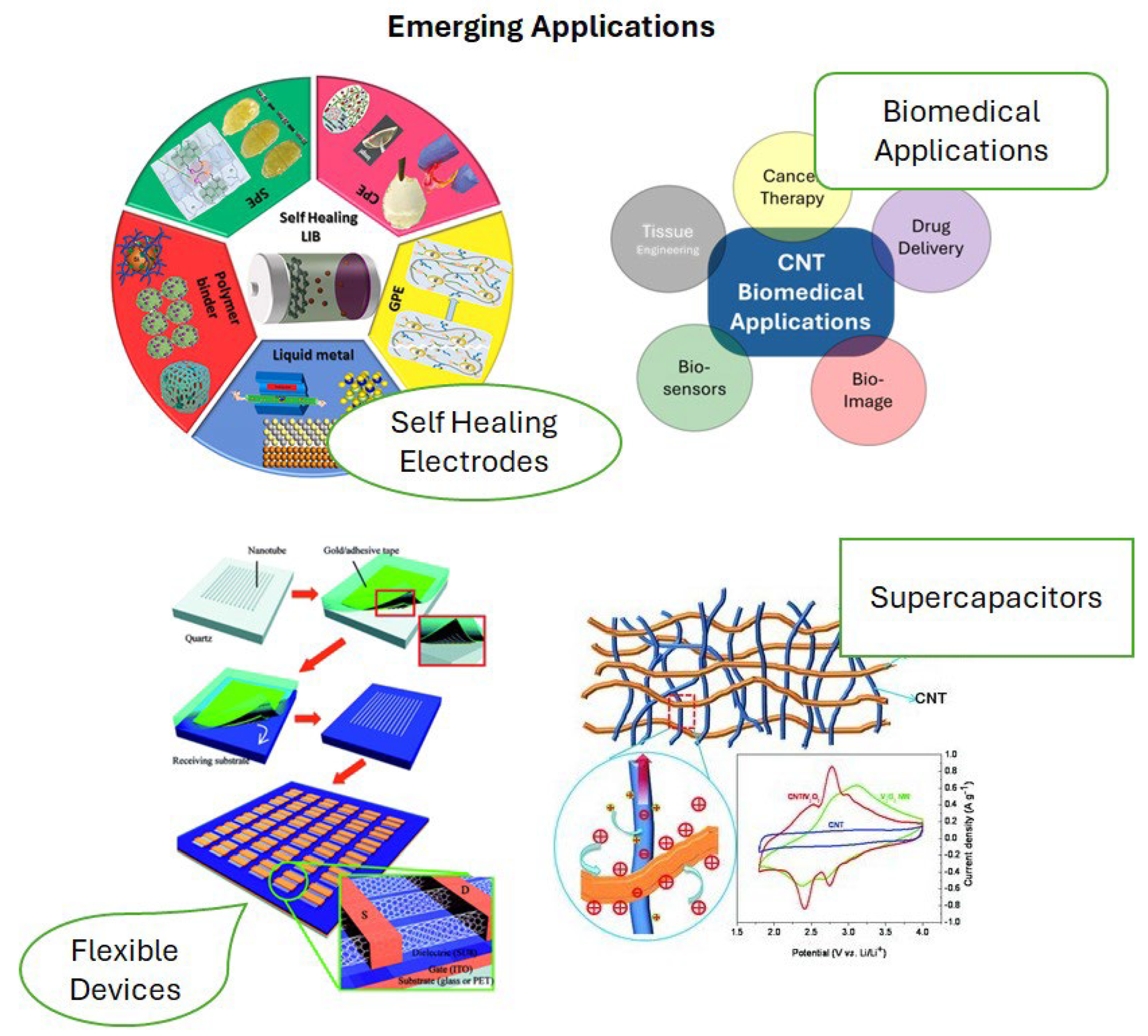

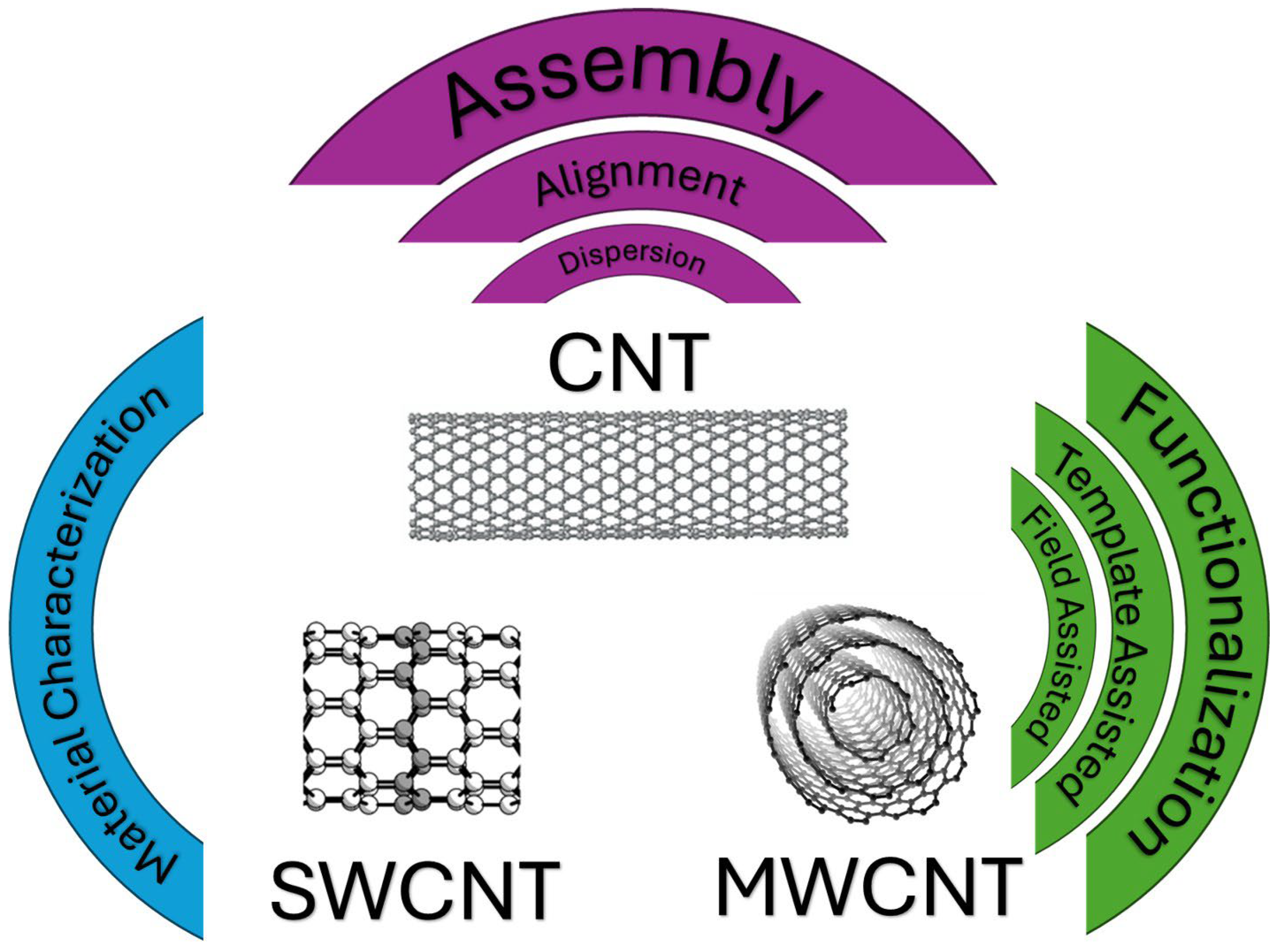

2. Foundational Architectures: Controlled Assembly and Functionalization of CNTs

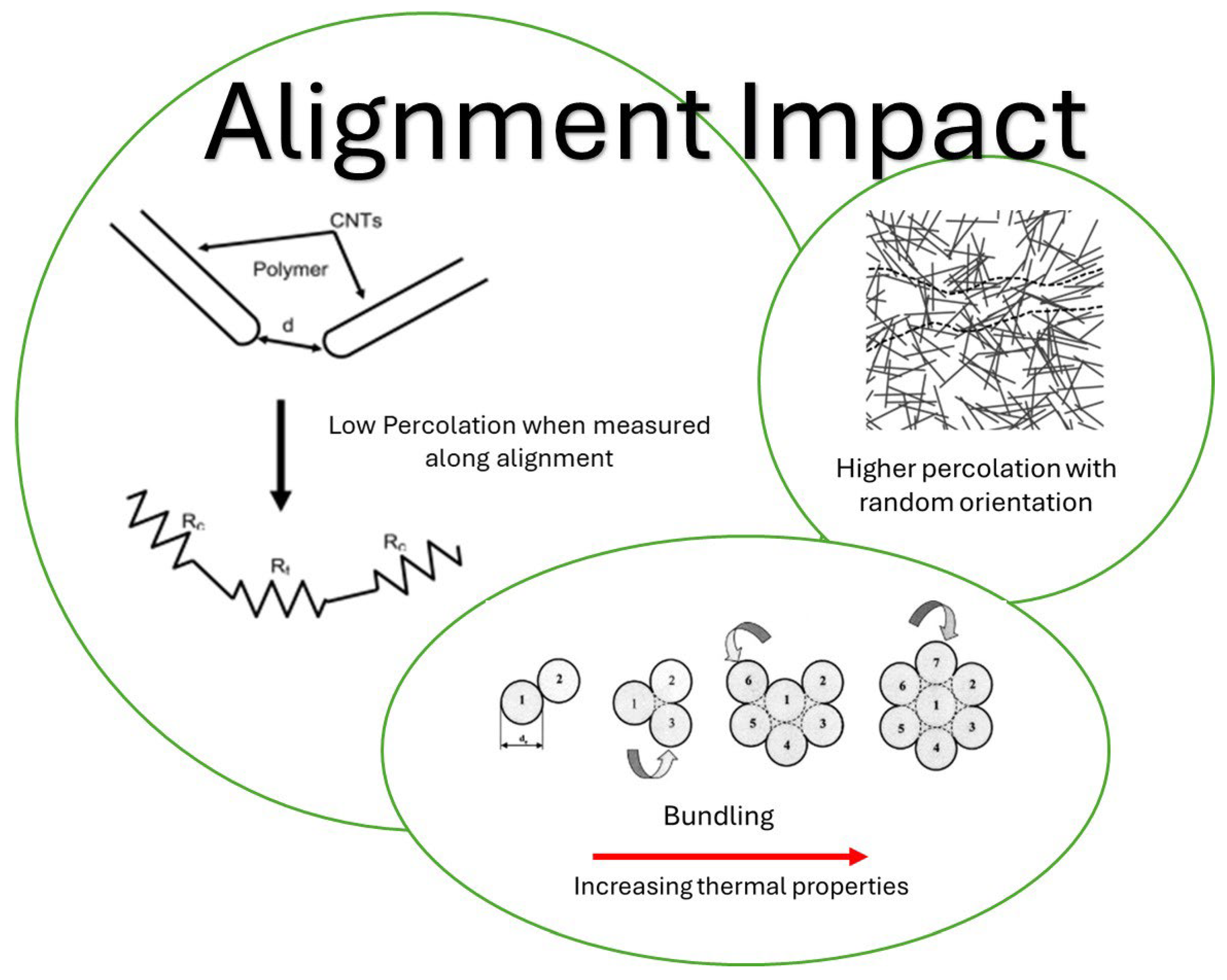

2.1. Impact of Alignment on Mechanical, Electrical, and Thermal Properties

2.2. Influence of Dispersion on Material Characteristics

2.3. Effects of Density on Material Performance

2.4. Challenges in Achieving Uniform and Scalable Assembly

2.5. Advanced Functionalization for Enhanced Interfacial Engineering

2.5.1. Covalent Functionalization: The Case of Fluorination

2.5.2. Spectroscopic Verification of Surface Chemistry: XPS, NEXAFS, and SXE Analysis

3. Mechanisms and Analysis of Self-Repair in CNT-Based Systems

3.1. Intrinsic Repair: Atomic-Level Healing in Carbon Lattices

3.1.1. Defect Annihilation and Bond Reconfiguration

3.1.2. Experimental Probes of Irradiation-Induced Healing: Insights from EELS and Auger Spectroscopy

3.2. Extrinsic Repair: Engineering Healing into the Composite

3.2.1. Reservoir-Based Healing: Microcapsules and Vascular Networks

3.2.2. The Multifaceted Role of CNTs in Matrix Reconstruction

3.3. A Modern Toolkit for Characterizing Self-Repair Efficiency

3.3.1. Mechanical and Morphological Restoration

3.3.2. In Situ Monitoring of Healing Dynamics with Raman Spectroscopy

3.3.3. Interfacial Chemistry in Repaired Zones via High-Powered Spectroscopy

4. Synergistic Effects of Molecular Assembly and Self-Repair: Influence of CNT Assembly

