High-Responsivity UV–Blue Photodetector Based on Nanostructured CdS and Prepared by Solution Processing

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Synthesis and Device Fabrication

2.2. Material and Device Performance Characterization

3. Results and Discussion

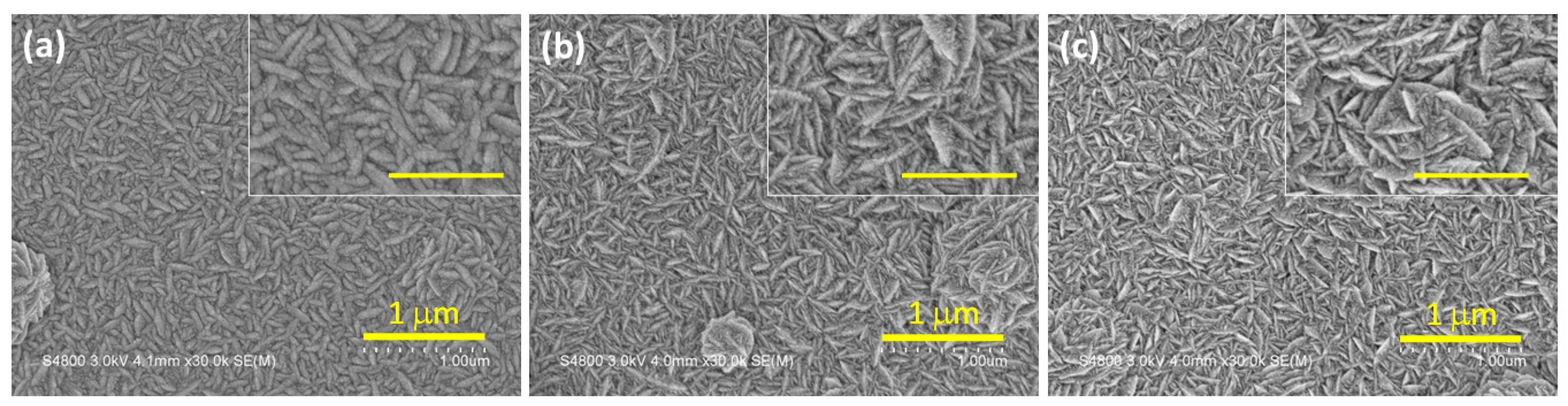

