Electrostatically Doped Junctionless Graphene Nanoribbon Tunnel Field-Effect Transistor for High-Performance Gas Sensing Applications: Leveraging Doping Gates for Multi-Gas Detection

Abstract

1. Introduction

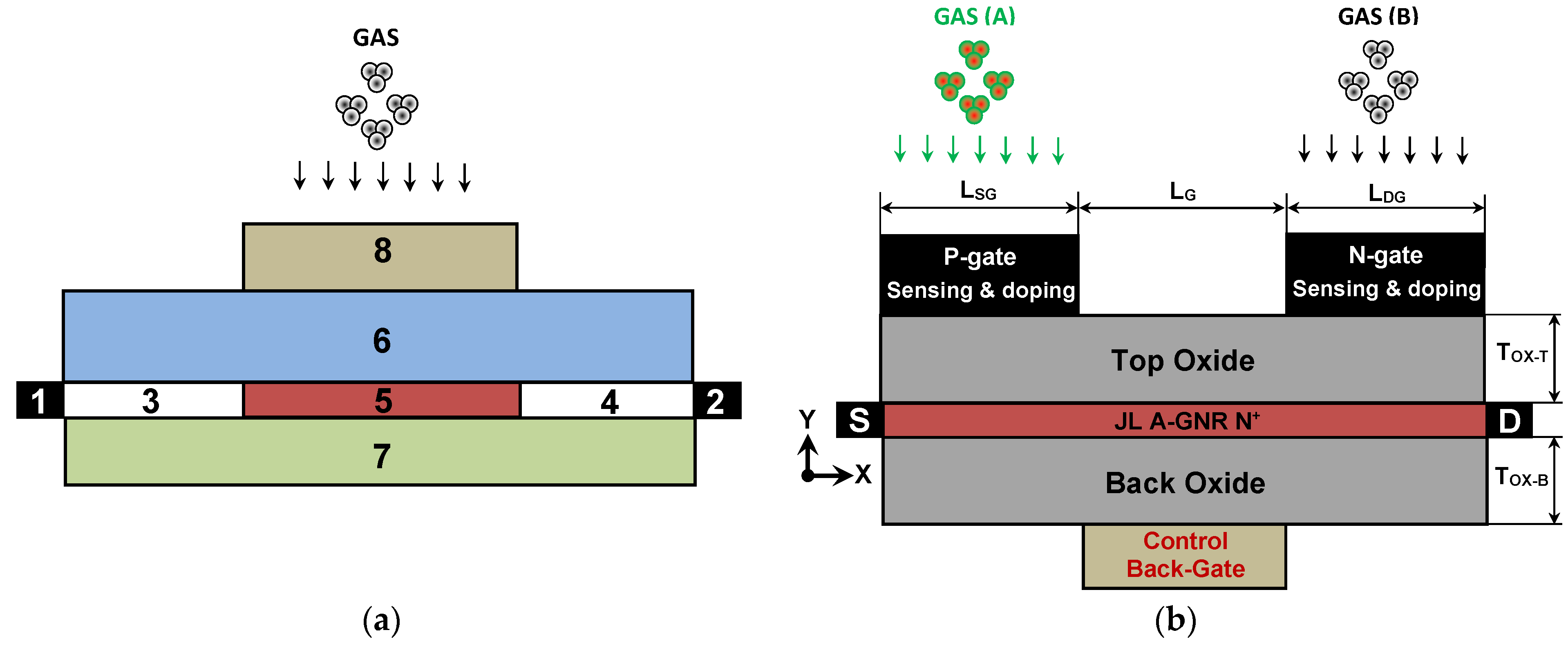

2. Nanosensor Structure and Multi-Gas Sensing Principle

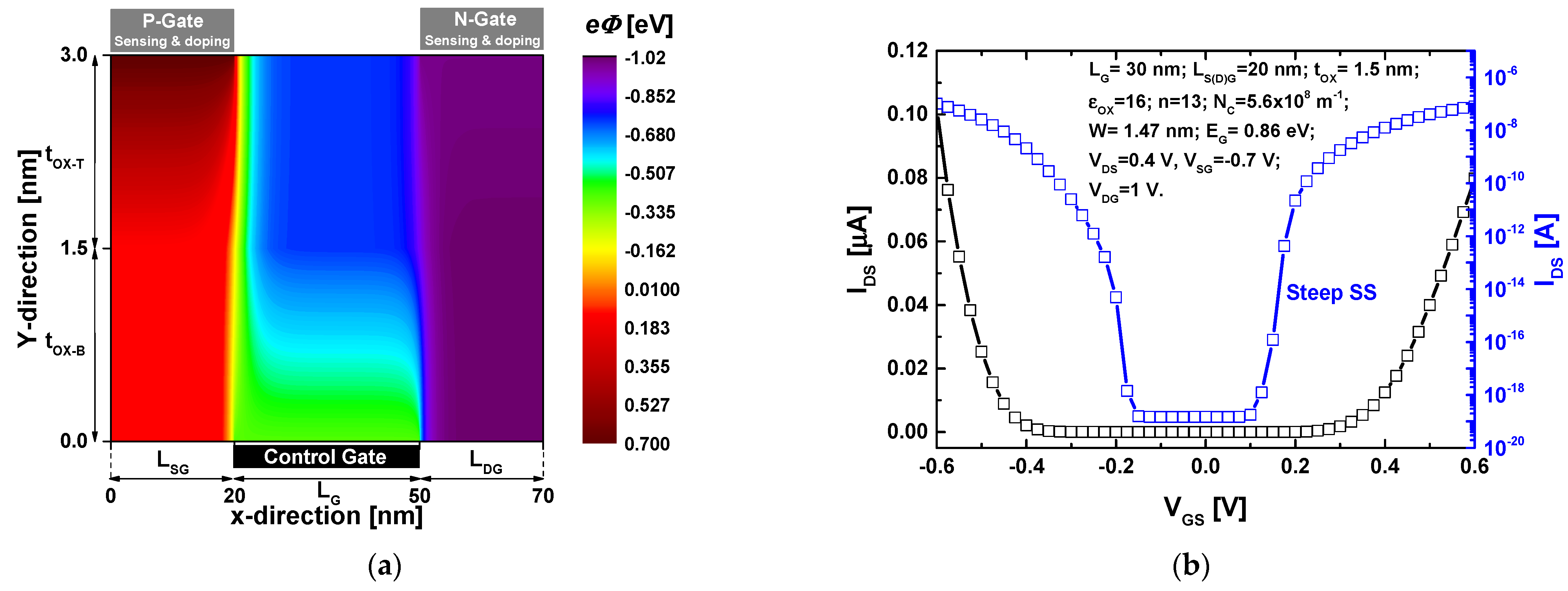

3. Quantum Simulation Approach

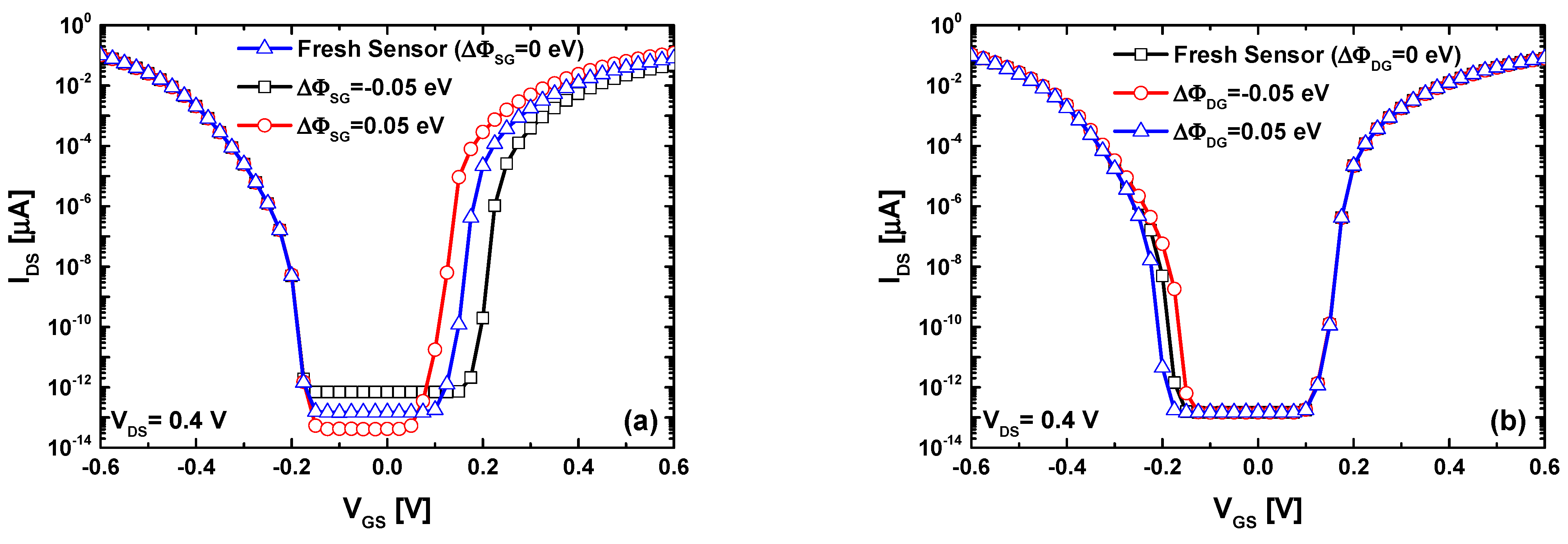

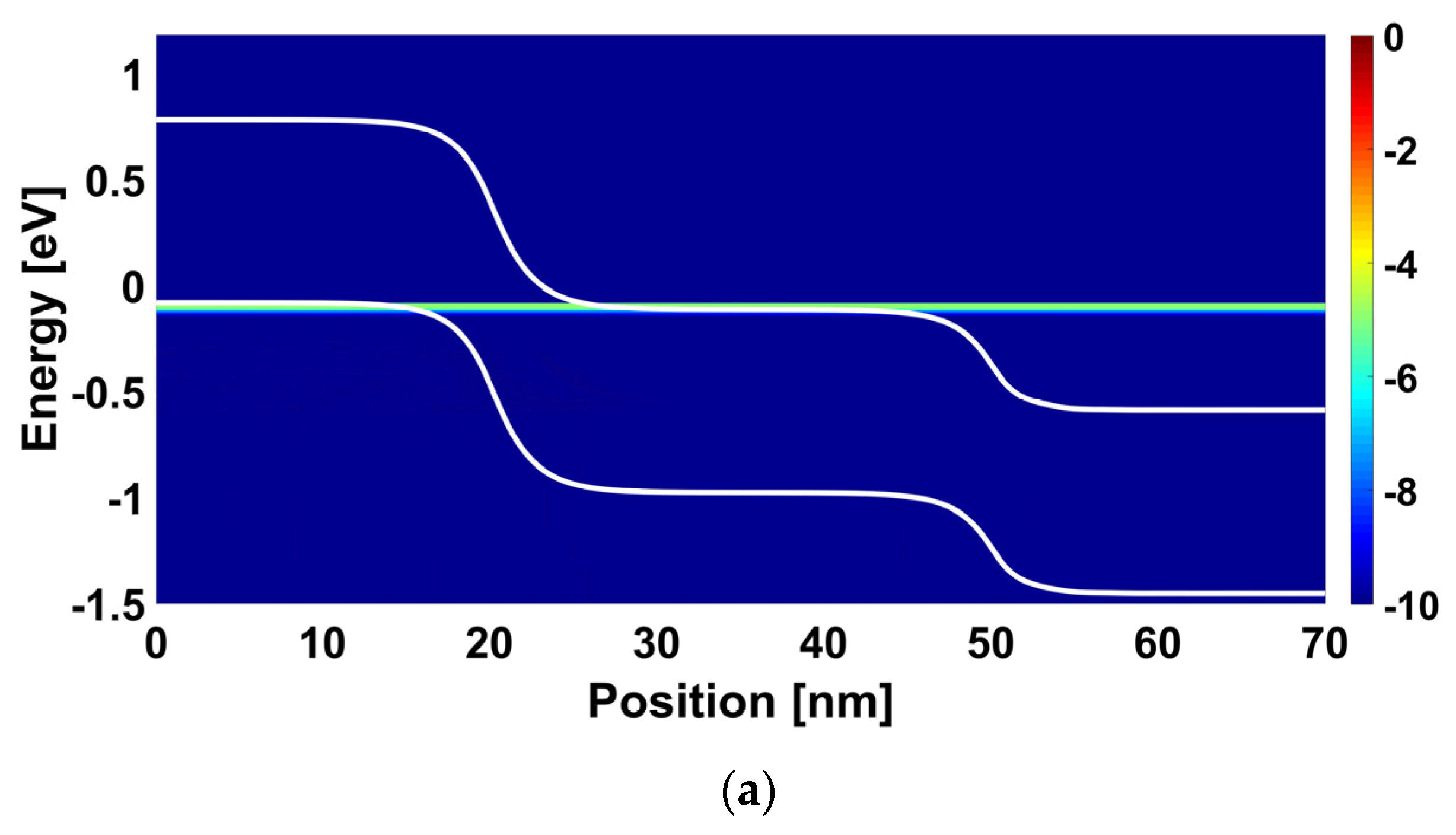

