Ultrathin MWCNT/Ti3C2Tx Hybrid Films for Electromagnetic Interference Shielding

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

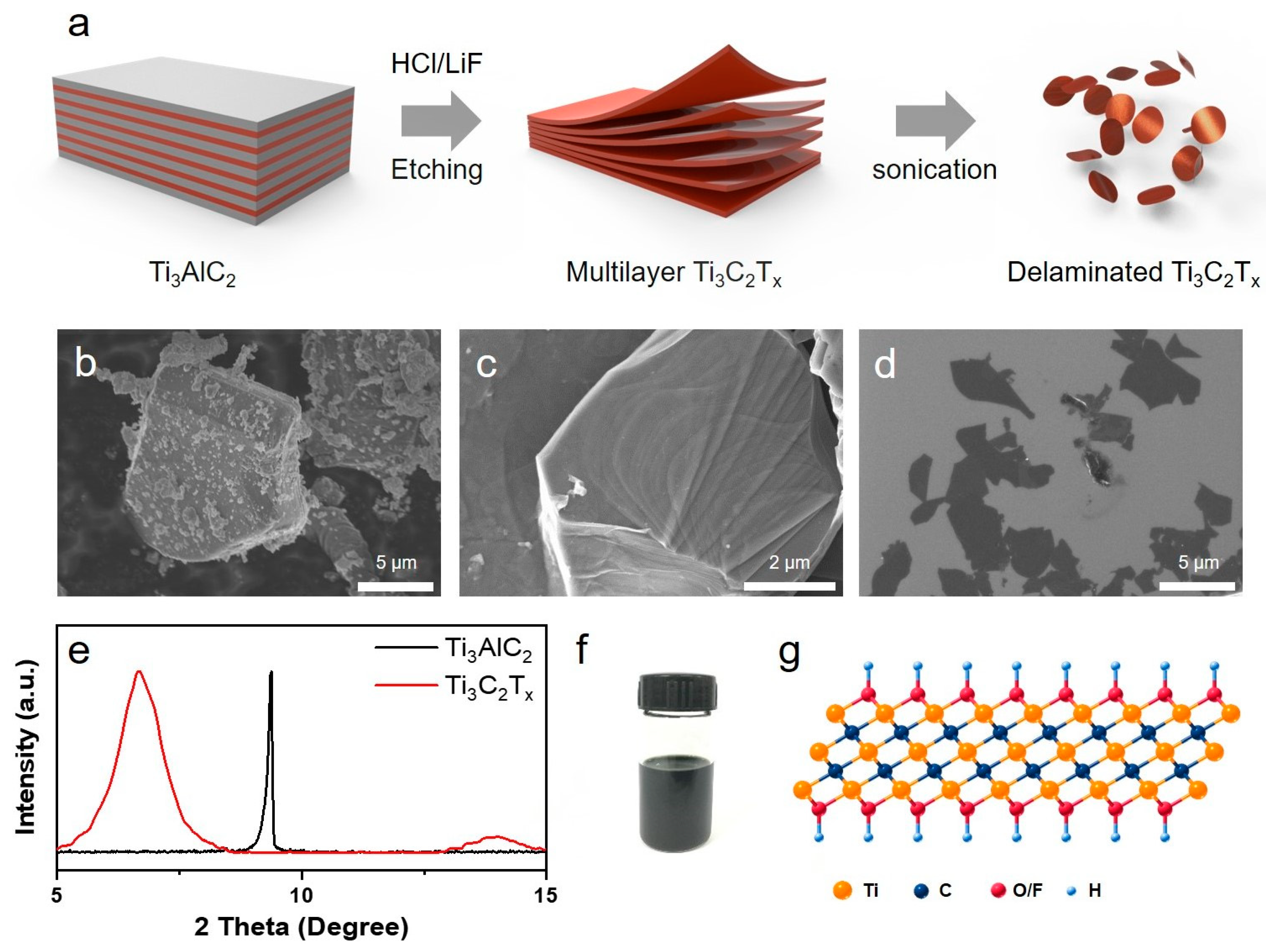

2.2. Preparation of Ti3C2Tx

