Synergistic Effect of MWCNT and CB on the Piezoresistive Properties of Laser Ablation Composites Strain Sensors

Abstract

1. Introduction

2. Experiment

2.1. Materials

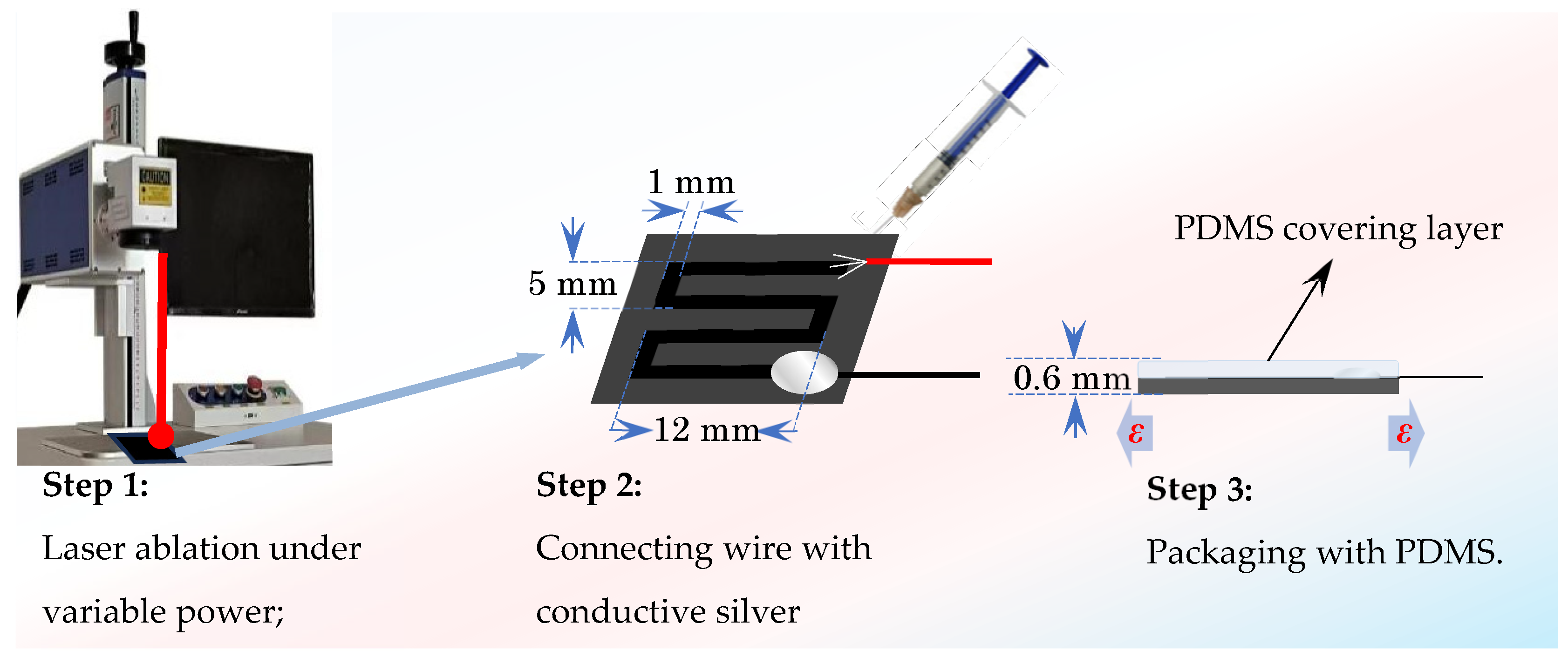

2.2. Fabrication of the Composite Strain Sensor with Laser Ablation

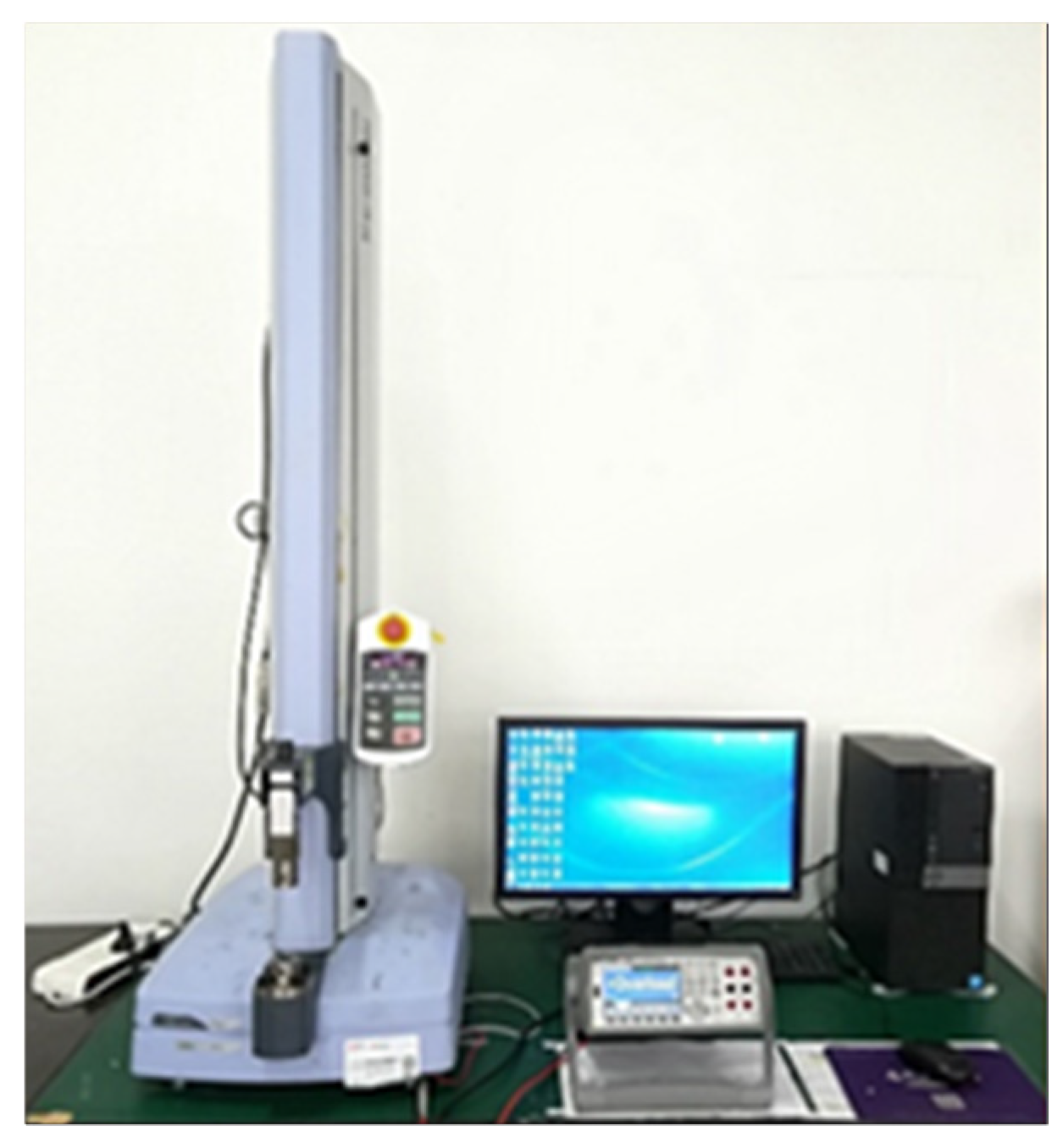

2.3. Experimental Tests

3. Results and Discussion

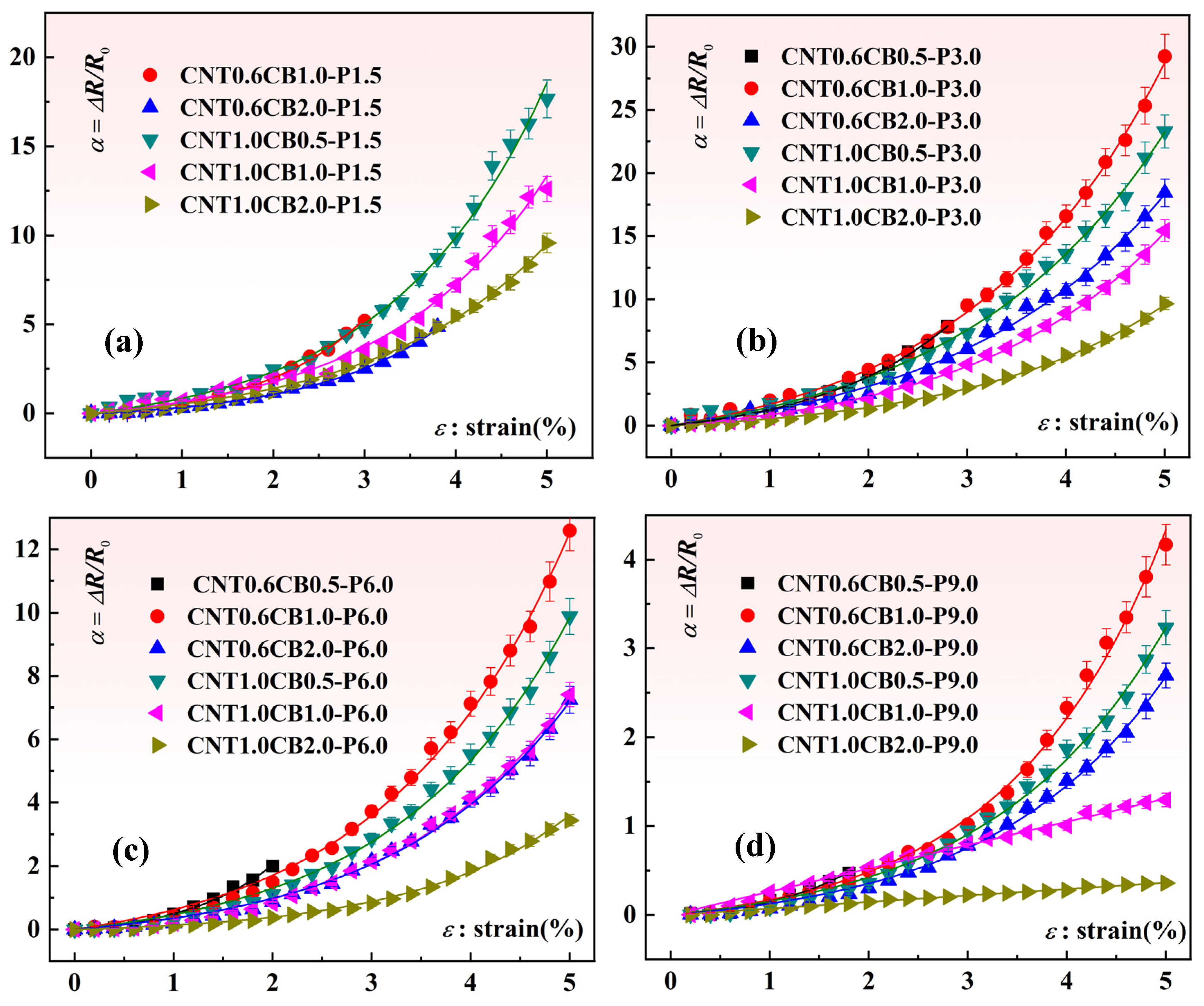

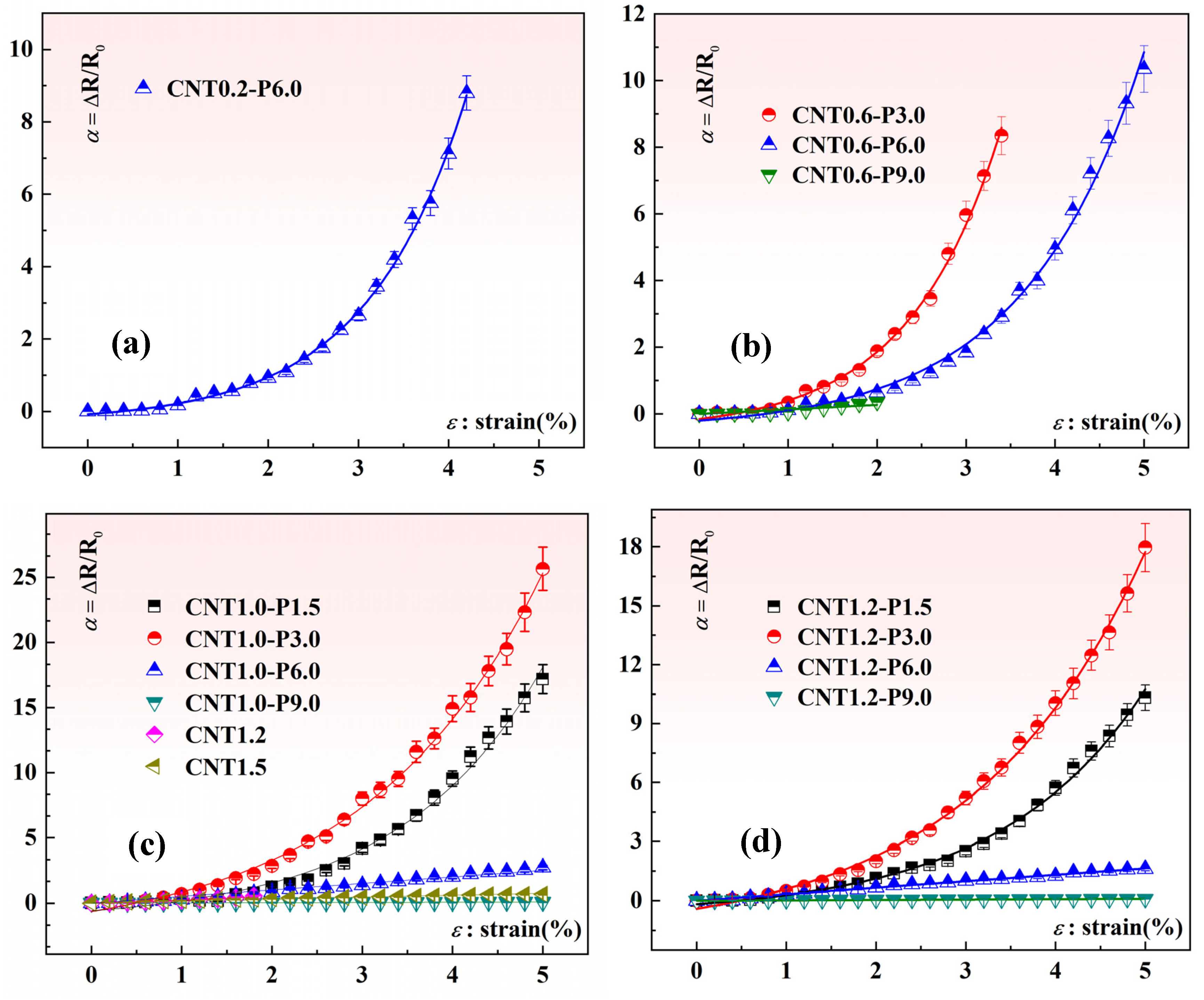

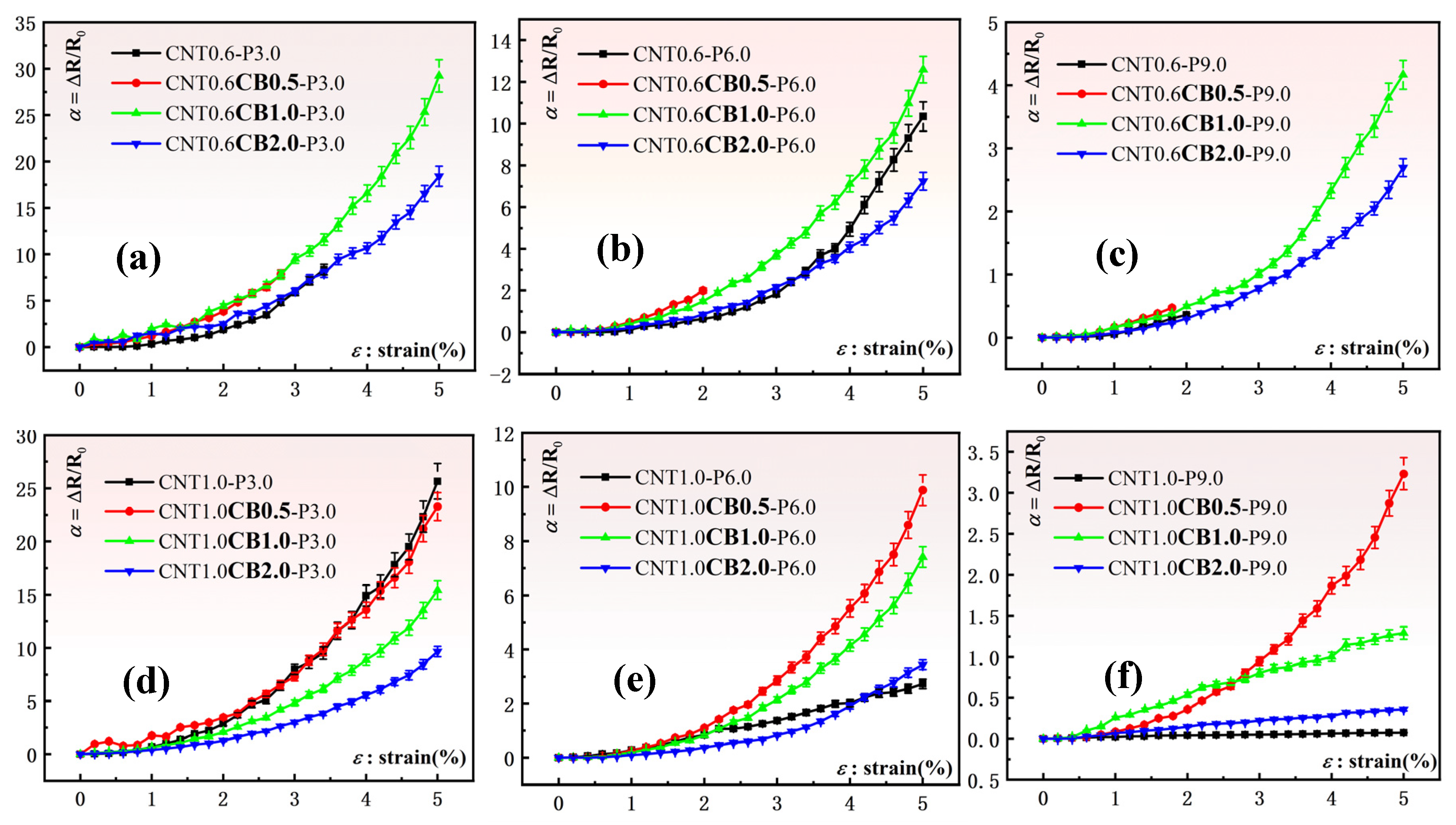

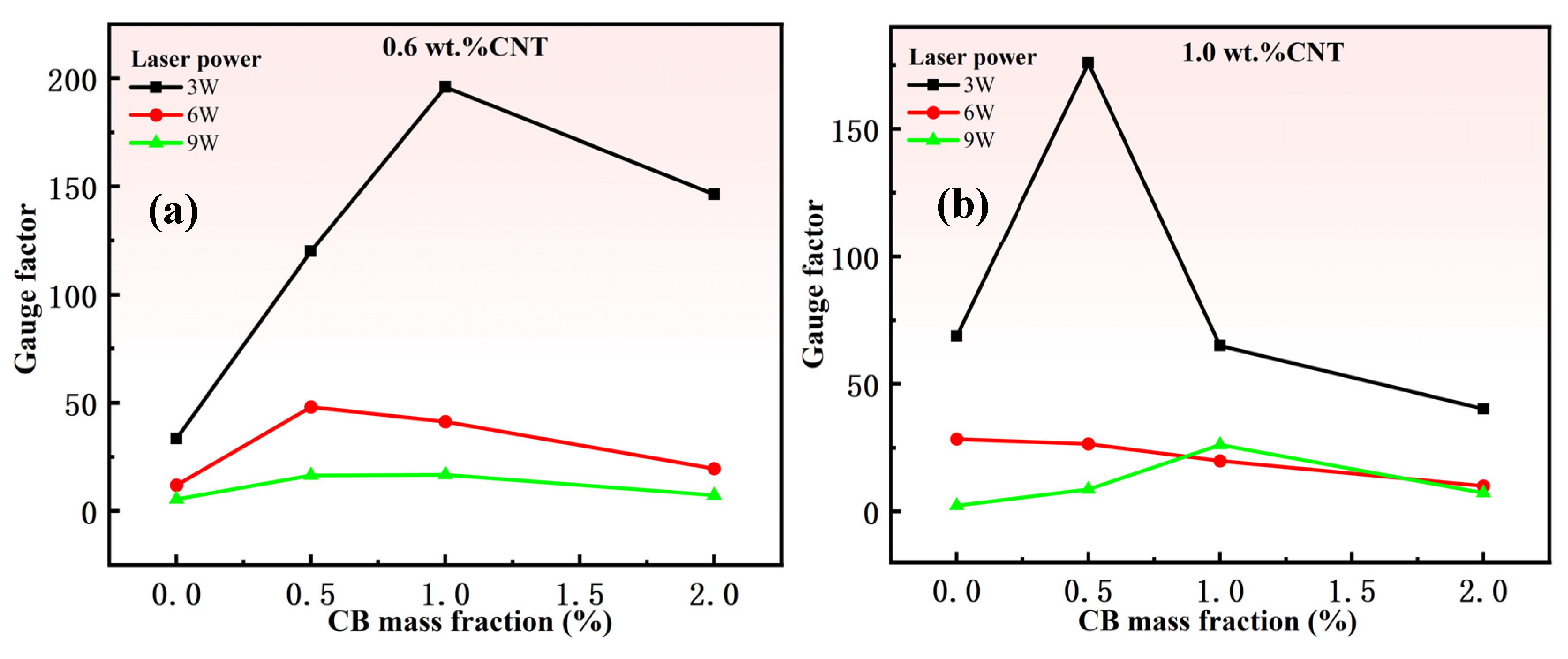

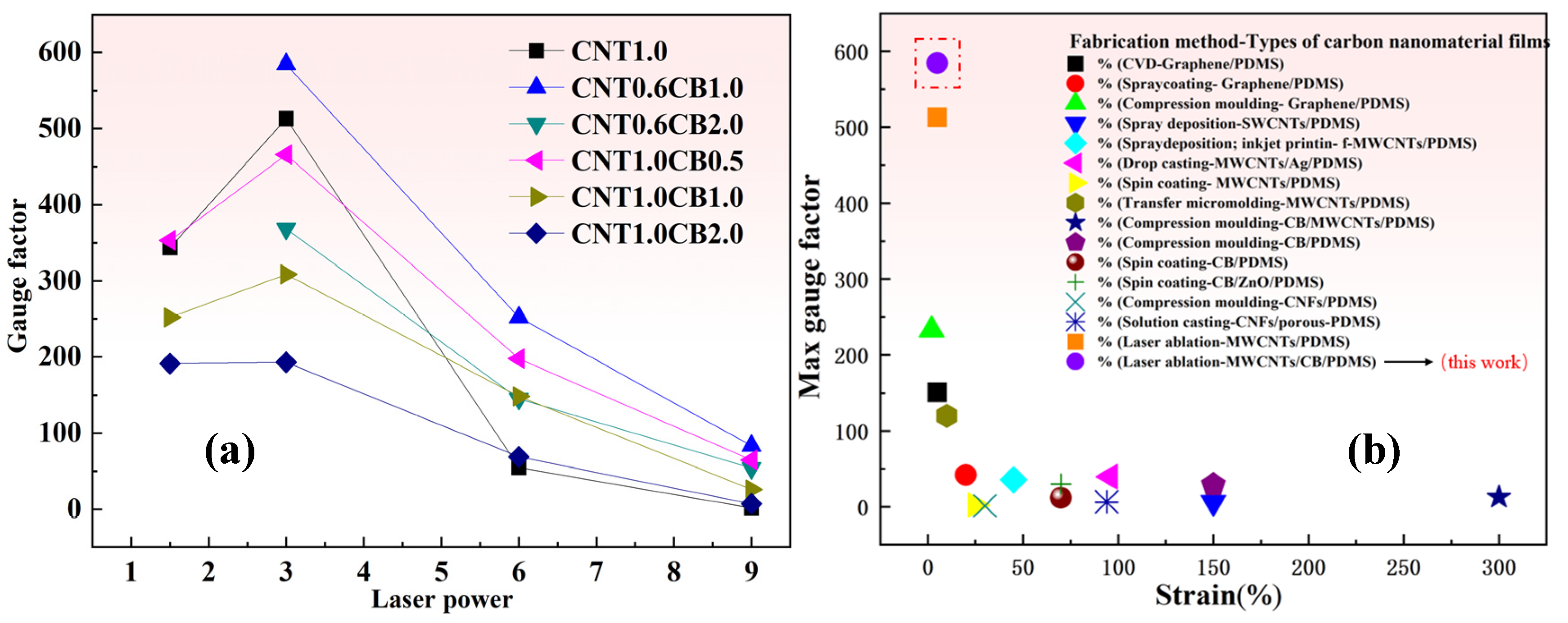

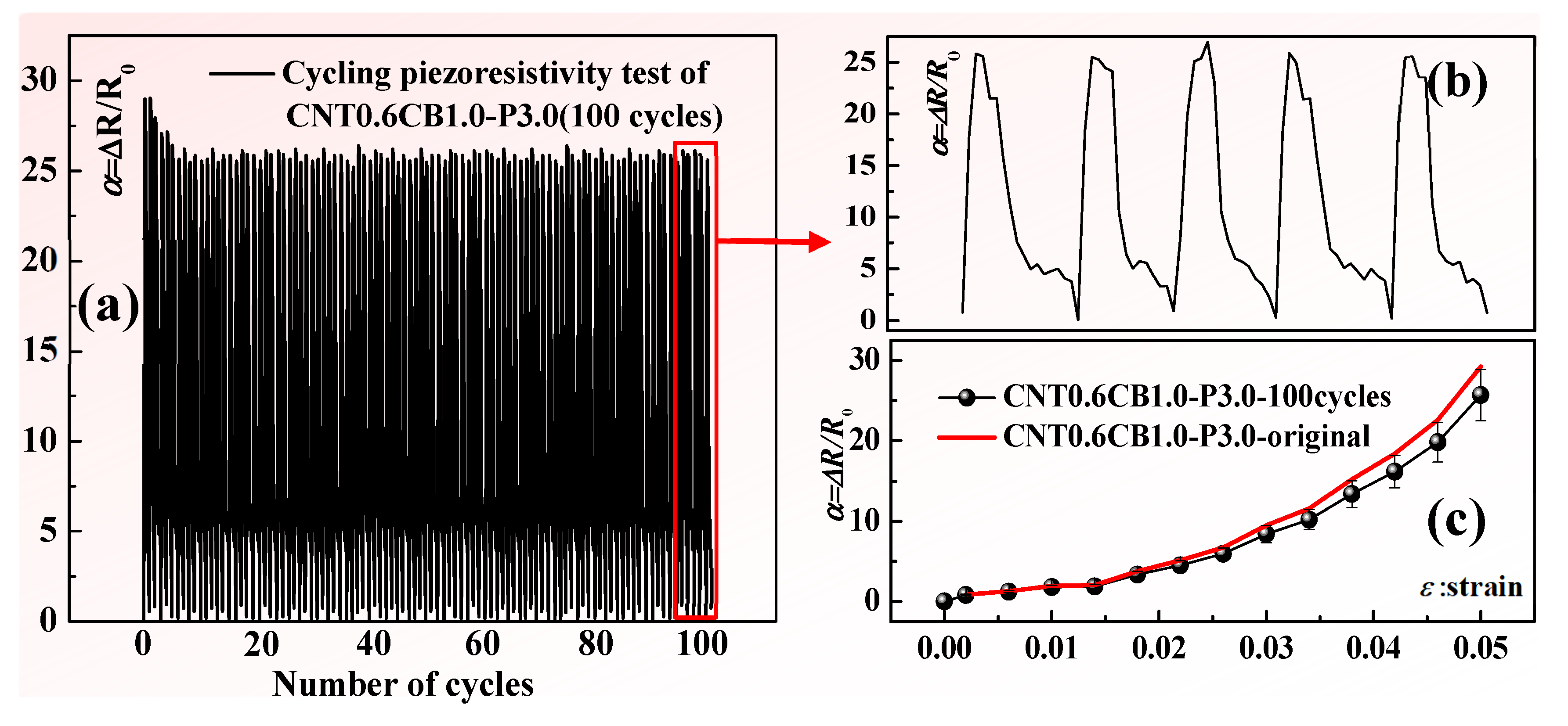

3.1. Sensing Performance of MWCNT/CB/PDMS Composite Laser-Ablated Strain Sensors

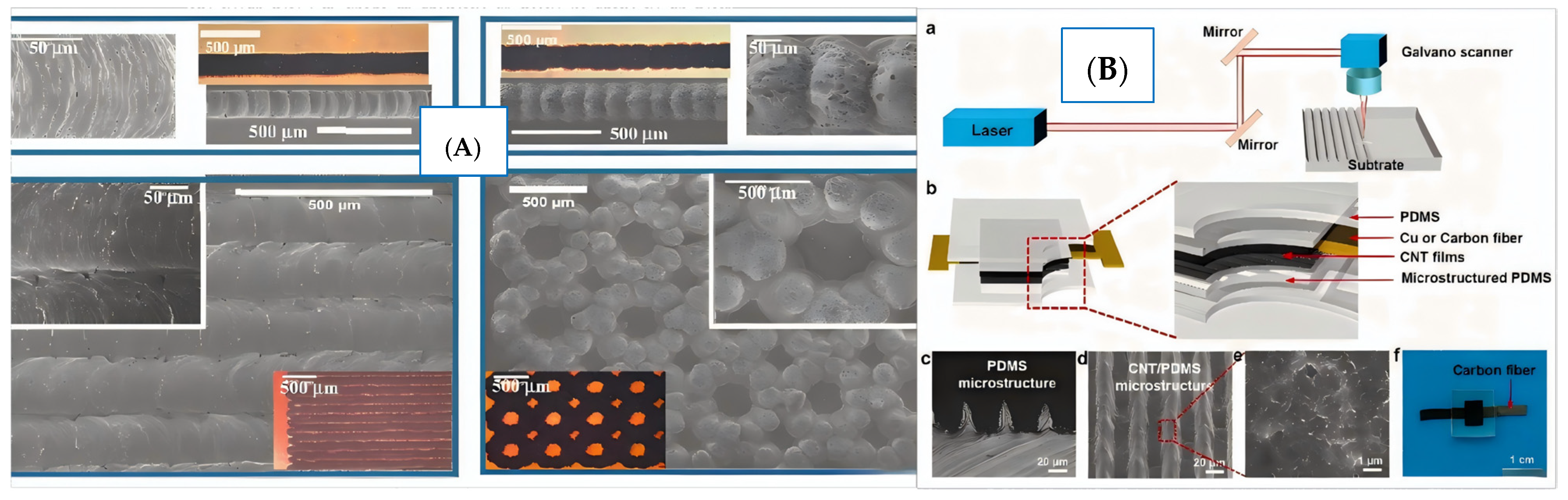

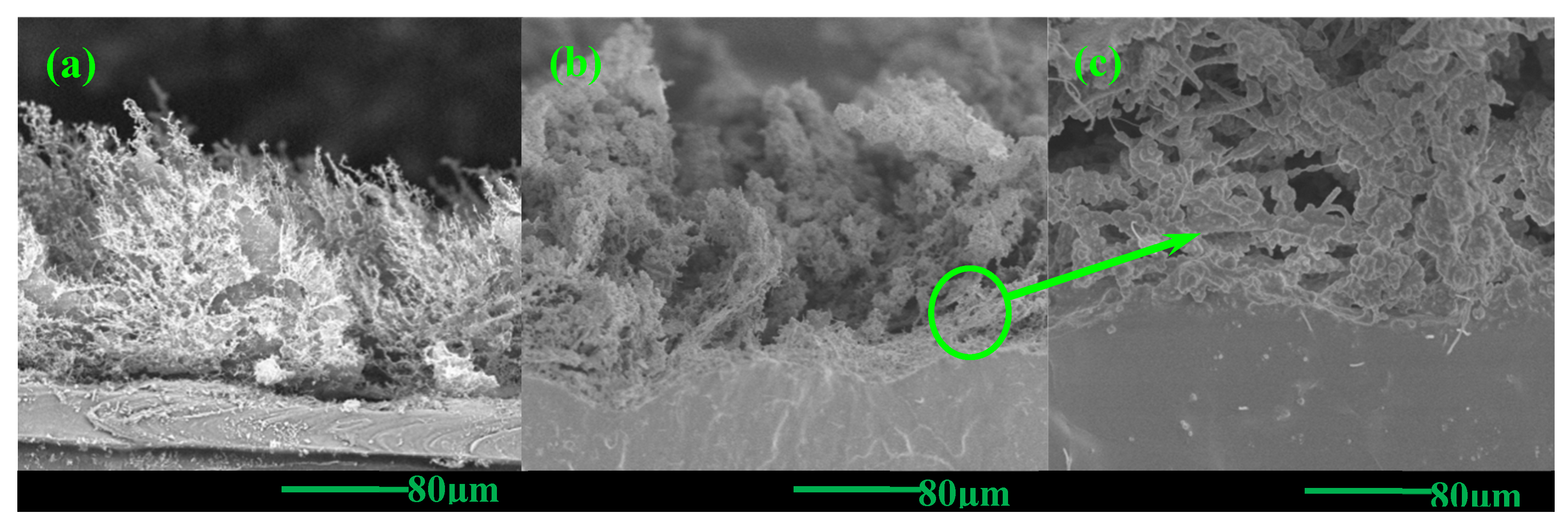

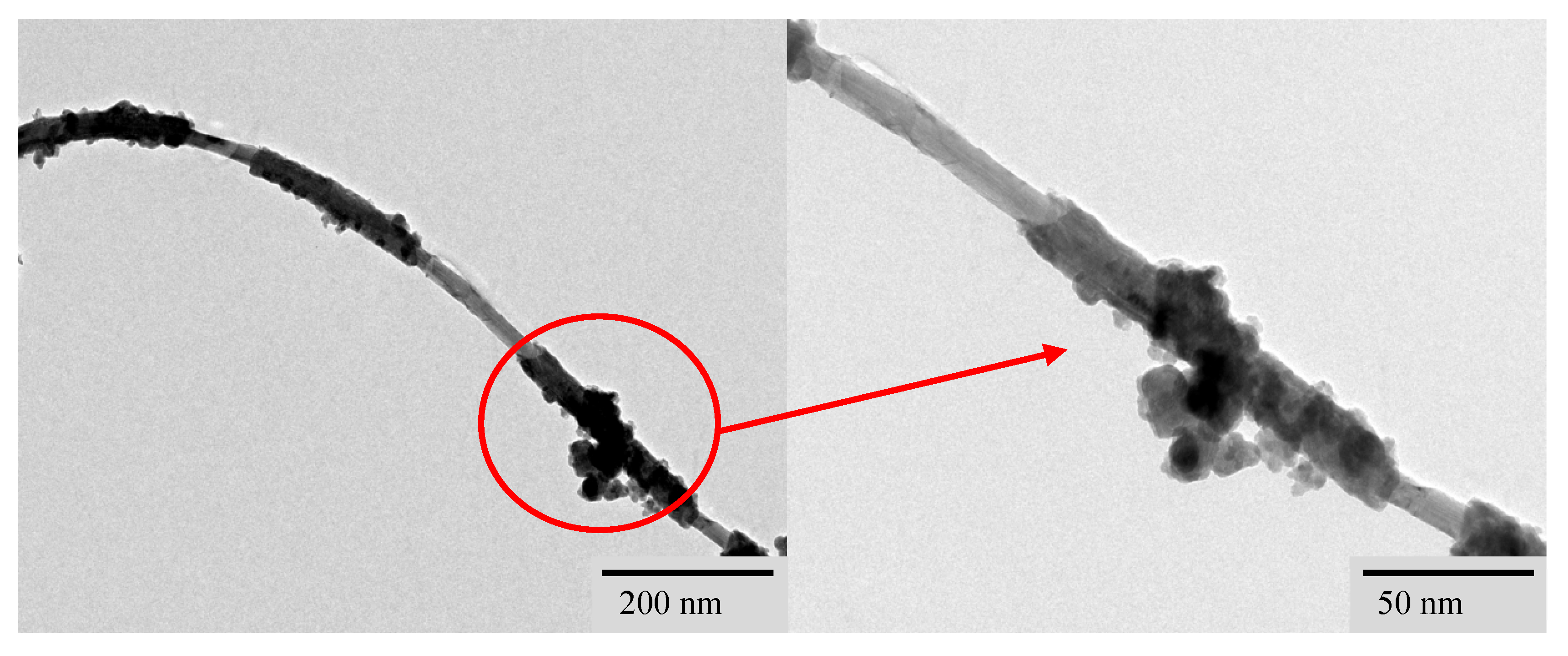

3.2. Microstructure Characterization and Mechanism Analysis

