Effect of Nano-Modified Recycled Wood Fibers on the Micro/Macro Properties of Rapid-Hardening Sulfoaluminate Cement-Based Composites

Abstract

1. Introduction

2. Experimental Procedure

2.1. Raw Materials

2.1.1. Cementitious Material

2.1.2. Fine Aggregate

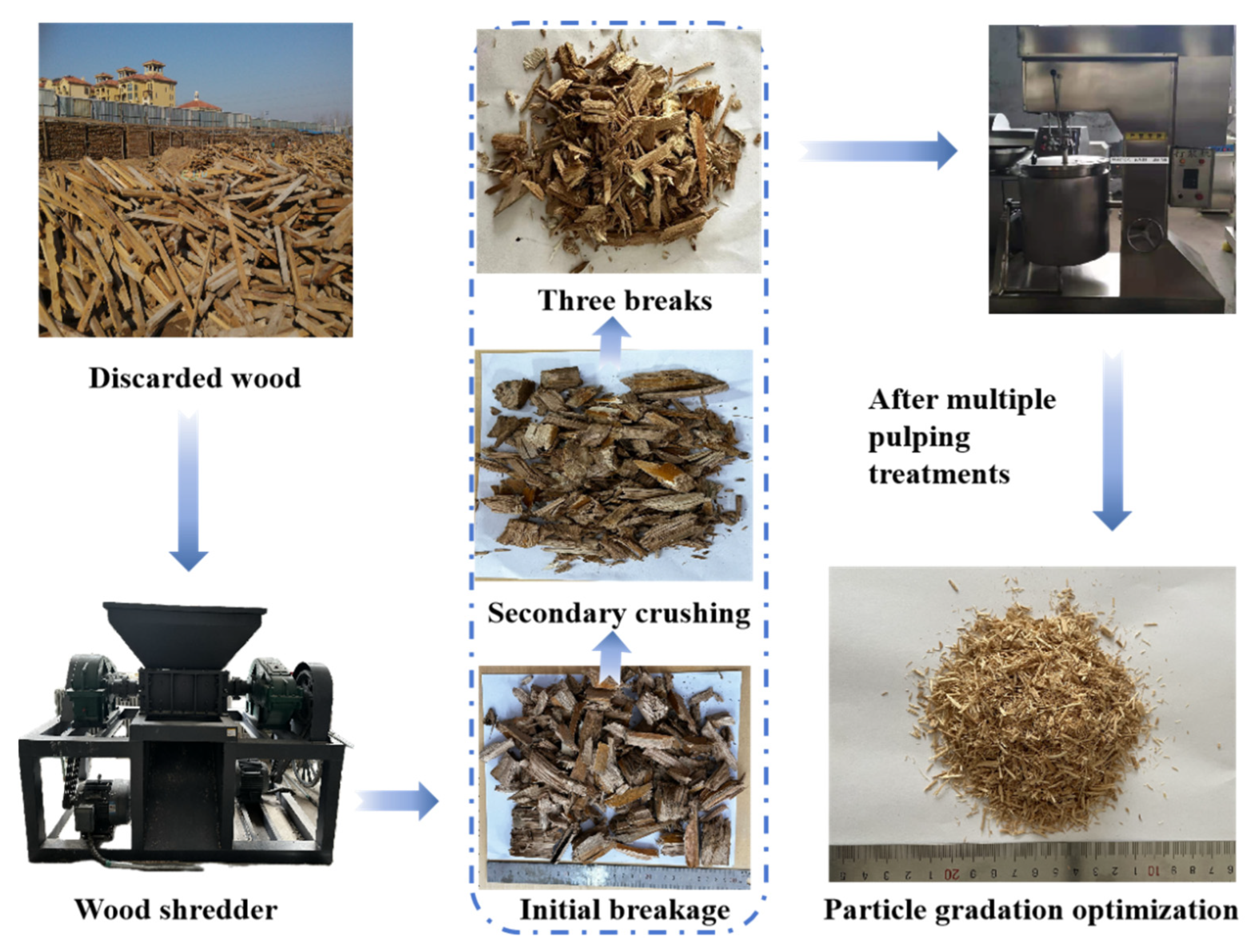

2.1.3. Recycled Wood Fibers

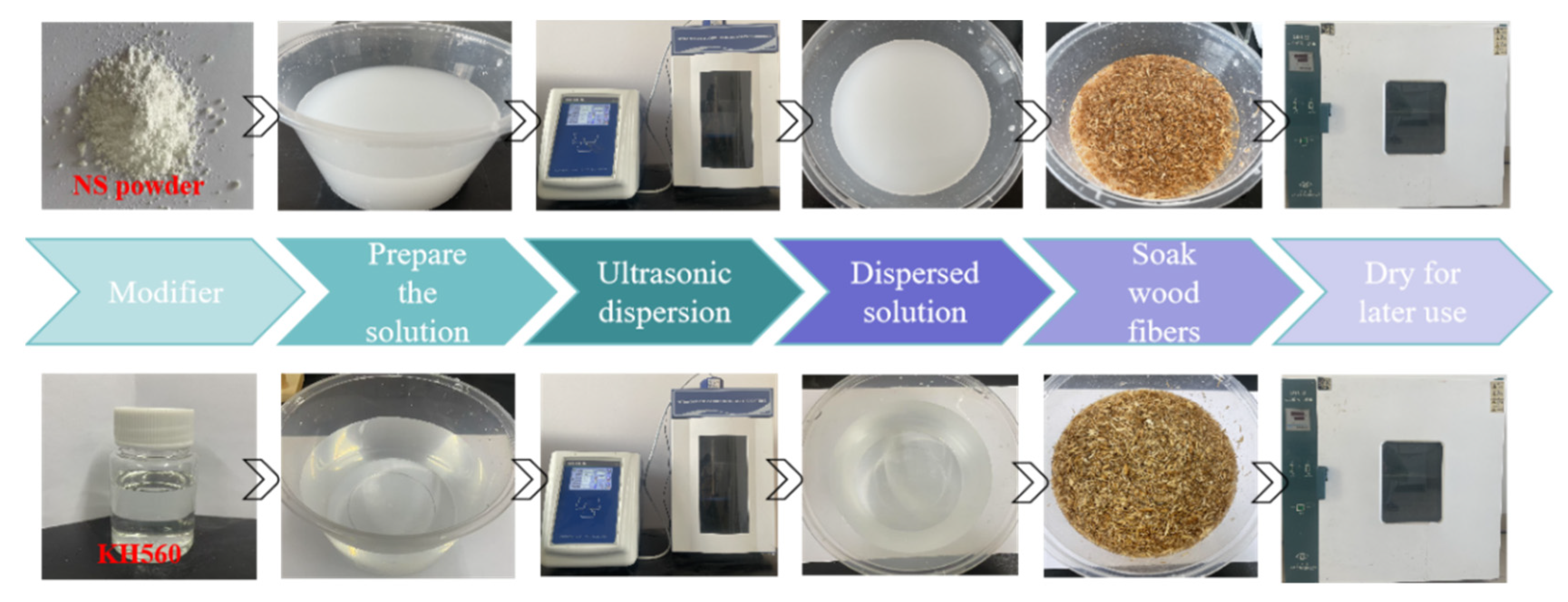

2.1.4. Modification of RWFs

2.1.5. Water-Reducing Agents

2.2. Mix Proportion Design of RWF-SAC Composites

2.3. Experimental Methods

3. Results and Discussion

3.1. Mechanical Properties of Different Modified RWF-SAC Composites

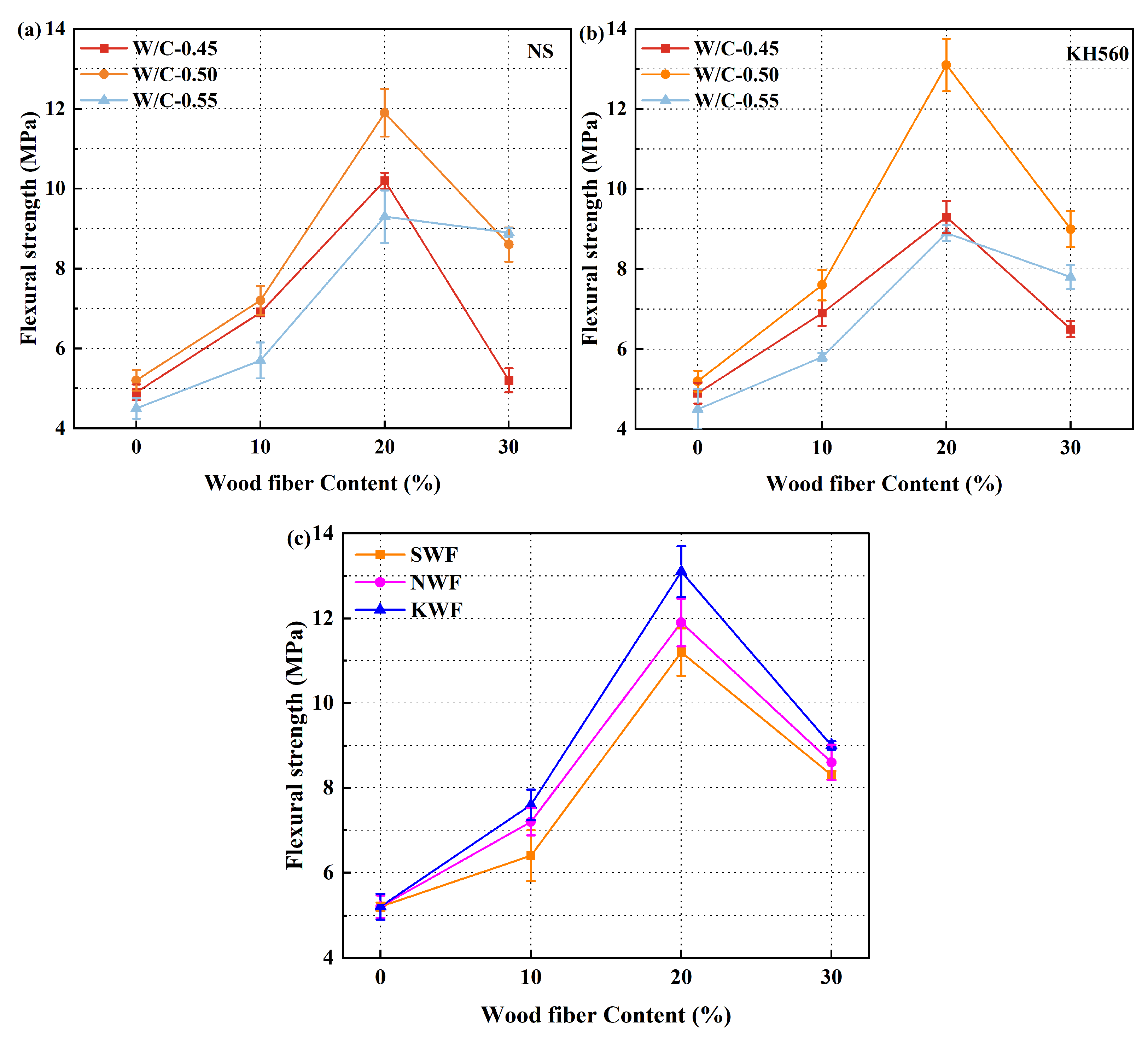

3.1.1. Flexural Strength of Modified RWF-SAC Composites

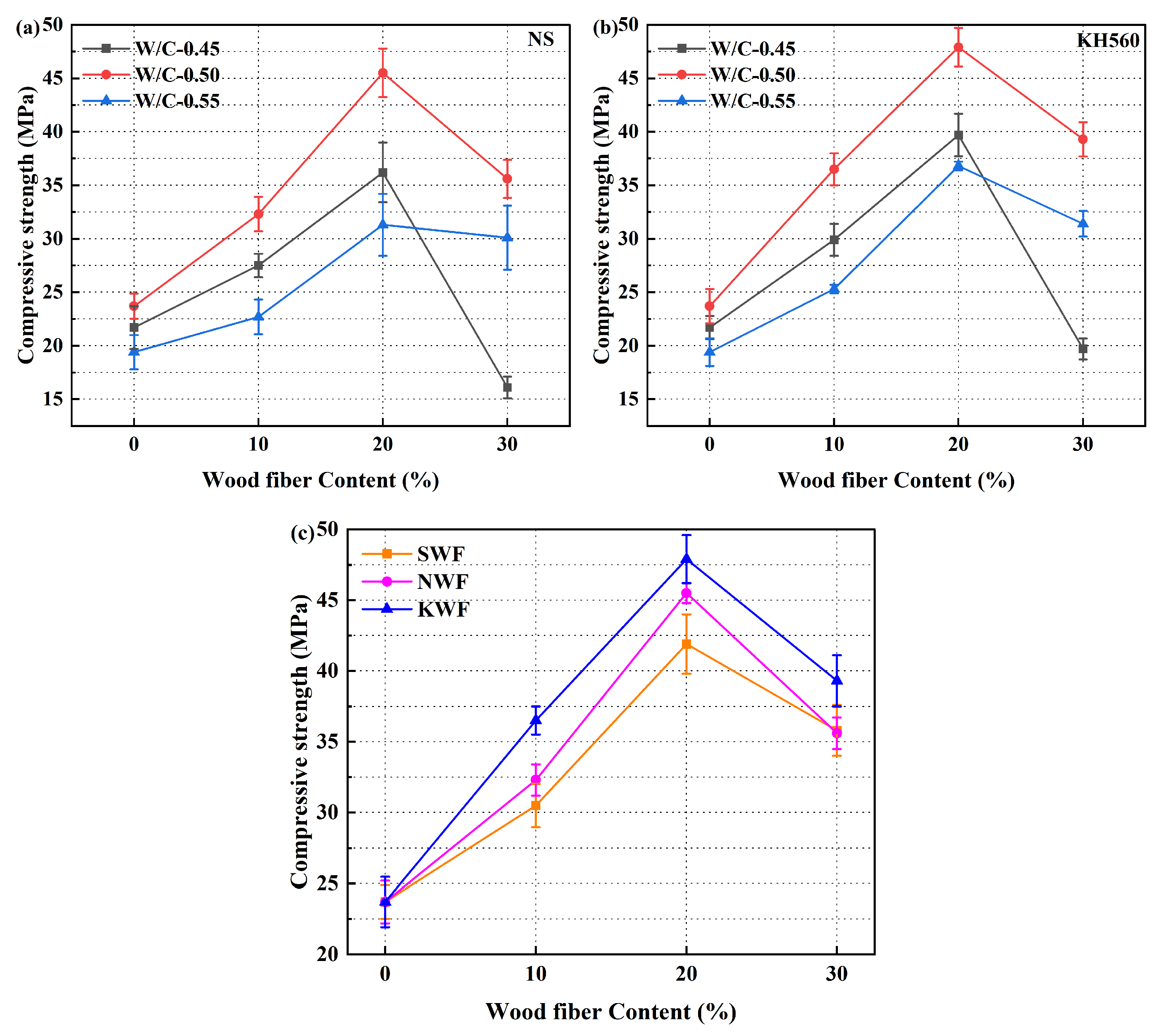

