Review of Ge(GeSn) and InGaAs Avalanche Diodes Operating in the SWIR Spectral Region

Abstract

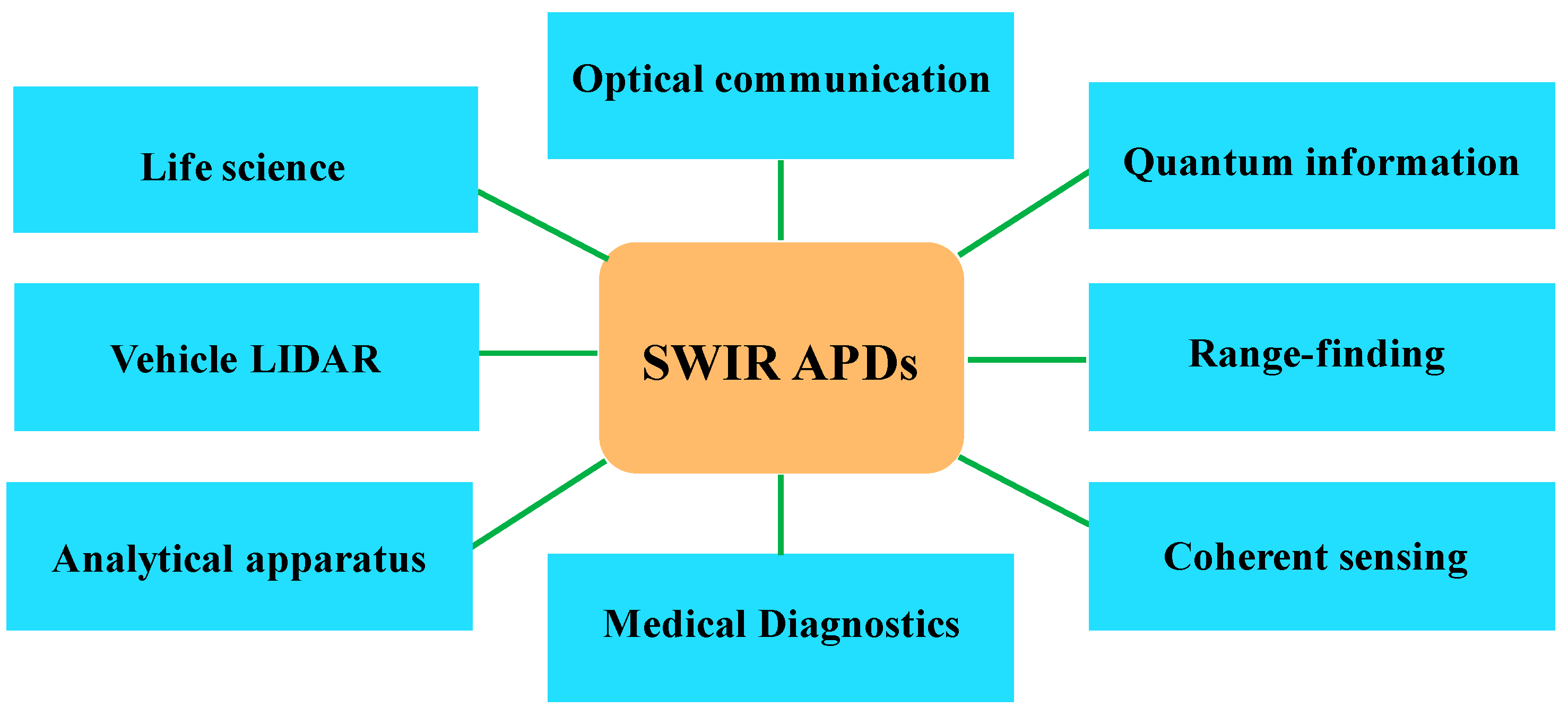

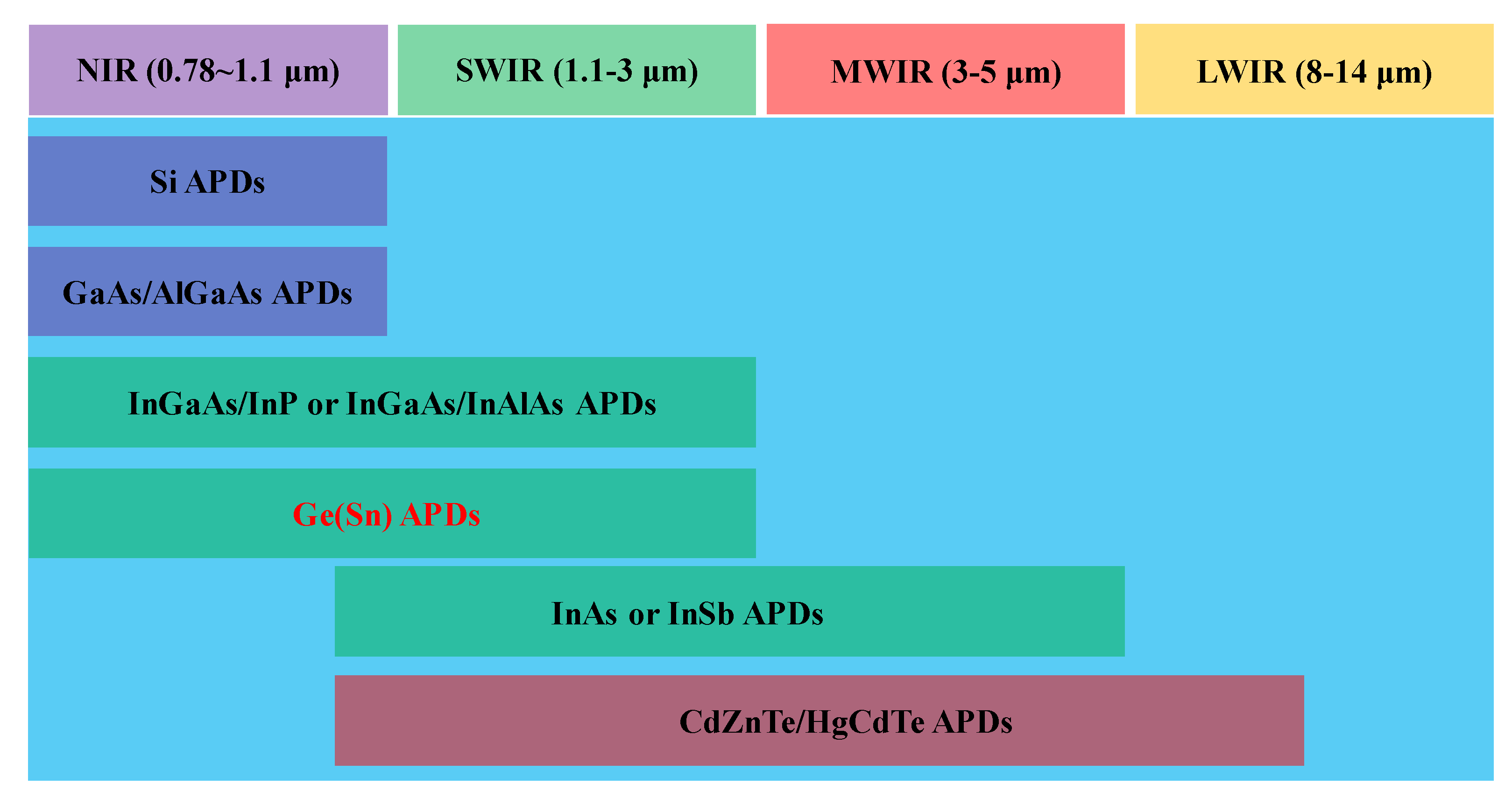

:1. Introduction

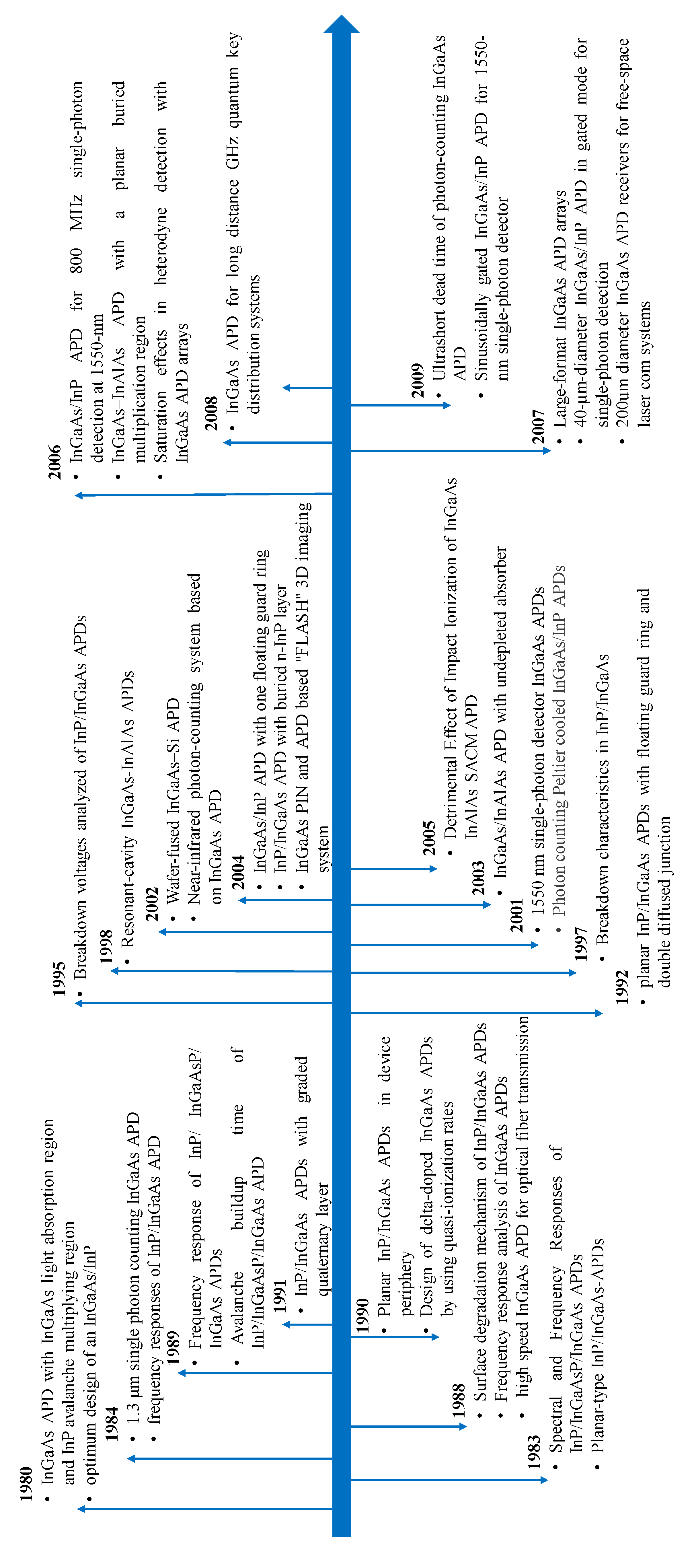

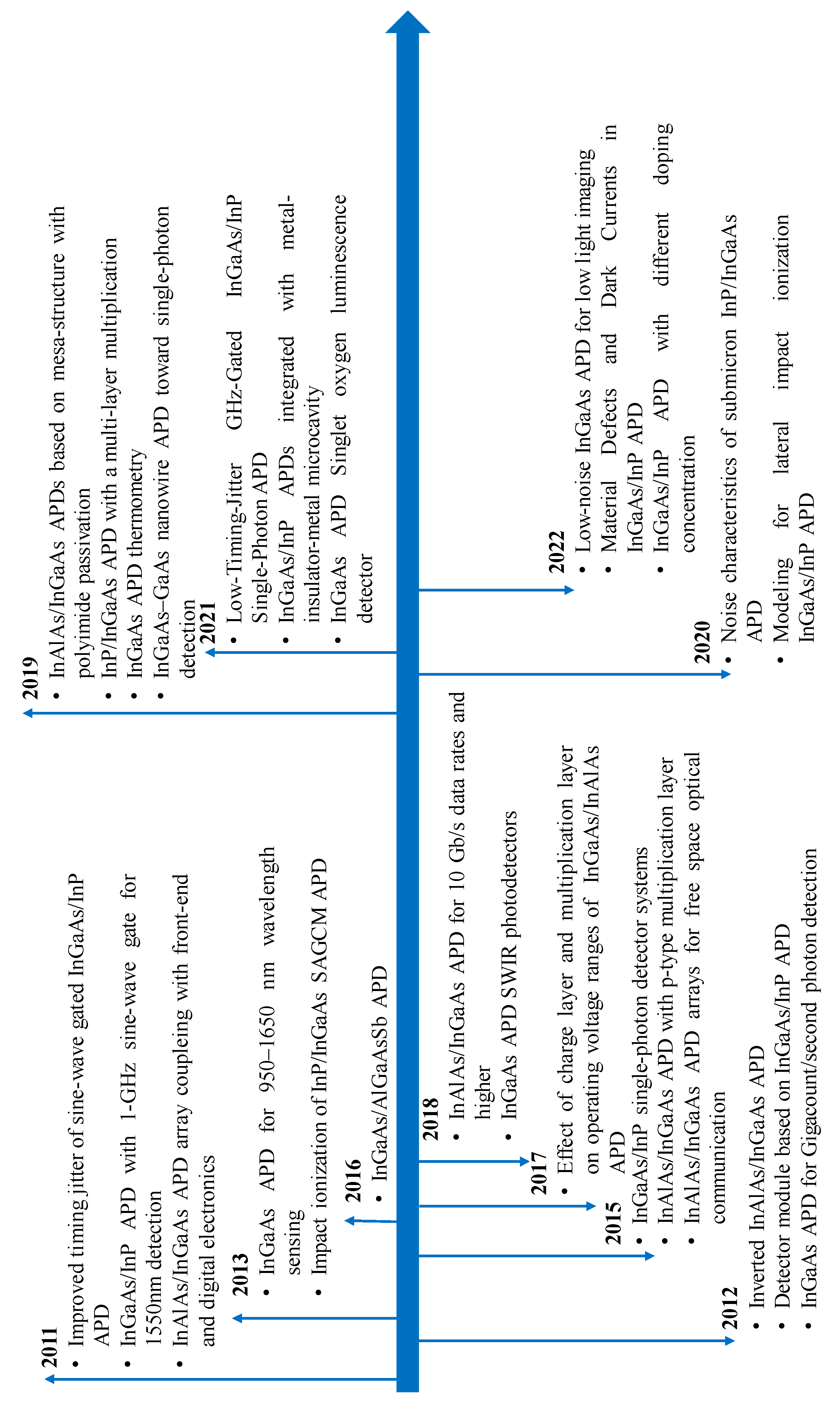

