Atomistic Observation of Defect Generation and Microstructural Evolution in Polycrystalline FeCrAl Alloys Under Different Irradiation Conditions

Abstract

1. Introduction

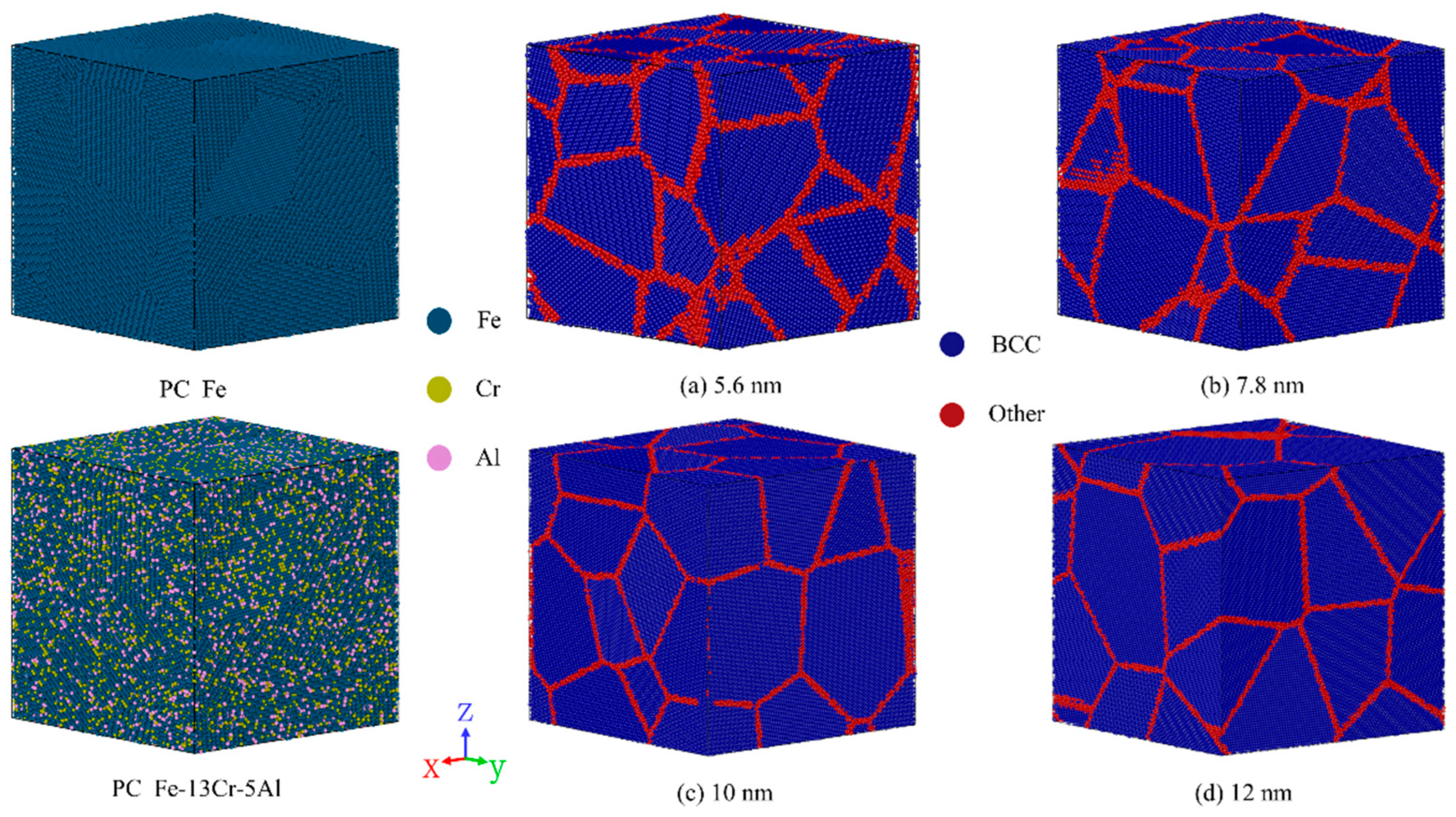

2. Model and Methodology

2.1. Atomic-Scale Model of PC FeCrAl Alloy

2.2. Simulation Method and Conditions

2.3. Method for Determining the Evolution Mechanism of Defect Structures

3. Results and Discussion

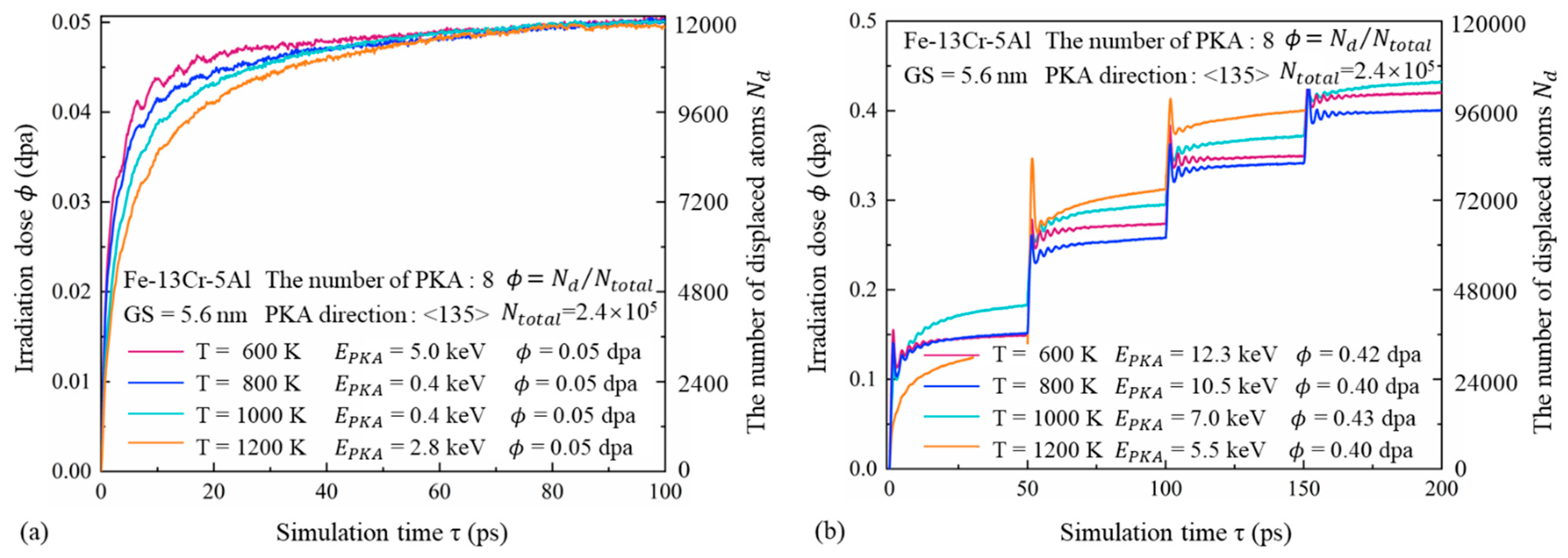

3.1. Quantitative Analysis of Radiation Damage Dose