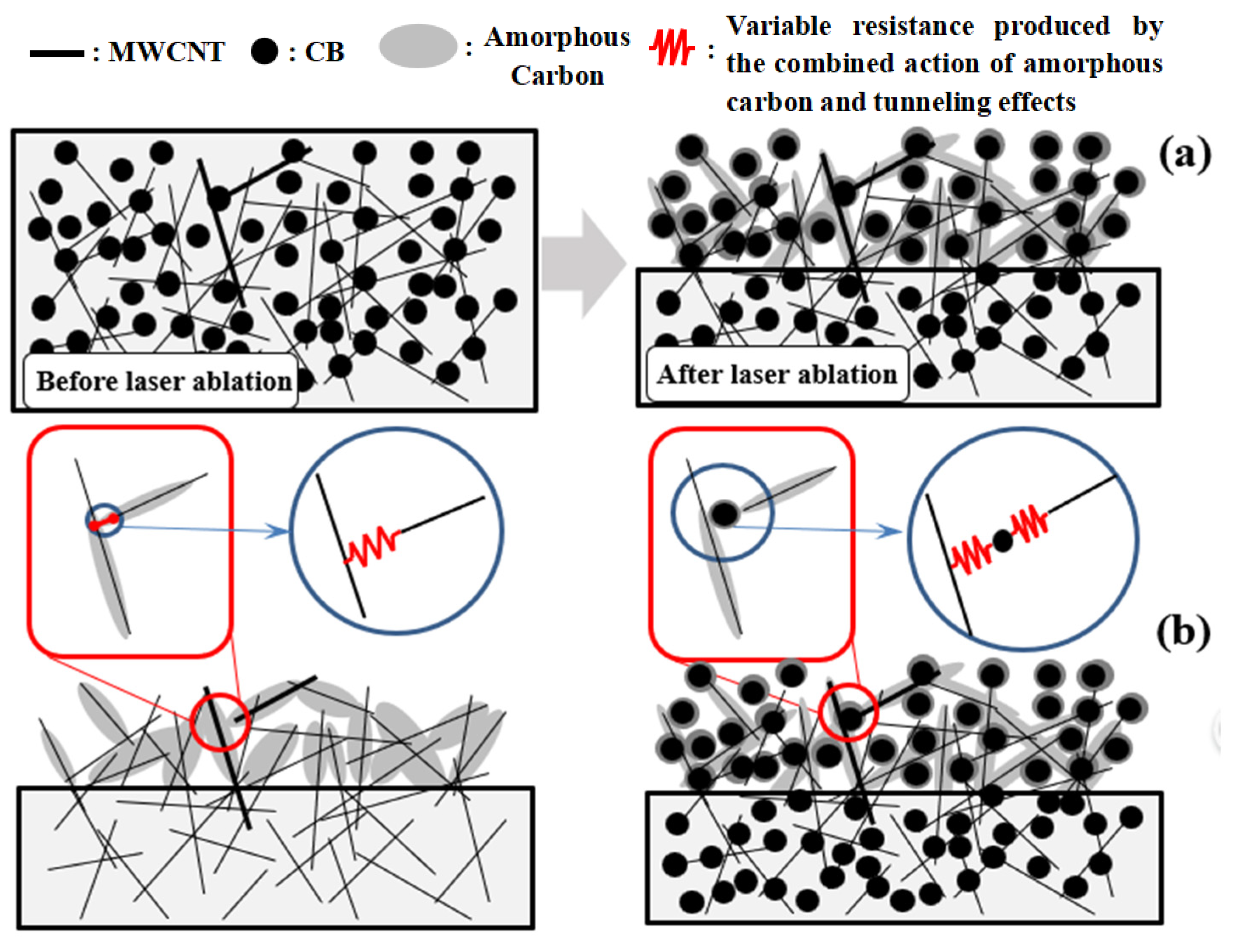

3.3. Analysis of the Synergistic Effect of Piezoresistive Resistance in Laser-Ablated Composite Material Sensors

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yee, M.J.; Mubarak, N.; Abdullah, E.; Khalid, M.; Walvekar, R.; Karri, R.R.; Nizamuddin, S.; Numan, A. Carbon nanomaterials based films for strain sensing application—A review. Nano-Struct. Nano-Objects 2019, 18, 100312. [Google Scholar] [CrossRef]

- Costa, P.; Nunes-Pereira, J.; Oliveira, J.; Silva, J.; Moreira, J.A.; Carabineiro, S.; Buijnsters, J.; Lanceros-Mendez, S. High-performance graphene-based carbon nanofiller/polymer composites for piezoresistive sensor applications. Compos. Sci. Technol. 2017, 153, 241–252. [Google Scholar] [CrossRef]

