The Effects of Incorporating Nanoclay in NVCL-NIPAm Hydrogels on Swelling Behaviours and Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Nanoclay-Incorporated Copolymers

Preparation of Aqueous Solutions

2.3. Design of Experiment with Swelling as the Response

2.4. Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy

2.5. Lower Critical Solution Temperature Determination

2.5.1. Cloud-Point Analysis

2.5.2. UV Spectroscopy

2.6. Pulsatile Swelling Studies

2.7. Rheological Analysis

2.8. Scanning Electron Microscopy

3. Results

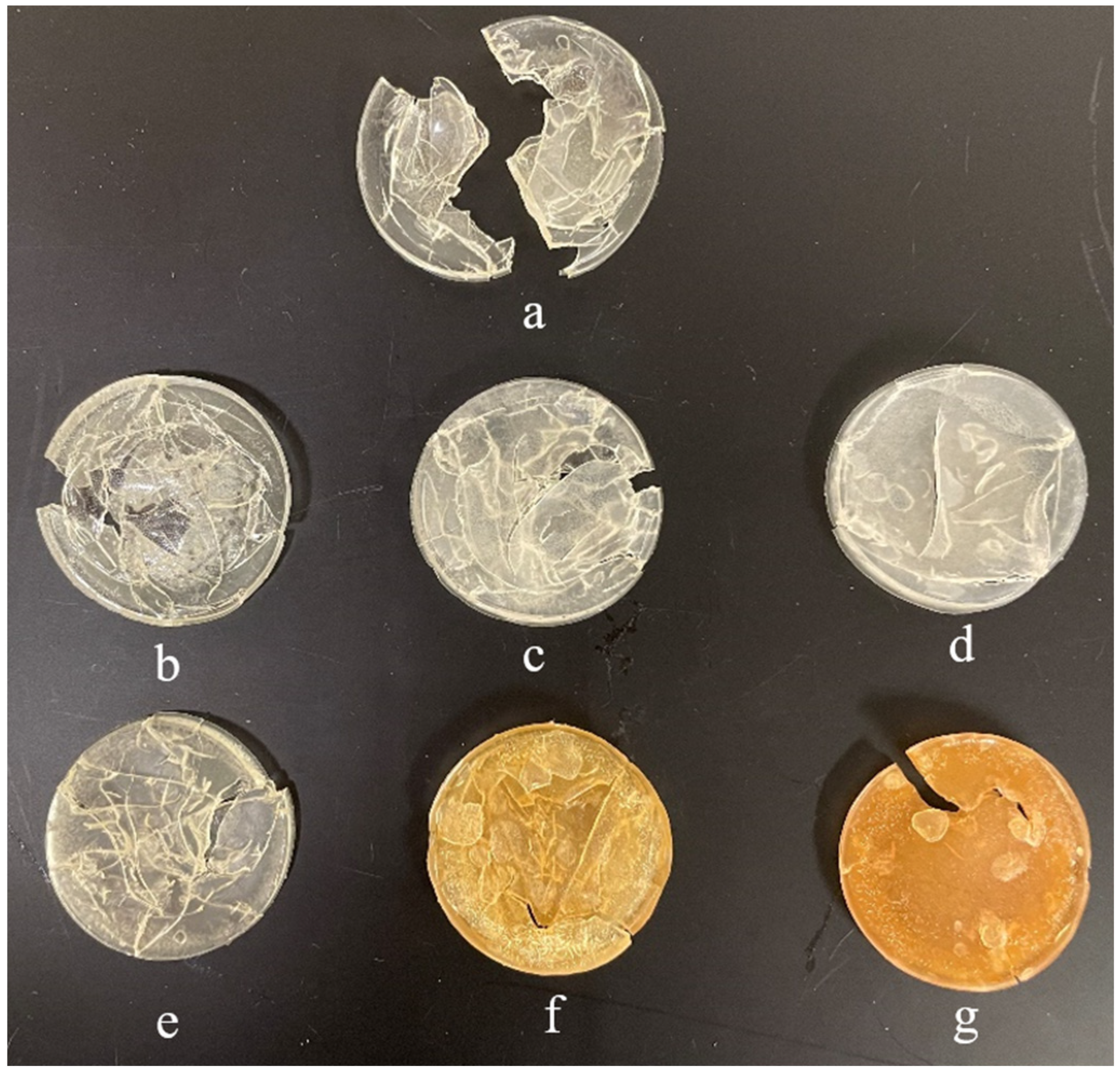