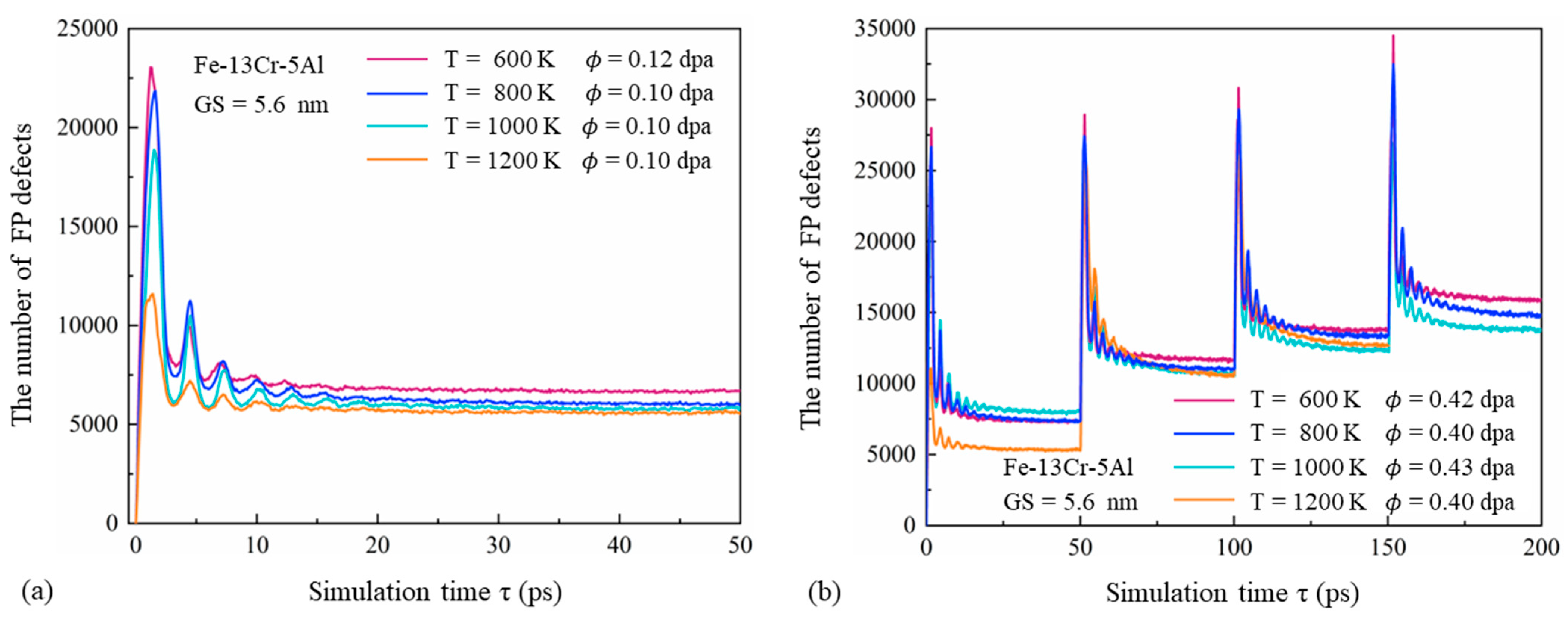

3.2. Displacement Cascade Evolution and Defect Number

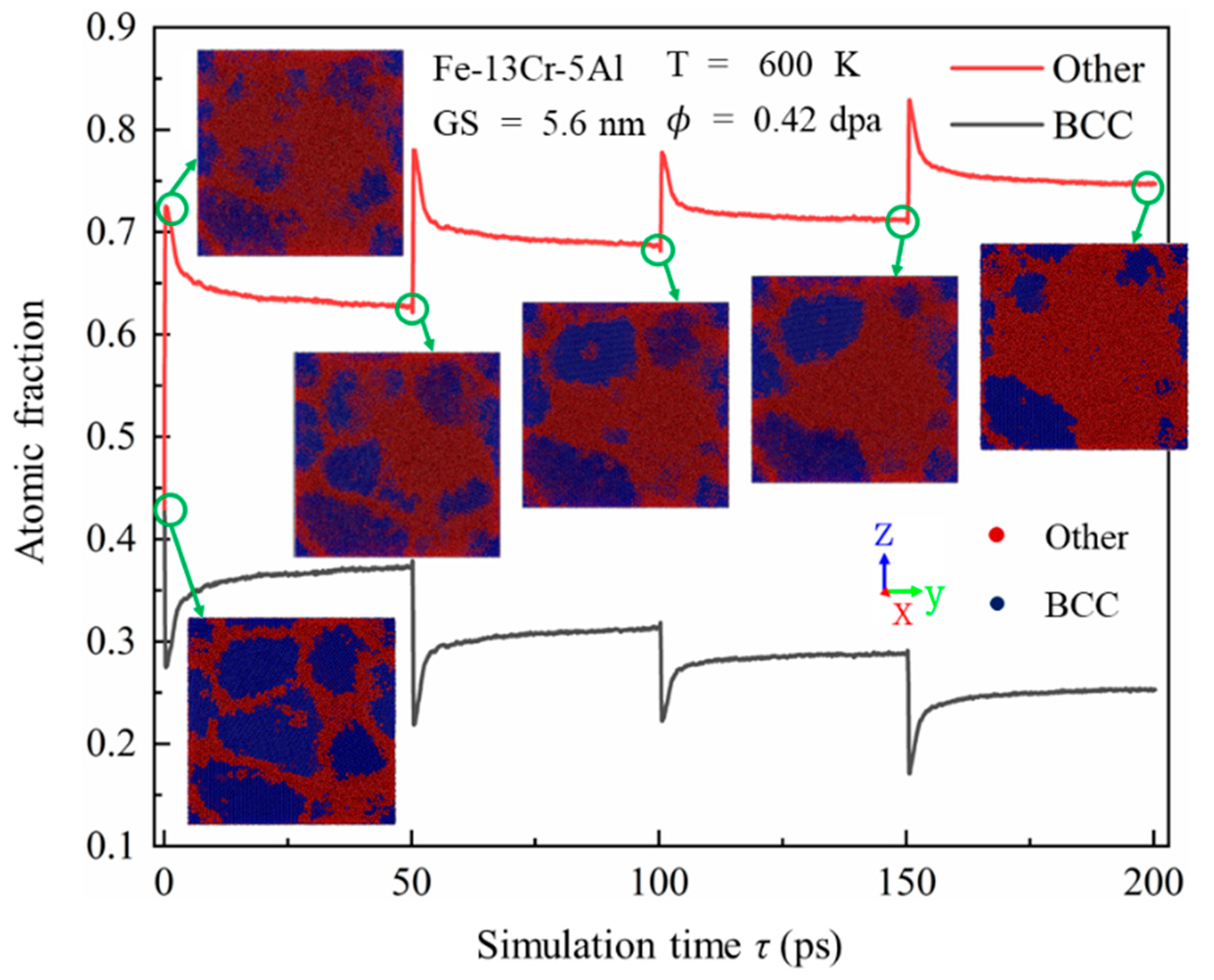

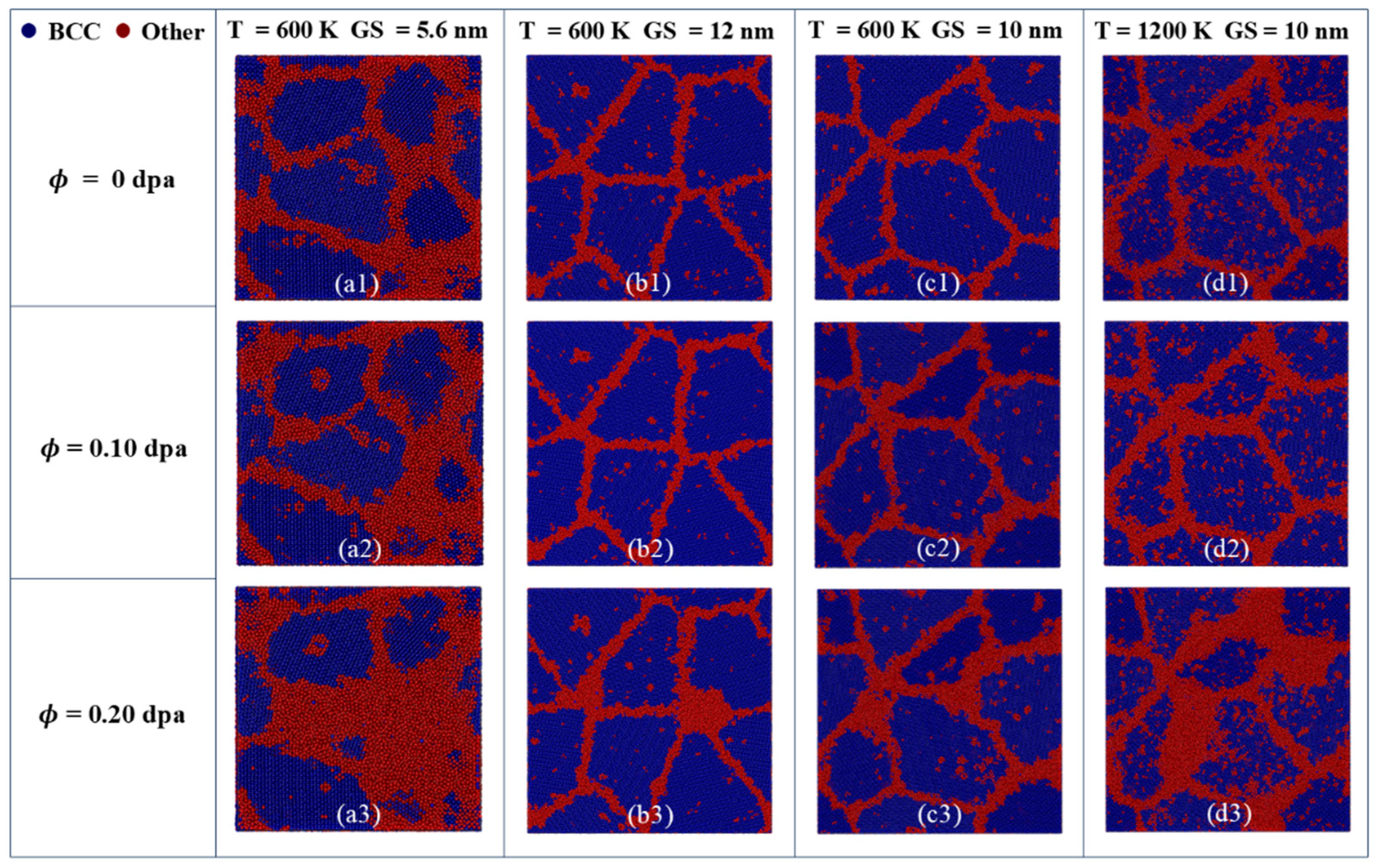

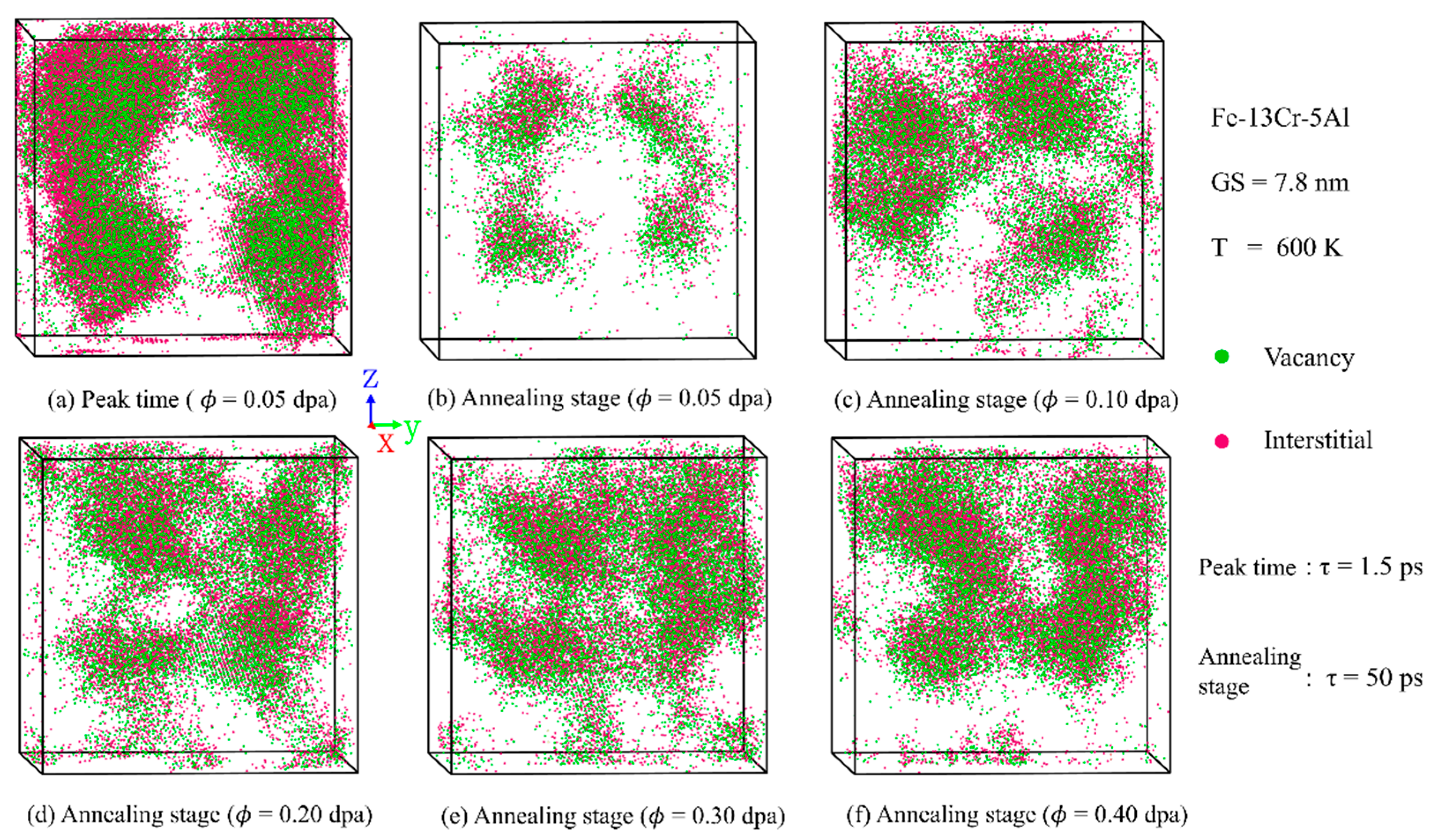

3.2.1. Cascade Evolution Under Different Irradiation Doses

Temperature Effect

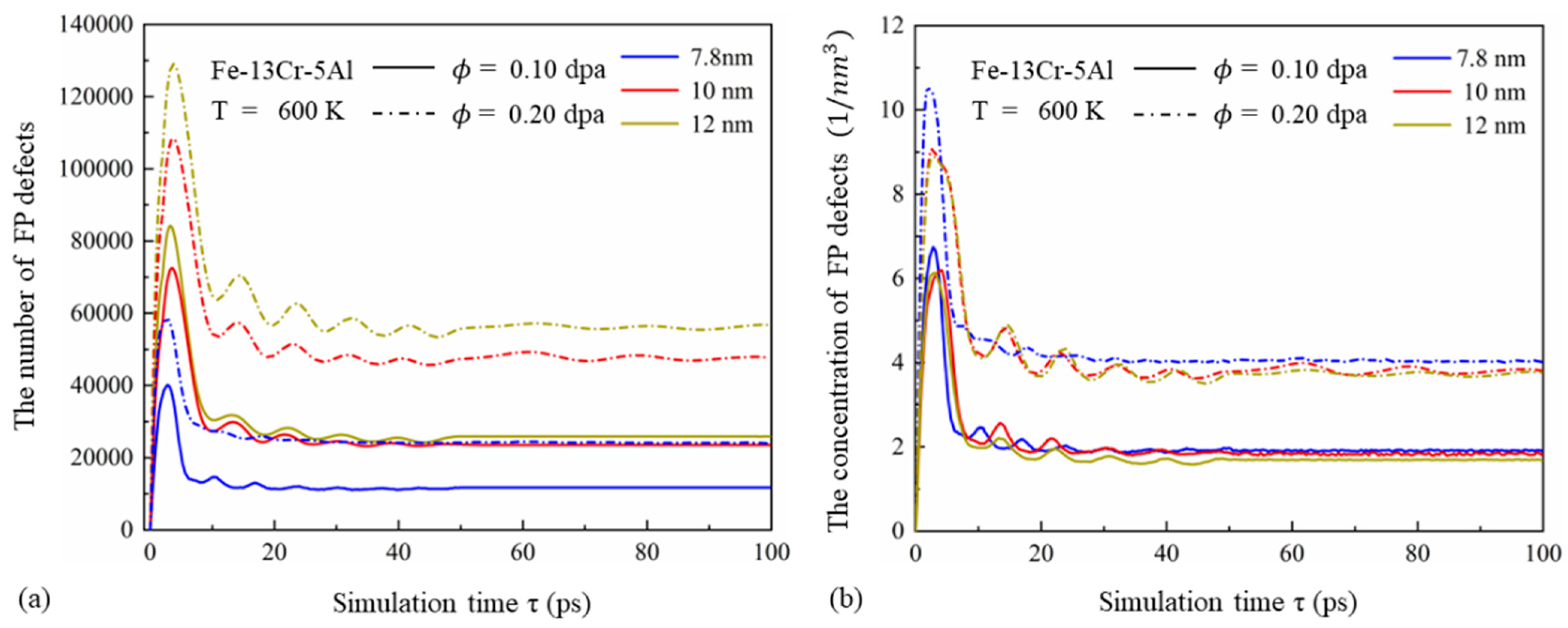

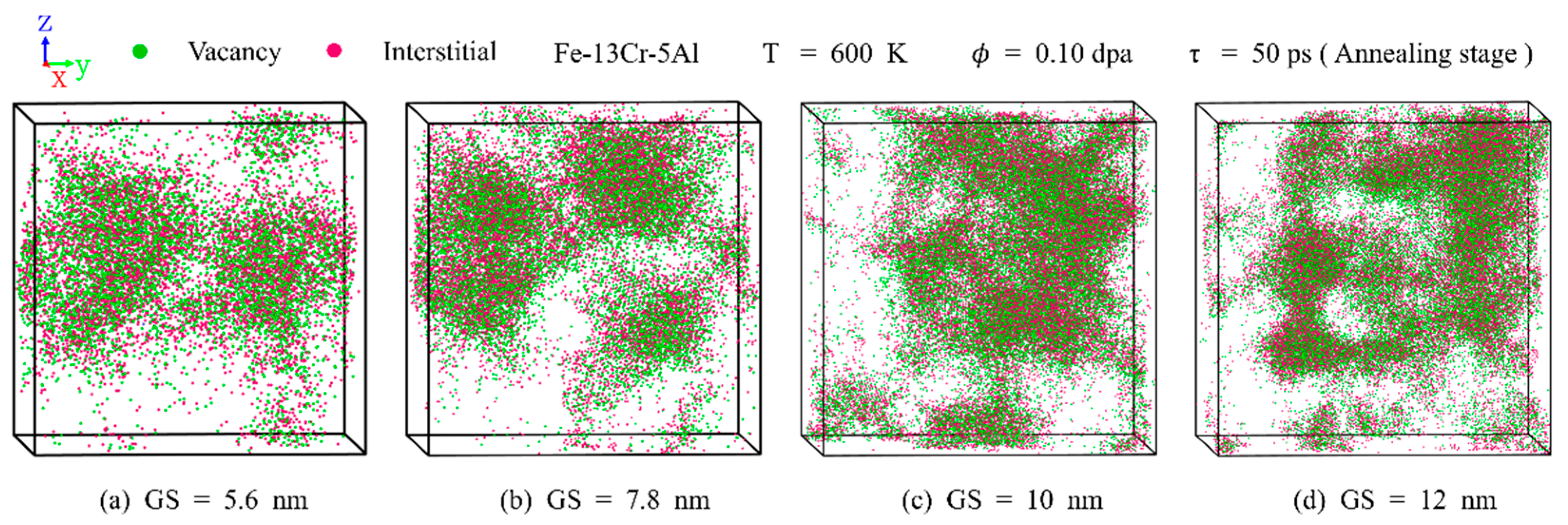

Grain Size Effect

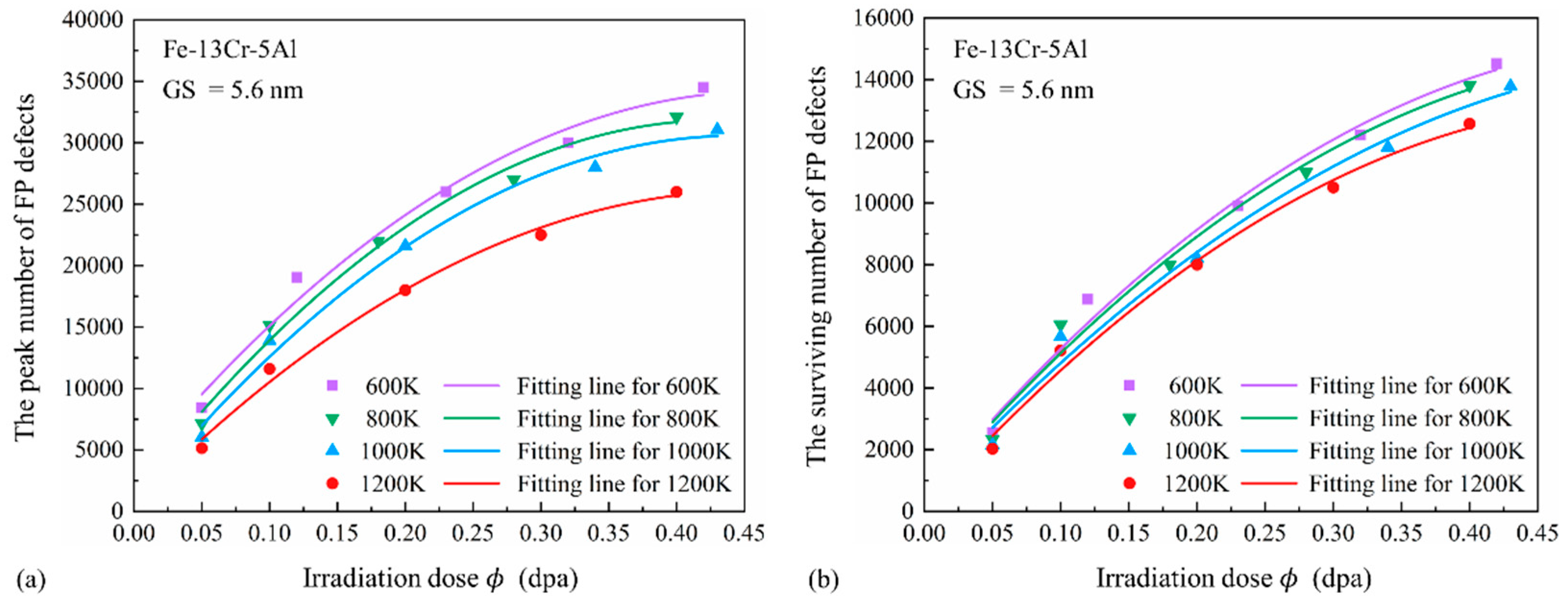

3.2.2. Influence of Irradiation Dose and Temperature on Defect Number

