Crack Detection of Reinforced Concrete Structure Using Smart Skin

Abstract

1. Introduction

2. Materials and Methods

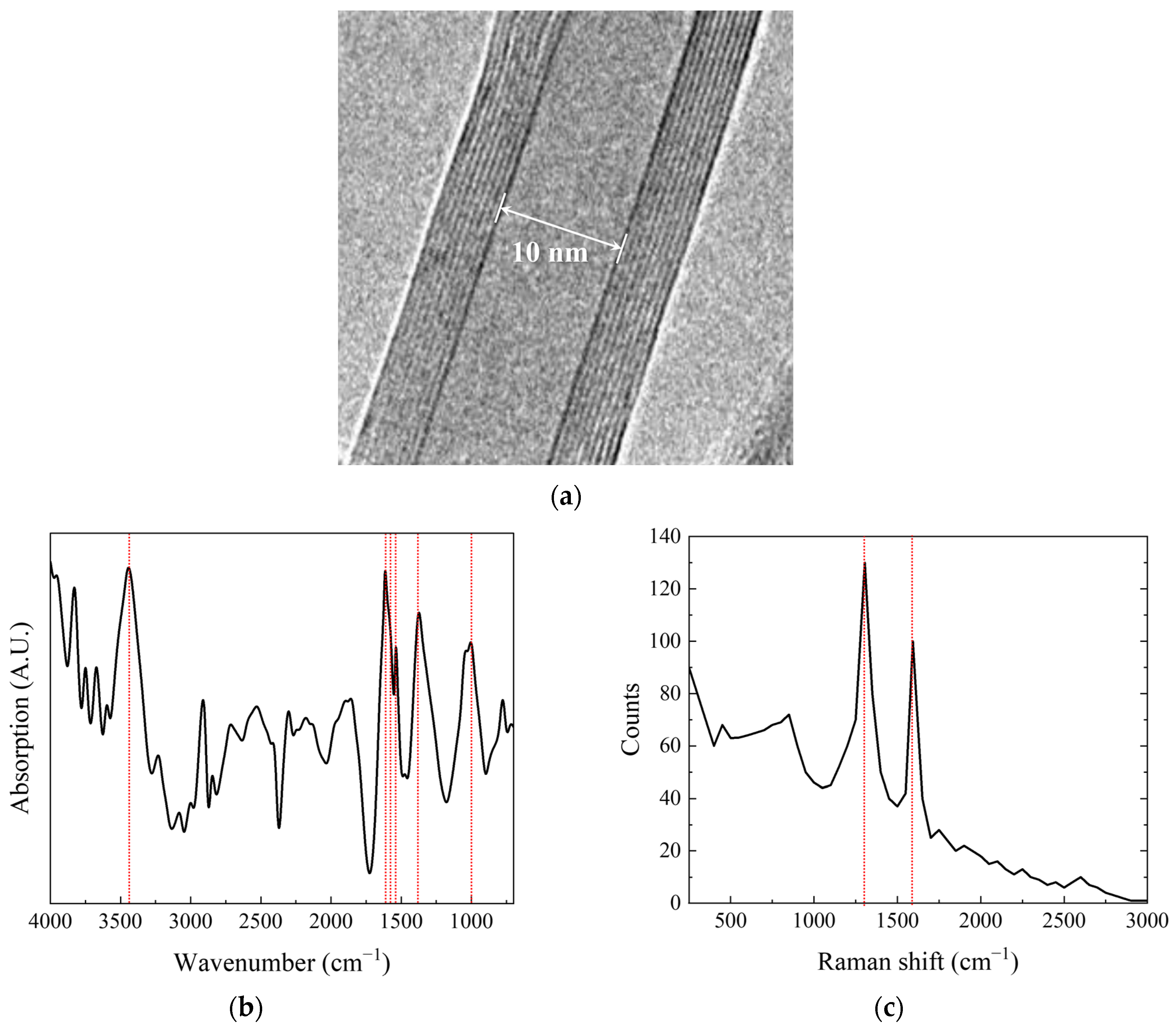

2.1. Materials

2.2. Fabrication Procedure

2.3. Characterization

3. Results and Discussion

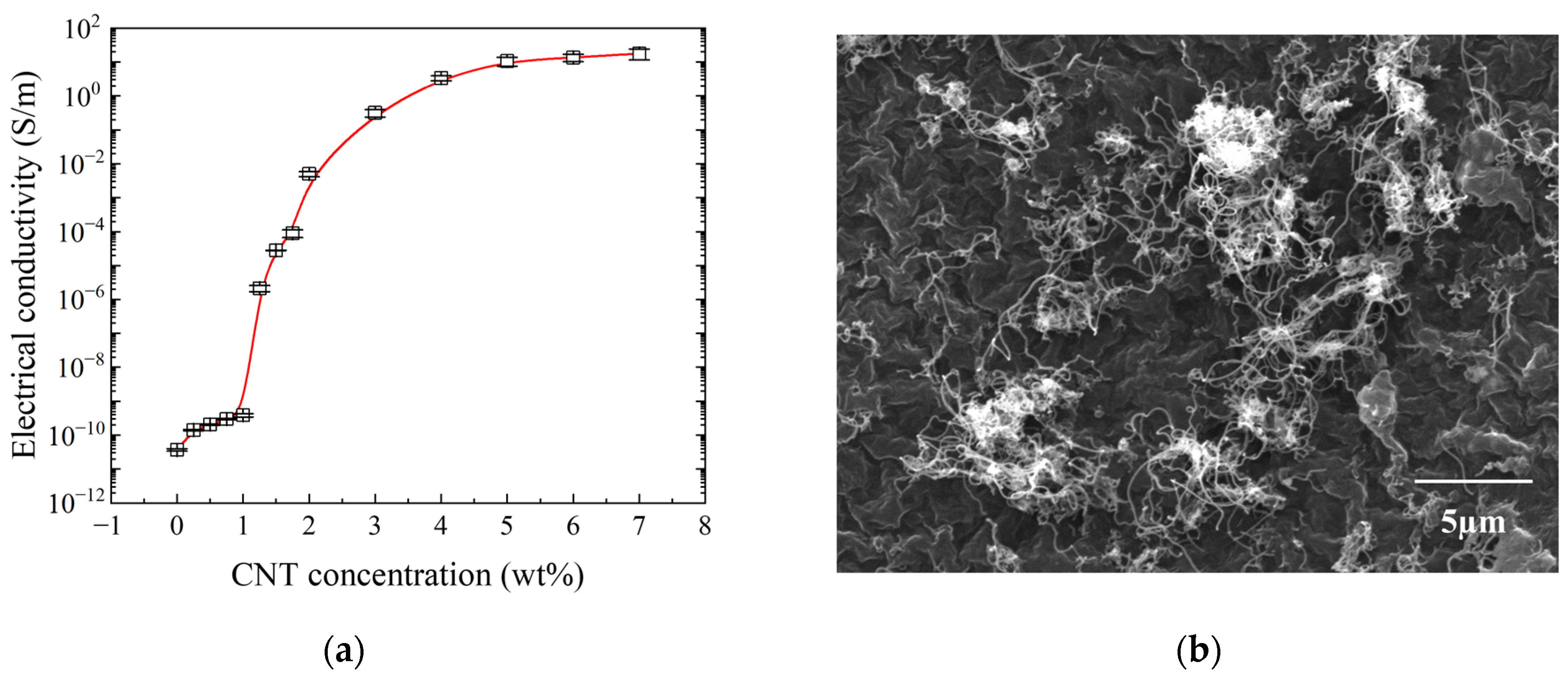

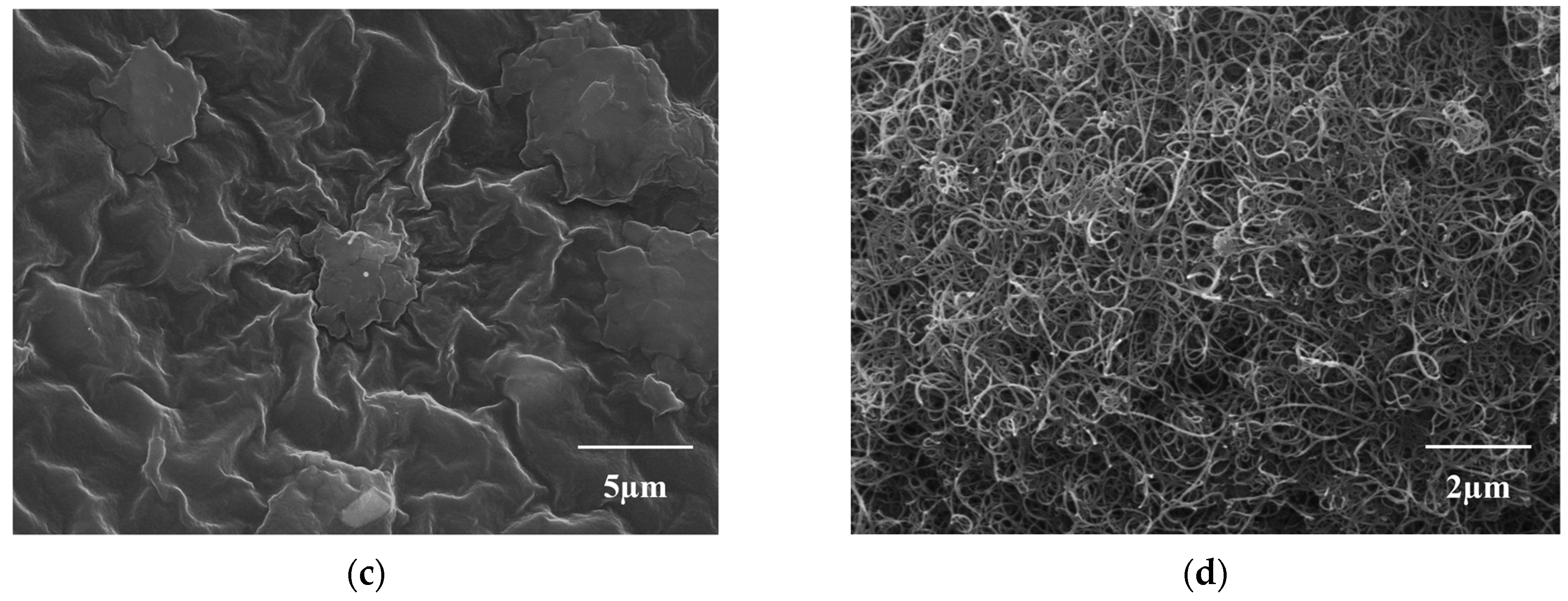

3.1. Electrical Conductivity of Smart Skin

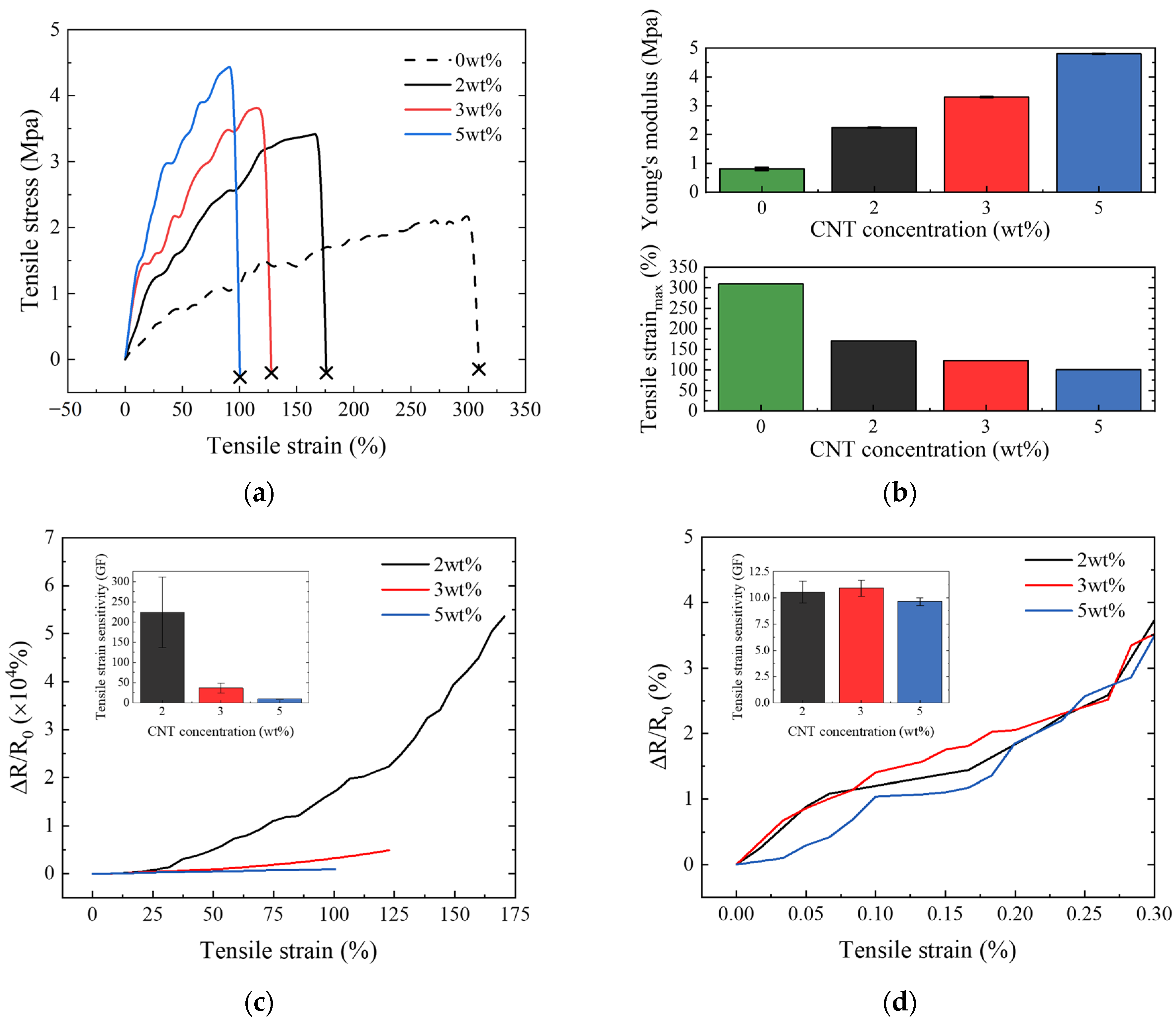

3.2. Electro-Mechanical Characterization of Smart Skin

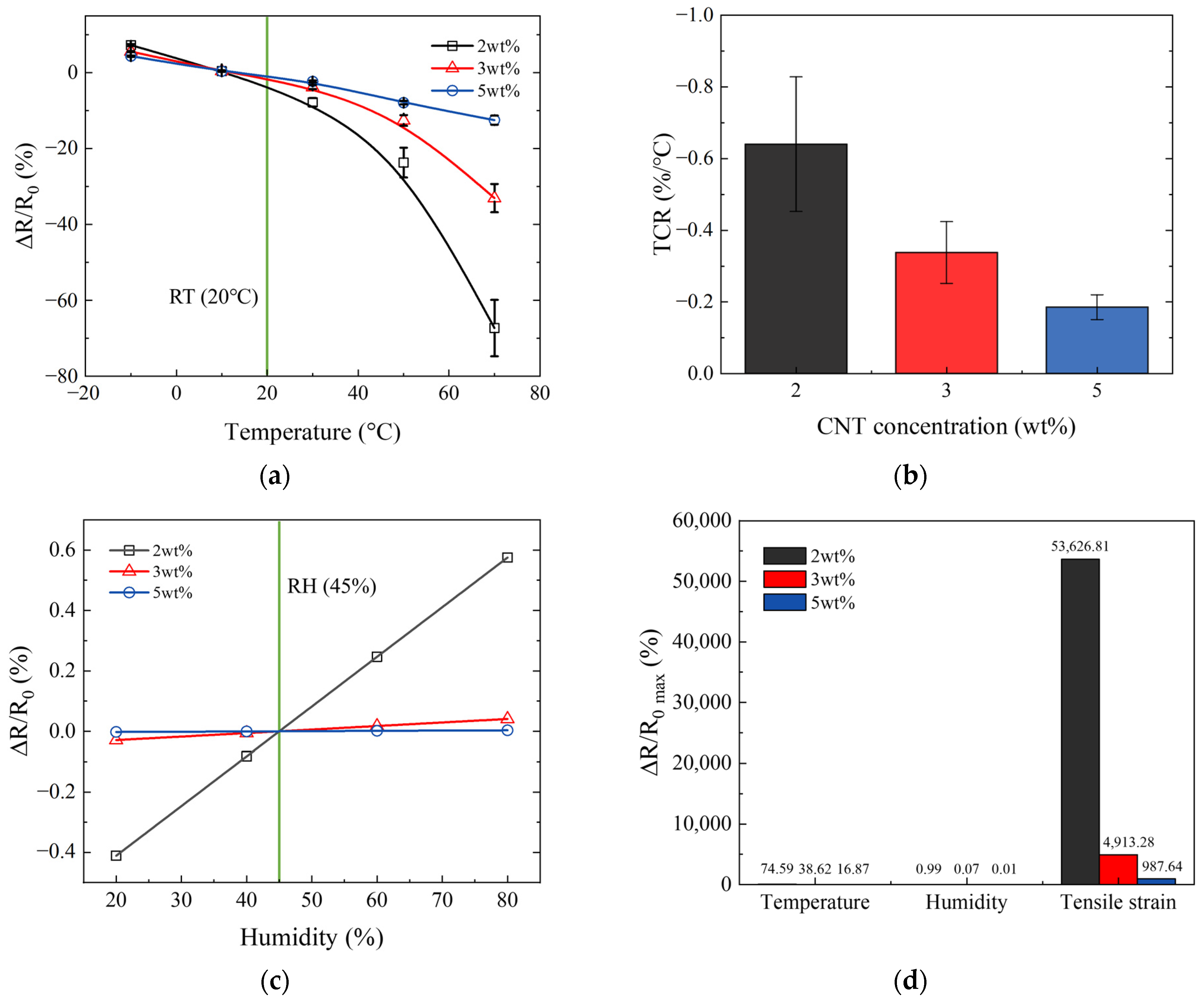

3.3. Electro-Environmental Characterization of Smart Skin

3.4. Application of Smart Skin to RC Structure