4.1. Impact of CNT Alignment on Healing Agent Transport and Diffusion

4.2. Role of CNT Dispersion in Damage Site Accessibility for Self-Repair Mechanisms

4.3. Demonstrations of Enhanced Durability Through Combined Approaches

5. Challenges and Future Opportunities in Self-Healing CNT Materials

5.1. Advanced Characterization Techniques for Studying Self-Healing Processes at Different Scales

5.2. Investigating the Long-Term Durability and Performance After Repeated Self-Repair Cycles

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hughes, K.J.; Iyer, K.A.; Bird, R.E.; Ivanov, J.; Banerjee, S.; Georges, G.; Zhou, Q.A. Review of Carbon Nanotube Research and Development: Materials and Emerging Applications. ACS Appl. Nano Mater. 2024, 7, 18695–18713. [Google Scholar] [CrossRef]

- Sultana, N.; Dewey, H.M.; Arellano, A.G.; Budhathoki-Uprety, J. Understanding the Molecular Assemblies of Single Walled Carbon Nanotubes and Tailoring their Photoluminescence for the Next-Generation Optical Nanosensors. Chem. Mater. 2024, 36, 4034–4053. [Google Scholar] [CrossRef]

- Shabnum, S.S.; Siranjeevi, R.; Raj, C.K.; Nivetha, P.; Benazir, K. A Comprehensive Review on Recent Progress in Carbon Nanotubes for Biomedical Application. Environ. Qual. Manag. 2025, 34, e70040. [Google Scholar] [CrossRef]

- Wulf, V.; Bisker, G. Integrating Single-Walled Carbon Nanotubes into Supramolecular Assemblies: From Basic Interactions to Emerging Applications. ACS Nano 2024, 18, 29380–29393. [Google Scholar] [CrossRef]

