Smart Cement-Based Materials Reinforced with CNT-Grafted CFs: Preparation and Performance Evaluation

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

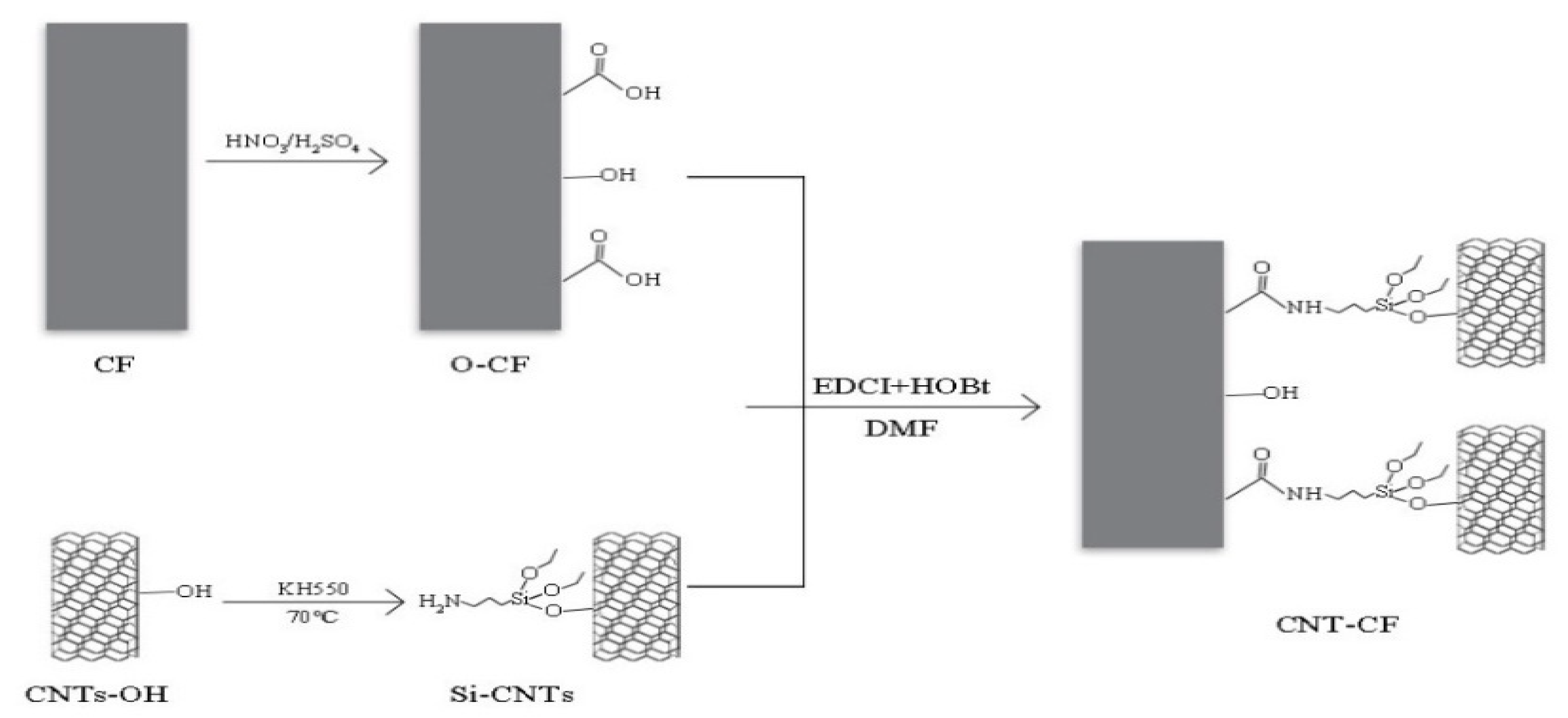

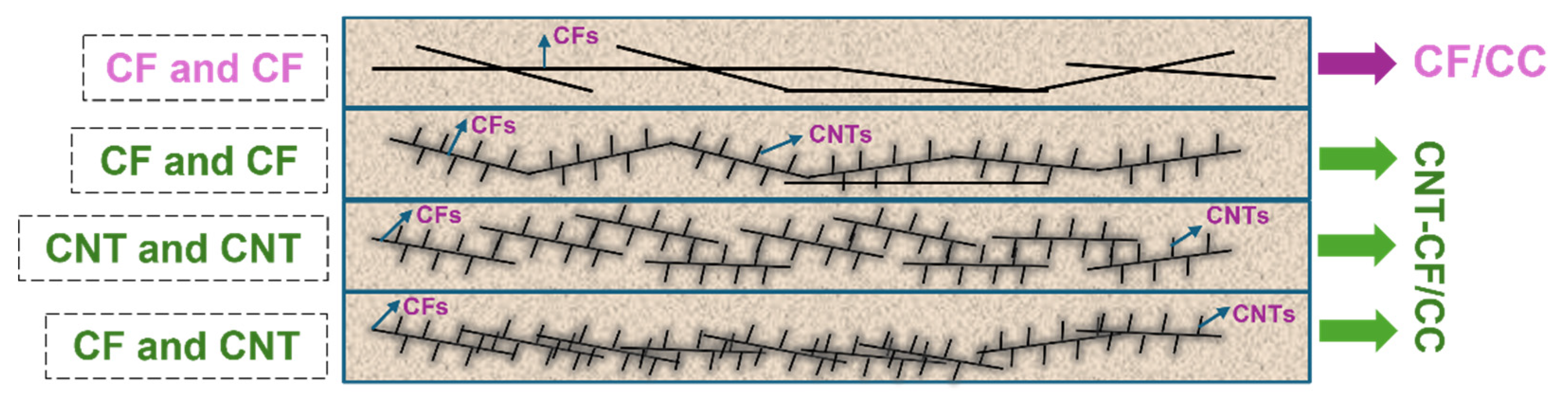

2.2. Preparation of the CNT-CF/CC

- (1)

- Pre-treatment of CFs

- (2)

- Pre-treatment of CNTs

- (3)

- Condensation reaction between CNTs and CFs

- (4)

