1. Introduction

The service performance of high-end equipment, such as aerospace, medical devices, and military equipment, depends largely on the performance of its components. Most components are used in extremely harsh environments; they are required to have strong load-bearing, extreme heat resistance, light weight, strong corrosion resistance, and high reliability. This poses a grave challenge to the components’ material, structure, process, and performance. Metal additive manufacturing (AM), also known as 3D printing, is a technique in which metal powders are formed by stacking them layer by layer and melting and bonding them, which has revolutionized the processing mode of traditional metal construction. This mainly includes several common processes, such as selective laser melting (SLM), electron beam melting (EBM), and powder bed fusion (PBF). Among them, laser selective melting (LSM) technology is one of the most popular and common research fields in AM technology. It uses a high-energy laser [

1] to focus on a thin layer of metal powder, precisely melting the powder and solidifying it into a layer. Then, it moves to the next layer to continue this process, which is suitable for manufacturing complex shapes and high-strength materials. Compared with the traditional metal processing mode, AM technology has high production flexibility, no need for conventional molds, fast manufacturing speed, the ability to manufacture complex geometric structures, and reduced material waste. With the advancement of technology, metal additive manufacturing technology has become an essential part of modern manufacturing. However, in its high-quality production processes, due to severe process instability, it is prone to defects such as pores, poor fusion, spheroidization, cracks, and surface roughness, resulting in scrapping of the workpiece. Quality control in an efficient production mode has become a key bottleneck because even a minor defect can lead to the failure of the entire product. Therefore, studying the intelligent defect detection algorithm of metal additive technology is of great significance.

Traditional defect detection techniques, such as optical microscopy or ultrasonic flaw detection, are often limited by the experience and skill level of the operator, making it challenging to automate inspections on a large scale quickly, as these techniques are prone to missed detections. To detect the generation of defects in real time and eliminate defective products promptly, the development of machine learning and deep neural networks provides new solutions for defect detection and classification. In advanced computer vision, the defect detection task is mainly optimized through two primary strategies—segment-based and integrated methods. Segment-based models include RCNN, Fast R-CNN, and Faster R-CNN [

2]. Based on the prior region proposal technology, features are extracted through convolutional neural networks (CNN) [

3,

4,

5], and then, each candidate region is finely classified, and its bounding box is adjusted separately. Although these studies provide high recognition accuracy, they do not have real-time recognition capabilities. However, for example, in the SSD (Single Shot multibox Detector) and YOLO (You Only Look Once) series, to balance efficiency and recognition accuracy, these models avoid the generation of candidate regions and directly distinguish the location and category of the predicted target in the whole image, which gives them a significant advantage in real-time identification of large-scale targets. In recent years, especially in convolutional neural network (CNN)-based object detection frameworks such as the YOLO series, machine learning algorithms have been widely used in defect detection, but due to the inaccurate image accuracy recognition of low-resolution and small targets, it is necessary to introduce new intelligent algorithms.

The YOLO series of object detection algorithms relies on their excellent detection speed and accuracy in defect detection [

6]. As Li et al. [

7] pointed out, although these technologies have made breakthroughs in improving the accuracy of defect detection, they still fall short when facing specific difficulties. Due to the lack of detailed information, CNNs may not be able to accurately identify potential defects in low-resolution scan results [

8]. Complex background interference often makes defect detection more difficult. The network needs stronger background noise suppression [

9], especially for small-sized targets, notably for defects with similar shapes but significant size differences, and existing models may be misjudged or missed. To overcome these challenges, researchers are constantly innovating technologies, such as combining multi-scale feature fusion, which can capture defect information at different scales [

10], and introducing attention mechanisms to enhance the network’s attention to critical regions. Li et al. [

11] proposed a steel defect detection algorithm based on the improved YOLO, which consists of 27 convolutional layers and improves the detection accuracy. Liang et al. [

12] proposed an improved YOLOv3-Tiny model, using K-means to enhance the regression accuracy and improve the network’s ability to extract feature information. Yu et al. [

13] improved the backbone network, embedding a fusion attention mechanism module and focusing more on channel and spatial data by introducing the Focal Loss function to solve the problem of uneven sample distribution. They proposed an improved algorithm of YOLOv4. Kwon H et al. [

14] presented a new QSAR model using semi-supervised metric learning techniques to assess which chemical functional groups affect bioactivities toward specific biological targets, Huang et al. [

15], to enhance the detection accuracy of the voids in laser-cladding damage-repair parts, creatively proposed the SP-YOLOv5 void detection algorithm. This research added the Coord attention mechanism module, rewrote the YOLOv5 network structure, and enhanced the network model’s detection ability for small target voids of the class. Bhagabati et al. [

16] proposed an improved detection algorithm based on YOLOv5s. This research added a multi-scale attention mechanism module and designed a recursive gated convolutional C3HNB module to address the complex spatial information of small target detection images. Lin et al. [

17] utilized mixed attention to optimize the detection of small targets in SAR images. This research combined channel attention, self-attention mechanism, and context feature fusion strategy to enhance detection performance. Shiga M et al. [

18] presented a novel approach for the classification and visualization of rock microstructure from micro-computed tomography images, leveraging pre-trained convolutional neural network (CNN) models (AlexNet, GoogLeNet, Inception v3 Net, ResNet, and DenseNet) combined with unsupervised machine learning (USML) techniques principal component analysis, multidimensional scaling, isometric mapping, t-distributed stochastic neighbor embedding (t-SNE), and uniform manifold approximation projection (UMAP)). Huang et al. [

19] designed the C3-ODCBS module, introducing the WIoUv3-Loss function and decoupled heads, enabling the model to exhibit higher detection accuracy on steel defects. Bearce et al. [

20], based on the improved YOLOv8n target lightweight detection algorithm DCD-YOLO, utilized the CDR module on the backbone network of YOLOv8 for feature extraction and added the bidirectional feature pyramid BiFPN at the neck to achieve more rapid and efficient multi-scale feature fusion, thereby enhancing its detection capability. Shin et al. [

21] made improvements based on YOLOv10 by introducing the attention mechanism EMA and using the SPPELAN module. They replaced the backbone with FasterNet. The study improved the detection accuracy, training efficiency, and complex defect recognition ability; the computational complexity was also kept low, ensuring the deployability and usefulness of the model in resource-constrained environments.

In summary, machine learning has achieved a certain degree of success in additive manufacturing defect detection; it has shown specific value and efficiency in existing application scenarios. There is still much room for improvement in the performance of known algorithms. Among them, the two key problems of defect detection in complex scenes and small target defect detection are particularly prominent, which are the most significant problems hindering the detection accuracy of the algorithm. There is an urgent need for innovative solutions to achieve substantial breakthroughs [

22], and the core highlight and major innovation of this research lies precisely in the fact that the research successfully overcomes the problems of defect detection in complex scenarios and small targets. A more systematic solution is thus proposed, effectively improving the current algorithm’s shortcomings in these aspects. The further expansion of the results of this study is expected to promote the overall leapfrog upgrade of the additive manufacturing industry at the two levels of quality control and production efficiency. It will build a solid theoretical foundation and technical support framework for the long-term and sustainable development of the field of additive manufacturing, lead the field to a new height of development, and stimulate more innovative applications and research explorations.

