Biopolymer Meets Nanoclay: Rational Fabrication of Superb Adsorption Beads from Green Precursors for Efficient Capture of Pb(II) and Dyes

Abstract

1. Introduction

2. Experimental

2.1. Materials and Reagents

2.2. Preparation of SA/PASP/RE Composite Beads

2.3. Adsorption Experiments

2.4. Adsorption of MB and Pb(II) in Different Natural Waters

2.5. Desorption and Recycling Experiment

2.6. Characterization

3. Results and Discussion

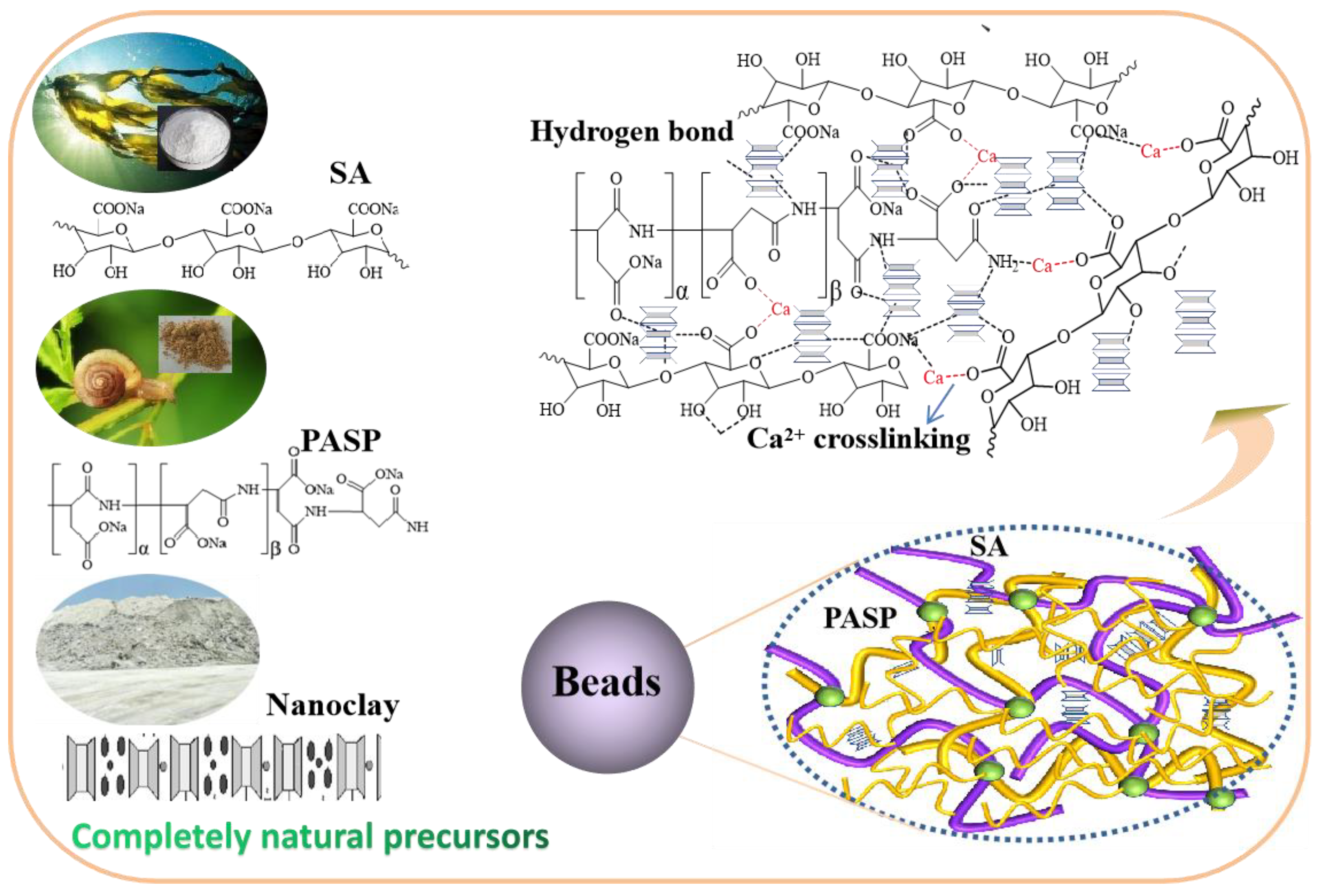

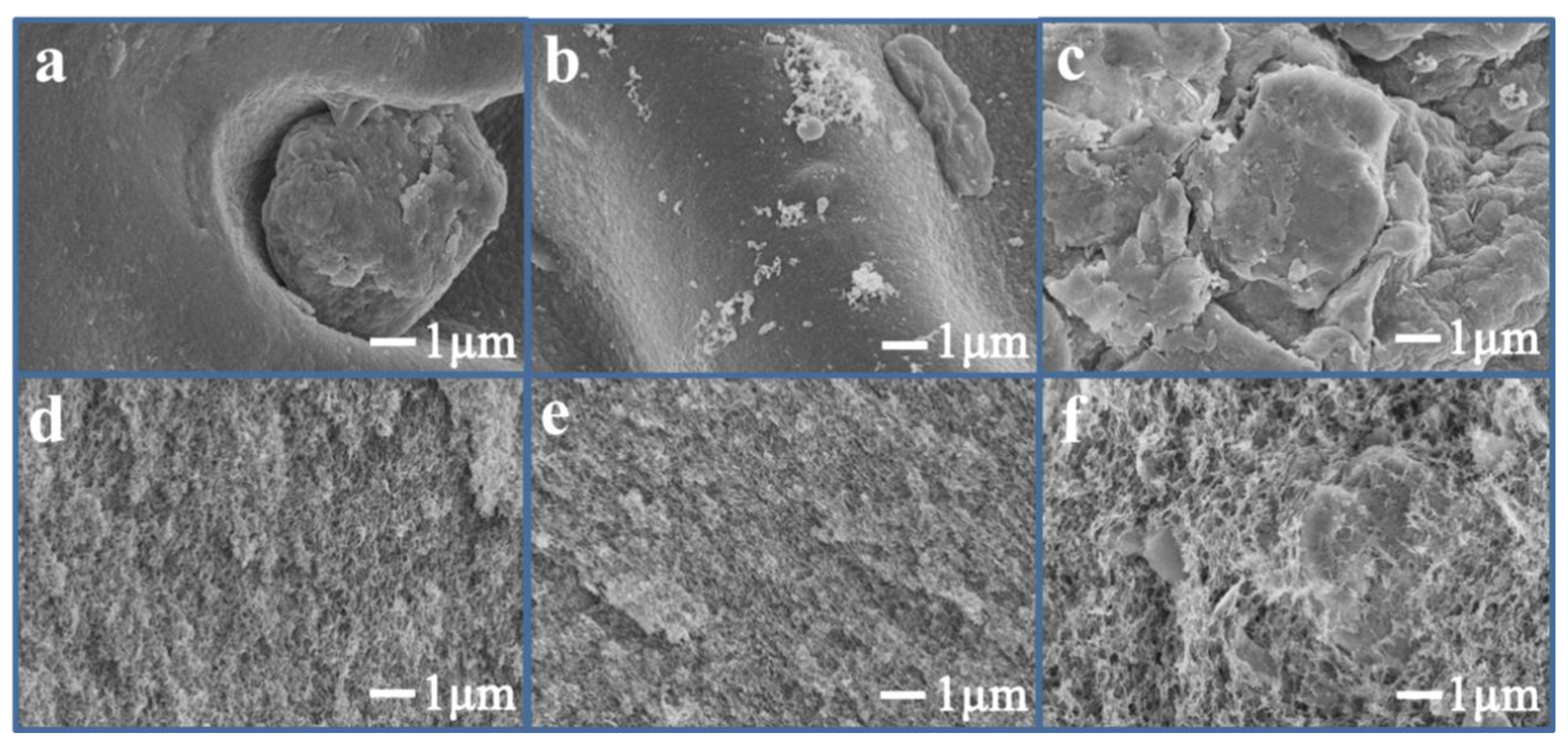

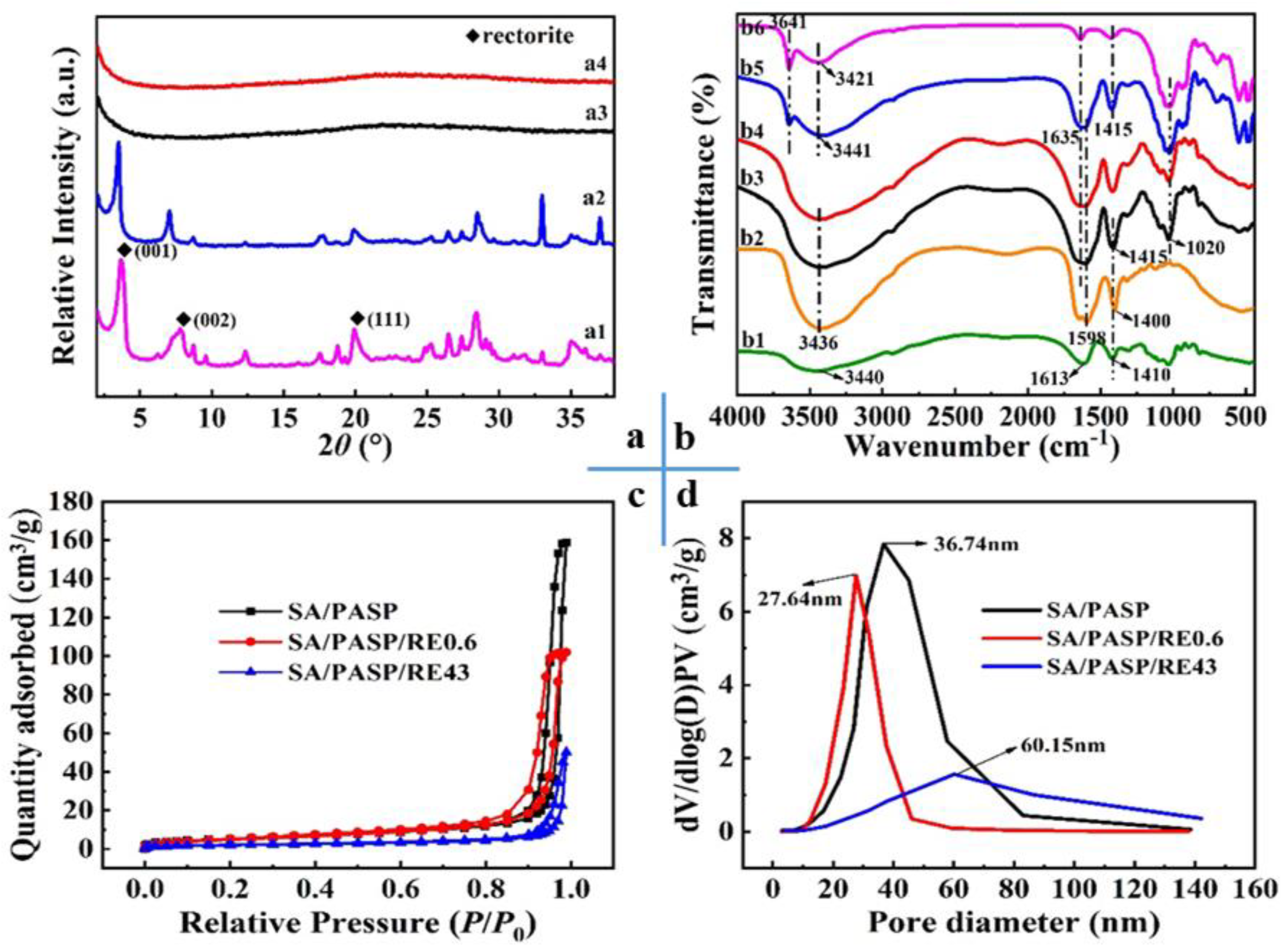

3.1. Structure and Morphology of Beads

3.2. Adsorption Properties

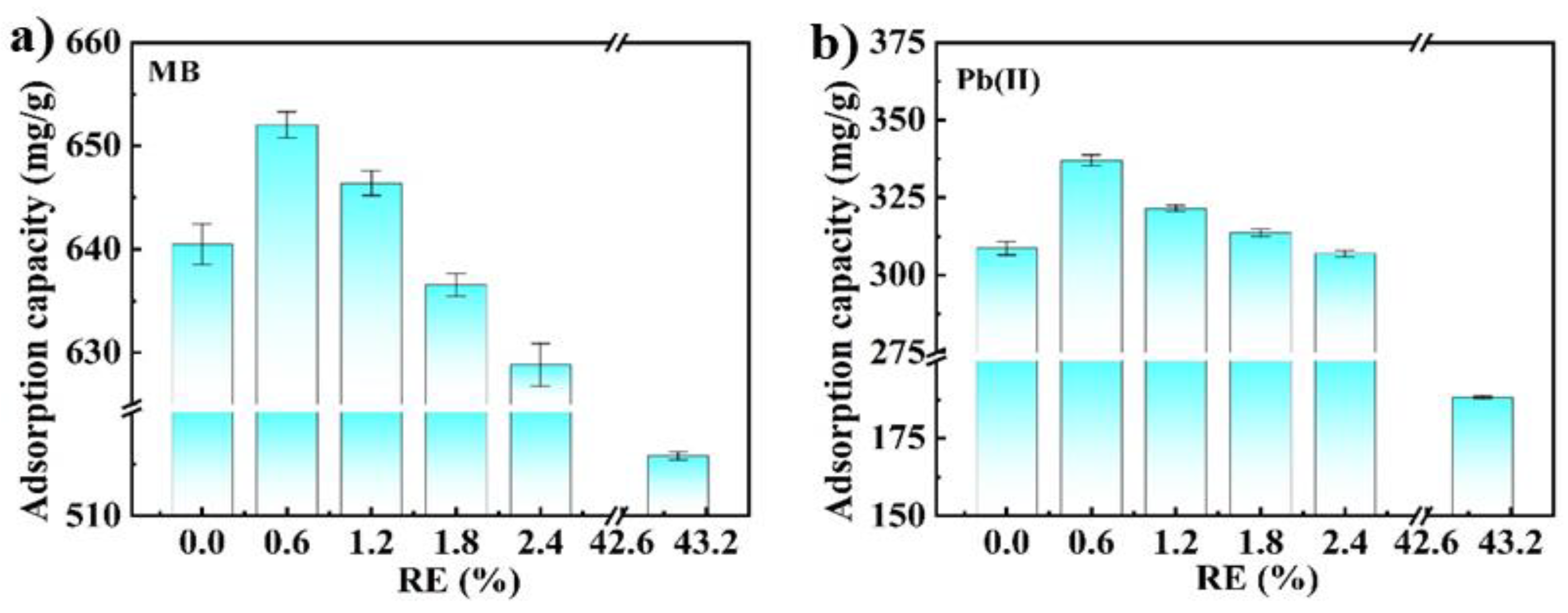

3.2.1. Effect of RE Content on Adsorption Capacity

3.2.2. Influence of External pH on Adsorption

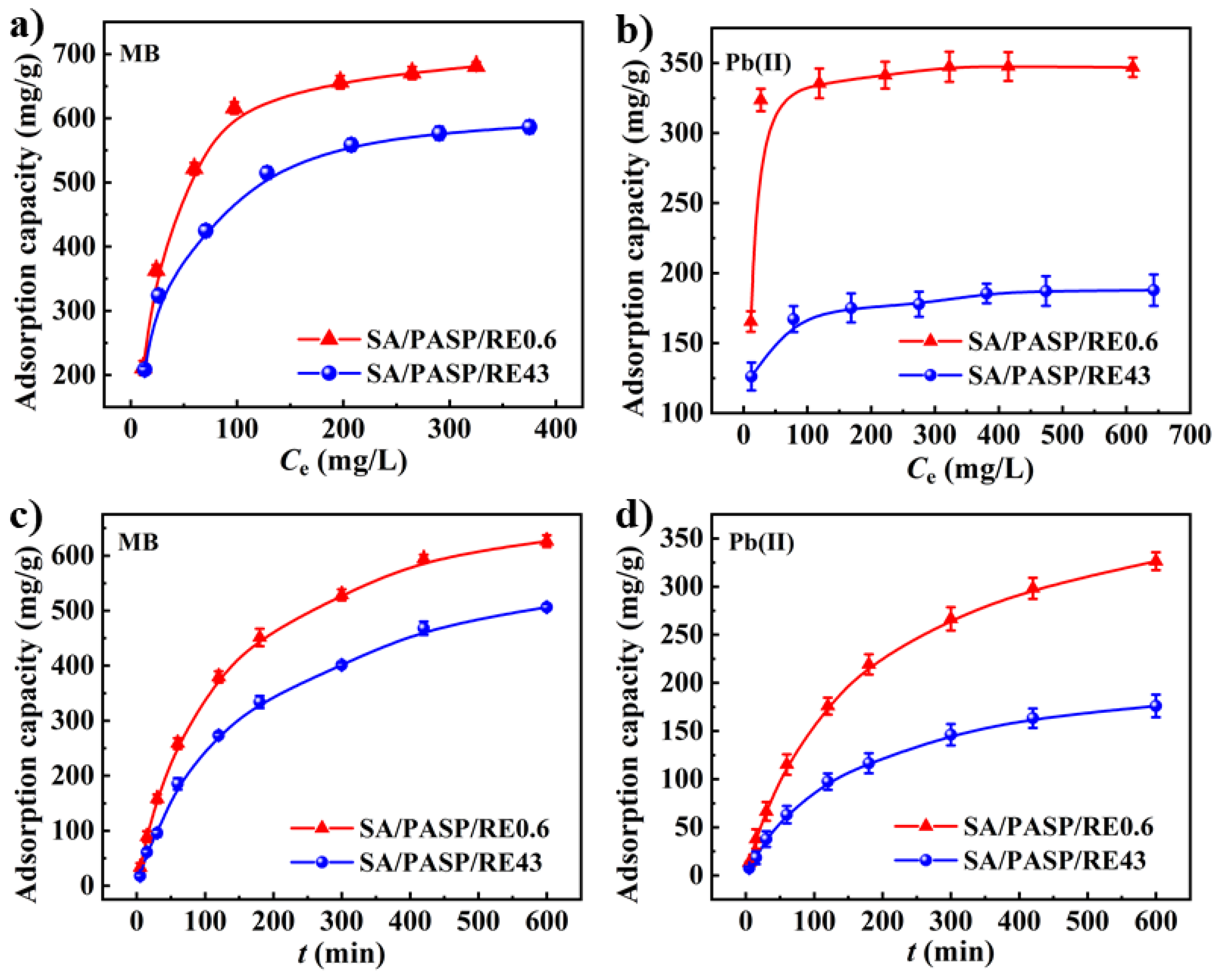

3.2.3. Adsorption Isotherms and Kinetics

3.2.4. Adsorption of MB and Pb(II) in Natural Water

3.2.5. Reusability