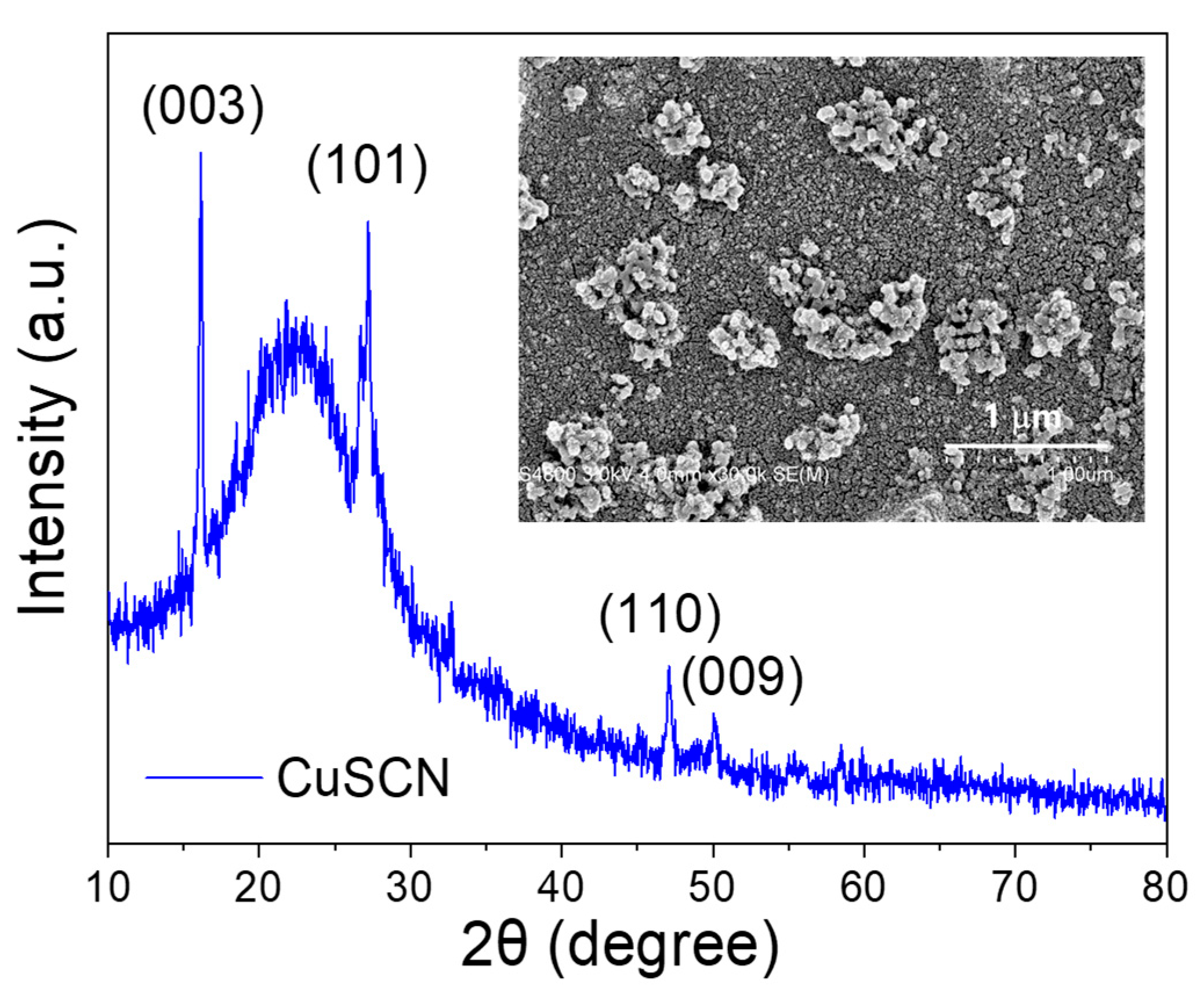

3.1. Nanostructured CdS Thin Films

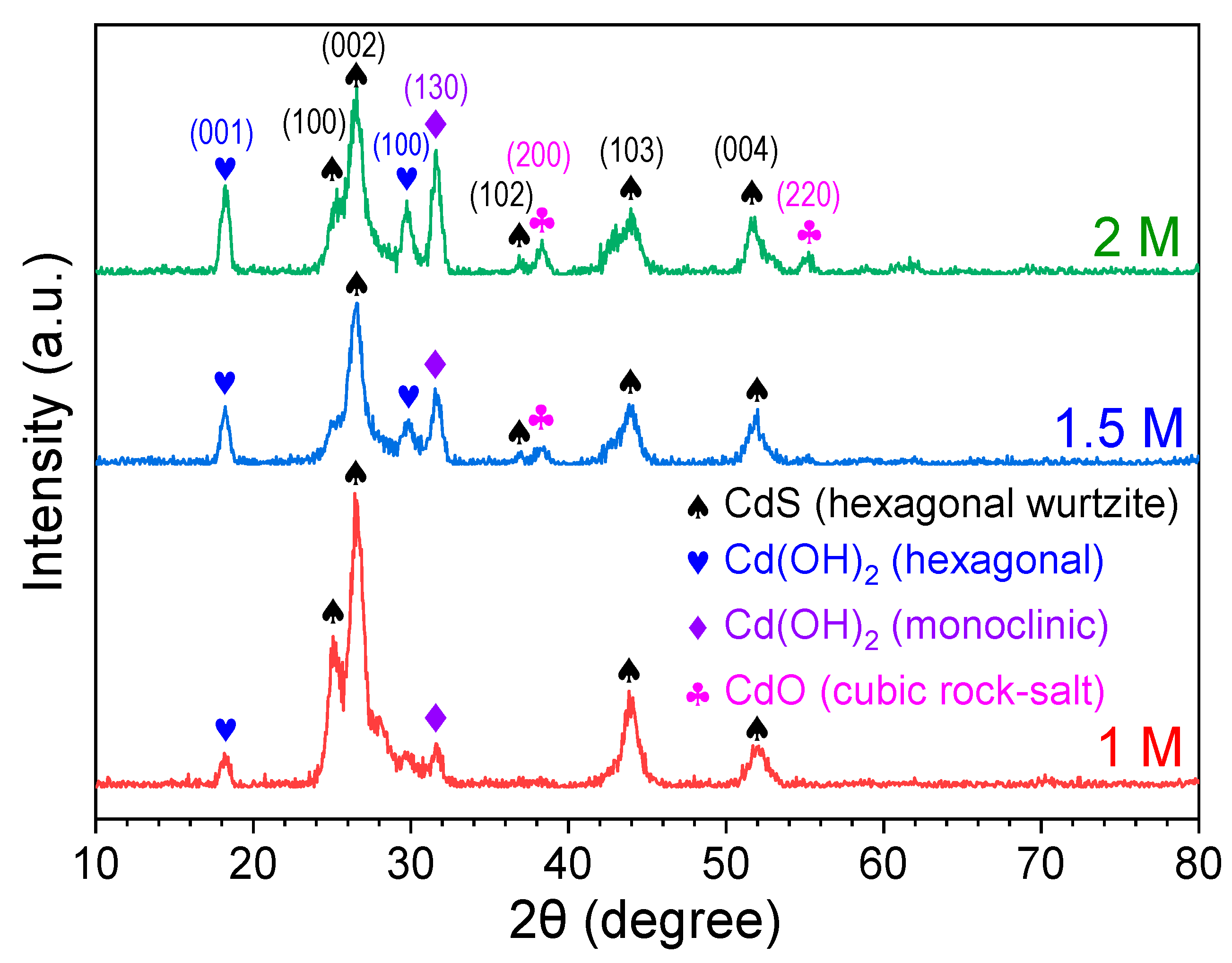

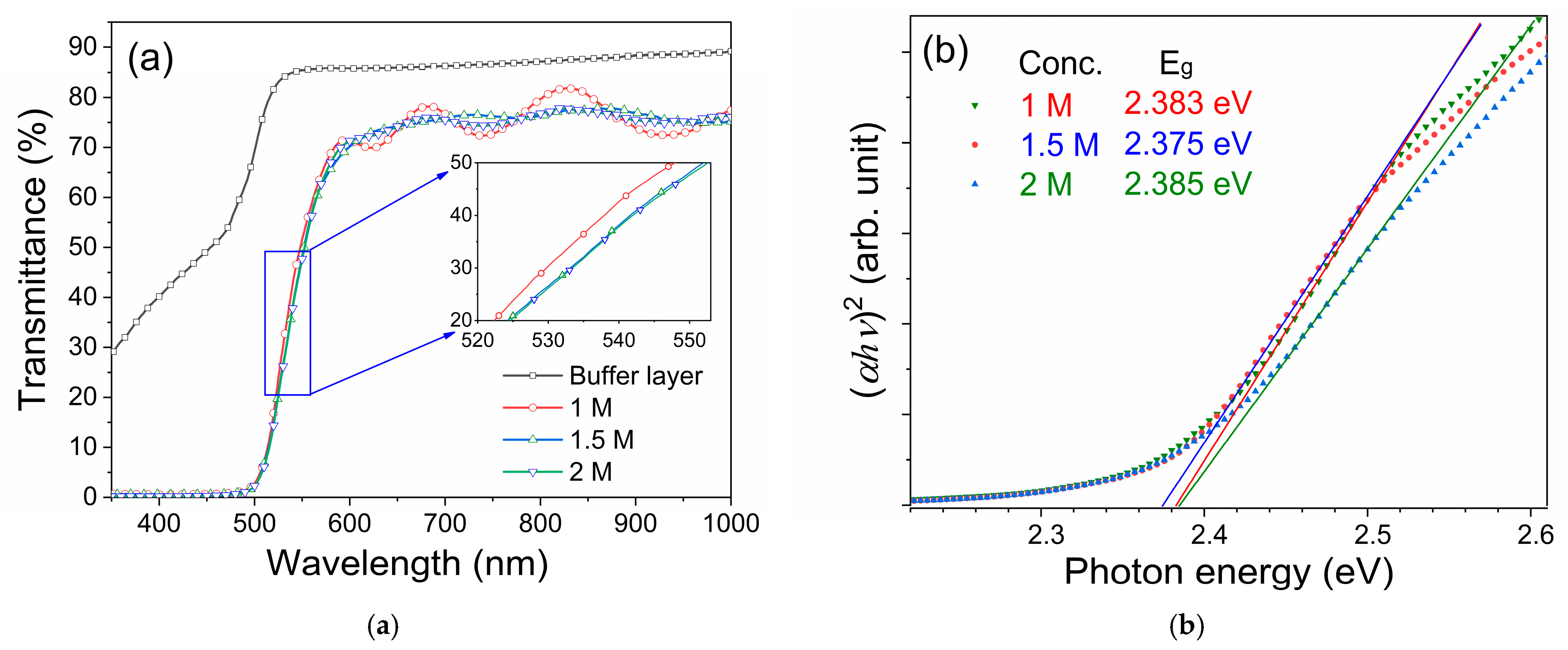

3.1.1. Structural and Optical Properties

| Sample | 2θ (°) | FWHM (°) | D (nm) | δ (×10−2 nm−2) | ε (×10−3) |

|---|---|---|---|---|---|

| 1 M | 26.62 | 1.092 | 7.48 | 1.79 | 5.18 |