3.1. Photopolymerisation

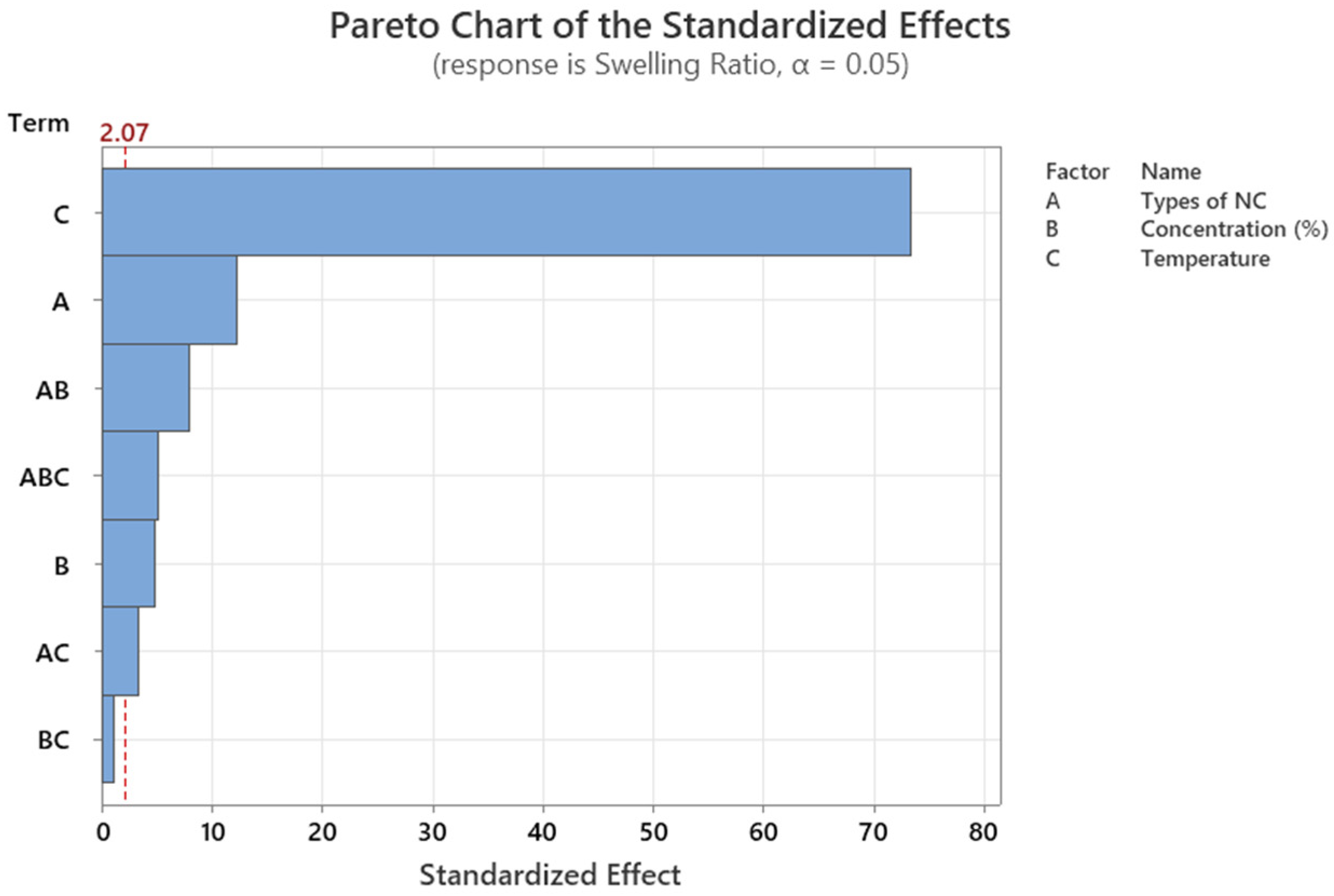

3.2. Design of Experiment with Swelling as the Response

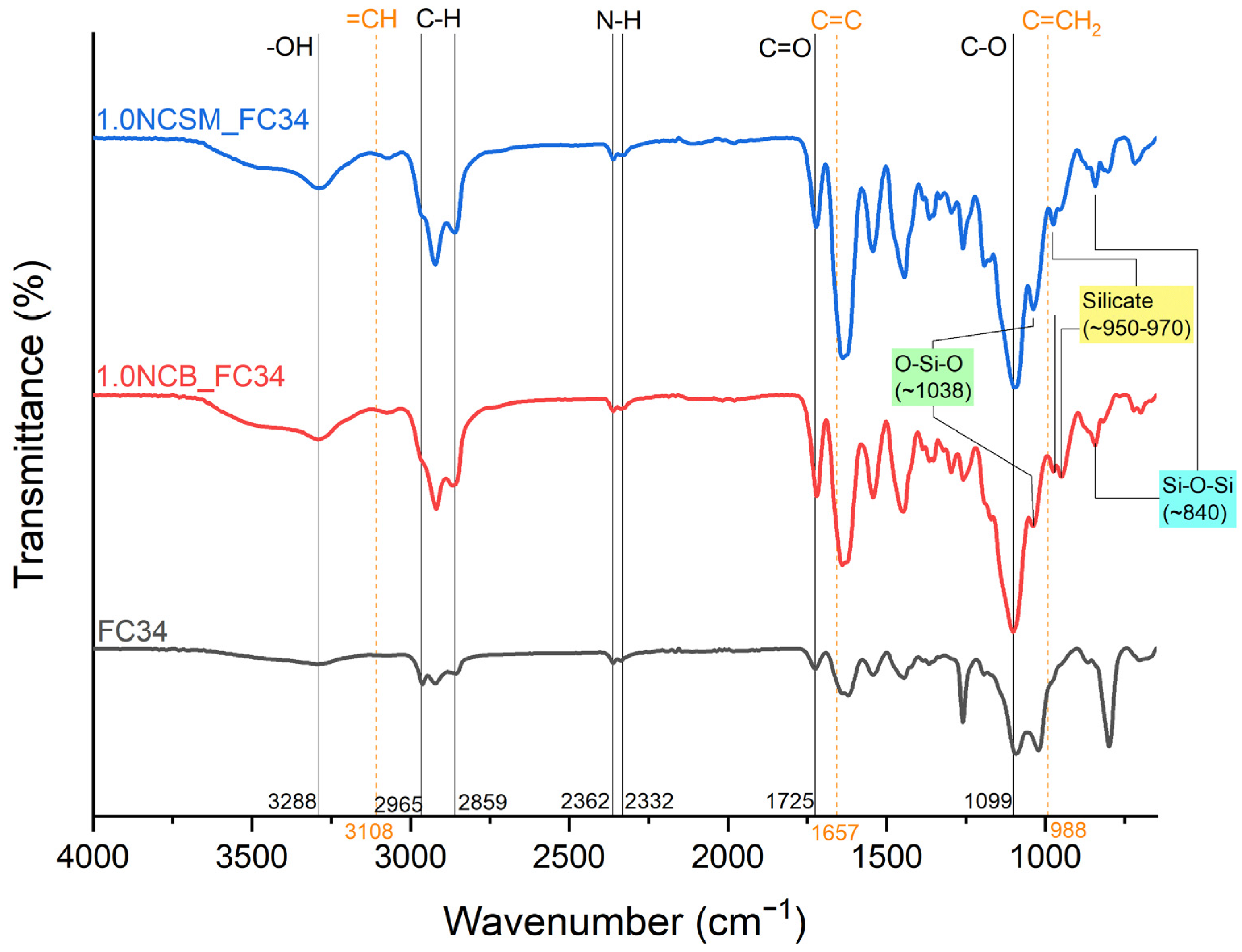

3.3. Attenuated Total Reflectance Fourier-Transform Infrared Spectroscopy

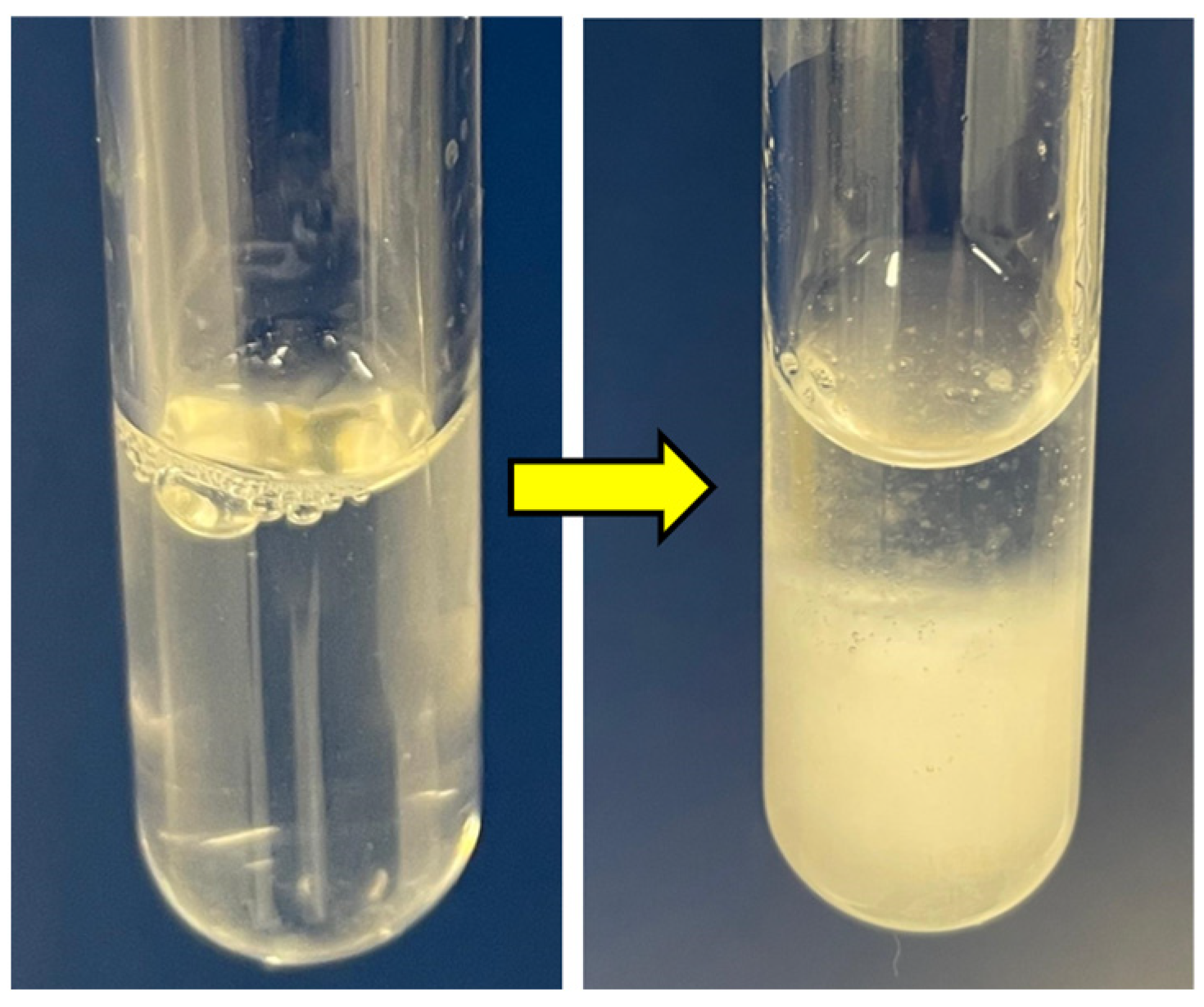

3.4. Lower Critical Solution Temperature Determination

3.5. Pulsatile Swelling Studies

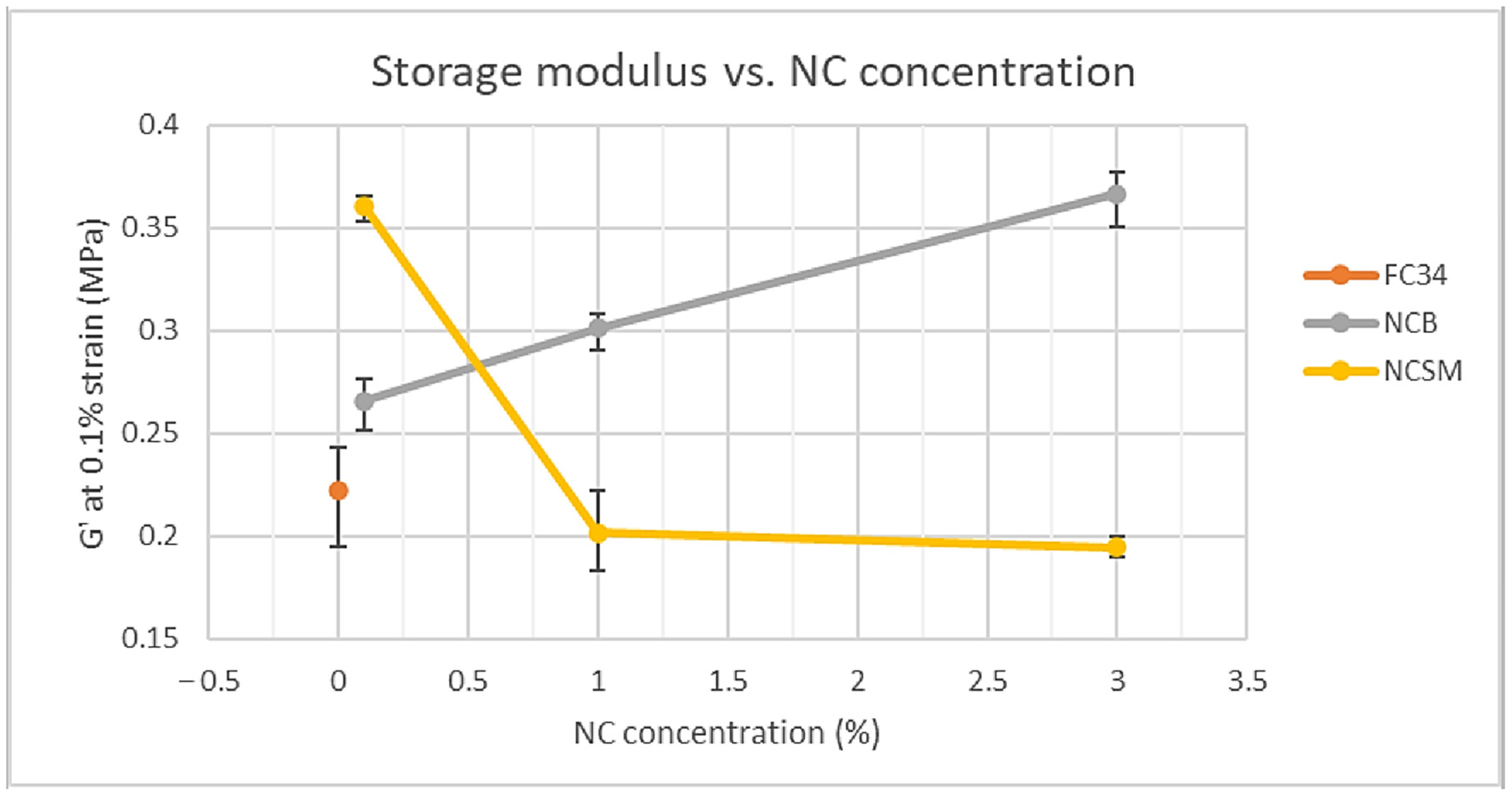

3.6. Rheological Analysis

3.7. Scanning Electron Microscopy

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| S | R-Sq | R-Sq (Adj) | R-Sq (Pred) |