3.3. Adsorption Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, J.X.; Yuan, X.S.; Wu, X.X.; Liu, L.; Guo, H.Y.; Xu, K.M.; Zhang, L.P.; Du, G.B. Preparation of nanocellulose-based aerogel and its research progress in wastewater treatment. Molecules 2023, 28, 3541. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Li, Y.; Jia, X.; Yang, J.; Miao, X.; Shao, D.; Wu, J.; Song, H. 2D/2D ultrathin polypyrrole heterojunct aerogel with synergistic photocatalytic-photothermal evaporation performance for efficient water purification. Desalination 2024, 574, 117295. [Google Scholar] [CrossRef]

- Jamali, M.; Akbari, A. Facile fabrication of magnetic chitosan hydrogel beads and modified by interfacial polymerization method and study of adsorption of cationic/anionic dyes from aqueous solution. J. Environ. Chem. Eng. 2021, 93, 105175. [Google Scholar] [CrossRef]

- Sultan, M. Polyurethane for removal of organic dyes from textile wastewater. Environ. Chem. Lett. 2017, 15, 347–366. [Google Scholar] [CrossRef]

- Chauhan, M.; Sharma, B.; Kumar, R.; Chaudhary, G.; Hassan, A.; Kumar, S. Green synthesis of CuO nanomaterials and their proficient use for organic waste removal and antimicrobial application. Environ. Res. 2019, 169, 85–95. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Song, H.; Li, Y.; Yang, J.; Jia, X.; Wang, S.; Yang, X. Integrated reduced graphene oxide/polypyrrole hybrid aerogels for simultaneous photocatalytic decontamination and water evaporation. Appl. Catal. B Environ. 2022, 301, 120820. [Google Scholar] [CrossRef]

- Ponce, J.; Peña, J.; Román, J.; Pastor, J.M. Recyclable photocatalytic composites based on natural hydrogels for dye degradation in wastewaters. Sep. Purif. Technol. 2022, 299, 121759. [Google Scholar] [CrossRef]

- Wang, Y.W.; Wang, W.B. Multiffunctional materials with controllable super-wettability for oil-water separation and removal of pollutants: Design, emerging applications and challenges. Carbon Neutralization 2023, 2, 378–412. [Google Scholar] [CrossRef]

- Wang, J.; Yao, J.; Wang, L.; Xue, Q.; Hu, Z.; Pan, B. Multivariate optimization of the pulse electrochemical oxidation for treating recalcitrant dye wastewater. Sep. Purif. Technol. 2020, 230, 115851. [Google Scholar] [CrossRef]

- Shikha, S.; Pattanayek, S.K. The surface chemical functionality and diffusion mediated adsorption of organophosphates from their low concentration. Chem. Eng. Res. Des. 2022, 188, 130–141. [Google Scholar] [CrossRef]

- Zhao, W.T.; Zhang, H.; He, Q.D.; Han, L.; Wang, T.Y.; Guo, F.; Wang, W.B. Controllable synthesis of porous silicate@carbon heterogeneous composite from Coal Gangue waste as eco-friendly superior scavenger of dyes. J. Clean. Prod. 2022, 363, 132466. [Google Scholar] [CrossRef]

- Yan, J.H.; Li, K.R. A magnetically recyclable polyampholyte hydrogel adsorbent functionalized with β-cyclodextrin and graphene oxide for cationic/anionic dyes and heavy metal ion wastewater remediation. Sep. Purif. Technol. 2021, 277, 119469. [Google Scholar] [CrossRef]