2. Research Progress for Ge(GeSn) and InGaAs SWIR APDs

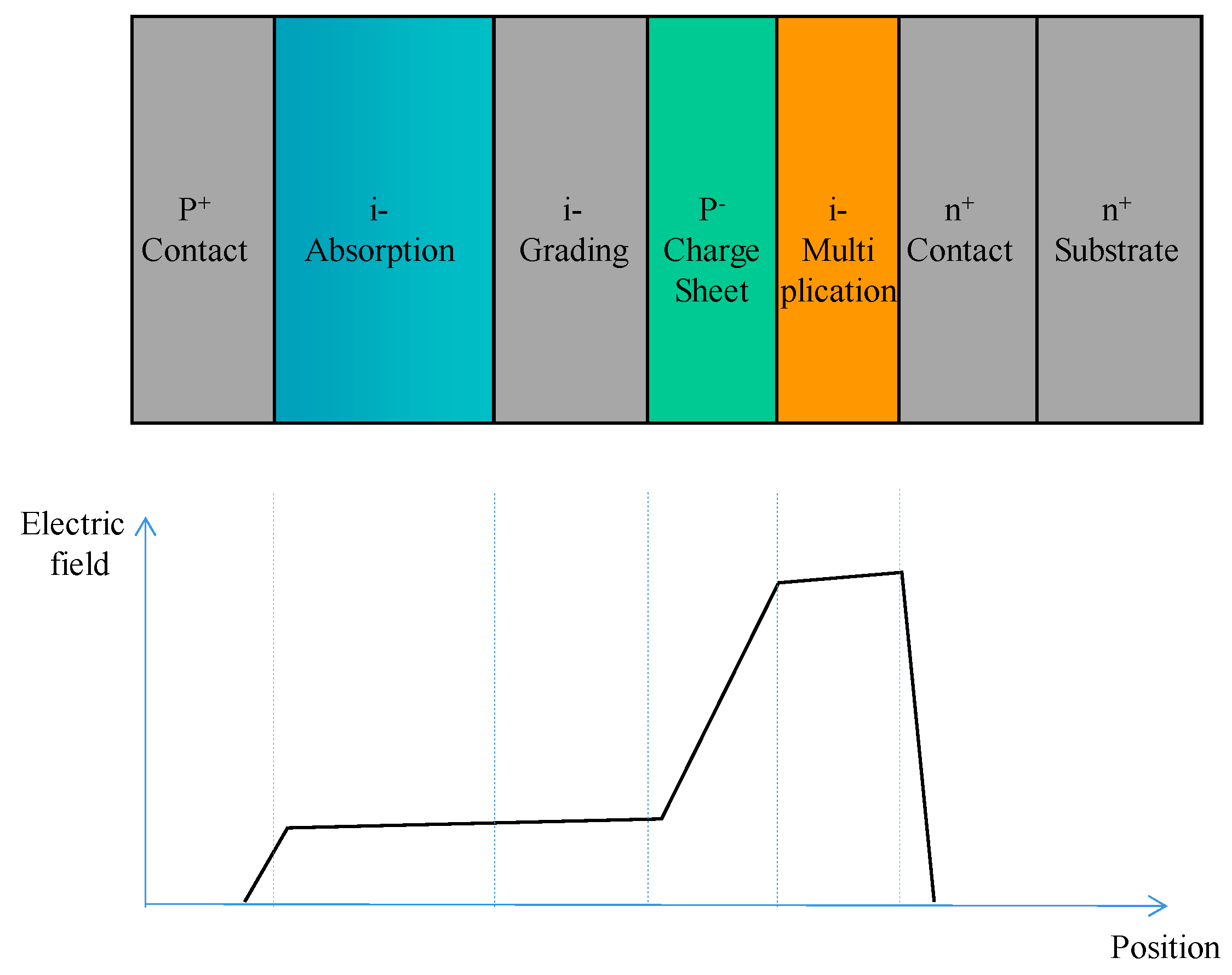

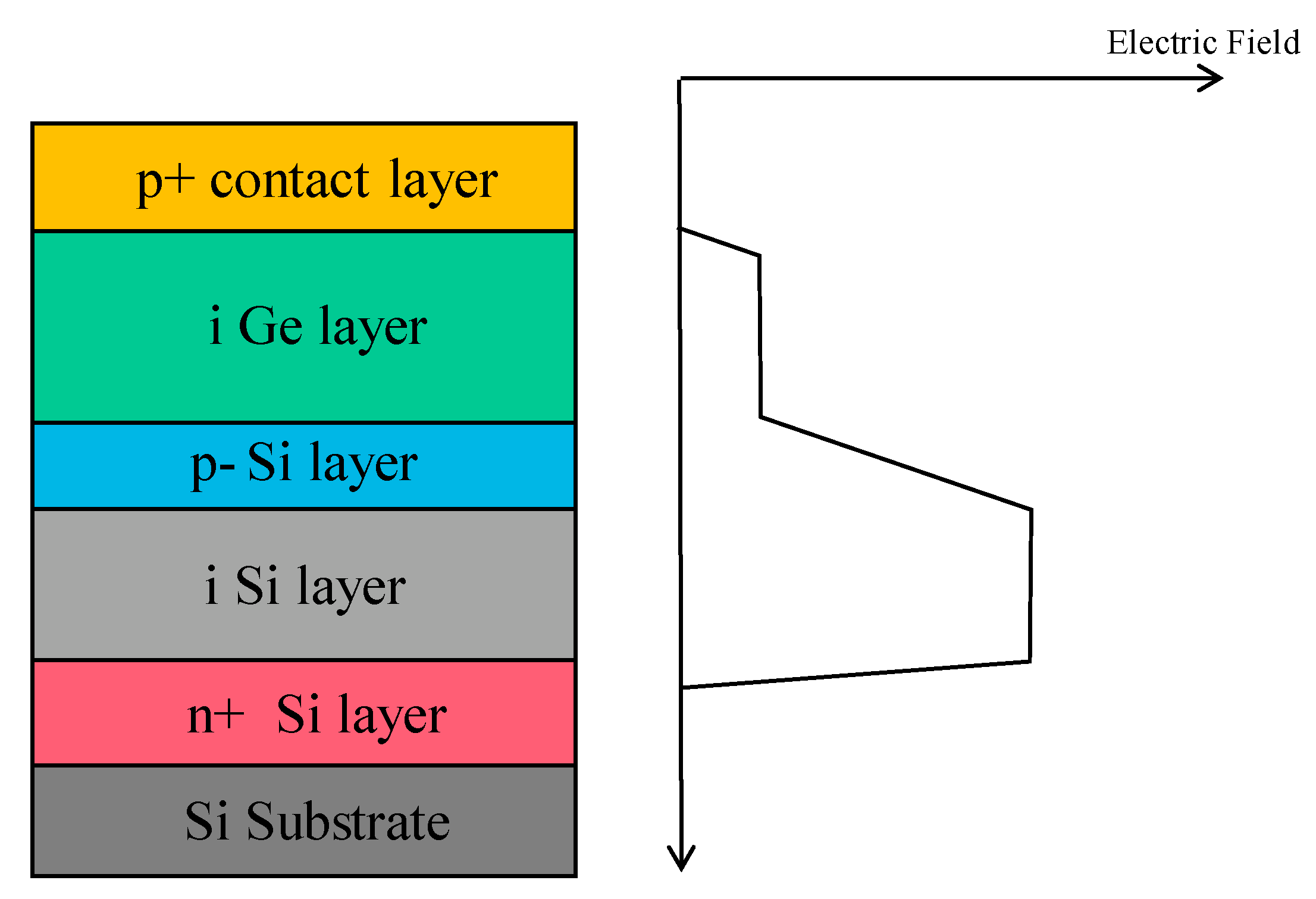

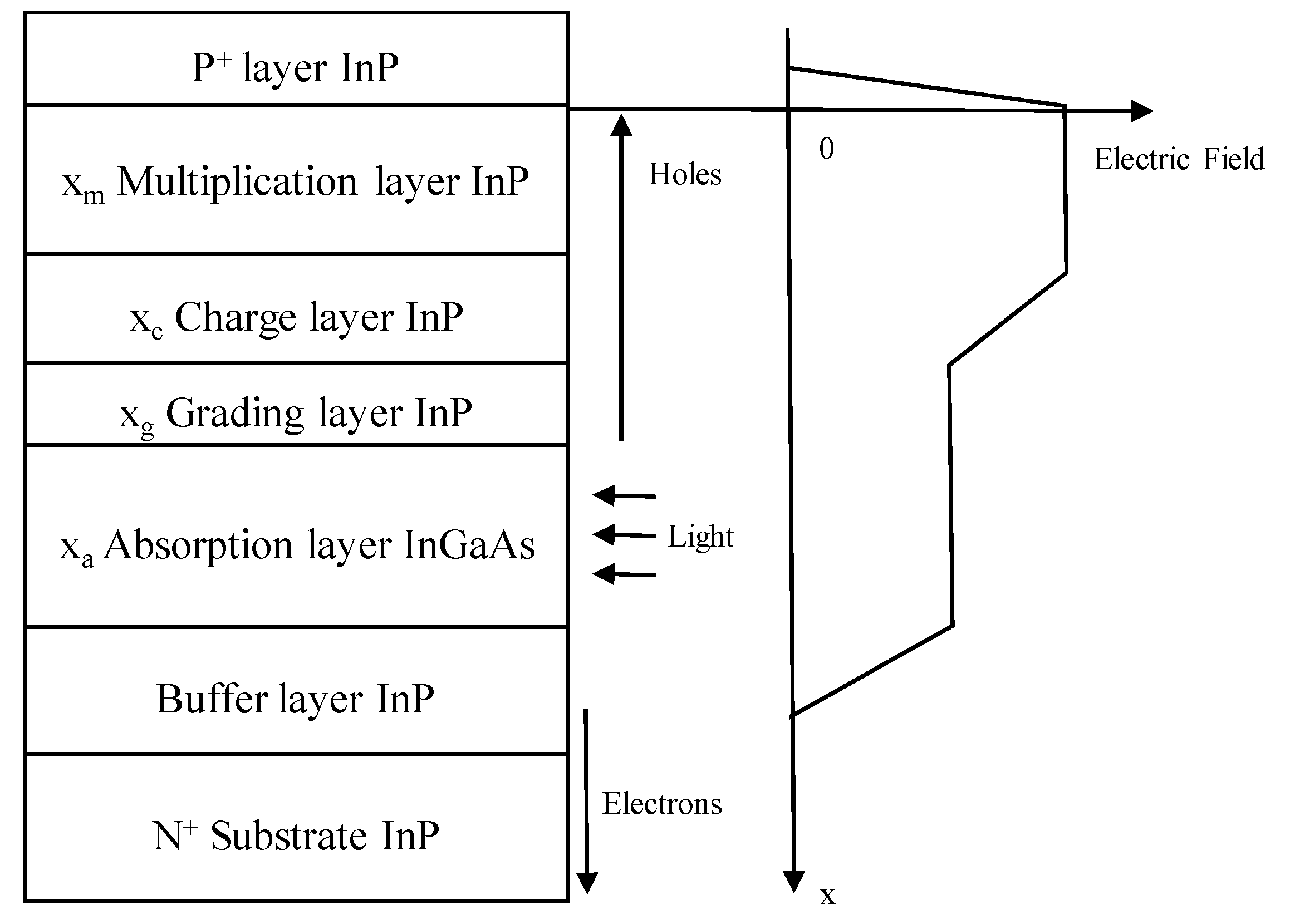

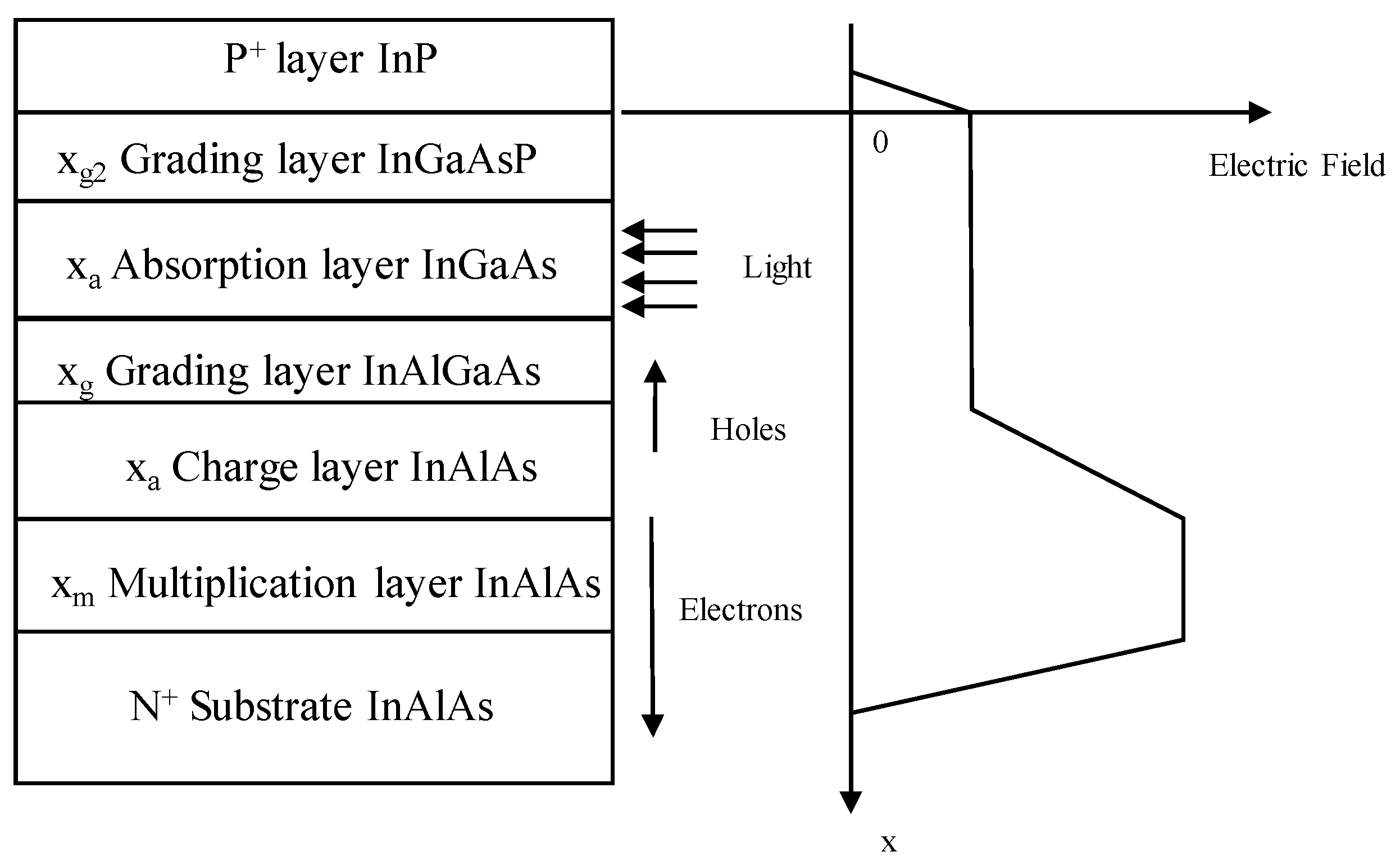

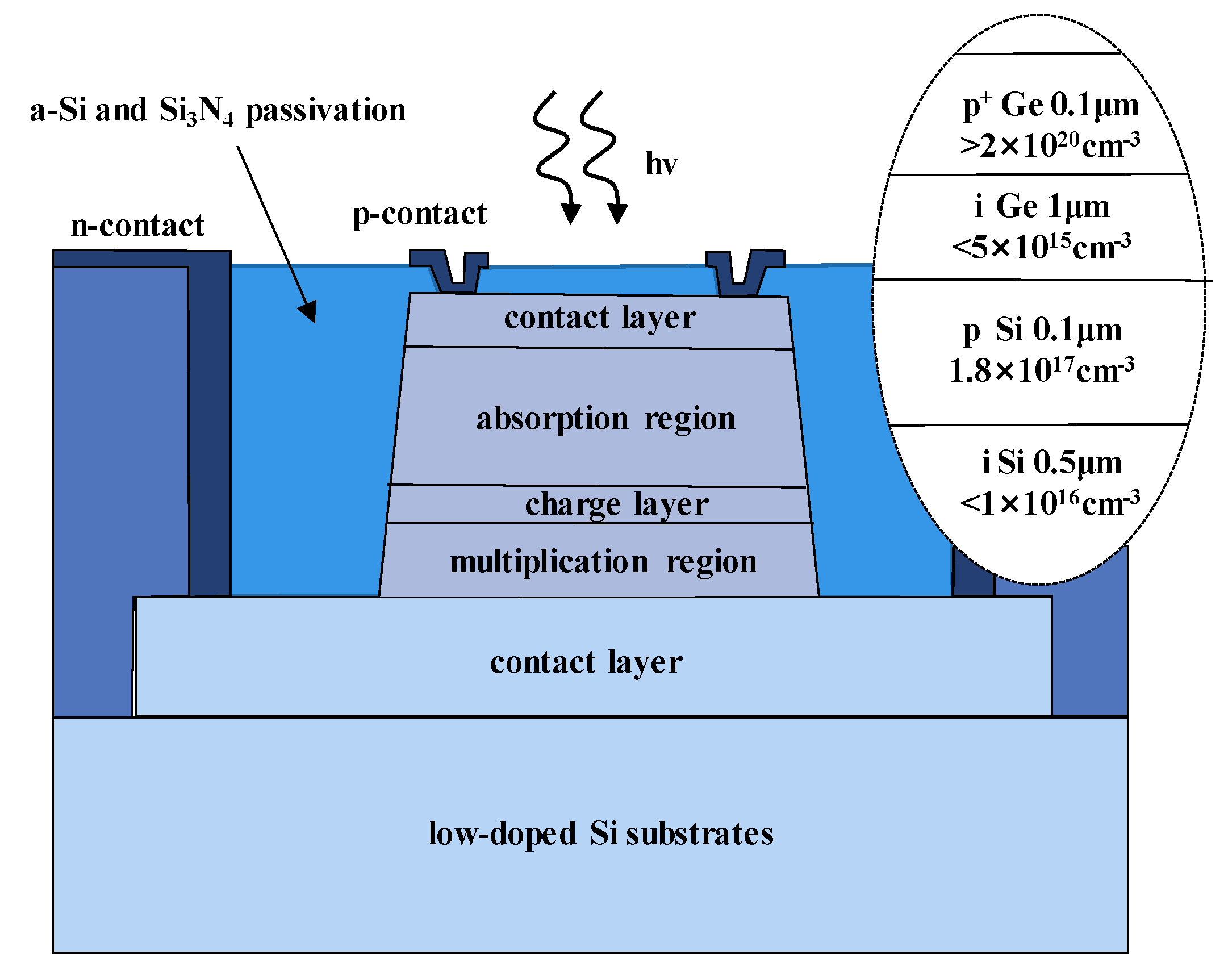

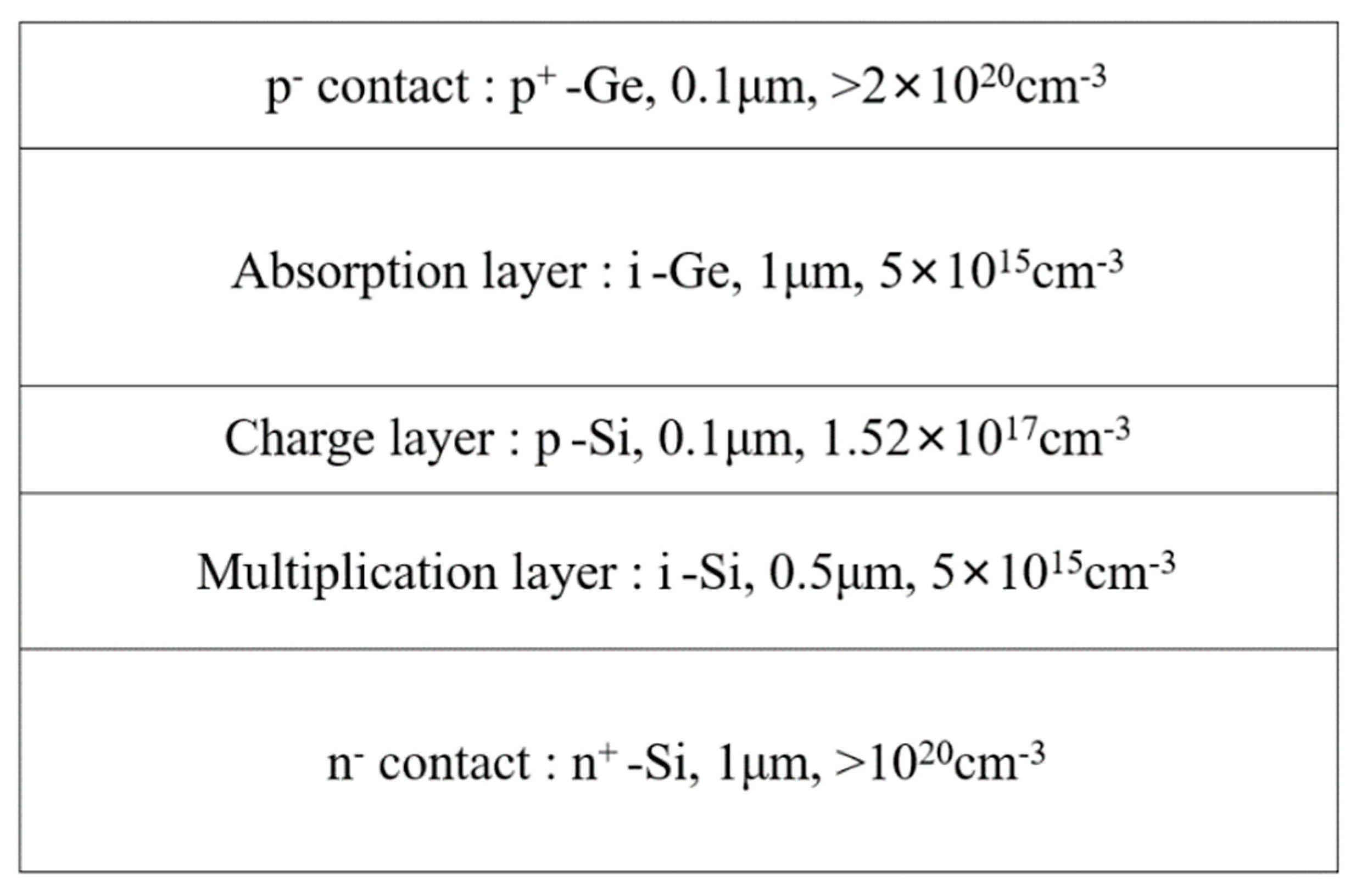