|---|---|---|---|

| 4.43613 | 99.61% | 99.39% | 98.97% |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 13 | 111,775 | 8598 | 436.91 | 0.000 |

| Blocks | 2 | 34 | 17 | 0.87 | 0.431 |

| Linear | 4 | 109,286 | 27,322 | 1388.34 | 0.000 |

| Types of NC | 1 | 2970 | 2970 | 150.93 | 0.000 |

| Concentration (%) | 2 | 583 | 291 | 14.81 | 0.000 |

| Temperature | 1 | 105,733 | 105,733 | 5372.82 | 0.000 |

| 2-Way Interactions | 5 | 1786 | 357 | 18.15 | 0.000 |

| Types of NC*Concentration (%) | 2 | 1509 | 754 | 38.33 | 0.000 |

| Types of NC*Temperature | 1 | 220 | 220 | 11.18 | 0.003 |

| Concentration (%)*Temperature | 2 | 58 | 29 | 1.46 | 0.253 |

| 3-Way Interactions | 2 | 668 | 334 | 16.98 | 0.000 |

| Types of NC*Concentration (%)*Temperature | 2 | 668 | 334 | 16.98 | 0.000 |

| Error | 22 | 433 | 20 | ||

| Total | 35 | 112,208 |

References

- Cao, H.; Duan, L.; Zhang, Y.; Cao, J.; Zhang, K. Current hydrogel advances in physicochemical and biological response-driven biomedical application diversity. Signal Transduct. Target. Ther. 2021, 6, 426. [Google Scholar] [CrossRef]