- Nizam, N.U.M.; Hanafiah, M.M.; Mahmoudi, E.; Mohammad, A.W.; Oyekanmi, A.A. Effective adsorptive removal of dyes and heavy metal using graphene oxide based Pre-treated with NaOH/H2SO4 rubber seed shells synthetic graphite Precursor: Equilibrium Isotherm, kinetics and thermodynamic studies. Sep. Purif. Technol. 2022, 289, 120730. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Strömvall, A.; Steenari, B.-M. Adsorption of Cd, Cu, Ni, Pb and Zn on Sphagnum peat from solutions with low metal concentrations. J. Hazard. Mater. 2008, 152, 885–891. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.L.; Li, Y.; Huang, J.; Zhou, Y.Z.; Li, B.L.; Liu, D.B. Efficiency and mechanism of adsorption of low concentration uranium in water by extracellular polymeric substances. J. Environ. Radioactiv. 2019, 197, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.Y.; Liu, X.Y.; Lu, H.; He, Q.D.; Ding, K.; Wang, X.H.; Wang, W.B.; Guo, F. Chitosan-based composite hydrogel with a rigid-in-flexible network structure for pH-universal ultra-efficient removal of dye. Int. J. Biol. Macromol. 2023, 241, 124579. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.P.; Hasi, Q.M.; Yu, J.L.; Guo, Y.Y.; Song, L.Y.; Wu, S.; Luo, X.P.; Chen, L.H. Carboxymethyl cellulose/sulfonated conjugated microporous polymer composite aerogel for efficient pollution removal and water evaporation. Sep. Purif. Technol. 2023, 324, 124518. [Google Scholar] [CrossRef]

- Wang, W.B.; Zhao, W.T.; Zhang, H.; Xu, J.; Zong, L.; Kang, Y.R.; Wang, A.Q. Mesoporous polymetallic silicate derived from naturally abundant mixed clay: A potential robust adsorbent for removal of cationic dye and antibiotic. Powder Technol. 2021, 390, 303–314. [Google Scholar] [CrossRef]

- Lai, K.C.; Lee, L.Y.; Hiew, B.Y.Z.; Thangalazhy-Gopakumar, S.; Gan, S. Environmental application of three-dimensional graphene materials as adsorbents for dyes and heavy metals: Review on ice-templating method and adsorption mechanisms. J. Environ. Sci. 2019, 79, 174–199. [Google Scholar] [CrossRef]

- Wang, Y.W.; Liu, X.Y.; He, Q.D.; Lu, H.; Guo, F.; Zhang, Y.J.; Wang, W.B. One-step efficient separation of heavy/light oils, dyes and water by simple filtration with a 3D architecture of functional mesh and sisal fiber felt. Sep. Purif. Technol. 2022, 286, 120461. [Google Scholar] [CrossRef]

- Hou, P.; Xing, G.; Tian, L.; Zhang, G.; Wang, H.; Yu, C.; Li, Y.; Wu, Z. Hollow carbon spheres/graphene hybrid aerogels as high-performance adsorbents for organic pollution. Sep. Purif. Technol. 2019, 213, 524–532. [Google Scholar] [CrossRef]

- He, Q.D.; Liu, X.Y.; Wang, Y.W.; Ding, K.; Ge, H.W.; Xie, C.Z.; Wang, W.B.; Guo, F. Circular conversion of waste rectorite@dye to efficient and pH-resistant heterogeneous silicate adsorbents for cyclic and complete dye removal. Appl. Clay Sci. 2022, 225, 106556. [Google Scholar] [CrossRef]

- Wang, W.B.; Wang, A.Q. Perspectives on green fabrication and sustainable utilization of adsorption materials for wastewater treatment. Chem. Eng. Res. Des. 2022, 187, 541–548. [Google Scholar] [CrossRef]

- Li, C.; Wang, X.; Meng, D.; Zhou, L. Facile synthesis of low-cost magnetic biosorbent from peach gum polysaccharide for selective and efficient removal of cationic dyes. Int. J. Biol. Macromol. 2018, 107, 1871–1878. [Google Scholar] [CrossRef] [PubMed]

- Metin, A.; Dogan, D.; Can, M. Novel magnetic gel beads based on ionically crosslinked sodium alginate and polyanetholesulfonic acid: Synthesis and application for adsorption of cationic dyes. Mater. Chem. Phys. 2020, 256, 123659. [Google Scholar] [CrossRef]

- Rahman, S.; Chowdhury, D. Guar gum-sodium alginate nanocomposite film as a smart fluorescence-based humidity sensor: A smart packaging material. Int. J. Biol. Macromol. 2022, 216, 571–582. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Pandey, S.; Arotiba, O.A. Development of a sodium alginate-based organic/inorganic superabsorbent composite hydrogel for adsorption of methylene blue. Carbohyd. Polym. 2016, 153, 34–36. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, H.; He, Q.D.; Xing, H.F.; Feng, K.; Guo, F.; Wang, W.B. Core-shell alginate beads as green reactor to synthesize grafted composite beads to efficiently boost single/co-adsorption of dyes and Pb(II). Int. J. Biol. Macromol. 2022, 206, 10–20. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Wu, Y.; Wang, Y.; Yu, J.; Xu, Y. Synthesis and characterization of a biodegradable polyaspartic acid/2-amino-2-methyl-1-propanol graft copolymer and evaluation of its scale and corrosion inhibition performance. RSC Adv. 2017, 7, 36714. [Google Scholar] [CrossRef]

- Ma, M.Z.; Chen, H.Z.; Zhang, W.; Feng, E.J.; Li, X.J.; Li, F.Q.; Xu, S.F.; Li, Y.W. Novel poly(amino acid)-type superplasticizers with enhanced dispersing performance for Portland cement doped with clay impurities. Colloids Surf. A 2022, 634, 127953. [Google Scholar] [CrossRef]