- Snowdon, M.R.; Sukhanova, E.V.; Popov, Z.I.; Li, S.; Nurdiwijayanto, L.; Taniguchi, T.; Ishihara, S.; Tanaka, T.; Kataura, H.; Tsukagoshi, K.; et al. Iptycene-Assisted Alignment of Chirality-Sorted SWCNTs for Field-Effect Transistors. ACS Appl. Nano Mater. 2025, 8, 944–951. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Maaza, M.; Bocchetta, P. Self-Healing Nanocomposites—Advancements and Aerospace Applications. J. Compos. Sci. 2023, 7, 148. [Google Scholar] [CrossRef]

- Hu, Z.; Hong, H. Review on Material Performance of Carbon Nanotube-Modified Polymeric Nanocomposites. Recent Prog. Mater. 2023, 5, 031. [Google Scholar] [CrossRef]

- Khan, S.U.; Pothnis, J.R.; Kim, J.-K. Effects of carbon nanotube alignment on electrical and mechanical properties of epoxy nanocomposites. Compos. Part A Appl. Sci. Manuf. 2013, 49, 26–34. [Google Scholar] [CrossRef]

- Souier, T.; Santos, S.; Al Ghaferi, A.; Stefancich, M.; Chiesa, M. Enhanced electrical properties of vertically aligned carbon nanotube-epoxy nanocomposites with high packing density. Nanoscale Res. Lett. 2012, 7, 630. [Google Scholar] [CrossRef] [PubMed]

- Kulakov, V.; Aniskevich, A.; Ivanov, S.; Poltimae, T.; Starkova, O. Effective electrical conductivity of carbon nanotube–epoxy nanocomposites. J. Compos. Mater. 2017, 51, 2979–2988. [Google Scholar] [CrossRef]

- Chen, J. Effects of Carbon Nanotube Structure, Purity, and Alignment on the Heat Conduction Properties of Carbon Films and Fibers. Online J. Mater. Sci. 2022, 1, 1–11. [Google Scholar] [CrossRef]