| 1.5 M | 26.62 | 1.017 | 8.03 | 1.55 | 4.82 |

| 2 M | 26.56 | 0.9709 | 8.41 | 1.41 | 4.89 |

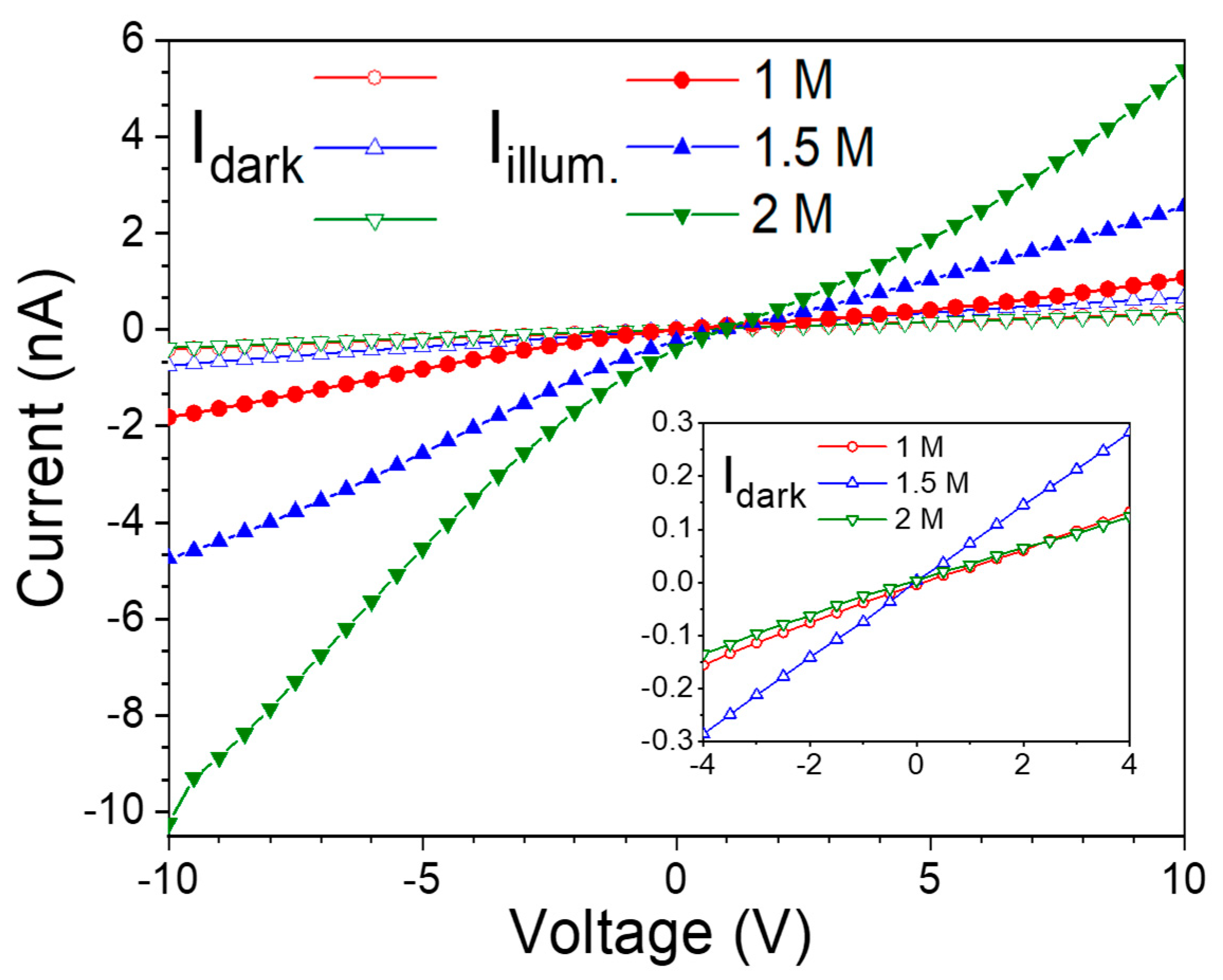

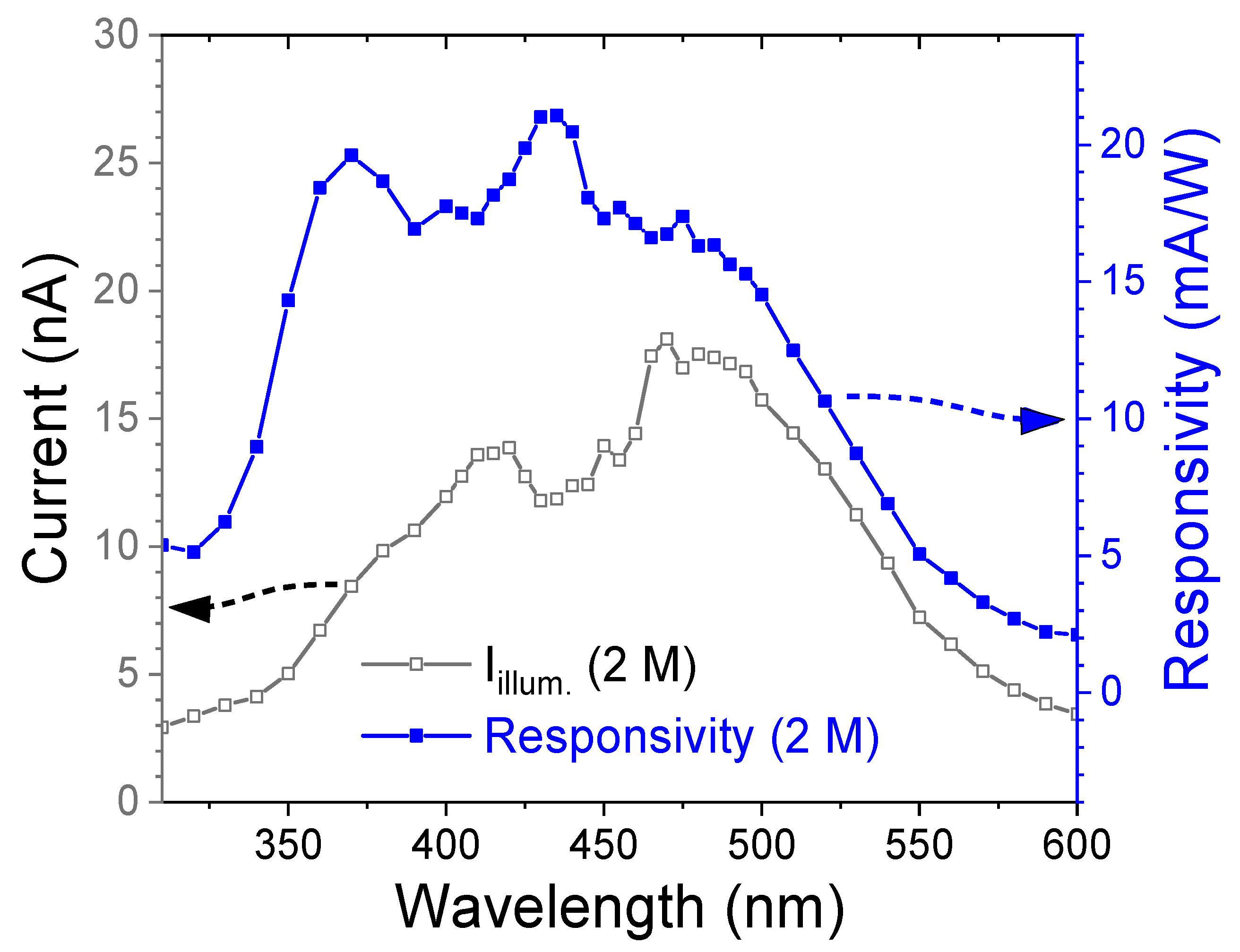

3.1.2. Current–Voltage and Photoresponse Properties

| Device Structure | Deposition Method | Wavelength, Voltage | R (mA/W) | D* (Jones) | Ref. |