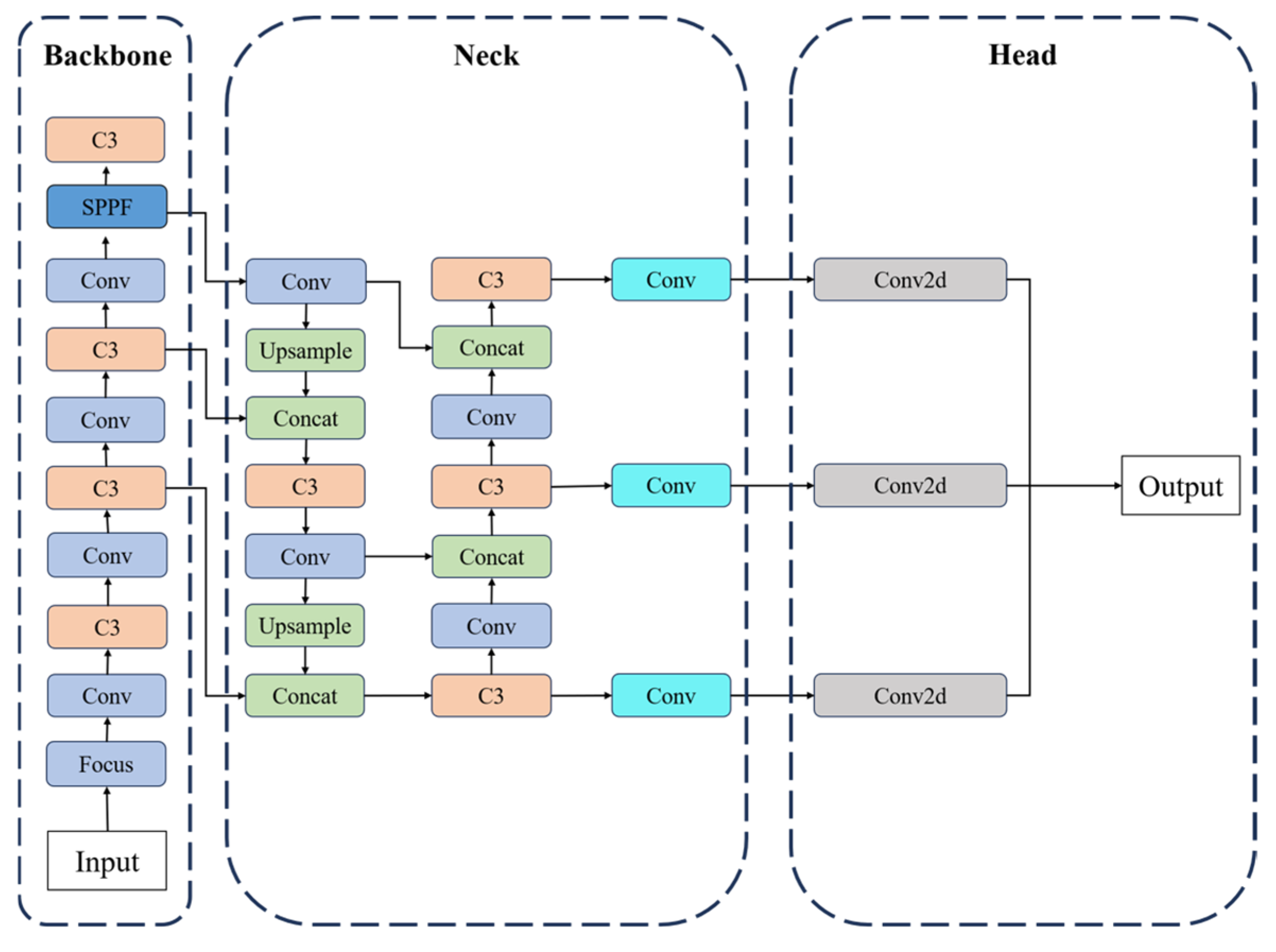

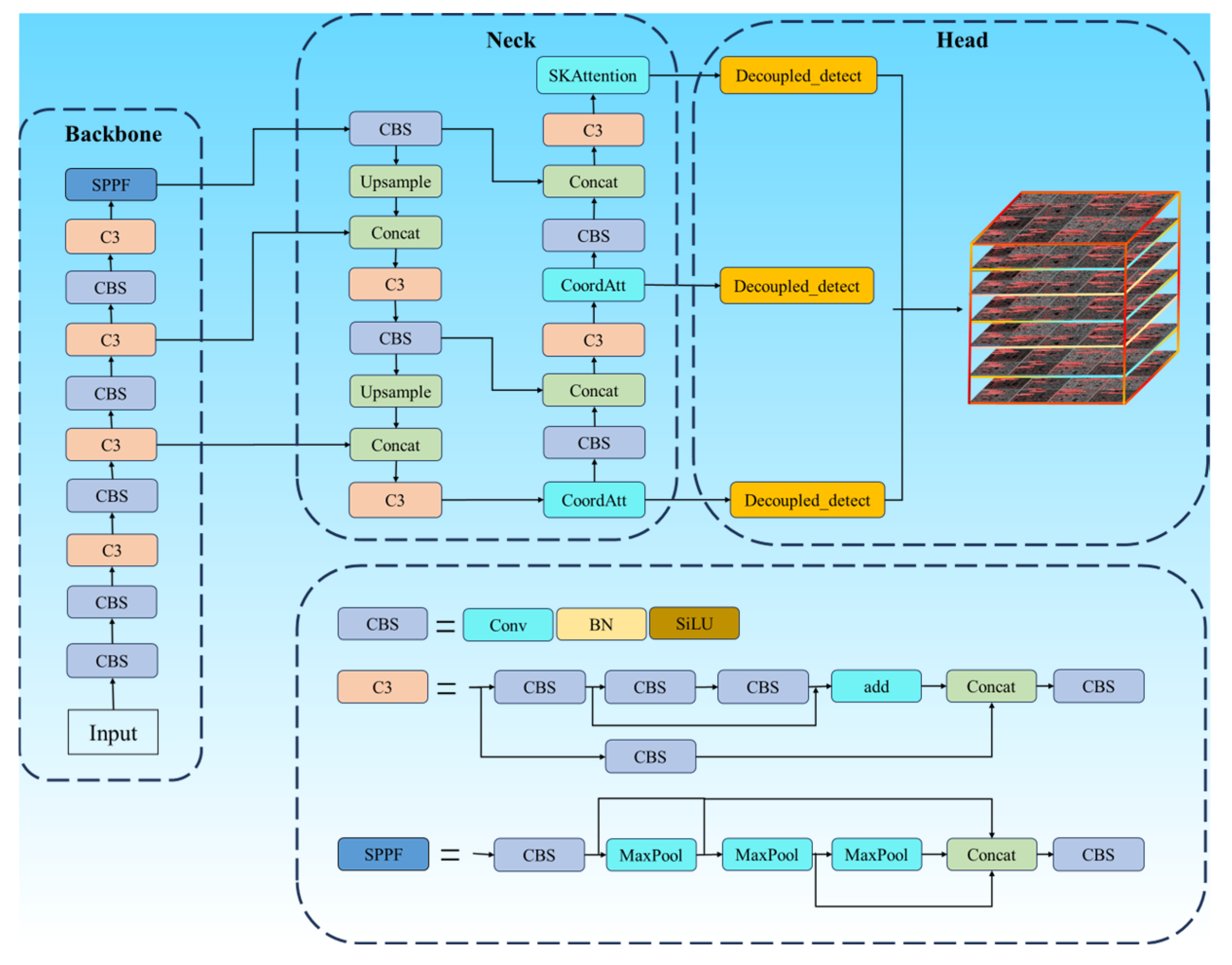

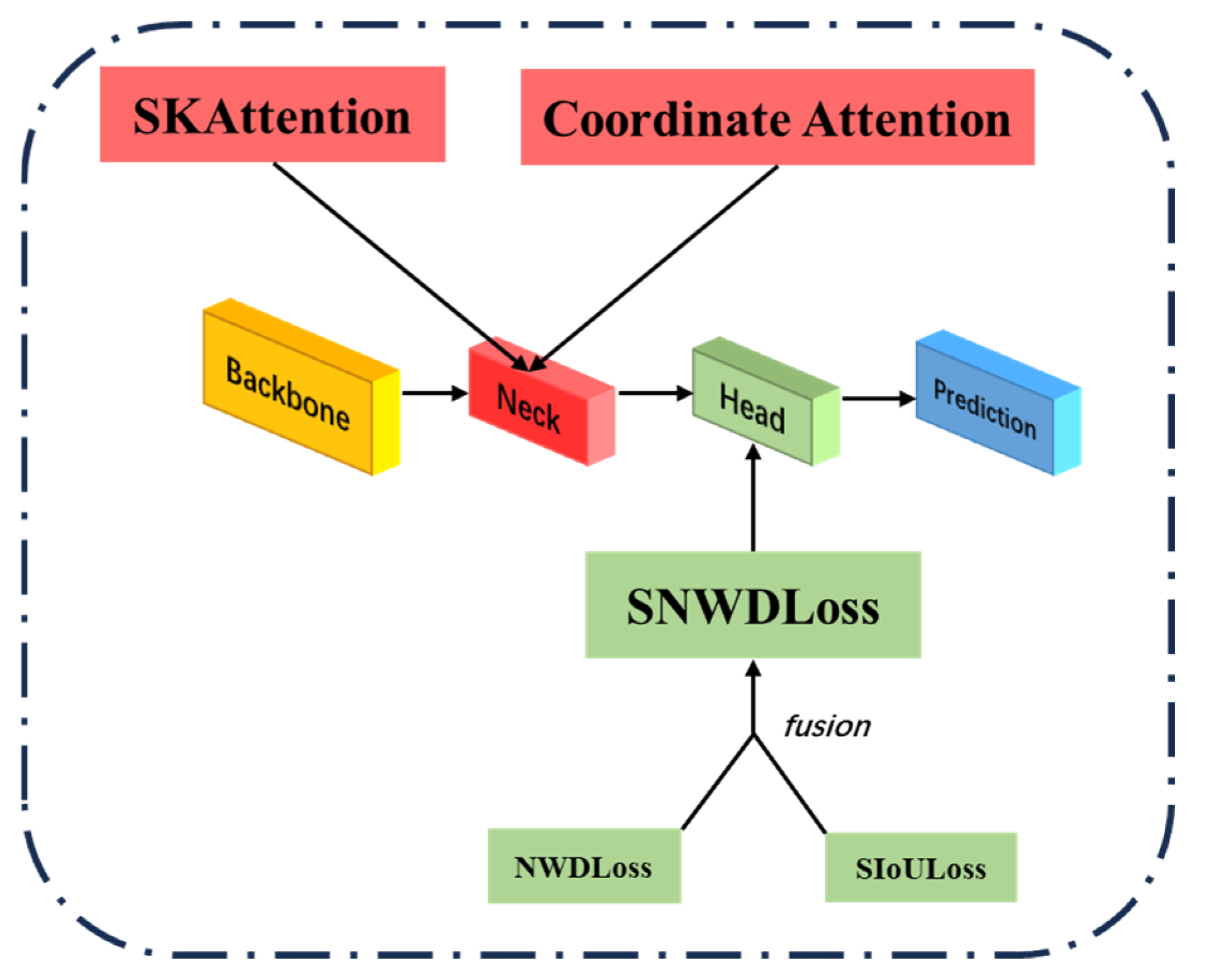

In this study, to further enhance the detection accuracy of defects, the network structure of YOLOv5 was modified based on YOLOv5s. (1) The SiOULoss function and the NWDLoss function were fused to creatively propose a new loss function, SNWDLoss, which accelerates the network convergence and improves the robustness. (2) The CA and SK attention mechanisms complement each other’s shortcomings and were combined into the bottleneck to effectively enhance the algorithm’s attention to local features and its ability to organize global sequence information.

The main contributions of this paper are as follows:

- (1)