- Ahmed, E.M. Hydrogel: Preparation, characterization, and applications: A review. J. Adv. Res. 2015, 6, 105–121. [Google Scholar] [CrossRef]

- Kotsuchibashi, Y. Recent advances in multi-temperature-responsive polymeric materials. Polym. J. 2020, 52, 681–689. [Google Scholar] [CrossRef]

- Haidari, H.; Kopecki, Z.; Sutton, A.T.; Garg, S.; Cowin, A.J.; Vasilev, K. pH-Responsive “Smart” Hydrogel for Controlled Delivery of Silver Nanoparticles to Infected Wounds. Antibiotics 2021, 10, 49. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Chen, C.; Cheng, Y. Magnetic-responsive hydrogels: From strategic design to biomedical applications. J. Control. Release 2021, 335, 541–556. [Google Scholar] [CrossRef]

- Wang, C.; Willner, B.; Willner, I. Redox-responsive and light-responsive DNA-based hydrogels and their applications. React. Funct. Polym. 2021, 166, 104983. [Google Scholar] [CrossRef]

- Yeingst, T.J.; Arrizabalaga, J.H.; Hayes, D.J. Ultrasound-Induced Drug Release from Stimuli-Responsive Hydrogels. Gels 2022, 8, 554. [Google Scholar] [CrossRef] [PubMed]

- Kolipaka, T.; Pandey, G.; Abraham, N.; Srinivasarao, D.A.; Raghuvanshi, R.S.; Rajinikanth, P.; Tickoo, V.; Srivastava, S. Stimuli-responsive polysaccharide-based smart hydrogels for diabetic wound healing: Design aspects, preparation methods and regulatory perspectives. Carbohydr. Polym. 2024, 324, 121537. [Google Scholar] [CrossRef] [PubMed]

- Askari, E.; Seyfoori, A.; Amereh, M.; Gharaie, S.S.; Ghazali, H.S.; Ghazali, Z.S.; Khunjush, B.; Akbari, M. Stimuli-Responsive Hydrogels for Local Post-Surgical Drug Delivery. Gels 2020, 6, 14. [Google Scholar] [CrossRef]

- Kasiński, A.; Zielińska-Pisklak, M.; Oledzka, E.; Sobczak, M. Smart Hydrogels—Synthetic Stimuli-Responsive Antitumor Drug Release Systems. Int. J. Nanomed. 2020, 15, 4541–4572. [Google Scholar] [CrossRef]

- Andrade, F.; Roca-Melendres, M.M.; Durán-Lara, E.F.; Rafael, D.; Schwartz, S., Jr. Stimuli-Responsive Hydrogels for Cancer Treatment: The Role of pH, Light, Ionic Strength and Magnetic Field. Cancers 2021, 13, 1164. [Google Scholar] [CrossRef]

- Amirthalingam, S.; Rajendran, A.K.; Moon, Y.G.; Hwang, N.S. Stimuli-responsive dynamic hydrogels: Design, properties and tissue engineering applications. Mater. Horizons 2023, 10, 3325–3350. [Google Scholar] [CrossRef]

- Hu, L.; Shu, T.; Wan, Y.; Fang, C.; Gao, F.; Serpe, M.J. Recent advances in stimuli-responsive polymers for sensing and actuation. Mol. Syst. Des. Eng. 2021, 6, 108–121. [Google Scholar] [CrossRef]

- Gonzalez-Urias, A.; Licea-Claverie, A.; Sañudo-Barajas, J.A.; González-Ayón, M.A. NVCL-Based Hydrogels and Composites for Biomedical Applications: Progress in the Last Ten Years. Int. J. Mol. Sci. 2022, 23, 4722. [Google Scholar] [CrossRef]

- Lanzalaco, S.; Armelin, E. Poly(N-isopropylacrylamide) and Copolymers: A Review on Recent Progresses in Biomedical Applications. Gels 2017, 3, 36. [Google Scholar] [CrossRef]

- Huang, H.; Qi, X.; Chen, Y.; Wu, Z. Thermo-sensitive hydrogels for delivering biotherapeutic molecules: A review. Saudi Pharm. J. 2019, 27, 990–999. [Google Scholar] [CrossRef]

- Zhuo, S.; Halligan, E.; Tie, B.S.H.; Breheny, C.; Geever, L.M. Lower Critical Solution Temperature Tuning and Swelling Behaviours of NVCL-Based Hydrogels for Potential 4D Printing Applications. Polymers 2022, 14, 3155. [Google Scholar] [CrossRef]