|---|---|---|---|---|---|

| CdS | PLD 1 | 365 nm, 0 V | 6210 | - | [32] |

| CdS:Al (3%) | Spray | 532 nm, 5 V | 2130 | 5.2 × 1011 | [33] |

| CdS:Na | Hydrothermal | 390 nm, - | 38 | 1.5 × 1010 | [34] |

| FTO/CdS:Cl | CBD | 365 nm, −2 V | 570 | 3.7 × 108 | [35] |

| 530 nm, −2 V | 1670 | 1.08 × 109 | |||

| CdS:Mg (3%) | CBD | 443 nm, 0 V | 11 | 4.4 × 108 | [20] |

| Au/CdS/Au | Evaporation | 420 nm, 10 V | 380 | 2.6 × 1013 | [36] |

| Al/CdS/Al | CBD | 435 nm, −10 V | 21.1 | 3.0 × 1011 | This study |

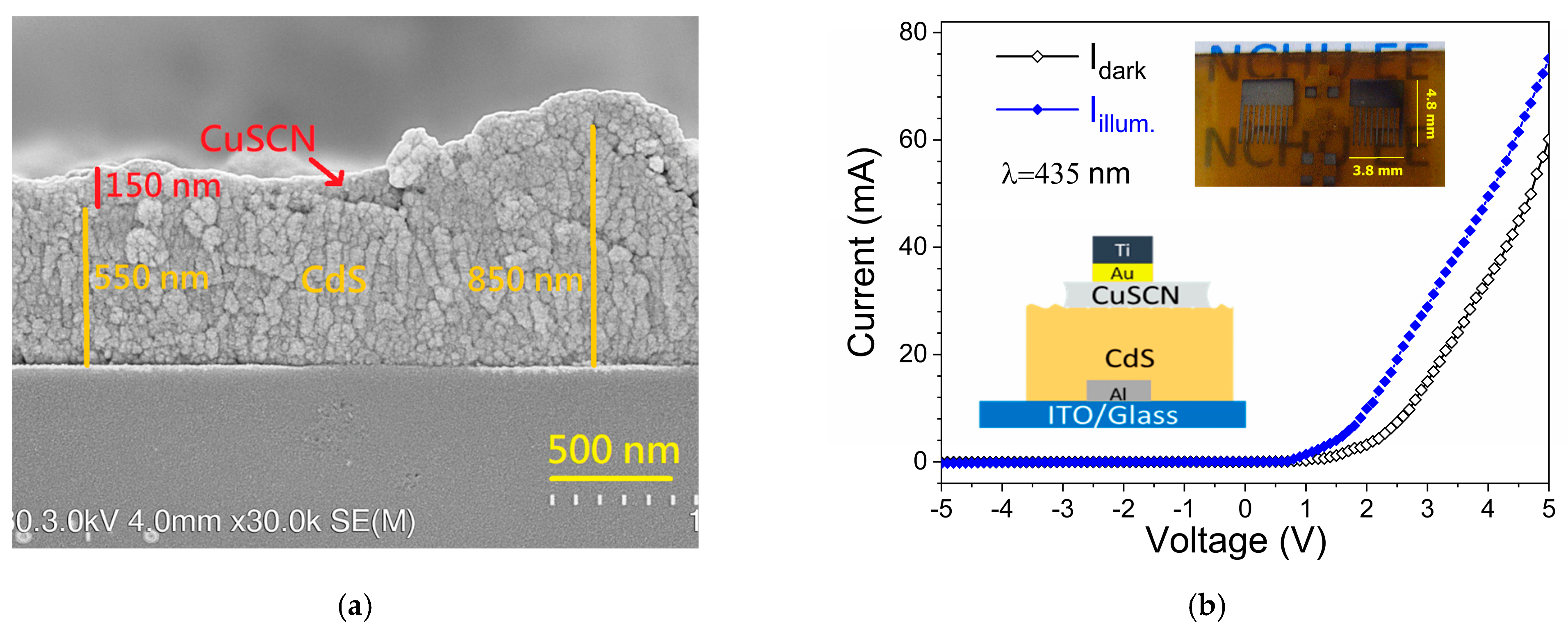

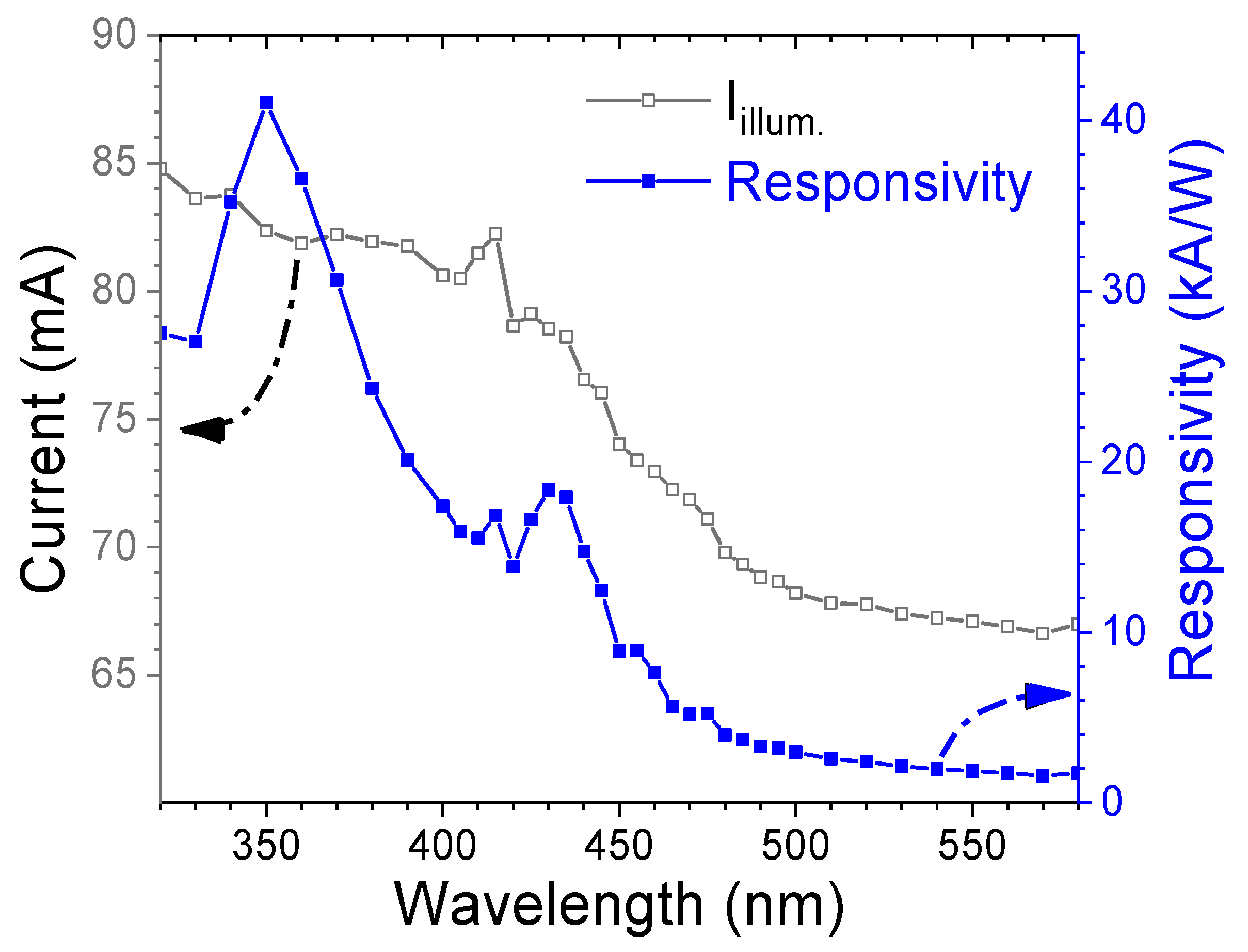

3.2. P-N Heterojunction Photodetector

| Device Structure | Deposition Method | Wavelength, Voltage | R (mA/W) | D* (Jones) | Ref. |

|---|---|---|---|---|---|

| CdS NR/Cs2AgBiBr6 | PVD | 440 nm, 3 V | 6.66 × 103 | 2.10 × 1014 | [43] |