- Zhao, C.; Yuan, W.; Liu, H.; Gu, B.; Hu, N.; Alamusi; Ning, Y.; Jia, F. Equivalent circuit model for the strain sensing characteristics of multi-walled carbon nanotube/polyvinylidene fluoride films in alternating current circuit. Carbon 2018, 129, 585–591. [Google Scholar] [CrossRef]

- Huang, K.; Xu, Q.; Ying, Q.; Gu, B.; Yuan, W. Wireless strain sensing using carbon nanotube composite film. Compos. Part B Eng. 2023, 256, 110650. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Yan, C.; Masuda, Z.; Fukunaga, H. Tunneling effect in a polymer/carbon nanotube nanocomposite strain sensor. Acta Mater. 2008, 56, 2929–2936. [Google Scholar] [CrossRef]

- Ke, K.; Pötschke, P.; Wiegand, N.; Krause, B.; Voit, B. Tuning the network structure in poly(vinylidene fluoride)/carbon nanotube nanocomposites using carbon black: Toward improvements of conductivity and piezoresistive sensitivity. ACS Appl. Mater. Interfaces 2016, 8, 14190–14199. [Google Scholar] [CrossRef]

- Cai, W.; Huang, Y.; Wang, D.; Liu, C.; Zhang, Y. Piezoresistive behavior of graphene nanoplatelets/carbon black/silicone rubber nanocomposite. J. Appl. Polym. Sci. 2014, 131, 39778. [Google Scholar] [CrossRef]

- Wu, D.; Lv, Q.; Feng, S.; Chen, J.; Chen, Y.; Qiu, Y.; Yao, X. Polylactide composite foams containing carbon nanotubes and carbon black: Synergistic effect of filler on electrical conductivity. Carbon 2015, 95, 380–387. [Google Scholar] [CrossRef]

- Dorigato, A.; Brugnara, M.; Pegoretti, A. Synergistic effects of carbon black and carbon nanotubes on the electrical resistivity of poly(butylene-terephthalate) nanocomposites. Adv. Polym. Technol. 2017, 37, 1744–1754. [Google Scholar] [CrossRef]

- Li, L.; Zhang, M.; Ruan, W. Studies on synergistic effect of CNT and CB nanoparticles on PVDF. Polym. Compos. 2014, 36, 2248–2254. [Google Scholar] [CrossRef]