- Halligan, E.; Zhuo, S.; Colbert, D.M.; Alsaadi, M.; Tie, B.S.H.; Bezerra, G.S.N.; Keane, G.; Geever, L.M. Modulation of the Lower Critical Solution Temperature of Thermoresponsive Poly(N-vinylcaprolactam) Utilizing Hydrophilic and Hydrophobic Monomers. Polymers 2023, 15, 1595. [Google Scholar] [CrossRef]

- Caló, E.; Khutoryanskiy, V.V. Biomedical applications of hydrogels: A review of patents and commercial products. Eur. Polym. J. 2015, 65, 252–267. [Google Scholar] [CrossRef]

- Zhang, X.N.; Zheng, Q.; Wu, Z.L. Recent advances in 3D printing of tough hydrogels: A review. Compos. Part B Eng. 2022, 238, 109895. [Google Scholar] [CrossRef]

- Xue, X.; Hu, Y.; Wang, S.; Chen, X.; Jiang, Y.; Su, J. Fabrication of physical and chemical crosslinked hydrogels for bone tissue engineering. Bioact. Mater. 2022, 12, 327–339. [Google Scholar] [CrossRef]

- Yang, J.; Liang, G.; Xiang, T.; Situ, W. Effect of crosslinking processing on the chemical structure and biocompatibility of a chitosan-based hydrogel. Food Chem. 2021, 354, 129476. [Google Scholar] [CrossRef]

- Tie, B.S.H.; Halligan, E.; Zhuo, S.; Keane, G.; Geever, L. Synthesis of NVCL-NIPAM Hydrogels Using PEGDMA as a Chemical Crosslinker for Controlled Swelling Behaviours in Potential Shapeshifting Applications. Gels 2023, 9, 248. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, M.; Huang, X.; Zhang, X.; Lu, C.; Song, J.; Yang, H. A bioinspired mineral-organic composite hydrogel as a self-healable and mechanically robust bone graft for promoting bone regeneration. Chem. Eng. J. 2021, 413, 127512. [Google Scholar] [CrossRef]

- Noori, S.; Kokabi, M.; Hassan, Z. Nanoclay Enhanced the Mechanical Properties of Poly(Vinyl Alcohol) /Chitosan /Montmorillonite Nanocomposite Hydrogel as Wound Dressing. Procedia Mater. Sci. 2015, 11, 152–156. [Google Scholar] [CrossRef]

- Xiang, C.; Zhang, Q.; Guo, Z.; Wang, Z.; Chen, W.; Li, X.; Wei, X.; Li, P. Facile preparation and properties of porous poly(vinyl alcohol)/trehalose/nano-clay hydrogels with high mechanical strength for potential application in bone tissue engineering. Eur. Polym. J. 2023, 197, 112336. [Google Scholar] [CrossRef]

- Xing, W.; Tang, Y. On mechanical properties of nanocomposite hydrogels: Searching for superior properties. Nano Mater. Sci. 2022, 4, 83–96. [Google Scholar] [CrossRef]

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A Review of the Synthesis and Applications of Polymer–Nanoclay Composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef]

- Zhuo, S.; Tie, B.S.H.; Keane, G.; Geever, L.M. Strategies for Developing Shape-Shifting Behaviours and Potential Applications of Poly (N-vinyl Caprolactam) Hydrogels. Polymers 2023, 15, 1511. [Google Scholar] [CrossRef]

- Zhuo, S.; Geever, L.M.; Halligan, E.; Tie, B.S.H.; Breheny, C. A Development of New Material for 4D Printing and the Material Properties Comparison between the Conventional and Stereolithography Polymerised NVCL Hydrogels. J. Funct. Biomater. 2022, 13, 262. [Google Scholar] [CrossRef]

- Halligan, E.; Tie, B.S.H.; Colbert, D.M.; Alsaadi, M.; Zhuo, S.; Keane, G.; Geever, L.M. Synthesis and Characterisation of Hydrogels Based on Poly (N-Vinylcaprolactam) with Diethylene Glycol Diacrylate. Gels 2023, 9, 439. [Google Scholar] [CrossRef]

- Cortez-Lemus, N.A.; Licea-Claverie, A. Poly(N-vinylcaprolactam), a comprehensive review on a thermoresponsive polymer becoming popular. Prog. Polym. Sci. 2016, 53, 1–51. [Google Scholar] [CrossRef]

- Tomal, W.; Ortyl, J. Water-Soluble Photoinitiators in Biomedical Applications. Polymers 2020, 12, 1073. [Google Scholar] [CrossRef]

- Williams, C.G.; Malik, A.N.; Kim, T.K.; Manson, P.N.; Elisseeff, J.H. Variable cytocompatibility of six cell lines with photoinitiators used for polymerizing hydrogels and cell encapsulation. Biomaterials 2005, 26, 1211–1218. [Google Scholar] [CrossRef]

- Antony, J. Design of Experiments for Engineers and Scientists; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Nandiyanto, A.B.D.; Oktiani, R.; Ragadhita, R. How to Read and Interpret FTIR Spectroscope of Organic Material. Indones. J. Sci. Technol. 2019, 4, 97–118. [Google Scholar] [CrossRef]

- Terzio, P.; Yücel, S.; Özçimen, D. The utilization of wheat HULL ash for the production of barium and calcium silicates. Lat. Am. Appl. Res. 2013, 43, 319–324. [Google Scholar]