| CdSxSe1−xNR/PbI2 NS | PVD | 600 nm, 2.5 V | 567 | 1.96 × 1015 | [44] |

| CdS NR/CdSxSe1−x NR | PVD | 510 nm, 1 V | 1.5 × 105 | 5.2 × 1011 | [45] |

| CdS-CdSTe-CdTe NBs | CVD | 405 nm, 5 V | 1.52 × 103 | 1.5 × 1010 | [46] |

| CdS/CdSxSe1−x NWs | CVD | 500 nm, 1 V | 118 | - | [47] |

| CdS NWs/Te NFs | CVD | 450 nm, 1 V | 126 | 1.03 × 1010 | [48] |

| CdS NWs/GeS CS | CVD | 405 nm, 1 V | 76.8 | - | [49] |

| CdS/ZnO NRs | CBD | 350 nm, 5 V | 12.9 | - | [50] |

| CdS/CuSCN | CBD | 350 nm, 5 V | 4.11 × 104 | 7.92 × 1013 | This study |

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Macfarlane, E.R.; Donaldson, P.J.; Grey, A.C. UV Light and the Ocular Lens: A Review of Exposure Models and Resulting Biomolecular Changes. Front. Ophthalmol. 2024, 4, 1414483. [Google Scholar] [CrossRef]