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H. Thermal Conductance of an Individual Single-Wall Carbon Nanotube above Room Temperature. Nano Lett. 2006, 6, 96–100. [Google Scholar] [CrossRef]

- Jakubinek, M.B.; Johnson, M.B.; White, M.A.; Jayasinghe, C.; Li, G.; Cho, W.; Schulz, M.J.; Shanov, V. Thermal and electrical conductivity of array-spun multi-walled carbon nanotube yarns. Carbon 2012, 50, 244–248. [Google Scholar] [CrossRef]

- Mannino, G.; Condorelli, M.; Compagnini, G.; Faraci, G. Raman amplification for trapped radiation in crystalline single Si nanoparticle. Sci. Rep. 2023, 13, 1014. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, Y.; Chia, L. Effects of carbon nanotube (CNT) geometries on the dispersion characterizations and adhesion properties of CNT reinforced epoxy composites. Compos. Struct. 2022, 296, 115942. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Feijoo, I.; Pena, G.; Cristóbal, M.J.; Cabeza, M.; Rey, P. Effect of Carbon Nanotube Content and Mechanical Milling Conditions on the Manufacture of AA7075/MWCNT Composites. Metals 2022, 12, 1020. [Google Scholar] [CrossRef]

- Maune, H.T.; Han, S.-p.; Barish, R.D.; Bockrath, M.; Iii, W.A.G.; Rothemund, P.W.K.; Winfree, E. Self-assembly of carbon nanotubes into two-dimensional geometries using DNA origami templates. Nat. Nanotechnol. 2010, 5, 61–66. [Google Scholar] [CrossRef]

- Nanda, J.; Maranville, C.; Bollin, S.C.; Sawall, D.; Ohtani, H.; Remillard, J.T.; Ginder, J.M. Thermal Conductivity of Single-Wall Carbon Nanotube Dispersions: Role of Interfacial Effects. J. Phys. Chem. C 2008, 112, 654–658. [Google Scholar] [CrossRef]

- Kotagiri, N.; Kim, J.W. Stealth nanotubes: Strategies of shielding carbon nanotubes to evade opsonization and improve biodistribution. Int. J. Nanomed. 2014, 9 (Suppl. 1), 85–105. [Google Scholar] [CrossRef][Green Version]

- Tayyab, S.; Apponi, A.; Betti, M.G.; Blundo, E.; Cavoto, G.; Frisenda, R.; Jiménez-Arévalo, N.; Mariani, C.; Pandolfi, F.; Polimeni, A.; et al. Spectromicroscopy Study of Induced Defects in Ion-Bombarded Highly Aligned Carbon Nanotubes. Nanomaterials 2024, 14, 77. [Google Scholar] [CrossRef]

- De Luca, P.; Siciliano, C.; B.Nagy, J.; Macario, A. The role of carbon nanotubes in the reactions of heterogeneous catalysis. Chem. Eng. Res. Des. 2023, 197, 74–84. [Google Scholar] [CrossRef]

- Spièce, J.; Lulla, K.; Picquendaele, P.d.C.d.; Divay, L.; Bezencenet, O.; Hackens, B.; Gehring, P.; Robson, A.J.; Evangeli, C.; Kolosov, O.V. Nanoscale Heat Transport of Vertically Aligned Carbon Nanotube Bundles for Thermal Management Applications. ACS Appl. Mater. Interfaces 2024, 16, 45671–45677. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, P.; Shi, R.; Xu, Y.; Zhang, L.; Fang, R.; Zhao, T.; Qi, S.; Jiang, L.; Liu, M. Super-tough and strong nanocomposite fibers by flow-induced alignment of carbon nanotubes on grooved hydrogel surfaces. Sci. China Mater. 2019, 62, 1332–1340. [Google Scholar] [CrossRef]

- Zecchi, S.; Cristoforo, G.; Piatti, E.; Torsello, D.; Ghigo, G.; Tagliaferro, A.; Rosso, C.; Bartoli, M. A Concise Review of Recent Advancements in Carbon Nanotubes for Aerospace Applications. Micromachines 2025, 16, 53. [Google Scholar] [CrossRef]

- Mohd Nurazzi, N.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.; Mahat, A.M.; Lee, C.L.; Aisyah, H.A.; et al. Fabrication, Functionalization, and Application of Carbon Nanotube-Reinforced Polymer Composite: An Overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef] [PubMed]

- Jeong, D.-R.; Yoon, S. Characterization of thin-walled self-healing microcapsules reinforced with multi-walled carbon nanotubes. Adv. Compos. Mater. 2024, 1–18. [Google Scholar] [CrossRef]

- Krestinin, A.V.; Kharitonov, A.P.; Shul’ga, Y.M.; Zhigalina, O.M.; Knerel’man, E.I.; Dubois, M.; Brzhezinskaya, M.M.; Vinogradov, A.S.; Preobrazhenskii, A.B.; Zvereva, G.I.; et al. Fabrication and characterization of fluorinated single-walled carbon nanotubes. Nanotechnologies Russ. 2009, 4, 60–78. [Google Scholar] [CrossRef]

- Tulevski, G.S.; Hannon, J.; Afzali, A.; Chen, Z.; Avouris, P.; Kagan, C.R. Chemically Assisted Directed Assembly of Carbon Nanotubes for the Fabrication of Large-Scale Device Arrays. J. Am. Chem. Soc. 2007, 129, 11964–11968. [Google Scholar] [CrossRef]

- Speranza, G. Characterization of Carbon Nanostructures by Photoelectron Spectroscopies. Materials 2022, 15, 4434. [Google Scholar] [CrossRef] [PubMed]