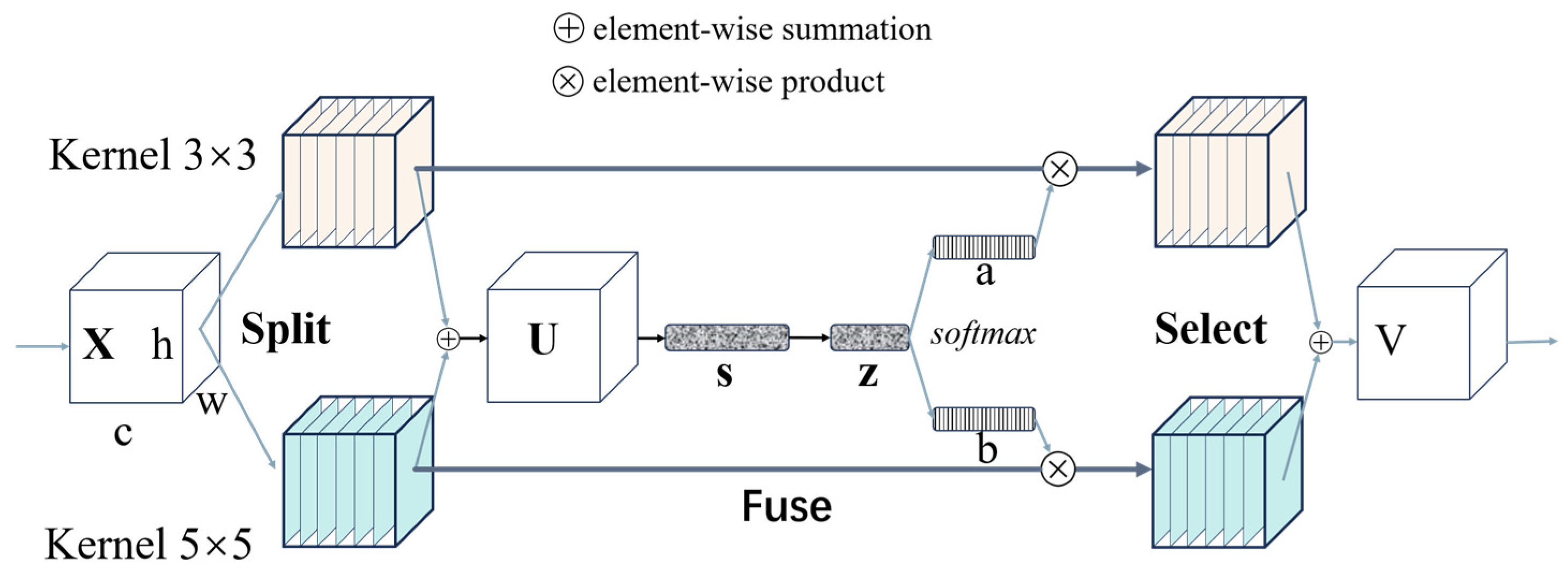

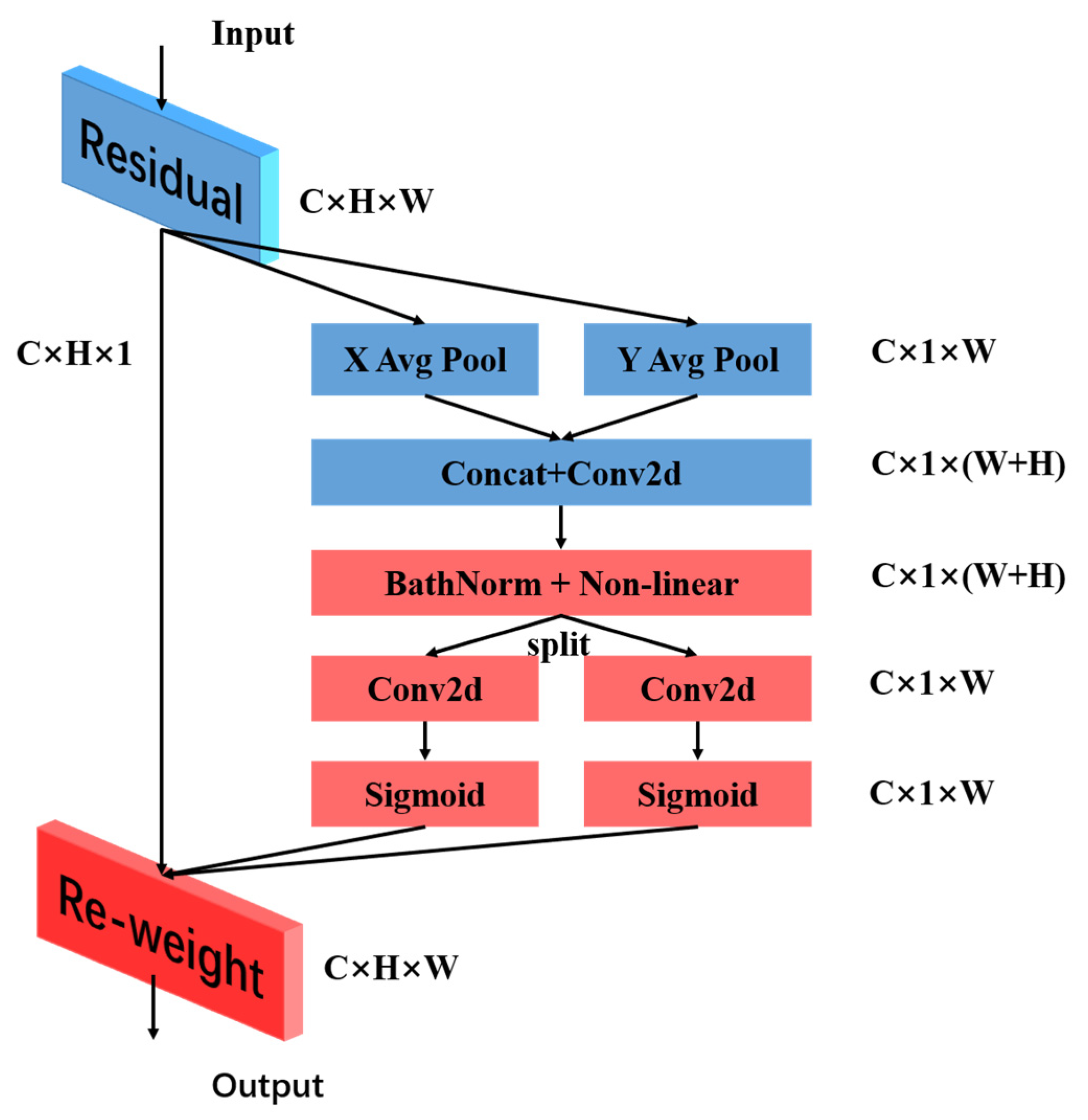

The CA attention mechanism module is designed to be highly flexible and resource-efficient. In this paper, the CA attention mechanism is seamlessly integrated into the bottleneck in the core architecture of the mobile network. The position information of channel attention and direction perception is cleverly integrated, which significantly improves the model’s accuracy in localization and recognition and shows excellent versatility and performance improvement in diverse tasks such as defect detection. To improve the computational efficiency of the model, this study introduced the SK attention mechanism into the bottleneck, focusing on the key parts of the task in the input feature map, better preserving the spatial structure of the image, and enhancing the adaptability and generalization of the model to various scenes. At the same time, the SK attention mechanism can be targeted at specific areas, such as defects, which can reduce the risk of overfitting.

- (2)

CioULoss was replaced with SIoULoss, a loss function in semi-supervised learning. It replaces the traditional CIoU Loss and guides the model to learn more representative features from only the model when the dataset of metal defects is relatively small. Meanwhile, the NWDLoss function is introduced into SIoULoss to consider the influence of noisy data and dynamically adjust the weight of each sample. This mechanism can adaptively handle the noise points in the defect dataset and reduce the impact of noise on model training.

- (3)

To improve the accuracy and production efficiency of defect detection in additive manufacturing parts, a novel defect identification network structure, SCK-YOLOv5, was innovatively designed. It is optimized on the classic YOLOV5 architecture, adding CA and SK attention mechanisms. Positioning is more accurate using a modified version of SIoULoss instead of the traditional CIoULoss. The SNWDLoss loss function model is innovatively proposed, combining the two loss functions of SIOULoss and NWDLoss to effectively improve the overall detection performance, significantly improving the model’s effectiveness in practical applications.

- (4)

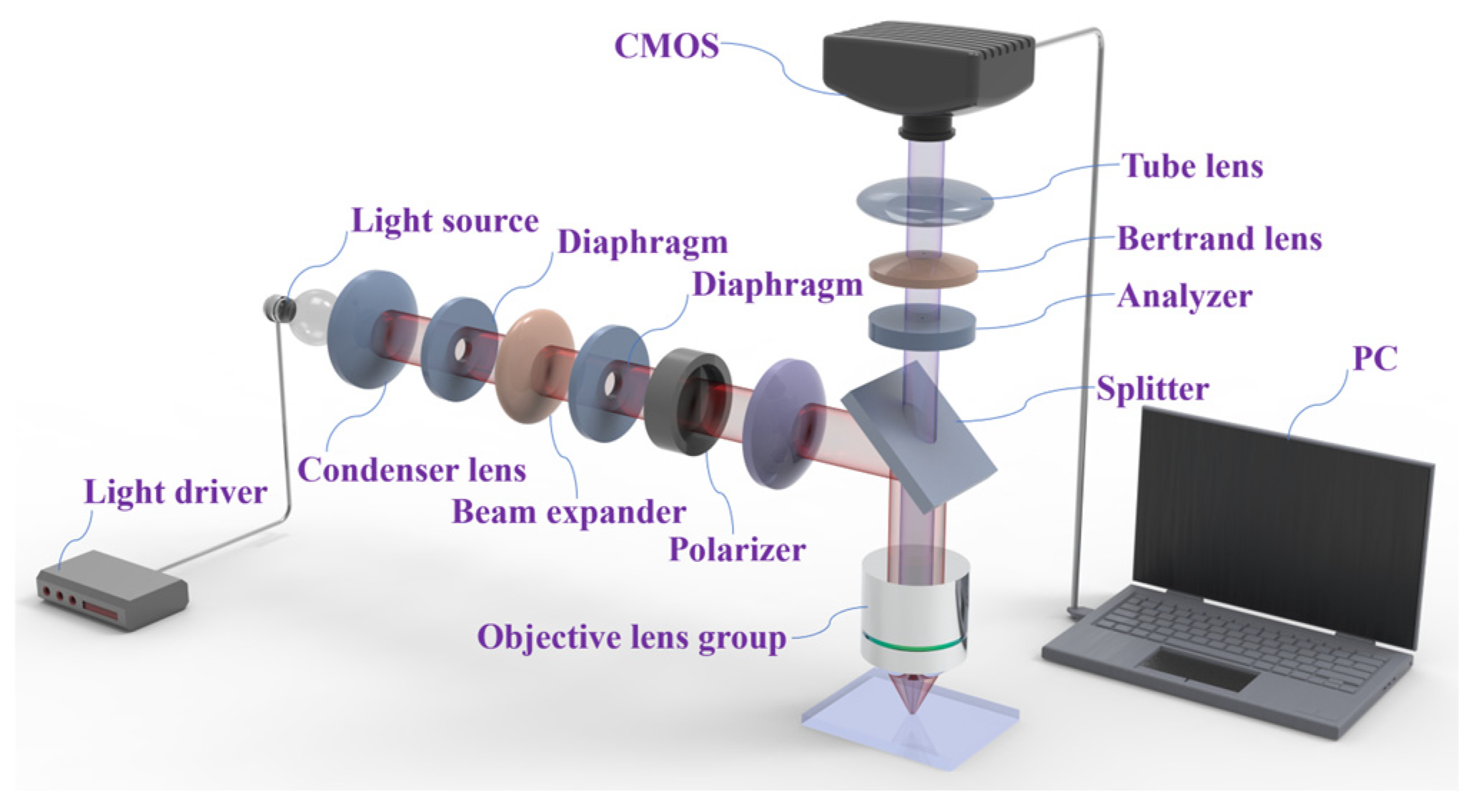

In this study, the innovative combination of polarization imaging and deep learning algorithms was used to highlight the defects of small targets, highlighted by the temperature of the metal surface and the phenomenon of high reflection, achieving high-precision detection of small target defects. This improves the detection accuracy and lays a solid foundation for quality control and safety assurance in related fields.