- Budai-Szűcs, M.; Kiss, E.L.; Szilágyi, B.Á.; Szilágyi, A.; Gyarmati, B.; Berkó, S.; Kovács, A.; Horvát, G.; Aigner, Z.; Soós, J.; et al. Mucoadhesive cyclodextrin-modified thiolated poly(aspartic acid) as a potential ophthalmic drug delivery system. Polymers 2018, 10, 199. [Google Scholar] [CrossRef] [PubMed]

- Chai, C.X.; Xu, Y.H.; Xu, Y.; Liu, S.H.; Zhang, L. Dopamine-modified polyaspartic acid as a green corrosion inhibitor for mild steel in acid solution. Eur. Polym. J. 2020, 137, 109946. [Google Scholar] [CrossRef]

- Ma, G.F.; Yang, Q.; Ran, F.T.; Dong, Z.B.; Lei, Z.Q. High performance and low cost composite superabsorbent based on polyaspartic acid and palygorskite clay. Appl. Clay Sci. 2015, 118, 21–28. [Google Scholar] [CrossRef]

- Bi, R.; Yin, D.; Zhang, S.Z.; Zhang, R.; Chen, F.F. Efficient removal of Pb(II) and Hg(II) with eco-friendly polyaspartic acid/ layered double hydroxide by host-guest interaction. Appl. Clay Sci. 2022, 225, 106536. [Google Scholar] [CrossRef]

- Liu, L.; Gao, Z.; Su, X.; Chen, X.; Jiang, L.; Yao, J. Adsorption removal of dyes from single and binary solutions using a cellulose-based bioadsorbent. ACS Sustain. Chem. Eng. 2015, 3, 432–442. [Google Scholar] [CrossRef]

- Xiao, W.D.; Xiao, L.P.; Xiao, W.Z.; Liu, K.; Zhang, Y.; Zhang, H.Y.; Sun, R.C. Cellulose-based bio-adsorbent from TEMPO-oxidized natural loofah for effective removal of Pb(II) and methylene blue. Int. J. Biol. Macromol. 2022, 218, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Santagata, M.; Johnston, C.T. A study of nanoconfined water in halloysite. Appl. Clay Sci. 2022, 221, 106467. [Google Scholar] [CrossRef]

- Wang, B.Y.; Zhang, W.X.; Jin, X.C.; Su, G.H. A diffusion model for the swelling of compacted Na-montmorillonite in water. Appl. Clay Sci. 2021, 214, 106301. [Google Scholar] [CrossRef]

- Uddin, M.K. A review on the adsorption of heavy metals by clay minerals, with special focus on the past decade. Chem. Eng. J. 2017, 308, 438–462. [Google Scholar] [CrossRef]

- Ngulube, T.; Gumbo, J.R.; Masindi, V.; Maity, A. An update on synthetic dyes adsorption onto clay based minerals: A state-of-art review. J. Environ. Manag. 2017, 191, 35–57. [Google Scholar] [CrossRef]

- Cao, X.; Chen, D.; Gu, H.Z.; Huang, A.; Ni, H.W. Improved bonding properties of rectorite clay slurry after wet/dry grinding. Appl. Clay Sci. 2019, 183, 105318. [Google Scholar] [CrossRef]

- Zhao, Y.; Shao, Z.Y.; Chen, C.L.; Hu, J.; Chen, H.L. Effect of environmental conditions on the adsorption behavior of Sr(II) by Na-rectorite. Appl. Clay Sci. 2014, 87, 1–6. [Google Scholar] [CrossRef]

- Yang, L.L.; Ma, X.Y.; Guo, N.N. Sodium alginate/Na+-rectorite composite microspheres: Preparation, characterization, and dye adsorption. Carbohyd. Polym. 2012, 90, 853–858. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Ma, X.; Guo, N. Simultaneous reduction of Cr (VI) and degradation of tetracycline hydrochloride by a novel iron-modified rectorite composite through heterogeneous photo-Fenton processes. Carbohyd. Polym. 2012, 90, 853–858. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.U.; Sultan, M.; Islam, A.; Sabir, A.; Hafeez, S.; Bibi, I.; Ahmed, M.N.; Khan, S.M.; Khan, R.U.; Iqbal, M. Sodium alginate blended membrane with polyurethane: Desalination performance and antimicrobial activity evaluation. Int. J. Biol. Macromol. 2021, 182, 72–81. [Google Scholar] [CrossRef] [PubMed]

- Oyarce, E.; Santander, P.; Butter, B.; Pizarro, G.D.; Sanchez, J. Use of sodium alginate biopolymer as an extracting agent of methylene blue in the polymer-enhanced ultrafiltration technique. J. Appl. Polym. Sci. 2021, 138, 50844. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, D.; Lv, X.; Xu, Y.; Cui, Y. Synthesis of polyaspartic acid/3-amino-1H-1,2,4-triazole-5-carboxylic acid hydrate graft copolymer and evaluation of its corrosion inhibition and scale inhibition performance. Desalination 2013, 327, 32–38. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, X.; Liang, Y. Synthesis of polyaspartic acid/graphene oxide grafted copolymer and evaluation of scale inhibition and dispersion performance. Diam. Relat. Mater. 2020, 108, 107949. [Google Scholar] [CrossRef]

- Feng, Z.; Liu, D.; Ma, X. The rectorite/carbon composites: Fabrication, modification and adsorption. Chemosphere 2016, 144, 621–627. [Google Scholar] [CrossRef]