- Brzhezinskaya, M.M.; Vinogradov, N.A.; Zimina, A.; Muradyan, V.E.; Shul’ga, Y.M.; Vinogradov, A.S. Characterization of fluorinated multiwalled carbon nanotubes with X-ray absorption, photoelectron and emission spectroscopies. Appl. Phys. A 2009, 94, 445–448. [Google Scholar] [CrossRef]

- Song, T.; Jiang, B.; Li, Y.; Ji, Z.; Zhou, H.; Jiang, D.; Seok, I.; Murugadoss, V.; Wen, N.; Colorado, H. Self-healing Materials: A Review of Recent Developments. ES Mater. Manuf. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Jamil, M.S.S.; Endot, N.A. Influence of Fluorine Substituents on the Electronic Properties of Selenium-N-Heterocyclic Carbene Compounds. Molecules 2020, 25, 5161. [Google Scholar] [CrossRef] [PubMed]

- Kausar, A. Self-healing polymer/carbon nanotube nanocomposite: A review. J. Plast. Film. Sheeting 2021, 37, 160–181. [Google Scholar] [CrossRef]

- Lanzara, G.; Yoon, Y.; Liu, H.; Peng, S.; Lee, W. Carbon nanotube reservoirs for self-healing materials. Nanotechnology 2009, 20, 335704. [Google Scholar] [CrossRef]

- Lazar, S.; Tiemeijer, P.; Schnohr, C.S.; Meledina, M.; Patzig, C.; Höche, T.; Longo, P.; Freitag, B. Enabling electron-energy-loss spectroscopy at very high energy losses: An opportunity to obtain X-ray absorption spectroscopy--like information using an electron microscope. Phys. Rev. Appl. 2025, 23, 054095. [Google Scholar] [CrossRef]

- Silva, S.R.P.; Stolojan, V. Electron energy loss spectroscopy of carbonaceous materials. Thin Solid Film. 2005, 488, 283–290. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, L.; Xu, Z.; Li, Y.; Shan, M.; Liu, L.; Guo, Q.; Chen, G.; Wang, Z.; Wang, C. Effects of ion irradiation on carbon nanotubes: A review. Int. J. Mater. Prod. Technol. 2012, 45, 1–30. [Google Scholar] [CrossRef]

- Brzhezinskaya, M.M.; Baitinger, E.M.; Shnitov, V.V. π-plasmons in ion-irradiated multiwall carbon nanotubes. Phys. B Condens. Matter 2004, 348, 95–100. [Google Scholar] [CrossRef]

- Korusenko, P.M.; Nesov, S.N.; Povoroznyuk, S.N.; Bolotov, V.V.; Knyazev, E.V.; Pushkarev, A.I.; Smirnov, D. Modifying the structure of multiwalled carbon nanotubes with continuous and pulsed ion beams. Phys. Solid State 2018, 60, 2616–2622. [Google Scholar] [CrossRef]

- Bolotov, V.; Korusenko, P.; Nesov, S.; Povoroznyuk, S. Effect of pulsed ion irradiation on the electronic structure of multi-walled carbon nanotubes. Phys. Solid State 2014, 56, 835–838. [Google Scholar] [CrossRef]

- Patrick, J.F.; Hart, K.R.; Krull, B.P.; Diesendruck, C.E.; Moore, J.S.; White, S.R.; Sottos, N.R. Continuous Self-Healing Life Cycle in Vascularized Structural Composites. Adv. Mater. 2014, 26, 4302–4308. [Google Scholar] [CrossRef]

- Kessler, M.R.; Sottos, N.R.; White, S.R. Self-healing structural composite materials. Compos. Part A Appl. Sci. Manuf. 2003, 34, 743–753. [Google Scholar] [CrossRef]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Wang, C.; Boulatov, R. Autonomic Self-Healing of Polymers: Mechanisms, Applications, and Challenges. Molecules 2025, 30, 469. [Google Scholar] [CrossRef]

- Tang, M.; Lei, K.; Zhao, X.; Hu, X.; He, Q.; Zhang, K.; Ma, X.; Ni, H.; Shu, Y.; Li, Z. Self-healing and highly adhesive conductive polydimethylsiloxane-based elastomers for chronic epilepsy monitoring. Nanoscale 2025, 17, 8624–8633. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Q.; Li, R.; Lomov, S.V.; Abaimov, S.G.; Xiong, K.; Zhang, H.; Chen, C.; Wu, Q. Self-sensing and self-healing innovative fiber-reinforced thermoplastic composite embedded with CNT film. J. Intell. Mater. Syst. Struct. 2023, 34, 1561–1571. [Google Scholar] [CrossRef]

- Jang, S.H.; Kim, D.; Park, Y.L. Accelerated Curing and Enhanced Material Properties of Conductive Polymer Nanocomposites by Joule Heating. Materials 2018, 11, 1775. [Google Scholar] [CrossRef]

- Ibrahim, O.O.; Oluwadunsin, J.D.; Antwi, M.; Mekunye, F.; Oluwatobi, M.A.; Olorunfemi, A.D.; Obanla, O.R.; Abdul-Rahman, M.I.; Babalola, K.O.; Babalola, O. The Evolution of Self-Healing Electrodes: A Critical Review of Nanomaterial Contributions. Am. J. Nanosci. 2025, 9, 8–31. [Google Scholar] [CrossRef]

- Gómez-Sánchez, J.; Fernández Sánchez-Romate, X.X.; Jiménez-Suárez, A.; Prolongo, S.G. Self-Healing Activation by Conventional Resistive Heating through the Addition of Carbon Nanotubes in Epoxy Systems Based on Covalent Adaptable Networks. ACS Appl. Polym. Mater. 2024, 6, 1106–1115. [Google Scholar] [CrossRef]