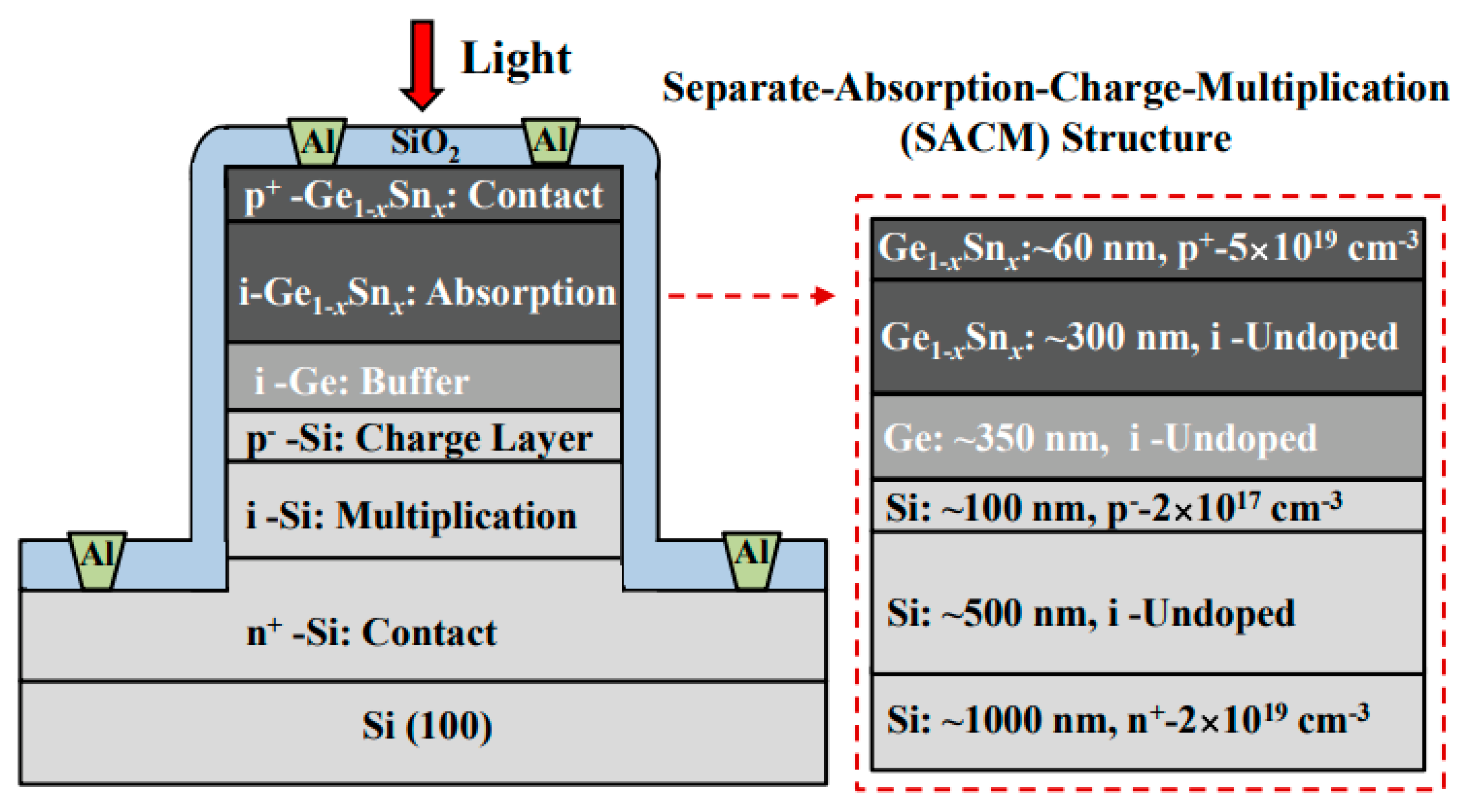

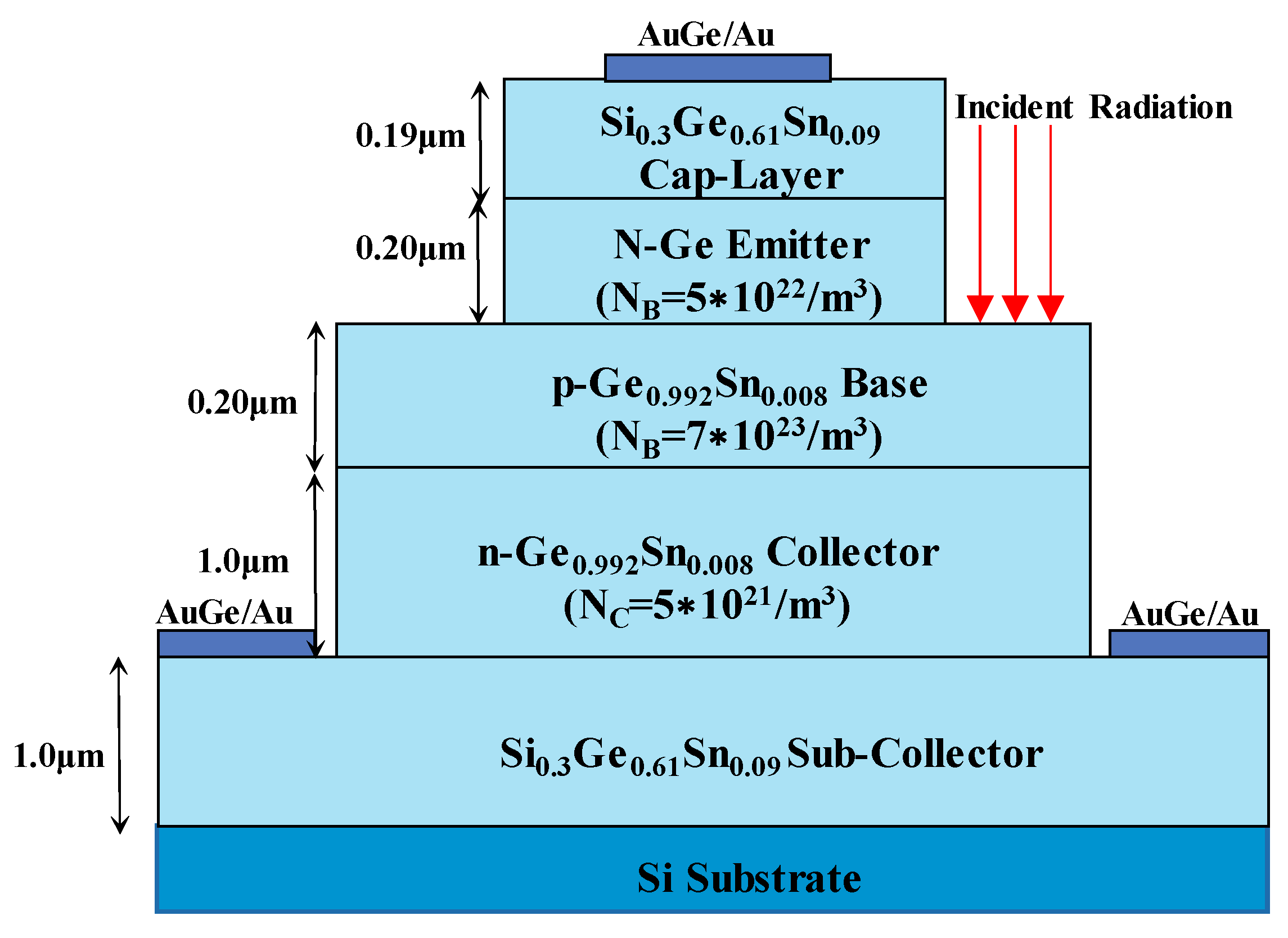

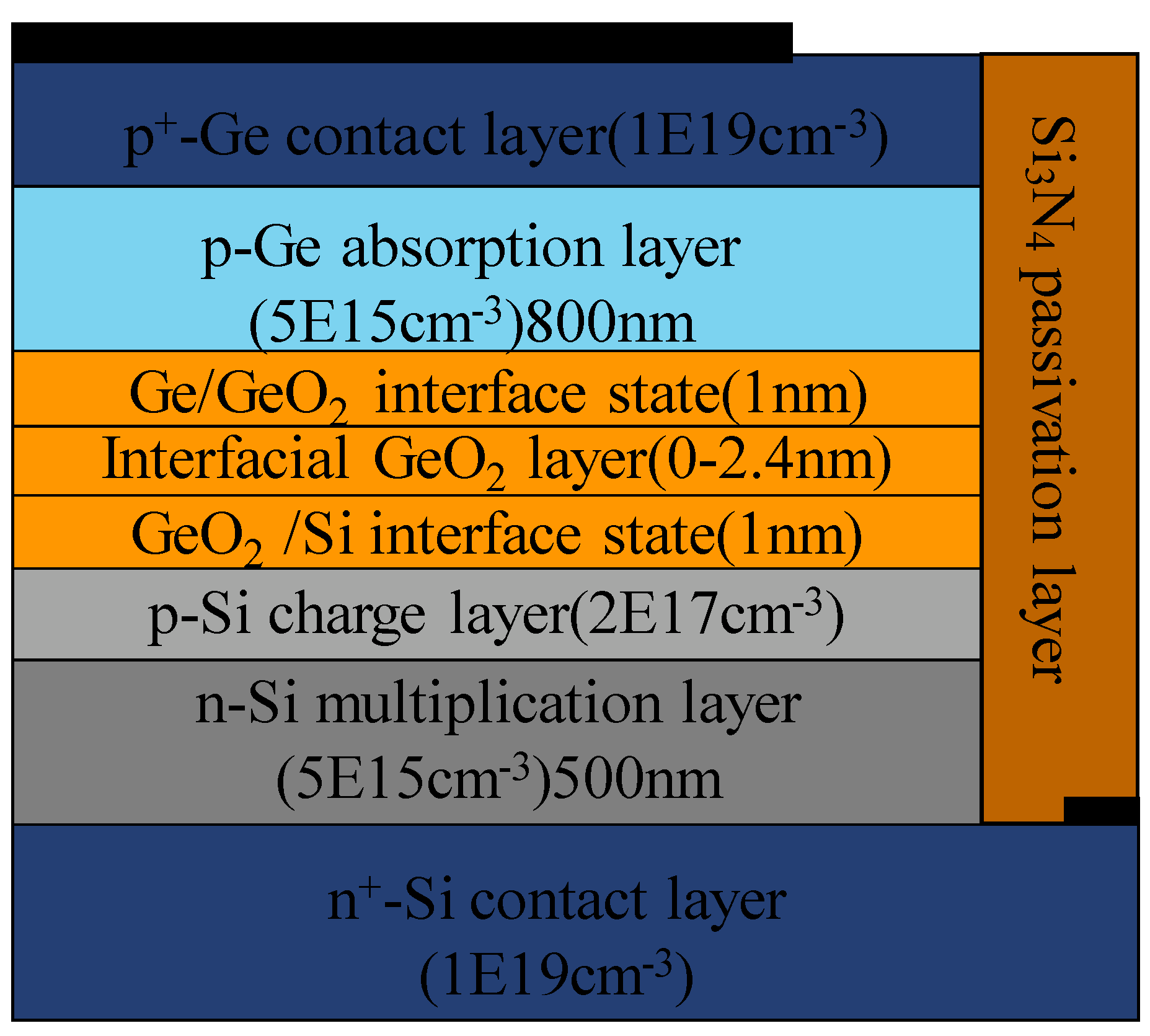

2.1. Typical Structures for Ge(GeSn) and InGaAs SWIR APDs

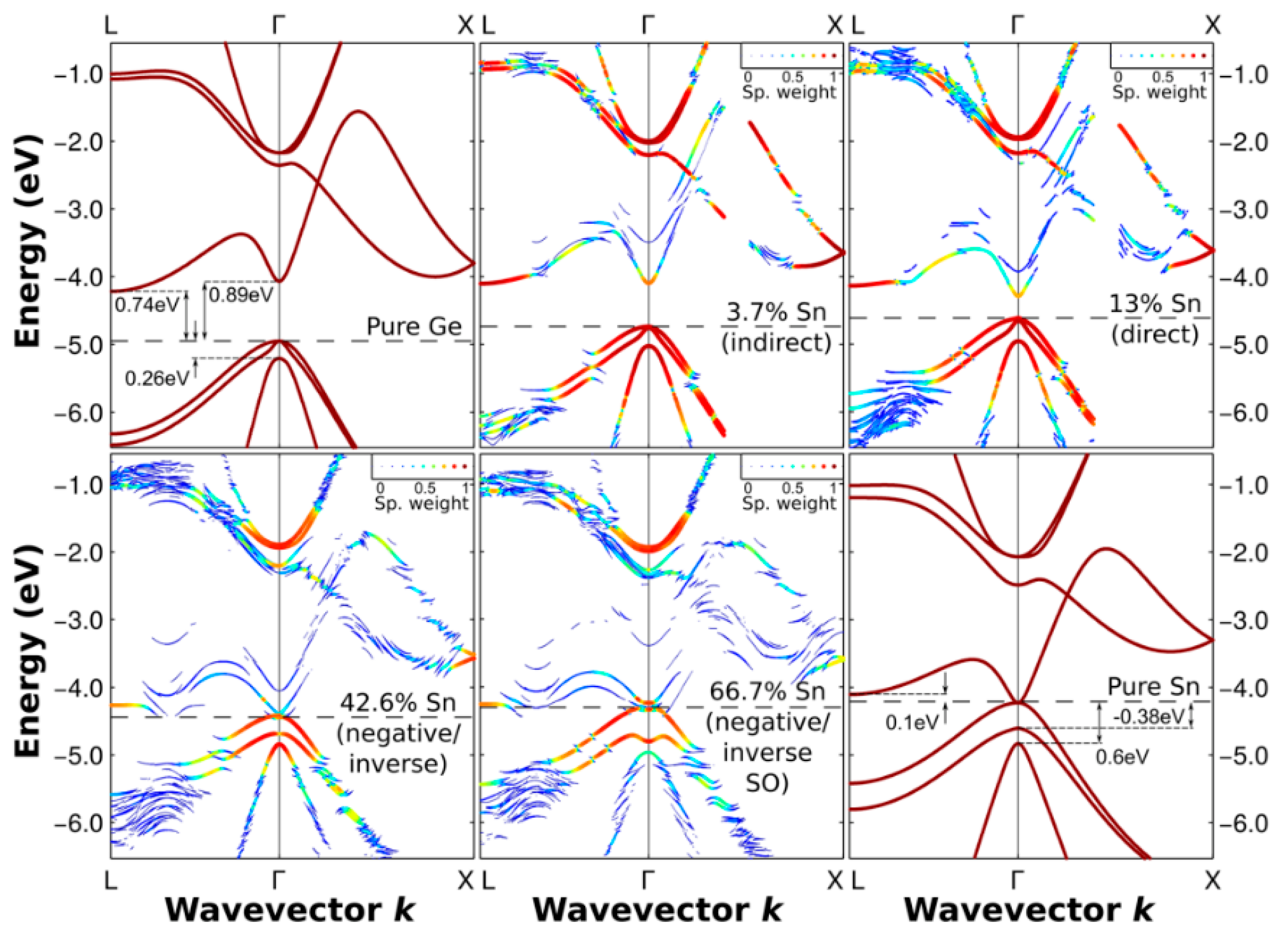

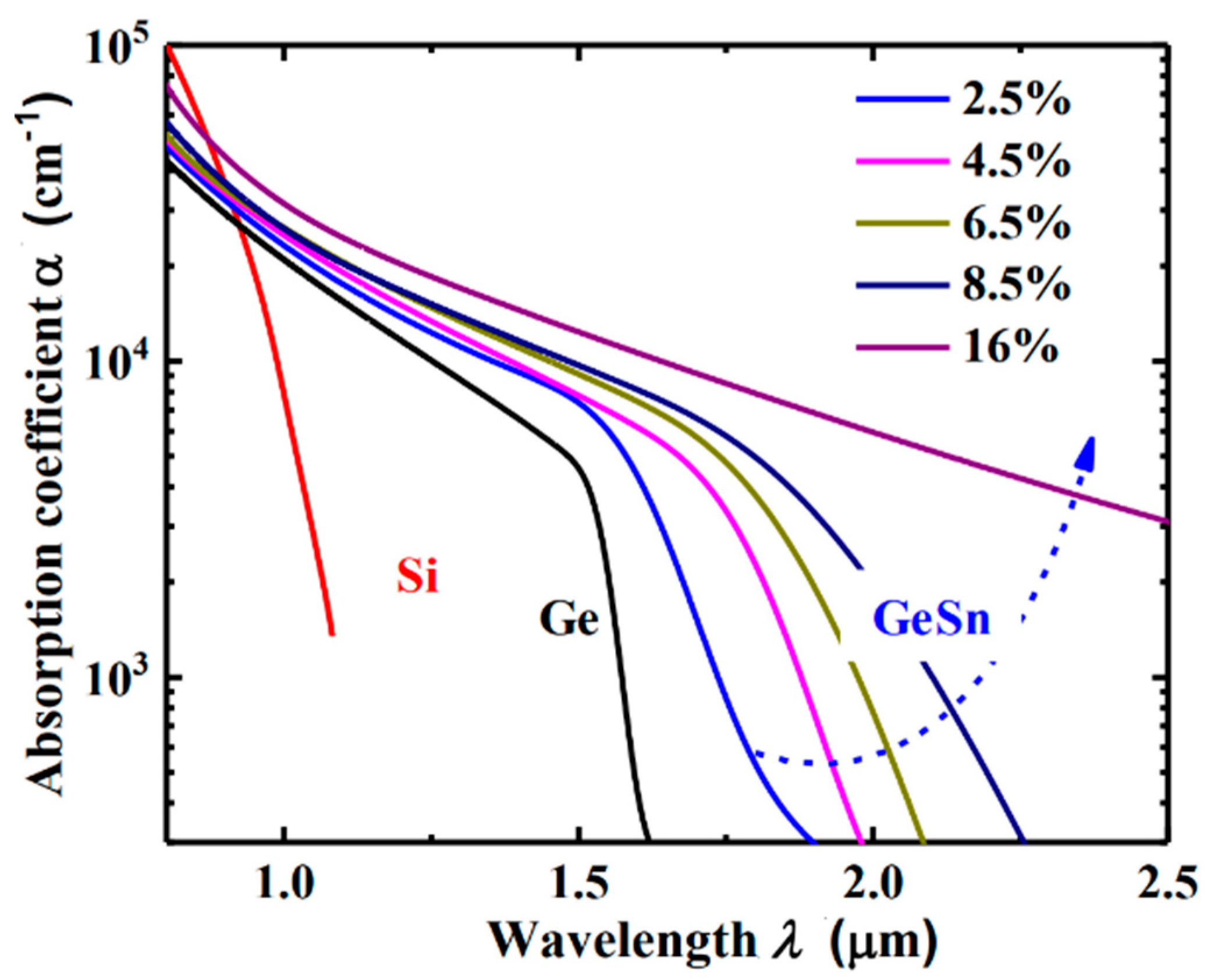

2.2. Research Progress for Ge (GeSn) SWIR APDs