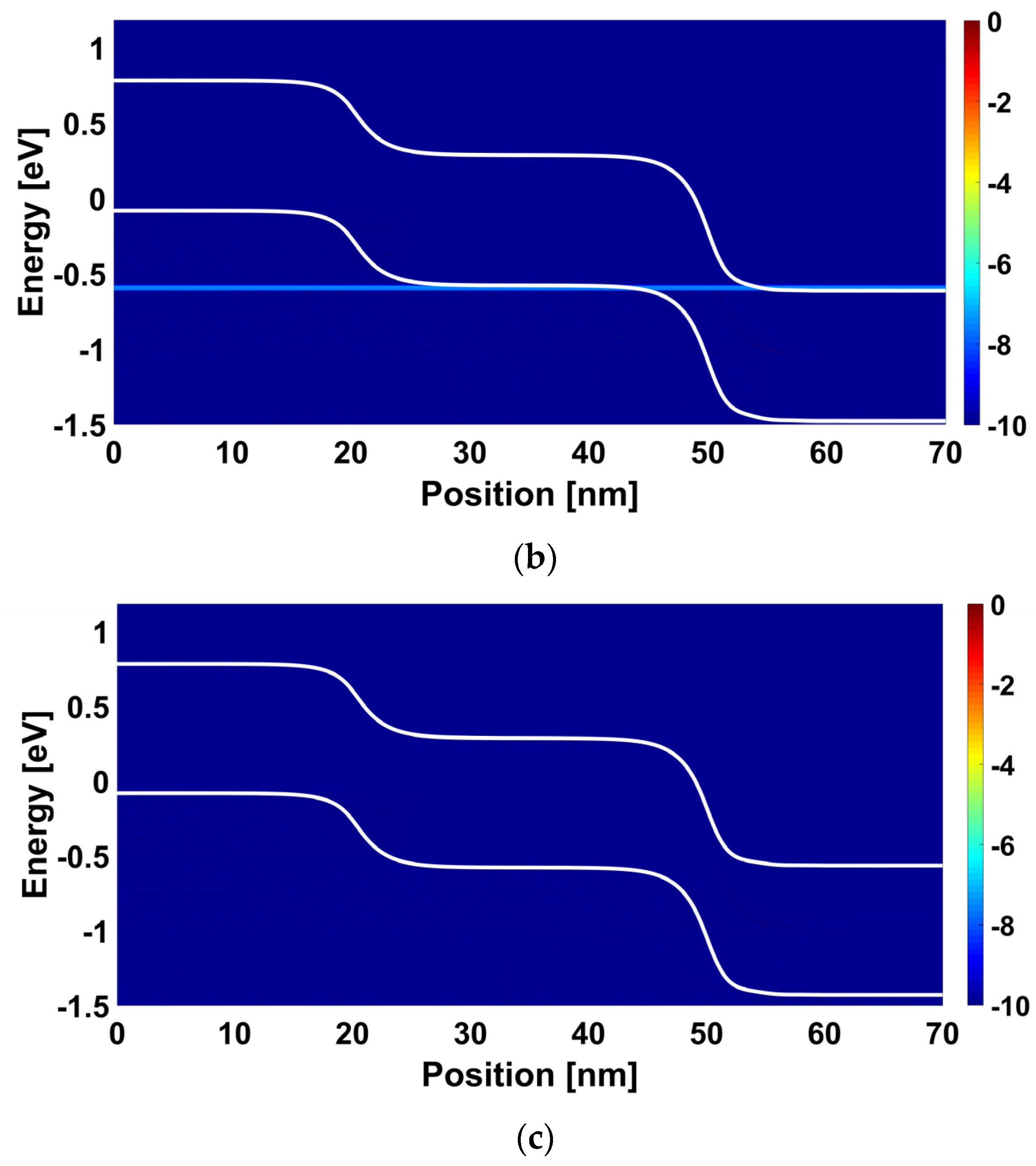

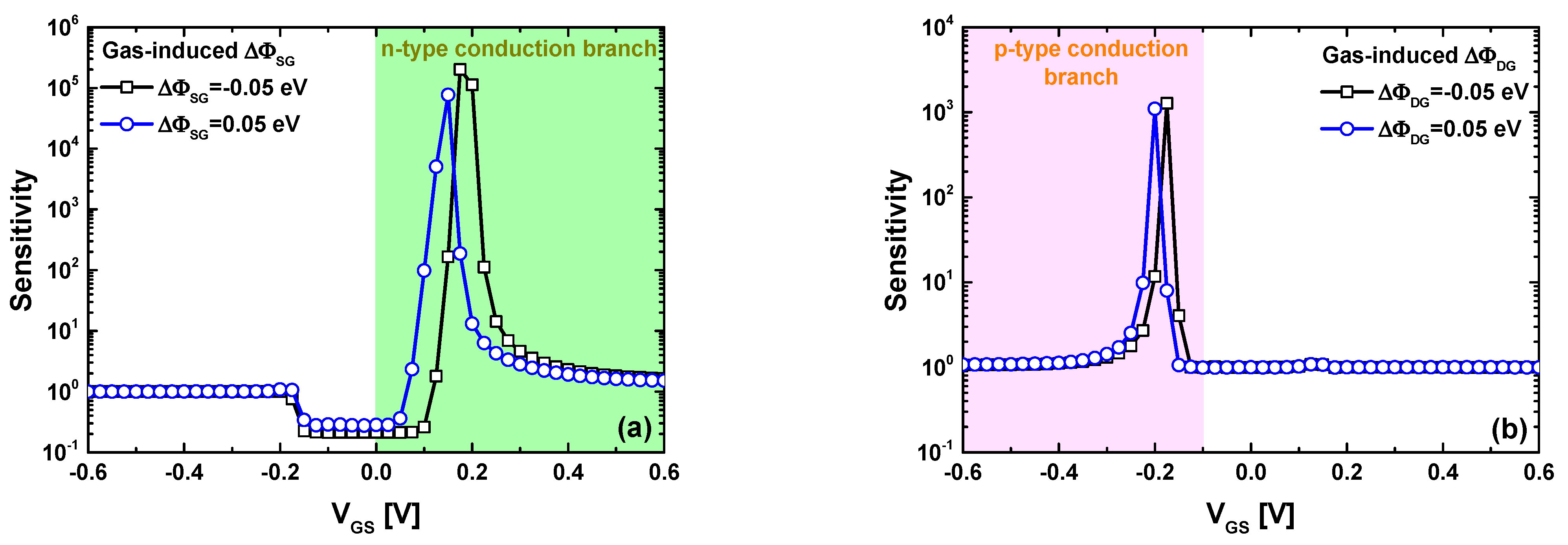

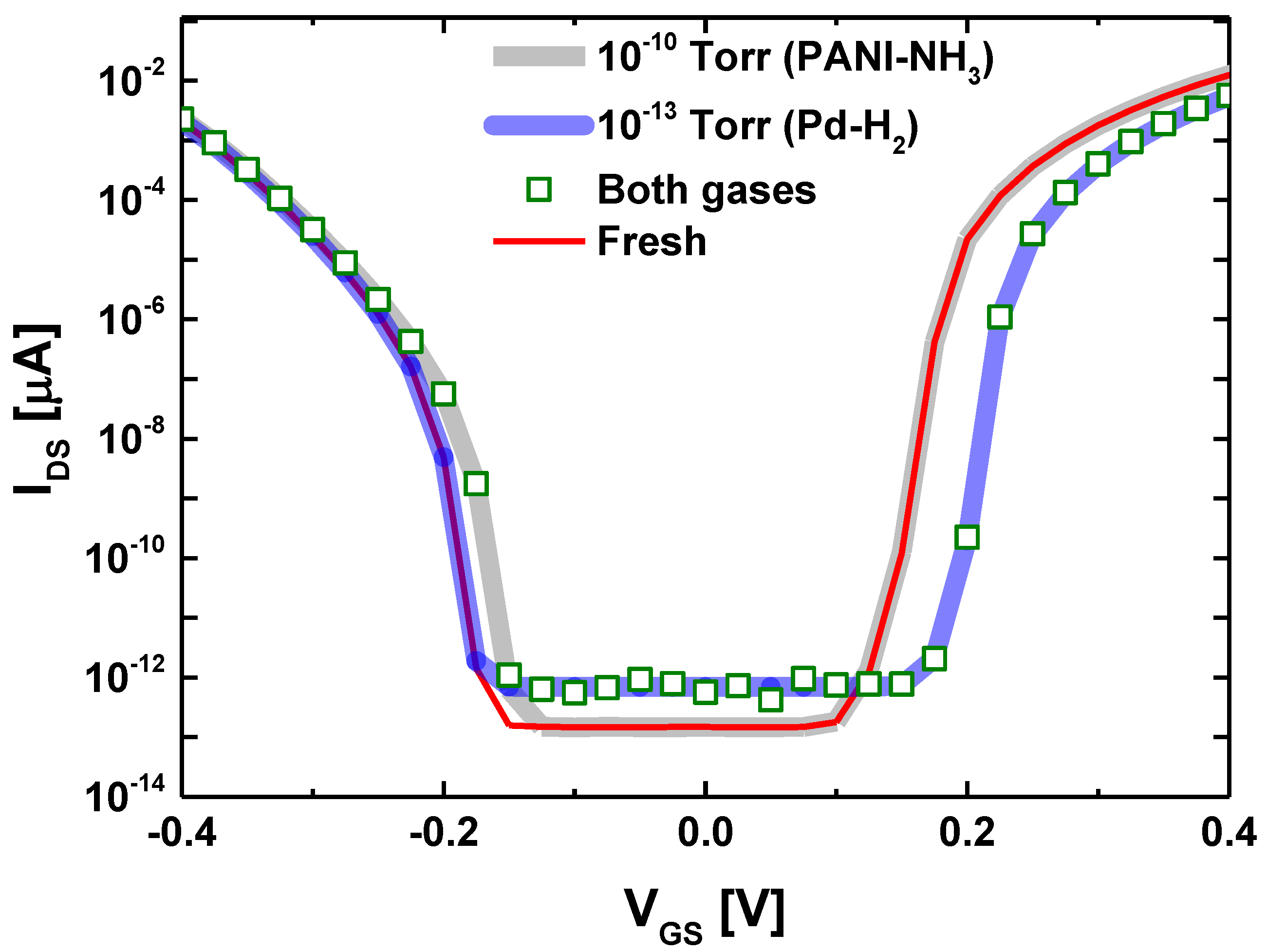

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Röck, F.; Barsan, N.; Weimar, U. Electronic Nose: Current Status and Future Trends. Chem. Rev. 2008, 108, 705–725. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A Survey on Gas Sensing Technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef]

