Research on the Poisson’s Ratio of Black Phosphorene Nanotubes Under Axial Tension

Abstract

1. Introduction

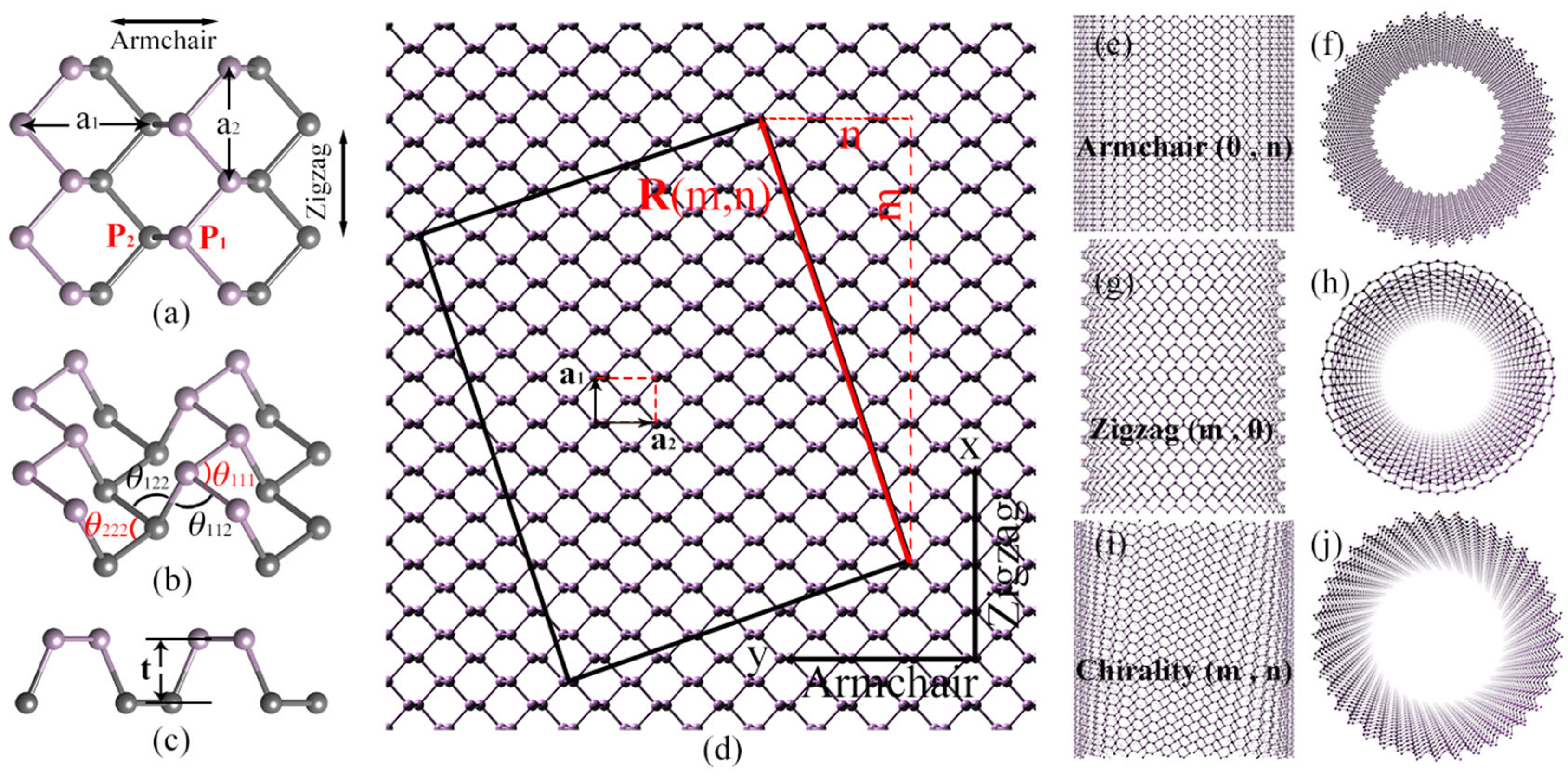

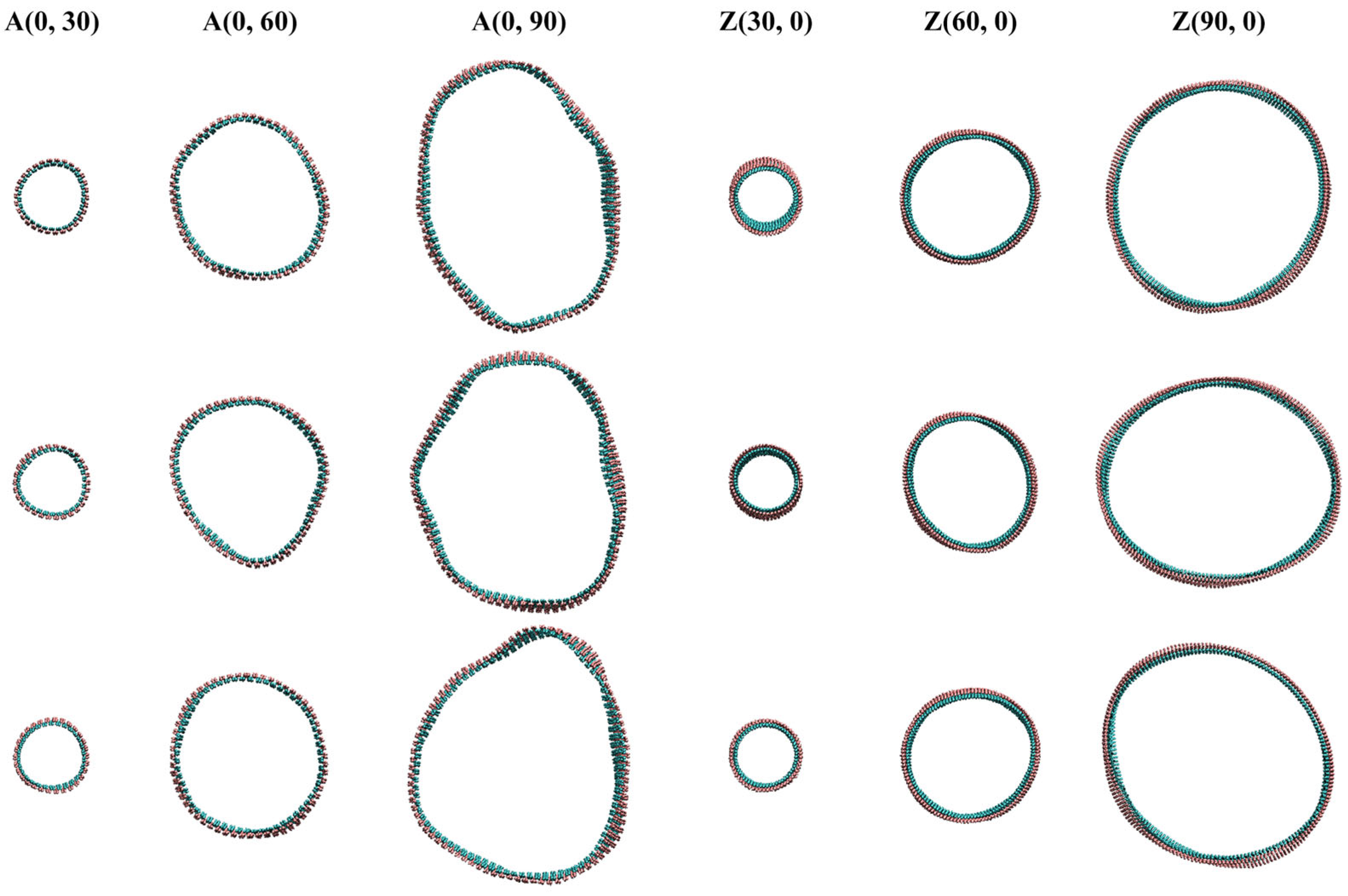

2. Models and Methods

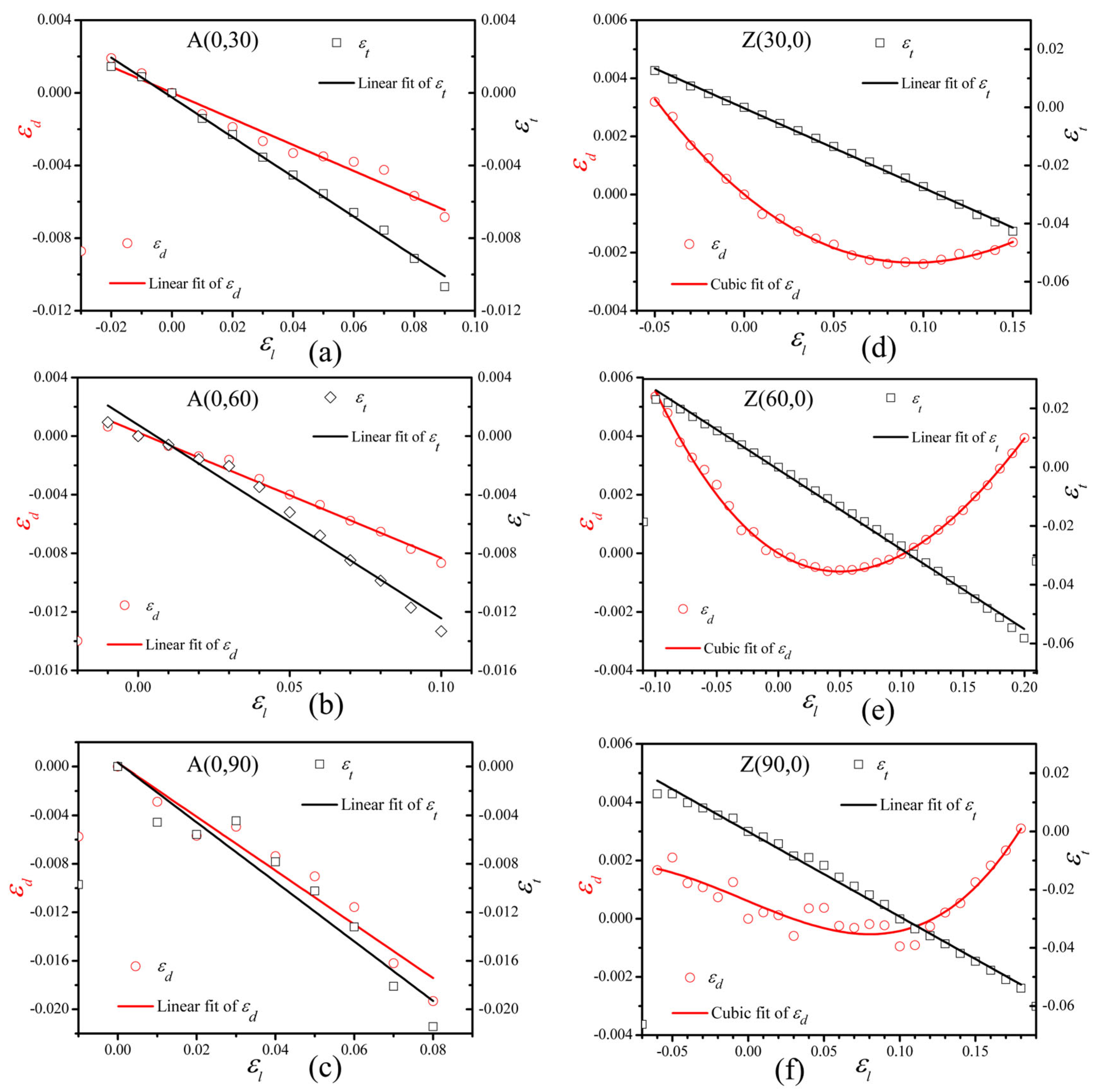

3. Results and Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lakes, R. Foam Structures with a Negative Poisson’s Ratio. Science 1987, 235, 1038–1040. [Google Scholar] [CrossRef]

- Jiang, J.-W.; Park, H.S. Negative poisson’s ratio in single-layer black phosphorus. Nat. Commun. 2014, 5, 4727. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.-W.; Kim, S.Y.; Park, H.S. Auxetic nanomaterials: Recent progress and future development. Appl. Phys. Rev. 2016, 3, 041101. [Google Scholar] [CrossRef]

- Borcea, C.S.; Ileana, S. Periodic Auxetics: Structure and Design. Q. J. Mech. Appl. Math. 2018, 71, 125–138. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Das, R.; Tran, P.; Ngo, T.D.; Xie, Y.M. Auxetic metamaterials and structures: A review. Smart Mater. Struct. 2018, 27, 023001. [Google Scholar] [CrossRef]