3. Experiments and Discussion

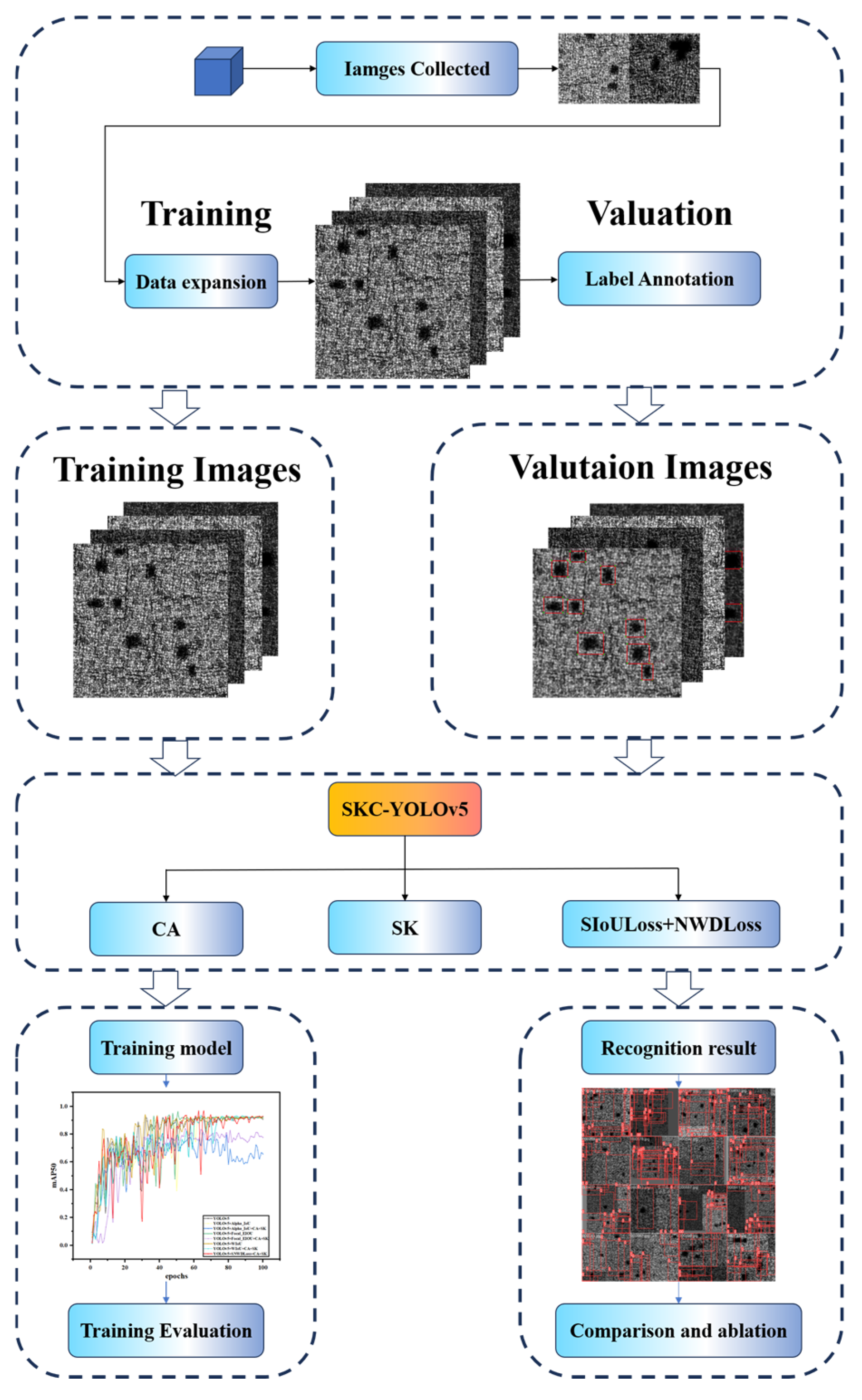

3.1. Dataset

The training dataset used in this study only contains metal additive manufacturing defects of the type of holes. It consists of 1000 instances of hole defects, each annotated with precise bounding boxes. These bounding boxes provide comprehensive and detailed information about the target’s position, size, and category. In this study, 100 instances of hole defects were selected as the validation set for experimental verification.

3.2. Experimental Environment

This study’s experimental environment is the Windows 10 operating system. All experiments were conducted on the software platform Python-3.9.19 torch-2.2.2+cu121 CUDA:0 (NVIDIA GeForce RTX 3060 Laptop GPU, Santa Clara, CA, USA). The experimental parameters were set as follows: 100 epochs of training rounds. The batch size is 16, the input image size is 640 × 640, and all other settings are default.

3.3. Performance Index

This study adopted precision, recall, mean average precision (mAP), and regression loss as evaluation criteria to verify the advantages of the SCK-YOLOv5 model.

Herein,

n: total number of categories;

Pij: total number of pixels in the real image that belong to category

i and are predicted as category

i;

: total number of pixels in the real image that belong to category

i but are predicted as category

j;

TP: true-positive number, i.e., the number of pixels that are positive in the labels and also positive in the prediction values;

TN: true-negative number, i.e., the number of pixels that are negative in the labels and also negative in the prediction values;

FP: false-positive number, i.e., the number of pixels that are negative in the labels but positive in the prediction values;

FN: false-negative number, i.e., the number of pixels that are positive in the labels but negative in the prediction values;

TP +

TN +

FP +

FN = total number of pixels;

TP +

TN = number of correctly classified pixels [

28].

3.3.1. Precision

Precision is also called inspection accuracy. It is the proportion of positive samples that are correctly predicted by the model. In defect detection, if the bounding box predicted by the model coincides with the real bounding box, it is considered a correct prediction.

The formula is as follows:

3.3.2. Recall

The recall is also known as the detection rate. It measures the model’s performance in detecting. It represents the percentage of the correctly predicted positive samples among the actual positive samples. It is used to evaluate the model’s ability to identify all truly positive samples. If the actual bounding box coincides with the predicted bounding box, then this sample is considered to have been correctly recalled.

3.3.3. Average Precision

Average precision (

AP) calculates the average precision across different categories.

AP integrates the changes of precision and recall and is an essential metric for evaluating the advantages and disadvantages of defect detection models.

3.3.4. mAP (Mean Average Precision)

mAP represents the average precision for multi-class problems. For binary classification problems,

mAP =

AP, and

mAP50 indicates the

mAP value at an

IoU threshold of 50%. As a comprehensive indicator, it simultaneously reflects precision, recall, and mean average precision. The higher the

mAP value, the more accurate the model is. The range of

mAP values is [0, 1], and the closer it is to 1, the better the detection effect.

AP and

mAP are comprehensive evaluation indicators that reflect the algorithm’s accuracy in identifying targets for individual and all classes. Higher

AP and

mAP values indicate that the YOLO algorithm model has higher confidence in detecting target objects.

3.3.5. mAP50–95

mAP50–95 is a more stringent evaluation metric. It calculates the mAP values within the range of IoU thresholds from 50% to 95% and then takes the average. This enables a more accurate assessment of the model’s performance under different IoU thresholds.

3.3.6. Regression Loss Class

Train/obj_loss is the loss value for objectness prediction during training. This pertains to the model’s ability to determine whether a specific object exists in an image. Val/obj_loss is the object loss value on the validation set, evaluating the model’s capability to detect objects in unseen data. Objectness loss is typically measured using binary cross-entropy (BCE) loss [

28].

To evaluate the accuracy of the training model proposed in this study, many experiments were conducted for comparison in this paper. (1) Quantitative analysis was carried out to compare several popular YOLO detection algorithms. It was verified that compared with other YOLO models, SCK-YOLOv5 was optimized and improved based on the YOLO system algorithm, providing higher detection accuracy and faster speed. (2) Ablation experiments were conducted to determine the degree of influence of a condition or parameter on the results. Compared with the original YOLOv5, this paper has four new schemes or methods. In the ablation experiment, we controlled one condition and parameter at a time, and by observing how the results changed, we determined which condition or parameter had a more pronounced effect on the results. The comparative experiment compares the loss values of several well-known loss functions applied to the live network. This comparison highlights the differences between the model studied in this paper and other loss models. Regarding the generalization experiment, we aimed to verify that the high recognition accuracy of the model proposed in our study is not limited to the defect dataset collected in this study, and it can also be applied in other datasets. We performed generalization experiments by conducting comparative experiments on a large number of defect datasets downloaded from the Internet, through which the extensiveness of the YOLO model proposed in this study can be verified, and the technique is mainly used to evaluate the effectiveness of new theories or improvement measures.