3.1.2. Compressive Strength of Modified RWF-SAC Composites

3.2. Dry Density of Modified RWF-SAC Composites

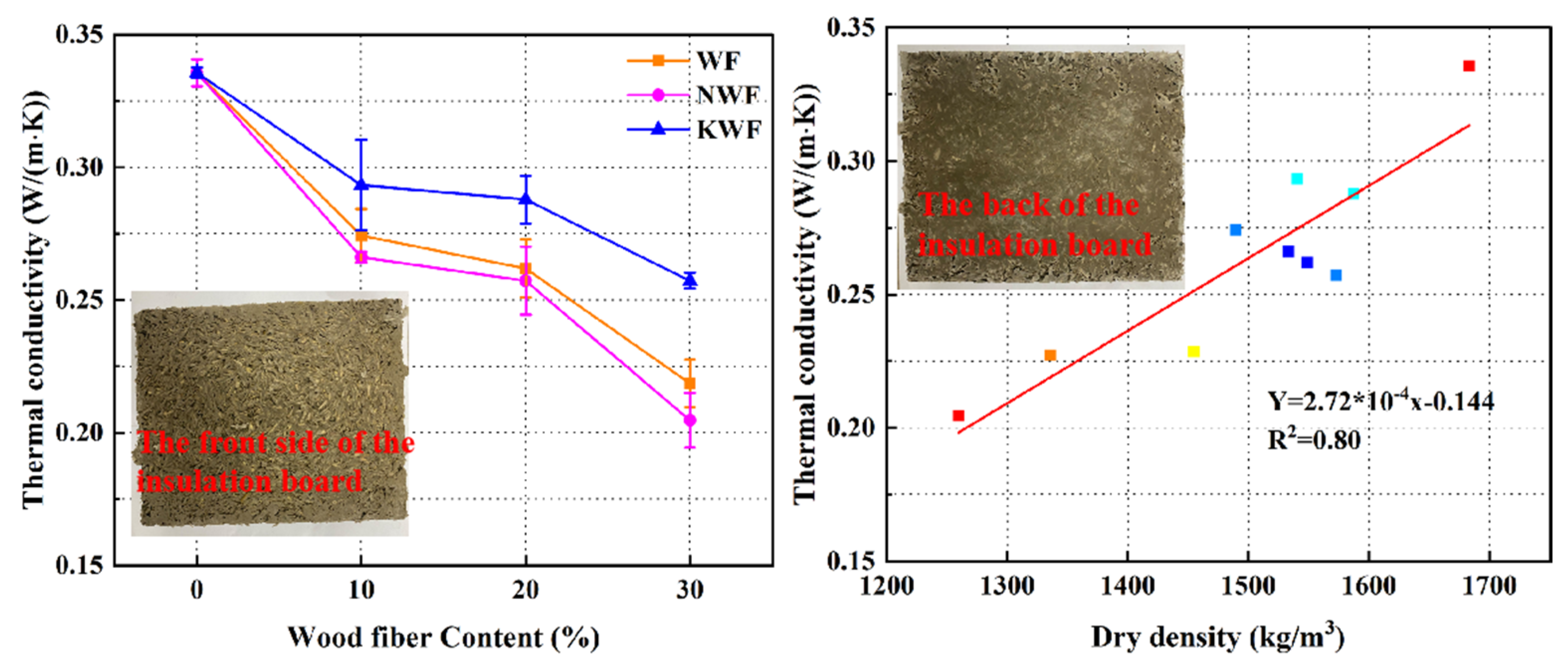

3.3. Thermal Conductivity of Modified RWF-SAC Composites

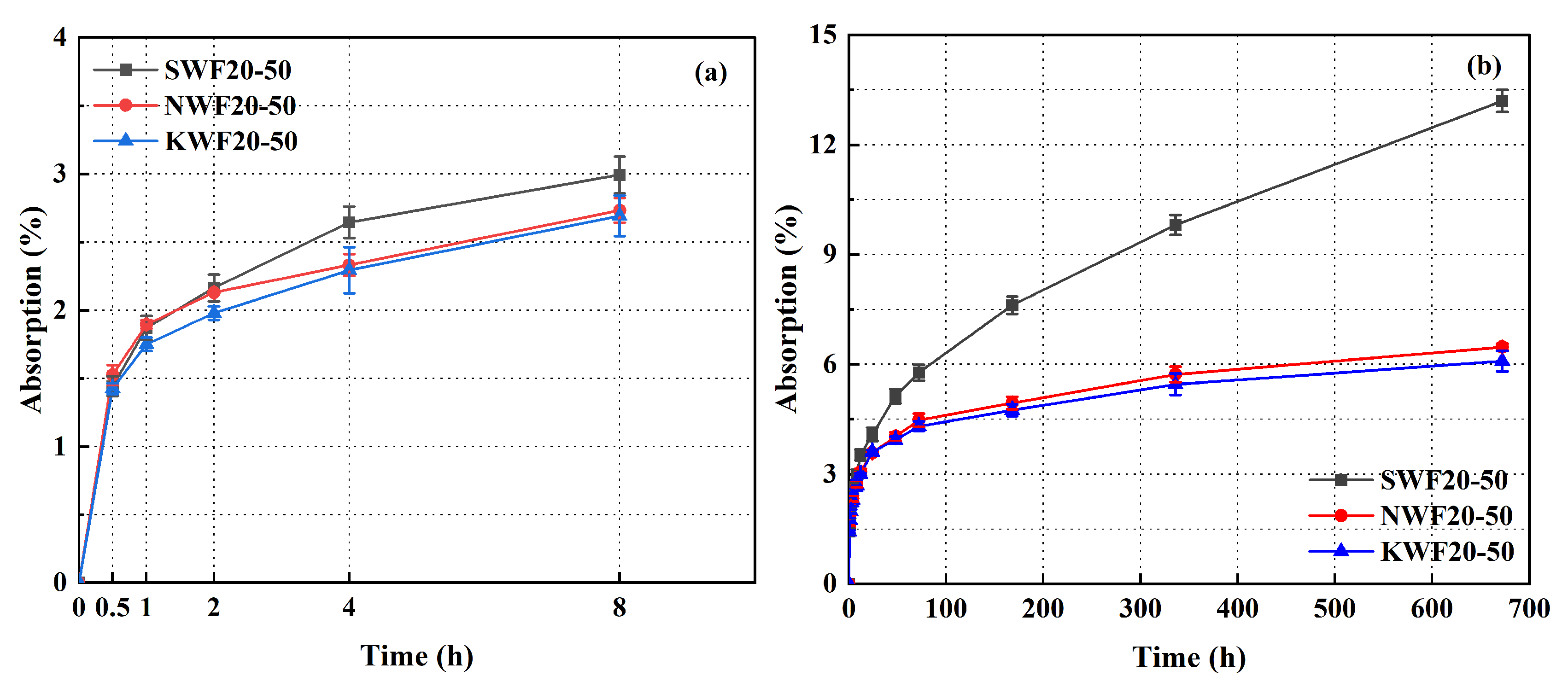

3.4. Water Absorption of Modified RWF-SAC Composites

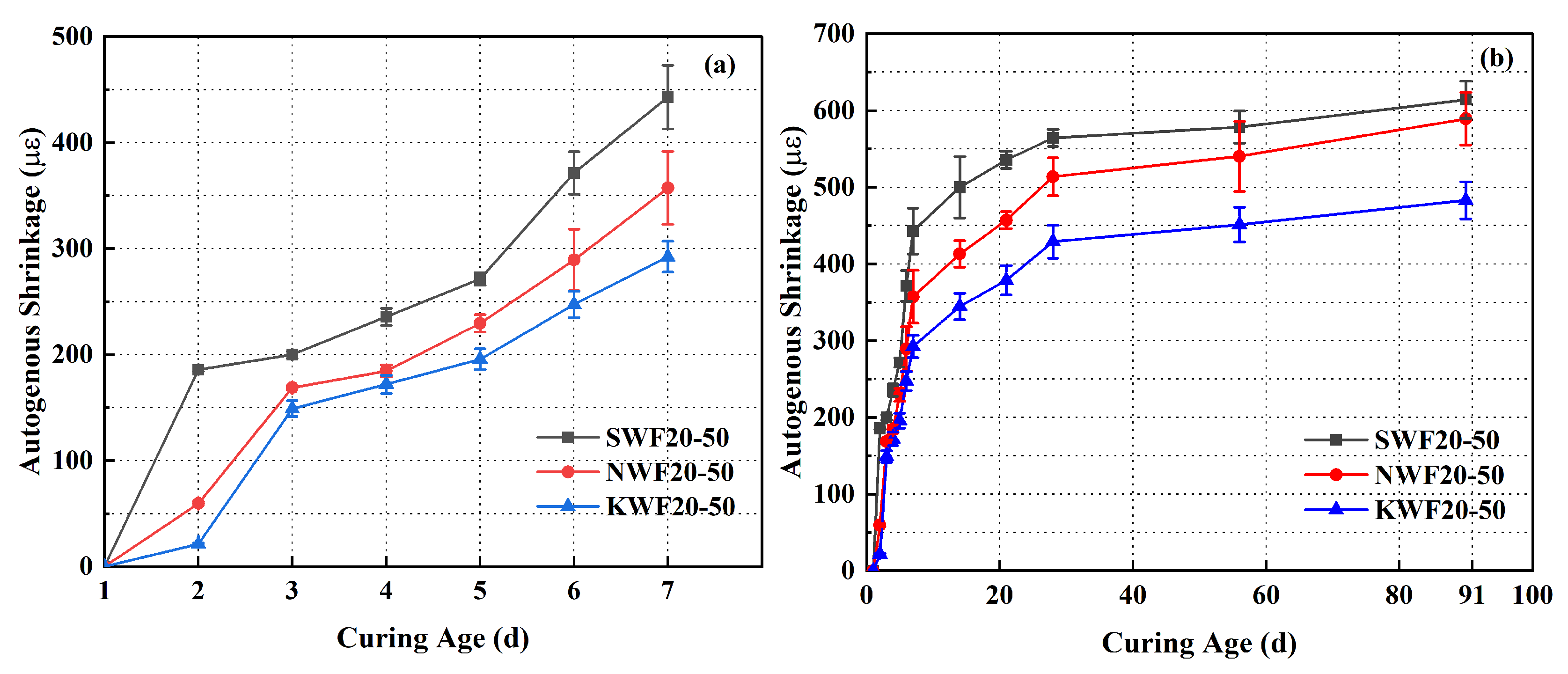

3.5. Shrinkage Properties of Modified RWF-SAC Composites

3.6. Microscopic Properties of Modified RWF-SAC Composites

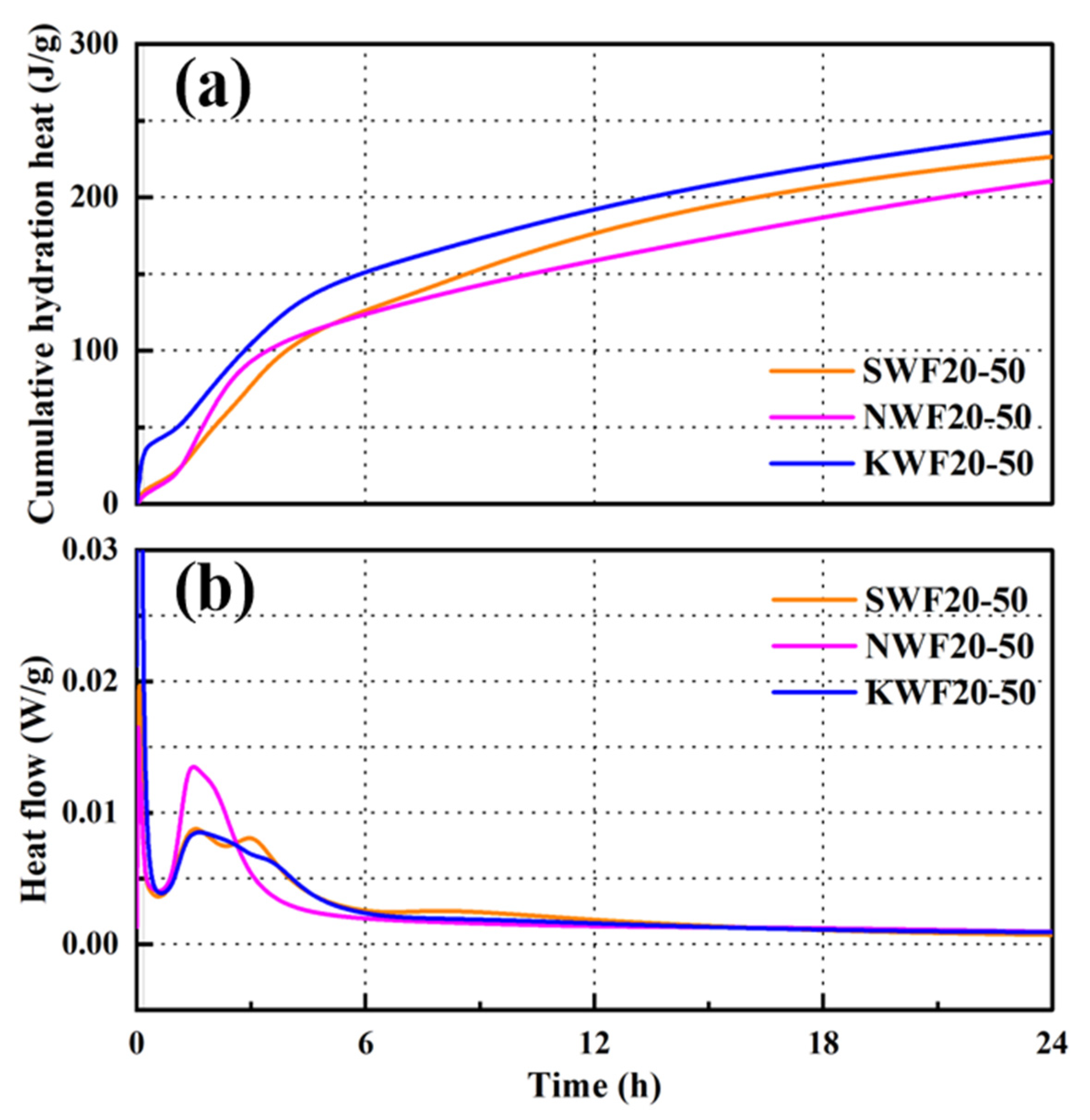

3.6.1. Hydration Characteristics of Modified RWF-SAC Composites

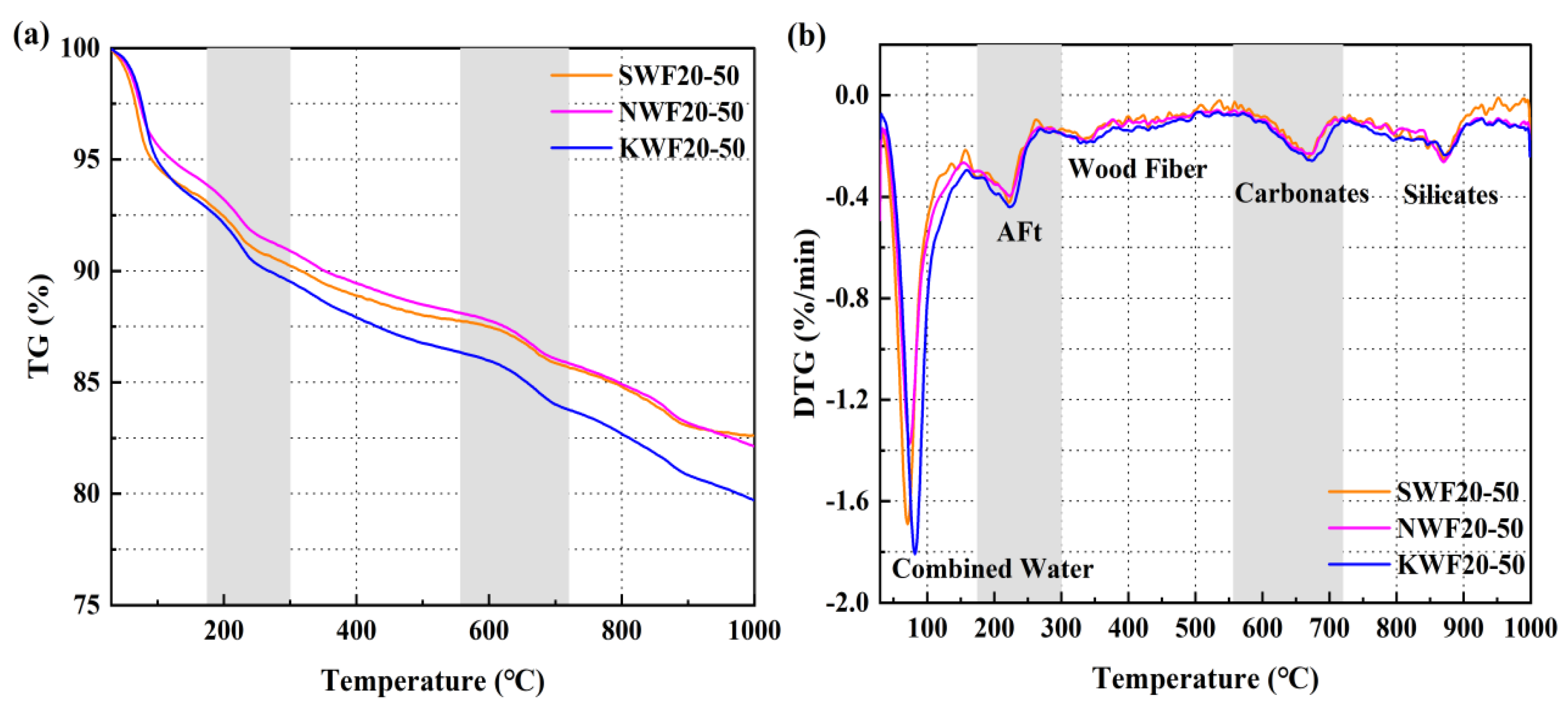

3.6.2. Thermogravimetric Analysis of Modified RWF-SAC Composites

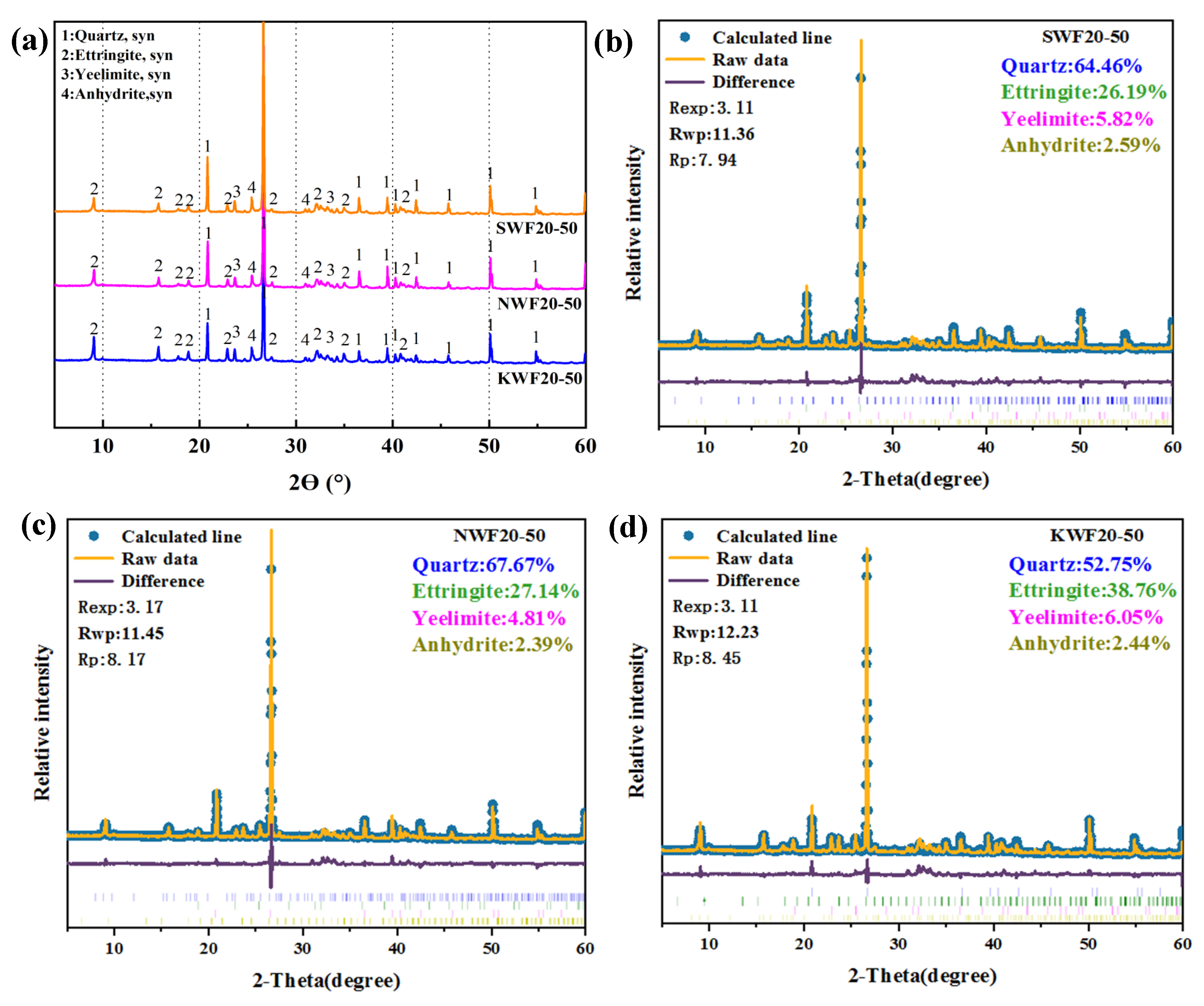

3.6.3. XRD Analysis of Modified RWF-SAC Composites