Peak and Surviving FP Defects

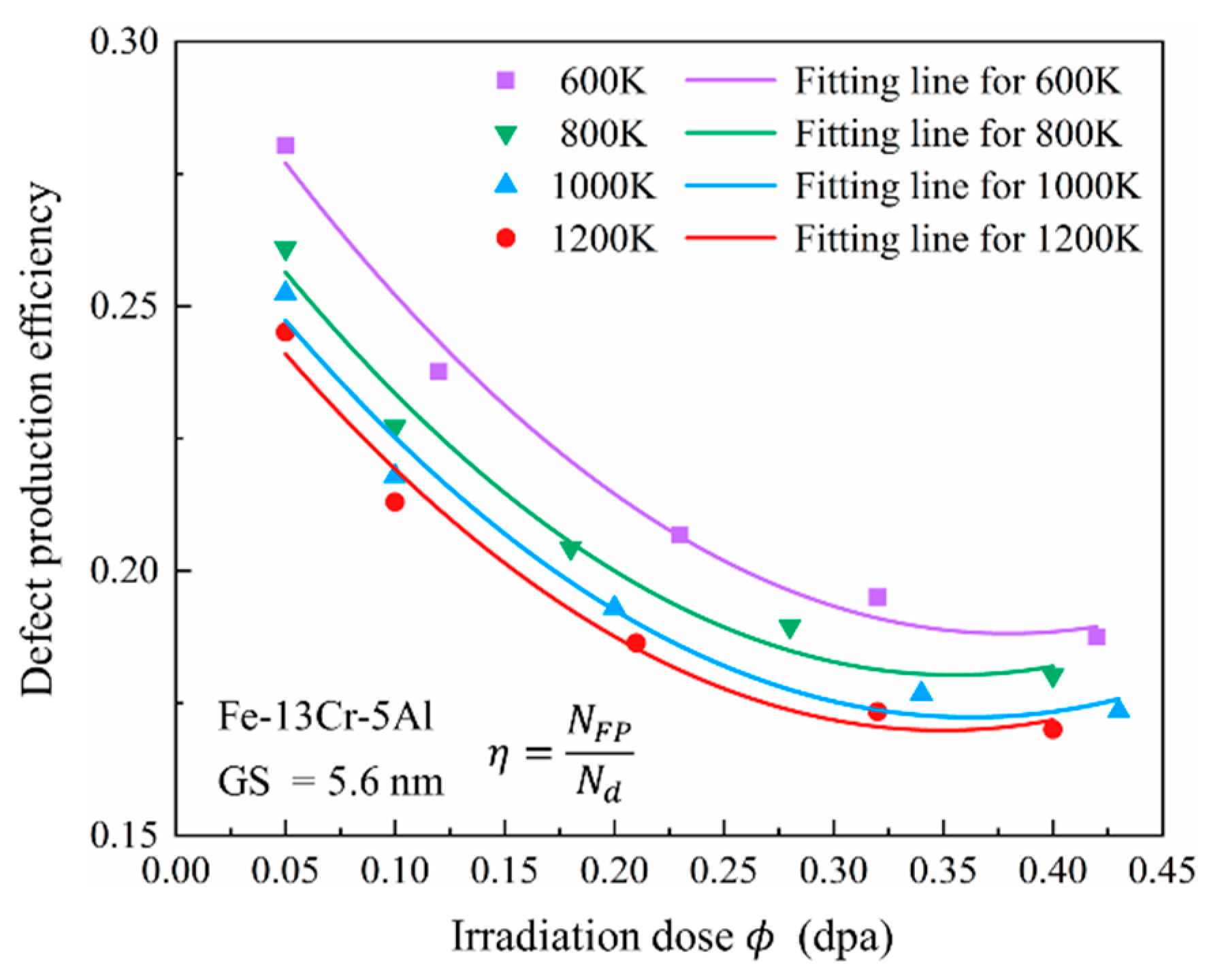

Defect Production Efficiency

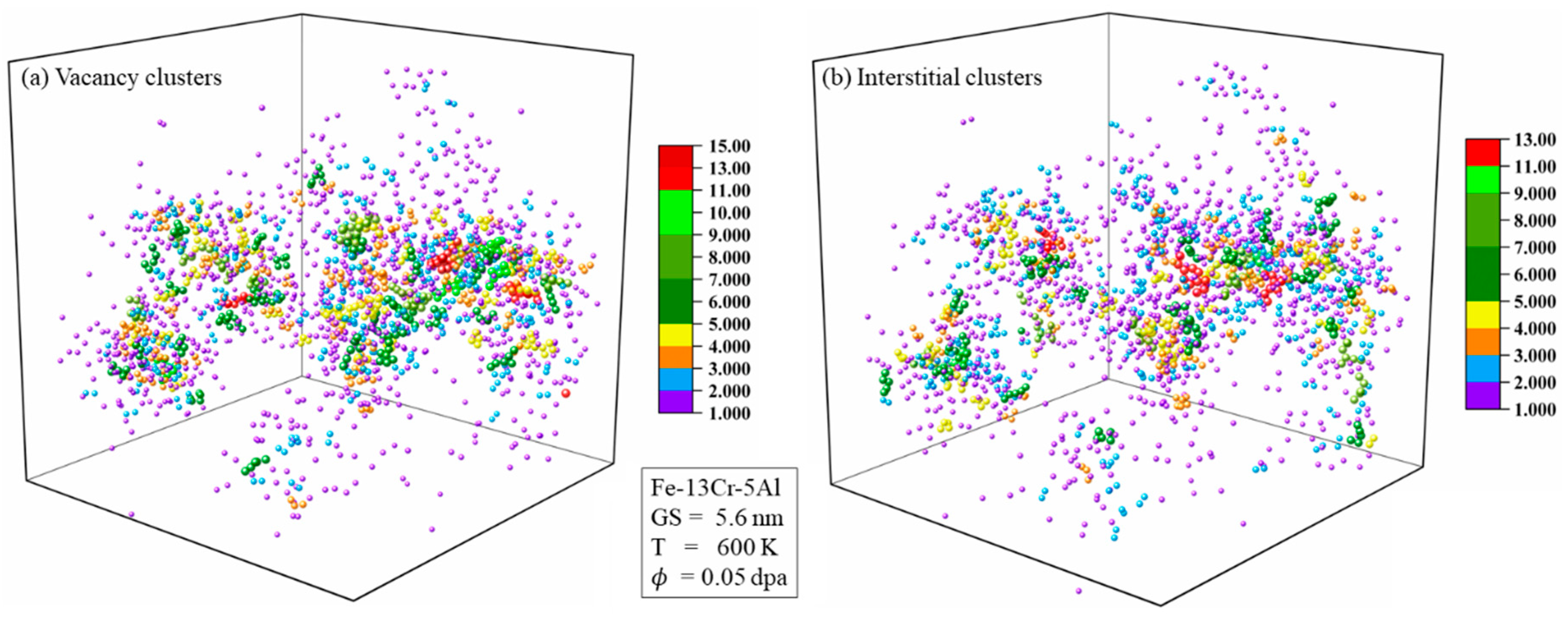

3.3. Distribution of Point Defects and Defect Clusters

3.3.1. Point Defects

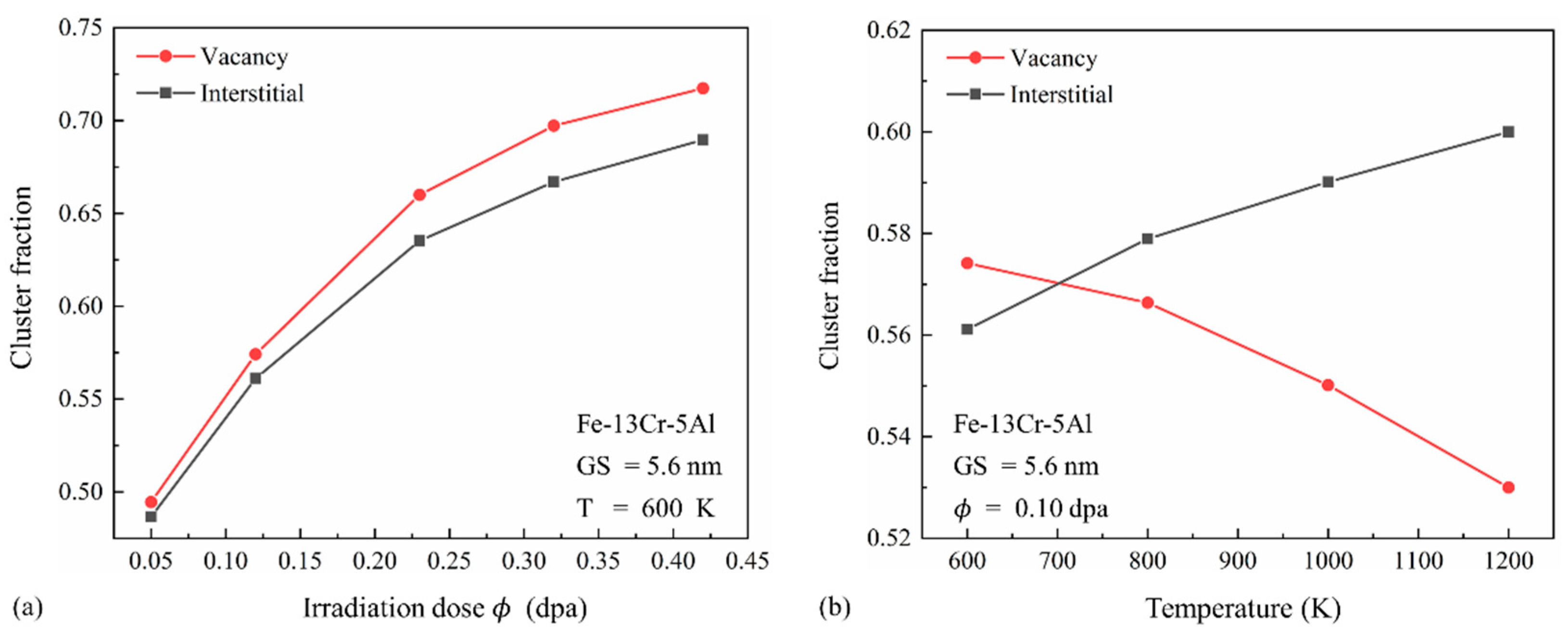

3.3.2. Defect Clusters

3.4. Evolution of Dislocation Defects

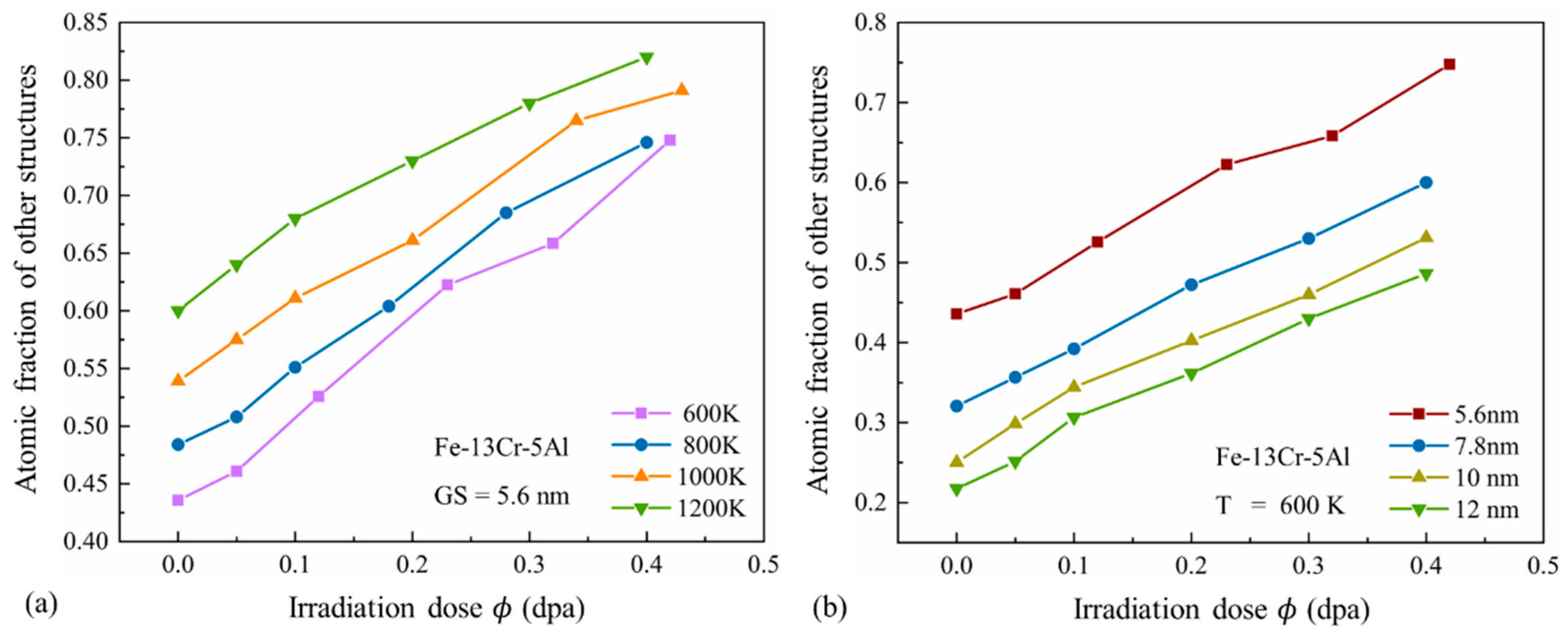

3.5. Formation and Evolution of Amorphous Structures

4. Conclusions

- (1)

- Temperature, irradiation dose, and GS have an important impact on the number and morphology of peak and surviving FPs. Temperature decreases the number of FPs, and this trend becomes more pronounced at higher doses. While the number of FPs increases substantially with GS, the FP concentration decreases slightly. With increasing dose and GS, or decreasing temperature, cascade regions transit from being independent to interconnected, and their shapes evolve from spherical to polymorphic.

- (2)

- FPs generated by cascades tend to aggregate, forming clusters. The cluster fraction goes up for both interstitials and vacancies with the increase in dose, and the cluster fraction of interstitials increases with temperature, while the vacancy fraction decreases. At lower temperatures, clustered vacancies are more than the clustered interstitials because the vacancies are close to each other, and interstitials are far from each other. However, elevated temperatures enhance interstitial mobility, enabling them to cluster more effectively and eventually surpass vacancy clusters.