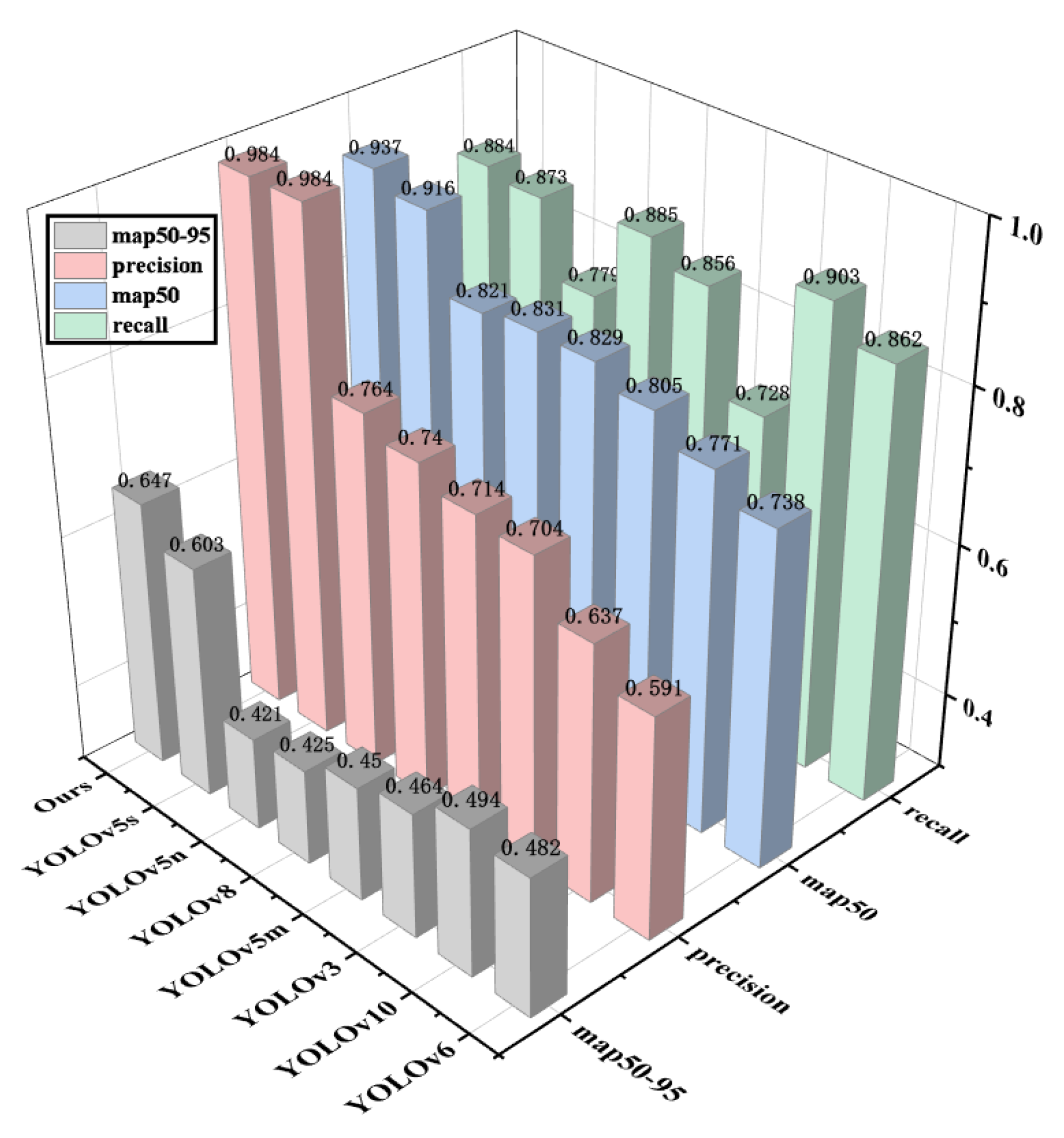

3.4. Quantitative Analysis

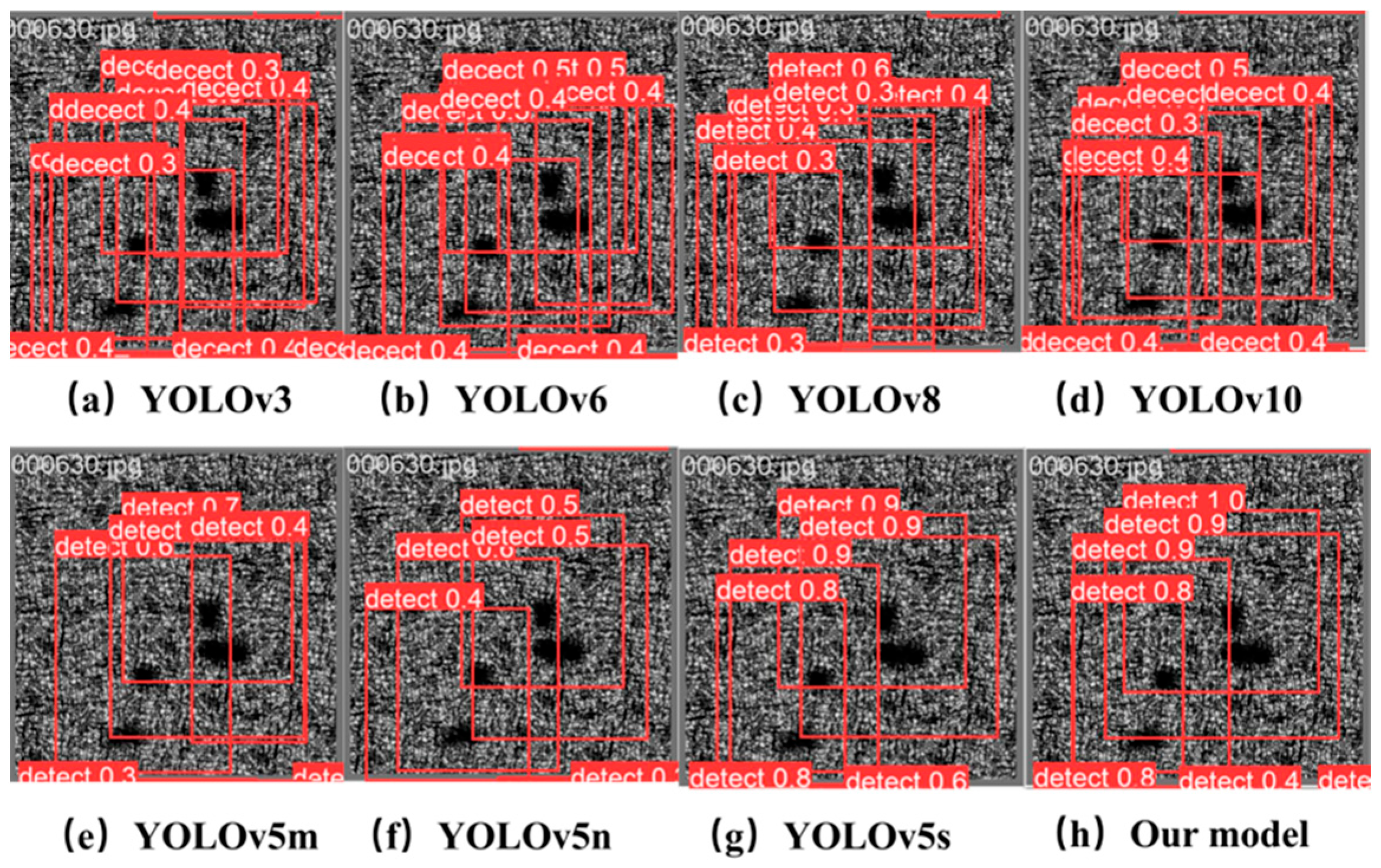

This study’s model was compared with commonly used methods and other improved approaches in recent years. In the quantitative analysis, the models selected by this study included YOLOv3, YOLOv5, YOLOv6, YOLOV8, YOLOv10, etc. The experimental results of different models are shown in

Figure 1 and

Figure 8.

From

Table 1 of the experimental results, the research found relatively similar values in this comparative test. Random factors caused the difference in the indicator. To verify that the model itself truly improved, this study ran the model five times under the same conditions and calculated the mean of the precision rate, the mean of the recall rate, the mean of the

mAP@50 rate, and the mean of the

mAP@50–95 rate. It is observable that compared with other baseline models, the overall performance of the YOLOv5 model is superior. The accuracy of YOLOv3 is around 0.7, while the detection effects of YOLOv5m, YOLOv5n, YOLOv6, and YOLOv8 are relatively similar, with their detection accuracy reaching around 0.75–0.8. The recall rate of YOLOv10 is relatively high, reaching 0.903. Still, its precision rate and average precision rate are relatively low, at 0.637 and 0.771, respectively, which are 35.2% and 16.3% lower than the model in this study. The detection accuracy of YOLOv5s reaches 0.984; meanwhile, its recall rate and average precision rate reach 0.873 and 0.916, respectively, showing great superiority over other models, but compared with the model in this study, its precision average rate is 0.5% lower, average recall rate is 1.2% lower, and the

mAP@50 is 1.8% lower. The map@50–95 metric of the model in this study improved by 4.4% compared to the original YOLOv5 model, and there was a significant improvement compared to other models in the YOLO series. The improvement of the map50-95 metric can prove that the introduction of SNWDLoss in this paper is of great help in improving the defect detection rate of small targets.

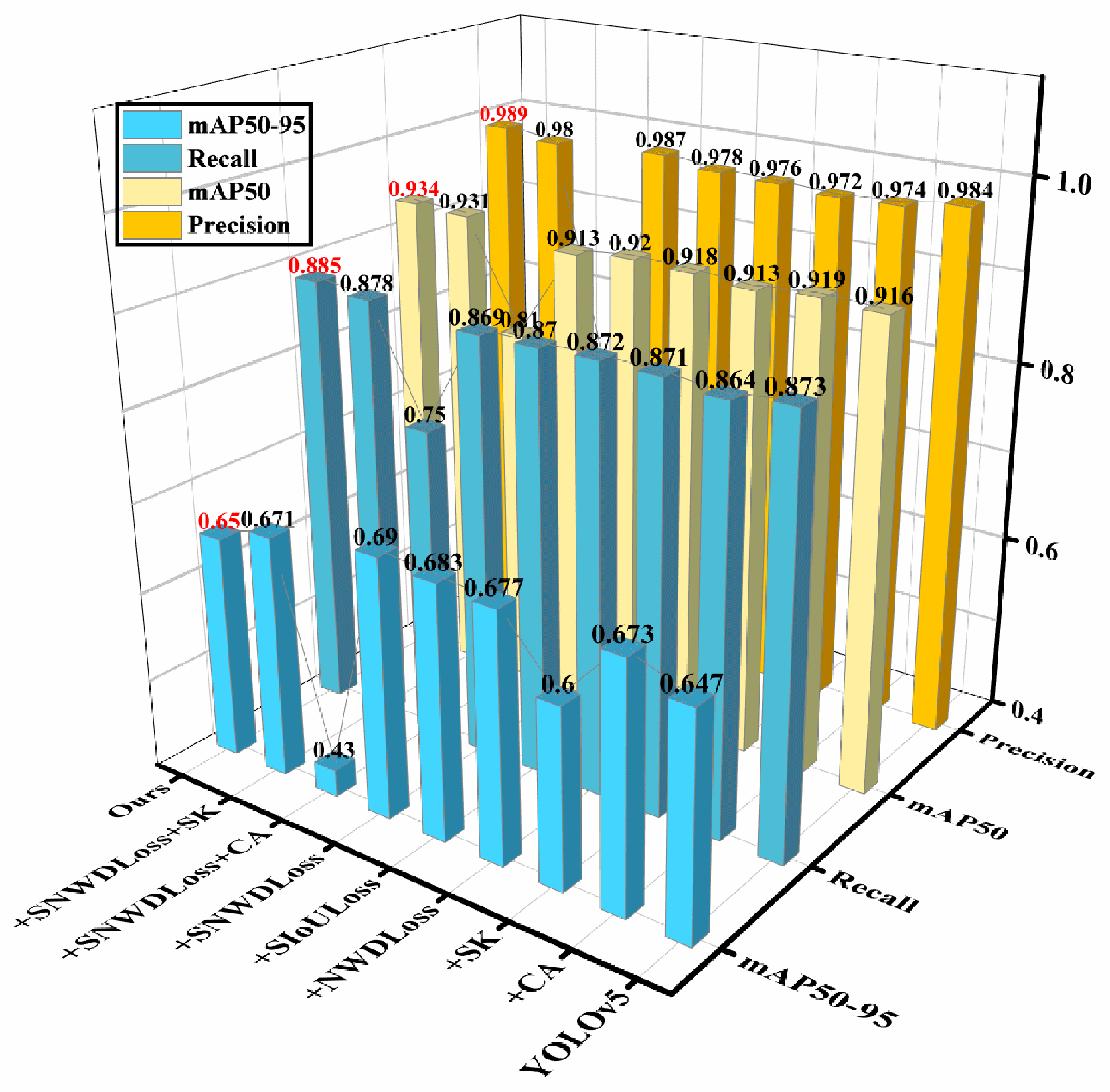

Through the intuitive comparison of the three-dimensional graph in

Figure 8 based on the experimental results, it is verified that YOLOv3 and YOLOv4 are not as effective as YOLOv5 in visual recognition. Due to the imperfection of the code algorithm of YOLOv6-v10, it is inferior to YOLOv5 in recognizing small targets. Compared with the original YOLO algorithm without improvement, the overall performance of YOLOv5s is undoubtedly the best. Therefore, this research focuses on the improvement based on YOLOv5s. Its accuracy rate increased by 0.5%, the recall rate increased by 1.2%, and the correctness and coverage of the surface model also improved. At the same time, after the improvement, this research achieved an increase of 1.8% in the average precision rate. This indicates that the scheme of introducing CA and SK attention mechanisms and the SIoULoss function proposed in this research is correct.