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gong, X.; Huang, K.; Wu, Y.H. Recent progress on screen-printed flexible sensors for human health monitoring. Sens. Actuators A Phys. 2022, 345, 113821. [Google Scholar] [CrossRef]

- Siahkouhi, M.; Razaqpur, G.; Hoult, N.A. Utilization of carbon nanotubes in concrete for structural health monitoring purposes: A review. Constr. Build. Mater. 2021, 309, 125137. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Martin, J.; Sánchez, M.; Ureña, A. Mechanical and crack-sensing capabilities of mode-i joints with carbon-nanotube-reinforced adhesive films under hydrothermal aging conditions. Nanomaterials 2020, 10, 2290. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.; Lee, J.; Kim, G.; Ryu, S.; Park, J. Deep neural network-based structural health monitoring technique for real-time crack detection and localization using strain gauge sensors. Sci. Rep. 2022, 12, 202004. [Google Scholar] [CrossRef] [PubMed]

- Baker, A.A.; Rajic, N.; Davis, C. Towards a practical structural health monitoring technology for patched cracks in aircraft structure. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1340–1352. [Google Scholar] [CrossRef]

- Bekzhanova, Z.; Memon, S.A.; Kim, J.R. Self-sensing cementitious composites: Review and perspective. Nanomaterials 2021, 11, 2355. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Staszewski, W.J.; Swamy, R.N. Smart sensing technologies for structural health monitoring of civil engineering structures. Adv. Civ. Eng. 2010, 2010, 724962. [Google Scholar] [CrossRef]