- (3)

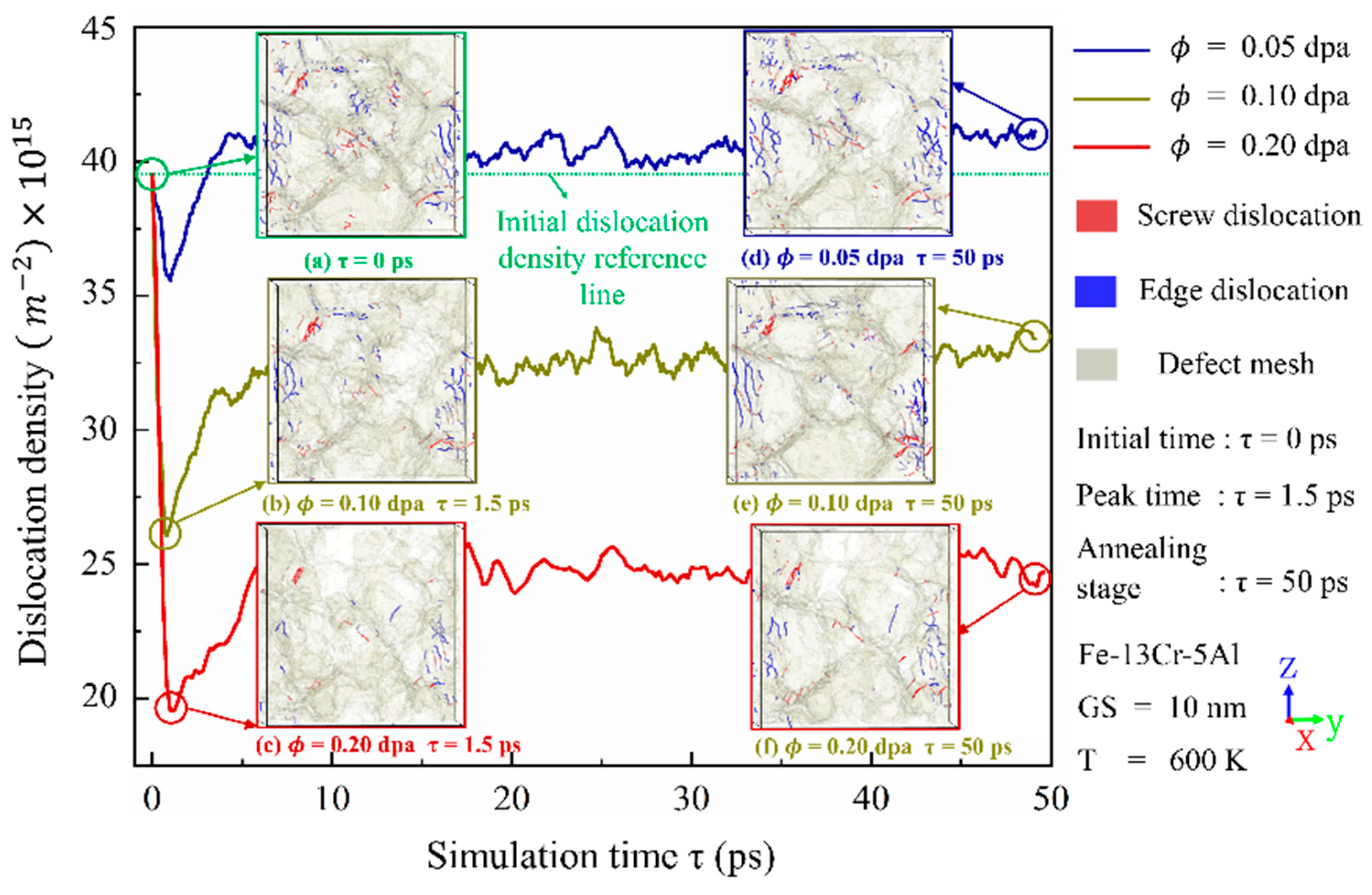

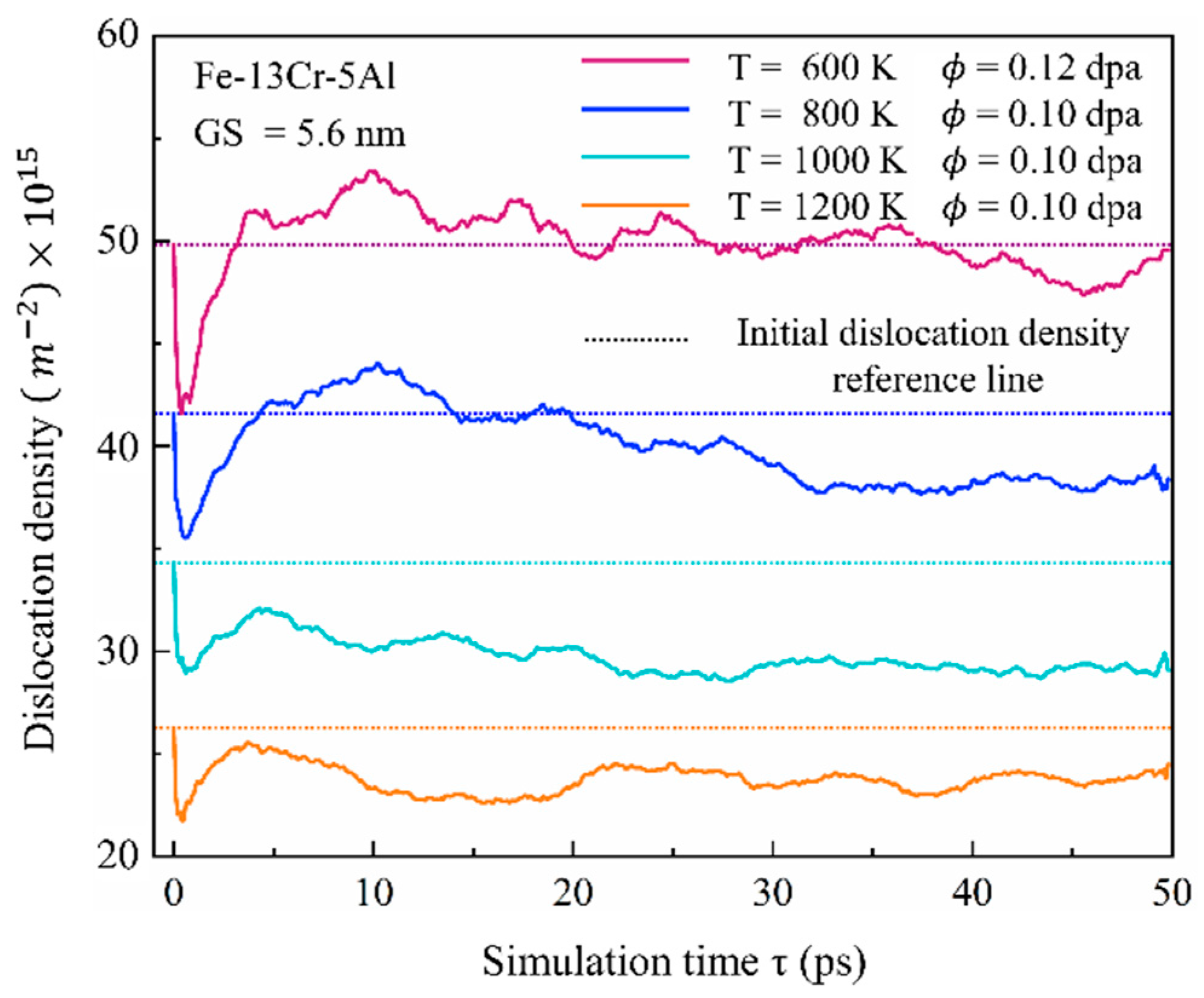

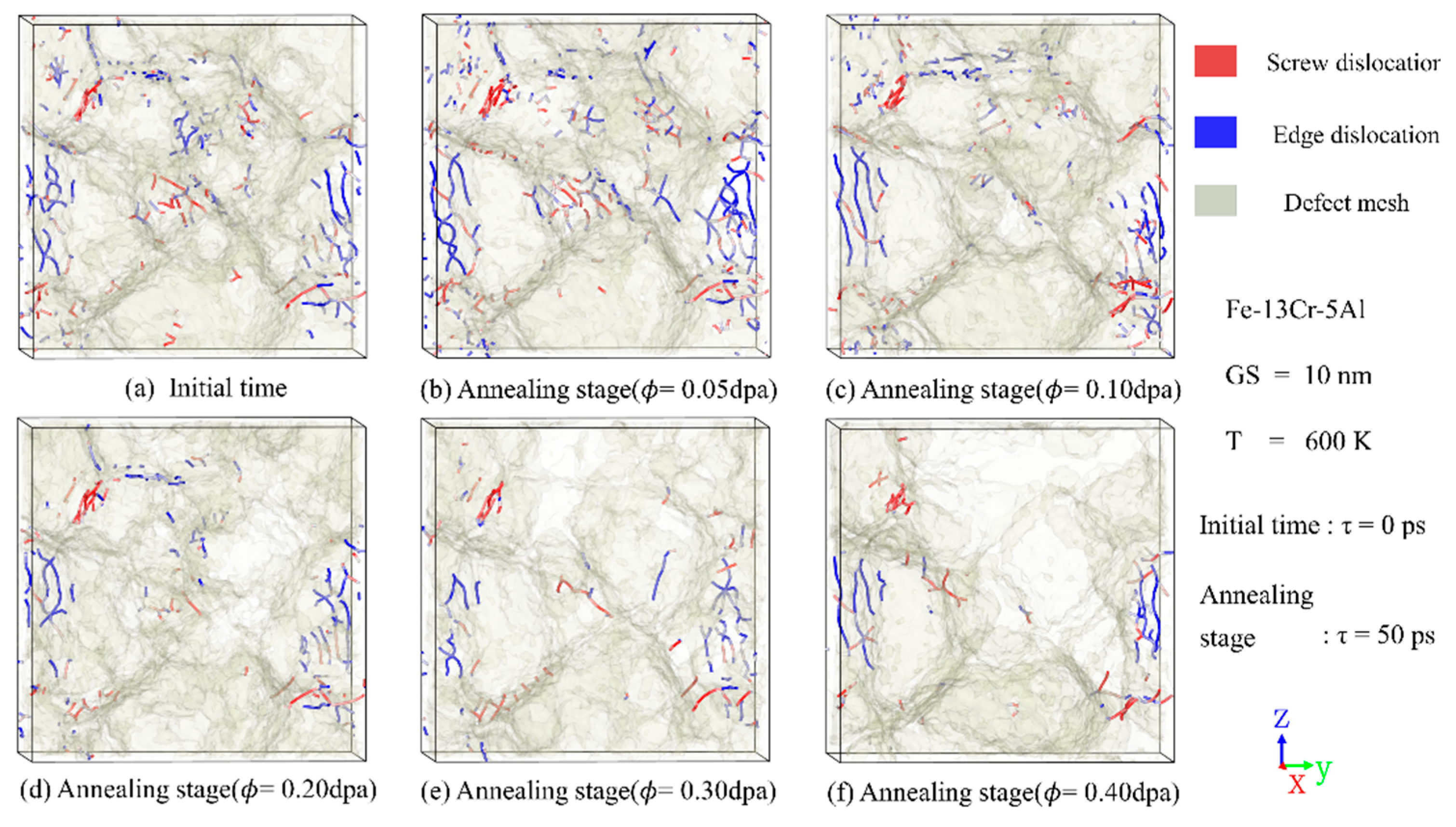

- FPs interact with existing dislocations, altering dislocation density and distribution during the early stages of irradiation damage in PC FeCrAl. Dislocation density decreases significantly with increasing dose and temperature. At lower doses, a slight increase in dislocation density is observed compared to the unirradiated model, but at higher doses, the dislocation density decreases markedly.