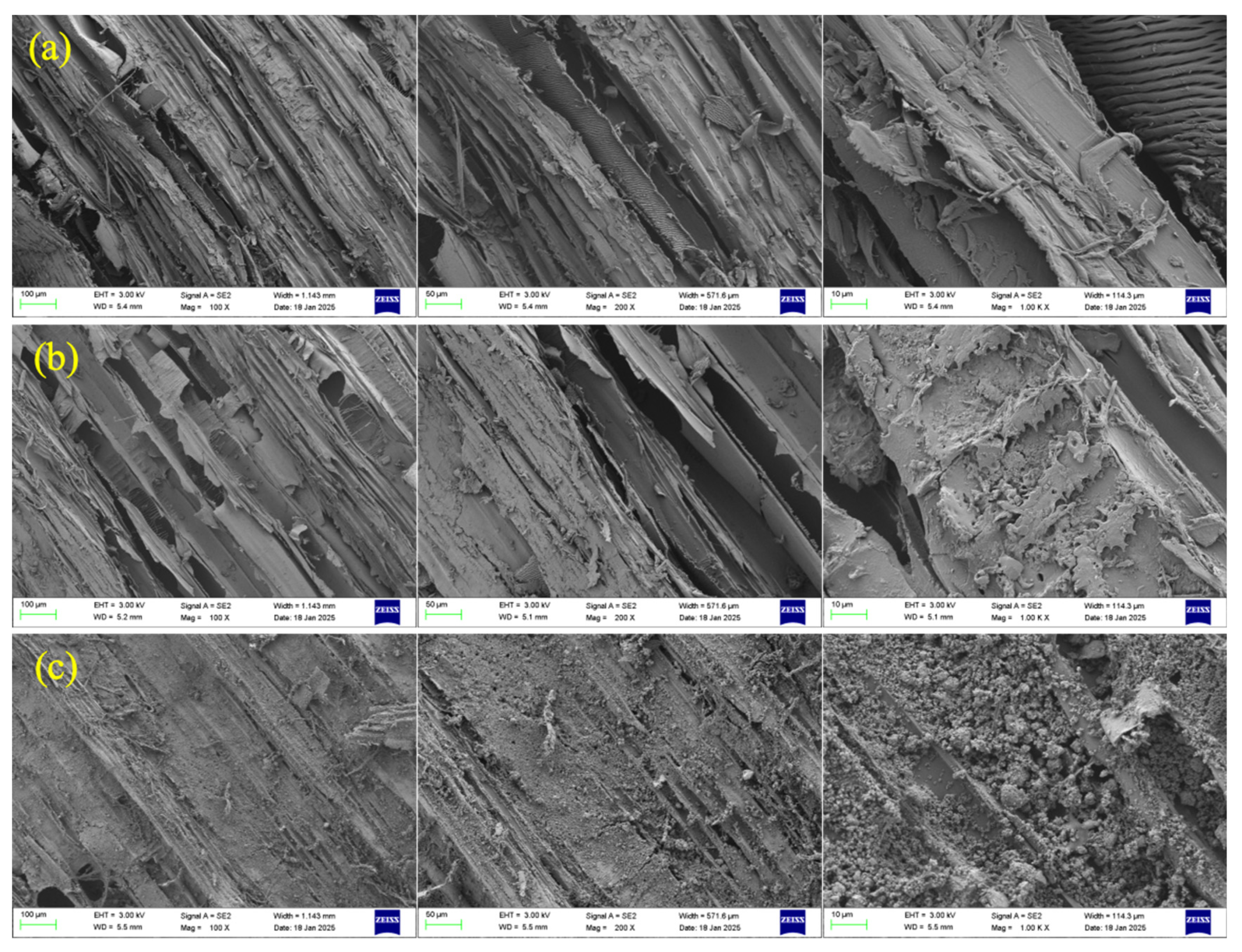

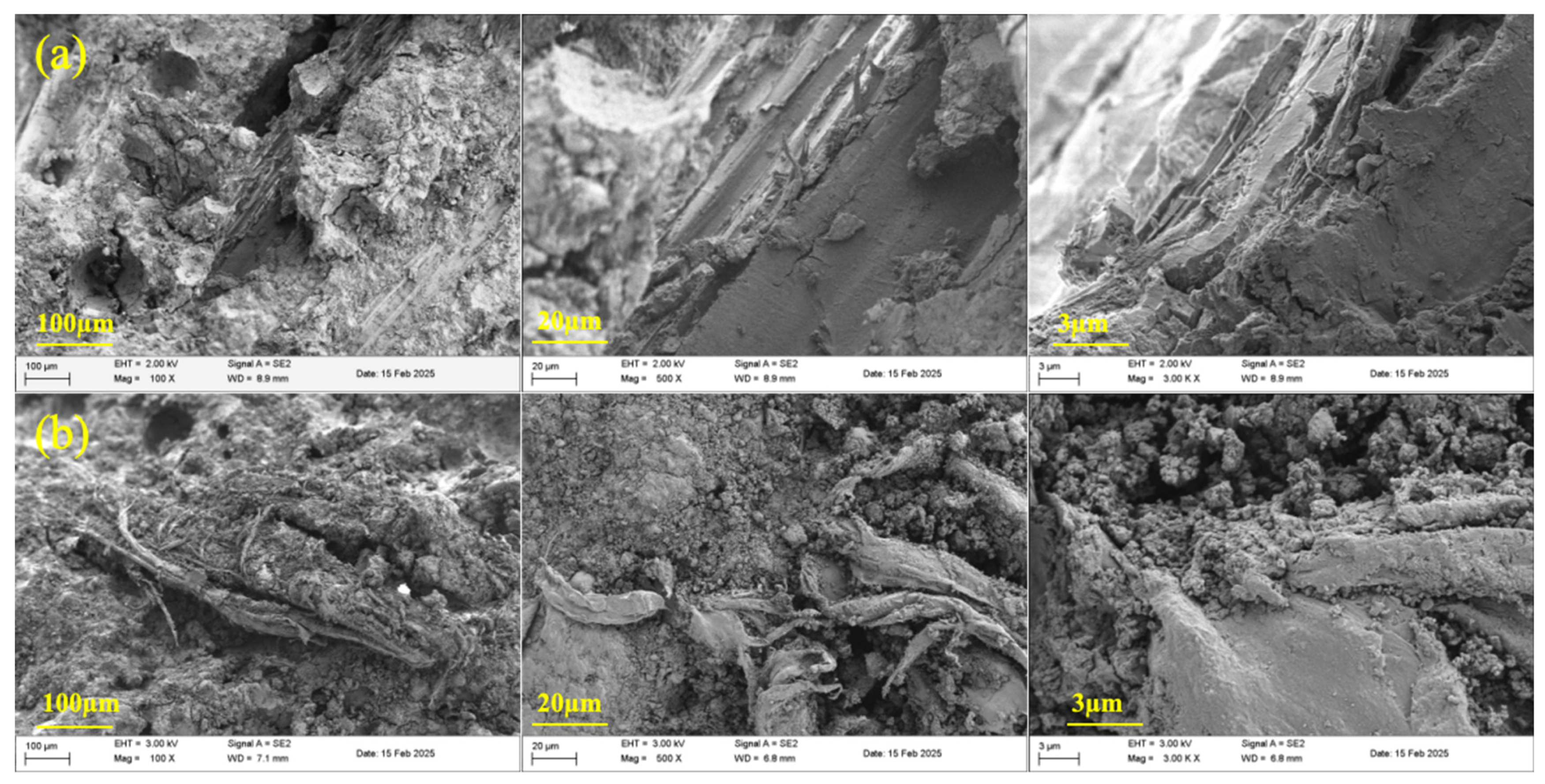

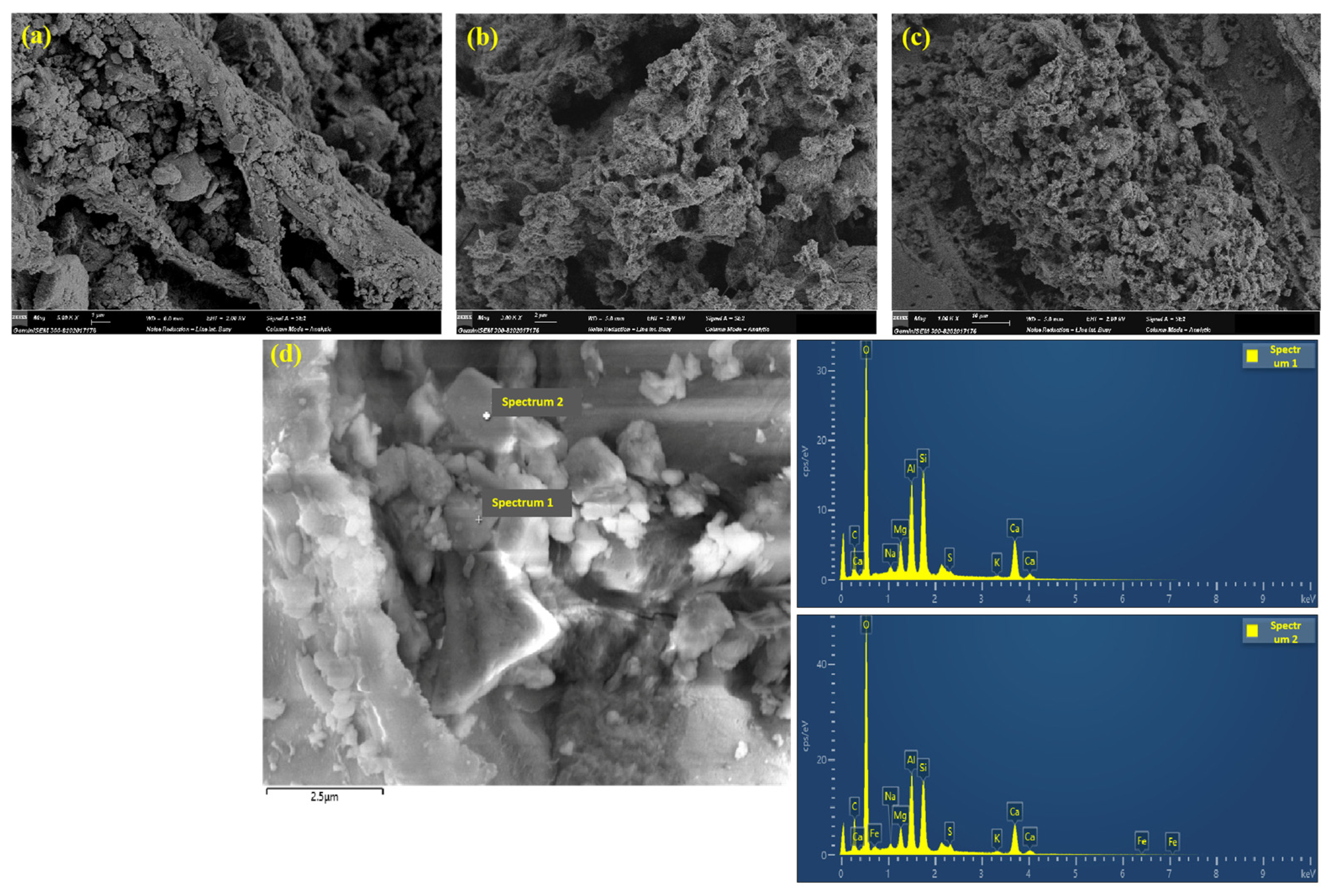

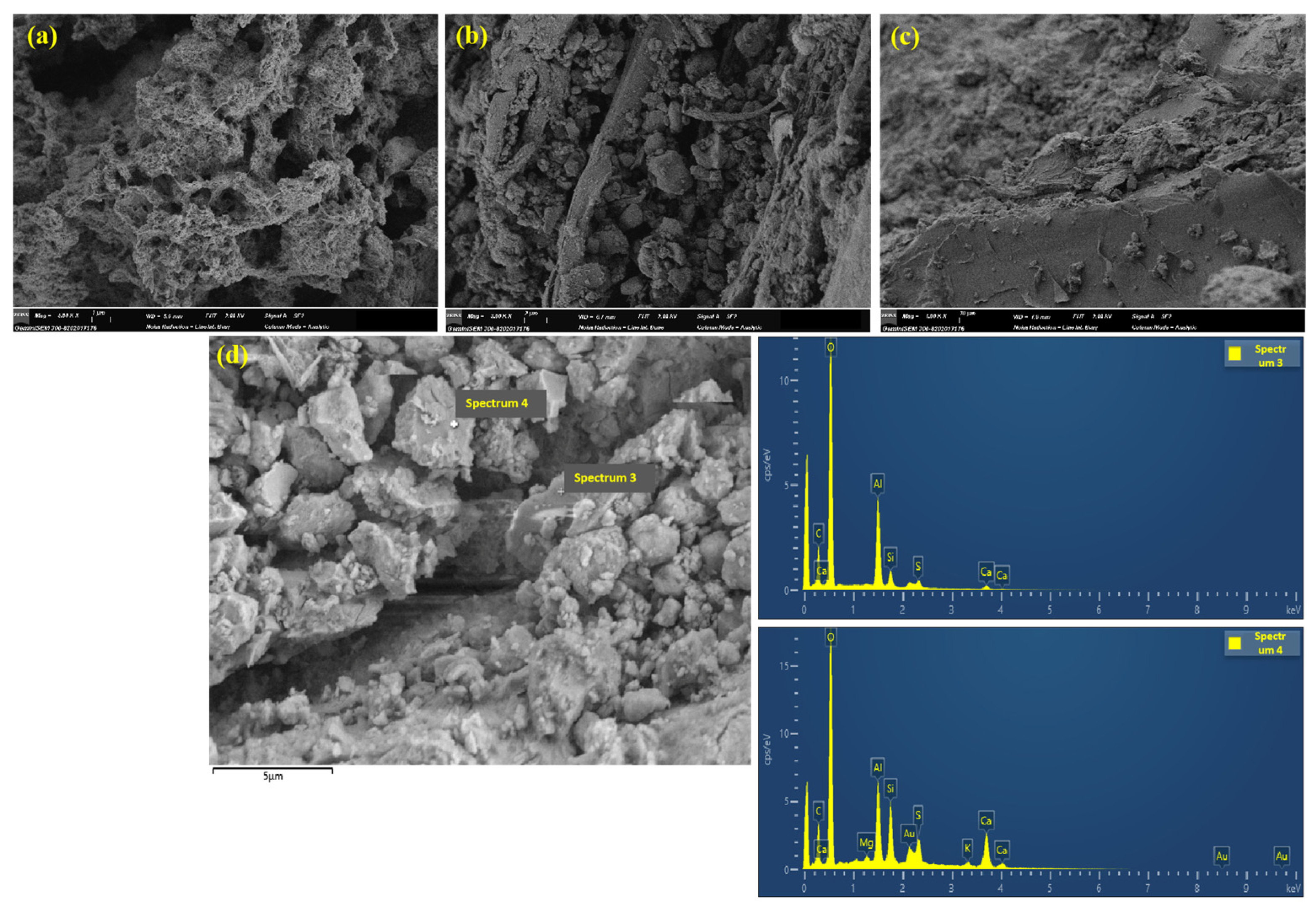

3.6.4. SEM Microscopic Morphology of Modified RWF-SAC Composites

4. Conclusions

- (1)

- The modified RWF-SAC cementitious composites demonstrate optimal mechanical performance at a water–cement ratio of 0.50 with 20% RWF content. Comparative analysis of differently modified RWF-SAC cementitious materials reveals that both NS and KH560 modifications enhance compressive strength, with KH560 exhibiting more pronounced effects, achieving 8.5% and 14.3% improvements in flexural and compressive strength, respectively, compared to the unmodified control group;

- (2)

