Mechanical Reinforcement of ABS with Optimized Nano Titanium Nitride Content for Material Extrusion 3D Printing

Abstract

:1. Introduction

2. Materials and Method

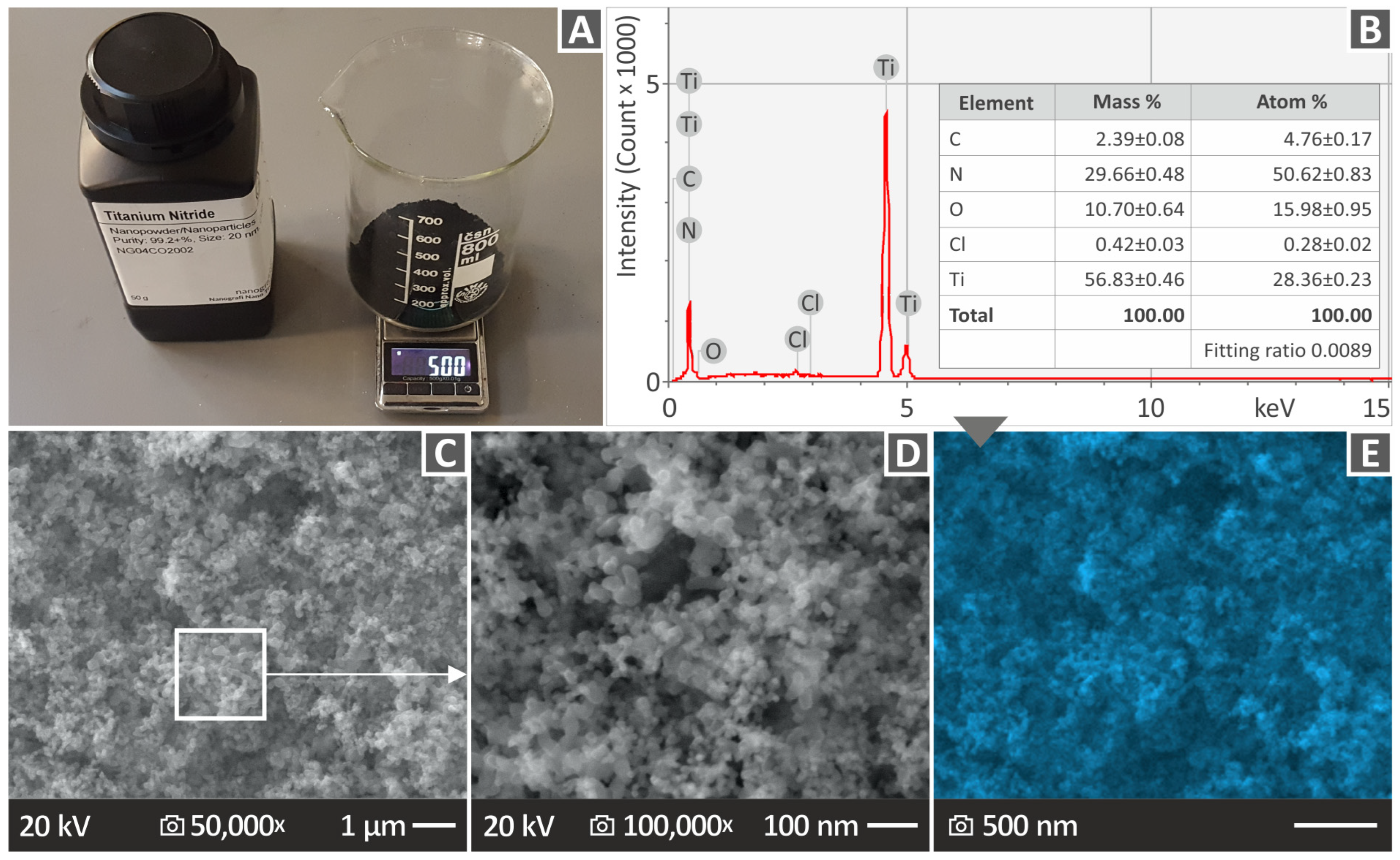

2.1. Materials

2.2. Nanocomposites Preparation

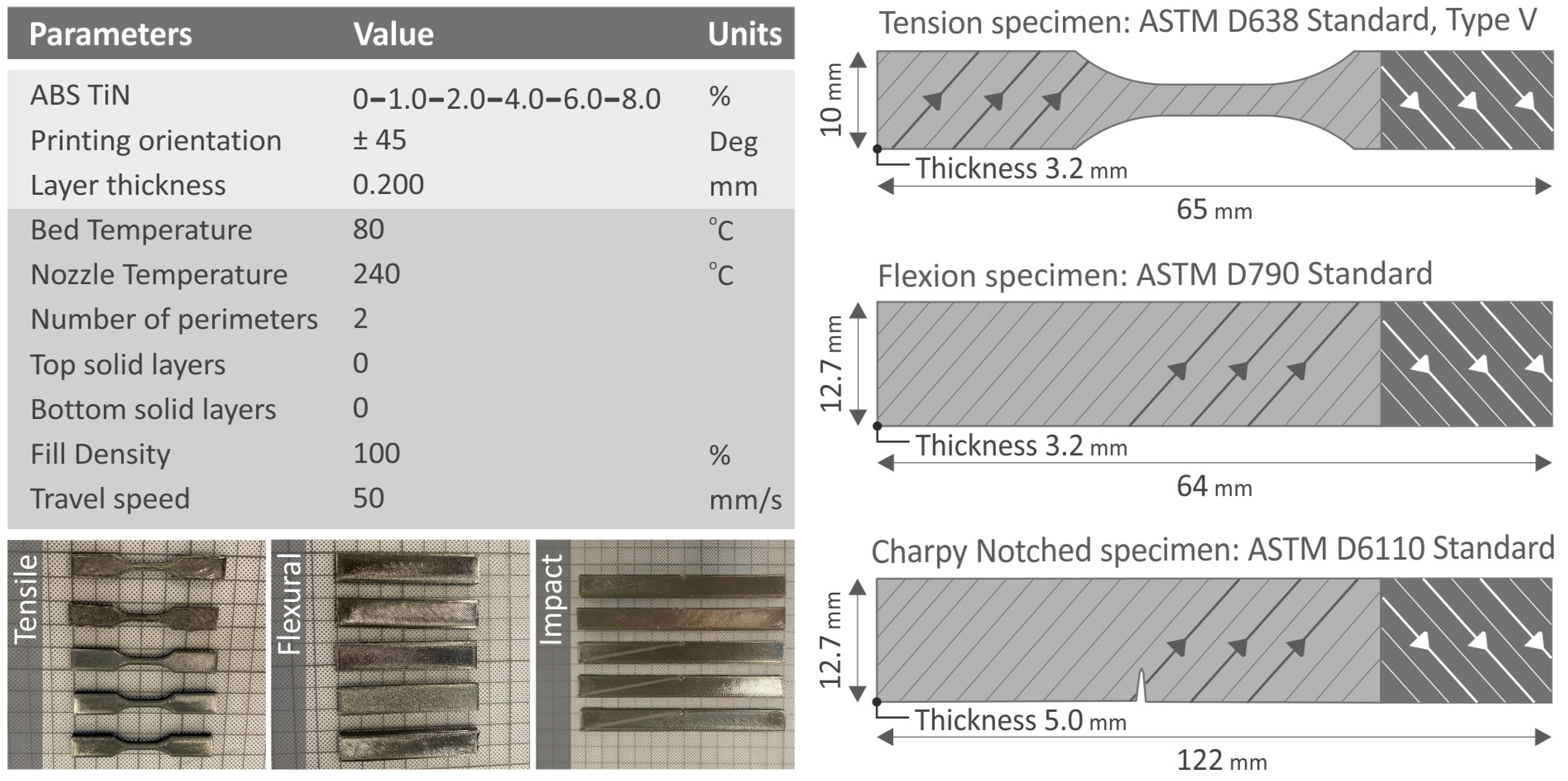

2.3. Fabrication of 3D-Printed Specimens

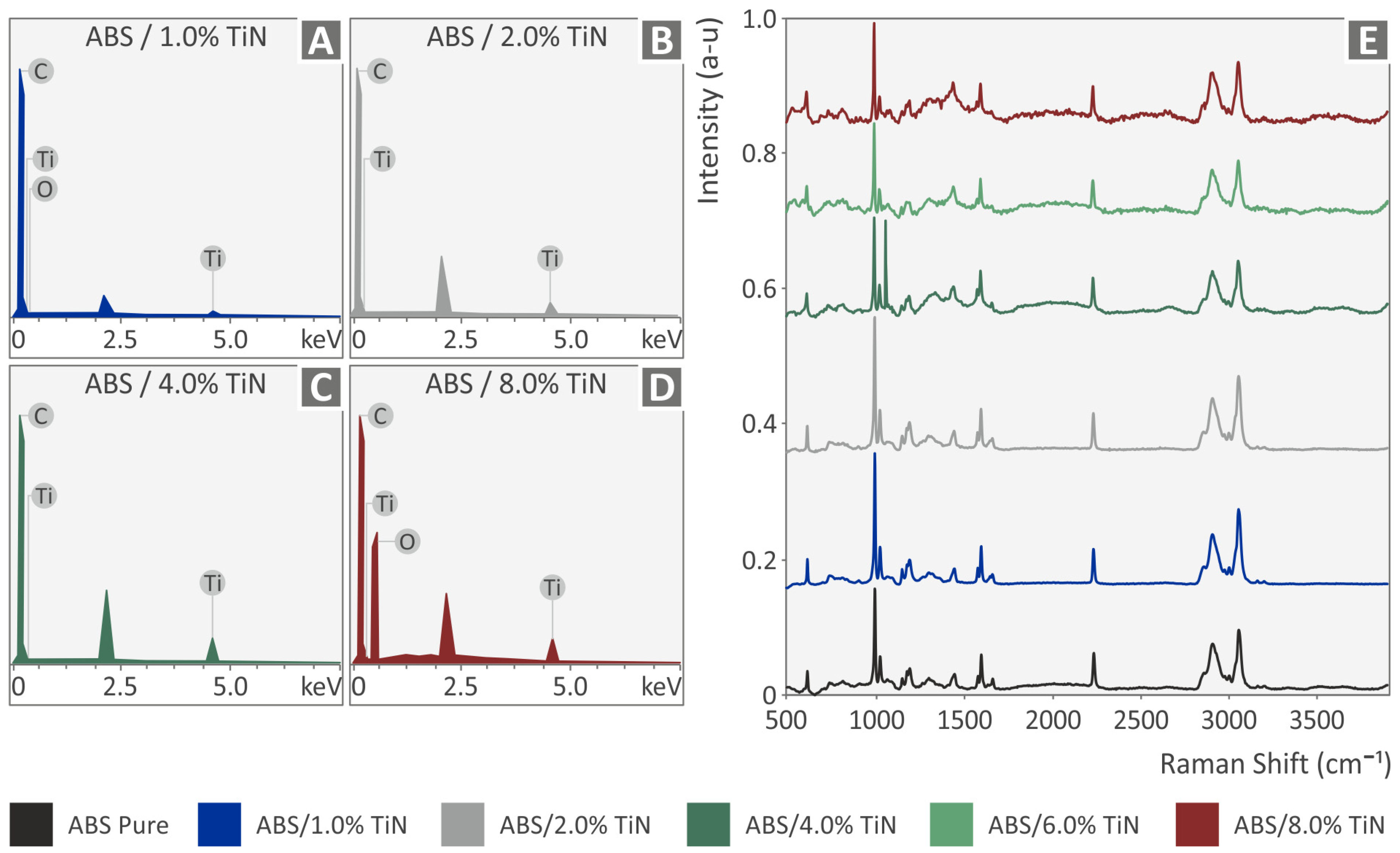

2.4. Thermogravimetric Analysis and Raman Spectroscopy Measurements

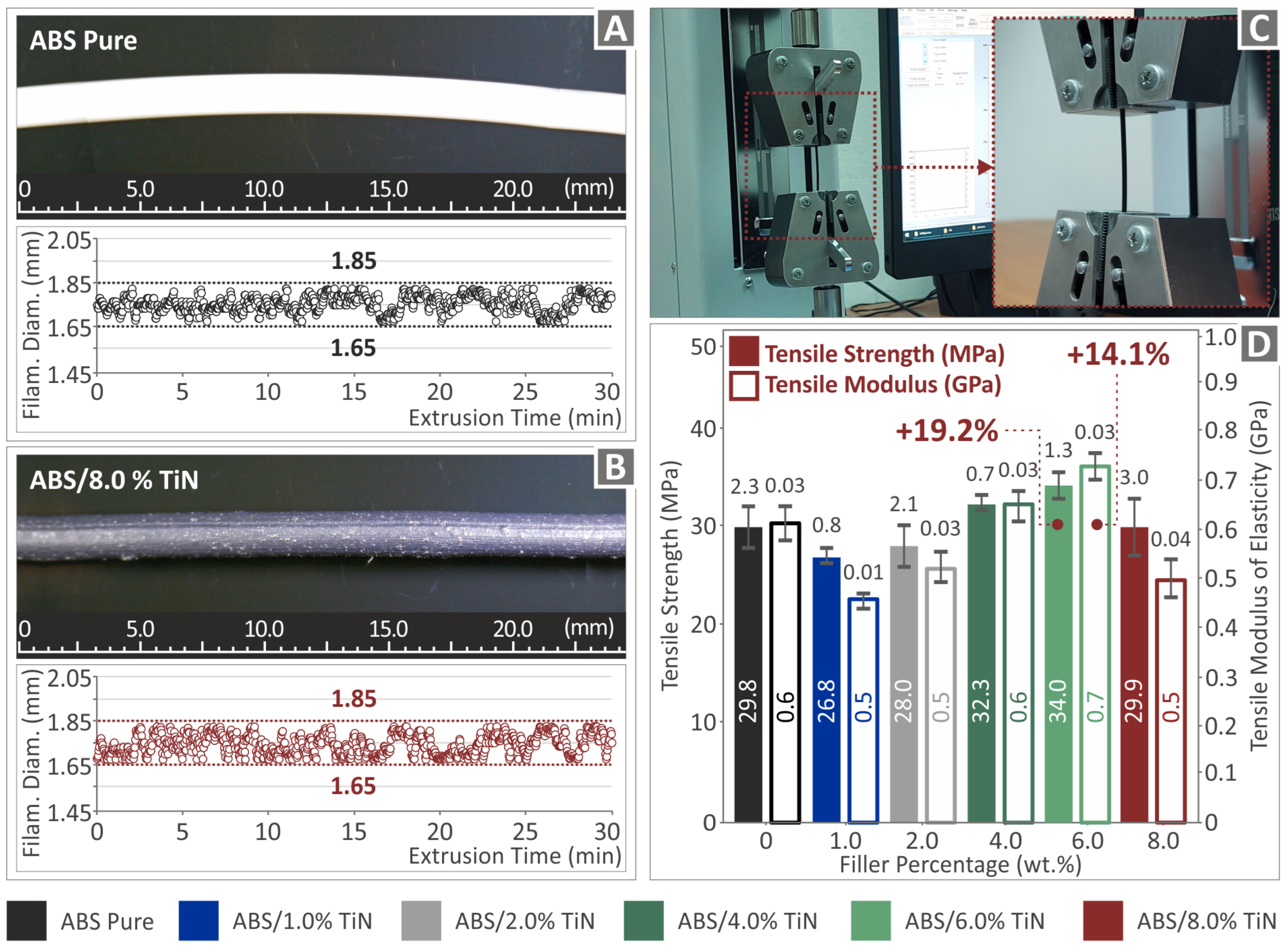

2.5. Evaluation of Produced Filaments

2.6. Mechanical Characterization

2.7. Morphological Characterization of 3D-Printed Specimens

3. Results

3.1. Thermogravimetric Analysis and Raman Spectroscopy Measurements

3.2. Filament Evaluation

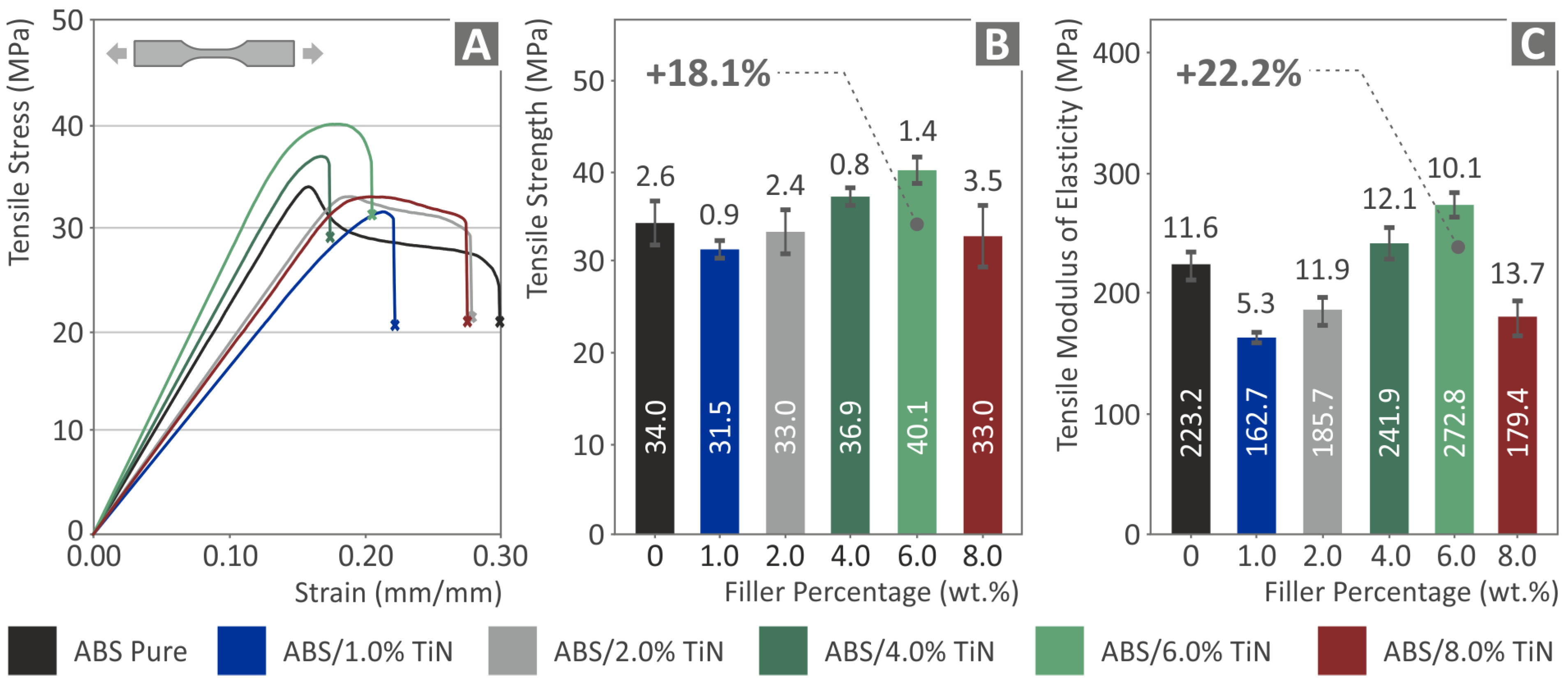

3.3. Mechanical Tests of the 3D-Printed Specimens

3.4. Morphological Characterization of the 3D-Printed Specimens