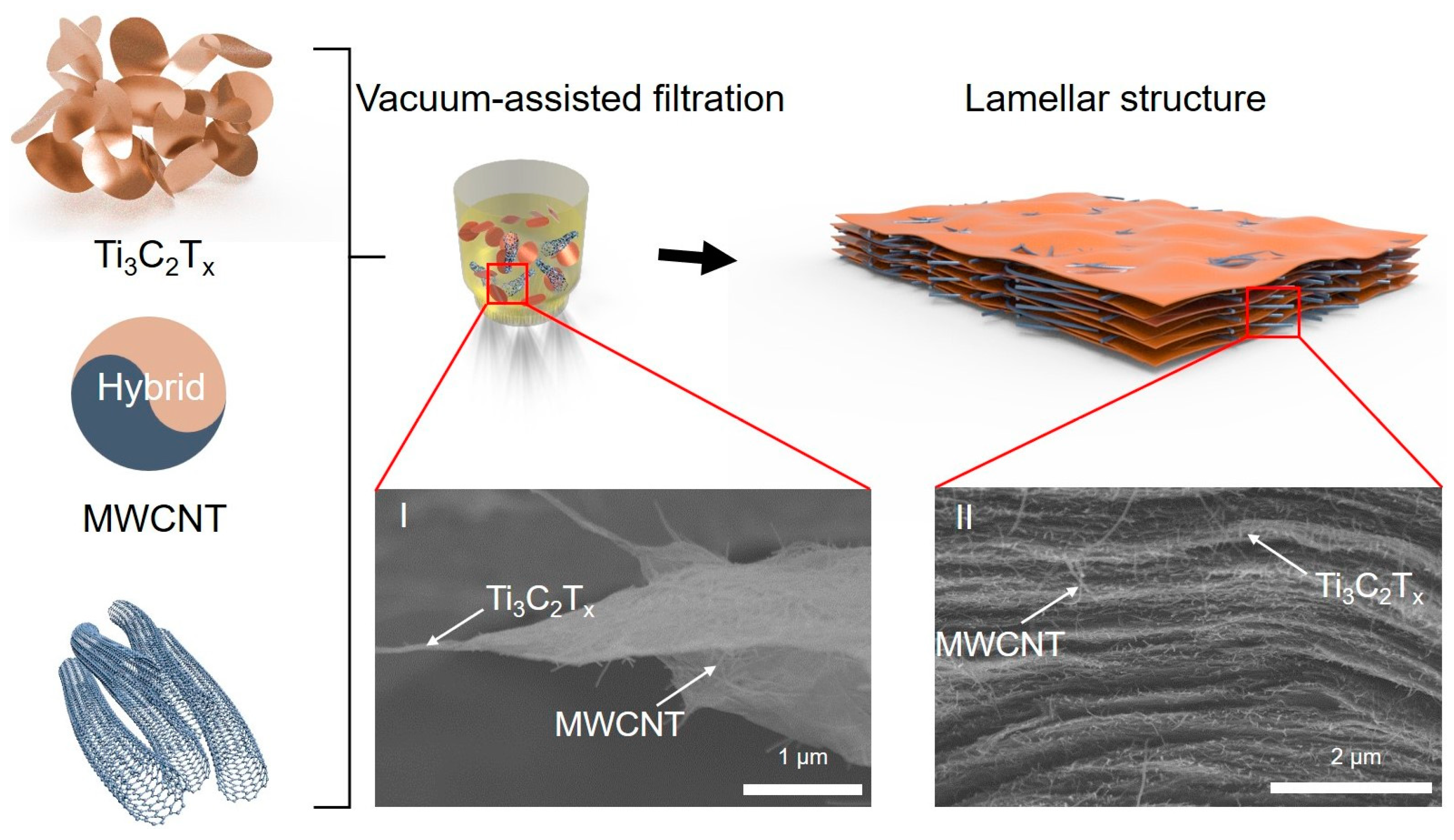

2.3. Preparation of MWCNT/Ti3C2Tx Hybrid Films

2.4. Characterization

2.5. EMI Shielding Effectiveness

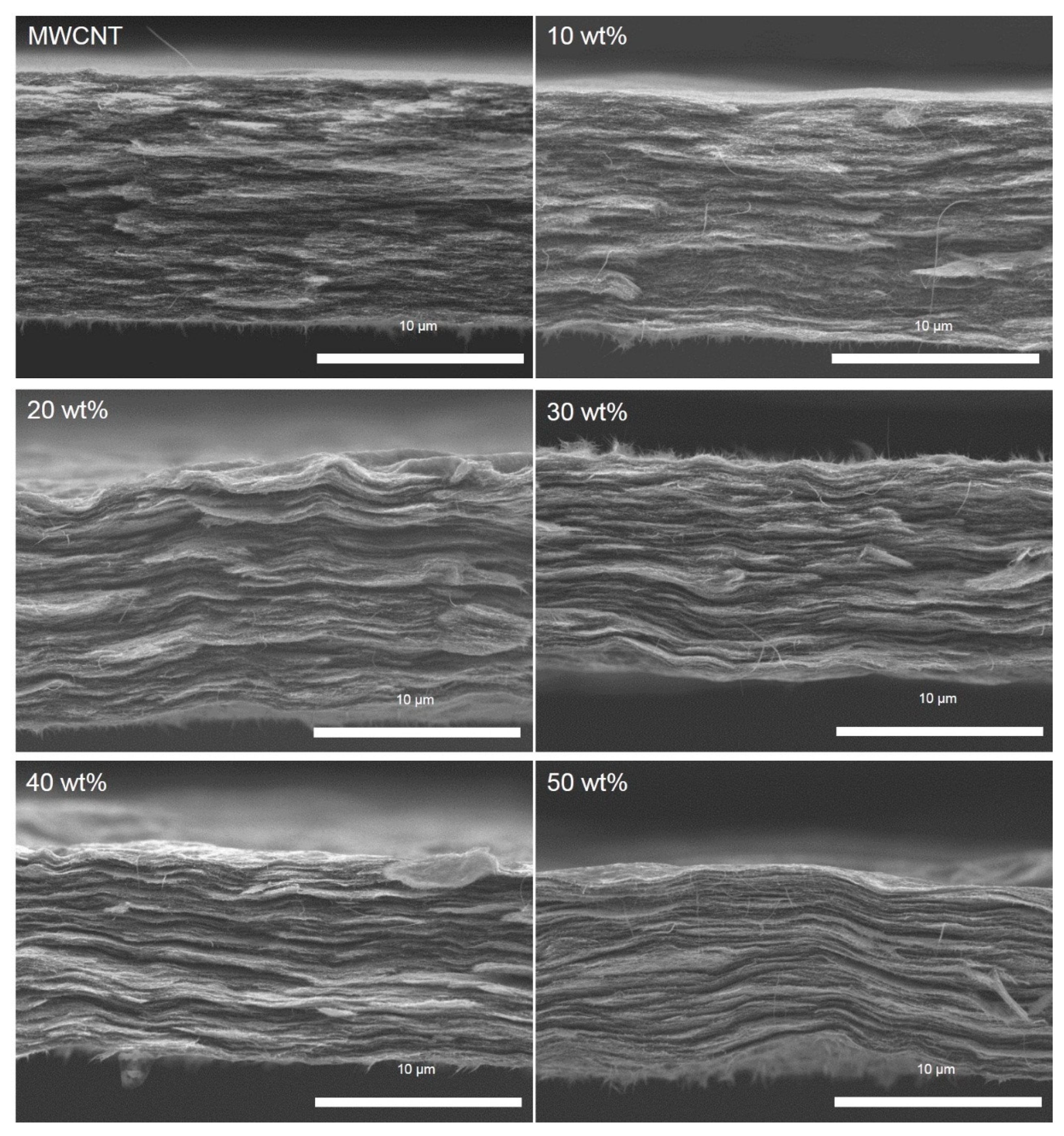

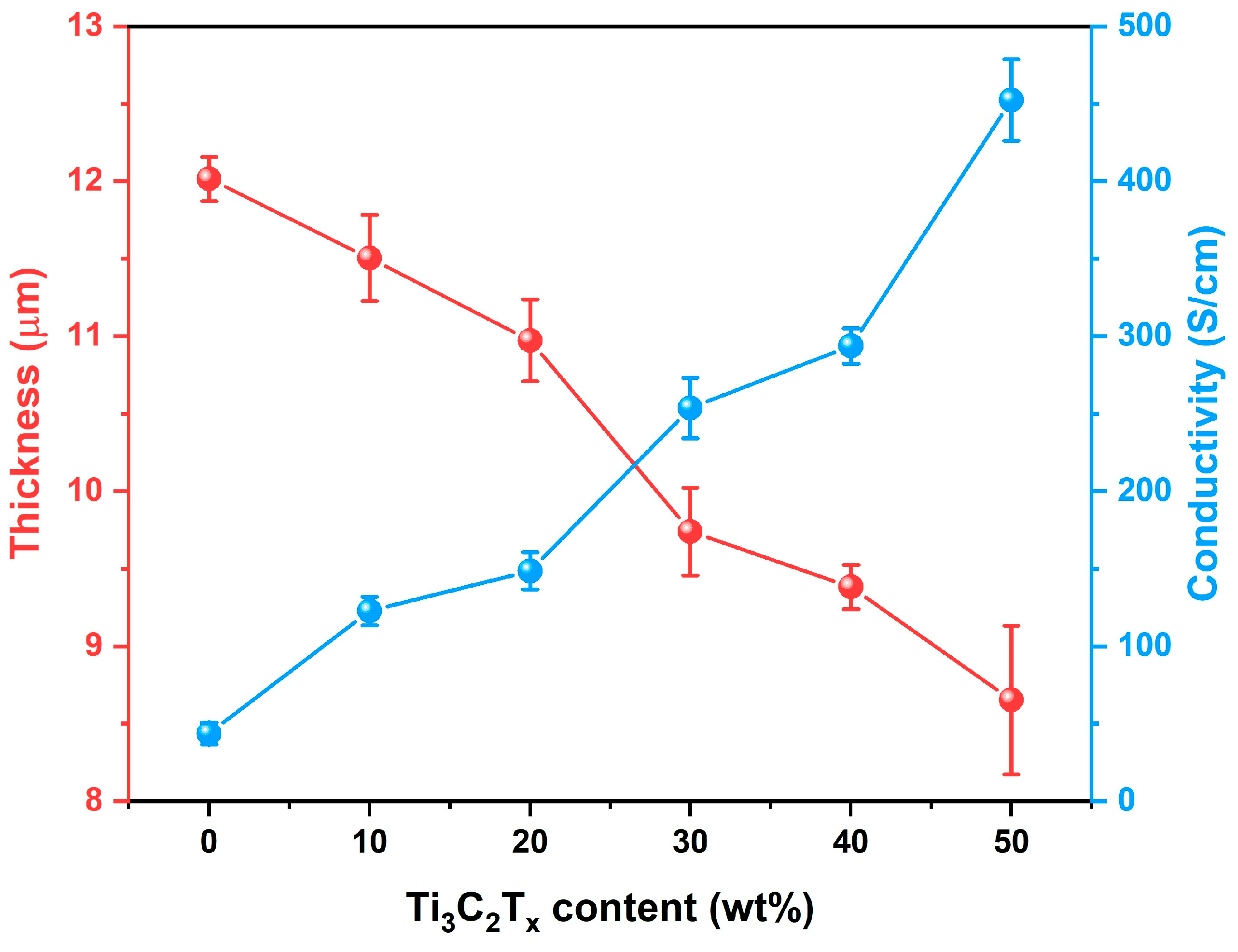