- Teng, Y.; Yu, Y.; Li, S.; Huang, Y.; Xu, D.; Tao, X. Ultraviolet Radiation and Basal Cell Carcinoma: An Environmental Perspective. Front. Public Health 2021, 9, 666528. [Google Scholar] [CrossRef] [PubMed]

- Marie, M.; Bigot, K.; Angebault, C.; Barrau, C.; Gondouin, P.; Pagan, D.; Fouquet, S.; Villette, T.; Sahel, J.; Lenaers, G.; et al. Light Action Spectrum on Oxidative Stress and Mitochondrial Damage in A2E-Loaded Retinal Pigment Epithelium Cells. Cell Death Dis. 2018, 9, 287. [Google Scholar] [CrossRef] [PubMed]

- Munsamy, A.J.; Moodley, M.; Khan, Z.; Govender, K.; Nkwanyana, M.; Cele, S.; Radebe, M. Evidence on the Effects of Digital Blue Light on the Eye: A Scoping Review. Afr. Vis. Eye Health 2022, 81, a685. [Google Scholar] [CrossRef]

- Pandey, S.; Ganguly, S.; Shukla, A.; Tripathi, A. Enhanced UV Photodetector Efficiency with a ZnO/Ga2O3 Heterojunction. ACS Appl. Electron. Mater. 2025, 7, 1173–1181. [Google Scholar] [CrossRef]

- Hosseini, A.; Abrari, M.; Sharifi Malvajerdi, S.; Mohseni, S.M.; Sun, H.; Ghanaatshoar, M. Stretchable and Flexible Metal-Semiconductor-Metal UV Photodetector Based on Silver-Doped ZnO Nanostructures Using a Drop-Casting Method. ACS Appl. Nano Mater. 2023, 6, 22036–22048. [Google Scholar] [CrossRef]

- Wang, F.H.; Tsai, C.E. ZnO Nanorod-Based Ultraviolet Photodetector Prepared on Patterned Sapphire Substrates. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 58–63. [Google Scholar] [CrossRef]

- Wang, F.-H.; Li, A.-J.; Liu, H.-W.; Kang, T. One-Dimensional ZnO Nanorod Array Grown on Ag Nanowire Mesh/ZnO Composite Seed Layer for H2 Gas Sensing and UV Detection Applications. Sensors 2024, 24, 5852. [Google Scholar] [CrossRef]

- Hwang, J.D.; Wang, F.H.; Kung, C.Y.; Chan, M.C. Using the Surface Plasmon Resonance of Au Nanoparticles to Enhance Ultraviolet Response of ZnO Nanorods-Based Schottky-Barrier Photodetectors. IEEE Trans. Nanotechnol. 2015, 14, 318–321. [Google Scholar] [CrossRef]

- Shang, G.; Tang, L.; Wu, G.; Yuan, S.; Jia, M.; Guo, X.; Zheng, X.; Wang, W.; Yue, B.; Teng, K.S. High-Performance NiO/TiO2/ZnO Photovoltaic UV Detector. Sensors 2023, 23, 2741. [Google Scholar] [CrossRef]

- Lin, S.Y.; He, Z.; To, Y.O.; Sou, I.K. MBE-Grown Fe: Pd/ZnSe Schottky-Barrier Photodetector: Distinguishing Blue + UV Light Levels among White Light Sources. Appl. Phys. Lett. 2023, 122, 061101. [Google Scholar] [CrossRef]

- Wu, Z.-C.; Liu, J.; Lu, X.-D.; Wang, J.; Huang, Z.-Y.; Zhu, Z.-G.; Wang, C.-C.; Wang, Y.; Liang, F.-X.; Luo, L.-B. Study of a Lead-Free Perovskite MA3Bi2Br9 Narrowband Photodetector for Blue-Light Detection. IEEE Trans. Electron Devices 2025, 72, 1828–1832. [Google Scholar] [CrossRef]

- Halge, D.I.; Narwade, V.N.; Kaawash, N.M.S.; Khanzode, P.M.; Shaikh, S.J.; Dadge, J.W.; Alegaonkar, P.S.; Hyam, R.S.; Bogle, K.A. High-Performance Blue Light Photodetector Based on PANI/CdS Heterojunction. Mater. Sci. Semicond. Process. 2024, 171, 108020. [Google Scholar] [CrossRef]

- Gupta, N.D.; Member, S.; Sumanth, K.; Yashwanth, P. Design and Fabrication of a Photodetector for UV/Blue Wavelength Region for Low-Light Intensity Levels Using InGaN/GaN Superlattice Structure. IEEE Trans. Electron Devices 2024, 71, 5494–5501. [Google Scholar] [CrossRef]

- Chen, L.; Xie, S.; Lan, J.; Chai, J.; Lin, T.; Hao, Q.; Chen, J.; Deng, X.; Hu, X.; Li, Y.; et al. High-Speed and High-Responsivity Blue Light Photodetector with an InGaN NR/PEDOT:PSS Heterojunction Decorated with Ag NWs. ACS Appl. Mater. Interfaces 2024, 16, 29477–29487. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Liu, Y.; Wu, Z.; Sun, S.; Zhang, H. Self-Driven and Blue-Enhanced Photodetectors Based on Organic/Inorganic Heterojunction of Pentacene and Bi2 Se3. ACS Appl. Nano Mater. 2024, 7, 170–183. [Google Scholar] [CrossRef]