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- de Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High Performance Polymer Nanocomposites for Additive Manufacturing Applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Shi, A.; Yang, L.; Shirowzhan, S.; Edwards, D.J. Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings 2020, 10, 231. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Additive Manufacturing Applications in Orthopaedics: A Review. 3-Print. Orthop. 2018, 9, 202–206. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.L.; Zhang, H.; Chong, T.H.; Yeong, W.Y. 3D Printing of Multilayered and Multimaterial Electronics: A Review. Adv. Electron. Mater. 2021, 7, 2100445. [Google Scholar] [CrossRef]

- Zhang, Z.; Fidan, I.; Allen, M. Detection of Material Extrusion In-Process Failures via Deep Learning. Inventions 2020, 5, 25. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kechagias, J.D. A Comprehensive Investigation of the 3D Printing Parameters’ Effects on the Mechanical Response of Polycarbonate in Fused Filament Fabrication. Prog. Addit. Manuf. 2022, 7, 713–722. [Google Scholar] [CrossRef]

- Koker, B.; Ruckdashel, R.; Abajorga, H.; Curcuru, N.; Pugatch, M.; Dunn, R.; Kazmer, D.O.; Wetzel, E.D.; Park, J.H. Enhanced Interlayer Strength and Thermal Stability via Dual Material Filament for Material Extrusion Additive Manufacturing. Addit. Manuf. 2022, 55, 102807. [Google Scholar] [CrossRef]

- Ai, J.-R.; Vogt, B.D. Size and Print Path Effects on Mechanical Properties of Material Extrusion 3D Printed Plastics. Prog. Addit. Manuf. 2022, 7, 1009–1021. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical Property of FDM Printed ABS: Influence of Printing Parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Vidakis, N.; Maniadi, A.; Petousis, M.; Vamvakaki, M.; Kenanakis, G.; Koudoumas, E. Mechanical and Electrical Properties Investigation of 3D-Printed Acrylonitrile–Butadiene–Styrene Graphene and Carbon Nanocomposites. J. Mater. Eng. Perform. 2020, 29, 1909–1918. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A Parametric Determination of Bending and Charpy’s Impact Strength of ABS and ABS-plus Fused Deposition Modeling Specimens. Prog. Addit. Manuf. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Oh, M.; Kim, W.D.; Zhang, M.; Kim, T.; Yoo, D.; Kim, S.H.; Lee, D. Mechanical Behavior of ABS Plastic-Matrix Nanocomposites with Three Different Carbon-Based Nanofillers. Polym. Bull. 2021, 78, 3751–3762. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Vairis, A.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Acrylonitrile-Butadiene-Styrene over Multiple Recycling Processes. Sustainability 2020, 12, 3568. [Google Scholar] [CrossRef]