- Loh, K.J.; Ryu, D. Multifunctional materials and nanotechnology for assessing and monitoring civil infrastructures. In Sensor Technologies for Civil Infrastructures; Woodhead Publishing: Sawston, UK, 2014; pp. 295–326. [Google Scholar]

- Altabey, W.A.; Noori, M. A dynamic analysis of smart and nanomaterials for new approaches to structural control and health monitoring. Materials 2023, 16, 3567. [Google Scholar] [CrossRef]

- Kang, I.; Schulz, M.J.; Lee, J.W.; Choi, G.R.; Jung, J.Y.; Choi, J.B.; Hwang, S. A Carbon Nanotube Smart Material for Structural Health Monitoring. Solid State Phenom. 2007, 120, 289–296. [Google Scholar] [CrossRef]

- Wan, Z.; Li, J.; Jia, M.; Li, J. Structural health monitoring of Three-Dimensional Braided Composite Material using Carbon Nanotube Thread Sensors. J. Mech. 2013, 29, 617–621. [Google Scholar] [CrossRef]

- D’Alessandro, A.; Rallini, M.; Ubertini, F.; Materazzi, A.L.; Kenny, J.M. Investigations on scalable fabrication procedures for self-sensing carbon nanotube cement-matrix composites for SHM applications. Cem. Concr. Compos. 2016, 65, 200–213. [Google Scholar] [CrossRef]

- Howser, R.; Dhonde, H.B.; Mo, Y.L. Self-sensing of carbon nanofiber concrete columns subjected to reversed cyclic loading. Smart Mater. Struct. 2011, 20, 085031. [Google Scholar] [CrossRef]