- The modified RWF-SAC cementitious composites exhibited a strong linear correlation (R2 = 0.80) between dry density and thermal conductivity. The experimental results demonstrated that the thermal conductivity of different modified RWF-SAC cementitious materials showed a decreasing trend with the increase in RWF content. While NS-modified samples showed a 6.8% reduction in thermal conductivity compared to the control group, the KH560-modified series displayed increased thermal conductivity while maintaining relatively low overall values;

- (3)

- Regarding the shrinkage performance, both modification methods significantly improved water absorption. The water absorption of NS and KH560 series cementitious materials were 6.47% and 6.09%, respectively, which were 6.72% and 7.1% lower than those of the control group. Shrinkage resistance was also markedly enhanced, as the KH560 modification reduced autogenous shrinkage by approximately 27.2%, representing the most effective improvement among all samples;

- (4)

- In terms of hydration characteristics, through the comparison of hydration characteristics of cementitious materials with different modified recycled wood fibers, it was found that the KH560-modified series had a relatively larger effect on cement hydration heat and could make cement hydration more adequate. The NS-modified series mainly improved the reflection rate during cement hydration, which might be related to the ability of NS particles to promote cement hydration;

- (5)

- XRD patterns and SEM analysis show that the modified treatment of RWF does not make the cementitious materials generate new hydration products but has a certain effect on the hydration product content. The KH560-modified RWF-SAC materials have better interfacial bonding properties, generating more hydration products, the porosity is significantly reduced, the internal structure is more dense, and the overall modified effect of the KH560 series is better than the NS modification series.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, T.J.; Mao, J.W.; Zhu, Y.H.; Zhou, J.; Zhou, A.; Gou, H.S.; Zhang, Y.F. Recycling shield soil dreg into green cementitious material for ultra-high performance concrete: Bridging waste management and sustainable construction. Sustain. Mater. Technol. 2025, 44, e01373. [Google Scholar] [CrossRef]