- Huang, X.-Y.; Chi, Z.-T.; Yang, W.; Deng, Y.; Xie, W.-F. Synthesis of Bi2O2CO3/In(OH)3·xH2O nanocomposites for isopropanol sensor with excellent performances at low temperature. Sens. Actuators B Chem. 2022, 361, 131715. [Google Scholar] [CrossRef]

- Wang, C.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metal Oxide Gas Sensors: Sensitivity and Influencing Factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef]

- Dey, A. Semiconductor metal oxide gas sensors: A review. Mater. Sci. Eng. B 2018, 229, 206–217. [Google Scholar] [CrossRef]

- Late, D.J.; Huang, Y.-K.; Liu, B.; Acharya, J.; Shirodkar, S.N.; Luo, J.; Yan, A.; Charles, D.; Waghmare, U.V.; Dravid, V.P.; et al. Sensing Behavior of Atomically Thin-Layered MoS2 Transistors. ACS Nano 2013, 7, 4879–4891. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Chen, P.; Hu, W. Organic field-effect transistor-based gas sensors. Chem. Soc. Rev. 2015, 44, 2087–2107. [Google Scholar] [CrossRef] [PubMed]

- Mabeck, J.T.; Malliaras, G.G. Chemical and biological sensors based on organic thin-film transistors. Anal. Bioanal. Chem. 2005, 384, 343–353. [Google Scholar] [CrossRef] [PubMed]

- Crone, B.; Dodabalapur, A.; Gelperin, A.; Torsi, L.; Katz, H.E.; Lovinger, A.J.; Bao, Z. Electronic sensing of vapors with organic transistors. Appl. Phys. Lett. 2001, 78, 2229–2231. [Google Scholar] [CrossRef]

- Sharma, B.; Sharma, A.; Kim, J.-S. Recent advances on H2 sensor technologies based on MOX and FET devices: A review. Sens. Actuators B Chem. 2018, 262, 758–770. [Google Scholar] [CrossRef]

- Janata, J.; Josowicz, M. Conducting polymers in electronic chemical sensors. Nat. Mater. 2003, 2, 19–24. [Google Scholar] [CrossRef] [PubMed]

- Janata, J.; Josowicz, M. Chemical modulation of work function as a transduction mechanism for chemical sensors. Acc. Chem. Res. 1998, 31, 241–248. [Google Scholar] [CrossRef]

- Domanský, K.; Baldwin, D.L.; Grate, J.W.; Hall, T.B.; Li, J.; Josowicz, M.; Janata, J. Development and calibration of field-effect transistor-based sensor array for measurement of hydrogen and ammonia gas mixtures in humid air. Anal. Chem. 1998, 70, 473–481. [Google Scholar] [CrossRef]

- Janata, J. Chemically sensitive field-effect transistors past present and future. ChemElectroChem 2022, 23, 9. [Google Scholar] [CrossRef]

- Wilson, D.M.; Hoyt, S.; Janata, J.; Booksh, K.; Obando, L. Chemical sensors for portable, handheld field instruments. IEEE Sens. J. 2001, 1, 256–274. [Google Scholar] [CrossRef]

- Gandhi, N.; Rathore, S.; Jaisawal, R.K.; Kondekar, P.N.; Dey, S.; Bagga, N. Unveiling the self-heating and process variation reliability of a junctionless FinFET-based hydrogen gas sensor. IEEE Sens. Lett. 2023, 7, 4503004. [Google Scholar] [CrossRef]

- Ghosh, R. Performance investigation of dual trench split-control-gate MOSFET as hydrogen gas sensor: A catalytic metal gate approach. IEEE Sens. Lett. 2023, 7, 2000804. [Google Scholar] [CrossRef]

- Panda, S.; Dash, S.; Mishra, G.P. Design and Investigation of a Single Gate Heterostructure Junctionless Tunnel FET for the Gas Detection. ECS J. Solid State Sci. Technol. 2023, 12, 041007. [Google Scholar] [CrossRef]

- Sehgal, H.D.; Pratap, Y.; Gupta, M.; Kabra, S. Performance investigation of novel Pt/Pd-SiO2 junctionless FinFET as a high sensitive hydrogen gas sensor for industrial applications. IEEE Sens. J. 2021, 21, 13356. [Google Scholar] [CrossRef]

- Josowicz, M.; Janata, J. Suspended gate field effect transistors modified with polypyrrole as alcohol sensor. Anal. Chem. 1986, 58, 514–517. [Google Scholar] [CrossRef]

- Mokkapati, S.; Jaiswal, N.; Gupta, M.; Kranti, A. Gate-all-around nanowire junctionless transistor-based hydrogen gas sensor. IEEE Sens. J. 2019, 19, 4758–4764. [Google Scholar] [CrossRef]

- Kumar, A. Palladium-based trench gate MOSFET for highly sensitive hydrogen gas sensor. Mater. Sci. Semicond. Process. 2020, 120, 105274. [Google Scholar] [CrossRef]

- Janata, J. Principles of Chemical Sensors; Springer: New York, NY, USA, 2009. [Google Scholar]