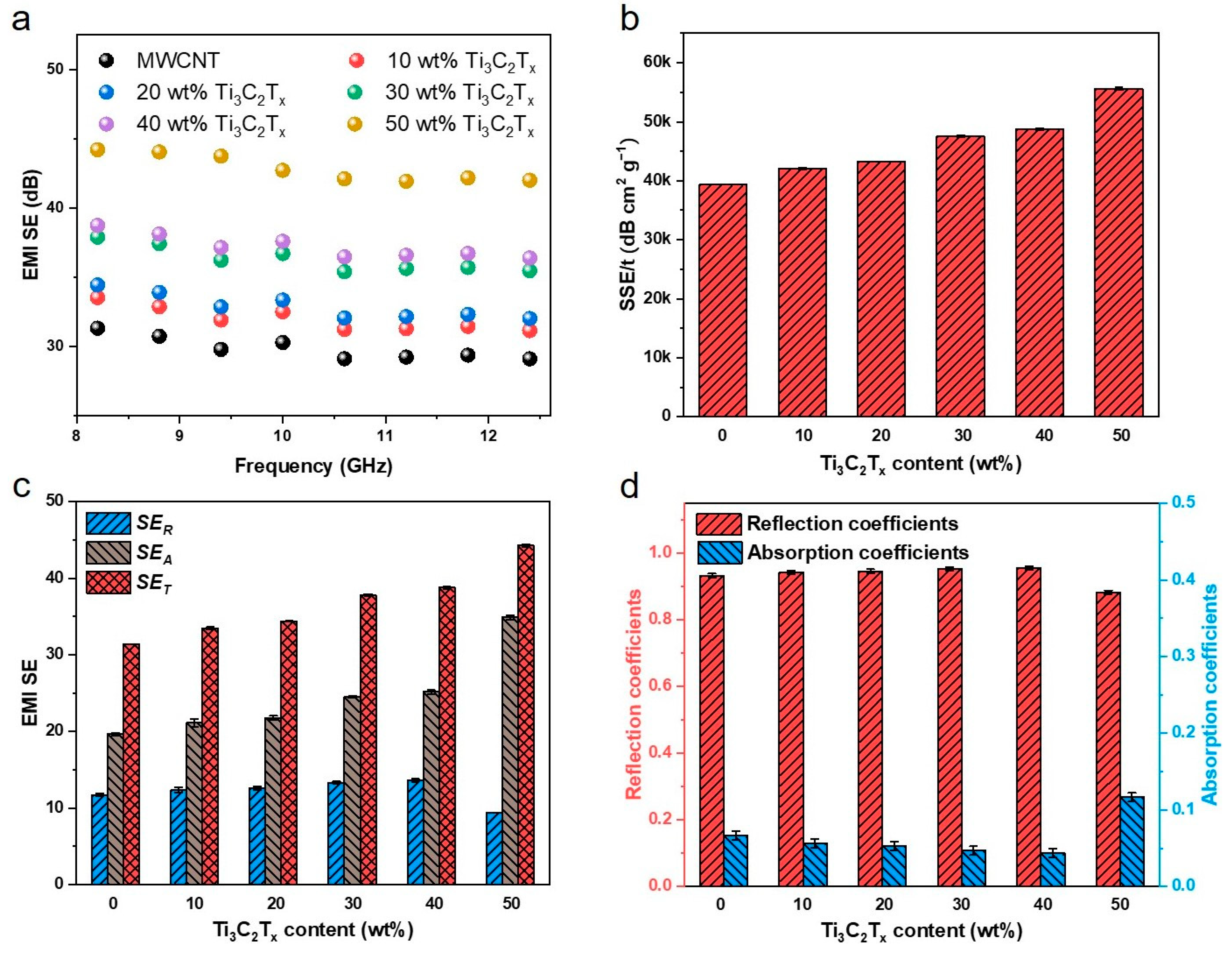

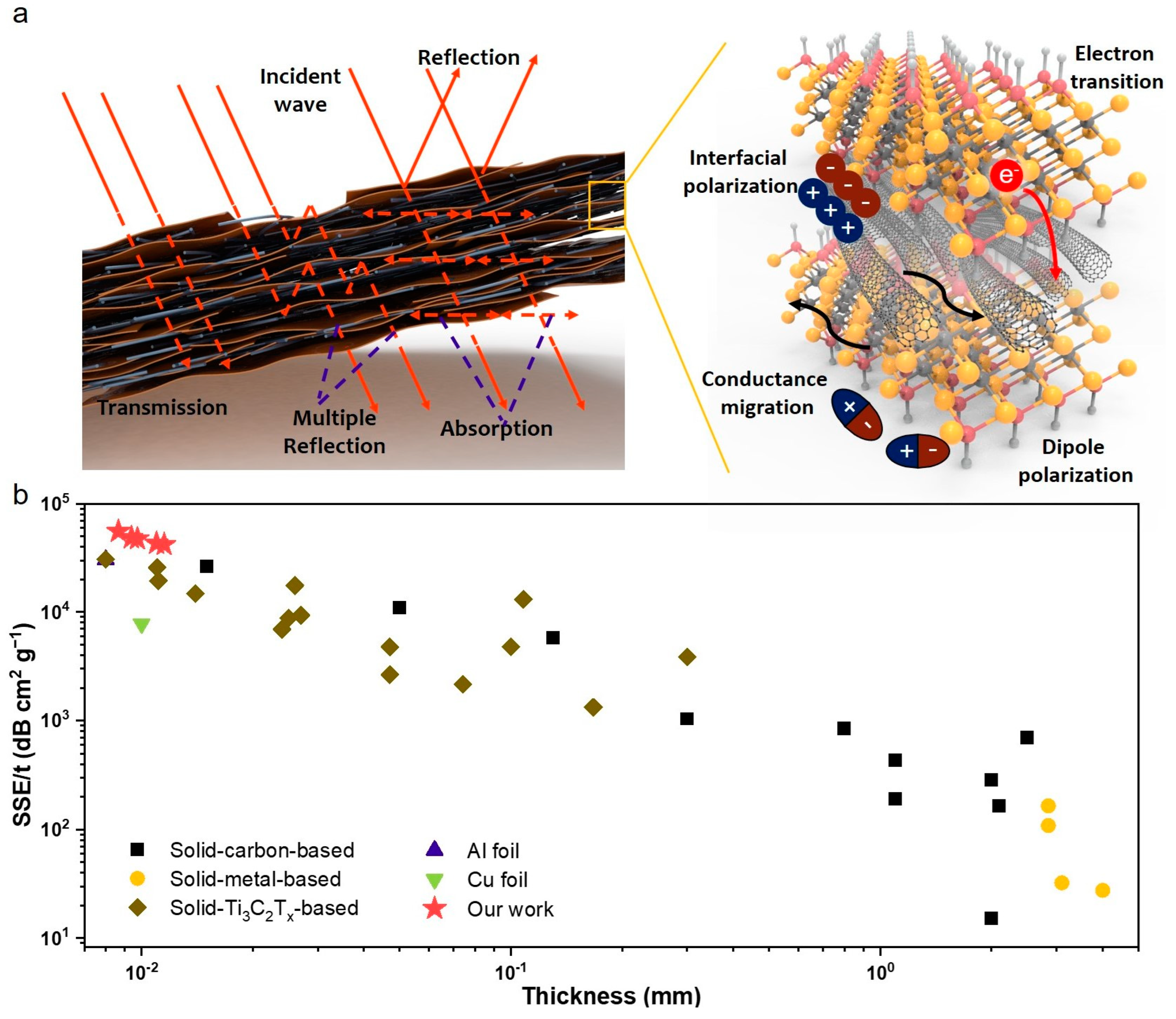

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wen, B.; Cao, M.; Lu, M.; Cao, W.; Shi, H.; Liu, J.; Wang, X.; Jin, H.; Fang, X.; Wang, W.; et al. Reduced graphene oxides: Light-weight and high-efficiency electromagnetic interference shielding at elevated temperatures. Adv. Mater. 2014, 26, 3484–3489. [Google Scholar] [CrossRef]

- Huang, Y.; Li, N.; Ma, Y.; Du, F.; Li, F.; He, X.; Lin, X.; Gao, H.; Chen, Y. The influence of single-walled carbon nanotube structure on the electromagnetic interference shielding efficiency of its epoxy composites. Carbon 2007, 45, 1614–1621. [Google Scholar] [CrossRef]