- Park, J.; Lee, J. Strain measurements of an aircraft wing using embedded CNT fiber sensor and wireless SHM sensor node. Funct. Compos. Struct. 2022, 4, 035004. [Google Scholar] [CrossRef]

- Nonn, S.; Schagerl, M.; Zhao, Y.; Gschossmann, S.; Kralovec, C. Application of electrical impedance tomography to an anisotropic carbon fiber-reinforced polymer composite laminate for damage localization. Compos. Sci. Technol. 2018, 160, 231–236. [Google Scholar] [CrossRef]

- Olejník, R.; Slobodian, P.; Matyáš, J.; Babar, D.G. High elastic polyurethane/carbon nanotube composite laminate for structure health monitoring by gain shifting of antenna sensing element. IOP Conf. Ser. Mater. Sci. Eng. 2016, 108, 012024. [Google Scholar] [CrossRef]

- Magazzù, A.; Marcuello, C. Investigation of soft matter nanomechanics by atomic force microscopy and optical tweezers: A comprehensive review. Nanomaterials 2023, 13, 963. [Google Scholar] [CrossRef] [PubMed]

- Szeląg, M. Mechano-physical properties and microstructure of carbon nanotube reinforced cement paste after thermal load. Nanomaterials 2017, 7, 267. [Google Scholar] [CrossRef] [PubMed]

- Al-Bahrani, M.; Cree, A. Micro-scale damage sensing in self-sensing nanocomposite material based CNTs. Compos. Part B Eng. 2021, 205, 108479. [Google Scholar] [CrossRef]

- Ahmad, M.; Mohd Jamir, M.; Abdul Majid, M.; Refaai, M.; Meng, C.; Abu Bakar, M. Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes. Nanotechnol. Rev. 2020, 11, 1977–1990. [Google Scholar] [CrossRef]

- Gupta, T.K.; Kumar, S.; Khan, A.Z.; Varadarajan, K.M.; Cantwell, W.J. Self-sensing performance of MWCNT-low density polyethylene nanocomposites. Mater. Res. Express 2018, 5, 105703. [Google Scholar] [CrossRef]

- Dinesh, A.; Sudharsan, S.T.; Haribala, S. Self-sensing cement-based sensor with carbon nanotube: Fabrication and properties—A review. Mater. Today Proc. 2021, 46, 5801–5807. [Google Scholar] [CrossRef]

- Lu, D.; Huo, Y.; Jiang, Z.; Zhong, J. Carbon nanotube polymer nanocomposites coated aggregate enabled highly conductive concrete for structural health monitoring. Carbon 2023, 206, 340–350. [Google Scholar] [CrossRef]

- Castañeda-Saldarriaga, D.L.; Alvarez-Montoya, J.; Martínez-Tejada, V.; Sierra-Pérez, J. Toward structural health monitoring of civil structures based on self-sensing concrete nanocomposites: A validation in a reinforced-concrete beam. Int. J. Concr. Struct. Mater. 2021, 15, 1–18. [Google Scholar] [CrossRef]

- Meoni, A.; D’Alessandro, A.; Downey, A.; García-Macías, E.; Rallini, M.; Materazzi, A.L.; Ubertini, F. An experimental study on static and dynamic strain sensitivity of embeddable smart concrete sensors doped with carbon nanotubes for SHM of large structures. Sensors 2018, 18, 831. [Google Scholar] [CrossRef]

- NanoLab, Inc. Carbon Nanotube TEM Image. NanoLab, Inc. 2017. Available online: https://www.nano-lab.com/nanotube-image3.html (accessed on 28 March 2024).

- NanoLab, Inc. FTIR of Multiwall Carbon Nanotubes PD15L5-20. NanoLab, Inc. 2017. Available online: https://sep.turbifycdn.com/ty/cdn/nanolab2000/FTIR-PD15L520.pdf?t=1711312795& (accessed on 28 March 2024).

- NanoLab, Inc. Multi Wall Carbon Nanotube Raman Data PD15L520 D:G Ratio 1.33:1. NanoLab, Inc. 2017. Available online: https://sep.turbifycdn.com/ty/cdn/nanolab2000/Raman-PD15L520.pdf?t=1711312795& (accessed on 28 March 2024).