- Huang, G.; Huo, S.; Xu, X.; Chen, W.; Jin, Y.; Li, R.; Song, P.; Wang, H. Realizing Simultaneous Improvements in Mechanical Strength, Flame Retardancy and Smoke Suppression of ABS Nanocomposites from Multifunctional Graphene. Compos. Part B Eng. 2019, 177, 107377. [Google Scholar] [CrossRef]

- Gao, A.; Zhao, F.; Wang, F.; Zhang, G.; Zhao, S.; Cui, J.; Yan, Y. Highly Conductive and Light-Weight Acrylonitrile-Butadiene-Styrene Copolymer/Reduced Graphene Nanocomposites with Segregated Conductive Structure. Compos. Part Appl. Sci. Manuf. 2019, 122, 1–7. [Google Scholar] [CrossRef]

- Song, P.; Cao, Z.; Fu, S.; Fang, Z.; Wu, Q.; Ye, J. Thermal Degradation and Flame Retardancy Properties of ABS/Lignin: Effects of Lignin Content and Reactive Compatibilization. Thermochim. Acta 2011, 518, 59–65. [Google Scholar] [CrossRef]

- Huang, G.; Han, D.; Jin, Y.; Song, P.; Yan, Q.; Gao, C. Fabrication of Nitrogen-Doped Graphene Decorated with Organophosphor and Lanthanum toward High-Performance ABS Nanocomposites. ACS Appl. Nano Mater. 2018, 1, 3204–3213. [Google Scholar] [CrossRef]

- Vairis, A.; Petousis, M.; Vidakis, N.; Savvakis, K. On the Strain Rate Sensitivity of Abs and Abs Plus Fused Deposition Modeling Parts. J. Mater. Eng. Perform. 2016, 25, 3558–3565. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the Strain Rate Sensitivity of Fused Filament Fabrication (FFF) Processed PLA, ABS, PETG, PA6, and PP Thermoplastic Polymers. Polymers 2020, 12, 2924. [Google Scholar] [CrossRef]

- Christiyan, K.G.J.; Chandrasekhar, U.; Venkateswarlu, K. A Study on the Influence of Process Parameters on the Mechanical Properties of 3D Printed ABS Composite. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012109. [Google Scholar] [CrossRef]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental Characterization of the Mechanical Properties of 3D-Printed ABS and Polycarbonate Parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Dwiyati, S.T.; Kholil, A.; Riyadi, R.; Putra, S.E. Influence of Layer Thickness and 3D Printing Direction on Tensile Properties of ABS Material. J. Phys. Conf. Ser. 2019, 1402, 066014. [Google Scholar] [CrossRef]

- Domínguez-Rodríguez, G.; Ku-Herrera, J.J.; Hernández-Pérez, A. An Assessment of the Effect of Printing Orientation, Density, and Filler Pattern on the Compressive Performance of 3D Printed ABS Structures by Fuse Deposition. Int. J. Adv. Manuf. Technol. 2018, 95, 1685–1695. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, L.; Golub, M.; Zhang, Y.; Yang, X.; Schlarman, K.; Zhang, J. Tensile, Creep, and Fatigue Behaviors of 3D-Printed Acrylonitrile Butadiene Styrene. J. Mater. Eng. Perform. 2018, 27, 57–62. [Google Scholar] [CrossRef]

- Vidakis, N.; David, C.N.; Petousis, M.; Sagris, D.; Mountakis, N. Optimization of Key Quality Indicators in Material Extrusion 3D Printing of Acrylonitrile Butadiene Styrene: The Impact of Critical Process Control Parameters on the Surface Roughness, Dimensional Accuracy, and Porosity. Mater. Today Commun. 2022, 34, 105171. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Y.; Wang, M.; Shi, S.; Jing, J. Fused Deposition Modeling 3D Printing of Novel Poly(Vinyl Alcohol)/Graphene Nanocomposite with Enhanced Mechanical and Electromagnetic Interference Shielding Properties. Ind. Eng. Chem. Res. 2020, 59, 8066–8077. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.A.; Tzounis, L. Mechanical Reinforcement Course of 3D Printed Polypropylene–Antimony Doped Tin Oxide Nanocomposites versus Filler Loading. Adv. Compos. Mater. 2022, 31, 235–256. [Google Scholar] [CrossRef]

- Ambone, T.; Torris, A.; Shanmuganathan, K. Enhancing the Mechanical Properties of 3D Printed Polylactic Acid Using Nanocellulose. Polym. Eng. Sci. 2020, 60, 1842–1855. [Google Scholar] [CrossRef]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Korlos, A.; Papadakis, V.; Moutsopoulou, A. Trilateral Multi-Functional Polyamide 12 Nanocomposites with Binary Inclusions for Medical Grade Material Extrusion 3D Printing: The Effect of Titanium Nitride in Mechanical Reinforcement and Copper/Cuprous Oxide as Antibacterial Agents. J. Funct. Biomater. 2022, 13, 115. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Spiridaki, M.; Kechagias, J.D. Mechanical Performance of Fused Filament Fabricated and 3D-Printed Polycarbonate Polymer and Polycarbonate/Cellulose Nanofiber Nanocomposites. Fibers 2021, 9, 74. [Google Scholar] [CrossRef]

- Lee, J.; Lee, H.; Cheon, K.-H.; Park, C.; Jang, T.-S.; Kim, H.-E.; Jung, H.-D. Fabrication of Poly(Lactic Acid)/Ti Composite Scaffolds with Enhanced Mechanical Properties and Biocompatibility via Fused Filament Fabrication (FFF)—Based 3D Printing. Addit. Manuf. 2019, 30, 100883. [Google Scholar] [CrossRef]