- Yan, Z.-C.; Biswas, C.S.; Stadler, F.J. Rheological Study on the Thermoreversible Gelation of Stereo-Controlled Poly(N-Isopropylacrylamide) in an Imidazolium Ionic Liquid. Polymers 2019, 11, 783. [Google Scholar] [CrossRef]

- Halligan, S.C.; Dalton, M.B.; Murray, K.A.; Dong, Y.; Wang, W.; Lyons, J.G.; Geever, L.M. Synthesis, characterisation and phase transition behaviour of temperature-responsive physically crosslinked poly (N-vinylcaprolactam) based polymers for biomedical applications. Mater. Sci. Eng. C 2017, 79, 130–139. [Google Scholar] [CrossRef]

- Killion, J.A.; Geever, L.M.; Devine, D.M.; Kennedy, J.E.; Higginbotham, C.L. Mechanical properties and thermal behaviour of PEGDMA hydrogels for potential bone regeneration application. J. Mech. Behav. Biomed. Mater. 2011, 4, 1219–1227. [Google Scholar] [CrossRef]

- Stetsyshyn, Y.; Raczkowska, J.; Harhay, K.; Gajos, K.; Melnyk, Y.; Dąbczyński, P.; Shevtsova, T.; Budkowski, A. Temperature-responsive and multi-responsive grafted polymer brushes with transitions based on critical solution temperature: Synthesis, properties, and applications. Colloid Polym. Sci. 2020, 299, 363–383. [Google Scholar] [CrossRef]

- Kimbell, G.; Azad, M.A. Chapter FIFTEEN—3D printing: Bioinspired materials for drug delivery. In Bioinspired and Biomimetic Materials for Drug Delivery; Nurunnabi, M., Ed.; Woodhead Publishing Series in Biomaterials; Woodhead Publishing: Sawston, UK, 2021; pp. 295–318. [Google Scholar] [CrossRef]

- Muralishwara, K.; Fernandes, L.; Kalkura, R.; Bangera, S. Effect of Surface Modified Montmorillonite Nanoclay on Tensile and Flexural Properties of Pineapple Leaf Fiber Reinforced Epoxy Composite. Mater. Res. 2023, 26, e20220437. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Krishnamurthy, K.; Rajasekar, R.; Rajeshkumar, G. An experimental study on the effect of nano-clay addition on mechanical and water absorption behaviour of jute fibre reinforced epoxy composites. J. Ind. Text. 2018, 49, 597–620. [Google Scholar] [CrossRef]

- Müller, C.M.; Laurindo, J.B.; Yamashita, F. Effect of nanoclay incorporation method on mechanical and water vapor barrier properties of starch-based films. Ind. Crops Prod. 2011, 33, 605–610. [Google Scholar] [CrossRef]

- Hiremath, P.; Ranjan, R.; DeSouza, V.; Bhat, R.; Patil, S.; Maddodi, B.; Shivamurthy, B.; Perez, T.C.; Naik, N. Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy. J. Compos. Sci. 2023, 7, 478. [Google Scholar] [CrossRef]

- Rahman, M.S.; Islam, M.M.; Islam, M.S.; Zaman, A.; Ahmed, T.; Biswas, S.; Sharmeen, S.; Rashid, T.U.; Rahman, M.M. Morphological Characterization of Hydrogels. In Cellulose-Based Superabsorbent Hydrogels; Mondal, M.I.H., Ed.; Springer International Publishing: Cham, Germay, 2019; pp. 819–863. [Google Scholar]

- Barbosa, L.C.M.; Bortoluzzi, D.B.; Ancelotti, A.C. Analysis of fracture toughness in mode II and fractographic study of composites based on Elium® 150 thermoplastic matrix. Compos. Part B Eng. 2019, 175, 107082. [Google Scholar] [CrossRef]

| Materials | Chemical Structures or Composition |

|---|---|

| N-vinylcaprolactam (NVCL) |  |

| N-isopropylacrylamide (NIPAm) |  |

| Poly(ethylene glycol) dimethacrylate (PEGDMA) |  |

| 4-(2-hydroxyethoxy) phenyl-(2-hydroxy-2-propyl) ketone (Irgacure 2959) |  |

| Bentonite clay | Al2H2O6Si |

| Monomers | Crosslinker | Photoinitiator | Additives | |||

|---|---|---|---|---|---|---|

| Formulation | NVCL (wt%) | NIPAm (wt%) | PEGDMA (wt%) | Irgacure 2959 (wt%) | NCSM (wt%) | NCB (wt%) |

| FC34 | 59.94 | 29.97 | 9.99 | 0.10 | - | - |

| 0.1NCB_FC34 | 59.94 | 29.97 | 9.99 | 0.10 | - | 0.1 |

| 1.0NCB_FC34 | 59.94 | 29.97 | 9.99 | 0.10 | - | 1.0 |

| 3.0NCB_FC34 | 59.94 | 29.97 | 9.99 | 0.10 | - | 3.0 |

| 0.1NCSM_FC34 | 59.94 | 29.97 | 9.99 | 0.10 | 0.1 | - |

| 1.0NCSM_FC34 | 59.94 | 29.97 | 9.99 | 0.10 | 1.0 | - |

| 3.0NCSM_FC34 | 59.94 | 29.97 | 9.99 | 0.10 | 3.0 | - |

| Monomers | Photoinitiator | Additives | |||

|---|---|---|---|---|---|

| Formulation | NVCL (wt%) | NIPAm (wt%) | Irgacure 2959 (wt%) | NCSM (wt%) | NCB (wt%) |