- Shen, Y.; Yu, X.; Wang, Y. Facile synthesis of modified rectorite (M-REC) for effective removal of anionic dye from water. J. Mol. Liq. 2019, 278, 12–18. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Physical and biophysical chemistry division commission on colloid and surface chemistry including catalysis. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Zeng, L.; Xie, M.; Zhang, Q.; Kang, Y.; Guo, X.; Xiao, H.; Peng, Y.; Luo, J. Chitosan/organic rectorite composite for the magnetic uptake of methylene blue and methyl orange. Carbohyd. Polym. 2015, 123, 89–98. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Wang, A. Evaluation of ammonium removal using a chitosan-g-poly (acrylic acid)/rectorite hydrogel composite. J. Hazard. Mater. 2009, 171, 671–677. [Google Scholar] [CrossRef] [PubMed]

- Langmuir, I. The constitution and fundamental properties of solids and liquids. Part I. Solids. J. Am. Chem. Soc. 1916, 38, 2221–2295. [Google Scholar] [CrossRef]

- Freundlich, H. Over the adsorption in solution. J. Phys. Chem. 1906, 57, 1100–1107. [Google Scholar]

- Zhang, Z.H.; Xu, J.Y.; Yang, X.L. MXene/sodium alginate gel beads for adsorption of methylene blue. Mater. Chem. Phys. 2021, 260, 124123. [Google Scholar] [CrossRef]

- Işık, B.; Uğraşkan, V. Adsorption of methylene blue on sodium alginate-flax seed ash beads: Isotherm, kinetic and thermodynamic studies. Int. J. Biol. Macromol. 2021, 167, 1156–1167. [Google Scholar] [CrossRef] [PubMed]

- Hu, T.; Liu, Q.; Gao, T.; Dong, K.; Wei, G.; Yao, J. Facile preparation of tannic acid-poly(vinyl alcohol)/sodium alginate hydrogel beads for methylene blue removal from simulated solution. ACS Omega 2018, 3, 7523–7531. [Google Scholar] [CrossRef] [PubMed]

- Alver, E.; Metin, A.Ü.; Brouers, F. Methylene blue adsorption on magnetic alginate/rice husk bio-composite. Int. J. Biol. Macromol. 2020, 154, 104–113. [Google Scholar] [CrossRef]

- Zhao, H.; Ouyang, X.-K.; Yang, L.-Y. Adsorption of lead ions from aqueous solutions by porous cellulose nanofiber–sodium alginate hydrogel beads. J. Mol. Liq. 2021, 324, 115122. [Google Scholar] [CrossRef]

- Ablouh, E.; Essaghraoui, A.; Eladlani, N.; Rhazi, M.; Taourirte, M. Uptake of Pb(II) onto nanochitosan/sodium alginate hybrid beads: Mechanism and kinetics study. Water Environ. Res. 2019, 91, 239–249. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Zhang, L.; Hu, D.; Yang, R.; Zhang, J.; Guan, Y.; Lv, F.; Gao, H. A mesoporous nanocellulose/sodium alginate/carboxymethyl-chitosan gel beads for efficient adsorption of Cu2+ and Pb2+. Int. J. Biol. Macromol. 2021, 187, 922–930. [Google Scholar] [CrossRef]

- Li, Z.; Chang, P.; Jiang, W. Mechanisms of Cu2+, triethylenetetramine (TETA), and Cu-TETA sorption on rectorite and its use for metal removal via metal-TETA complexation. J. Hazard. Mater. 2019, 373, 187–196. [Google Scholar] [CrossRef]

- Shi, J.; Guo, C.; Lei, C.; Liu, Y.; Hou, X.; Zheng, X.; Hu, Q. High-performance biochar derived from the residue of Chaga mushroom (Inonotus obliquus) for pollutants removal. Bioresour. Technol. 2022, 344, 126268. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, J.; Lu, A.; Shen, J.; Xu, J.; Jiang, H. Controllable synthesis of cubic magnetic MgFe2O4 derived from MgFe-LDHs for efficient removal of methyl orange. Chem. Eng. J. 2022, 428, 131174. [Google Scholar] [CrossRef]

- Zhang, W.; Ou, J.; Tang, M.; He, Q.; Long, A.; Luo, S.; Sun, S.; Wan, J.; Gao, Y.; Zhou, L.; et al. Physically-crosslinked activated CaCO3/polyaniline-polypyrrole-modified GO/alginate hydrogel sorbent with highly efficient removal of copper(II) from aqueous solution. Chem. Eng. J. 2022, 431, 133375. [Google Scholar] [CrossRef]

- Kwak, H.W.; Hong, Y.; Lee, M.E.; Jin, H.-J. Sericin-derived activated carbon-loaded alginate bead: An effective and recyclable natural polymer-based adsorbent for methylene blue removal. Int. J. Biol. Macromol. 2018, 120, 906–914. [Google Scholar] [CrossRef]

- Heybet, E.N.; Ugraskan, V.; Isik, B.; Yazici, O. Adsorption of methylene blue dye on sodium alginate/polypyrrole nanotube composites. Int. J. Biol. Macromol. 2021, 193, 88–99. [Google Scholar] [CrossRef]

- Gao, T.; Guan, G.; Wang, X.; Lou, T. Electrospun molecularly imprinted sodium alginate/polyethylene oxide nanofibrous membranes for selective adsorption of methylene blue. Int. J. Biol. Macromol. 2022, 207, 62–71. [Google Scholar] [CrossRef]

- Xiao, J.; Lv, W.; Xie, Z.; Tan, Y.; Song, Y.; Zheng, Q. Environmentally friendly reduced graphene oxide as a broad-spectrum adsorbent for anionic and cationic dyes via π-π interaction. J. Mater. Chem. A 2016, 4, 12126–12135. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, H.; Xu, J.; Du, X.; Cheng, X.; Du, Z.; Wang, H. Fabrication of MXene/PEI functionalized sodium alginate aerogel and its excellent adsorption behavior for Cr(VI) and Congo Red from aqueous solution. J. Hazard. Mater. 2021, 416, 125777. [Google Scholar] [CrossRef] [PubMed]