- Pazhamannil, R.V.; Edacherian, A. Property Enhancement Approaches of Fused Filament Fabrication Technology: A Review. Polym. Eng. Sci. 2022, 62, 1356–1376. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Savvakis, K.; Maniadi, A.; Koudoumas, E. A Comprehensive Investigation of the Mechanical Behavior and the Dielectrics of Pure Polylactic Acid (PLA) and PLA with Graphene (GnP) in Fused Deposition Modeling (FDM). Int. J. Plast. Technol. 2019, 23, 195–206. [Google Scholar] [CrossRef]

- Blanco, I. The Use of Composite Materials in 3D Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef]

- Skorski, M.R.; Esenther, J.M.; Ahmed, Z.; Miller, A.E.; Hartings, M.R. The Chemical, Mechanical, and Physical Properties of 3D Printed Materials Composed of TiO2-ABS Nanocomposites. Sci. Technol. Adv. Mater. 2016, 17, 89–97. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Maniadi, A. Mechanical Properties of 3D-Printed ABS with Combinations of Two Fillers: Graphene Nanoplatelets, TiO2, ATO Nanocomposites, and Zinc Oxide Micro (ZnOm). In Recent Advances in Manufacturing Processes and Systems; Dave, H.K., Dixit, U.S., Nedelcu, D., Eds.; Springer Nature Singapore: Singapore, 2022; pp. 635–645. [Google Scholar]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Liebscher, M.; Tzounis, L. Mechanical Properties of 3D-Printed Acrylonitrile–Butadiene–Styrene TiO2 and ATO Nanocomposites. Polymers 2020, 12, 1589. [Google Scholar] [CrossRef]

- Cholleti, E.R.; Gibson, I. ABS Nano Composite Materials in Additive Manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012038. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Al-Anid, H.K.; Husain, Y.A.; El-Ghanem, H.M.; Jawad, S.A. Impedance Characteristics and Conductivity of CNT/ABS Nanocomposites. J. Phys. Appl. Phys. 2013, 46, 385305. [Google Scholar] [CrossRef]

- Sezer, H.K.; Eren, O. FDM 3D Printing of MWCNT Re-Inforced ABS Nano-Composite Parts with Enhanced Mechanical and Electrical Properties. J. Manuf. Process. 2019, 37, 339–347. [Google Scholar] [CrossRef]

- Jyoti, J.; Basu, S.; Singh, B.P.; Dhakate, S.R. Superior Mechanical and Electrical Properties of Multiwall Carbon Nanotube Reinforced Acrylonitrile Butadiene Styrene High Performance Composites. Compos. Part B Eng. 2015, 83, 58–65. [Google Scholar] [CrossRef]

- Shenavar, A.; Abbasi, F. Morphology, Thermal, and Mechanical Properties of Acrylonitrile–Butadiene–Styrene/Carbon Black Composites. J. Appl. Polym. Sci. 2007, 105, 2236–2244. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.; Rumpf, R.C.; Kim, N.S. Thermo-Mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2015, 44, 771–777. [Google Scholar] [CrossRef]

- Li, Y.; Shimizu, H. Improvement in Toughness of Poly(l-Lactide) (PLLA) through Reactive Blending with Acrylonitrile–Butadiene–Styrene Copolymer (ABS): Morphology and Properties. Eur. Polym. J. 2009, 45, 738–746. [Google Scholar] [CrossRef]

- Aalaie, J.; Rahmatpour, A. Study on Preparation and Properties of Acrylonitrile-Butadiene-Styrene/Montmorillonite Nanocomposites. J. Macromol. Sci. Part B 2007, 46, 1255–1265. [Google Scholar] [CrossRef]

- Karahaliou, E.-K.; Tarantili, P.A. Preparation of Poly(Acrylonitrile-Butadiene-Styrene)/Montmorillonite Nanocomposites and Degradation Studies during Extrusion Reprocessing. J. Appl. Polym. Sci. 2009, 113, 2271–2281. [Google Scholar] [CrossRef]

- Nikzad, M.; Masood, S.H.; Sbarski, I. Thermo-Mechanical Properties of a Highly Filled Polymeric Composites for Fused Deposition Modeling. Mater. Des. 2011, 32, 3448–3456. [Google Scholar] [CrossRef]

- Zhu, Y.G.; Li, Z.Q.; Zhang, D.; Tanimoto, T. Abs/Iron Nanocomposites Prepared by Cryomilling. J. Appl. Polym. Sci. 2006, 99, 501–505. [Google Scholar] [CrossRef]

- Milionis, A.; Languasco, J.; Loth, E.; Bayer, I.S. Analysis of Wear Abrasion Resistance of Superhydrophobic Acrylonitrile Butadiene Styrene Rubber (ABS) Nanocomposites. Chem. Eng. J. 2015, 281, 730–738. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A.; Koudoumas, E.; Kenanakis, G.; Romanitan, C.; Tutunaru, O.; Suchea, M.; Kechagias, J. The Mechanical and Physical Properties of 3D-Printed Materials Composed of ABS-ZnO Nanocomposites and ABS-ZnO Microcomposites. Micromachines 2020, 11, 615. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Mountakis, N.; Kechagias, J.D. Friction Stir Welding Optimization of 3D-Printed Acrylonitrile Butadiene Styrene in Hybrid Additive Manufacturing. Polymers 2022, 14, 2474. [Google Scholar] [CrossRef] [PubMed]

- Kechagias, J.D.; Ninikas, K.; Petousis, M.; Vidakis, N. Laser Cutting of 3D Printed Acrylonitrile Butadiene Styrene Plates for Dimensional and Surface Roughness Optimization. Int. J. Adv. Manuf. Technol. 2022, 119, 2301–2315. [Google Scholar] [CrossRef]