- Vhanalkar, S.A.V.; Patil, V.L.; Patil, S.M.; Deshmukh, S.P.; Patil, P.S.; Kim, J.H. Chemical and Gas Sensing Property Tuning of Cadmium Sulfide Thin Films. Mater. Sci. Eng. B 2022, 282, 115787. [Google Scholar] [CrossRef]

- Chaudhary, N.; Chaudhary, R.; Kesari, J.P.; Patra, A. An Eco-Friendly and Inexpensive Solvent for Solution Processable CuSCN as a Hole Transporting Layer in Organic Solar Cells. Opt. Mater. 2017, 69, 367–371. [Google Scholar] [CrossRef]

- Chaudhary, N.; Naqvi, S.; Rathore, D.; Rathi, S.; Patra, A. Solvent Influenced Morphology Control of Hole Transport Layer of CuSCN on Performance of Organic Solar Cells. Mater. Chem. Phys. 2022, 282, 125898. [Google Scholar] [CrossRef]

- Yılmaz, S.; Toreli, S.B.; Tomakin, M.; Polat, I.; Bacaksız, E. CBD-Synthesized Mg-Doped CdS Thin Films for Hybrid Solar Cells and Self-Powered Photodetectors. Phys. B Condens. Matter 2025, 696, 416622. [Google Scholar] [CrossRef]

- Husham, M.; Hassan, Z.; Selman, A.M.; Allam, N.K. Physical Microwave-Assisted Chemical Bath Deposition of Nanocrystalline CdS Thin Films with Superior Photodetection Characteristics. Sens. Actuators A 2015, 230, 9–16. [Google Scholar] [CrossRef]

- Jayaramaiah, J.R.; Jayanth, V.; Shamanth, R. Structural Elucidation and Optical Analysis on Europium Doped Cadmium Sulphide Nano Thin Films. Opt. Int. J. Light Electron Opt. 2020, 208, 164079. [Google Scholar] [CrossRef]

- Zhang, D.; Xie, Q.; Cai, H.; Zhang, X.; Li, S. Synthesis and Separation Property of Flower-like Cd (OH)2 Microstructures via a Simple Solution Route. Appl. Surf. Sci. 2010, 256, 6224–6227. [Google Scholar] [CrossRef]

- Mirzaei, A.; Jamshidi, E.; Morshedloo, E.; Javanshir, S. Carrageenan Assisted Synthesis of Morphological Diversity of CdO and Cd(OH)2 with High Antibacterial Activity. Mater. Res. Express 2021, 8, 065006. [Google Scholar] [CrossRef]

- Shkir, M.; Alshahrani, T. Engineering the Physical Properties of CdS Thin Films through Incorporation of Fe Dopant for Photodetector Applications. J. Phys. Chem. Solids 2023, 177, 111282. [Google Scholar] [CrossRef]

- Ruiz-ortega, R.C.; Esquivel-mendez, L.A.; Gonzalez-trujillo, M.A.; Hernandez-vasquez, C.; Matsumoto, Y.; Albor-aguilera, M.D.L. Comprehensive Analysis of CdS Ultrathin Films Modified by the Substrate Position inside the Reactor Container Using the CBD Technique. ACS Omega 2023, 8, 31725–31737. [Google Scholar] [CrossRef]

- Sivagamai, D.; Priyadarshini, B.G. Composition Dependent Structural, Morphological, Optical and Electrical Properties of CdS:Co Window Layer Grown by Chemical Bath Deposition. Mater. Sci. Energy Technol. 2020, 3, 709–718. [Google Scholar] [CrossRef]

- Wang, F.; Chen, M.; Liu, H.; Kang, T. Influence of Rapid Thermal Annealing Time on Physical Properties of Mg and F Co-Doped ZnO Thin Films Deposited by Radio Frequency Magnetron Sputtering. Thin Solid Film. 2022, 757, 139393. [Google Scholar] [CrossRef]

- Chen, R.; Qian, L.; Xu, S.; Wan, S.; Ma, M.; Zhang, L.; Jiang, R. In Situ Fabrication of CdS/Cd(OH)2 for Effective Visible Light-Driven Photocatalysis. Nanomaterials 2023, 13, 2453. [Google Scholar] [CrossRef]

- Zhang, Z.; Kong, F.; Yuan, B.; Liao, Y.; Rena, X.; Hou, Y. CdO Decorated CdS Nanorod for Enhanced Photocatalytic Reduction of CO2 to CO. RSC Adv. 2023, 13, 17362. [Google Scholar] [CrossRef]

- Kublitski, J.; Hofacker, A.; Boroujeni, B.K.; Benduhn, J.; Nikolis, V.C.; Kaiser, C.; Spoltore, D.; Kleemann, H.; Fischer, A.; Ellinger, F.; et al. Reverse Dark Current in Organic Photodetectors and the Major Role of Traps as Source of Noise. Nat. Commun. 2021, 12, 551. [Google Scholar] [CrossRef] [PubMed]

- Belaid, W.; Gezgin, S.Y.; Kabatas, M.A.B.-M.; Eker, Y.R.; Kiliç, H.Ş. Utilizing Gold Nanoparticle Decoration for Enhanced UV Photodetection in CdS Thin Films Fabricated by Pulsed Laser Deposition: Exploiting Plasmon-Induced Effects. Nanomaterials 2024, 14, 416. [Google Scholar] [CrossRef] [PubMed]

- Kumar, K.D.A.; Mele, P.; Golovynskyi, S.; Khan, A.; El-Toni, A.M.; Ansari, A.A.; Gupta, R.K.; Ghaithan, H.; AlFaify, S.; Murahari, P. Insight into Al Doping Effect on Photodetector Performance of CdS and CdS:Mg Films Prepared by Self-Controlled Nebulizer Spray Technique. J. Alloys Compd. 2021, 892, 160801. [Google Scholar] [CrossRef]

- Awad, M.A.; Shaban, M.; Rabia, M. The Efficiency of M (M = Li, Na, or Cs) Doped CdS Nanomaterials in Optoelectronic Applications. Int. J. Energy Res. 2022, 46, 8443–8451. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.; Zhou, B.; Cao, H.; Yang, X.; Li, B.; Zhang, J.; Feng, L.; Zeng, G.; Zhong, Z.; et al. Research on FTO/CBD-CdS:Cl Thin Film Photodetector with a Vertical Structure. Appl. Phys. A Mater. Sci. Process. 2021, 127, 560. [Google Scholar] [CrossRef]