- Gan, Z.; Zhuge, Y.; Thambiratnam, D.P.; Chan, T.H.; Zahra, T.; Asad, M. Recent advances in auxetics: Applications in cementitious composites. Int. J. Prot. Struct. 2022, 13, 295–316. [Google Scholar] [CrossRef]

- Shukla, S.; Behera, B. Auxetic fibrous structures and their composites: A review. Compos. Struct. 2022, 290, 115530. [Google Scholar] [CrossRef]

- Dong, S.; Hu, H. Sensors Based on Auxetic Materials and Structures: A Review. Materials 2023, 16, 3603. [Google Scholar] [CrossRef]

- Shukla, S.; Behera, B.K. Auxetic fibrous materials and structures in medical engineering—A review. J. Text. Inst. 2022, 114, 1078–1089. [Google Scholar] [CrossRef]

- Lv, Y.; Zhang, Y.; Gong, N.; Li, Z.X.; Lu, G.; Xiang, X. On the out-of-Plane Compression of a Miura-Ori Patterned Sheet. Int. J. Mech. Sci. 2019, 105022, 161–162. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, G.; You, Z. Large deformation and energy absorption of additively manufactured auxetic materials and structures: A review. Compos. Part B Eng. 2020, 201, 108340. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, G.; Wang, Z.; Ruan, D.; Alomarah, A.; Durandet, Y. Large deformation of an auxetic structure in tension: Experiments and finite element analysis. Compos. Struct. 2018, 184, 92–101. [Google Scholar] [CrossRef]

- Du, Y.; Maassen, J.; Wu, W.; Luo, Z.; Xu, X.; Ye, P.D. Auxetic Black Phosphorus: A 2D Material with Negative Poisson’s Ratio. Nano Lett. 2016, 16, 6701–6708. [Google Scholar] [CrossRef]

- Jiang, J.-W.; Chang, T.; Guo, X.; Park, H.S. Intrinsic Negative Poisson’s Ratio for Single-Layer Graphene. Nano Lett. 2016, 16, 5286–5290. [Google Scholar] [CrossRef]

- Jiang, J.-W.; Park, H.S. Negative Poisson’s Ratio in Single-Layer Graphene Ribbons. Nano Lett. 2016, 16, 2657–2662. [Google Scholar] [CrossRef]

- Wan, J.; Jiang, J.-W.; Park, H.S. Negative Poisson’s ratio in graphene oxide. Nanoscale 2017, 9, 4007–4012. [Google Scholar] [CrossRef] [PubMed]

- Yuan, K.; Li, M.-Y.; Liu, Y.-Z.; Li, R.-Z. Design and Prediction of a Novel Two-Dimensional Carbon Nanostructure with In-Plane Negative Poisson’s Ratio. J. Nanomater. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Zhao, S.; Hu, H.; Kamrul, H.; Chang, Y.; Zhang, M. Development of auxetic warp knitted fabrics based on reentrant geometry. Text. Res. J. 2019, 90, 344–356. [Google Scholar] [CrossRef]

- Qin, G.; Qin, Z. Negative Poisson’s ratio in two-dimensional honeycomb structures. npj Comput. Mater. 2020, 6, 1–6. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, C.; Pei, L.; Li, J.; Wang, R. Molecular Dynamics Simulation of the Negative Poisson’s Ratio in Graphene/Cu Nanolayered Composites: Implications for Scaffold Design and Telecommunication Cables. ACS Appl. Nano Mater. 2019, 3, 496–505. [Google Scholar] [CrossRef]

- Sun, M.; Schwingenschlögl, U. Unique Omnidirectional Negative Poisson’s Ratio in δ-Phase Carbon Monochalcogenides. J. Phys. Chem. C 2021, 125, 4133–4138. [Google Scholar] [CrossRef]

- Ho, V.H.; Ho, D.T.; Nguyen, C.T.; Kim, S.Y. Negative out-of-plane Poisson’s ratio of bilayer graphane. Nanotechnology 2022, 33, 255705. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, L.; Zhang, F.; Chen, Q.; Zhan, Y.; Meng, L.; Zheng, X.; Wang, H.; Qin, Z.; Qin, G. The consistent behavior of negative Poisson’s ratio with interlayer interactions. Mater. Adv. 2022, 3, 4334–4341. [Google Scholar] [CrossRef]