- Krasnikov, D.V.; Bokova-Sirosh, S.N.; Tsendsuren, T.-O.; Romanenko, A.I.; Obraztsova, E.D.; Volodin, V.A.; Kuznetsov, V.L. Influence of the Growth Temperature on the Defective Structure of the Multi-Walled Carbon Nanotubes. Phys. Status Solidi 2018, 255, 1700255. [Google Scholar] [CrossRef]

- Jackson, E.M.; Laibinis, P.E.; Collins, W.E.; Ueda, A.; Wingard, C.D.; Penn, B. Development and thermal properties of carbon nanotube-polymer composites. Compos. Part B Eng. 2016, 89, 362–373. [Google Scholar] [CrossRef]

- Lutz, T.; Donovan, K.J. Macroscopic scale separation of metallic and semiconducting nanotubes by dielectrophoresis. Carbon 2005, 43, 2508–2513. [Google Scholar] [CrossRef]

- Krupke, R.; Hennrich, F.; Löhneysen, H.; Kappes, M.M. Separation of Metallic from Semiconducting Single-Walled Carbon Nanotubes. Science 2003, 301, 344–347. [Google Scholar] [CrossRef]

- Pozdnyakov, A.O.; Brzhezinskaya, M.M.; Vinogradov, A.S.; Friedrich, K. NEXAFS Spectra of Polymer-nanocarbon Composites. Fuller. Nanotub. Carbon Nanostruct. 2008, 16, 471–474. [Google Scholar] [CrossRef]

- Arora, B.; Attri, P. Carbon nanotubes (CNTs): A potential nanomaterial for water purification. J. Compos. Sci. 2020, 4, 135. [Google Scholar] [CrossRef]

- Fan, L.; Feng, C.; Zhao, W.; Qian, L.; Wang, Y.; Li, Y. Directional neurite outgrowth on superaligned carbon nanotube yarn patterned substrate. Nano Lett. 2012, 12, 3668–3673. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Martinez, X.; Hawkey, A.; Bohnet, K.; Lindenthal, S.; Zaumseil, J. Composites of Isotropic and Aligned Semiconducting Single-Walled Carbon Nanotubes with Conjugated Polymers for Air-Processed Thermoelectrics. J. Mater. Chem. A 2025, 13, 28129–28139. [Google Scholar] [CrossRef]

- Li, H.; Zheng, M.; Fagan, J.A. Precise Partitioning of Metallic Single-Wall Carbon Nanotubes and Enantiomers through Aqueous Two-Phase Extraction. ACS Nano 2025, 19, 14137–14149. [Google Scholar] [CrossRef] [PubMed]

- Lyu, M.; Li, C.; Liu, Y.; Li, Y.; Zheng, M. A salt-driven mechanism for precise chirality sorting of carbon nanotubes. Sci. Adv. 2025, 11, eadx3958. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Huang, Q.; Liu, Y.; Chen, Y.; Guo, B.; Zhang, L. Uniaxial Stretching-Induced Alignment of Carbon Nanotubes in Cross-Linked Elastomer Enabled by Dynamic Cross-Link Reshuffling. ACS Macro Lett. 2019, 8, 1575–1581. [Google Scholar] [CrossRef] [PubMed]

- Naveen, V.; Deshpande, A.P.; Raja, S. Self-healing microcapsules encapsulated with carbon nanotubes for improved thermal and electrical properties. RSC Adv. 2020, 10, 33178–33188. [Google Scholar] [CrossRef]

- Xian, G.; Qi, X.; Shi, J.; Tian, J.; Xiao, H. Toughened and self-healing carbon nanotube/epoxy resin composites modified with polycaprolactone filler for coatings, adhesives and FRP. J. Build. Eng. 2025, 111, 113207. [Google Scholar] [CrossRef]

- Duan, L.; Shen, W.; Chen, L.; Zhu, L. Resin precoating solutions containing aminated carbon nanotubes for the improvement of mechanical characteristics and repair behavior of carbon/glass composite laminates. J. Compos. Mater. 2025, 00219983251341617. [Google Scholar] [CrossRef]

- Wang, L.; Ge, Z.; Zhang, N.; Feng, Y.; Ling, Y.; Zhang, H. Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials. Nanotechnol. Rev. 2024, 13, 20230209. [Google Scholar] [CrossRef]

- Zamal, H.H.; Barba, D.; Aïssa, B.; Haddad, E.; Rosei, F. Recovery of electro-mechanical properties inside self-healing composites through microencapsulation of carbon nanotubes. Sci. Rep. 2020, 10, 2973. [Google Scholar] [CrossRef]

- Ouyang, Q.; Liu, L.; Wu, Z. Electrothermally Self-Healing Delamination Cracks in Carbon/Epoxy Composites Using Sandwich and Tough Carbon Nanotube/Copolymer Interleaves. Polymers 2022, 14, 4313. [Google Scholar] [CrossRef]

- Sambandan, S. Self-Repair in Circuits—Automating Open Fault Repair in Integrated Circuits Using Field-Induced Aggregation of Carbon Nanotubes. IEEE Trans. Electron Devices 2012, 59, 1773–1779. [Google Scholar] [CrossRef]

- Wang, H.; Yang, Y.; Zhang, M.; Wang, Q.; Xia, K.; Yin, Z.; Wei, Y.; Ji, Y.; Zhang, Y. Electricity-Triggered Self-Healing of Conductive and Thermostable Vitrimer Enabled by Paving Aligned Carbon Nanotubes. ACS Appl. Mater. Interfaces 2020, 12, 14315–14322. [Google Scholar] [CrossRef]