- (4)

- FPs preferentially migrate to and are absorbed at GBs, leading to a noticeable increase in GB thickness with rising dose. When the accumulated dose exceeds a critical threshold, regions near GBs undergo a transformation into an amorphous phase. The amorphization process accelerates with higher dose and temperature, and smaller GS results in a more extensive amorphous transformation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Saito, S. Role of Nuclear Energy to a Future Society of Shortage of Energy Resources and Global Warming. J. Nucl. Mater. 2010, 398, 1–9. [Google Scholar] [CrossRef]

- Terrani, K.A.; Zinkle, S.J.; Snead, L.L. Advanced Oxidation-Resistant Iron-Based Alloys for LWR Fuel Cladding. J. Nucl. Mater. 2014, 448, 420–435. [Google Scholar] [CrossRef]

- Motta, A.; Couet, A.; Comstock, R. Corrosion of Zirconium Alloys Used for Nuclear Fuel Cladding. Annu. Rev. Mater. Res. 2015, 45, 311–343. [Google Scholar] [CrossRef]

- Katoh, Y.; Vasudevamurthy, G.; Nozawa, T.; Snead, L.L. Properties of Zirconium Carbide for Nuclear Fuel Applications. J. Nucl. Mater. 2013, 441, 718–742. [Google Scholar] [CrossRef]

- Tanaka, S.-I. Accident at the Fukushima Dai-Ichi Nuclear Power Stations of TEPCO. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 2012, 88, 471–484. [Google Scholar] [CrossRef]

- Rajendran, R.; Chikhalikar, A.S.; Roy, I.; Abouelella, H.; Qu, H.J.; Umretiya, R.V.; Hoffman, A.K.; Rebak, R.B. Effect of Aging and α′ Segregation on Oxidation and Electrochemical Behavior of FeCrAl Alloys. J. Nucl. Mater. 2024, 588, 154751. [Google Scholar] [CrossRef]

- Qu, H.J.; Higgins, M.; Abouelella, H.; Cappia, F.; Burns, J.; He, L.; Massey, C.; Harp, J.; Field, K.G.; Howard, R.; et al. FeCrAl Fuel/Clad Chemical Interaction in Light Water Reactor Environments. J. Nucl. Mater. 2023, 587, 154717. [Google Scholar] [CrossRef]

- Raiman, S.S.; Field, K.G.; Rebak, R.B.; Yamamoto, Y.; Terrani, K.A. Hydrothermal Corrosion of 2nd Generation FeCrAl Alloys for Accident Tolerant Fuel Cladding. J. Nucl. Mater. 2020, 536, 152221. [Google Scholar] [CrossRef]

- Terrani, K.A.; Pint, B.A.; Kim, Y.-J.; Unocic, K.A.; Yang, Y.; Silva, C.M.; Meyer, H.M.; Rebak, R.B. Uniform Corrosion of FeCrAl Alloys in LWR Coolant Environments. J. Nucl. Mater. 2016, 479, 36–47. [Google Scholar] [CrossRef]

- Field, K.G.; Briggs, S.A.; Sridharan, K.; Howard, R.H.; Yamamoto, Y. Mechanical Properties of Neutron-Irradiated Model and Commercial FeCrAl Alloys. J. Nucl. Mater. 2017, 489, 118–128. [Google Scholar] [CrossRef]

- Gamble, K.A.; Barani, T.; Pizzocri, D.; Hales, J.D.; Terrani, K.A.; Pastore, G. An Investigation of FeCrAl Cladding Behavior under Normal Operating and Loss of Coolant Conditions. J. Nucl. Mater. 2017, 491, 55–56. [Google Scholar] [CrossRef]

- Ye, T.; Yao, H.; Wu, Y.; Zhang, J.; Wu, J.; Wang, M.; Tian, W.; Su, G.H.; Qiu, S. Primary Radiation Damage Characteristics in Displacement Cascades of FeCrAl Alloys. J. Nucl. Mater. 2021, 549, 152909. [Google Scholar] [CrossRef]

- Jiang, L.; Li, M.; Fu, B.; Cui, J.; Hou, Q. Electronic Effects on Radiation Damage in α-Iron: A Molecular Dynamics Study. Chin. Phys. B 2024, 33, 036103. [Google Scholar] [CrossRef]

- Rahman, M.H.; Rasel, M.; Smyth, C.; Waryoba, D.; Haque, A. Radiation Damage Mitigation in FeCrAl Alloy at Sub-Recrystallization Temperatures. Materials 2024, 18, 124. [Google Scholar] [CrossRef] [PubMed]

- Bachhav, M.; Robert Odette, G.; Marquis, E.A. α′ Precipitation in Neutron-Irradiated Fe–Cr Alloys. Scr. Mater. 2014, 74, 48–51. [Google Scholar] [CrossRef]

- Matijasevic, M.; Almazouzi, A. Effect of Cr on the Mechanical Properties and Microstructure of Fe–Cr Model Alloys after n-Irradiation. J. Nucl. Mater. 2008, 377, 147–154. [Google Scholar] [CrossRef]

- Malerba, L.; Caro, A.; Wallenius, J. Multiscale Modelling of Radiation Damage and Phase Transformations: The Challenge of FeCr Alloys. J. Nucl. Mater. 2008, 382, 112–125. [Google Scholar] [CrossRef]

- Zhang, D.; Briggs, S.A.; Field, K.G. Role of Refractory Inclusions in the Radiation-Induced Microstructure of APMT. J. Nucl. Mater. 2018, 505, 165–173. [Google Scholar] [CrossRef]

- Cui, Y.; Aydogan, E.; Gigax, J.G.; Wang, Y.; Misra, A.; Maloy, S.A.; Li, N. In Situ Micro-Pillar Compression to Examine Radiation-Induced Hardening Mechanisms of FeCrAl Alloys. Acta Mater. 2021, 202, 255–265. [Google Scholar] [CrossRef]

- Briggs, S.A.; Edmondson, P.D.; Littrell, K.C.; Yamamoto, Y.; Howard, R.H.; Daily, C.R.; Terrani, K.A.; Sridharan, K.; Field, K.G. A Combined APT and SANS Investigation of α′ Phase Precipitation in Neutron-Irradiated Model FeCrAl Alloys. Acta Mater. 2017, 129, 217–228. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Pint, B.A.; Terrani, K.A.; Field, K.G.; Yang, Y.; Snead, L.L. Development and Property Evaluation of Nuclear Grade Wrought FeCrAl Fuel Cladding for Light Water Reactors. J. Nucl. Mater. 2015, 467, 703–716. [Google Scholar] [CrossRef]

- Kobayashi, S.; Takasugi, T. Mapping of 475 °C Embrittlement in Ferritic Fe–Cr–Al Alloys. Scr. Mater. 2010, 63, 1104–1107. [Google Scholar] [CrossRef]

- Sahi, Q.-A.; Kim, Y.-S. Primary Radiation Damage Characterization of α-Iron under Irradiation Temperature for Various PKA Energies. Mater. Res. Express 2018, 5, 046518. [Google Scholar] [CrossRef]

- Zhang, M.; Peng, W.; Zhang, H.; Wu, B.; Sun, K.; Fang, L. The Effect of PKA Directions on the Primary Radiation Damage in the Alpha Iron Nanowires. Mater. Chem. Phys. 2019, 232, 16–22. [Google Scholar] [CrossRef]

- Campañá, C.; Boyle, K.; Miller, R. Grain Boundary Motion Assisted via Radiation Cascades in Bcc Fe. Phys. Rev. B 2008, 78, 134114. [Google Scholar] [CrossRef]

- Abrikosov, I.; Ponomareva, A.; Barannikova, S.; Hellman, O.; Vekilova, O.; Simak, S.; Ruban, A. Multiscale Approach to Theoretical Simulations of Materials for Nuclear Energy Applications: Fe-Cr and Zr-Based Alloys. MRS Proc. 2013, 1514, 3. [Google Scholar] [CrossRef]

- Wong, K.L.; Lee, H.-J.; Shim, J.-H.; Sadigh, B.; Wirth, B.D. Multiscale Modeling of Point Defect Interactions in Fe–Cr Alloys. J. Nucl. Mater. 2009, 386–388, 227–230. [Google Scholar] [CrossRef]