- Waldiya, M.; Narasimman, R.; Bhagat, D.; Vankhade, D.; Mukhopadhyay, I. Nanoparticulate CdS 2D Array by Chemical Bath Deposition: Characterization and Optoelectronic Study. Mater. Chem. Phys. 2019, 226, 26–33. [Google Scholar] [CrossRef]

- Er, U.; Icli, C.K.; Ozenbas, M. Spin-Coated Copper(I) Thiocyanate as a Hole Transport Layer for Perovskite Solar Cells. J. Solid State Electrochem. 2020, 24, 293–304. [Google Scholar] [CrossRef]

- Coskun, E.; Gullu, H.H.; Colakoglu, T.; Emir, C.; Bozdogan, E.; Parlak, M. Effects of Si Nanowire on the Device Properties of N-ZnSe/p-Si Heterostructure. J. Mater. Sci. Mater. Electron. 2019, 30, 4760–4765. [Google Scholar] [CrossRef]

- Shaban, H.; Mahdy, M.A.; El Zawawi, I. ZnSe and Cd0.6Zn0.4Te for Isotype Heterojunction (IHJ) for Photovoltaic Applications. Phys. B Condens. Matter 2025, 707, 417197. [Google Scholar] [CrossRef]

- Javaid, K.; Anjum, R.; Ali, A.; Mahmood, K.; Shehzad, U.; Anwar, H.; Saleem, M.; Rasheed, Z.; Waheed, H.; Afzal, Z.; et al. Band Offset Engineering to Improve Electrical Transport Properties of P-NiO/n-ZnO Heterojunction Diode. J. Alloys Compd. 2025, 1018, 179281. [Google Scholar] [CrossRef]

- Abdulwahab, A.M.; Al-mahdi, E.A.; Al-osta, A.; Qaid, A.A. Structural, Optical and Electrical Properties of CuSCN Nano-Powders Doped with Li for Optoelectronic Applications. Chin. J. Phys. 2021, 73, 479–492. [Google Scholar] [CrossRef]

- Han, S.; Zhao, Q.; Hou, Q.; Ding, Y.; Quan, J.; Zhang, Y.; Wu, F.; Lu, Y.; Zhang, H.; Li, H.; et al. Flexible; Active P-typed Copper(I) Thiocyanate (p-CuSCN) Films as Self-powered Photodetectors for Large-scale Optoelectronic Systems. Mater. Today Electron. 2023, 5, 100048. [Google Scholar] [CrossRef]

- Liu, A.; Ding, J.; Tan, Q.; Yang, P.; Liu, Y. Ultrahigh-Performance Photodetectors Based on Low-Dimensional Cs2AgBiBr6/CdS Heterojunction. J. Colloid Interface Sci. 2025, 679, 316–323. [Google Scholar] [CrossRef]

- Nawaz, M.Z.; Gulzar, H.; Masood, I.; Saleem, M.S.; Khaleeq, A.; Hasan, W.; Imran, M.; Li, M.; Noor, H.M.; Khan, H.; et al. Broadband Flexible Photodetectors Based on CdSxSe1-x/PbI2 Heterojunctions. ACS Appl. Electron. Mater. 2024, 6, 4381–4390. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, Y.; Fan, P.; Feng, Y.; Lan, J.; Xu, G.; Zhu, X. Polar-Induced Selective Epitaxial Growth of Multijunction Nanoribbons for High-Performance Optoelectronics. ACS Appl. Mater. Interfaces 2019, 11, 15813–15820. [Google Scholar] [CrossRef]

- Tang, M.; Xu, P.; Wen, Z.; Chen, X.; Pang, C.; Xu, X.; Meng, C.; Liu, X.; Tian, H.; Raghavan, N.; et al. Fast Response CdS-CdSxTe1-x-CdTe Core-Shell Nanobelt Photodetector. Sci. Bull. 2018, 63, 1118–1124. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Yan, H.; Luo, Y.; Pan, A.; Zhang, H.; Ho, J.C.; Yu, K.M. On-Nanowire Axial Heterojunction Design for High-Performance Photodetectors. ACS Nano 2016, 10, 8474–8481. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, L.; Wang, X. High-Performance 1D CdS/2D Te Heterojunction Photodetector. J. Phys. Conf. Ser. 2024, 2809, 012034. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, M. Enhancing and Broadening the Photoresponse of CdS Nanowire by Constructing Core–Shell Heterostructure. Appl. Phys. Lett. 2024, 125, 023103. [Google Scholar] [CrossRef]

- Lam, K.; Hsiao, Y.; Ji, L.; Fang, T.; Hsiao, K.; Chu, T. High-Sensitive Ultraviolet Photodetectors Based on ZnO Nanorods/CdS Heterostructures. Nanoscale Res. Lett. 2017, 12, 31. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, J.-R.; Wang, F.-H.; Liu, H.-W.; Kang, T.-K. High-Responsivity UV–Blue Photodetector Based on Nanostructured CdS and Prepared by Solution Processing. Nanomaterials 2025, 15, 1212. https://doi.org/10.3390/nano15161212

Lai J-R, Wang F-H, Liu H-W, Kang T-K. High-Responsivity UV–Blue Photodetector Based on Nanostructured CdS and Prepared by Solution Processing. Nanomaterials. 2025; 15(16):1212. https://doi.org/10.3390/nano15161212

Chicago/Turabian StyleLai, Jian-Ru, Fang-Hsing Wang, Han-Wen Liu, and Tsung-Kuei Kang. 2025. "High-Responsivity UV–Blue Photodetector Based on Nanostructured CdS and Prepared by Solution Processing" Nanomaterials 15, no. 16: 1212. https://doi.org/10.3390/nano15161212

APA StyleLai, J.-R., Wang, F.-H., Liu, H.-W., & Kang, T.-K. (2025). High-Responsivity UV–Blue Photodetector Based on Nanostructured CdS and Prepared by Solution Processing. Nanomaterials, 15(16), 1212. https://doi.org/10.3390/nano15161212