- Wen, B.; Wang, X.X.; Cao, W.Q.; Shi, H.L.; Lu, M.M.; Wang, G.; Jin, H.B.; Wang, W.Z.; Yuan, J.; Cao, M.S. Reduced graphene oxides: The thinnest and most lightweight materials with highly efficient microwave attenuation performances of the carbon world. Nanoscale 2014, 6, 5754–5761. [Google Scholar] [CrossRef] [PubMed]

- Roosli, M. Radiofrequency electromagnetic field exposure and non-specific symptoms of ill health: A systematic review. Environ. Res. 2008, 107, 277–287. [Google Scholar] [CrossRef]

- Li, D.K.; Chen, H.; Ferber, J.R.; Odouli, R.; Quesenberry, C. Exposure to Magnetic Field Non-Ionizing Radiation and the Risk of Miscarriage: A Prospective Cohort Study. Sci. Rep. 2017, 7, 17541. [Google Scholar] [CrossRef]

- Gong, X.; Hu, T.; Zhang, Y.; Zeng, Y.; Zhang, Y.; Jiang, Z.; Tan, Y.; Zou, Y.; Wang, J.; Dai, J.; et al. Trunk-Inspired SWCNT-Based Wrinkled Films for Highly-Stretchable Electromagnetic Interference Shielding and Wearable Thermotherapy. Nano-Micro Lett. 2024, 16, 243. [Google Scholar] [CrossRef]

- Shui, X.; Chung, D.D.L. Nickel filament polymer-matrix composites with low surface impedance and high electromagnetic interference shielding effectiveness. J. Electron. Mater. 1997, 26, 928–934. [Google Scholar] [CrossRef]

- Zhu, J.; Wei, S.; Haldolaarachchige, N.; Young, D.P.; Guo, Z. Electromagnetic Field Shielding Polyurethane Nanocomposites Reinforced with Core–Shell Fe–Silica Nanoparticles. J. Phys. Chem. C 2011, 115, 15304–15310. [Google Scholar] [CrossRef]

- Wu, S.; Zou, M.; Li, Z.; Chen, D.; Zhang, H.; Yuan, Y.; Pei, Y.; Cao, A. Robust and Stable Cu Nanowire@Graphene Core-Shell Aerogels for Ultraeffective Electromagnetic Interference Shielding. Small 2018, 14, 1800634. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.H.; Jin, H.; Chen, M.J.; Li, W.W.; Zhou, L.C.; Zhang, Z. Lightweight and Anisotropic Porous MWCNT/WPU Composites for Ultrahigh Performance Electromagnetic Interference Shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhou, L.; Xue, X.; Zhang, Z. Microstructure Design of Lightweight, Flexible, and High Electromagnetic Shielding Porous Multiwalled Carbon Nanotube/Polymer Composites. Small 2017, 13, 1701388. [Google Scholar] [CrossRef]

- Feng, R.; Zhu, W.; Yang, W.; Li, S.; Zhang, C.; Li, Z.; Du, S.; Li, Y. Scalable production of flexible and multifunctional graphene-based polymer composite film for high-performance electromagnetic interference shielding. Carbon 2024, 233, 119875. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Q.; Xue, X.; Li, M.; Sun, X.; Zhao, J.; Zhang, W.; Lu, C. Waste flame-retardant polyurethane foam/ground tire rubber/carbon nanotubes composites with hierarchical segregated structures for high efficiency electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2023, 169, 107530. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Zhao, W.; Feng, Y.; Zhou, B.; Liu, C. Flexible, hierarchical MXene@SWNTs transparent conductive film with multi-source thermal response for electromagnetic interference shielding. Compos. Sci. Technol. 2024, 249, 110484. [Google Scholar] [CrossRef]

- Han, Z.; Niu, Y.; Shi, X.; Pan, D.; Liu, H.; Qiu, H.; Chen, W.; Xu, B.B.; El-Bahy, Z.M.; Hou, H.; et al. MXene@c-MWCNT Adhesive Silica Nanofiber Membranes Enhancing Electromagnetic Interference Shielding and Thermal Insulation Performance in Extreme Environments. Nano-Micro Lett. 2024, 16, 195. [Google Scholar] [CrossRef]

- Li, B.; Yang, Y.; Wu, N.; Zhao, S.; Jin, H.; Wang, G.; Li, X.; Liu, W.; Liu, J.; Zeng, Z. Bicontinuous, High-Strength, and Multifunctional Chemical-Cross-Linked MXene/Superaligned Carbon Nanotube Film. ACS Nano 2022, 16, 19293–19304. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Z.H.; Chen, M.J.; Jin, H.; Li, W.W.; Xue, X.; Zhou, L.C.; Pei, Y.M.; Zhang, H.; Zhang, Z. Thin and flexible multi-walled carbon nanotube/waterborne polyurethane composites with high-performance electromagnetic interference shielding. Carbon 2016, 96, 768–777. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Y.; Li, Z.; Ma, J.; Zhou, K.; Liu, C.; Shen, C.; Feng, Y. Fire/heat-resistant, anti-corrosion and folding Ti2C3Tx MXene/single-walled carbon nanotube films for extreme-environmental EMI shielding and solar-thermal conversion applications. J. Mater. Chem. C 2021, 9, 10425–10434. [Google Scholar] [CrossRef]