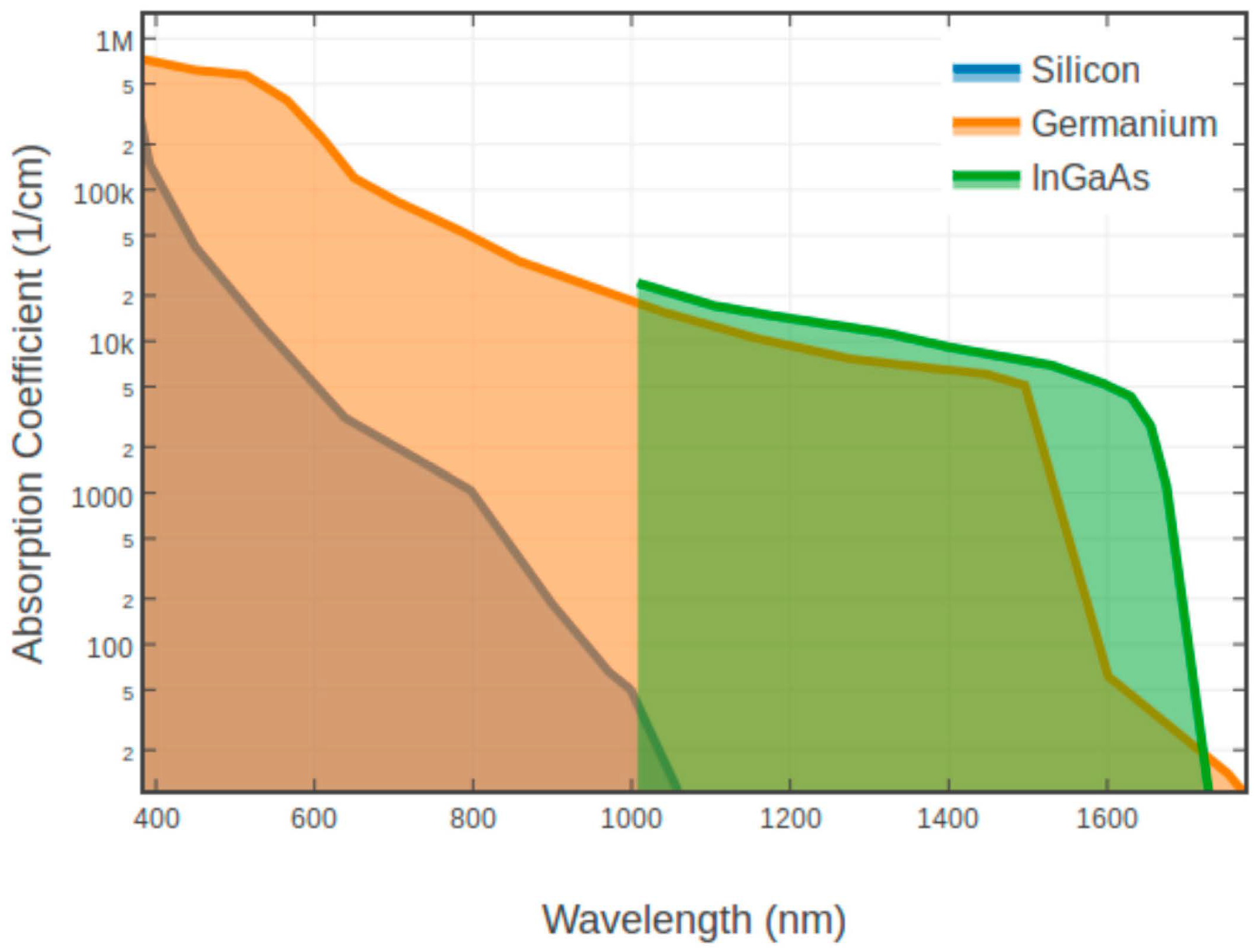

2.2.1. Material Properties for Ge and GeSn

| Year | Institution | Methods | Sn (%) | Ref. |

|---|---|---|---|---|

| 1987 | University of Notre Dame | Tight-binding calculations using virtual-crystal approximation (VCA). | >20 | [48] |