- Molding method

2.3. Test and Measurement

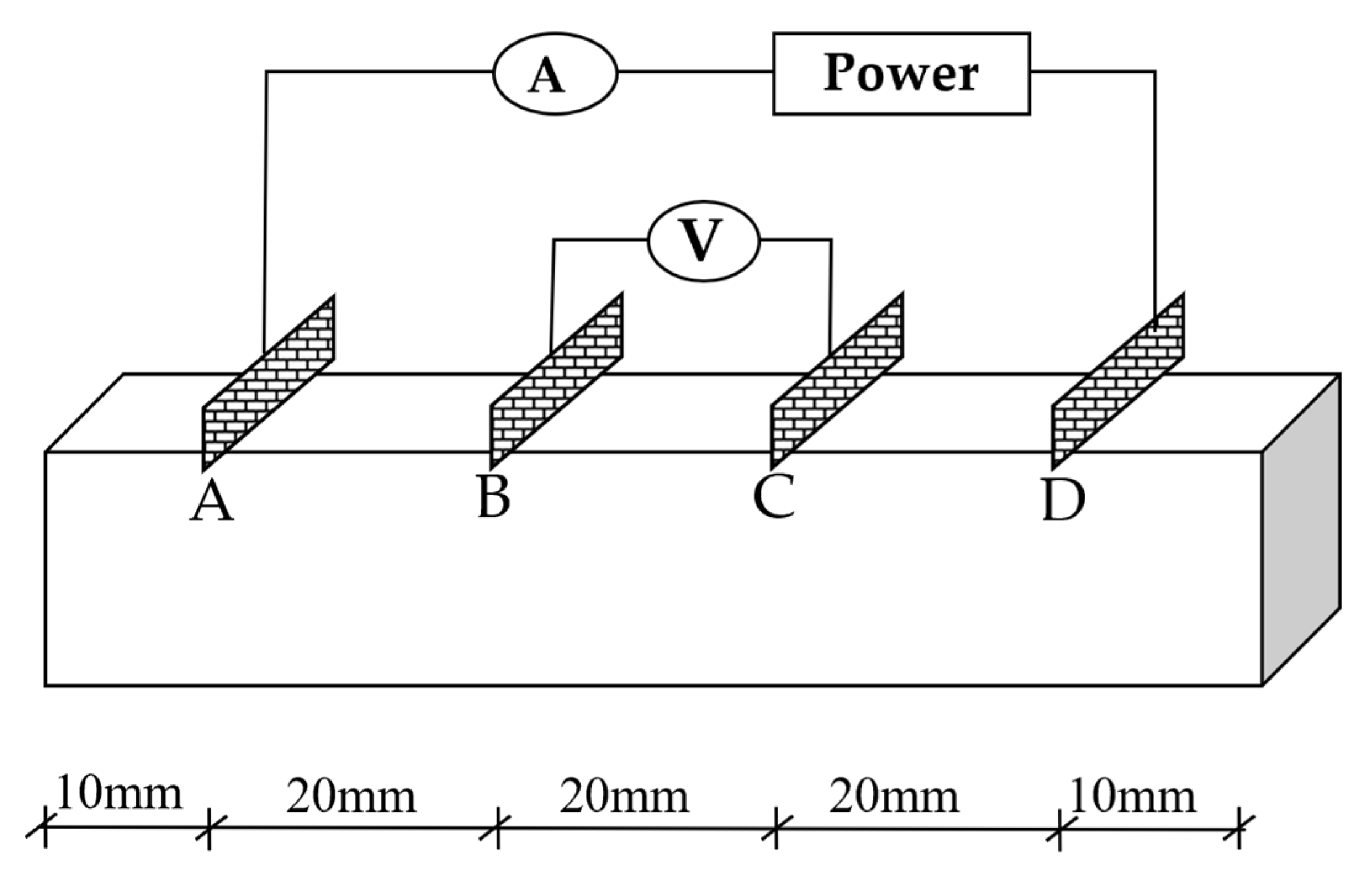

2.3.1. Conductivity

2.3.2. Sensitivity

- Humidity sensitivity

- 2.

- Temperature sensitivity

- 3.