- Yu, L.; Wang, Y.; Zheng, X.; Wang, H.; Qin, Z.; Qin, G. Emerging negative Poisson’s ratio driven by strong intralayer interaction response in rectangular transition metal chalcogenides. Appl. Surf. Sci. 2022, 610, 155478. [Google Scholar] [CrossRef]

- Zhu, Y.; Cao, X.; Tan, Y.; Wang, Y.; Hu, J.; Li, B.; Chen, Z. Single-Layer MoS2: A Two-Dimensional Material with Negative Poisson’s Ratio. Coatings 2023, 13, 283. [Google Scholar] [CrossRef]

- Ren, K.; Ma, X.; Liu, X.; Xu, Y.; Huo, W.; Li, W.; Zhang, G. Prediction of 2D IV–VI semiconductors: Auxetic materials with direct bandgap and strong optical absorption. Nanoscale 2022, 14, 8463–8473. [Google Scholar] [CrossRef] [PubMed]

- Wen, Y.; Gao, E.; Hu, Z.; Xu, T.; Lu, H.; Xu, Z.; Li, C. Chemically modified graphene films with tunable negative Poisson’s ratios. Nat. Commun. 2019, 10, 2446. [Google Scholar] [CrossRef]

- Guan, J.; Zhu, Z.; Tománek, D. High Stability of Faceted Nanotubes and Fullerenes of Multiphase Layered Phosphorus: A Computational Study. Phys. Rev. Lett. 2014, 113, 226801. [Google Scholar] [CrossRef]

- Guo, H.; Lu, N.; Dai, J.; Wu, X.; Zeng, X.C. Phosphorene Nanoribbons, Phosphorus Nanotubes, and Van Der Waals Multilayers. J. Phys. Chem. C 2014, 118, 14051–14059. [Google Scholar] [CrossRef]

- Shahnazari, A.; Ansari, R.; Rouhi, S. On the stability characteristics of zigzag phosphorene nanotubes: A finite element investigation. J. Alloy Compd. 2017, 702, 388–398. [Google Scholar] [CrossRef]

- Cai, K.; Wan, J.; Wei, N.; Cai, H.; Qin, Q.-H. Thermal stability of a free nanotube from single-layer black phosphorus. Nanotechnology 2016, 27, 235703. [Google Scholar] [CrossRef]

- Fernández-Escamilla, H.N.; Quijano-Briones, J.J.; Tlahuice-Flores, A. Chiral phosphorus nanotubes: Structure, bonding, and electronic properties. Phys. Chem. Chem. Phys. 2016, 18, 12414–12418. [Google Scholar] [CrossRef]

- Seifert, G.; Hernández, E. Theoretical prediction of phosphorus nanotubes. Chem. Phys. Lett. 2000, 318, 355–360. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, J.; Zhang, P.; Ding, Y. Strain/stress engineering on the mechanical and electronic properties of phosphorene nanosheets and nanotubes. RSC Adv. 2017, 7, 51466–51474. [Google Scholar] [CrossRef]

- Shi, J.; Cai, K.; Liu, L.-N.; Qin, Q.-H. Self-assembly of a parallelogram black phosphorus ribbon into a nanotube. Sci. Rep. 2017, 7, 1–10. [Google Scholar] [CrossRef]

- Cai, K.; Liu, L.; Shi, J.; Qin, Q.H. Winding a nanotube from black phosphorus nanoribbon onto a CNT at low temperature: A molecular dynamics study. Mater. Des. 2017, 121, 406–413. [Google Scholar] [CrossRef]

- Cai, K.; Shi, J.; Liu, L.; Qin, Q. Fabrication of an ideal nanoring from a black phosphorus nanoribbon upon movable bundling carbon nanotubes. Nanotechnology 2017, 28, 385603. [Google Scholar] [CrossRef] [PubMed]

- Cai, K.; Liu, L.; Shi, J.; Qin, Q.H. Self-Assembly of a Jammed Black Phosphorus Nanoribbon on a Fixed Carbon Nanotube. J. Phys. Chem. C 2017, 121, 10174–10181. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, D.; Xiao, D.; Ma, C.; Du, H.; Li, X.; Zhang, L.; Huang, J.; Huang, H.; Jia, C.; et al. Assembly of Ring-Shaped Phosphorus within Carbon Nanotube Nanoreactors. Angew. Chem. Int. Ed. Engl. 2017, 56, 1850–1854. [Google Scholar] [CrossRef]