| 1989 | Swiss Federal Institute of Technology | Self-consistent ab initio pseudo-potential calculations in VCA. | 27–74 | [49] |

| 1999 | Michigan Technical University | First-principles calculation in nonlocal density approximation to density functional theory (GGA) with Becke exchange functional with Ferdew-Wang’s correlation functional. | 50 | [50] |

| 2007 | University of Leeds | Charge self-consistent pseudo-potential Xα method. | 17 | [51] |

| 2008 | Fudan University | First-principles fully relativistic band structure method and a more accurate approach that considers core-level volume deformation (VD) potential. | 25, 50, 75 | [52] |

| 2011 | Stanford University | First-principles calculations using density function theory (DFT) with GAA+U. | 3, 6 | [53] |

| 2012 | National University of Singapore | Empirical pseudo-potential method (EPM), 8-band k.p method | 0–20. | [54] |

| 2012 | Shenyang University of Technology | First principles calculations based on norm-conserving pseudo-potentials, density function theory (DFT), and density functional perturbation theory (DFPT). | —— | [55] |

| 2013 | Stanford University | Virtual crystal approximation (VCA) within the framework of the nonlocal empirical pseudo-potential method (NL-EPM). | 0–20, 7 | [56] |

| 2014 | ETH Zurich | Empirical pseudopotential method (EPM) along with virtual crystal approximation (VCA). | 0–20 | [57] |

| 2015 | Chinese Academy of Science, Institute of Semiconductor | First-principle calculations based on DFT are performed using the Vienna ab initio simulation package (VASP) code. To correct the underestimation of the bandgap, the GGA+U approach with Perdew–Burke–Ernzerhof (PBE) is employed to describe the electron exchange and correlation. | 0–20, 8.5 | [58] |

| 2017 | Wroclaw University of Science and Technology | First-principle calculations based on DFT along with Tran and Blaha MBJLDA functions. All calculations have been performed with the all-electron full potential WIEN2k code, which has recently been proven to be one of the most accurate DFT codes. | 3.7–66.7 | [46] |

| 2018 | University College Cork | First-principle calculations based on DFT, including Heyd Scuseri Ernzerhof (HSE) hybrid functions, using the Vienna Ab initio Simulation Package (VASP). | 6.25 | [59] |

| 2019 | National Chiao Tung University | Nonlocal empirical pseudopotential method (EPM) with modified virtual crystal approximation (VCA), 8-band k.p model. | 0–15, 7.1 | [60] |

| 2019 | Nanyang Technological University | Empirical tight binding and ab initio methods, full-zone 30-band k.p model. | 0–30, 7.25 | [61] |

| 2020 | George Washington Unviersity | Combining statistical sampling based on the Monte Carlo method and density functional theory (DFT) calculation using the Vienna Ab initio Simulation Package (VASP) based on the projector augmented wave method. | 25, 8 | [62] |

| 2020 | Tiangong University | First-principle calculation via the sX-LDA method, using the Cambridge Sequential Total Energy Package (CASTEP) code based on the DFT, The norm-conserving pseudopotentials (NCPP) are used to describe the interactions between the electrons and ionic cores. | 0–30, 6.25 | [63] |

| 2021 | University College Cork | First-principle calculations based on Kohn–Sham DFT, Structural relaxations are carried out in the local density approximation (LDA), and electronic band structures are calculated using the Tran–Blaha modified Becke–Johnson (TB-mBJ) meta-generalized gradient approximation (meta-GGA) exchange-correlation potential in order to overcome the band gap underestimation typical of the LDA in the Kohn–Sham formalism. | 0–100, 5, 11, 25 | [64] |