- Saheb, A.; Josowicz, M.; Janata, J. Chemically sensitive field-effect transistor with polyaniline–ionic liquid composite gate. Anal. Chem. 2008, 80, 4214–4219. [Google Scholar] [CrossRef]

- Bhattacharyya, P. Fabrication strategies and measurement techniques for performance improvement of graphene/graphene derivative based FET gas sensor devices: A review. IEEE Sens. J. 2021, 21, 10231–10240. [Google Scholar] [CrossRef]

- Sarkar, D.; Gossner, H.; Hansch, W.; Banerjee, K. Tunnel-field-effect-transistor based gas-sensor: Introducing gas detection with a quantum-mechanical transducer. Appl. Phys. Lett. 2013, 102, 023110. [Google Scholar] [CrossRef]

- Tamersit, K.; Ramezani, Z.; Amiri, I.S. Improved performance of sub-10-nm band-to-band tunneling n-i-n graphene nanoribbon field-effect transistors using underlap engineering: A quantum simulation study. J. Phys. Chem. Solids 2021, 160, 110312. [Google Scholar] [CrossRef]

- Tamersit, K. New nanoscale band-to-band tunneling junctionless GNRFETs: Potential high-performance devices for the ultrascaled regime. J. Comput. Electron. 2021, 20, 1147–1156. [Google Scholar] [CrossRef]

- Yousefi, R.; Shabani, M.; Arjmandi, M.; Ghoreishi, S. A computational study on electrical characteristics of a novel band-to-band tunneling graphene nanoribbon FET. Superlattices Microstruct. 2013, 60, 169–178. [Google Scholar] [CrossRef]

- Som, D.; Majumdar, B.; Kundu, S.; Kanungo, S. Investigation of charge plasma enhanced tunnel field effect transistor for hydrogen gas sensing application. IEEE Sens. Lett. 2020, 4, 1500404. [Google Scholar] [CrossRef]

- Anam, A.; Anand, S.; Amin, S.I. Design and performance analysis of tunnel field effect transistor with buried strained Si1-xGex source structure based biosensor for sensitivity enhancement. IEEE Sens. J. 2020, 20, 13178–13185. [Google Scholar] [CrossRef]

- Panda, S.; Dash, S. Application of a charge plasma tunnel FET with SiGe pocket as an effective hydrogen gas sensor. ECS J. Solid State Sci. Technol. 2023, 12, 031003. [Google Scholar] [CrossRef]

- Tamersit, K. An ultra-sensitive gas nanosensor based on asymmetric dual-gate graphene nanoribbon field-effect transistor: Proposal and investigation. J. Comput. Electron. 2019, 18, 846–855. [Google Scholar] [CrossRef]

- Kumar, N.; Raman, A. Prospective sensing applications of novel heteromaterial based dopingless nanowire-TFET at low operating voltage. IEEE Trans. Nanotechnol. 2020, 19, 527–534. [Google Scholar] [CrossRef]

- Mishra, V.; Agarwal, L.; Tiwari, C.; Gupta, S.K. Potential sensing application of oxygen gas with charge plasma based negative capacitance Tunnel FET. Silicon 2022, 15, 3251–3260. [Google Scholar] [CrossRef]

- Ghosh, R.; Sarkhel, S.; Saha, P. Design and analysis of Z shaped InGa0.5As0.5/Si tunnel FET using non-equilibrium Green’s function model for hydrogen gas sensing application. Micro Nanostruct. 2023, 182, 207651. [Google Scholar] [CrossRef]

- Yousefi, R. Effect of uniaxial strain on the subthreshold swing of ballistic carbon nanotube FETs. Phys. E Low-Dimens. Syst. Nanostruct. 2011, 43, 1896–1901. [Google Scholar] [CrossRef]

- Desai, S.B.; Madhvapathy, S.R.; Sachid, A.B.; Llinas, J.P.; Wang, Q.; Ahn, G.H.; Pitner, G.; Kim, M.J.; Bokor, J.; Hu, C.; et al. MoS2 transistors with 1-nanometer gate lengths. Science 2016, 354, 99–102. [Google Scholar] [CrossRef]

- Ionescu, A.M.; Riel, H. Tunnel field-effect transistors as energy-efficient electronic switches. Nature 2011, 479, 329–337. [Google Scholar] [CrossRef]

- Sarkar, D.; Xie, X.; Liu, W.; Cao, W.; Kang, J.; Gong, Y.; Kraemer, S.; Ajayan, P.M.; Banerjee, K.A. subthermionic tunnel field-effect transistor with an atomically thin channel. Nature 2015, 526, 91–95. [Google Scholar] [CrossRef]

- Ghosh, B.; Akram, M.W. Junctionless tunnel field effect transistor. IEEE Electron Device Lett. 2013, 34, 584–586. [Google Scholar] [CrossRef]

- Anantram, M.P.; Lundstrom, M.S.; Nikonov, D.E. Modeling of nanoscale devices. Proc. IEEE 2008, 96, 1511–1550. [Google Scholar] [CrossRef]

- Colinge, J.-P.; Lee, C.-W.; Afzalian, A.; Akhavan, N.D.; Yan, R.; Ferain, I.; Razavi, P.; O’Neill, B.; Blake, A.; White, M.; et al. Nanowire transistors without junctions. Nat. Nanotechnol. 2010, 5, 225–229. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhao, W.; Seabaugh, A. Low-subthreshold-swing tunnel transistors. IEEE Electron Device Lett. 2006, 27, 297–300. [Google Scholar] [CrossRef]

- Toh, E.-H.; Wang, G.H.; Samudra, G.; Yeo, Y.-C. Device physics and design of germanium tunneling field-effect transistor with source and drain engineering for low power and high-performance applications. J. Appl. Phys. 2008, 103, 15. [Google Scholar] [CrossRef]

- Fiori, G.; Iannaccone, G. Simulation of graphene nanoribbon field-effect transistors. IEEE Electron Device Lett. 2007, 28, 760–762. [Google Scholar] [CrossRef]