- Pu, W.; Fu, D.; Wang, Z.; Gan, X.; Lu, X.; Yang, L.; Xia, H. Realizing Crack Diagnosing and Self-Healing by Electricity with a Dynamic Crosslinked Flexible Polyurethane Composite. Adv. Sci. 2018, 5, 1800101. [Google Scholar] [CrossRef]

- Gong, Y.; Xu, J.; Yan, E.-H.; Cai, J.-H. The Self-Healing Performance of Carbon-Based Nanomaterials Modified Asphalt Binders Based on Molecular Dynamics Simulations. Front. Mater. 2021, 7, 599551. [Google Scholar] [CrossRef]

- Hou, F.-C.; Wu, X.-H.; Lin, Z.-C.; Chang, J.-B.; Ma, X.; Fang, T.; Sun, J.; Song, L. Formation behavior of single-walled carbon nanotube end-caps at high temperatures: A combined ReaxFF MD with DFT study. Comput. Mater. Sci. 2025, 258, 114025. [Google Scholar] [CrossRef]

- Sabet, M. Advanced Functionalization Strategies for Carbon Nanotube Polymer Composites: Achieving Superior Dispersion and Compatibility. Polym.-Plast. Technol. Mater. 2025, 64, 465–494. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J.; Feo, L.; Chow, C.L.; Lau, D. Developments and Applications of Carbon Nanotube Reinforced Cement-Based Composites as Functional Building Materials. Front. Mater. 2022, 9, 861646. [Google Scholar] [CrossRef]

- Paladugu, S.R.M.; Sreekanth, P.S.R.; Sahu, S.K.; Naresh, K.; Karthick, S.A.; Venkateshwaran, N.; Ramoni, M.; Mensah, R.A.; Das, O.; Shanmugam, R. A Comprehensive Review of Self-Healing Polymer, Metal, and Ceramic Matrix Composites and Their Modeling Aspects for Aerospace Applications. Materials 2022, 15, 8521. [Google Scholar] [CrossRef]

- Zhu, Y.-F.; Ma, C.; Zhang, W.; Zhang, R.-P.; Koratkar, N.; Liang, J. Alignment of multiwalled carbon nanotubes in bulk epoxy composites via electric field. J. Appl. Phys. 2009, 105, 054319. [Google Scholar] [CrossRef]

- Joh, H.; Anoop, G.; Jo, S.; Seol, W.; Park, S.M.; Eom, K.; Lee, H.J.; Jo, J.Y. Enhanced Flexible Thermoelectric Performance in Polymer–CNT Composites via Carbon Nanotube Alignment. ACS Appl. Energy Mater. 2025, 8, 3178–3184. [Google Scholar] [CrossRef]

- Del Bosque, A.; Calderón-Villajos, R.; Sánchez, M.; Ureña, A. Multifunctional Carbon Nanotubes-Reinforced Surlyn Nanocomposites: A Study of Strain-Sensing and Self-Healing Capabilities. Nanomaterials 2022, 12, 2878. [Google Scholar] [CrossRef]

- Choi, K.; Noh, A.; Kim, J.; Hong, P.H.; Ko, M.J.; Hong, S.W. Properties and Applications of Self-Healing Polymeric Materials: A Review. Polymers 2023, 15, 4408. [Google Scholar] [CrossRef]

- Zhang, Y.; Bai, Y.; Yan, B. Functionalized carbon nanotubes for potential medicinal applications. Drug Discov. Today 2010, 15, 428–435. [Google Scholar] [CrossRef] [PubMed]

- Dong, Z.-J.; Sun, B.; Zhu, H.; Yuan, G.-M.; Li, B.-L.; Guo, J.-G.; Li, X.-K.; Cong, Y.; Zhang, J. A review of aligned carbon nanotube arrays and carbon/carbon composites: Fabrication, thermal conduction properties and applications in thermal management. New Carbon Mater. 2021, 36, 873–892. [Google Scholar] [CrossRef]

- Ezeigwe, E.R.; Dong, L.; Manjunatha, R.; Tan, M.; Yan, W.; Zhang, J. A review of self-healing electrode and electrolyte materials and their mitigating degradation of Lithium batteries. Nano Energy 2021, 84, 105907. [Google Scholar] [CrossRef]

- Chen, Z.; Augustyn, V.; Wen, J.; Zhang, Y.; Shen, M.; Dunn, B.; Lu, Y. High-performance supercapacitors based on intertwined CNT/V2O5 nanowire nanocomposites. Adv. Mater. 2011, 23, 791–795. [Google Scholar] [CrossRef]

- Ishikawa, F.N.; Chang, H.K.; Ryu, K.; Chen, P.C.; Badmaev, A.; Gomez De Arco, L.; Shen, G.; Zhou, C. Transparent electronics based on transfer printed aligned carbon nanotubes on rigid and flexible substrates. ACS Nano 2009, 3, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Murjani, B.O.; Kadu, P.S.; Bansod, M.; Vaidya, S.S.; Yadav, M.D. Carbon nanotubes in biomedical applications: Current status, promises, and challenges. Carbon Lett. 2022, 32, 1207–1226. [Google Scholar] [CrossRef] [PubMed]

| Technique | Acronym | Information Provided | Application in Self-Healing Analysis | Advantages/Limitations |

|---|---|---|---|---|

| Raman Spectroscopy | - | Vibrational modes, molecular structure, defect density (ID/IG ratio), stress/strain state. | In situ monitoring of polymerization kinetics; quantitative mapping of defect healing; assessing stress transfer at healed interface. | Non-destructive, high spatial resolution/Signal can be weak, with fluorescence interference. |