- Carmona-Ramirez, J.D.; Bedoya-Henao, C.A.; Cabrera-Poloche, F.D.; Taborda-Llano, I.; Viana-Casas, G.A.; Restrepo-Baena, Q.J.; Tobón, J.L. Exploring sustainable construction: A case study on the potential of municipal solid waste incineration ashes as building materials in San Andres island. Case Stud. Constr. Mater. 2025, 22, e04351. [Google Scholar] [CrossRef]

- Jiang, T.Q.; Chen, B.; Bai, J.W.; Liu, B.; Chen, M.J. Improving mechanism for recycling efficiency of ceramic construction solid waste and properties of composite backfill based on aggregate particle size distribution. Constr. Build. Mater. 2024, 436, 136826. [Google Scholar] [CrossRef]

- Shahzad, Q.; Wang, X.J.; Wang, W.L.; Wan, Y.; Li, G.L.; Ren, C.Z.; Mao, Y.P. Coordinated adjustment and optimization of setting time, flowability, and mechanical strength for construction 3D printing material derived from solid waste. Constr. Build. Mater. 2020, 259, 119854. [Google Scholar] [CrossRef]

- Hossain, S.K.S.; Roy, P.K. Fabrication of sustainable ceramic board using solid-wastes for construction purpose. Constr. Build. Mater. 2019, 222, 26–40. [Google Scholar] [CrossRef]

- Jiao, Y.; Fang, X.W.; Shen, C.N.; Tian, J.; Huang, S.; Jang, W.C. Research Progress on the Resource Recycling and Reuse of Brick-Concrete Construction Waste. J. Civ. Environ. Eng. 2025, 1–14. Available online: http://kns.cnki.net/kcms/detail/50.1218.TU.20250414.1008.002.html (accessed on 14 April 2025).

- Wang, P.H.; Xu, C.Y.; Li, Q.Y.; Wang, L.; Guo, Y.X. Experimental study on the preparation of wood aggregate recycled concrete using waste wood and recycled fine aggregate from construction and demolition wastes. J. Build. Eng. 2024, 90, 109471. [Google Scholar] [CrossRef]

- Xu, C.Y.; Guo, Y.X.; Li, Q.Y.; Kong, Z.; Shao, C.H. Advancing sustainable infrastructure: Leveraging forestry waste fibers to enhance crack resistance and durability in repair mortar. Case Stud. Constr. Mater. 2024, 21, e04089. [Google Scholar] [CrossRef]

- Sun, X.F.; Wu, T.Q.; Xun, Z.P.; Pan, L.J. Splitting tensile mechanical properties and failure mechanism of steel fiber recycled concrete. Bull. Chin. Ceram. Soc. 2025, 44, 883–891. [Google Scholar] [CrossRef]

- El Abd, A.; Taman, M.; Behiry, R.N.; El-Naggar, M.R.; Eissa, M.; Bar, W.A.; Mongy, T.; Mohammed, G.A.; Hassan, A.M.A. Amer Characteristics and neutron imaging of capillary water absorption for metakaolin and steel fiber reinforced slag based-geopolymer mortars. J. Build. Eng. 2024, 82, 107960. [Google Scholar] [CrossRef]

- Zhan, Y.L.; Lin, J.G.; Si, R.Z.; Gao, W.Y.; Chen, X.Q. Fluidity and mechanical properties of basalt fiber Cement Mortar under different Mix ratios. J. Tongji Univ. (Nat. Sci. Ed.) 2023, 51, 1804–1812. [Google Scholar]

- Cakir, F. Evaluation of mechanical properties of chopped glass/basalt fibers reinforced polymer mortars. Case Stud. Constr. Mater. 2021, 15, e00612. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Liu, C.; Cheng, P.F.; Li, Z.; Han, Y.; Wang, X.Y. Enhancing the interfacial compatibility and self-healing performance of microbial mortars by nano-SiO2-modified basalt fibers. Cem. Concr. Compos. 2024, 152, 105650. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of glass fibre reinforced polymer (GFRP) composite wastes in concrete: A critical review and cost benefit analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Zainal, S.M.I.S.; Wong, C.W.; Rizalman, A.N.; Majain, N.; Lim, C.H.; Sarbatly, R. Characterization and mixing sequence to enhance glass fiber performance in cement mixture. Mater. Struct. 2024, 57, 163. [Google Scholar] [CrossRef]

- Gu, Z.C.; Chen, P.Y.; Wang, C.; Wang, A.G.; Wang, Y.H.; Qian, P.; Li, X.K. Bio-inspired polydopamine modification of recycled carbon fibers for improving the performance of recycled carbon fiber reinforced mortars. Constr. Build. Mater. 2024, 414, 134912. [Google Scholar] [CrossRef]

- Zhang, G.Z.; Li, S.; Li, H.F.; Zhang, K.; Cheng, P.F. Enhancing self-healing performance of microbial mortar through carbon fiber reinforcement: An experimental analysis. J. Build. Eng. 2024, 91, 109499. [Google Scholar] [CrossRef]

- Wei, S.; Xiao, Z.R.; Fan, L.L. Current Situation and Development Trend of Manufacturing Artificial Boards from Waste Wood Materials. For. Fire Prev. 2024, 42, 115–118. [Google Scholar]

- Xu, C.Y.; Li, Q.Y.; Wang, P.H.; Guo, Y.H. Preparation and performance research of ecological concrete using waste wood. Case Stud. Constr. Mater. 2024, 20, e03221. [Google Scholar] [CrossRef]

- Yang, B.Q.; Zhu, Q.J. Research on the Resource Utilization of Wood Processing Waste. Agric. Technol. Equip. 2024, 4, 37–38+45. [Google Scholar]

- Shehata, N.; Mohamed, O.A.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Geopolymer concrete as green building materials: Recent applications, sustainable development and circular economy potentials. Sci. Total Environ. 2022, 836, 155577. [Google Scholar] [CrossRef] [PubMed]

- Sodangi, M.; Kazmi, Z.A. Integrated Evaluation of the Impediments to the Adoption of Coconut Palm Wood as a Sustainable Material for Building Construction. Sustainability 2020, 12, 7676. [Google Scholar] [CrossRef]

- Zhu, H.H.; Yang, L.; Liu, J.H.; Shi, C.J. The influence of poplar wood fibers on the fluidity, mechanical properties and self-shrinkage of mortar. Bull. Chin. Ceram. Soc. 2024, 43, 487–494+533. [Google Scholar] [CrossRef]

- Zhou, X.L.; Shi, S.F.; Feng, B.Q.; Liu, J.D.; Bai, Z.R. The influence of waste recycled wood fibers on the mechanical and thermal insulation properties of lightweight thermal insulation mortar. Residence 2024, 10, 245–247. [Google Scholar]

- Liu, C.; Xiao, P.Y.; Wang, X.Y.; Li, Q.Y.; Shan, T.Q.; Wang, L.; Yue, G.B.; Chen, M.X. Mechanical properties and shrinkage behavior of alkali-activated recycled mortar incorporating waste wood powder. Case Stud. Constr. Mater. 2025, 22, e04324. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Sinyoung, S.; Kajitvichyanukul, P. Comparative microstructures and mechanical properties of mortar incorporating wood fiber waste from various curing conditions. Case Stud. Constr. Mater. 2022, 16, e00855. [Google Scholar] [CrossRef]

- Tong, Y.Y.; Zhang, W.; Li, M.Y.; Ngo, T.T.; Wang, Q.N.; Zeng, W.; Li, B.Y. Mechanical and thermal properties of structural lightweight bamboo fiber-reinforced insulating mortar. Case Stud. Constr. Mater. 2025, 22, e04462. [Google Scholar] [CrossRef]

- Rebec, K.M.; Turk, J.; Kunaver, M. Quantifying the environmental implication of cotton-Fiber-based Nanocrystalline cellulose: A life-cycle assessment. Sustain. Prod. Consum. 2024, 45, 192–202. [Google Scholar] [CrossRef]

- Operato, L.; Vitiello, L.; Aprea, P.; Ambrogi, V.; Luna, M.S.; Filippone, G. Life cycle assessment of poly(lactic acid)-based green composites filled with pine needles or kenaf fibers. J. Clean. Prod. 2023, 387, 135901. [Google Scholar] [CrossRef]

- Shahid, A.T.; Silvestre, J.D.; Hofmann, M.; Garrido, M.; Correia, J.R. Life cycle assessment of an innovative bio-based unsaturated polyester resin and its use in glass fibre reinforced bio-composites produced by vacuum infusion. J. Clean. Prod. 2024, 441, 140906. [Google Scholar] [CrossRef]

- Liu, T.; Liu, Z.; Zhou, Z.Z.; Shi, S.Q.; Aladejana, J.T.; Gong, S.S.; Fang, Z.; Li, J.Z. A novel sol-gel strategy for constructing wood fibers and aramid nanofiber nanocomposite with strong, tough and recyclable properties. Compos. Sci. Technol. 2023, 238, 110026. [Google Scholar] [CrossRef]

- Gao, J.S.; Wang, X.; Xu, Q.; Kuai, B.B.; Wang, Z.H.; Cai, L.P.; Ge, S.B.; Zhang, Y.L.; Li, G. Efficient preparation and properties of wood fiber transparent materials with powdered wood. Ind. Crops Prod. 2023, 193, 116291. [Google Scholar] [CrossRef]