- Fiorito, E.; Porcedda, G.; Brundu, L.; Passiu, C.; Atzei, D.; Ennas, G.; Elsener, B.; Fantauzzi, M.; Rossia, A. Calcium carbonate as sorbent for lead removal from wastewaters. Chemosphere 2022, 296, 133897. [Google Scholar] [CrossRef] [PubMed]

- Borup, R.L.; Sauer, D.E.; Stuve, E.M. An exsitu study of electrodeposited lead on platinum (111) I. Examination of the surface redox behavior of lead and dynamic emersion. Surf. Sci. 1993, 293, l0–l26. [Google Scholar] [CrossRef]

- Shi, T.; Xie, Z.; Zhu, Z.; Shi, W.; Liu, Y.; Liu, M. Highly efficient and selective adsorption of heavy metal ions by hydrazide-modified sodium alginate. Carbohyd. Polym. 2022, 276, 118797. [Google Scholar] [CrossRef] [PubMed]

- Dong, K.; Xu, K.; Wei, N.; Fang, Y.; Qin, Z. Three-dimensional porous sodium alginate/gellan gum environmentally friendly aerogel: Preparation, characterization, adsorption, and kinetics studies. Chem. Eng. Res. Des. 2022, 179, 118797. [Google Scholar] [CrossRef]

- Wang, W.; Fan, M.; Ni, J.; Peng, W.; Cao, Y.; Li, H.; Huang, Y.; Fan, G.; Zhao, Y.; Song, S. Efficient dye removal using fixed-bed process based on porous montmorillonite nanosheet/poly(acrylamide-co-acrylic acid)/sodium alginate hydrogel beads. Appl. Clay Sci. 2022, 219, 106443. [Google Scholar] [CrossRef]

- Ho, Y.S.; McKay, G.A. comparison of chemisorption kinetic models applied to pollutant removal on various sorbents. Process Saf. Environ. 1998, 76, 332–340. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Da’ana, D.A. Guidelines for the use and interpretation of adsorption isotherm models: A review. J. Hazard. Mater. 2020, 393, 122383. [Google Scholar] [CrossRef]

- Fernandes, E.P.; Silva, T.S.; Carvalho, C.M.; Selvasembian, R.; Chaukura, N.; Oliveira, L.M.T.M.; Meneghetti, S.M.P.; Meili, L. Efficient adsorption of dyes by γ-alumina synthesized from aluminum wastes: Kinetics, isotherms, thermodynamics and toxicity assessment. J. Environ. Chem. Eng. 2021, 9, 106198. [Google Scholar] [CrossRef]

- Deng, J.L.; Yang, L.L.; Liang, G.Z. Preparation, characterization and swelling behaviors sodium alginate-graft-acrylic acid/Na+ rectorite superabsorbent composites. J. Inorg. Organomet. Polym. Mater. 2013, 23, 525–532. [Google Scholar] [CrossRef]

| Adsorbates | Adsorbents | Initial Concentration (mg/L) | AC (mg/g) | Ref. |

|---|---|---|---|---|

| MB | MXene/SA gel beads | 160 | 91.12 | [56] |

| SA–flax seed ash beads | 120 | 333.0 | [57] | |

| Tannic acid–poly(vinyl alcohol)/SA Beads | 160 | 147.0 | [58] | |

| Magnetic SA/rice husk bio-composite | 500 | 274.9 | [59] | |

| SA/PASP/RE0.6 | 700 | 680.83 | This work | |

| SA/PASP/RE43 | 700 | 586.46 | This work | |

| Pb(II) | Porous cellulose nanofiber–SA beads | 800 | 318 | [60] |

| Nanochitosan/SA beads | 150 | 178.57 | [61] | |

| Nanocellulose/SA/carboxymethyl-chitosan beads | 300 | 472.59 | [62] | |

| SA/PASP/RE0.6 | 700 | 347.50 | This work | |

| SA/PASP/RE43 | 700 | 187.78 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, J.; Wang, X.; Zhang, H.; Liu, X.; Wang, W.; He, Q.; Guo, F. Biopolymer Meets Nanoclay: Rational Fabrication of Superb Adsorption Beads from Green Precursors for Efficient Capture of Pb(II) and Dyes. Nanomaterials 2024, 14, 766. https://doi.org/10.3390/nano14090766

Qi J, Wang X, Zhang H, Liu X, Wang W, He Q, Guo F. Biopolymer Meets Nanoclay: Rational Fabrication of Superb Adsorption Beads from Green Precursors for Efficient Capture of Pb(II) and Dyes. Nanomaterials. 2024; 14(9):766. https://doi.org/10.3390/nano14090766

Chicago/Turabian StyleQi, Jie, Xue Wang, Huan Zhang, Xiangyu Liu, Wenbo Wang, Qingdong He, and Fang Guo. 2024. "Biopolymer Meets Nanoclay: Rational Fabrication of Superb Adsorption Beads from Green Precursors for Efficient Capture of Pb(II) and Dyes" Nanomaterials 14, no. 9: 766. https://doi.org/10.3390/nano14090766

APA StyleQi, J., Wang, X., Zhang, H., Liu, X., Wang, W., He, Q., & Guo, F. (2024). Biopolymer Meets Nanoclay: Rational Fabrication of Superb Adsorption Beads from Green Precursors for Efficient Capture of Pb(II) and Dyes. Nanomaterials, 14(9), 766. https://doi.org/10.3390/nano14090766