- Liu, L.X.; Chen, W.; Zhang, H.B.; Wang, Q.W.; Guan, F.; Yu, Z.Z. Flexible and Multifunctional Silk Textiles with Biomimetic Leaf-Like MXene/Silver Nanowire Nanostructures for Electromagnetic Interference Shielding, Humidity Monitoring, and Self-Derived Hydrophobicity. Adv. Funct. Mater. 2019, 29, 1905197. [Google Scholar] [CrossRef]

- Fu, H.; Yang, Z.; Zhang, Y.; Zhu, M.; Jia, Y.; Chao, Z.; Hu, D.; Li, Q. SWCNT-modulated folding-resistant sandwich-structured graphene film for high-performance electromagnetic interference shielding. Carbon 2020, 162, 490–496. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Man Hong, S.; Koo, C.M.; Gogotsi, Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [PubMed]

- Dillon, A.D.; Ghidiu, M.J.; Krick, A.L.; Griggs, J.; May, S.J.; Gogotsi, Y.; Barsoum, M.W.; Fafarman, A.T. Highly Conductive Optical Quality Solution-Processed Films of 2D Titanium Carbide. Adv. Funct. Mater. 2016, 26, 4162–4168. [Google Scholar] [CrossRef]

- Hu, G.; Cen, Z.; Xiong, Y.; Liang, K. Progress of high performance Ti3C2Tx MXene nanocomposite films for electromagnetic interference shielding. Nanoscale 2023, 15, 5579–5597. [Google Scholar] [CrossRef]

- Liu, R.; Miao, M.; Li, Y.; Zhang, J.; Cao, S.; Feng, X. Ultrathin Biomimetic Polymeric Ti3C2Tx MXene Composite Films for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 44787–44795. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for Synthesis and Processing of Two-Dimensional Titanium Carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Wang, Q.-W.; Zhang, H.-B.; Liu, J.; Zhao, S.; Xie, X.; Liu, L.; Yang, R.; Koratkar, N.; Yu, Z.-Z. Multifunctional and Water-Resistant MXene-Decorated Polyester Textiles with Outstanding Electromagnetic Interference Shielding and Joule Heating Performances. Adv. Funct. Mater. 2019, 29, 1806819. [Google Scholar] [CrossRef]

- Akuzum, B.; Maleski, K.; Anasori, B.; Lelyukh, P.; Alvarez, N.J.; Kumbur, E.C.; Gogotsi, Y. Rheological Characteristics of 2D Titanium Carbide (MXene) Dispersions: A Guide for Processing MXenes. ACS Nano 2018, 12, 2685–2694. [Google Scholar] [CrossRef] [PubMed]

- Simon, R.M. Emi Shielding Through Conductive Plastics. Polym.-Plast. Technol. Eng. 1981, 17, 1–10. [Google Scholar] [CrossRef]

- Das, N.C.; Liu, Y.; Yang, K.; Peng, W.; Maiti, S.; Wang, H. Single-walled carbon nanotube/poly(methyl methacrylate) composites for electromagnetic interference shielding. Polym. Eng. Sci. 2009, 49, 1627–1634. [Google Scholar] [CrossRef]

- Yan, D.-X.; Pang, H.; Li, B.; Vajtai, R.; Xu, L.; Ren, P.-G.; Wang, J.-H.; Li, Z.-M. Structured Reduced Graphene Oxide/Polymer Composites for Ultra-Efficient Electromagnetic Interference Shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Song, W.-L.; Guan, X.-T.; Fan, L.-Z.; Cao, W.-Q.; Wang, C.-Y.; Zhao, Q.-L.; Cao, M.-S. Magnetic and conductive graphene papers toward thin layers of effective electromagnetic shielding. J. Mater. Chem. A 2015, 3, 2097–2107. [Google Scholar] [CrossRef]

- Agnihotri, N.; Chakrabarti, K.; De, A. Highly efficient electromagnetic interference shielding using graphite nanoplatelet/poly(3,4-ethylenedioxythiophene)–poly(styrenesulfonate) composites with enhanced thermal conductivity. RSC Adv. 2015, 5, 43765–43771. [Google Scholar] [CrossRef]

- Pande, S.; Chaudhary, A.; Patel, D.; Singh, B.P.; Mathur, R.B. Mechanical and electrical properties of multiwall carbon nanotube/polycarbonate composites for electrostatic discharge and electromagnetic interference shielding applications. RSC Adv. 2014, 4, 13839–13849. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Saadeh, W.H.; Sundararaj, U. EMI shielding effectiveness of carbon based nanostructured polymeric materials: A comparative study. Carbon 2013, 60, 146–156. [Google Scholar] [CrossRef]