| FP34 | 66.60 | 33.30 | 0.10 | - | - |

| 0.1NCB_FP34 | 66.60 | 33.30 | 0.10 | - | 0.1 |

| 1.0NCB_FP34 | 66.60 | 33.30 | 0.10 | - | 1.0 |

| 3.0NCB_FP34 | 66.60 | 33.30 | 0.10 | - | 3.0 |

| 0.1NCSM_FP34 | 66.60 | 33.30 | 0.10 | 0.1 | - |

| 1.0NCSM_FP34 | 66.60 | 33.30 | 0.10 | 1.0 | - |

| 3.0NCSM_FP34 | 66.60 | 33.30 | 0.10 | 3.0 | - |

| Factors | Levels | Values |

|---|---|---|

| NC types | 2 | NCB, NCSM |

| Percentages of NC (%) | 3 | 0.1, 1.0, 3.0 |

| Swelling temperature (°C) | 2 | 20, 50 |

| StdOrder | Types of NC | Concentration (%) | Temperature (°C) | Swelling Ratio (%) |

|---|---|---|---|---|

| 1 | NCB | 0.1 | 20 | 150 |

| 2 | NCB | 0.1 | 50 | 48 |

| 3 | NCSM | 0.1 | 20 | 149 |

| 4 | NCSM | 0.1 | 50 | 30 |

| 5 | NCB | 1.0 | 20 | 158 |

| 6 | NCB | 1.0 | 50 | 41 |

| 7 | NCSM | 1.0 | 20 | 118 |

| 8 | NCSM | 1.0 | 50 | 26 |

| 9 | NCB | 3.0 | 20 | 160 |

| 10 | NCB | 3.0 | 50 | 42 |

| 11 | NCSM | 3.0 | 20 | 126 |

| 12 | NCSM | 3.0 | 50 | 23 |

| 13 | NCB | 0.1 | 20 | 142 |

| 14 | NCB | 0.1 | 50 | 43 |

| 15 | NCSM | 0.1 | 20 | 155 |

| 16 | NCSM | 0.1 | 50 | 35 |

| 17 | NCB | 1.0 | 20 | 160 |

| 18 | NCB | 1.0 | 50 | 40 |

| 19 | NCSM | 1.0 | 20 | 129 |

| 20 | NCSM | 1.0 | 50 | 28 |

| 21 | NCB | 3.0 | 20 | 160 |

| 22 | NCB | 3.0 | 50 | 41 |

| 23 | NCSM | 3.0 | 20 | 111 |

| 24 | NCSM | 3.0 | 50 | 22 |

| 25 | NCB | 0.1 | 20 | 147 |

| 26 | NCB | 0.1 | 50 | 34 |

| 27 | NCSM | 0.1 | 20 | 155 |

| 28 | NCSM | 0.1 | 50 | 37 |

| 29 | NCB | 1.0 | 20 | 154 |

| 30 | NCB | 1.0 | 50 | 39 |

| 31 | NCSM | 1.0 | 20 | 127 |

| 32 | NCSM | 1.0 | 50 | 27 |

| 33 | NCB | 3.0 | 20 | 156 |

| 34 | NCB | 3.0 | 50 | 39 |

| 35 | NCSM | 3.0 | 20 | 109 |

| 36 | NCSM | 3.0 | 50 | 20 |

| Formulation | Cloud-Point (°C) | UV Spectroscopy (°C) |

|---|---|---|

| FP34 | 32 | 31 |

| 0.1NCB_FP34 | 32 | 31 |

| 1.0NCB_FP34 | 32 | 31 |

| 3.0NCB_FP34 | 32 | 31 |

| 0.1NCSM_FP34 | 32 | 31 |

| 1.0NCSM_FP34 | 32 | 31 |

| 3.0NCSM_FP34 | 32 | 31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tie, B.S.H.; Manaf, E.; Halligan, E.; Zhuo, S.; Keane, G.; Geever, J.; Geever, L. The Effects of Incorporating Nanoclay in NVCL-NIPAm Hydrogels on Swelling Behaviours and Mechanical Properties. Nanomaterials 2024, 14, 597. https://doi.org/10.3390/nano14070597

Tie BSH, Manaf E, Halligan E, Zhuo S, Keane G, Geever J, Geever L. The Effects of Incorporating Nanoclay in NVCL-NIPAm Hydrogels on Swelling Behaviours and Mechanical Properties. Nanomaterials. 2024; 14(7):597. https://doi.org/10.3390/nano14070597

Chicago/Turabian StyleTie, Billy Shu Hieng, Eyman Manaf, Elaine Halligan, Shuo Zhuo, Gavin Keane, Joseph Geever, and Luke Geever. 2024. "The Effects of Incorporating Nanoclay in NVCL-NIPAm Hydrogels on Swelling Behaviours and Mechanical Properties" Nanomaterials 14, no. 7: 597. https://doi.org/10.3390/nano14070597

APA StyleTie, B. S. H., Manaf, E., Halligan, E., Zhuo, S., Keane, G., Geever, J., & Geever, L. (2024). The Effects of Incorporating Nanoclay in NVCL-NIPAm Hydrogels on Swelling Behaviours and Mechanical Properties. Nanomaterials, 14(7), 597. https://doi.org/10.3390/nano14070597