- Tang, P.; Zhang, R.; Shi, R.; Bin, Y. Synergetic effects of carbon nanotubes and carbon fibers on electrical and self-heating properties of high-density polyethylene composites. J. Mater. Sci. 2014, 50, 1565–1574. [Google Scholar] [CrossRef]

- Socher, R.; Krause, B.; Hermasch, S.; Wursche, R.; Pötschke, P. Electrical and thermal properties of polyamide 12 composites with hybrid fillers systems of multiwalled carbon nanotubes and carbon black. Compos. Sci. Technol. 2011, 71, 1053–1059. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Pan, F.; Zhang, J.; Karimzadeh, F. A Numerical study on electrical percolation of polymer-matrix composites with hybrid fillers of carbon nanotubes and carbon black. J. Nanomater. 2014, 2014, 614797. [Google Scholar] [CrossRef]

- Ismail, H.; Ramly, A.F.; Othman, N. The effect of carbon black/multiwall carbon nanotube hybrid fillers on the properties of natural rubber nanocomposites. Polym. Plast. Technol. Eng. 2011, 50, 660–666. [Google Scholar] [CrossRef]

- Yan, N.; Wu, J.K.; Zhan, Y.H.; Xia, H.S. Carbon nanotubes/carbon black synergistic reinforced natural rubber composites. Plast. Rubber Compos. 2013, 38, 290–296. [Google Scholar] [CrossRef]

- Nakaramontri, Y.; Pichaiyut, S.; Wisunthorn, S.; Nakason, C. Hybrid carbon nanotubes and conductive carbon black in natural rubber composites to enhance electrical conductivity by reducing gaps separating carbon nanotube encapsulates. Eur. Polym. J. 2017, 90, 467–484. [Google Scholar] [CrossRef]

- Wu, J.-K.; Ye, C.-C.; Liu, T.; An, Q.-F.; Song, Y.-H.; Lee, K.-R.; Hung, W.-S.; Gao, C.-J. Synergistic effects of CNT and GO on enhancing mechanical properties and separation performance of polyelectrolyte complex membranes. Mater. Des. 2017, 119, 38–46. [Google Scholar] [CrossRef]