To more intuitively prove that this study’s improved method is effective compared with other models, we selected several representative YOLO model detection cases for qualitative analysis. This study selected 630 specific representative images containing defects from the test set. As shown in

Figure 9, they represent the prediction structures of the models in this study: YOLOv3, YOLOv4, YOLOv5, YOLOv8, YOLOv10, and SCK-YOLOv5.

Regarding the above algorithms, the recognition accuracy of YOLOv3 is mostly around 0.3, which is relatively low, and there are numerous false detections. The recognition accuracy of YOLOv6 improved to 0.4 compared to YOLOv3, but there are still countless false detections. The recognition accuracy of YOLOv5m and YOLOv5n is around 0.6, and although they identified all four defects without any missed detections or false detections, their recognition accuracy is still relatively poor. The recognition accuracy of YOLOv6 is around 0.5, and there are multiple false detections. Most of the recognition rates of YOLOv8 are around 0.4, and numerous false detections exist. The recognition rate of YOLOv10 is approximately 0.4 as well. Compared to YOLOv8, the false detection rate is lower. However, YOLOv5s has a relatively higher recognition rate, with an average accuracy of 0.9. Due to the other algorithms mentioned above, this research algorithm achieved a recognition result with a confidence level 1. It can identify all four defects in the image without any missed or false detections, demonstrating the superiority of the improved algorithm in this study and reflecting the flexibility and accuracy of the enhanced loss function.

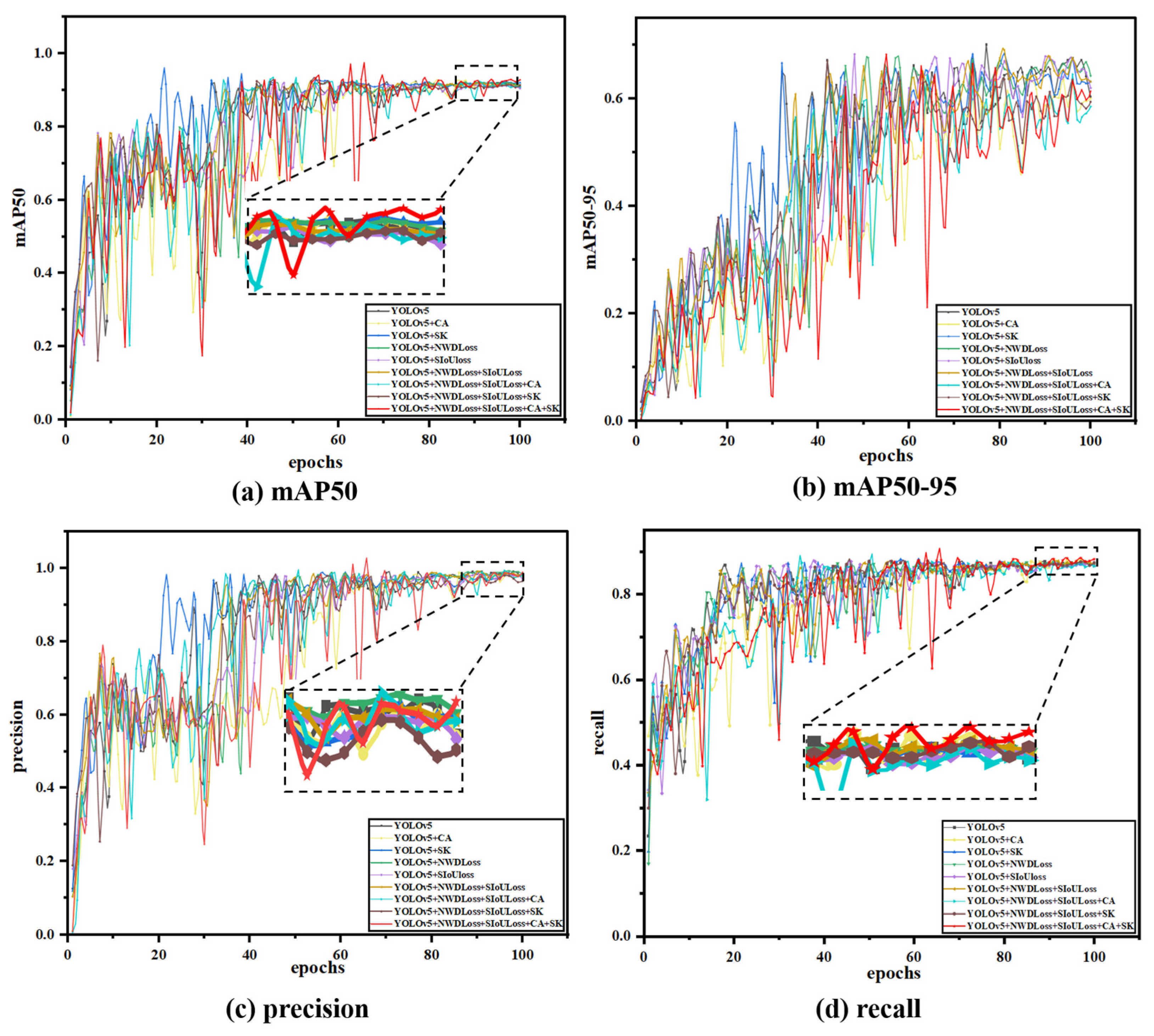

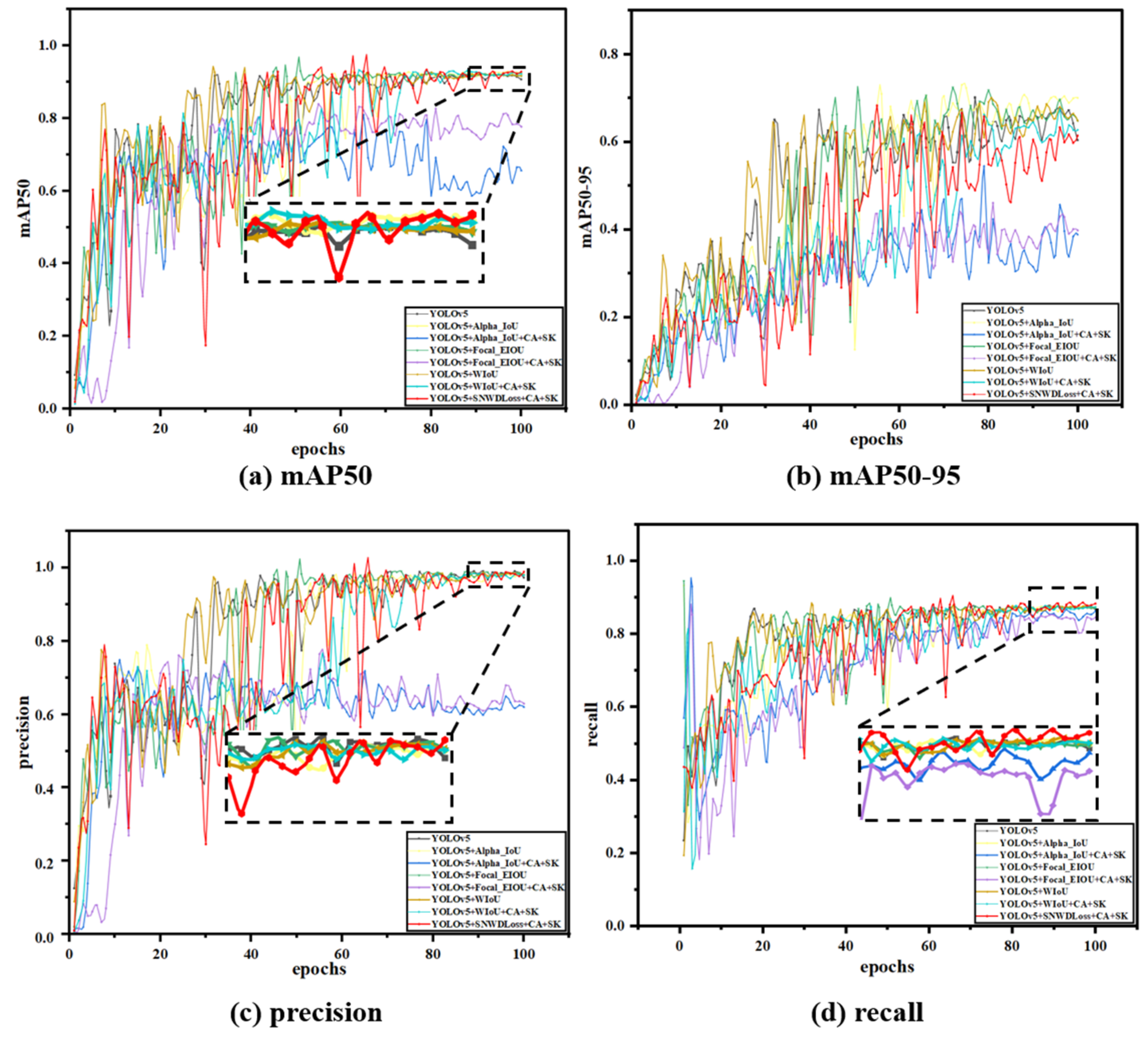

3.5. Ablation Experiment

This study conducted ablation experiments to verify the improved model’s effectiveness. Ablation experiments are a scientific exploration tool that analyzes the significance of each variable on the final result by changing the key variables in the experimental design one by one. We can compare conditional, non-specific situations to identify the key parts of the system’s efficiency, and the advantage of this approach is that it provides evidence of causality, which we believe is necessary to compare the system’s efficiency. It helps us to study how each element affects the model’s performance, and we can add or remove individual elements one by one until we obtain the best performance of the model. In this study, we performed nine sets of improved ablation experiments, and the training results are shown in

Figure 10, with different colored curves representing the training results of the model with various enhancement components.