- Piezoresistive property

2.3.3. Microscopic Characterization

3. Results and Discussion

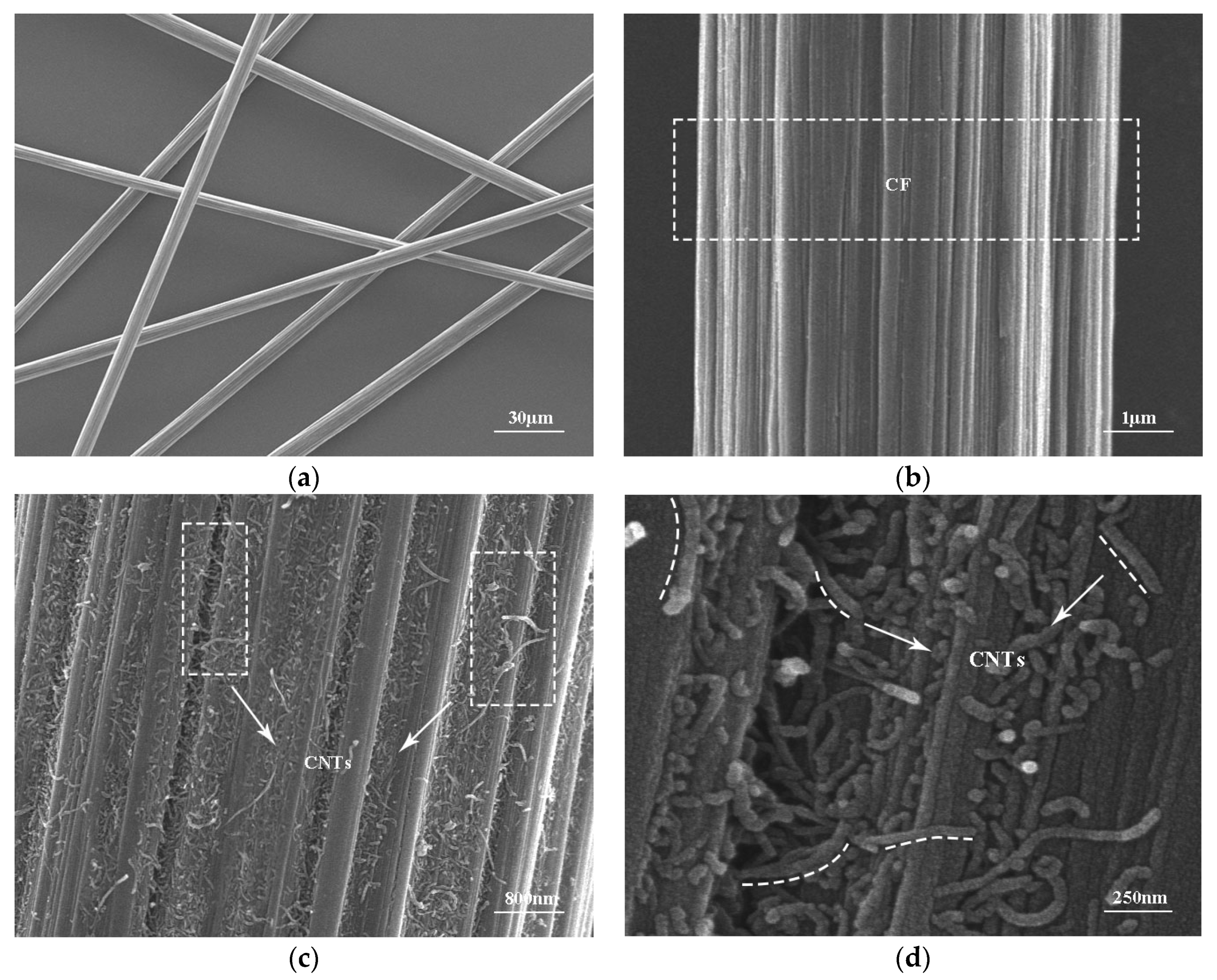

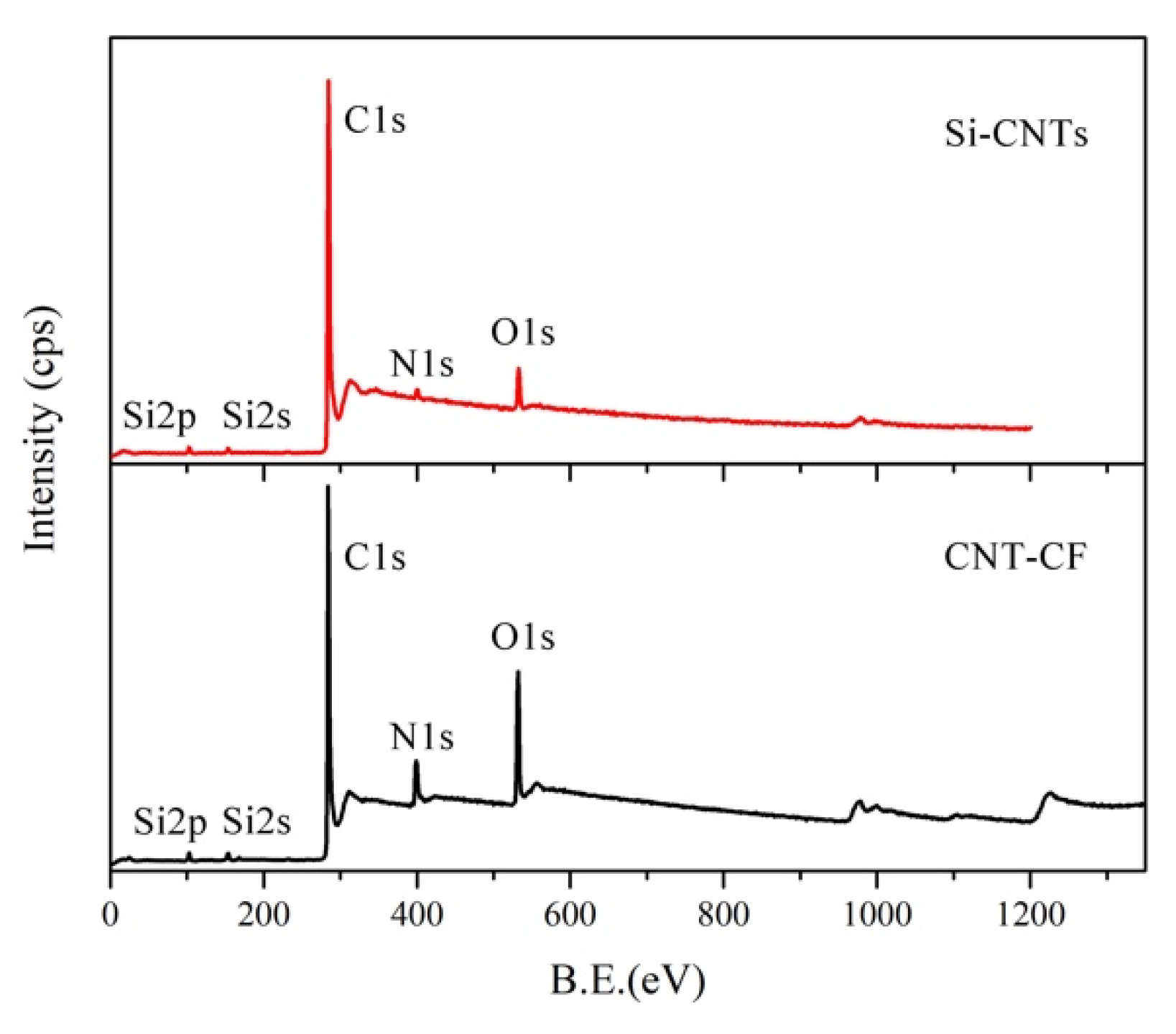

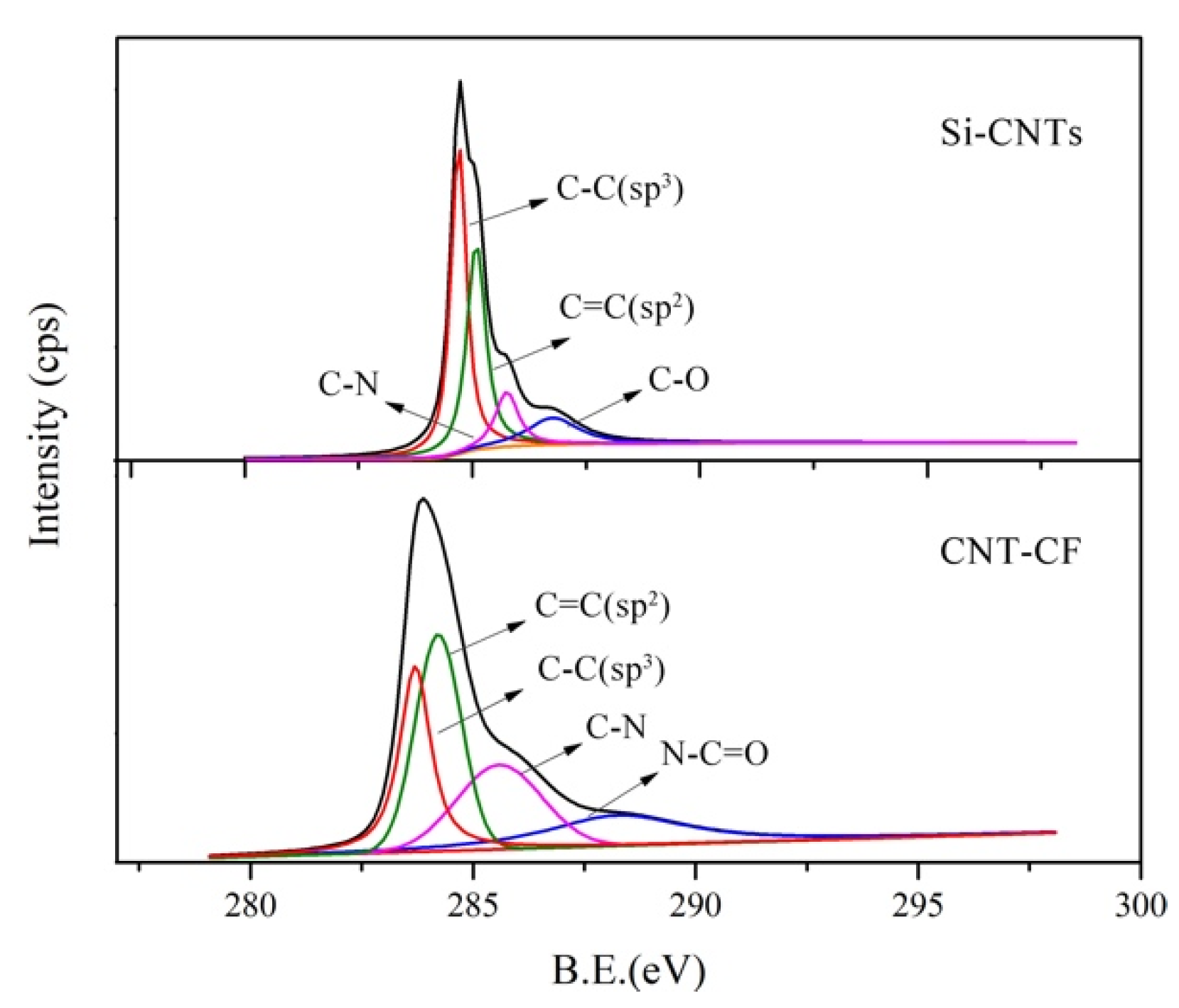

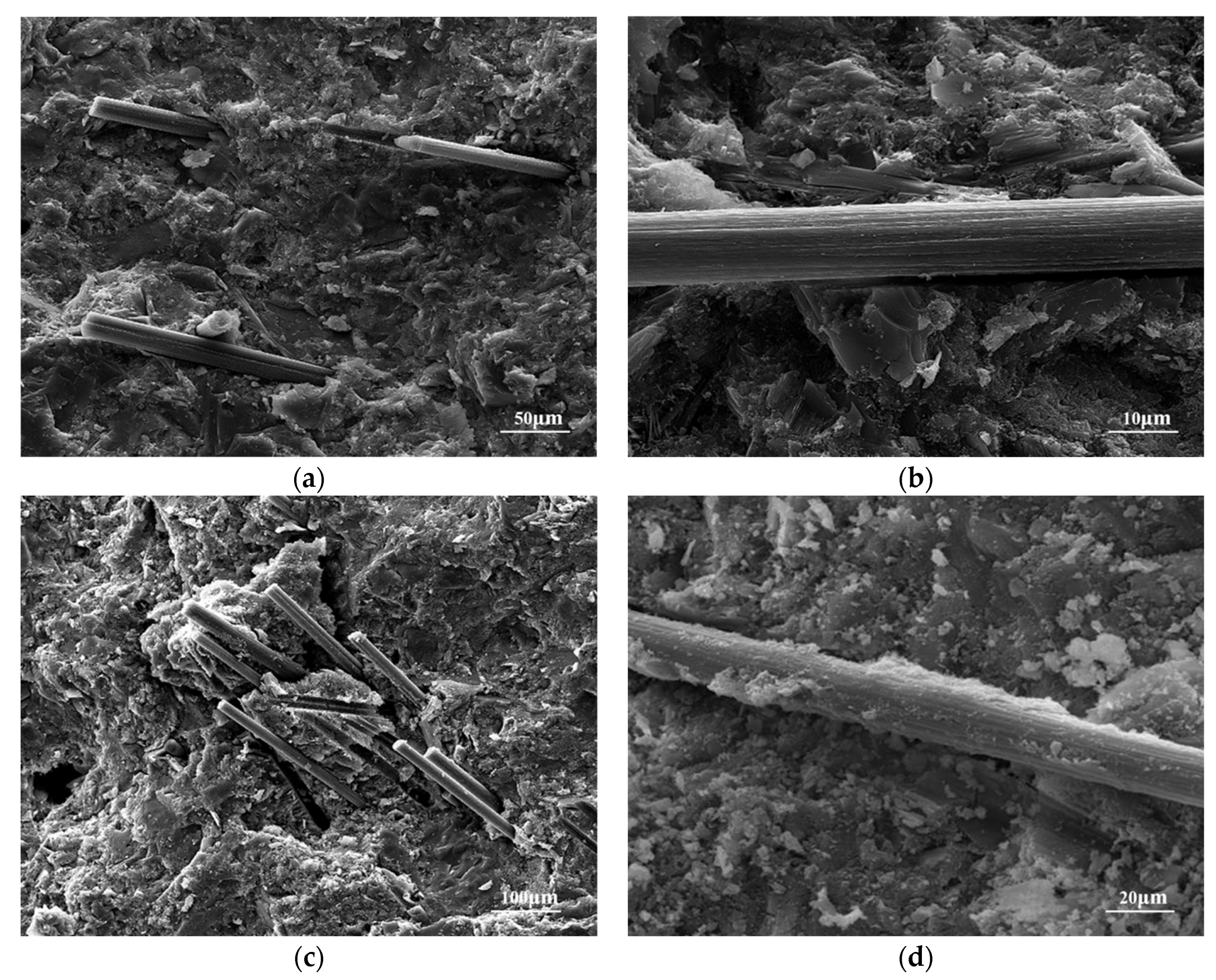

3.1. Characterization of CNT-CFs

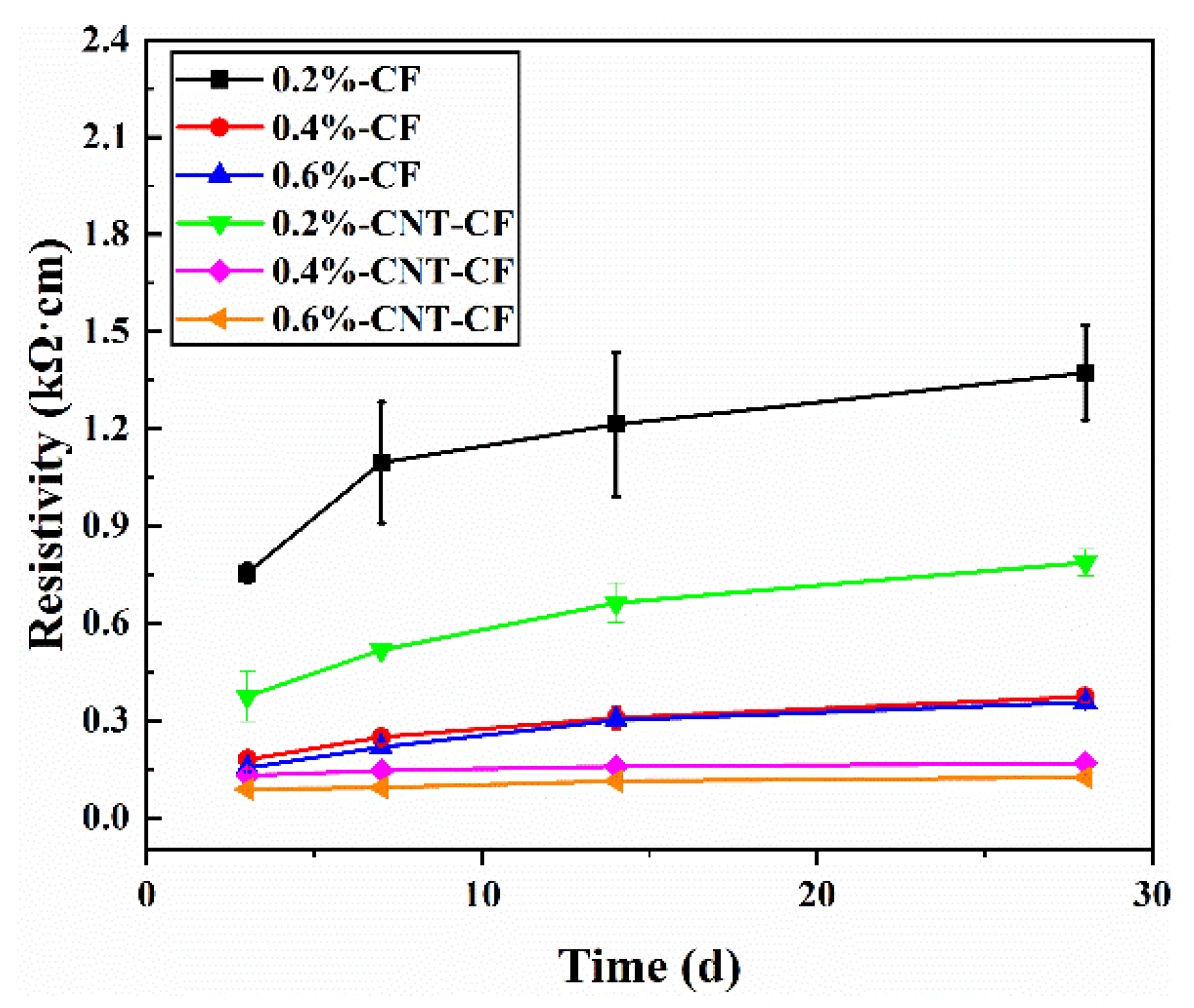

3.2. Test Results of Conductivity

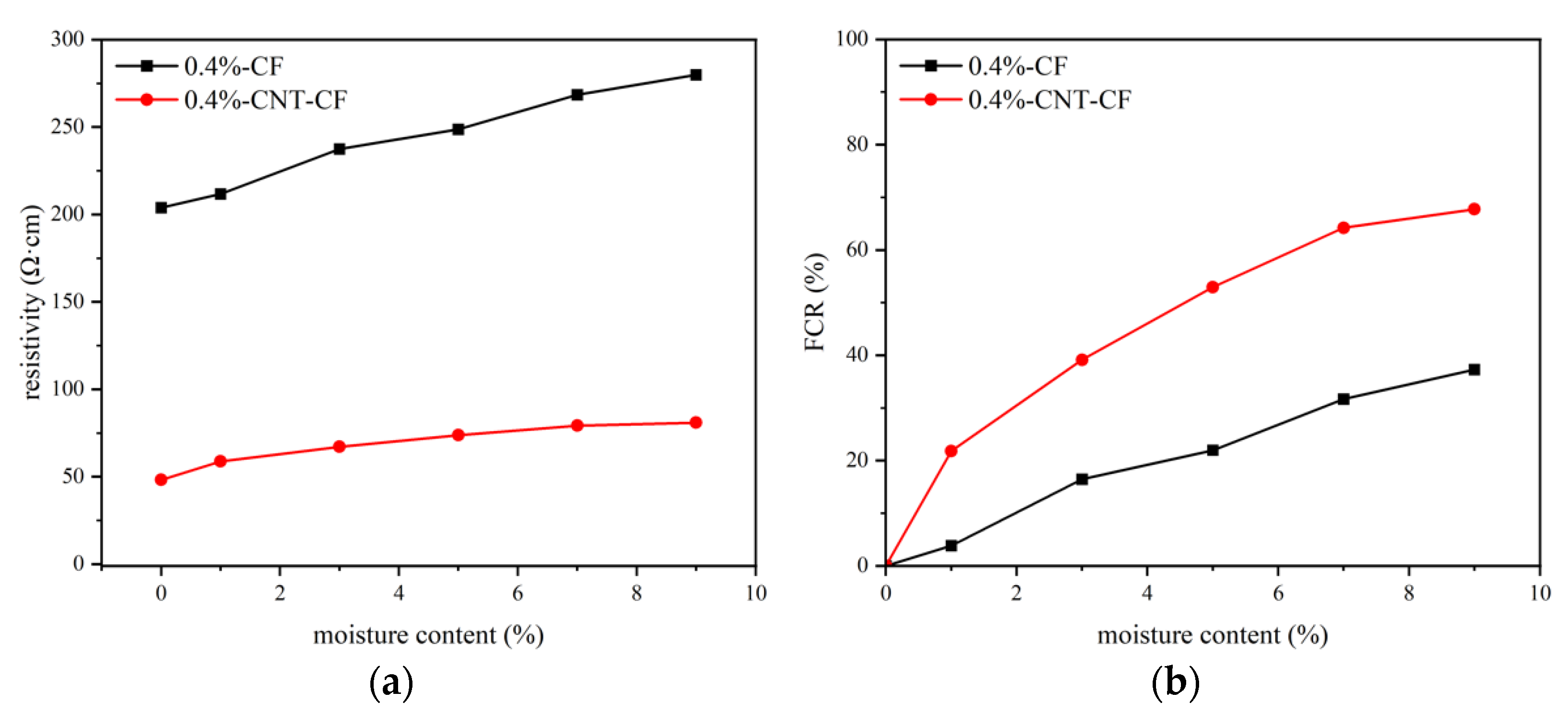

3.3. Test Results of Humidity Sensitivity

3.4. Test Results of Temperature Sensitivity

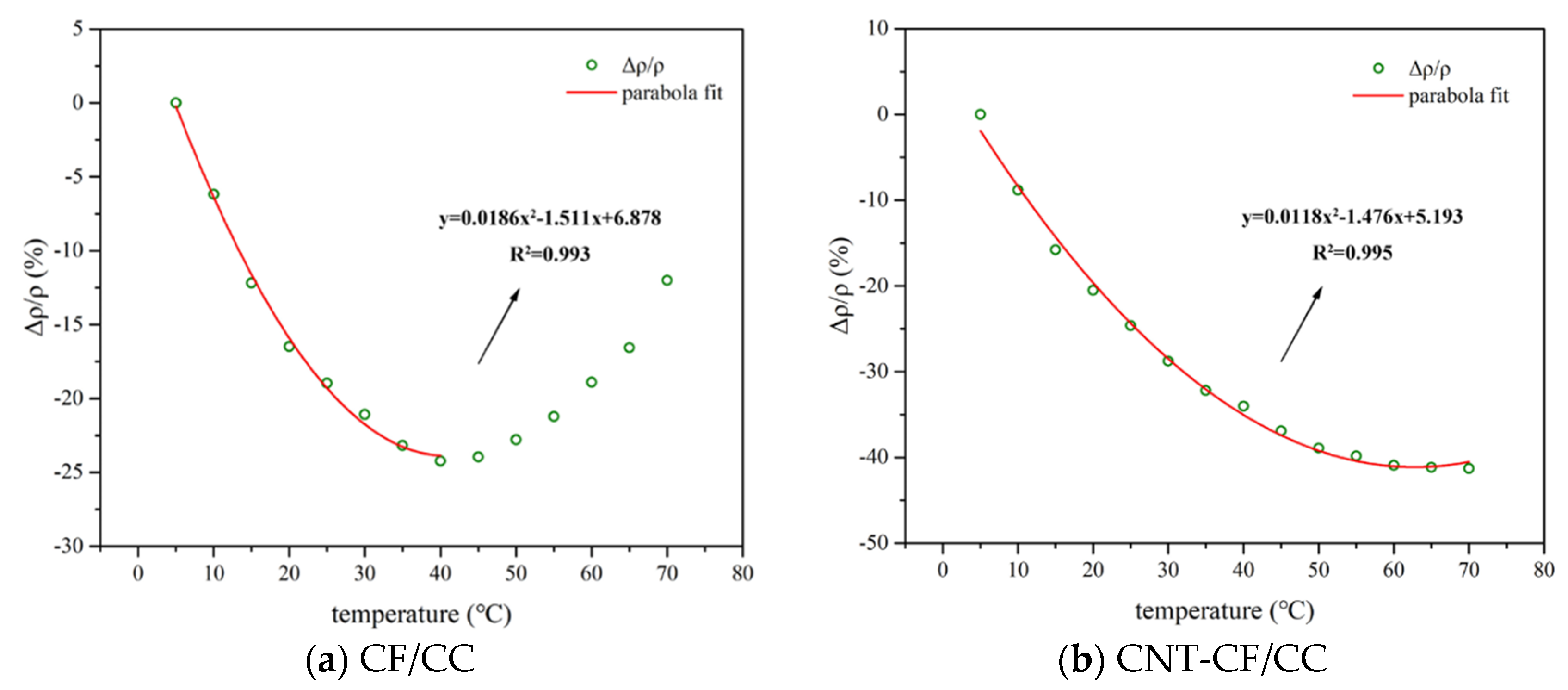

3.4.1. The Conductivity Variation in Samples with Temperature

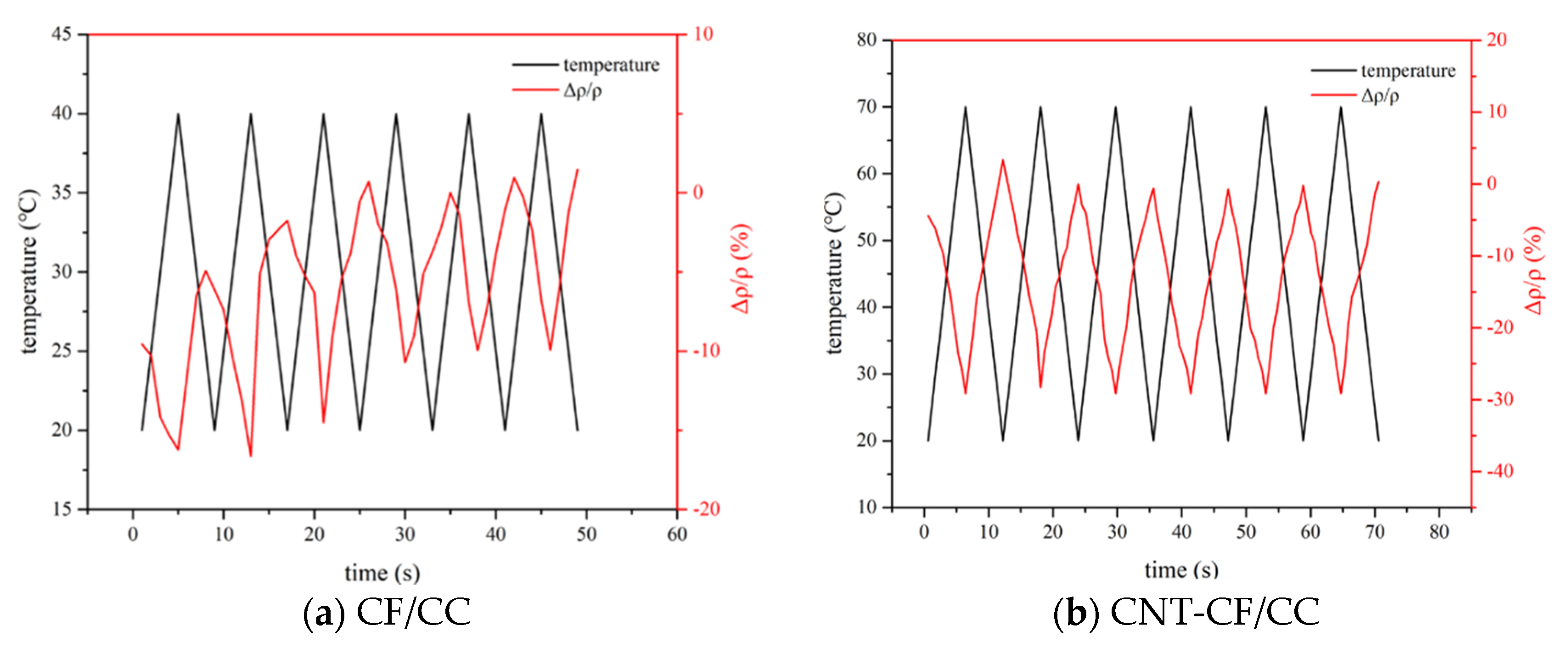

3.4.2. Effect of Temperature Cycling on the Conductivity of Different Samples

3.5. Test Results of the Piezoresistive Property

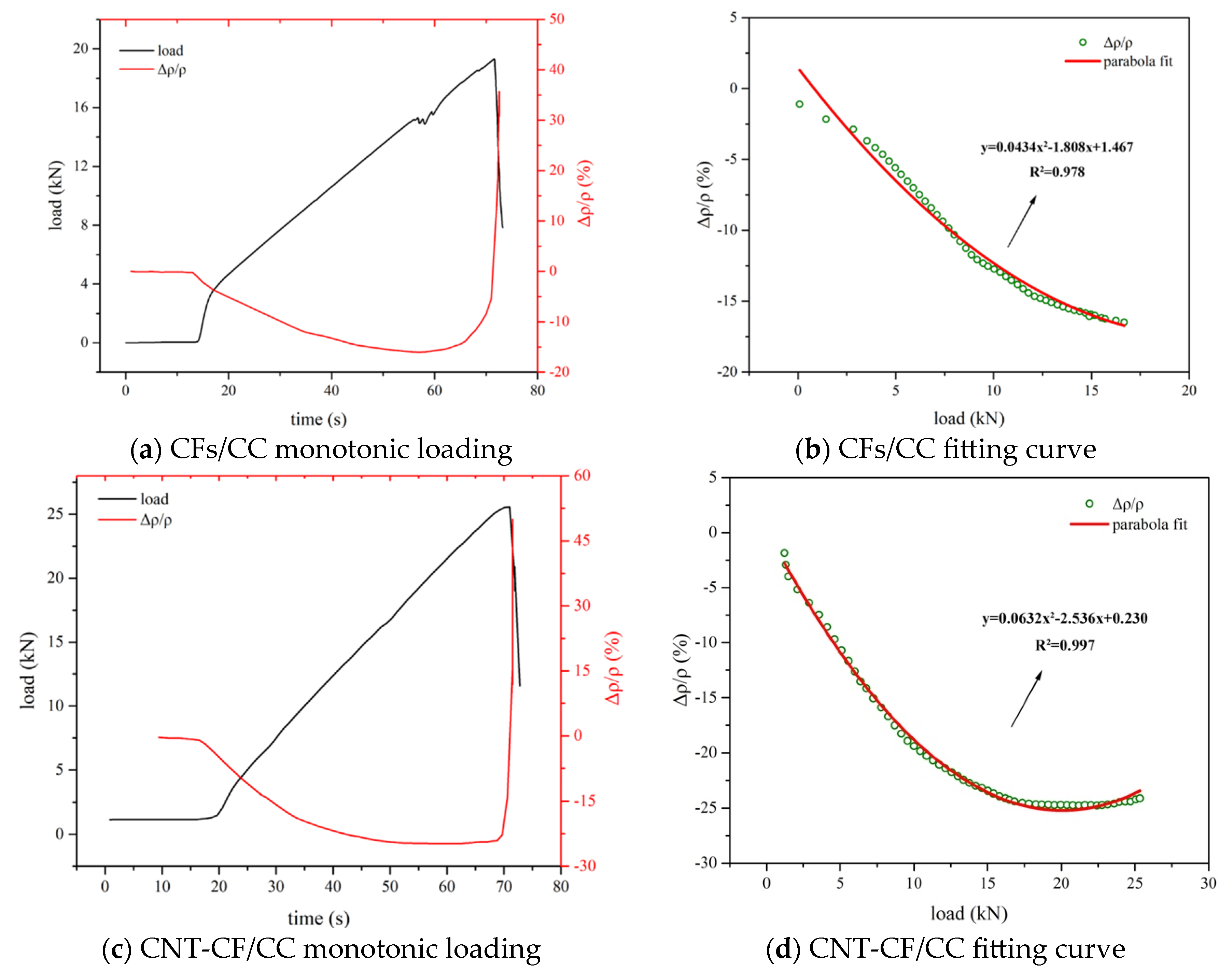

3.5.1. Effect of Monotonic Loading on the Conductivity of Various Samples

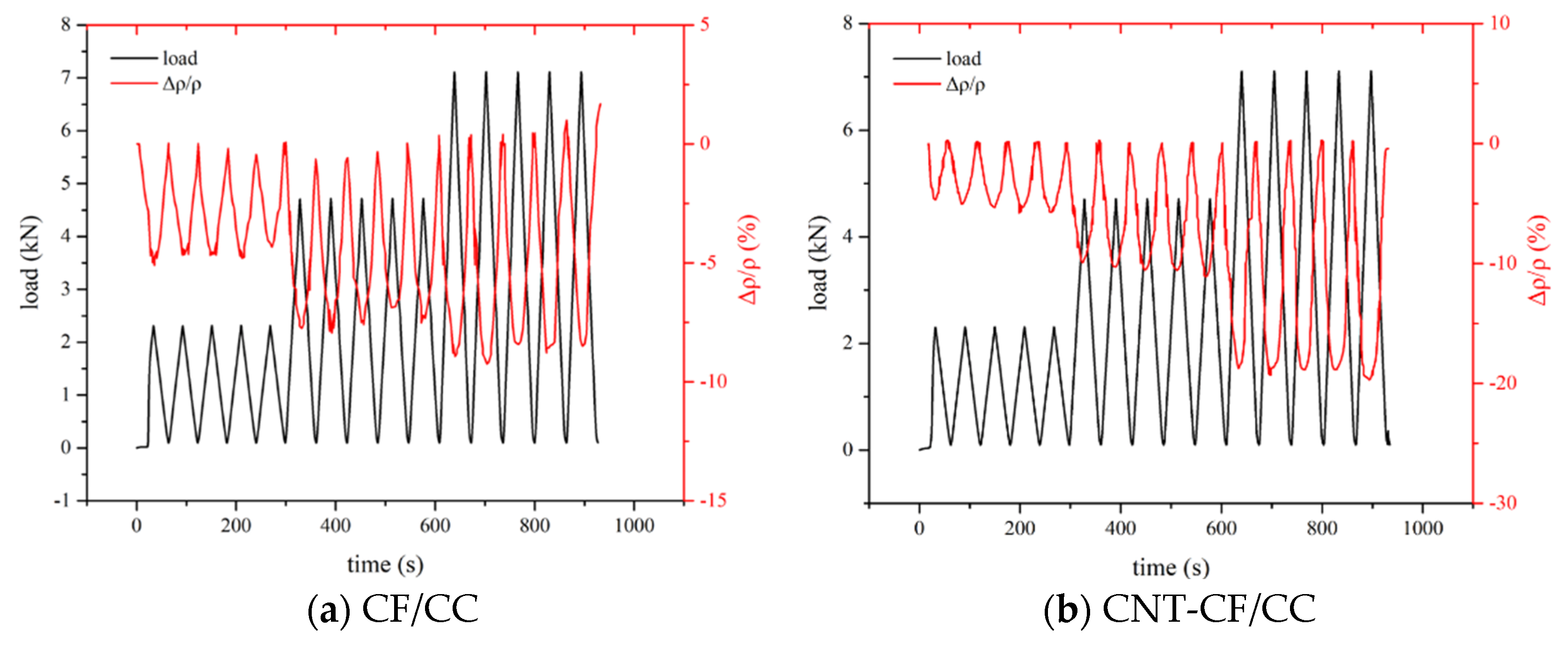

3.5.2. Effect of Cyclic Loading on the Conductivity of Various Samples