- Arjmand, M.; Apperley, T.; Okoniewski, M.; Sundararaj, U. Comparative study of electromagnetic interference shielding properties of injection molded versus compression molded multi-walled carbon nanotube/polystyrene composites. Carbon 2012, 50, 5126–5134. [Google Scholar] [CrossRef]

- Ghosh, P.; Chakrabarti, A. Conducting carbon black filled EPDM vulcanizates: Assessment of dependence of physical and mechanical properties and conducting character on variation of filler loading. Eur. Polym. J. 2000, 36, 1043–1054. [Google Scholar] [CrossRef]

- Zhou, E.; Xi, J.; Guo, Y.; Liu, Y.; Xu, Z.; Peng, L.; Gao, W.; Ying, J.; Chen, Z.; Gao, C. Synergistic effect of graphene and carbon nanotube for high-performance electromagnetic interference shielding films. Carbon 2018, 133, 316–322. [Google Scholar] [CrossRef]

- Lu, S.; Shao, J.; Ma, K.; Chen, D.; Wang, X.; Zhang, L.; Meng, Q.; Ma, J. Flexible, mechanically resilient carbon nanotube composite films for high-efficiency electromagnetic interference shielding. Carbon 2018, 136, 387–394. [Google Scholar] [CrossRef]

- Zhang, D.; Villarreal, M.G.; Cabrera, E.; Benatar, A.; James Lee, L.; Castro, J.M. Performance study of ultrasonic assisted processing of CNT nanopaper/solventless epoxy composite. Compos. Part B Eng. 2019, 159, 327–335. [Google Scholar] [CrossRef]

- Cao, W.T.; Chen, F.F.; Zhu, Y.J.; Zhang, Y.G.; Jiang, Y.Y.; Ma, M.G.; Chen, F. Binary Strengthening and Toughening of MXene/Cellulose Nanofiber Composite Paper with Nacre-Inspired Structure and Superior Electromagnetic Interference Shielding Properties. ACS Nano 2018, 12, 4583–4593. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.X.; Wang, J.F.; Dai, L.Z.; Liu, X.Y.; Li, L.; Yang, Y.Y.; Cao, Y.X.; Wang, W.J.; Wu, H.; Guo, S.Y. Flame-retardant poly(vinyl alcohol)/MXene multilayered films with outstanding electromagnetic interference shielding and thermal conductive performances. Chem. Eng. J. 2020, 380, 122475. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, J.; Zhang, X.; Tian, D.; Zhan, Z.; Lu, C. Ultrathin MXene/Calcium Alginate Aerogel Film for High-Performance Electromagnetic Interference Shielding. Adv. Mater. Interfaces 2019, 6, 1802040. [Google Scholar] [CrossRef]

- Zhan, Z.Y.; Song, Q.C.; Zhou, Z.H.; Lu, C.H. Ultrastrong and conductive MXene/cellulose nanofiber films enhanced by hierarchical nano-architecture and interfacial interaction for flexible electromagnetic interference shielding. J. Mater. Chem. C 2019, 7, 9820–9829. [Google Scholar] [CrossRef]

- Liang, W.; Wu, J.; Zhang, S.; Zhao, P.-Y.; Zuo, X.; Wang, G.-S. Construction of PI-MXene-MWCNT nanocomposite film integrating conductive gradient with sandwich structure for high-efficiency electromagnetic interference shielding in extreme environments. Carbon 2024, 228, 119328. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, C.; He, J.; Tian, J.; Wu, W.; Li, J.; Zhang, J.; Yu, H.; Zhang, X.; Lu, M. Ultrathin MWCNT/Ti3C2Tx Hybrid Films for Electromagnetic Interference Shielding. Nanomaterials 2025, 15, 6. https://doi.org/10.3390/nano15010006

Weng C, He J, Tian J, Wu W, Li J, Zhang J, Yu H, Zhang X, Lu M. Ultrathin MWCNT/Ti3C2Tx Hybrid Films for Electromagnetic Interference Shielding. Nanomaterials. 2025; 15(1):6. https://doi.org/10.3390/nano15010006

Chicago/Turabian StyleWeng, Chuanxin, Junzhe He, Jiangxiao Tian, Wei Wu, Jinjin Li, Jiulin Zhang, Haitao Yu, Xuechuan Zhang, and Mingming Lu. 2025. "Ultrathin MWCNT/Ti3C2Tx Hybrid Films for Electromagnetic Interference Shielding" Nanomaterials 15, no. 1: 6. https://doi.org/10.3390/nano15010006

APA StyleWeng, C., He, J., Tian, J., Wu, W., Li, J., Zhang, J., Yu, H., Zhang, X., & Lu, M. (2025). Ultrathin MWCNT/Ti3C2Tx Hybrid Films for Electromagnetic Interference Shielding. Nanomaterials, 15(1), 6. https://doi.org/10.3390/nano15010006