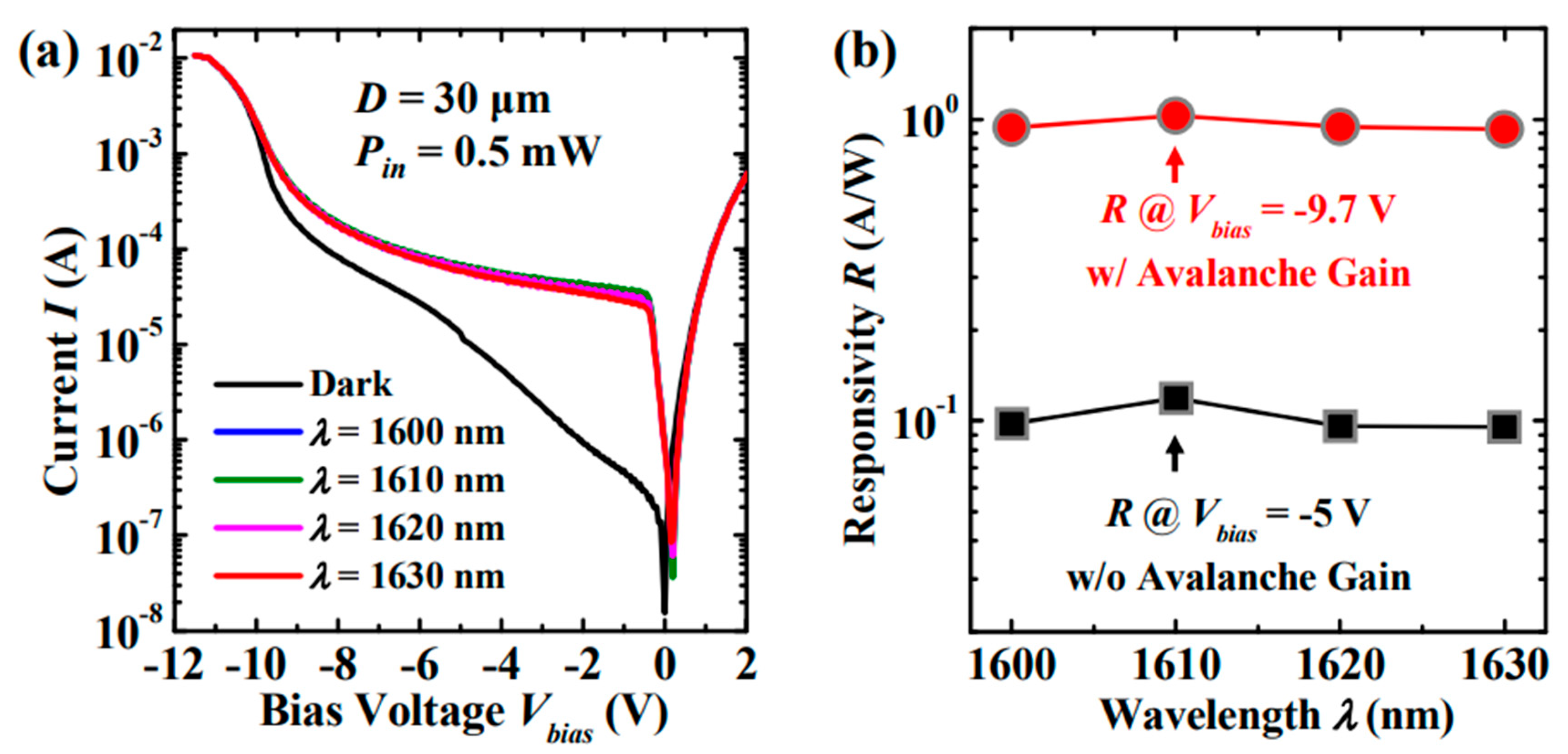

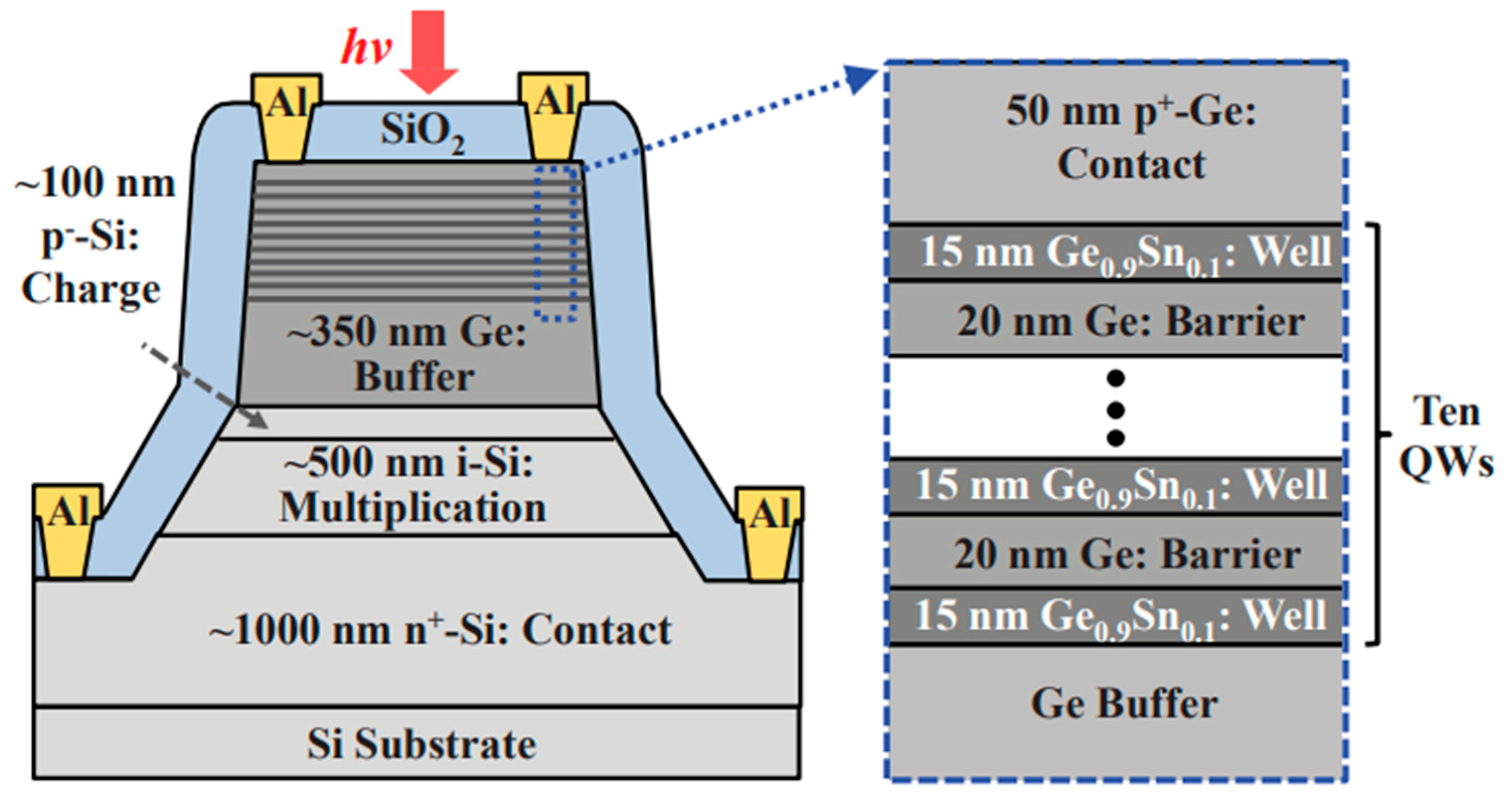

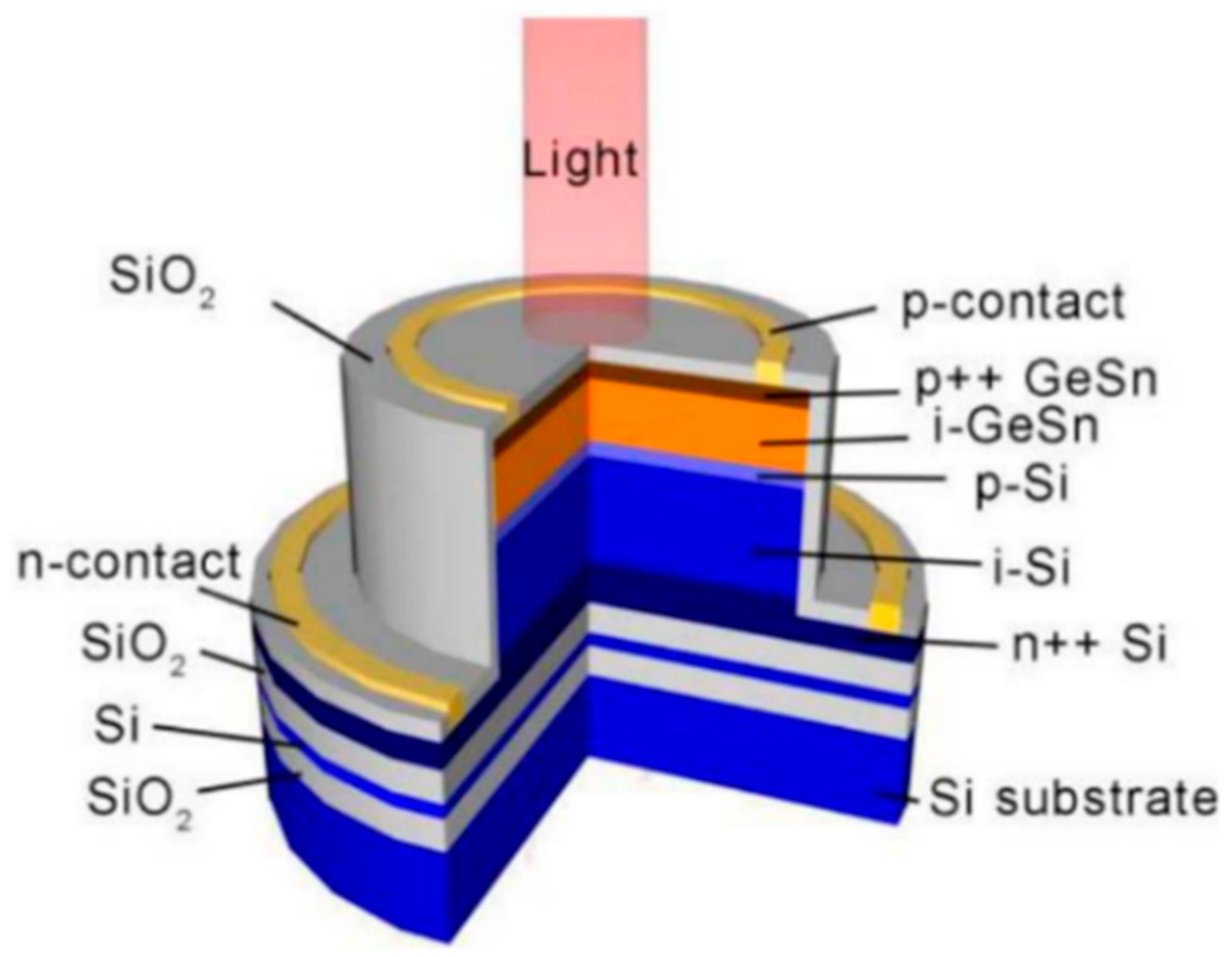

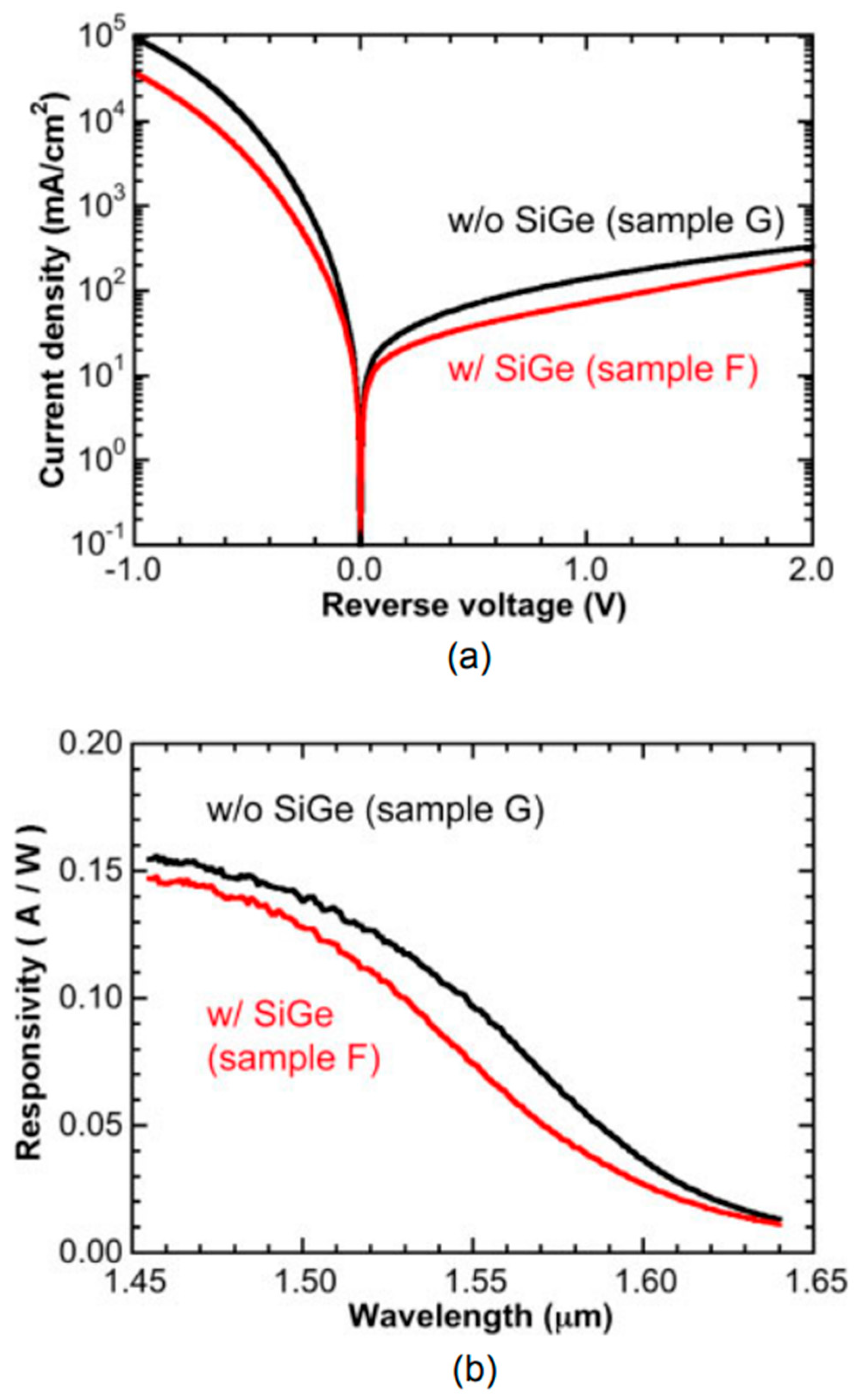

2.2.2. Mesa Geometry Ge(GeSn)/Si APDs

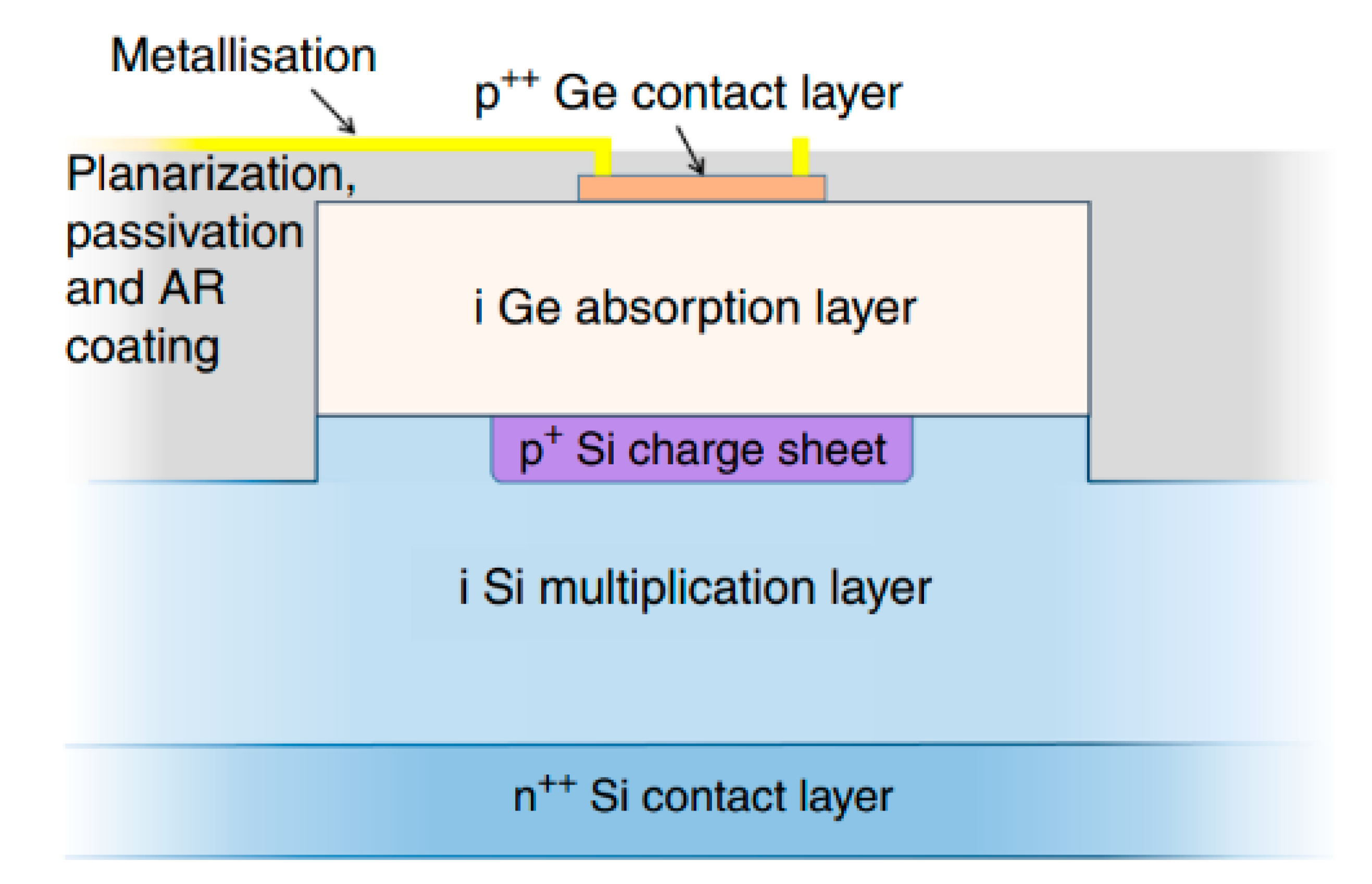