- Khan, A.; Puttegowda, M.; Jagadeesh, P.; Marwani, H.M.; Asiri, A.M.; Manikandan, A.; Parwaz Khan, A.A.; Ashraf, G.M.; Rangappa, S.M.; Siengchin, S. Review on Nitride Compounds and Its Polymer Composites: A Multifunctional Material. J. Mater. Res. Technol. 2022, 18, 2175–2193. [Google Scholar] [CrossRef]

- Guan, J.; Derdouri, A.; Ashrafi, B.; Benhalima, A.; Kim, K.S.; Daroszewska, M.; Simard, B. Boron Nitride Nanotubes Reinforced Polycarbonate Nanocomposites. Mater. Today Commun. 2019, 20, 100586. [Google Scholar] [CrossRef]

- Wu, H.Z.; Chou, T.C.; Mishra, A.; Anderson, D.R.; Lampert, J.K.; Gujrathi, S.C. Characterization of Titanium Nitride Thin Films. Thin Solid Films 1990, 191, 55–67. [Google Scholar] [CrossRef]

- Santecchia, E.; Hamouda, A.M.S.; Musharavati, F.; Zalnezhad, E.; Cabibbo, M.; Spigarelli, S. Wear Resistance Investigation of Titanium Nitride-Based Coatings. Ceram. Int. 2015, 41, 10349–10379. [Google Scholar] [CrossRef]

- Wolfe, D.E.; Singh, J. Microstructural Evolution of Titanium Nitride (TiN) Coatings Produced by Reactive Ion Beam-Assisted, Electron Beam Physical Vapor Deposition (RIBA, EB-PVD). J. Mater. Sci. 1999, 34, 2997–3006. [Google Scholar] [CrossRef]

- Machunze, R.; Janssen, G.C.A.M. Stress and Strain in Titanium Nitride Thin Films. Thin Solid Films 2009, 517, 5888–5893. [Google Scholar] [CrossRef]

- Jiao, Q.; Zhou, T.; Zhang, N.; Liu, S.; Huang, Q.; Bi, W.; Chu, W.; Wu, X.; Zhu, Y.; Feng, Y.; et al. High-Surface-Area Titanium Nitride Nanosheets as Zinc Anode Coating for Dendrite-Free Rechargeable Aqueous Batteries. Sci. China Mater. 2022, 65, 1771–1778. [Google Scholar] [CrossRef]

- Shi, X.; Xu, L.; Munar, M.L.; Ishikawa, K. Hydrothermal Treatment for TiN as Abrasion Resistant Dental Implant Coating and Its Fibroblast Response. Mater. Sci. Eng. C 2015, 49, 1–6. [Google Scholar] [CrossRef]

- Huang, H.-H.; Hsu, C.-H.; Pan, S.-J.; He, J.-L.; Chen, C.-C.; Lee, T.-L. Corrosion and Cell Adhesion Behavior of TiN-Coated and Ion-Nitrided Titanium for Dental Applications. Appl. Surf. Sci. 2005, 244, 252–256. [Google Scholar] [CrossRef]

- van Hove, R.P.; Sierevelt, I.N.; van Royen, B.J.; Nolte, P.A. Titanium-Nitride Coating of Orthopaedic Implants: A Review of the Literature. BioMed Res. Int. 2015, 2015, 485975. [Google Scholar] [CrossRef] [PubMed]

- Patsalas, P.; Kalfagiannis, N.; Kassavetis, S. Optical Properties and Plasmonic Performance of Titanium Nitride. Materials 2015, 8, 3128–3154. [Google Scholar] [CrossRef]

- Briggs, J.A.; Naik, G.V.; Zhao, Y.; Petach, T.A.; Sahasrabuddhe, K.; Goldhaber-Gordon, D.; Melosh, N.A.; Dionne, J.A. Temperature-Dependent Optical Properties of Titanium Nitride. Appl. Phys. Lett. 2017, 110, 101901. [Google Scholar] [CrossRef]

- De Silva, K.-G.-G.C.; Finale, M.; Chowdhury, S. Plasmon Mediated Deposition of Ni on Titanium Nitride Nanoparticles: Applications in Enhanced Photoreduction of Bicarbonate. Mater. Res. Bull. 2022, 152, 111834. [Google Scholar] [CrossRef]

- Guler, U.; Zemlyanov, D.; Kim, J.; Wang, Z.; Chandrasekar, R.; Meng, X.; Stach, E.; Kildishev, A.V.; Shalaev, V.M.; Boltasseva, A. Plasmonic Titanium Nitride Nanostructures via Nitridation of Nanopatterned Titanium Dioxide. Adv. Opt. Mater. 2017, 5, 1600717. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, W.; Li, Y.; Yang, W.; Wang, G. Flexural Properties and Fracture Behavior of CF/PEEK in Orthogonal Building Orientation by FDM: Microstructure and Mechanism. Polymers 2019, 11, 656. [Google Scholar] [CrossRef]

- Sadegh, M.; Parast, A.; Bagheri, A.; Kami, A.; Azadi, M. Bending Fatigue Behavior of Fused Filament Fabrication 3D-Printed ABS and PLA Joints with Rotary Friction Welding. Prog. Addit. Manuf. 2022, 7, 1345–1361. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.Y.; Tagarielli, V.L. Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Tzounis, L.; Hegde, M.; Liebscher, M.; Dingemans, T.; Pötschke, P.; Paipetis, A.S.; Zafeiropoulos, N.E.; Stamm, M. All-Aromatic SWCNT-Polyetherimide Nanocomposites for Thermal Energy Harvesting Applications. Compos. Sci. Technol. 2018, 156, 158–165. [Google Scholar] [CrossRef]

- Liebscher, M.; Tzounis, L.; Pötschke, P.; Heinrich, G. Influence of the Viscosity Ratio in PC/SAN Blends Filled with MWCNTs on the Morphological, Electrical, and Melt Rheological Properties. Polymer 2013, 54, 6801–6808. [Google Scholar] [CrossRef]