4. Discussion

5. Conclusions

- (1)

- Characterization of the CNT-CF through SEM reveals that compared to untreated CFs, the surface of the CNT-CFs was rougher. This structural feature has profound implications for the properties of the CNT-CF/CC.

- (2)

- In the test results of XPS, characteristic functional groups introduced by coupling agents on the CNTs could be seen in the spectrum, confirming the effectiveness of the grafting method. Analysis of chemical bonds within the CNT-CFs showed that strong chemical bonding connected the CNTs and CFs, successfully.

- (3)

- The resistivity of the CNT-CF/CC increased continuously during curing. Compared to the CF/CC, there is a significant improvement in conductivity for the CNT-CF/CC. The incorporation of CNTs provided additional conductive pathways, thereby improving its electrical properties.

- (4)

- Compared to the CF/CC, the CNT-CF/CC demonstrated superior moisture sensitivity. The resistivity of specimens increased with rising moisture content. Water infiltration adversely affected the conductivity of the composite by disrupting conductive pathway formation.

- (5)

- Compared to the CF/CC, the CNT-CF/CC exhibited enhanced thermal sensitivity as well. The CNT-CF/CC showed better measurement range and performance stability. The bond between the CNT-CF and the cement matrix was tighter, resulting in improved conduction stability in the test.

- (6)

- Compared to the CF/CC, the CNT-CF/CC also displayed superior piezoresistivity. Under monotonic loading, both the failure load and FCR values of the CNT-CF/CC were greater. Under cyclic loading, the curve stability remained robust, and piezoresistive performance was more stable. The anchoring connection between the CNT-CFs and the cement matrix was identified as a primary factor.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, T.; Li, Z.; Guo, J.; Gong, H.; Gu, C. Research progress on CNTs/CNFs-modified cement-based composites—A review. Constr. Build. Mater. 2019, 202, 290–307. [Google Scholar] [CrossRef]

- Olofin, I. Nano-Cement Engineered Wood-boards (NCEW)—A review on wood-cement composite, materials, new technologies and future perspectives. J. Build. Eng. 2025, 99, 111571. [Google Scholar] [CrossRef]

- Yesudhas Jayakumari, B.; Nattanmai Swaminathan, E.; Partheeban, P. A review on characteristics studies on carbon nanotubes-based cement concrete. Constr. Build. Mater. 2023, 367, 130344. [Google Scholar] [CrossRef]

- Sheikh, T.M.; Anwar, M.P.; Muthoosamy, K.; Jaganathan, J.; Chan, A.; Mohamed, A.A. The mechanics of carbon-based nanomaterials as cement reinforcement—A critical review. Constr. Build. Mater. 2021, 303, 124441. [Google Scholar] [CrossRef]

- Suchorzewski, J.; Prieto, M.; Mueller, U. An experimental study of self-sensing concrete enhanced with multi-wall carbon nanotubes in wedge splitting test and DIC. Constr. Build. Mater. 2020, 262, 120871. [Google Scholar] [CrossRef]