- Gao, J.S.; Wang, X.; Tong, J.W.; Kuai, B.B.; Wang, Z.H.; Zhang, Y.L.; Li, G.; Huang, Z.H.; Cai, L.P. Large size translucent wood fiber reinforced PMMA porous composites with excellent thermal, acoustic and energy absorption properties. Compos. Commun. 2022, 30, 101059. [Google Scholar] [CrossRef]

- Ozyhar, T.; Baradel, F.; Zoppe, J. Effect of functional mineral additive on processability and material properties of wood-fiber reinforced poly (lactic acid) (PLA) composites. Compos. Part A-Appl. Sci. Manuf. 2020, 132, 105827. [Google Scholar] [CrossRef]

- Lin, C.; Luo, Q.; Kanstad, T.; Grammatikos, S.; Ji, G. A comprehensive study on the physico-mechanical properties of a sustainable mortar reinforced by waste wood fiber. Constr. Build. Mater. 2025, 461, 139928. [Google Scholar] [CrossRef]

- Chen, G.W.; Gupta, A.; Mekonnen, T.H. Silane-modified wood fiber filled EPDM bio-composites with improved thermomechanical properties. Compos. Part A Appl. Sci. Manuf. 2022, 159, 107029. [Google Scholar] [CrossRef]

- Bastidas, S.A.; Petroche, D.M.; Cornejo, M.H.; Martinez-Echevarria, M.J. Effect of aging process on mechanical performance of reinforced mortar with NaOH abaca fibers. Case Stud. Constr. Mater. 2024, 20, e03122. [Google Scholar] [CrossRef]

- Lakshmaiya, N.; Karthick, M.; Bhaskar, K.; Chukka, N.D.K.R.; Ross, N.S.; Maranan, R. Development of eco friendly hybrid nanocomposites with improved antibacterial and mechanical properties through NaOH treated natural fibers. Results Eng. 2025, 26, 104996. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.T.; Feng, Z.X.; Ge, L.C.; Li, R.Y.; Liu, S. Study on the interfacial bonding properties between alkali-treated bamboo fibers and high-performance seawater sea-sand concrete. Constr. Build. Mater. 2024, 426, 136190. [Google Scholar] [CrossRef]

- Ghamarpoor, R.; Jamshidi, M.; Alhaeehm, Z.A.K. Synthesis of Hybrid/Superhydrophobic Coupling Agent Grafted Nano SiO2 and Its Use in Fabrication of Rubber Nanocomposite with Outstanding Oil/Water Separation Capability. Results Eng. 2024, 22, 102270. [Google Scholar] [CrossRef]

- Huang, S.; Chen, J.; Li, Z.Y.; Su, D.H.; Zhang, B.W.; Gao, Y.; Luo, Z.G. Synthesis and characterization of grafted nano-silica copolymerized fluid loss additive for oil well cement at ultra-high temperature of 240 °C. Constr. Build. Mater. 2025, 483, 141740. [Google Scholar] [CrossRef]

- Xiang, Y.Y.; Li, Y.S.; Xu, Z.H.; Deng, J.N.; Cui, H.H.; Sun, G.X. Highly efficient resistance to chloride ion penetration and enhanced compressive strength in cement coupled with cationic polymer grafted nano-silica. Constr. Build. Mater. 2025, 478, 141420. [Google Scholar] [CrossRef]

- Zhang, B.J.; Xiong, Y.; Liu, S.; Wang, X.B.; Yan, H.B. Grafting SiO2 layer on CaCO3 whisker to enhance the mechanical properties with oil well cement. Constr. Build. Mater. 2024, 456, 139174. [Google Scholar] [CrossRef]

- Radhakrishnan, N.; Chellapandian, M.; Singh, B.S. Engineering characteristics, techno-economic feasibility and life cycle assessment of bio-fiber based green engineered cementitious composites. J. Build. Eng. 2024, 96, 110521. [Google Scholar] [CrossRef]

- Dong, B.Q.; Liu, C.X.; Shumuye, E.D.; Zhang, Y.Y.; Zhong, H.; Fang, G.H. Effect of nano-silica on mechanical properties and microstructure of engineered geopolymer composites. Cem. Concr. Compos. 2025, 156, 105849. [Google Scholar] [CrossRef]

- Liu, R.; Xiao, H.G.; Geng, J.H.; Du, J.J.; Liu, M. Effect of nano-CaCO3 and nano-SiO2 on improving the properties of carbon fibre-reinforced concrete and their pore-structure models. Constr. Build. Mater. 2020, 244, 118297. [Google Scholar] [CrossRef]

- You, J.J.; Song, Q.Y.; Tan, D.; Yang, C.; Liu, Y.F. Mechanical properties and microstructure of basalt fiber-biobased- basic magnesium sulfate cement. Cem. Concr. Compos. 2023, 137, 104934. [Google Scholar] [CrossRef]

- Pan, Y.R.; Zhang, M.; Zhang, J.; Zhu, X.Y.; Bian, H.G.; Wang, C.H. Effect of Silane Coupling Agent on Modification of Areca Fiber/Natural Latex. Materials 2020, 13, 4896. [Google Scholar] [CrossRef]

| Chemical Composition | CaO | Al2O3 | SO3 | SiO2 | MgO | Fe2O3 | TiO2 | L.o.I. |

|---|---|---|---|---|---|---|---|---|

| Proportion | 51.5 | 22.47 | 8.93 | 8.77 | 3.88 | 3.69 | 0.34 | 0.42 |

| Fine Aggregate | Voidage/% | Micro-Powder Content/% | Mud Content/% | Crushing Index/% |

|---|---|---|---|---|

| Natural river sand | 37 | 0.9 | 0.8 | 11.2 |

| Group Number | Water–Cement Ratio | The Amount of RWFs /% | Modification Method | Raw Material/g | ||||

|---|---|---|---|---|---|---|---|---|

| Sand | RWF | Cement | Water | PCE | ||||

| NWF0-45 | 0.45 | 0 | NS | 800 | 0 | 800 | 360 | 8 |

| KWF0-45 | KH560 | |||||||

| NWF10-45 | 10 | NS | 700 | 70 | 700 | 315 | 7 | |

| KWF10-45 | KH560 | |||||||

| NWF20-45 | 20 | NS | 600 | 120 | 600 | 270 | 6 | |

| KWF20-45 | KH560 | |||||||

| NWF30-45 | 30 | NS | 500 | 150 | 500 | 225 | 5 | |

| KWF30-45 | KH560 | |||||||

| NWF0-50 | 0.50 | 0 | NS | 800 | 0 | 800 | 400 | 8 |

| KWF0-50 | KH560 | |||||||

| NWF10-50 | 10 | NS | 700 | 70 | 700 | 350 | 7 | |

| KWF10-50 | KH560 | |||||||

| NWF20-50 | 20 | NS | 600 | 120 | 600 | 300 | 6 | |

| KWF20-50 | KH560 | |||||||

| NWF30-50 | 30 | NS | 500 | 150 | 500 | 250 | 5 | |

| KWF30-50 | KH560 | |||||||

| NWF0-55 | 0.55 | 0 | NS | 800 | 0 | 800 | 440 | 8 |

| KWF0-55 | KH560 | |||||||

| NWF10-55 | 10 | NS | 700 | 70 | 700 | 385 | 7 | |

| KWF10-55 | KH560 | |||||||

| NWF20-55 | 20 | NS | 600 | 120 | 600 | 330 | 6 | |

| KWF20-55 | KH560 | |||||||

| NWF30-55 | 30 | NS | 500 | 150 | 500 | 275 | 5 | |

| KWF30-55 | KH560 | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Wang, L.; Li, Y.; Li, Q.; Yue, G.; Guo, Y.; Wang, M.; Zhou, X. Effect of Nano-Modified Recycled Wood Fibers on the Micro/Macro Properties of Rapid-Hardening Sulfoaluminate Cement-Based Composites. Nanomaterials 2025, 15, 993. https://doi.org/10.3390/nano15130993

Ma C, Wang L, Li Y, Li Q, Yue G, Guo Y, Wang M, Zhou X. Effect of Nano-Modified Recycled Wood Fibers on the Micro/Macro Properties of Rapid-Hardening Sulfoaluminate Cement-Based Composites. Nanomaterials. 2025; 15(13):993. https://doi.org/10.3390/nano15130993

Chicago/Turabian StyleMa, Chunyu, Liang Wang, Yujiao Li, Qiuyi Li, Gongbing Yue, Yuanxin Guo, Meinan Wang, and Xiaolong Zhou. 2025. "Effect of Nano-Modified Recycled Wood Fibers on the Micro/Macro Properties of Rapid-Hardening Sulfoaluminate Cement-Based Composites" Nanomaterials 15, no. 13: 993. https://doi.org/10.3390/nano15130993

APA StyleMa, C., Wang, L., Li, Y., Li, Q., Yue, G., Guo, Y., Wang, M., & Zhou, X. (2025). Effect of Nano-Modified Recycled Wood Fibers on the Micro/Macro Properties of Rapid-Hardening Sulfoaluminate Cement-Based Composites. Nanomaterials, 15(13), 993. https://doi.org/10.3390/nano15130993