- Choi, Y.W.; Lee, Y.; Kim, K.; Zettl, A.; Cohen, M.L. Atomic and Electronic Structures of 1D Phosphorus Nanoring and Nanohelix. ACS Nano 2025, 19, 12155–12160. [Google Scholar] [CrossRef]

- Badehian, H.A.; Gharbavi, K. Effect of silicon doping on the electronic and optical properties of phosphorous nanotubes. Optik 2021, 225, 165808. [Google Scholar] [CrossRef]

- Fernández-Escamilla, H.N.; Guerrero-Sanchez, J.; Martínez-Guerra, E.; Takeuchi, N. Structural and Electronic Properties of Double-Walled Black Phosphorene Nanotubes: A Density Functional Theory Study. J. Phys. Chem. C 2019, 123, 7217–7224. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, L.; Wang, Z.; Li, J.; Li, H. Effect of C and O dopant atoms on the electronic properties of black phosphorus nanotubes. Comput. Mater. Sci. 2019, 156, 292–300. [Google Scholar] [CrossRef]

- Li, Q.; Wang, H.; Yang, C.; Li, Q.; Rao, W. Theoretical prediction of high carrier mobility in single-walled black phosphorus nanotubes. Appl. Surf. Sci. 2018, 441, 1079–1085. [Google Scholar] [CrossRef]

- Li, C.; Xie, Z.; Chen, Z.; Cheng, N.; Wang, J.; Zhu, G. Tunable Bandgap and Optical Properties of Black Phosphorene Nanotubes. Materials 2018, 11, 304. [Google Scholar] [CrossRef]

- Ou, P.; Zhou, X.; Li, X.-Y.; Chen, Y.; Chen, C.; Meng, F.; Song, J. Single-Walled Black Phosphorus Nanotube as a NO2 Gas Sensor. Mater. Today Commun. 2022, 31, 103434. [Google Scholar] [CrossRef]

- Maria, J.P.; Nagarajan, V.; Chandiramouli, R. Chemosensing nature of black phosphorene nanotube towards C14H9Cl5 and C10H5Cl7 molecules – A first-principles insight. Comput. Theor. Chem. 2021, 1196, 113109. [Google Scholar] [CrossRef]

- Kazerooni, H.B.; Ghayour, R.; Pesaran, F. Analysis and application of zigzag phosphorene nanotube as gas nanosensor. Appl. Phys. A 2021, 127, 1–10. [Google Scholar] [CrossRef]

- Saravanan, S.; Nagarajan, V.; Chandiramouli, R. Adsorption insights of amine vapors on black phosphorene nanotubes—A first-principles study. Mater. Res. Express 2019, 6, 105518. [Google Scholar] [CrossRef]

- Cao, J.; Shi, J.; Hu, Y.; Wu, M.; Ouyang, C.; Xu, B. Lithium ion adsorption and diffusion on black phosphorene nanotube: A first-principles study. Appl. Surf. Sci. 2017, 392, 88–94. [Google Scholar] [CrossRef]

- Zhang, W.; Cui, Y.; Zhu, C.; Huang, B.; Yan, S.; Lou, Y.; Zhang, P. Sequential hydrogen storage in phosphorene nanotubes: A molecular dynamics study. Int. J. Hydrogen Energy 2023, 48, 23909–23916. [Google Scholar] [CrossRef]

- Wang, H.; Gao, Q.; Liu, C.; Cao, Y.; Liu, S.; Zhang, B.; Hu, Z.; Sun, J. Anisotropic black phosphorene nanotube anodes afford ultrafast kinetic rate or extra capacities for Li-ion batteries. Chin. Chem. Lett. 2022, 33, 3842–3848. [Google Scholar] [CrossRef]

- Tran, K.; Taylor, P.D.; Spencer, M.J.S. Electromechanical strain response of phosphorene nanotubes. J. Phys. Mater. 2024, 7, 035001. [Google Scholar] [CrossRef]

- Cuba-Supanta, G.; Fernández-Escamilla, H.N.; Guerrero-Sanchez, J.; Rojas-Tapia, J.; Takeuchi, N. Structural properties and thermal stability of multi-walled black phosphorene nanotubes and their operation as temperature driven nanorotors. Nanoscale 2020, 12, 18313–18321. [Google Scholar] [CrossRef]