Figure 9 shows the dynamic distribution of the gas cavity as the metal solidifies when the laser is completely stopped, and a gas cavity is formed in the middle of the melt pool. At this time, the laser radiation intensity is high, the depth of the small holes created during laser irradiation is appropriate, and the gas cavity is located in the middle of the metal material. When the laser stops heating, due to the gas cavity formation position and the distance between the metal surface being more appropriate, the gas cavity can reach the metal surface in a limited period. When the gas cavity reaches the metal surface, the liquid metal continues to solidify the molding. However, suppose the laser stops heating at an inappropriate time. In that case, it may result in the liquid phase metal not being able to fill all of the gas cavity when the gas cavity reaches the metal surface, resulting in an uneven metal surface.

As shown in

Table 2, this study introduces four improvements to the YOLOv5 model to enhance its performance and efficiency. In this study, the code of YOLOv5s (a better-performing version of YOLOv5) was improved by introducing an attention mechanism and a loss function. It achieved specific improvements in accuracy, recall, and average accuracy. In this section, the results are analyzed through fusion experiments. Since several sets of results among the various indicators are pretty similar, and to avoid the lack of rigor in academic research due to numerical differences and fundamental differences, each group of experiments in this section was repeated for five training sessions, and then, the average value was taken, and the confidence range was marked.

The performance of precision and recall was relatively similar across the nine ablation experiments. After adding a single attention mechanism and loss function, both showed a certain degree of decline. The precision (P) decreased from 0.98 to 0.97, and the recall rate (R) dropped from approximately 0.873 to around 0.87. However, after integrating the two loss functions (SNWDLoss), the precision (P) rose to 0.987, which was higher than the original precision of 0.984. Subsequently, when integrating a single attention mechanism, the precision (P) decreased again, and in one of the groups, it was even lower than 0.712. After analysis, this might be due to the CA attention mechanism failing to extract the feature information processed by SIoULoss effectively. However, when combined with other improvement measures, the recall rate (R) improved to 0.878. Finally, after integrating four improvement measures and further optimizing the network structure, the precision (P) and recall rate (R) reached their maximum values of 0.989 and 0.885, respectively.

The average precision (

mAP) of the nine sets of ablation experiments can better reflect the model’s advantages in this study. After adding the attention mechanism and the loss function, the

mAP improved to varying degrees, especially the CA attention mechanism, and the two loss functions has a significant enhancing effect on the

mAP. After introducing CA alone and the two loss functions separately, the average precision increased to around 0.92. Then, the four improvements were fused, achieving an average accuracy of 0.934, 1.8% higher than before. Overall, the recognition effect was significantly improved. To facilitate a more intuitive comparison, this article presents the data in a three-dimensional format, as shown in

Figure 11.

We analyzed the improvement mechanism. SIoULoss is a new-style loss function. In the training process using the classic cross-entropy loss on datasets with class imbalance, there are some problems. SIoULoss can solve these problems. It is particularly good at dealing with small objects and those that are hard to classify. In model training, we will encounter samples that are not easy to distinguish; for example, background noise is like some interference information, which will affect the judgment of the model. By adjusting the importance of negative samples, we pay more attention to non-interfering information. The model will not be affected too much by the interference information, such as background noise, and can concentrate more on learning those essential features, and the accuracy of the overall detection of the model will be improved. We introduced NWDLoss and SIoULoss to detect defects and segment instances so that the inspection results can be more accurate when encountering objects with complex shapes and significant size differences. Wasserstein distance is a more straightforward way to measure spatial differences in features. It is convenient to display the working process of the model visually. Coordinating attention mechanisms places more emphasis on location information. This allows the network to understand the position relationship between objects and the environment information they are in and measure the information more directly, which strengthens the perception of object boundaries and makes the model more accurate when locating the position of objects. Selective Kernel Attention allows the network to dynamically adjust the weights based on the local features of each pixel in the input image. Selecting and combining different filters makes the model more flexible when extracting features, and the extracted features are more targeted and unique. When we combine these four mechanisms in YOLOV5, we can effectively solve the problems of positioning accuracy, small target defect detection, and robustness of complex scenes in the defect detection process, making up for the shortcomings of the previous version, such as resolution dependence, false alarms, and missed detection. These mechanisms improve the model’s ability to understand the situation and process local details. Their combined effect is to optimize the model’s response to various conditions so that it can significantly improve defect detection performance while maintaining good speed.

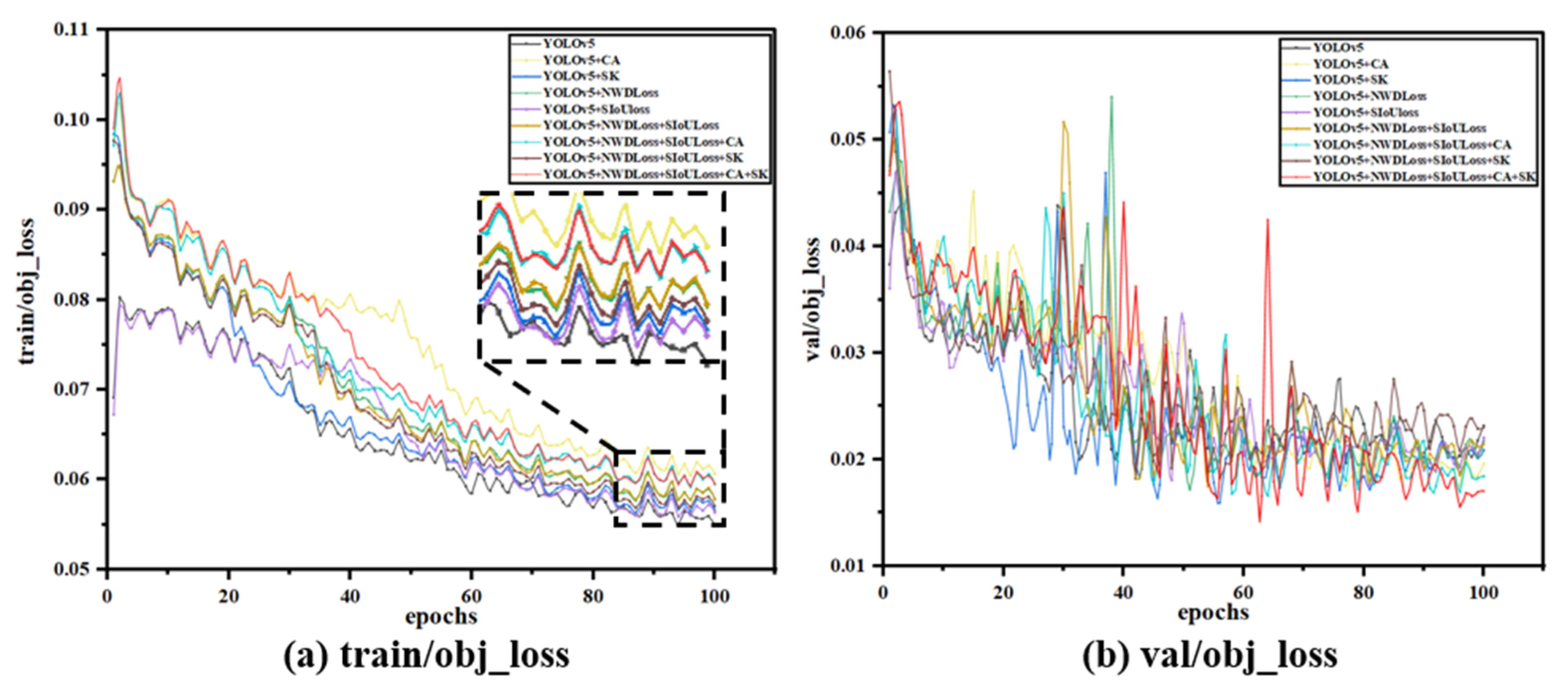

As shown in

Figure 12, the validation loss (val_loss) of the model established in this study is significantly lower than that of other models, reaching a minimum loss value (close to 0.015). The lower the val_loss, the better the model’s understanding and fit of the validation data, the stronger the generalization ability, and the better the performance balance was achieved, and training strategies such as learning rate adjustment and regularization may have played a role in making the model less error-prone while maintaining consistency with new samples. Combined with these four mechanisms, YOLOV5 can effectively solve the problems of positioning accuracy, small target defect detection, and robustness of complex scenes in defect detection. It can compensate for possible defects such as resolution dependence, false alarms, and missed detections in the previous version. These improvements enhance the model’s global understanding and local detailing, and their combined effect optimizes the model’s response to various situations, allowing it to improve defect detection performance while maintaining speed significantly.

3.6. Loss Function Comparative Experiment

To verify the advantages of the new loss function, SNWDLoss, proposed in this study, a comparative experiment was conducted. Several popularly improved loss functions, such as CIoU, WIoU, Focal_EIoU, and Alpha_IoU, were compared with the model of this study. Different loss function models are shown in

Figure 13.

SNWDLoss is an innovative loss function composed of SioULoss and NWDLoss. Compared with other loss function models, the newly proposed SNWDLoss has greatly improved accuracy, recall, and average accuracy. Unlike traditional IOU losses, this study’s design takes into account both the accuracy of defect edge detection and the consistency of the overall structure.

In

Figure 13, this study found that SNWDLoss exhibited higher accuracy and completeness in the target recognition task, and its accuracy (P), recall (R), and average accuracy (

mAP) achieved the best performance among the above models. This may be because SNWDLoss considers both center point and boundary information, improving the accuracy of object positioning, reducing misclassification and missed detections, and helping to alleviate confusion between classes, as SNWDLoss is partly concerned with dice coefficients. SNWDLoss exhibits higher robustness and generalization than loss functions focusing only on a single factor.

Thanks to the better boundary-matching mechanism provided by SIOU, it can handle a variety of complex scenarios, including small target defect detection and background interference, and the experimental results confirm that SNWDLoss, as a new type of loss function, has a significant effect on improving the overall performance and stability of the model. This also shows that the design strategy of the loss function can effectively enhance the performance of the deep learning model in the field of defect detection. The advantage of SNWDLoss lies in its comprehensive and targeted optimization, which enables the model to make more accurate predictions in defect detection tasks and better demonstrate performance benefits in real-world applications.