- Chung, K.L.; Wang, L.; Ghannam, M.; Guan, M.; Luo, J. Prediction of concrete compressive strength based on early-age effective conductivity measurement. J. Build. Eng. 2021, 35, 101998. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Razaqpur, G.; Hoult, N.A.; Hajmohammadian Baghban, M.; Jing, G. Utilization of carbon nanotubes (CNTs) in concrete for structural health monitoring (SHM) purposes: A review. Constr. Build. Mater. 2021, 309, 125137. [Google Scholar] [CrossRef]

- Jang, D.; Park, J.; Choi, S.; Bang, J.; Choi, J.; Kim, J.; Yang, B.; Jeon, H. Novel approach for crack detections and rapid repairment methods in cement-based self-heating composites for smart infrastructures. Compos. Part B Eng. 2025, 293, 112126. [Google Scholar] [CrossRef]

- Wu, H.; Li, D.; Zhao, Z.; Tan, S.; Wang, M.; Ma, Q.; Wu, J.; Cai, G. Smart cement for fire alarms and indoor climate control. Chem. Eng. J. 2024, 482, 148298. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Shen, L.; Sun, Z.; Sheng, D. Piezoresistivity of smart carbon nanotubes (CNTs) reinforced cementitious composite under integrated cyclic compression and impact. Compos. Struct. 2020, 241, 112106. [Google Scholar] [CrossRef]

- Qiao, G.; Guo, B.; Li, Z.; Ou, J.; He, Z. Corrosion behavior of a steel bar embedded in a cement-based conductive composite. Constr. Build. Mater. 2017, 134, 388–396. [Google Scholar] [CrossRef]

- Belli, A.; Mobili, A.; Bellezze, T.; Tittarelli, F. Commercial and recycled carbon/steel fibers for fiber-reinforced cement mortars with high electrical conductivity. Cem. Concr. Compos. 2020, 109, 103569. [Google Scholar] [CrossRef]

- Cheng, X.; Tian, W.; Gao, J.; He, L.; Zhang, J.; Wang, X. Effect of multiwalled carbon nanotube size on electrical properties of cement mortar composites. Mag. Concr. Res. 2023, 75, 595–606. [Google Scholar] [CrossRef]

- Danoglidis, P.A.; Konsta-Gdoutos, M.S.; Gdoutos, E.E.; Shah, S.P. Strength, energy absorption capability and self-sensing properties of multifunctional carbon nanotube reinforced mortars. Constr. Build. Mater. 2016, 120, 265–274. [Google Scholar] [CrossRef]

- Mohammad Ali Mousavi, A.S.-N.A.B.A.A.; Kamal, H.K. Cement Paste Modified by Nano-Montmorillonite and Carbon Nanotubes. ACI Mater. J. 2022, 119, 173–185. [Google Scholar] [CrossRef]

- Rennhofer, H.; Zanghellini, B. Dispersion state and damage of carbon nanotubes and carbon nanofibers by ultrasonic dispersion: A review. Nanomaterials 2021, 11, 1469. [Google Scholar] [CrossRef]

- Jintoku, H.; Matsuzawa, Y. Influence of the chemical structure of aromatic dispersants on the dispersion of carbon nanotubes. Colloids Surf. A Physicochem. Eng. Asp. 2023, 663, 131081. [Google Scholar] [CrossRef]

- Rajendran, D.; Ramalingame, R.; Adiraju, A.; Nouri, H.; Kanoun, O. Role of Solvent Polarity on Dispersion Quality and Stability of Functionalized Carbon Nanotubes. J. Compos. Sci. 2022, 6, 26. [Google Scholar] [CrossRef]

- Kim, J.-H.; Tugelbayev, A.; An, S.H.; Lee, J.U.; Chung, C.-W. Dispersion quality of aqueously dispersed MWCNT affected by step sonication process and its impact on mechanical strength of cement paste: A comparison between polycarboxylate based high range water reducers and air entraining agent. Constr. Build. Mater. 2024, 435, 136712. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Rudžionis, Ž.; Rajapriya, R. The effect of carbon nanotubes on the flowability, mechanical, microstructural and durability properties of cementitious composite: An overview. Sustainability 2020, 12, 8362. [Google Scholar] [CrossRef]

- Sobolkina, A.; Mechtcherine, V.; Khavrus, V.; Maier, D.; Mende, M.; Ritschel, M.; Leonhardt, A. Dispersion of carbon nanotubes and its influence on the mechanical properties of the cement matrix. Cem. Concr. Compos. 2012, 34, 1104–1113. [Google Scholar] [CrossRef]

- Liu, L.; Xu, J.; Yin, T.; Wang, Y.; Chu, H. Improved conductivity and piezoresistive properties of Ni-CNTs cement-based composites under magnetic field. Cem. Concr. Compos. 2021, 121, 104089. [Google Scholar] [CrossRef]

- Ma, C.; Liu, H.-Y.; Du, X.; Mach, L.; Xu, F.; Mai, Y.-W. Fracture resistance, thermal and electrical properties of epoxy composites containing aligned carbon nanotubes by low magnetic field. Compos. Sci. Technol. 2015, 114, 126–135. [Google Scholar] [CrossRef]

- Lavagna, L.; Musso, S.; Ferro, G.; Pavese, M. Cement-based composites containing functionalized carbon fibers. Cem. Concr. Compos. 2018, 88, 165–171. [Google Scholar] [CrossRef]

- Oumer, A.; Lee, C.; Ahn, E.; Gwon, S. Review on self-heating electrically conductive cementitious composites: Focus on deicing and electrical curing. Constr. Build. Mater. 2024, 439, 137232. [Google Scholar] [CrossRef]

- Chung, D.D.L. A critical review of electrical-resistance-based self-sensing in conductive cement-based materials. Carbon 2023, 203, 311–325. [Google Scholar] [CrossRef]

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Kim, G.M.; Yoon, H.N.; Lee, H.K. Autogenous shrinkage and electrical characteristics of cement pastes and mortars with carbon nanotube and carbon fiber. Constr. Build. Mater. 2018, 177, 428–435. [Google Scholar] [CrossRef]

- Kim, G.M.; Yang, B.J.; Yoon, H.N.; Lee, H.K. Synergistic effects of carbon nanotubes and carbon fibers on heat generation and electrical characteristics of cementitious composites. Carbon 2018, 134, 283–292. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, C.; Qin, J.; Su, S.; Wang, Y.; Wang, Q.; Yu, M.; Wei, H. Interfacial improvement of carbon fiber/epoxy composites using one-step method for grafting carbon nanotubes on the fibers at ultra-low temperatures. Carbon 2020, 164, 133–142. [Google Scholar] [CrossRef]

- Mirsalehi, S.A.; Ali, Y.A.; Sazgar, A. Characterization of the interface and interphase region in the multi-walled carbon nanotube modified epoxy resin/carbon fiber hybrid nanocomposite. Compos. Interfaces 2022, 29, 675–693. [Google Scholar] [CrossRef]

- Wu, B.; Xu, X.; Luo, S.; Yan, D.; Song, K.; Zhang, X.; He, F. Study on the Mechanical Properties and Strengthening Mechanism of Interface-Modified Carbon Fiber Mesh Reinforced Cement-Based Composites with SCA&HMC. Molecules 2019, 24, 3989. [Google Scholar] [CrossRef]

- Cui, H.; Jin, Z.; Zheng, D.; Tang, W.; Li, Y.; Yun, Y.; Lo, T.Y.; Xing, F. Effect of carbon fibers grafted with carbon nanotubes on mechanical properties of cement-based composites. Constr. Build. Mater. 2018, 181, 713–720. [Google Scholar] [CrossRef]

- Liu, X.; Wang, G.; Yu, J.; Liu, R.; Lyu, K.; Zuo, J.; Shah, S.P. Stress-sensitivity of carbon nanotube-grafted-carbon fiber incorporated cement-based composites. J. Build. Eng. 2023, 64, 105589. [Google Scholar] [CrossRef]

- Liu, X.; Bo, J.; Gang, L.; Junqing, Z.; Jing, X.; Shah, S.P. Research on the smart behavior of MCNT grafted CF/cement-based composites. Fuller. Nanotub. Carbon Nanostructures 2021, 29, 844–851. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Wang, S.; Xu, J.; Liu, K.; Quan, X.; Liu, B. Evaluation of industrial byproduct iron ore tailings and carbon fiber cement-based materials under sulfate freeze-thaw cycles: Durability, piezoresistivity, and microscopic mechanism. J. Build. Eng. 2024, 86, 108795. [Google Scholar] [CrossRef]