- Guan, L.; Chen, G.; Tao, J. Prediction of the electronic structure of single-walled black phosphorus nanotubes. Phys. Chem. Chem. Phys. 2016, 18, 15177–15181. [Google Scholar] [CrossRef]

- Yang, J.; Xie, Y.; Wang, S.; Jiang, N.; Chen, L.; Wang, X.; Zhang, J. Manipulating the electronic, magnetic, and optical properties of single-walled armchair phosphorus nanotubes by encapsulating transition metal nanowires. Mater. Today Commun. 2022, 34, 105253. [Google Scholar] [CrossRef]

- Liu, P.; Pei, Q.-X.; Huang, W.; Zhang, Y.-W. Mechanical properties and fracture behaviour of defective phosphorene nanotubes under uniaxial tension. J. Phys. D Appl. Phys. 2017, 50, 485303. [Google Scholar] [CrossRef]

- Nguyen, V.-T. Effects of Missing Atom Defect on the Mechanical Properties of Black Phosphorene Nanotube. Int. J. Eng. Res. Appl. 2018, 8, 29–32. [Google Scholar]

- Sorkin, V.; Zhang, Y.-W. Effect of vacancies on the mechanical properties of phosphorene nanotubes. Nanotechnology 2018, 29, 235707. [Google Scholar] [CrossRef]

- Liu, P.; Pei, Q.-X.; Huang, W.; Zhang, Y.-W. Strength and buckling behavior of defective phosphorene nanotubes under axial compression. J. Mater. Sci. 2018, 53, 8355–8363. [Google Scholar] [CrossRef]

- Ansari, R.; Shahnazari, A.; Rouhi, S. A density-functional-theory-based finite element model to study the mechanical properties of zigzag phosphorene nanotubes. Phys. E Low-Dimens. Syst. Nanostructures 2017, 88, 272–278. [Google Scholar] [CrossRef]

- Chen, W.-H.; Yu, C.-F.; Chen, I.-C.; Cheng, H.-C. Mechanical property assessment of black phosphorene nanotube using molecular dynamics simulation. Comput. Mater. Sci. 2017, 133, 35–44. [Google Scholar] [CrossRef]

- Hao, J.; Wang, Z.; Peng, Y.; Wang, Y. Structure and elastic properties of black phosphorus nanotubes: A first-principles study. Phys. Status solidi (b) 2017, 254, 1700276. [Google Scholar] [CrossRef]

- Wang, L.; Wang, C. Negative/zero thermal expansion in black phosphorus nanotubes. Phys. Chem. Chem. Phys. 2018, 20, 28726–28731. [Google Scholar] [CrossRef]

- Hao, F.; Liao, X.; Xiao, H.; Chen, X. Thermal conductivity of armchair black phosphorus nanotubes: A molecular dynamics study. Nanotechnology 2016, 27, 155703. [Google Scholar] [CrossRef]

- Lakes, R.S. Negative-Poisson’s-Ratio Materials: Auxetic Solids. Annu. Rev. Mater. Res. 2017, 47, 63–81. [Google Scholar] [CrossRef]

- Yuan, K.; Zhao, Y.; Li, M.; Liu, Y. Predicting an ideal 2D carbon nanostructure with negative Poisson’s ratio from first principles: Implications for nanomechanical devices. Carbon Lett. 2021, 31, 1227–1235. [Google Scholar] [CrossRef]

- Gao, Y.; Wen, M.; Zhang, X.; Wu, F.; Xia, Q.; Wu, H.; Dong, H. Factors affecting the negative Poisson’s ratio of black phosphorus and black arsenic: Electronic effects. Phys. Chem. Chem. Phys. 2021, 23, 3441–3446. [Google Scholar] [CrossRef]

- Jiang, J.-W.; Rabczuk, T.; Park, H.S. A Stillinger–Weber potential for single-layered black phosphorus, and the importance of cross-pucker interactions for a negative Poisson’s ratio and edge stress-induced bending. Nanoscale 2015, 7, 6059–6068. [Google Scholar] [CrossRef] [PubMed]