- Huang, K.; Ning, H.; Hu, N.; Wu, X.; Wang, S.; Weng, S.; Yuan, W.; Alamusi; Wu, L.; Liu, Y. Synergistic effect of CB and MWCNT on the strain-induced DC and AC electrical properties of PVDF-HFP composites. Carbon 2019, 144, 509–518. [Google Scholar] [CrossRef]

- Hu, N.; Itoi, T.; Akagi, T.; Kojima, T.; Xue, J.; Yan, C.; Atobe, S.; Fukunaga, H.; Yuan, W.; Ning, H.; et al. Ultrasensitive strain sensors made from metal-coated carbon nanofiller/epoxy composites. Carbon 2013, 51, 202–212. [Google Scholar] [CrossRef]

- Oliva-Avilés, A.; Avilés, F.; Sosa, V. Electrical and piezoresistive properties of multi-walled carbon nanotube/polymer composite films aligned by an electric field. Carbon 2011, 49, 2989–2997. [Google Scholar] [CrossRef]

- Choi, G.; Lee, J.W.; Cha, J.Y.; Kim, Y.-J.; Choi, Y.-S.; Schulz, M.J.; Moon, C.K.; Lim, K.T.; Kim, S.Y.; Kang, I. A spray-on carbon nanotube artificial neuron strain sensor for composite structural health monitoring. Sensors 2016, 16, 1171. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, A.; Lanceros-Mendez, S. Piezoresistive response of spray-printed carbon nanotube/poly(vinylidene fluoride) composites. Compos. Part B Eng. 2016, 96, 242–247. [Google Scholar] [CrossRef]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes–Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef]

- Shin, S.; So, H. Effect of 3D printing raster angle on reversible thermo-responsive composites using PLA/paper bilayer. Smart Mater. Struct. 2020, 29, 105016. [Google Scholar] [CrossRef]

- Shin, S.; So, H. Time-dependent motion of 3D-printed soft thermal actuators for switch application in electric circuits. Addit. Manuf. 2021, 39, 101893. [Google Scholar] [CrossRef]

- Li, J.; Zhao, S.; Zeng, X.; Huang, W.; Gong, Z.; Zhang, G.; Sun, R.; Wong, C.-P. Highly stretchable and sensitive strain sensor based on facilely prepared three-dimensional graphene foam composite. ACS Appl. Mater. Interfaces 2016, 8, 18954–18961. [Google Scholar] [CrossRef]

- Lv, L.; Zhang, P.; Xu, T.; Qu, L. Ultrasensitive pressure sensor based on an ultralight sparkling graphene block. ACS Appl. Mater. Interfaces 2017, 9, 22885–22892. [Google Scholar] [CrossRef]

- El-Kady, M.F.; Kaner, R.B. Direct laser writing of graphene electronics. ACS Nano 2014, 8, 8725–8729. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Cui, Y.-L.; Mi, W.-T.; Yang, Y.; Xie, D.; Ren, T.-L. Scalable fabrication of high-performance and flexible graphene strain sensors. Nanoscale 2014, 6, 699–705. [Google Scholar] [CrossRef]

- Tian, H.; Yang, Y.; Xie, D.; Cui, Y.-L.; Mi, W.-T.; Zhang, Y.; Ren, T.-L. Wafer-scale integration of graphene-based electronic, optoelectronic and electroacoustic devices. Sci. Rep. 2014, 4, 3598. [Google Scholar] [CrossRef]

- Guo, L.; Jiang, H.-B.; Shao, R.-Q.; Zhang, Y.-L.; Xie, S.-Y.; Wang, J.-N.; Li, X.-B.; Jiang, F.; Chen, Q.-D.; Zhang, T.; et al. Two-beam-laser interference mediated reduction, patterning and nanostructuring of graphene oxide for the production of a flexible humidity sensing device. Carbon 2012, 50, 1667–1673. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, J.; Cai, H.; Wu, Y.; Ding, H.; Pan, N.; Wang, X. Highly sensitive and skin-like pressure sensor based on asymmetric double-layered structures of reduced graphite oxide. Sens. Actuators B Chem. 2018, 255, 1262–1267. [Google Scholar] [CrossRef]

- Luo, S.; Hoang, P.T.; Liu, T. Direct laser writing for creating porous graphitic structures and their use for flexible and highly sensitive sensor and sensor arrays. Carbon 2016, 96, 522–531. [Google Scholar] [CrossRef]

- Gong, T.; Zhang, H.; Huang, W.; Mao, L.; Ke, Y.; Gao, M.; Yu, B. Highly responsive flexible strain sensor using polystyrene nanoparticle doped reduced graphene oxide for human health monitoring. Carbon 2018, 140, 286–295. [Google Scholar] [CrossRef]

- Duan, X.; Luo, J.; Yao, Y.; Liu, T. A Route toward ultrasensitive layered carbon based piezoresistive sensors through hierarchical contact design. ACS Appl. Mater. Interfaces 2017, 9, 43133–43142. [Google Scholar] [CrossRef]

- Milenov, T.; Dimov, D.; Nikolov, A.; Stankova, N.; Avramova, I.; Karashanova, D.; Georgieva, B.; Avdeev, G.; Karaivanova, D.; Valcheva, E. Synthesis of graphene–like phases by laser ablation of micro-crystalline graphite in water suspension. Surfaces Interfaces 2021, 27, 101494. [Google Scholar] [CrossRef]

- Lu, C.; Gao, Y.; Yu, G.; Xu, M.; Tan, J.; Xuan, F. Laser-microengineered flexible electrodes with enhanced sensitivity for wearable pressure sensors. Sens. Actuators A Phys. 2018, 281, 124–129. [Google Scholar] [CrossRef]

- Huang, K.; Ning, H.; Hu, N.; Liu, F.; Wu, X.; Wang, S.; Liu, Y.; Zou, R.; Yuan, W.; Alamusi; et al. Ultrasensitive MWCNT/PDMS composite strain sensor fabricated by laser ablation process. Compos. Sci. Technol. 2020, 192, 108105. [Google Scholar] [CrossRef]

| Sample | Nanofillers | Addition Amount (wt.) | Sample | Nanofillers | Addition Amount (wt.) |