- Li, H.; Liebscher, M.; Zhao, D.; Yin, B.; Du, Y.; Yang, J.; Kaliske, M.; Mechtcherine, V. A review of carbon fiber surface modification methods for tailor-made bond behavior with cementitious matrices. Prog. Mater. Sci. 2023, 132, 101040. [Google Scholar] [CrossRef]

- Chen, Q.; Peng, Q.; Zhao, X.; Sun, H.; Wang, S.; Zhu, Y.; Liu, Z.; Wang, C.; He, X. Grafting carbon nanotubes densely on carbon fibers by poly(propylene imine) for interfacial enhancement of carbon fiber composites. Carbon 2020, 158, 704–710. [Google Scholar] [CrossRef]

- Laachachi, A.; Vivet, A.; Nouet, G.; Ben Doudou, B.; Poilâne, C.; Chen, J.; Bo Bai, J.; Ayachi, M.H. A chemical method to graft carbon nanotubes onto a carbon fiber. Mater. Lett. 2008, 62, 394–397. [Google Scholar] [CrossRef]

- Liebscher, M.; Tzounis, L.; Junger, D.; Dinh, T.T.; Mechtcherine, V. Electrical Joule heating of cementitious nanocomposites filled with multi-walled carbon nanotubes: Role of filler concentration, water content, and cement age. Smart Mater. Struct. 2020, 29, 125019. [Google Scholar] [CrossRef]

- Del Moral, B.; Baeza, F.J.; Navarro, R.; Galao, O.; Zornoza, E.; Vera, J.; Farcas, C.; Garcés, P. Temperature and humidity influence on the strain sensing performance of hybrid carbon nanotubes and graphite cement composites. Constr. Build. Mater. 2021, 284, 122786. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Ansari, R. Thermomechanical investigation of unidirectional carbon fiber-polymer hybrid composites containing CNTs. Int. J. Mech. Mater. Des. 2019, 15, 471–488. [Google Scholar] [CrossRef]

- Ying, W.; Zhang, G.; Liu, Q.; Yang, Y. Predicting the time-dependent hydro-thermo-mechanical properties of cement-based materials based on thermodynamic and multi-scale modeling. Constr. Build. Mater. 2021, 276, 122155. [Google Scholar] [CrossRef]

- Wang, L.; Shen, A.; Wang, W.; Yang, J.; He, Z.; Zhijie, T. Graphene/nickel/carbon fiber composite conductive asphalt: Optimization, electrical properties and heating performance. Case Stud. Constr. Mater. 2022, 17, e01402. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Notani, M.A.; Kazemiyan Zadeh, A.; Nahvi, A.; Sassani, A.; Ceylan, H. Electrically conductive asphalt concrete: An alternative for automating the winter maintenance operations of transportation infrastructure. Compos. Part B Eng. 2019, 173, 106985. [Google Scholar] [CrossRef]

- Buasiri, T.; Habermehl-Cwirzen, K.; Krzeminski, L.; Cwirzen, A. Sensing mechanisms of nanomodified Portland cement composites. Cem. Concr. Compos. 2024, 151, 105602. [Google Scholar] [CrossRef]

- Tugelbayev, A.; Kim, J.-H.; Lee, J.U.; Chung, C.-W. The effect of acid treated multi-walled carbon nanotubes on the properties of cement paste prepared by ultrasonication with polycarboxylate ester. J. Build. Eng. 2023, 64, 105638. [Google Scholar] [CrossRef]

- Yan, X.; Cui, H.; Qin, Q.; Tang, W.; Zhou, X. Study on Utilization of Carboxyl Group Decorated Carbon Nanotubes and Carbonation Reaction for Improving Strengths and Microstructures of Cement Paste. Nanomaterials 2016, 6, 153. [Google Scholar] [CrossRef]

- Mardani, M.; Hossein Hosseini Lavassani, S.; Adresi, M.; Rashidi, A. Piezoresistivity and mechanical properties of self-sensing CNT cementitious nanocomposites: Optimizing the effects of CNT dispersion and surfactants. Constr. Build. Mater. 2022, 349, 128127. [Google Scholar] [CrossRef]

- Zhang, L.; Ding, S.; Dong, S.; Li, Z.; Ouyang, J.; Yu, X.; Han, B. Piezoresistivity, mechanisms and model of cement-based materials with CNT/NCB composite fillers. Mater. Res. Express 2017, 4, 125704. [Google Scholar] [CrossRef]

- Lin, Z.; Tang, X.; Jin, W.; Zhao, X.; Zhang, J.; Chu, H.; Jiang, L. Piezoresistive performance of cement-based composites with two-dimensional MXene subjected to various loading conditions and water content. Cem. Concr. Compos. 2024, 150, 105554. [Google Scholar] [CrossRef]

| Density | Standard Consistency Water Consumption | Specific Surface Area | Condensation Time | Flexural Strength | Compressive Strength | |||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3 d | 28 d | 3 d | 28 d | |||

| 3.2 g/cm3 | 0.273 | 350 m2/kg | 182 min | 225 min | 5.3 Mpa | 9.4 Mpa | 22.7 Mpa | 50.2 Mpa |

| Length | Diameter | Tensile Strength | Tensile Modulus | Density | Carbon Content | Resistivity |

|---|---|---|---|---|---|---|

| 5 mm | 7 μm | 4.53 Gpa | 230 Gpa | 1.79 g/cm3 | 93% | 1.6 μΩ·cm |

| Purity (wt%) | Outer Diameter (nm) | Length (μm) | Specific Surface Area (m2/g) | Ash Content (wt.%) | Conductivity (s/cm) | -OH Content (wt.%) |

|---|---|---|---|---|---|---|

| >95 | 5–15 | 0.5–2 | 0.27 | ~2.1 | >100 | 5.58 wt.% |

| Sample | Cement (g) | Water (g) | CFs (wt.%) | CNT-CFs (wt.%) | Dispersant-CF (wt.%) | Defoamer (g) |

|---|---|---|---|---|---|---|

| CF/CC | 200 | 80 | 0.2 | 0 | 0.2 | 0.26 |

| 0.4 | 0 | 0.4 | ||||

| 0.6 | 0 | 0.6 | ||||

| CNT -CF/CC | 200 | 80 | 0 | 0.2 | 0.2 | 0.26 |

| 0 | 0.4 | 0.4 | ||||

| 0 | 0.6 | 0.6 |

| Sample | 15%- Failure Load | 30%- Failure Load | 45%- Failure Load | Average |

|---|---|---|---|---|

| CF/CC | 0.65 | 0.53 | 0.40 | 0.53 |

| CNT-CF/CC | 0.82 | 0.73 | 0.71 | 0.75 |

| Sample | Best Resistivity | Best SES | Best Improvement on SES |

|---|---|---|---|

| Oriented technique [22] | about 104 Ω·cm | 2.36 | Increase by 35% |

| Grafting technique [35] | about 0.4 kΩ·cm | 0.22 | Decrease by 27.76% |

| Grafting technique (this article) | 0.12 kΩ·cm | 0.82 | Increase by 77.50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Guo, X.; Zuo, J.; Liu, A.; Li, H.; Fu, F.; Wang, G.; Hu, Q.; Shah, S.P. Smart Cement-Based Materials Reinforced with CNT-Grafted CFs: Preparation and Performance Evaluation. Nanomaterials 2025, 15, 823. https://doi.org/10.3390/nano15110823

Liu X, Guo X, Zuo J, Liu A, Li H, Fu F, Wang G, Hu Q, Shah SP. Smart Cement-Based Materials Reinforced with CNT-Grafted CFs: Preparation and Performance Evaluation. Nanomaterials. 2025; 15(11):823. https://doi.org/10.3390/nano15110823

Chicago/Turabian StyleLiu, Xiaoyan, Xiangwei Guo, Junqing Zuo, Aihua Liu, Haifeng Li, Feng Fu, Gangao Wang, Qianwen Hu, and Surendra P. Shah. 2025. "Smart Cement-Based Materials Reinforced with CNT-Grafted CFs: Preparation and Performance Evaluation" Nanomaterials 15, no. 11: 823. https://doi.org/10.3390/nano15110823

APA StyleLiu, X., Guo, X., Zuo, J., Liu, A., Li, H., Fu, F., Wang, G., Hu, Q., & Shah, S. P. (2025). Smart Cement-Based Materials Reinforced with CNT-Grafted CFs: Preparation and Performance Evaluation. Nanomaterials, 15(11), 823. https://doi.org/10.3390/nano15110823