- Ho, D.T.; Park, S.D.; Kwon, S.Y.; Park, K.; Kim, S.Y. Negative Poisson’s Ratios in Metal Nanoplates. Nat. Commun. 2014, 5, 3255. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Jiang, J.-W. An empirical description for the hinge-like mechanism in single-layer black phosphorus: The angle–angle cross interaction. Acta Mech. Solida Sin. 2017, 30, 227–233. [Google Scholar] [CrossRef]

- Jiang, J.-W. Parametrization of Stillinger–Weber potential based on valence force field model: Application to single-layer MoS2and black phosphorus. Nanotechnology 2015, 26, 315706. [Google Scholar] [CrossRef]

- Sha, Z.-D.; Pei, Q.-X.; Ding, Z.; Jiang, J.-W.; Zhang, Y.-W. Mechanical properties and fracture behavior of single-layer phosphorene at finite temperatures. J. Phys. D Appl. Phys. 2015, 48, 395303. [Google Scholar] [CrossRef]

- Yang, Z.; Zhao, J.; Wei, N. Temperature-dependent mechanical properties of monolayer black phosphorus by molecular dynamics simulations. Appl. Phys. Lett. 2015, 107, 023107. [Google Scholar] [CrossRef]

- Sorkin, V.; Zhang, Y.W. Mechanical properties of phosphorene nanotubes: A density functional tight-binding study. Nanotechnology 2016, 27, 395701. [Google Scholar] [CrossRef] [PubMed]

- Ansari, R.; Aghdasi, P.; Shahnazari, A. A comprehensive study of mechanical properties in armchair phosphorene nanotubes using DFT-based finite element analysis. Appl. Phys. A 2024, 130, 1–12. [Google Scholar] [CrossRef]

| A(0, 30) | A(0, 60) | A(0, 90) | Z(30, 0) | Z(60, 0) | Z(90, 0) | |

|---|---|---|---|---|---|---|

| Dout | 43.93 | 85.29 | 124.98 | 34.35 | 65.69 | 97.10 |

| Din | 39.71 | 81.11 | 120.88 | 30.15 | 64.7 | 92.90 |

| t | 2.11 | 2.09 | 2.05 | 2.10 | 2.11 | 2.10 |

| A(0, 30) | A(0, 60) | A(0, 90) | |

|---|---|---|---|

| νd | 0.072 | 0.086 | 0.222 |

| νt | 0.110 | 0.132 | 0.246 |

| Z(0, 30) | Z(0, 60) | Z(0, 90) | |

|---|---|---|---|

| ν1 | 0.051 | 0.026 | 0.022 |

| ν2 | 0.291 | 0.275 | 0.01 |

| ν3 | −0.161 | −0.244 | 1.038 |

| νt | 0.274 | 0.271 | 0.292 |

| Researcher | Method and Package | ABPNTs(νd) | ZBPNTs (ν1/νd) | ABPNTs(νt) | ZBPNTs(νt) |

|---|---|---|---|---|---|

| This paper | MD (LAMMPS) | 0.072–0.222 | −0.055~0.088 | 0.110–0.246 | 0.274–0.292 |

| Chen et al. [62] | Force field (COMPASS) | -- | -- | 0.45 | 0.11 |

| Sorkin et al. [76] | Tight binding | 0.47 | 0.07 | 0.11 | 0.21 |

| Ansari et al. [77] | DFT-FEM | -- | -- | 0.47 | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, X.; Fan, T.; Zhang, K. Research on the Poisson’s Ratio of Black Phosphorene Nanotubes Under Axial Tension. Nanomaterials 2025, 15, 1259. https://doi.org/10.3390/nano15161259

Tan X, Fan T, Zhang K. Research on the Poisson’s Ratio of Black Phosphorene Nanotubes Under Axial Tension. Nanomaterials. 2025; 15(16):1259. https://doi.org/10.3390/nano15161259

Chicago/Turabian StyleTan, Xinjun, Touwen Fan, and Kaiwang Zhang. 2025. "Research on the Poisson’s Ratio of Black Phosphorene Nanotubes Under Axial Tension" Nanomaterials 15, no. 16: 1259. https://doi.org/10.3390/nano15161259

APA StyleTan, X., Fan, T., & Zhang, K. (2025). Research on the Poisson’s Ratio of Black Phosphorene Nanotubes Under Axial Tension. Nanomaterials, 15(16), 1259. https://doi.org/10.3390/nano15161259