- Wode, F.; Tzounis, L.; Kirsten, M.; Constantinou, M.; Georgopanos, P.; Rangou, S.; Zafeiropoulos, N.E.; Avgeropoulos, A.; Stamm, M. Selective Localization of Multi-Wall Carbon Nanotubes in Homopolymer Blends and a Diblock Copolymer. Rheological Orientation Studies of the Final Nanocomposites. Polymer 2012, 53, 4438–4447. [Google Scholar] [CrossRef]

- Maniadi, A.; Vamvakaki, M.; Petousis, M.; Vidakis, N.; Suchea, M.; Sevastaki, M.; Viskadourakis, Z.; Kenanakis, G.; Koudoumas, E. Effect of Zinc Oxide Concentration on the Dielectric Properties of 3D Printed Acrylonitrile Butadiene Styrene Nanocomposites. In Proceedings of the International Semiconductor Conference, CAS, Sinaia, Romania, 9–11 October 2019; Volume 2019. [Google Scholar]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D Printed Thermoelectric Polyurethane/Multiwalled Carbon Nanotube Nanocomposites: A Novel Approach towards the Fabrication of Flexible and Stretchable Organic Thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Maravelakis, E.; Zaoutsos, S.; Kechagias, J.D. Mechanical Response Assessment of Antibacterial PA12/TiO2 3D Printed Parts: Parameters Optimization through Artificial Neural Networks Modeling. Int. J. Adv. Manuf. Technol. 2022, 121, 785–803. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Miao, W.; Zhang, Y.; Gao, H.; Hui, D. Mechanical Properties of Nanomaterials: A Review. Nanotechnol. Rev. 2020, 9, 259–273. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Concepts and Conflicts in Nanoparticles Reinforcement to Polymers beyond Hydrodynamics. Prog. Mater. Sci. 2016, 84, 1–58. [Google Scholar] [CrossRef]

| Tensile | |

| Sample | Type V with a thickness of 3.2 mm |

| Strain rate | 10 mm/min |

| Standard | ASTM D638–02a |

| Device | Imada MX2 (Northbrook, IL, USA) |

| Flexural | |

| Test Type | Three-point bending |

| Span length | 52 mm |

| Strain rate | 10 mm/min |

| Standard | ASTM D790 |

| Device | Imada MX2 (Northbrook, IL, USA) |

| Impact | |

| Test Type | Charpy |

| Samples | Notched |

| Release height | 367 mm |

| Standard | ASTM D6110 |

| Device | Terco MT 220 (Kungens Kurva, Sweden) |

| Microhardness | |

| Method | Vickers |

| Applied load to the specimen during the indentation | 200 gF |

| Indentations’ duration | 10 s |

| Standard | ASTM E384–17 |

| Device | 300 Innova Test (Maastricht, The Netherlands) |

| Pure ABS | ABS/TiN 1 wt. % | ABS/TiN 2 wt. % | ABS/TiN 4 wt. % | ABS/TiN 6 wt. % | ABS/TiN 8 wt. % | |

|---|---|---|---|---|---|---|

| Tensile stregth (MPa) | 34.0 | 31.5 | 33.0 | 36.9 | 40.1 | 33.0 |

| Tensile modulus of elasticity (MPa) | 223.2 | 167.2 | 185.7 | 214.9 | 272.8 | 179.4 |

| Tensile toughness (MJ/m3) | 5.2 | 4.5 | 5.1 | 4.2 | 4.6 | 5.1 |

| Flexural stregth (MPa) | 48.3 | 47.7 | 60.7 | 65.5 | 66.1 | 63.9 |

| Flexural modulus of elasticity (GPa) | 1.7 | 1.6 | 1.8 | 2.0 | 2.4 | 2.2 |

| Flexural toughness (MJ/m3) | 1.5 | 1.5 | 2.0 | 2.2 | 2.3 | 2.2 |

| Impact strength (kJ/m2) | 22.7 | 18.9 | 18.3 | 20.1 | 19.5 | 15.1 |

| Microhardness (HV) | 10.8 | 11.7 | 11.8 | 12.5 | 13.4 | 17.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Mangelis, P.; Petousis, M.; Mountakis, N.; Papadakis, V.; Moutsopoulou, A.; Tsikritzis, D. Mechanical Reinforcement of ABS with Optimized Nano Titanium Nitride Content for Material Extrusion 3D Printing. Nanomaterials 2023, 13, 669. https://doi.org/10.3390/nano13040669

Vidakis N, Mangelis P, Petousis M, Mountakis N, Papadakis V, Moutsopoulou A, Tsikritzis D. Mechanical Reinforcement of ABS with Optimized Nano Titanium Nitride Content for Material Extrusion 3D Printing. Nanomaterials. 2023; 13(4):669. https://doi.org/10.3390/nano13040669

Chicago/Turabian StyleVidakis, Nectarios, Panagiotis Mangelis, Markos Petousis, Nikolaos Mountakis, Vassilis Papadakis, Amalia Moutsopoulou, and Dimitris Tsikritzis. 2023. "Mechanical Reinforcement of ABS with Optimized Nano Titanium Nitride Content for Material Extrusion 3D Printing" Nanomaterials 13, no. 4: 669. https://doi.org/10.3390/nano13040669

APA StyleVidakis, N., Mangelis, P., Petousis, M., Mountakis, N., Papadakis, V., Moutsopoulou, A., & Tsikritzis, D. (2023). Mechanical Reinforcement of ABS with Optimized Nano Titanium Nitride Content for Material Extrusion 3D Printing. Nanomaterials, 13(4), 669. https://doi.org/10.3390/nano13040669