| X-ray Photoelectron Spectroscopy | XPS | Elemental composition, chemical state, C-F/C-O/C-N bonding environments. | Verifying CNT functionalization; characterizing surface chemistry of fractured and healed surfaces. | Quantitative, high chemical specificity/Surface sensitive (~10 nm), requires vacuum. |

| Near-Edge X-ray Absorption Fine Structure | NEXAFS | Unoccupied electronic states, bond hybridization (sp2/sp3), molecular orientation. | Confirming covalent bond formation during functionalization or healing; probing polymer chain alignment at interfaces. | Sensitive to bonding and orientation/Requires synchrotron source. |

| Electron Energy Loss Spectroscopy | EELS | Elemental composition, electronic structure (plasmons, C K-edge), bonding state. | Atomic-resolution analysis of defects induced by irradiation; characterizing bonding across the healed interface in a TEM. | Very high spatial resolution/Requires electron-transparent samples, potential beam damage. |

| Auger Electron Spectroscopy | AES | Elemental composition, chemical state (from C KVV lineshape). | Characterizing the “fingerprint” of carbon bonding (graphitic vs. disordered) at surfaces before/after damage and healing. | Extremely surface sensitive (~1–3 nm)/Can be destructive, requires vacuum. |

| Soft X-ray Emission Spectroscopy | SXE | Occupied electronic states (valence band). | Provides a complete picture of electronic structural changes when combined with NEXAFS. | Complements NEXAFS/Requires synchrotron source. |

| Reference | Material | CNT Assembly Method | Mechanism | Key |

|---|---|---|---|---|

| Zamal et al., 2020 [66] | Polymer composite | Dispersion in microcapsules | Polymers | Up to 80% restoration of mechanical and electrical properties. |

| Gómez-Sánchez et al., 2024 [50] | Epoxy | Homogeneous dispersion | Joule heating of CNT network | Efficient crack recovery with homogeneous resistive heating, healing over 90% of material. |

| Ouyang et al., 2022 [67] | Carbon fiber polymer | Network in interleaves | Joule heating at interlayer | Delamination repair. |

| Sambandan, 2012 [68] | Integrated circuits | Dispersion in fluid | Electric-field-induced aggregation | Automated open fault repair triggered by the electric field across the gap. |

| Wang et al., 2020 [69] | Liquid crystal | Paving aligned sheets | Joule heating of aligned CNT sheets | Healing of scratches with almost no loss of mechanical properties. |

| Lanzara et al., 2009 [35] | Polymer composite | Nanoreservoirs | Healing agent release from ruptured CNTs | Potential for tougher and automated self-healing materials. |

| Pu et al., 2018 [70] | Polyurethane composite colydimethylsiloxane (PDMS) | Dispersion | Joule heating via retro-Diels–Alder, polymerization | Crack diagnosing and rapid, repeatable self-healing by electricity or NIR light. Healing time reduced from 24 h to 10 min. |

| Zhao et al., 2023 [47] | Fiber-reinforced thermoplastic | Embedded film | Joule heating of CNT film | 87% self-healing efficiency in terms of flexural strength after low-energy impact. |

| Gong et al., 2021 [71] | Asphalt binder | Dispersion | Enhanced thermal conductivity for healing | Up to 652% enhancement of mean square displacement at optimal temperatures. |

| Application Area | Application Examples | Mechanisms Involved | Reference |

|---|---|---|---|

| Energy Storage | Electrodes in batteries and supercapacitors (flexible, solid-state) | CNT network rearrangement in self-healing polymer matrix | Ibrahim et al., 2025 [49] |

| Energy Storage | Joule heating for localized repair in epoxy/CNT systems | Thermal activation by the Joule effect | Gómez-Sánchez et al., 2024 [50] |

| Sensors | Strain and pressure sensors, electronic skin | CNT network sensing and matrix repair; dynamic cross-linking and hydrogen bonding in hydrogels | Del Bosque et al., 2022 [78] |

| Biomedical | Protective coatings for implants | Extrinsic self-healing using encapsulated agents | Choi et al., 2023 [79] |

| Biomedical | Drug delivery systems | Potential enhancement of delivery vehicle durability | Zhang et al., 2010 [80] |

| Aerospace/Automotive | Self-sensing structural components | Potential integration of self-healing for damage repair | Dong et al., 2021 [81] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snowdon, M.R.; Rathod, S.; Liang, R.L.F.; Freire-Gormaly, M. Architecting Durability: Synergies in Assembly, Self-Repair, and Advanced Characterization of Carbon Nanotube Materials. Nanomaterials 2025, 15, 1352. https://doi.org/10.3390/nano15171352

Snowdon MR, Rathod S, Liang RLF, Freire-Gormaly M. Architecting Durability: Synergies in Assembly, Self-Repair, and Advanced Characterization of Carbon Nanotube Materials. Nanomaterials. 2025; 15(17):1352. https://doi.org/10.3390/nano15171352

Chicago/Turabian StyleSnowdon, Monika R., Shasvat Rathod, Robert L. F. Liang, and Marina Freire-Gormaly. 2025. "Architecting Durability: Synergies in Assembly, Self-Repair, and Advanced Characterization of Carbon Nanotube Materials" Nanomaterials 15, no. 17: 1352. https://doi.org/10.3390/nano15171352

APA StyleSnowdon, M. R., Rathod, S., Liang, R. L. F., & Freire-Gormaly, M. (2025). Architecting Durability: Synergies in Assembly, Self-Repair, and Advanced Characterization of Carbon Nanotube Materials. Nanomaterials, 15(17), 1352. https://doi.org/10.3390/nano15171352