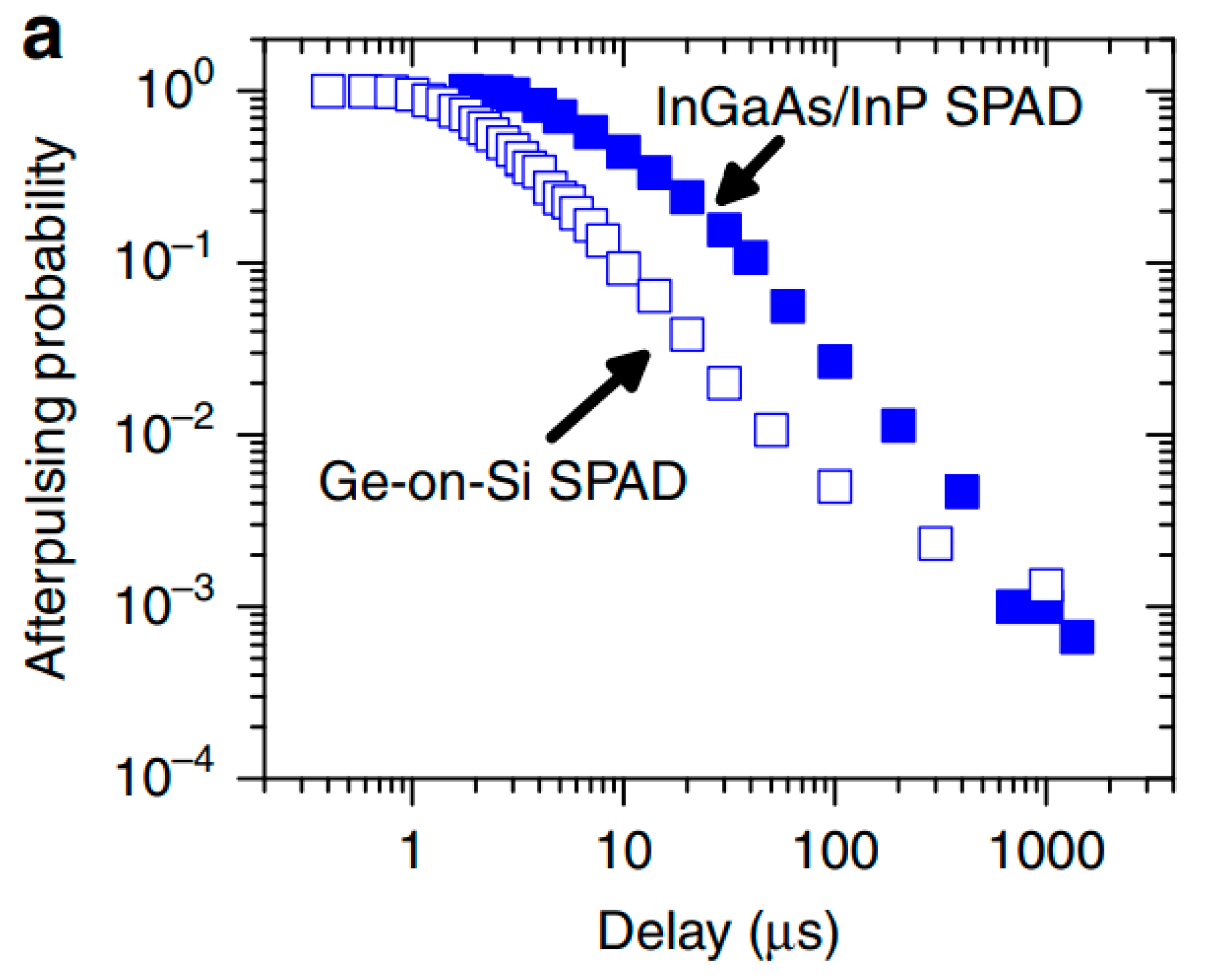

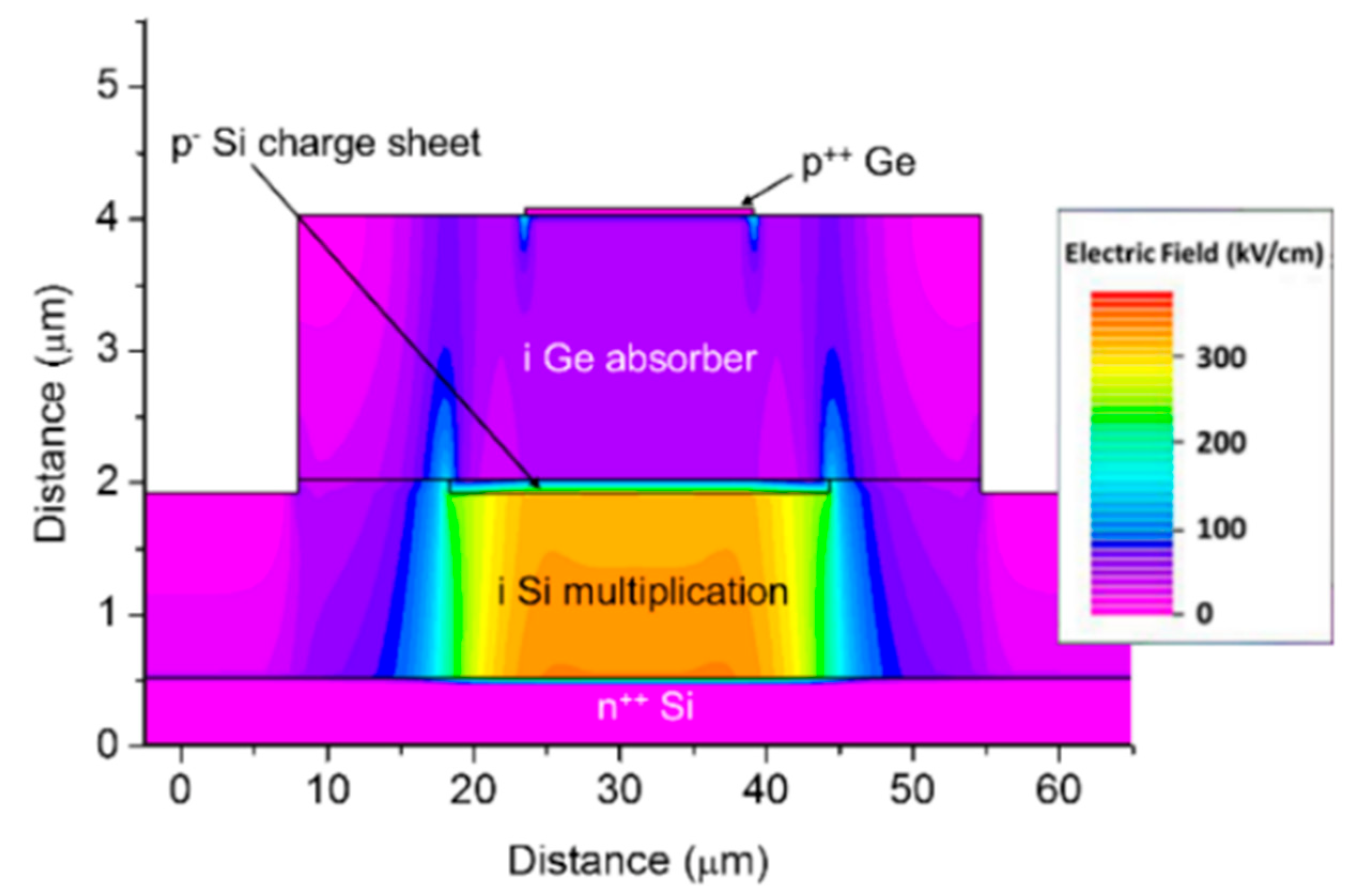

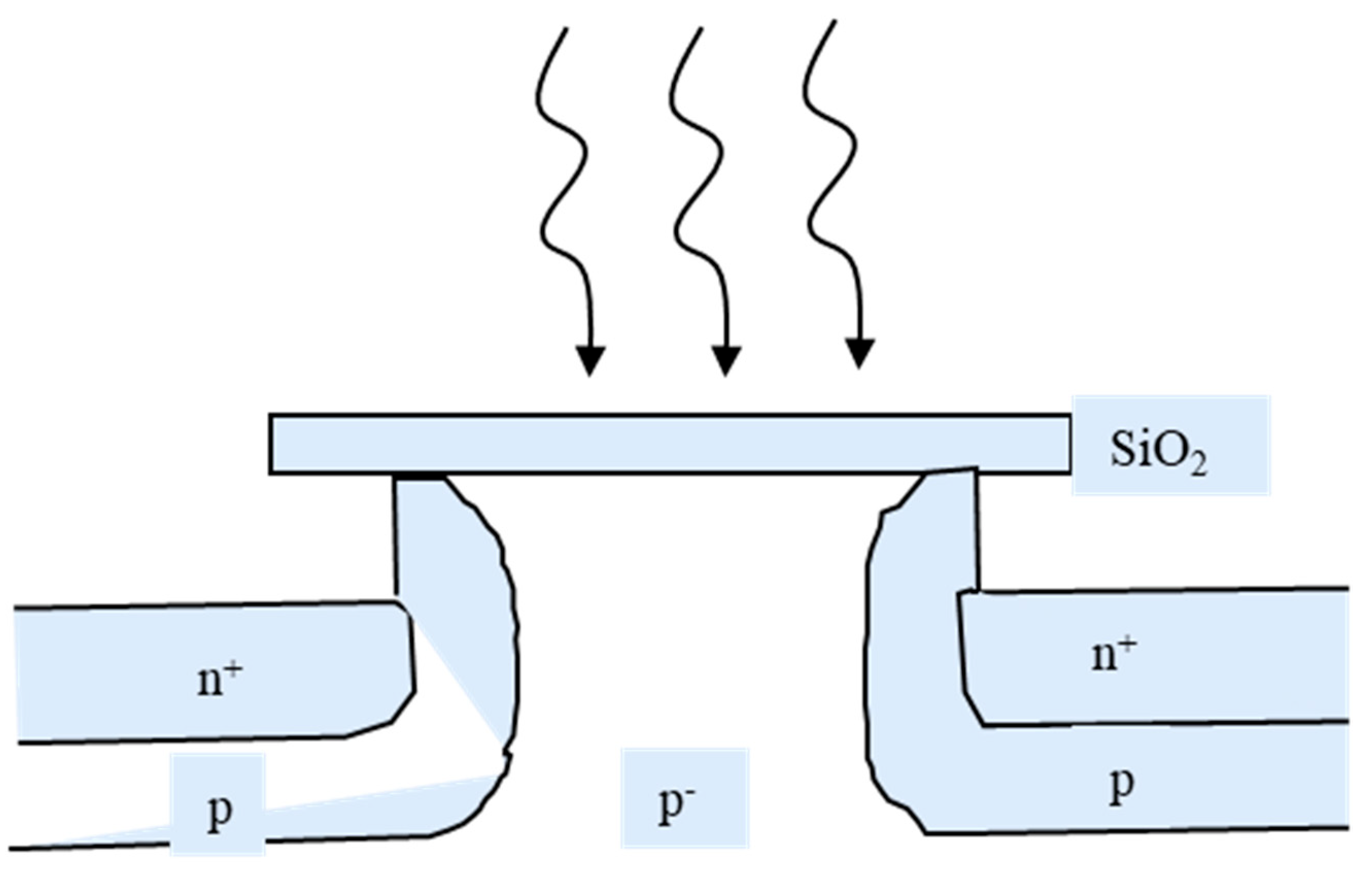

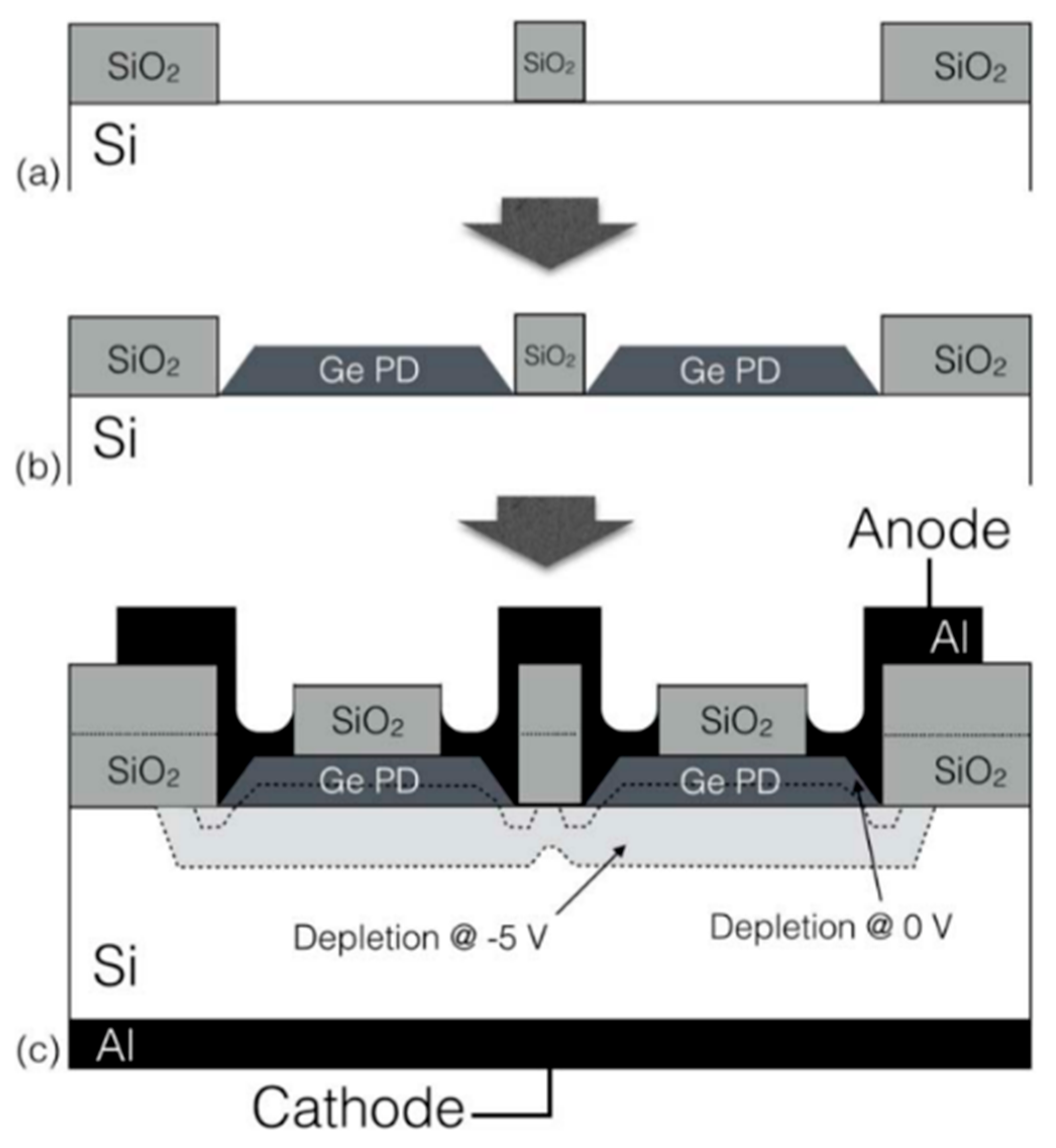

2.2.3. Planar Geometry Ge/Si APDs

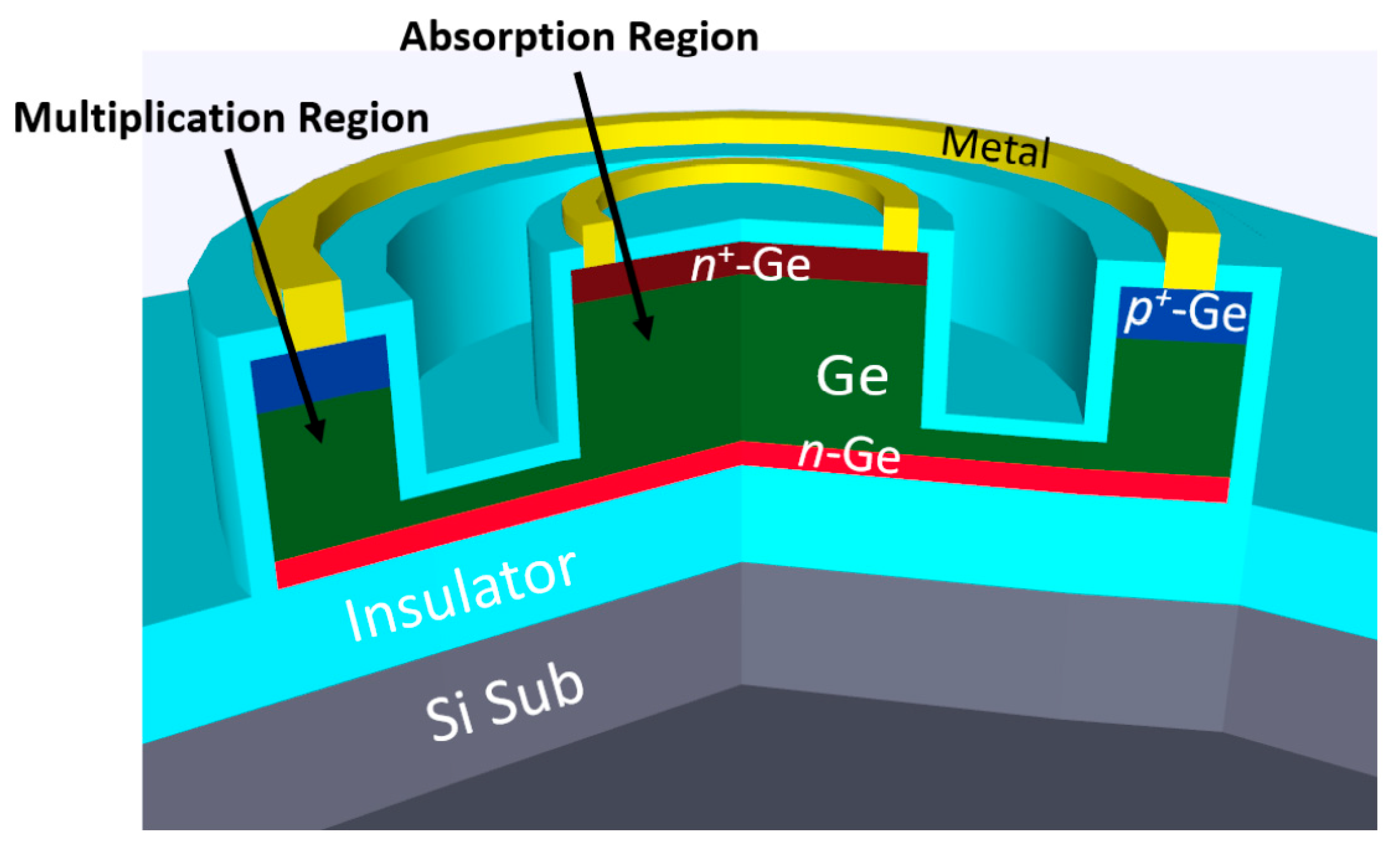

2.2.4. Other Novel Ge(GeSn) Avalanche Device Structures