- Jang, S.H.; Li, L.Y. Self-sensing carbon nanotube composites exposed to glass transition temperature. Materials 2020, 13, 259. [Google Scholar] [CrossRef]

- Jang, S.H.; Yin, H. Effective electrical conductivity of carbon nanotube-polymer composites: A simplified model and its validation. Mater. Res. Express 2015, 2, 045602. [Google Scholar] [CrossRef]

- Jang, S.H.; Yin, H. Characterization and modeling of the effective electrical conductivity of a carbon nanotube/polymer composite containing chain-structured ferromagnetic particles. J. Compos. Mater. 2017, 51, 171–178. [Google Scholar] [CrossRef]

- Vertuccio, L.; Guadagno, L.; Spinelli, G. Smart coatings of epoxy based CNTs designed to meet practical expectations in aeronautics. Compos. Part B Eng. 2018, 147, 42–46. [Google Scholar] [CrossRef]

- Yang, W.; Chung, D.D.L. Effect of temperature on the electrical conduction and dielectric behavior of solder. J. Mater. Sci. Mater. Electron. 2021, 32, 6511–6519. [Google Scholar] [CrossRef]

- Tortorich, R.P.; Choi, J.W. Inkjet printing of carbon nanotubes. Nanomaterials 2013, 3, 453–468. [Google Scholar] [CrossRef]

- Huang, M.L.; Shi, Y.D.; Wang, M. A comparative study on nanoparticle network-dependent electrical conductivity, electromagnetic wave shielding effectiveness and rheological properties in multiwall carbon nanotubes filled polymer nanocomposites. Polym. Compos. 2023, 44, 1188–1200. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Sabaruddin, F.A.; Harussani, M.M.; Kamarudin, S.H.; Rayung, M.; Asyraf, M.R.M.; Aisyah, H.A.; Norrrahim, M.N.F.; Ilyas, R.A.; Abdullah, N.; et al. Mechanical performance and applications of cnts reinforced polymer composites—A review. Nanomaterials 2021, 11, 2186. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xie, H.; Cheng, R. Effects of carbon nanotube diameter and functionality on the properties of soy polyol-based polyurethane. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1620–1626. [Google Scholar] [CrossRef]

- Hajializadeh, S.; Barikani, M.; Moemen, B.A. Synthesis and characterization of multiwall carbon nanotube waterborne polyurethane nanocomposites. Polym. Int. 2017, 66, 1074–1083. [Google Scholar] [CrossRef]

- Lee, H.; Watanabe, K.; Kim, M. Handspinning enabled highly concentrated carbon nanotubes with controlled orientation in nanofibers. Sci. Rep. 2016, 6, 37590. [Google Scholar] [CrossRef] [PubMed]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. A 1921, 221, 163–198. [Google Scholar]

- Curbach, M.; Jesse, F. High-performance textile-reinforced concrete. Struct. Eng. Int. 1999, 9, 289–291. [Google Scholar] [CrossRef]

- Mehta, P.K.; Gerwick, B.C. Cracking-corrosion interaction in concrete exposed to marine environment. Concr. Int. 1982, 4, 45–51. [Google Scholar]

- Oliva-Avilés, A.I.; Avilés, F.; Sosa, V. Electrical and piezoresistive properties of multi-walled carbon nanotube/polymer composite films aligned by an electric field. Carbon 2011, 49, 2989–2997. [Google Scholar] [CrossRef]

- Thuau, D.; Ducrot, P.; Poulin, P.; Dufour, I.; Ayela, C. Integrated electromechanical transduction schemes for polymer MEMS sensors. Micromachines 2018, 9, 197. [Google Scholar] [CrossRef]

- Li, Q.; Li, J.; Tran, D.; Luo, C.; Gao, Y.; Yu, C.; Xuan, F.-Z. Engineering of carbon nanotube/polydimethylsiloxane nanocomposites with enhanced sensitivity for wearable motion sensors. J. Mater. Chem. C 2017, 5, 11092–11099. [Google Scholar] [CrossRef]

- Hu, N.; Karube, Y.; Arai, M.; Watanabe, T.; Yan, C.; Li, Y.; Liu, Y.; Fukunaga, H. Investigation on sensitivity of a polymer/carbon nanotube composite strain sensor. Carbon 2010, 48, 680–687. [Google Scholar] [CrossRef]

- Lee, S.J.; Jung, Y.J.; Park, J.W.; Jang, S.H. Temperature detectable surface coating with carbon nanotube/epoxy composites. Nanomaterials 2022, 12, 2369. [Google Scholar] [CrossRef] [PubMed]