- Zhao, P.; Guo, J. Modeling edge effects in graphene nanoribbon field-effect transistors with real and mode space methods. J. Appl. Phys. 2009, 105, 034503. [Google Scholar] [CrossRef]

- Koswatta, S.O.; Hasan, S.; Lundstrom, M.S.; Anantram, M.P.; Nikonov, D.E. Nonequilibrium Green’s Function Treatment of Phonon Scattering in Carbon-Nanotube Transistors. IEEE Trans. Electron Devices 2007, 54, 2339–2351. [Google Scholar] [CrossRef]

- Franklin, A.D.; Luisier, M.; Han, S.-J.; Tulevski, G.; Breslin, C.M.; Gignac, L.; Lundstrom, M.S.; Haensch, W. Sub-10 nm Carbon Nanotube Transistor. Nano Lett. 2012, 12, 758–762. [Google Scholar] [CrossRef]

- Chin, S.-K.; Seah, D.; Lam, K.-T.; Samudra, G.S.; Liang, G. Device Physics and Characteristics of Graphene Nanoribbon Tunneling FETs. IEEE Trans. Electron Devices 2010, 57, 3144–3152. [Google Scholar] [CrossRef]

- Gautam, R.; Saxena, M.; Gupta, R.S.; Gupta, M. Gate-all-around nanowire MOSFET with catalytic metal gate for gas sensing applications. IEEE Trans. Nanotechnol. 2013, 12, 939–944. [Google Scholar] [CrossRef]

- Tsukada, K.; Inoue, H.; Katayama, F.; Sakai, K.; Kiwa, T. Changes in work function and electrical resistance of Pt thin films in the presence of hydrogen gas. Jpn. J. Appl. Phys. 2011, 51, 015701. [Google Scholar] [CrossRef]

- Pandey, P.; Kaur, H. Exploring the performance of palladium gated–SiGe channel—Polarity controllable–FET for hydrogen gas monitoring applications. Micro Nanostruct. 2022, 169, 207357. [Google Scholar] [CrossRef]

- Miyahara, Y.; Tsukada, K.; Miyagi, H. Field-effect transistor using a solid electrolyte as a new oxygen sensor. J. Appl. Phys. 1988, 63, 2431–2434. [Google Scholar] [CrossRef]

- Datta, S. Nanoscale device modeling: The Green’s function method. Superlattices Microstruct. 2000, 28, 253–278. [Google Scholar] [CrossRef]

- Luisier, M.; Schenk, A.; Fichtner, W. Quantum transport in two- and three-dimensional nanoscale transistors: Coupled mode effects in the nonequilibrium Green’s function formalism. J. Appl. Phys. 2006, 100, 043713. [Google Scholar] [CrossRef]

- Zhao, P.; Chauhan, J.; Guo, J. Computational study of tunneling transistor based on graphene nanoribbon. Nano Lett. 2009, 9, 684–688. [Google Scholar] [CrossRef] [PubMed]

- Tahaei, S.H.; Ghoreishi, S.S.; Yousefi, R.; Aderang, H. A computational study of a carbon nanotube junctionless tunneling field-effect transistor (CNT-JLTFET) based on the charge plasma concept. Superlattices Microstruct. 2018, 125, 168–176. [Google Scholar] [CrossRef]

- Kumar, M.; Jit, S. A Novel four-terminal ferroelectric tunnel FET for quasi-ideal switch. IEEE Trans. Nanotechnol. 2015, 14, 600–602. [Google Scholar] [CrossRef]

- Ghoreishi, S.S.; Saghafi, K.; Yousefi, R.; Moravvej-Farshi, M.K. Graphene nanoribbon tunnel field effect transistor with lightly doped drain: Numerical simulations. Superlattices Microstruct. 2014, 75, 245–256. [Google Scholar] [CrossRef]

- Lu, Y.; Guo, J. Local strain in tunneling transistors based on graphene nanoribbons. Appl. Phys. Lett. 2010, 97, 073105. [Google Scholar] [CrossRef]

- Tamersit, K. Improved switching performance of nanoscale p-i-n carbon nanotube tunneling field-effect transistors using metal-ferroelectric-metal gating approach. ECS J. Solid State Sci. Technol. 2021, 10, 031004. [Google Scholar] [CrossRef]

- Seabaugh, A.C.; Zhang, Q. Low-voltage tunnel transistors for beyond CMOS logic. Proc. IEEE 2010, 98, 2095–2110. [Google Scholar] [CrossRef]

- Tamersit, K.; Kouzou, A.; Bourouba, H.; Kennel, R.; Abdelrahem, M. Synergy of electrostatic and chemical doping to improve the performance of junctionless carbon nanotube tunneling field-effect transistors: Ultrascaling, energy-efficiency, and high switching performance. Nanomaterials 2022, 12, 462. [Google Scholar] [CrossRef] [PubMed]

- Avouris, P.; Wind, S.J. Carbon nanotube electronics. Proc. IEEE 2003, 9, 1772–1784. [Google Scholar] [CrossRef]

- Tamersit, K.; Madan, J.; Kouzou, A.; Pandey, R.; Kennel, R.; Abdelrahem, M. Role of junctionless mode in improving the photosensitivity of sub-10 nm carbon nanotube/nanoribbon field-effect phototransistors: Quantum simulation, performance assessment, and comparison. Nanomaterials 2022, 12, 1639. [Google Scholar] [CrossRef]

- Tamersit, K. Energy-efficient carbon nanotube field-effect phototransistors: Quantum simulation, device physics, and photosensitivity analysis. IEEE Sens. J. 2022, 22, 288. [Google Scholar] [CrossRef]

- Qiu, C.; Zhang, Z.; Xiao, M.; Yang, Y.; Zhong, D.; Peng, L.-M. Scaling carbon nanotube complementary transistors to 5-nm gate lengths. Science 2017, 355, 271–276. [Google Scholar] [CrossRef] [PubMed]