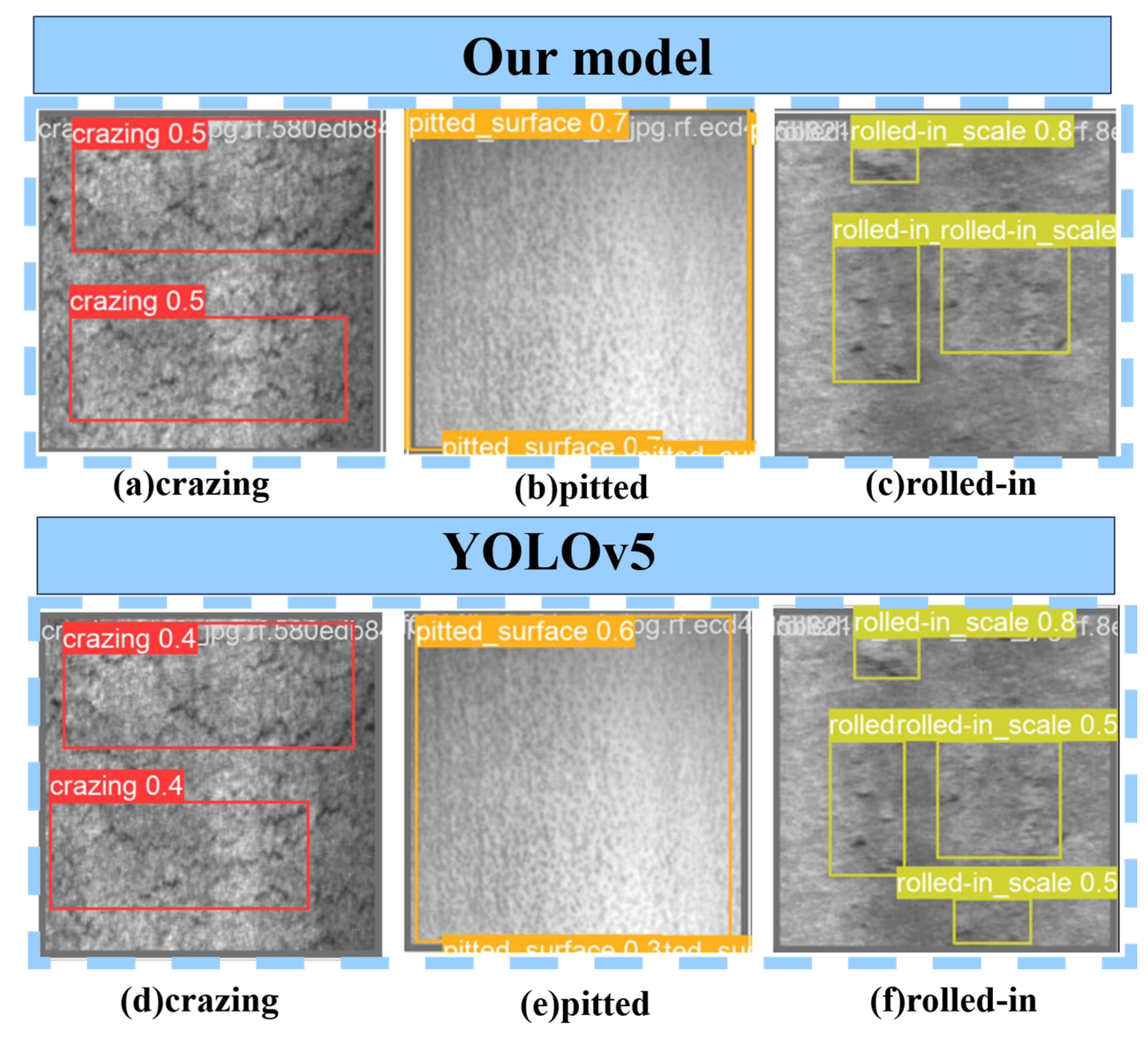

3.7. Universal Experiment

To demonstrate the advantages of the current research model compared to other models, this study conducted a qualitative analysis of the SCK-YOLOv5 and YOLOv5 models. A steel surface defect dataset (NEU-DET) created by the Song Kechen team from Northeastern University was selected. This dataset contains 1800 images. The images in this dataset are widely used by many people and have not been processed before. This universal experimental study did not perform any image processing-related operations on the images within the NEU-DET dataset. The first column shows the test results of the YOLOv5 model, and the second column shows the test results of the KSC-YOLOv5 model.

The results in the graph in

Figure 14 illustrate how well the new model proposed in this study performs in dealing with missed and false detections. Compared with the YOLOV5 model, which already has relatively good recognition accuracy, the SCK-YOLOV5 model in this study shows higher accuracy in detecting metal surface defects such as cracks and pitting surfaces. The SCK-YOLOV5 model makes up for the missed detection of YOLOV5 in rolling in-scale inspection, effectively reducing the error rate. These image representations emphasize the SCK-YOLOV5 model’s ability to accurately identify metal surface defects even in complex visual scenarios, thereby enhancing the robustness and reliability of visual recognition in real-world applications. As shown in

Figure 14.

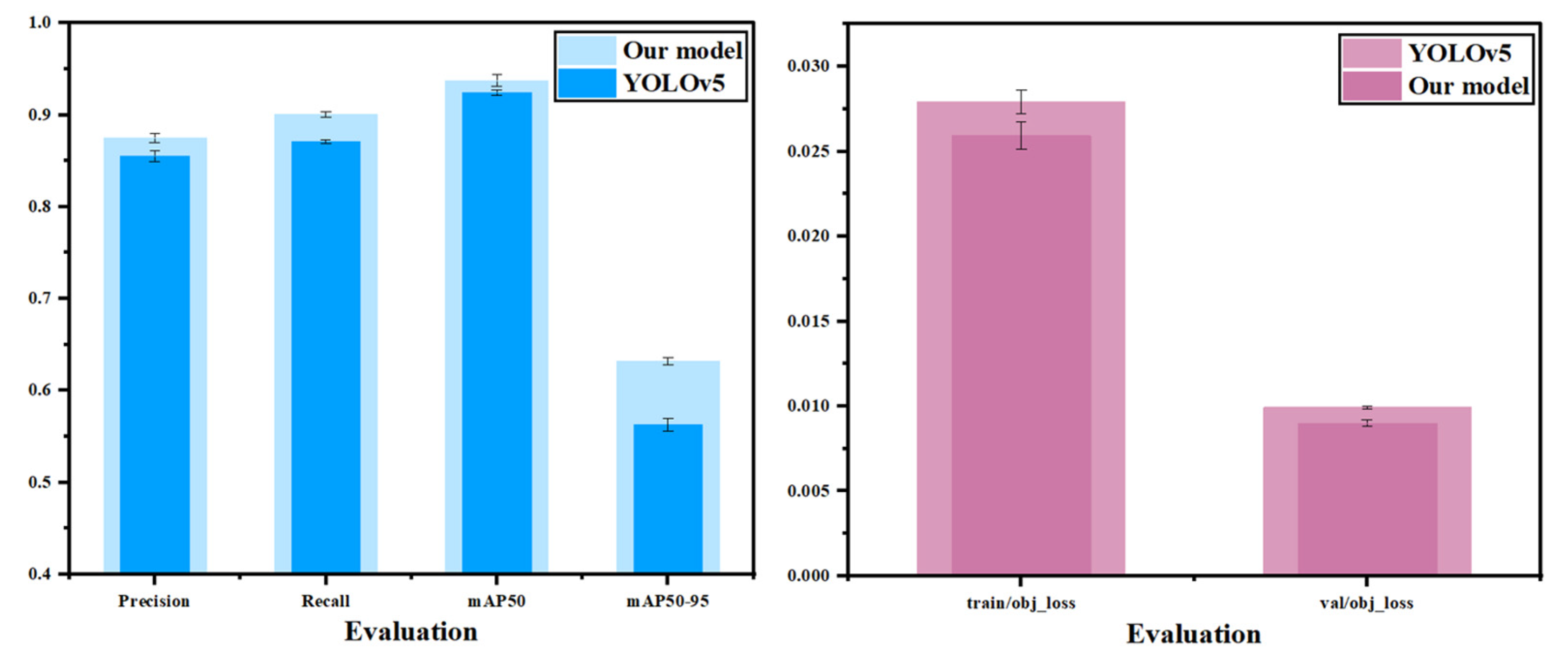

To further verify the numerical performance of the model in this study on the NEU-DET dataset, bar chart data comparison is adopted such

Figure 15 in this section. The mean values of the five experiments in each group were taken. The black intervals in the figure represent the confidence intervals of each experimental index. It can be seen as shown in the figure that in the four metrics of precision (P), recall (R) rate,

mAP@50, and

mAP@50–95, the model studied in this experiment is significantly superior to the source YOLOv5 model, and there is no overlap of confidence intervals between the models, which proves the practicability of the model studied in this experiment on the NEU-DET dataset.

4. Conclusions

Precisely detecting surface defects in metal components made through additive manufacturing poses substantial technical challenges. One of the thorny issues is dealing with highly reflective surfaces. Such surfaces can cause traditional optical measurement methods to yield distorted results. As industrial applications demand micron-level quality control for crucial components more often, the existing vision systems are struggling. They have trouble maintaining the accuracy of inspections when faced with different degrees of surface reflectivity and complex defect shapes. To tackle these limitations, we studied and developed the SCK-YOLOV5 framework.

We created this framework by systematically integrating deep learning optimization techniques and the principles of polarization physics. Our proposed architecture combines the SIoULoss with the normalized Wasserstein distance (NWD) metric learning. This combination is beneficial as it helps enhance the stability of the bounding box used for object detection. Additionally, it boosts the system’s sensitivity to minor defects that might otherwise be overlooked. We employed a hybrid attention mechanism that utilizes coordinate attention (CA) and selective kernel (SK) convolution. This mechanism enables the system to extract features adaptively across various spatial scales. Moreover, the framework can effectively reduce specular reflection by integrating polarization imaging. In doing so, it can retain the defect features that traditional RGB-based systems usually fail to capture or tend to obscure.

Experimental verification has demonstrated that our SCK-YOLOV5 framework significantly outperforms the baseline YOLOV5. Specifically, the accuracy increased by 0.5 percentage points, the recall rate increased by 1.2 percentage points, and the mAP@50 improved by 1.8%. Our framework provides a reliable method for automatically detecting defects in high-precision additive manufacturing applications. Also, it successfully bridges an essential gap between the field of surface physics and data-driven inspection algorithms. However, SCK-YOLOv5 still has room to improve its accuracy of defect recognition. To further optimize the model, we plan to apply it to datasets other than defect detection.