|---|---|---|---|---|---|

| CNT0.2 | MWCNT | 0.2% | CNT0.6 | MWCNT | 0.6% |

| CNT1.0 | MWCNT | 1.0% | CNT1.2 | MWCNT | 1.2% |

| CNT1.5 | MWCNT | 1.5% | CB0.5 | CB | 0.5% |

| CB1.0 | CB | 1.0% | CB2.0 | CB | 2.0% |

| CNT0.6CB0.5 | MWCNT/CB | 0.6%/0.5% | CNT0.6CB1.0 | MWCNT/CB | 0.6%/1.0% |

| CNT0.6CB2.0 | MWCNT/CB | 0.6%/2.0% | CNT1.0CB0.5 | MWCNT/CB | 1.0%/0.5% |

| CNT1.0CB1.0 | MWCNT/CB | 1.0%/1.0% | CNT1.0CB2.0 | MWCNT/CB | 1.0%/2.0% |

| Sample | Laser Power | Sample | Laser Power | Sample | Laser Power |

|---|---|---|---|---|---|

| CNT0.2-P1.5 | 1.5 w | CNT0.2-P3.0 | 3.0 w | CNT0.2-P6.0 | 6.0 w |

| CNT0.6-P1.5 | 1.5 w | CNT0.6-P3.0 | 3.0 w | CNT0.6-P6.0 | 6.0 w |

| CNT1.0-P1.5 | 1.5 w | CNT1.0-P3.0 | 3.0 w | CNT1.0-P6.0 | 6.0 w |

| CNT1.2-P1.5 | 1.5 w | CNT1.2-P3.0 | 3.0 w | CNT1.2-P6.0 | 6.0 w |

| CNT0.2-P9.0 | 9.0 w | CNT0.6CB0.5-P1.5 | 1.5 w | CNT1.0CB1.0-P1.5 | 1.5 w |

| CNT0.6-P9.0 | 9.0 w | CNT0.6CB1.0-P1.5 | 1.5 w | CNT1.0CB2.0-P1.5 | 1.5 w |

| CNT1.0-P9.0 | 9.0 w | CNT0.6CB2.0-P1.5 | 1.5 w | CNT0.6CB0.5-P3.0 | 3.0 w |

| CNT1.2-P9.0 | 9.0 w | CNT1.0CB0.5-P1.5 | 1.5 w | CNT0.6CB1.0-P3.0 | 3.0 w |

| CNT0.6CB2.0-P3.0 | 3.0 w | CNT0.6CB0.5-P6.0 | 6.0 w | CNT1.0CB1.0-P6.0 | 6.0 w |

| CNT1.0CB0.5-P3.0 | 3.0 w | CNT0.6CB1.0-P6.0 | 6.0 w | CNT1.0CB2.0-P6.0 | 6.0 w |

| CNT1.0CB1.0-P3.0 | 3.0 w | CNT0.6CB2.0-P6.0 | 6.0 w | CNT0.6CB0.5-P9.0 | 9.0 w |

| CNT1.0CB2.0-P3.0 | 3.0 w | CNT1.0CB0.5-P6.0 | 6.0 w | CNT0.6CB1.0-P9.0 | 9.0 w |

| CNT0.6CB2.0-P9.0 | 9.0 w | CNT1.0CB1.0-P9.0 | 9.0 w | CB2.0-P1.5 | 1.5 w |

| CNT1.0CB0.5-P9.0 | 9.0 w | CNT1.0CB2.0-P9.0 | 9.0 w | CB2.0-P3.0 | 3.0 w |

| CB2.0-P6.0 | 6.0 w | CB2.0-P9.0 | 9.0 w |

| Sample | Resistance | Sample | Resistance | Sample | Resistance |

|---|---|---|---|---|---|

| CB0.5-P1.5 | - | CB1.0-P1.5 | -- | CB2.0-P1.5 | - |

| CB0.5-P3.0 | - | CB1.0-P3.0 | - | CB2.0-P3.0 | - |

| CB0.5-P6.0 | - | CB1.0-P6.0 | - | CB2.0-P6.0 | 32.4 MΩ |

| CB0.5-P9.0 | - | CB1.0-P9.0 | - | CB2.0-P9.0 | - |

| CNT0.2-P1.5 | - | CNT0.6-P1.5 | - | CNT1.0-P1.5 | 238.1 kΩ |

| CNT0.2-P3.0 | - | CNT0.6-P3.0 | - | CNT1.0-P3.0 | 127.6 kΩ |

| CNT0.2-P6.0 | - | CNT0.6-P6.0 | 159.6 kΩ | CNT1.0-P6.0 | 39.6 kΩ |

| CNT0.2-P9.0 | 209.3 kΩ | CNT0.6-P9.0 | 35.1 kΩ | CNT1.0-P9.0 | 19.7 kΩ |

| CNT1.2-P1.5 | 108.3 kΩ | CNT1.2-P3.0 | 85.1 kΩ | CNT1.2-P6.0 | 23.8 kΩ |

| CNT1.2-P9.0 | 12.3 kΩ | ||||

| CNT0.6CB0.5-P1.5 | - | CNT0.6CB0.5-P3.0 | 318.5 kΩ | CNT0.6CB0.5-P6.0 | 244.7 kΩ |

| CNT0.6CB0.5-P9.0 | 109.5 kΩ | CNT0.6CB1.0-P1.5 | 715.4 kΩ | CNT0.6CB1.0-P3.0 | 306.6 kΩ |

| CNT0.6CB1.0-P6.0 | 218.7 kΩ | CNT0.6CB1.0-P9.0 | 114.2 kΩ | CNT0.6CB2.0-P1.5 | 581.7 kΩ |

| CNT0.6CB2.0-P3.0 | 404.2 kΩ | CNT0.6CB2.0-P6.0 | 213.7 kΩ | CNT0.6CB2.0-P9.0 | 105.5 kΩ |

| CNT1.0CB0.5-P1.5 | 203.7kΩ | CNT1.0CB0.5-P3.0 | 125.4 kΩ | CNT1.0CB0.5-P6.0 | 35.8 kΩ |

| CNT1.0CB0.5-P9.0 | 22.6 kΩ | CNT1.0CB1.0-P1.5 | 208.1 kΩ | CNT1.0CB1.0-P3.0 | 114.4 kΩ |

| CNT1.0CB1.0-P6.0 | 38.9 kΩ | CNT1.0CB1.0-P9.0 | 21.7 kΩ | CNT1.0CB2.0-P1.5 | 188.4 kΩ |

| CNT1.0CB2.0-P3.0 | 99.3 kΩ | CNT1.0CB2.0-P6.0 | 30.6 kΩ | CNT1.0CB2.0-P9.0 | 19.9 kΩ |

| CNT Mass Fraction % | Laser Power (W) | CB Mass Fraction % | Initial Resistance (kΩ) |

|---|---|---|---|

| 0.6 | 3 | 0 | Exceed the instrument’s range |

| 0.6 | 3 | 0.5 | 318.5 |

| 0.6 | 3 | 1 | 306.6 |

| 0.6 | 3 | 2 | 404.2 |

| 0.6 | 6 | 0 | 159.6 |

| 0.6 | 6 | 0.5 | 244.7 |

| 0.6 | 6 | 1 | 218.7 |

| 0.6 | 6 | 2 | 213.7 |

| 0.6 | 9 | 0 | 35.1 |

| 0.6 | 9 | 0.5 | 109.5 |

| 0.6 | 9 | 1 | 114.2 |

| 0.6 | 9 | 2 | 105.5 |

| 1 | 3 | 0 | 127.6 |

| 1 | 3 | 0.5 | 125.4 |

| 1 | 3 | 1 | 114.4 |

| 1 | 3 | 2 | 99.3 |

| 1 | 6 | 0 | 39.6 |

| 1 | 6 | 0.5 | 35.8 |

| 1 | 6 | 1 | 38.9 |

| 1 | 6 | 2 | 30.6 |

| 1 | 9 | 0 | 19.7 |

| 1 | 9 | 0.5 | 22.6 |

| 1 | 9 | 1 | 21.7 |

| 1 | 9 | 2 | 19.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; Tan, R.; Wang, S.; Yuan, Y.; Huang, K.; Wang, Z.; Zhang, S.; Khan, S.B.; Yuan, W.; Hu, N. Synergistic Effect of MWCNT and CB on the Piezoresistive Properties of Laser Ablation Composites Strain Sensors. Nanomaterials 2025, 15, 997. https://doi.org/10.3390/nano15130997

Yin S, Tan R, Wang S, Yuan Y, Huang K, Wang Z, Zhang S, Khan SB, Yuan W, Hu N. Synergistic Effect of MWCNT and CB on the Piezoresistive Properties of Laser Ablation Composites Strain Sensors. Nanomaterials. 2025; 15(13):997. https://doi.org/10.3390/nano15130997

Chicago/Turabian StyleYin, Shikang, Richao Tan, Sitian Wang, Yuan Yuan, Kaiyan Huang, Ziying Wang, Shijie Zhang, Sadaf Bashir Khan, Weifeng Yuan, and Ning Hu. 2025. "Synergistic Effect of MWCNT and CB on the Piezoresistive Properties of Laser Ablation Composites Strain Sensors" Nanomaterials 15, no. 13: 997. https://doi.org/10.3390/nano15130997

APA StyleYin, S., Tan, R., Wang, S., Yuan, Y., Huang, K., Wang, Z., Zhang, S., Khan, S. B., Yuan, W., & Hu, N. (2025). Synergistic Effect of MWCNT and CB on the Piezoresistive Properties of Laser Ablation Composites Strain Sensors. Nanomaterials, 15(13), 997. https://doi.org/10.3390/nano15130997