- Kar, A.K. Bio inspired computing—A review of algorithms and scope of applications. Expert Syst. Appl. 2016, 59, 20–32. [Google Scholar] [CrossRef]

- Tamersit, K.; Djeffal, F. A computationally efficient hybrid approach based on artificial neural networks and the wavelet transform for quantum simulations of graphene nanoribbon FETs. J. Comput. Electron. 2019, 18, 813–825. [Google Scholar] [CrossRef]

- Wang, J.; Kim, Y.-H.; Ryu, J.; Jeong, C.; Choi, W.; Kim, D. Artificial Neural Network-Based Compact Modeling Methodology for Advanced Transistors. IEEE Trans. Electron Devices 2021, 68, 1318–1325. [Google Scholar] [CrossRef]

- Ballard, Z.; Brown, C.; Madni, A.M.; Ozcan, A. Machine learning and computation-enabled intelligent sensor design. Nat. Mach. Intell. 2021, 3, 556–565. [Google Scholar] [CrossRef]

- Jiao, H.; Wang, X.; Wu, S.; Chen, Y.; Chu, J.; Wang, J. Ferroelectric field effect transistors for electronics and optoelectronics. Appl. Phys. Rev. 2023, 10, 011310. [Google Scholar] [CrossRef]

- Salahuddin, S.; Datta, S. Use of Negative Capacitance to Provide Voltage Amplification for Low Power Nanoscale Devices. Nano Lett. 2007, 8, 405–410. [Google Scholar] [CrossRef] [PubMed]

- Si, M.; Su, C.-J.; Jiang, C.; Conrad, N.J.; Zhou, H.; Maize, K.D.; Qiu, G.; Wu, C.-T.; Shakouri, A.; Alam, M.A.; et al. Steep-slope hysteresis-free negative capacitance MoS2 transistors. Nat. Nanotechnol. 2017, 13, 24–28. [Google Scholar] [CrossRef] [PubMed]

- Tamersit, K.; Moaiyeri, M.H.; Jooq, M.K.Q. Leveraging negative capacitance ferroelectric materials for performance boosting of sub-10 nm graphene nanoribbon field-effect transistors: A quantum simulation study. Nanotechnology 2022, 33, 465204. [Google Scholar] [CrossRef]

- Zhou, C.; Chai, Y. Ferroelectric-Gated Two-Dimensional-Material-Based Electron Devices. Adv. Electron. Mater. 2017, 3, 1600400. [Google Scholar] [CrossRef]

- Tamersit, K.; Jooq, M.K.Q.; Moaiyeri, M.H. Analog/RF performance assessment of ferroelectric junctionless carbon nanotube FETs: A quantum simulation study. Phys. E Low-Dimens. Syst. Nanostruct. 2021, 134, 114915. [Google Scholar] [CrossRef]

- Zhirnov, V.V.; Cavin, R.K. Negative capacitance to the rescue? Nat. Nanotechnol. 2008, 3, 77–78. [Google Scholar] [CrossRef]

- Guo, J. Modeling of graphene nanoribbon devices. Nanoscale 2012, 4, 5538–5548. [Google Scholar] [CrossRef]

- Tamersit, K. Performance Assessment of a New Radiation Dosimeter Based on Carbon Nanotube Field-Effect Transistor: A Quantum Simulation Study. IEEE Sens. J. 2019, 19, 3314–3321. [Google Scholar] [CrossRef]

- Datta, S. Electronic Transport in Mesoscopic Systems; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Tamersit, K. Asymmetric dual-gate junctionless GNR tunnel FET as a high-performance photosensor with an electrostatically improved photosensitivity: A Quantum simulation study. IEEE Sens. J. 2023, 23, 27431–27437. [Google Scholar] [CrossRef]

- Tamersit, K.; Djeffal, F. Boosting the performance of a nanoscale graphene nanoribbon field-effect transistor using graded gate engineering. J. Comput. Electron. 2018, 17, 1276–1284. [Google Scholar] [CrossRef]

- Ren, Z.; Venugopal, R.; Goasguen, S.; Datta, S. nanoMOS 2.5: A two-dimensional simulator for quantum transport in double-gate MOSFETs. IEEE Trans. Electron Devices 2003, 50, 1914–1925. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamersit, K.; Kouzou, A.; Rodriguez, J.; Abdelrahem, M. Electrostatically Doped Junctionless Graphene Nanoribbon Tunnel Field-Effect Transistor for High-Performance Gas Sensing Applications: Leveraging Doping Gates for Multi-Gas Detection. Nanomaterials 2024, 14, 220. https://doi.org/10.3390/nano14020220

Tamersit K, Kouzou A, Rodriguez J, Abdelrahem M. Electrostatically Doped Junctionless Graphene Nanoribbon Tunnel Field-Effect Transistor for High-Performance Gas Sensing Applications: Leveraging Doping Gates for Multi-Gas Detection. Nanomaterials. 2024; 14(2):220. https://doi.org/10.3390/nano14020220

Chicago/Turabian StyleTamersit, Khalil, Abdellah Kouzou, José Rodriguez, and Mohamed Abdelrahem. 2024. "Electrostatically Doped Junctionless Graphene Nanoribbon Tunnel Field-Effect Transistor for High-Performance Gas Sensing Applications: Leveraging Doping Gates for Multi-Gas Detection" Nanomaterials 14, no. 2: 220. https://doi.org/10.3390/nano14020220

APA StyleTamersit, K., Kouzou, A., Rodriguez, J., & Abdelrahem, M. (2024). Electrostatically Doped Junctionless Graphene Nanoribbon Tunnel Field-Effect Transistor for High-Performance Gas Sensing Applications: Leveraging Doping Gates for Multi-Gas Detection. Nanomaterials, 14(2), 220. https://doi.org/10.3390/nano14020220