- Zymelka, D.; Yamashita, T.; Takamatsu, S.; Itoh, T.; Kobayashi, T. Printed strain sensor with temperature compensation and its evaluation with an example of applications in structural health monitoring. Jpn. J. Appl. Phys. 2017, 56, 05EC02. [Google Scholar] [CrossRef]

- Mohiuddin, M.; van Hoa, S. Electrical resistance of CNT-PEEK composites under compression at different temperatures. Nanoscale Res. Lett. 2011, 6, 419. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Sivasankar, V.S.; Dasgupta, A.; Das, S. Ultrathin and ultrasensitive printed carbon nanotube-based temperature sensors capable of repeated uses on surfaces of widely varying curvatures and wettabilities. ACS Appl. Mater. Interfaces 2021, 13, 10257–10270. [Google Scholar] [CrossRef]

- Liu, L.; Ye, X.; Wu, K.; Han, R.; Zhou, Z.; Cui, T. Humidity sensitivity of multi-walled carbon nanotube networks deposited by dielectrophoresis. Sensors 2019, 9, 1714–1721. [Google Scholar] [CrossRef] [PubMed]

- Sanli, A.; Benchirouf, A.; Müller, C.; Kanoun, O. Study of the humidity effect on the electrical impedance of MWCNT epoxy nanocomposites. Impedance Spectrosc. 2019, 2019, 25–32. [Google Scholar]

- Yuan, W.; Qian, H.; Liu, Y.; Wang, Z.; Yu, C. Highly sensitive temperature and humidity sensor based on carbon nanotube-assisted mismatched single-mode fiber structure. Micromachines 2019, 10, 521. [Google Scholar] [CrossRef]

- Ratnasari, D.; Nazir, F.; Toresano LH, Z.; Pawiro, S.A.; Soejoko, D.S. The correlation between effective renal plasma flow (ERPF) and glomerular filtration rate (GFR) with renal scintigraphy 99mTc-DTPA study. J. Phys. Conf. Ser. 2016, 694, 012062. [Google Scholar] [CrossRef]

- Selvanathan, M.; Jayabalan, N.; Saini, G.K.; Supramaniam, M.; Hussin, N. Employee productivity in malaysian private higher educational institutions. J. Archaeol. Egyptol. 2020, 17, 66–79. [Google Scholar]

- Almashhadani, M.; Mishra, A.; Yazici, A.; Younas, M. Challenges in Agile Software Maintenance for Local and Global Development: An Empirical Assessment. Information 2023, 14, 261. [Google Scholar] [CrossRef]

| CNT Concentration (wt%) | Full-Range Strain | Fracture Strain | Metal-Type Strain Gauge Sensitivity | ||

|---|---|---|---|---|---|

| Sensitivity | Error Range | Sensitivity | Error Range | ||

| 2 | 224.0 | ±87.0 | 10.5 | ±1.0 | 2.0–3.2 |

| 3 | 36.5 | ±11.8 | 10.9 | ±0.8 | |

| 5 | 9.8 | ±0.9 | 9.6 | ±0.4 | |

| Section | Correlation Coefficient (r) |

|---|---|

| A | 0.90 |

| B | 0.93 |

| C | 0.99 |

| D | 0.94 |

| E | 0.90 |

| Scale of Correlation Coefficient (r) | Value |

|---|---|

| 0 < r ≤ 0.19 | Very low correlation |

| 0.20 < r ≤ 0.39 | Low correlation |

| 0.40 < r ≤ 0.59 | Moderate correlation |

| 0.60 < r ≤ 0.79 | High correlation |

| 0.80 < r ≤ 1.00 | Very high correlation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, Y.-J.; Jang, S.-H. Crack Detection of Reinforced Concrete Structure Using Smart Skin. Nanomaterials 2024, 14, 632. https://doi.org/10.3390/nano14070632

Jung Y-J, Jang S-H. Crack Detection of Reinforced Concrete Structure Using Smart Skin. Nanomaterials. 2024; 14(7):632. https://doi.org/10.3390/nano14070632

Chicago/Turabian StyleJung, Yu-Jin, and Sung-Hwan Jang. 2024. "Crack Detection of Reinforced Concrete Structure Using Smart Skin" Nanomaterials 14, no. 7: 632. https://doi.org/10.3390/nano14070632

APA StyleJung, Y.-J., & Jang, S.-H. (2024). Crack Detection of Reinforced Concrete Structure Using Smart Skin. Nanomaterials, 14(7), 632. https://doi.org/10.3390/nano14070632