- Malerba, L.; Terentyev, D.; Olsson, P.; Chakarova, R.; Wallenius, J. Molecular Dynamics Simulation of Displacement Cascades in Fe–Cr Alloys. J. Nucl. Mater. 2004, 329–333, 1156–1160. [Google Scholar] [CrossRef]

- Terentyev, D.; Malerba, L. On the Correlation between Self-Interstitial Cluster Diffusivity and Irradiation-Induced Swelling in Fe-Cr Alloys. Philos. Mag. Lett. 2005, 85, 587–594. [Google Scholar] [CrossRef]

- Edmondson, P.D.; Briggs, S.A.; Yamamoto, Y.; Howard, R.H.; Sridharan, K.; Terrani, K.A.; Field, K.G. Irradiation-Enhanced α′ Precipitation in Model FeCrAl Alloys. Scr. Mater. 2016, 116, 112–116. [Google Scholar] [CrossRef]

- Zheng, D.; Chen, D.; Guo, Z.; Cui, X.; Mao, Y.; Zhao, Z. Displacement Cascade under High-Energy Irradiation and Tensile Property in Fe-Cr-Al Alloys: A Molecular Dynamics Simulation. Mater. Today Commun. 2023, 37, 107133. [Google Scholar] [CrossRef]

- Aghamiri, S.M.S.; Sowa, T.; Ukai, S.; Oono, N.; Sakamoto, K.; Yamashita, S. Microstructure and Texture Evolution and Ring-Tensile Properties of Recrystallized FeCrAl ODS Cladding Tubes. Mater. Sci. Eng. A 2020, 771, 138636. [Google Scholar] [CrossRef]

- Qiao, Y.; Wang, P.; Qi, W.; Du, S.; Liu, Z.; Meng, F.; Zhang, X.; Wang, K.; Li, Q.; Yao, Z.; et al. Mechanism of Al on FeCrAl Steam Oxidation Behavior and Molecular Dynamics Simulations. J. Alloys Compd. 2020, 828, 154310. [Google Scholar] [CrossRef]

- Wei, J.; Li, S.; Zhou, W.; Shen, P.; Ren, S.; Hu, A.; Zhou, W. First-Principles Investigation of Water Adsorption on FeCrAl (1 1 0) Surfaces. Appl. Surf. Sci. 2019, 465, 259–266. [Google Scholar] [CrossRef]

- Hirel, P. Atomsk: A Tool for Manipulating and Converting Atomic Data Files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Faken, D.; Jónsson, H. Systematic Analysis of Local Atomic Structure Combined with 3D Computer Graphics. Comput. Mater. Sci. 1994, 2, 279–286. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Liao, X.; Gong, H.; Chen, Y.; Liu, G.; Deng, H. Interatomic Potentials and Defect Properties of Fe–Cr–Al Alloys. J. Nucl. Mater. 2020, 541, 152421. [Google Scholar] [CrossRef]

- Yao, H.; Ye, T.; Yu, W.; Wang, P.; Chen, P. Atomic-Scale Investigation of Creep Behavior and Deformation Mechanism in Nanocrystalline FeCrAl Alloys. Mater. Des. 2021, 206, 109766. [Google Scholar] [CrossRef]

- Yao, H.; Ye, T.; Wang, P.; Wu, J.; Zhang, J.; Chen, P. Structural Evolution and Transitions of Mechanisms in Creep Deformation of Nanocrystalline FeCrAl Alloys. Nanomaterials 2023, 13, 631. [Google Scholar] [CrossRef]

- Dai, H.; Yu, M.; Dong, Y.; Setyawan, W.; Gao, N.; Wang, X. Effect of Cr and Al on Elastic Constants of FeCrAl Alloys Investigated by Molecular Dynamics Method. Metals 2022, 12, 558. [Google Scholar] [CrossRef]

- Ye, T.; Wu, Y.; Wang, Z.; Zhang, J.; Wang, M.; Chen, P.; Tian, W.; Su, G.H.; Qiu, S. Simulation of Threshold Displacement Energy in Fe-Cr-Al Alloys Using Molecular Dynamics. J. Nucl. Mater. 2024, 588, 154821. [Google Scholar] [CrossRef]

- Liao, X.; Chen, Y.; Gong, H.; Liu, T.; Deng, H.; Hu, W.; Gao, F. The Stability and Behavior of Cr-Rich α′ Precipitates under Cascade Damage in Fe-15Cr-8Al Ternary Alloys: An Atomic-Scale Simulation Study. J. Nucl. Mater. 2022, 570, 153955. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and Analysis of Atomistic Simulation Data with OVITO–the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 2154–2162. [Google Scholar] [CrossRef]

- Zhang, J.; He, H.; Liu, W.; Kang, L.; Yun, D.; Chen, P. Effects of Grain Boundaries on the Radiation-Induced Defects Evolution in BCC Fe–Cr Alloy: A Molecular Dynamics Study. Nucl. Mater. Energy 2020, 22, 100726. [Google Scholar] [CrossRef]

- Reali, L.; Boleininger, M.; Mason, D.R.; Dudarev, S.L. Atomistic Simulations of Athermal Irradiation Creep and Swelling of Copper and Tungsten at High Dose. Acta Mater. 2025, 288, 120814. [Google Scholar] [CrossRef]

- Niu, M.; Wang, H.; Huang, X. Positron Annihilation Investigation of Hardening Behavior Induced by Fe2+ Irradiation in Low-Cr FeCrAl Alloys. J. Mater. Res. Technol. 2023, 24, 7291–7301. [Google Scholar] [CrossRef]

- Li, S.; Hu, J.; Chen, W.-Y.; Yu, J.; Li, M.; Wang, Y. Evolution of Cellular Dislocation Structures and Defects in Additively Manufactured Austenitic Stainless Steel under Ion Irradiation. Scr. Mater. 2020, 178, 245–250. [Google Scholar] [CrossRef]

- Massey, C.P.; Zhang, D.; Briggs, S.A.; Edmondson, P.D.; Yamamoto, Y.; Gussev, M.N.; Field, K.G. Deconvoluting the Effect of Chromium and Aluminum on the Radiation Response of Wrought FeCrAl Alloys After Low-Dose Neutron Irradiation. J. Nucl. Mater. 2021, 549, 152804. [Google Scholar] [CrossRef]

- Wan, Q.; Yang, B.; Chen, Y.M.; Liu, H.D.; Ren, F. Grain Size Dependence of the Radiation Tolerances of Nano-Amorphous Ti-Si-N Composite Coatings. Appl. Surf. Sci. 2019, 466, 179–184. [Google Scholar] [CrossRef]

- Barr, C.M.; Chen, E.Y.; Nathaniel, J.E.; Lu, P.; Adams, D.P.; Dingreville, R.; Boyce, B.L.; Hattar, K.; Medlin, D.L. Irradiation-Induced Grain Boundary Facet Motion: In Situ Observations and Atomic-Scale Mechanisms. Sci. Adv. 2025, 8, eabn0900. [Google Scholar] [CrossRef] [PubMed]

| Grain Size (nm) | The Number of Atoms (×105) | Fraction of GB * Atoms (%) | Simulation Box Size (nm) | The Number of Grains |

|---|---|---|---|---|

| 5.6 | 2.4 | 24.2 | 14.1 | 16 |

| 7.8 | 4.8 | 17.4 | 17.9 | 12 |

| 10.0 | 10.1 | 13.7 | 22.9 | 12 |

| 12.0 | 12.2 | 12.0 | 24.4 | 8 |

| Grain Size (nm) | 5.6 | 7.8 | 10 | 12 |

|---|---|---|---|---|

| Relaxation time of NVT/NPT ensembles (ps) | 500 | 1000 | 1500 | 2000 |

| The number of PKA per cascade | 8 | 16 | 27 | 36 |

| The initial energy of PKA (keV) | 2.8–12.3 | 4.8–24.6 | 5.9–29.0 | 5.4–26.5 |

| Temperature (K) | 600, 800, 1000, 1200 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, H.; Wu, C.; Ye, T.; Wang, P.; Wu, J.; Wu, Y.; Chen, P. Atomistic Observation of Defect Generation and Microstructural Evolution in Polycrystalline FeCrAl Alloys Under Different Irradiation Conditions. Nanomaterials 2025, 15, 988. https://doi.org/10.3390/nano15130988

Yao H, Wu C, Ye T, Wang P, Wu J, Wu Y, Chen P. Atomistic Observation of Defect Generation and Microstructural Evolution in Polycrystalline FeCrAl Alloys Under Different Irradiation Conditions. Nanomaterials. 2025; 15(13):988. https://doi.org/10.3390/nano15130988

Chicago/Turabian StyleYao, Huan, Changwei Wu, Tianzhou Ye, Pengfei Wang, Junmei Wu, Yingwei Wu, and Ping Chen. 2025. "Atomistic Observation of Defect Generation and Microstructural Evolution in Polycrystalline FeCrAl Alloys Under Different Irradiation Conditions" Nanomaterials 15, no. 13: 988. https://doi.org/10.3390/nano15130988

APA StyleYao, H., Wu, C., Ye, T., Wang, P., Wu, J., Wu, Y., & Chen, P. (2025). Atomistic Observation of Defect Generation and Microstructural Evolution in Polycrystalline FeCrAl Alloys Under Different Irradiation Conditions. Nanomaterials, 15(13), 988. https://doi.org/10.3390/nano15130988