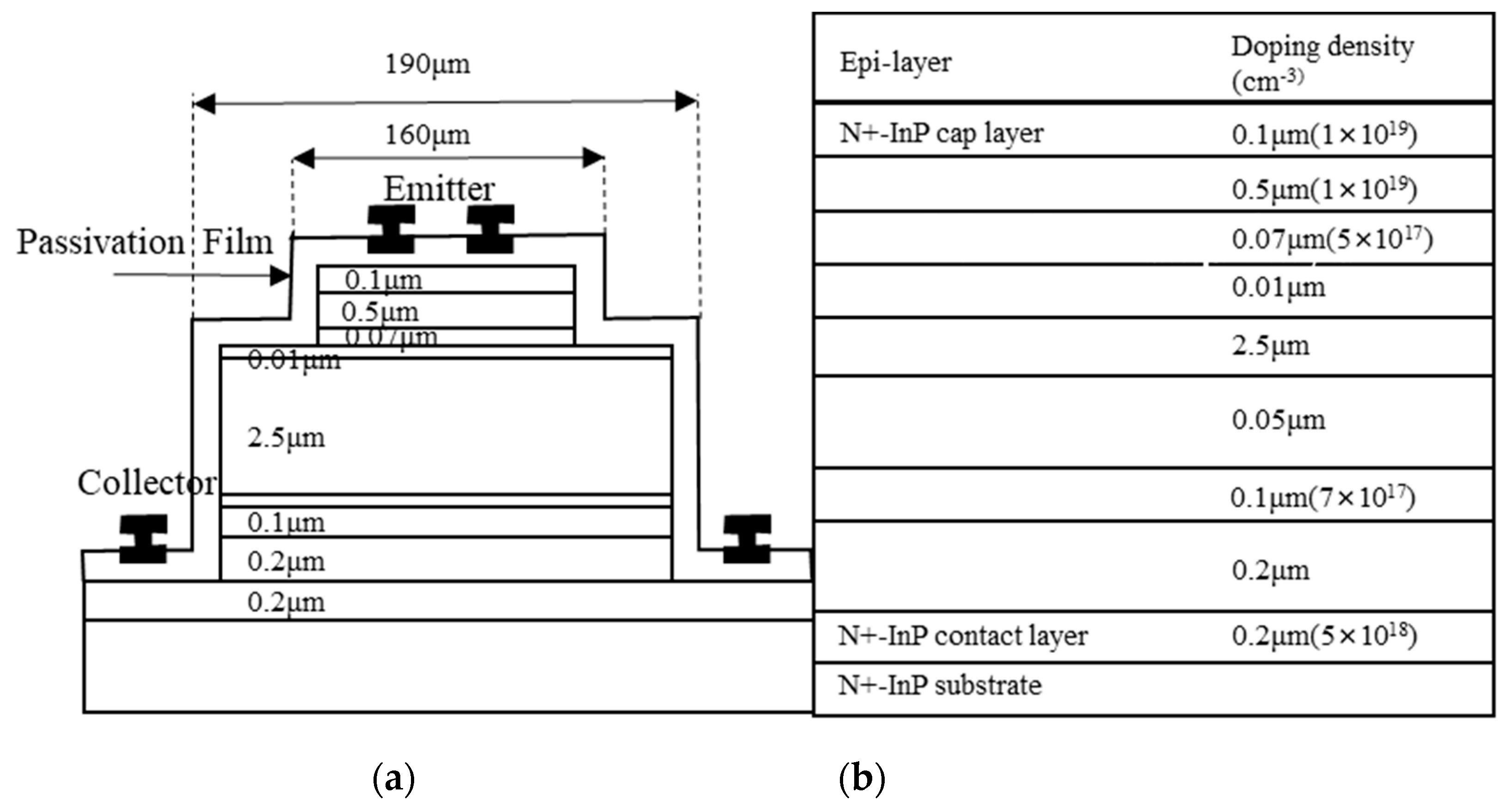

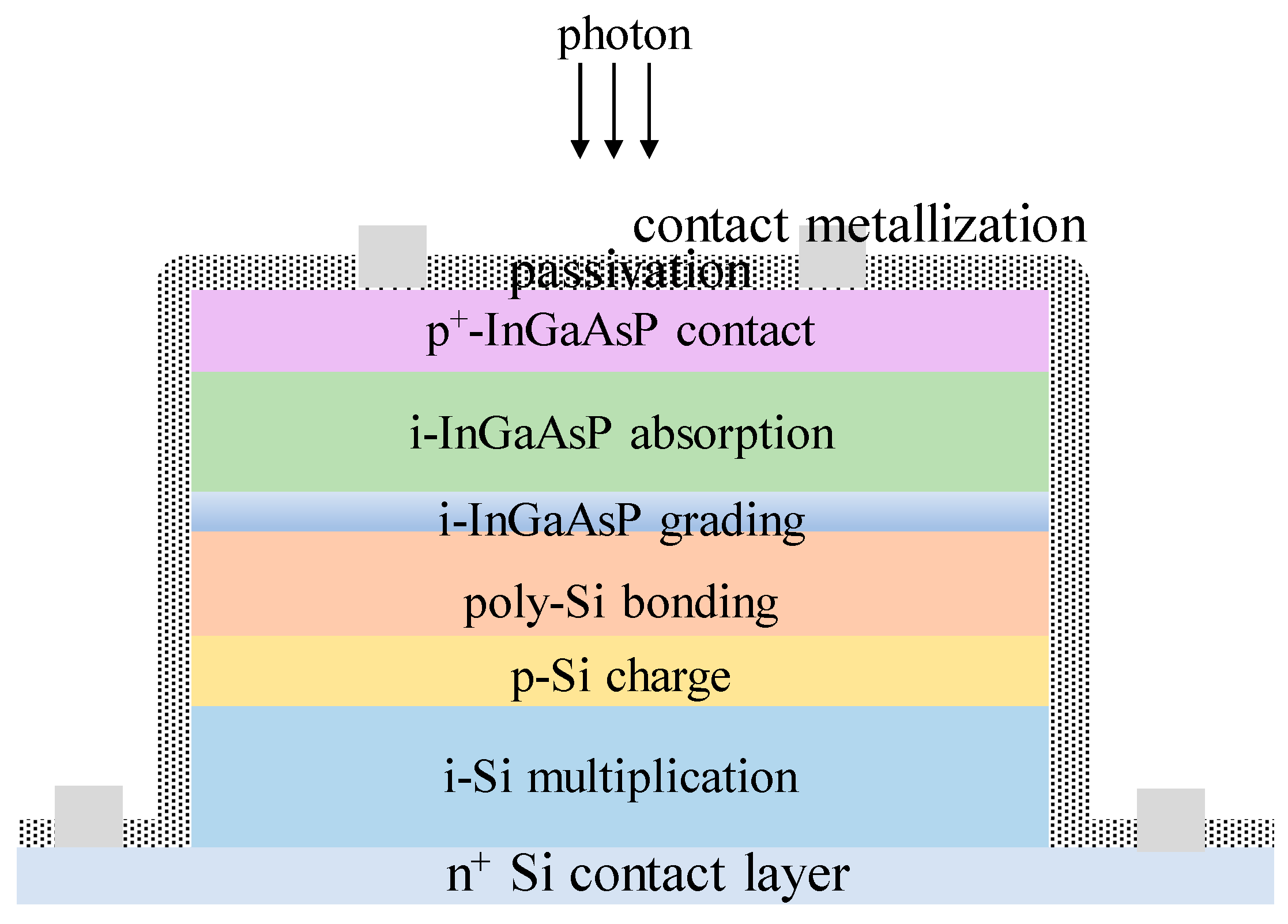

2.3. Research Progress for InGaAs SWIR APDs

2.3.1. Material Property for InGaAs

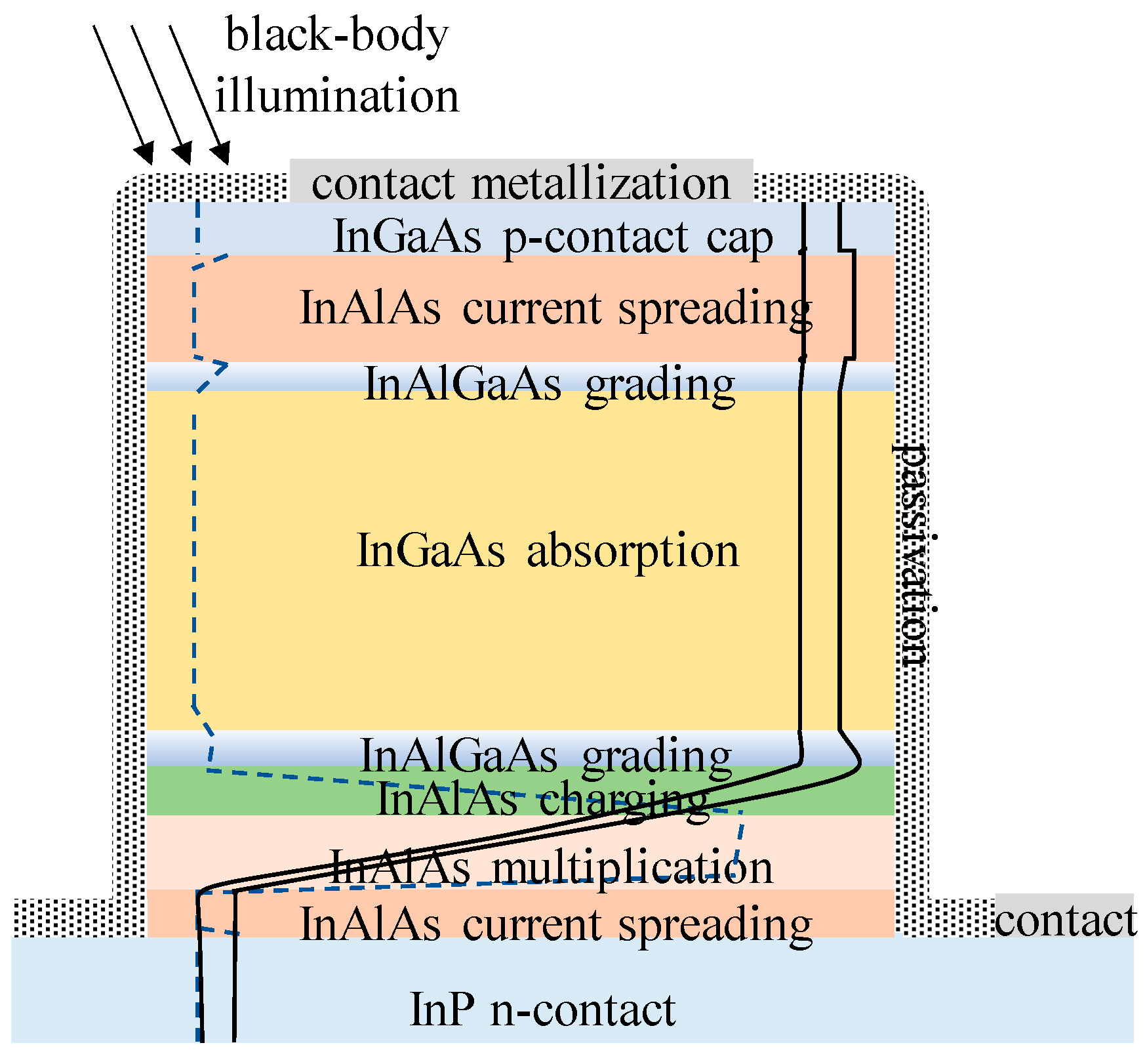

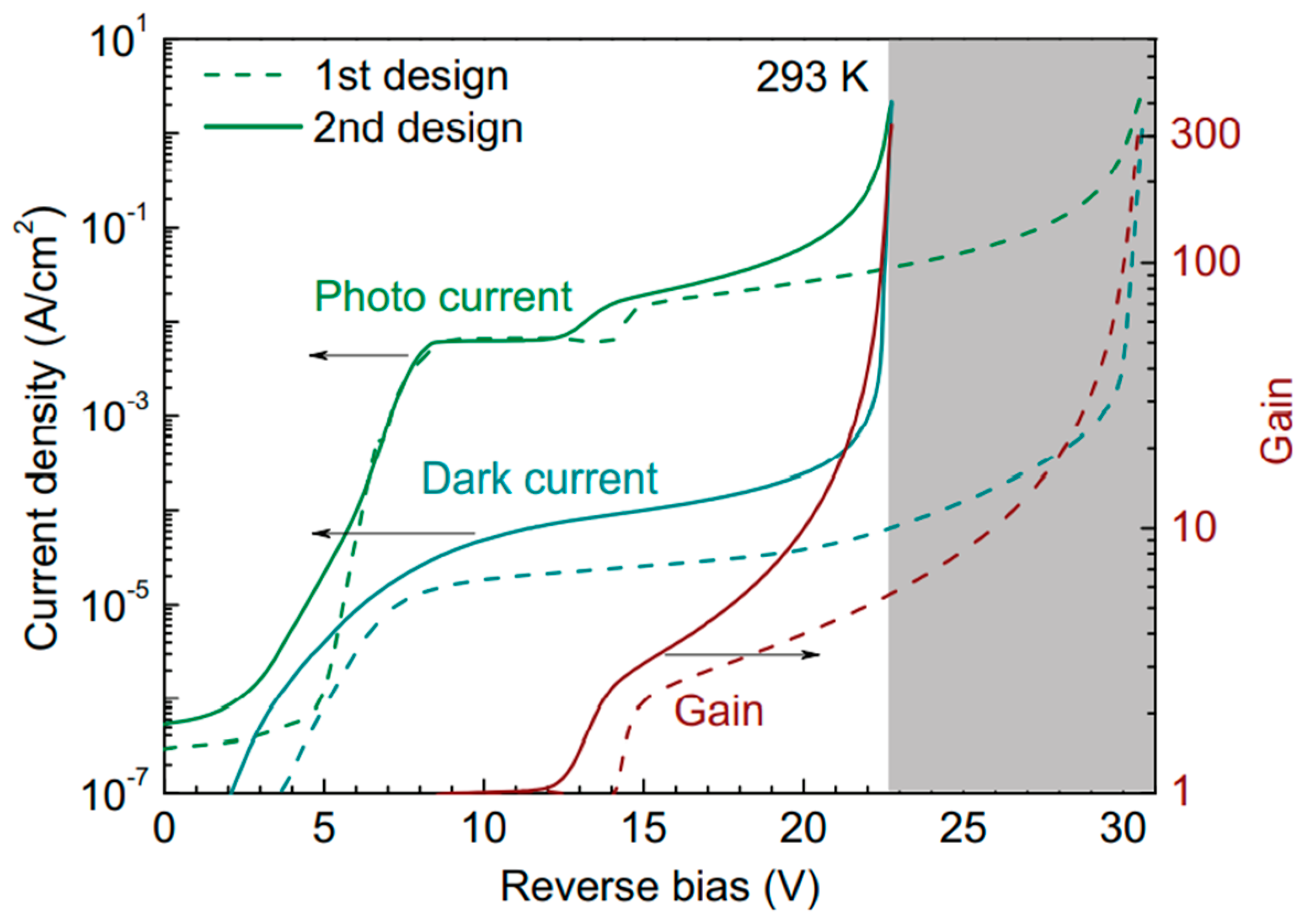

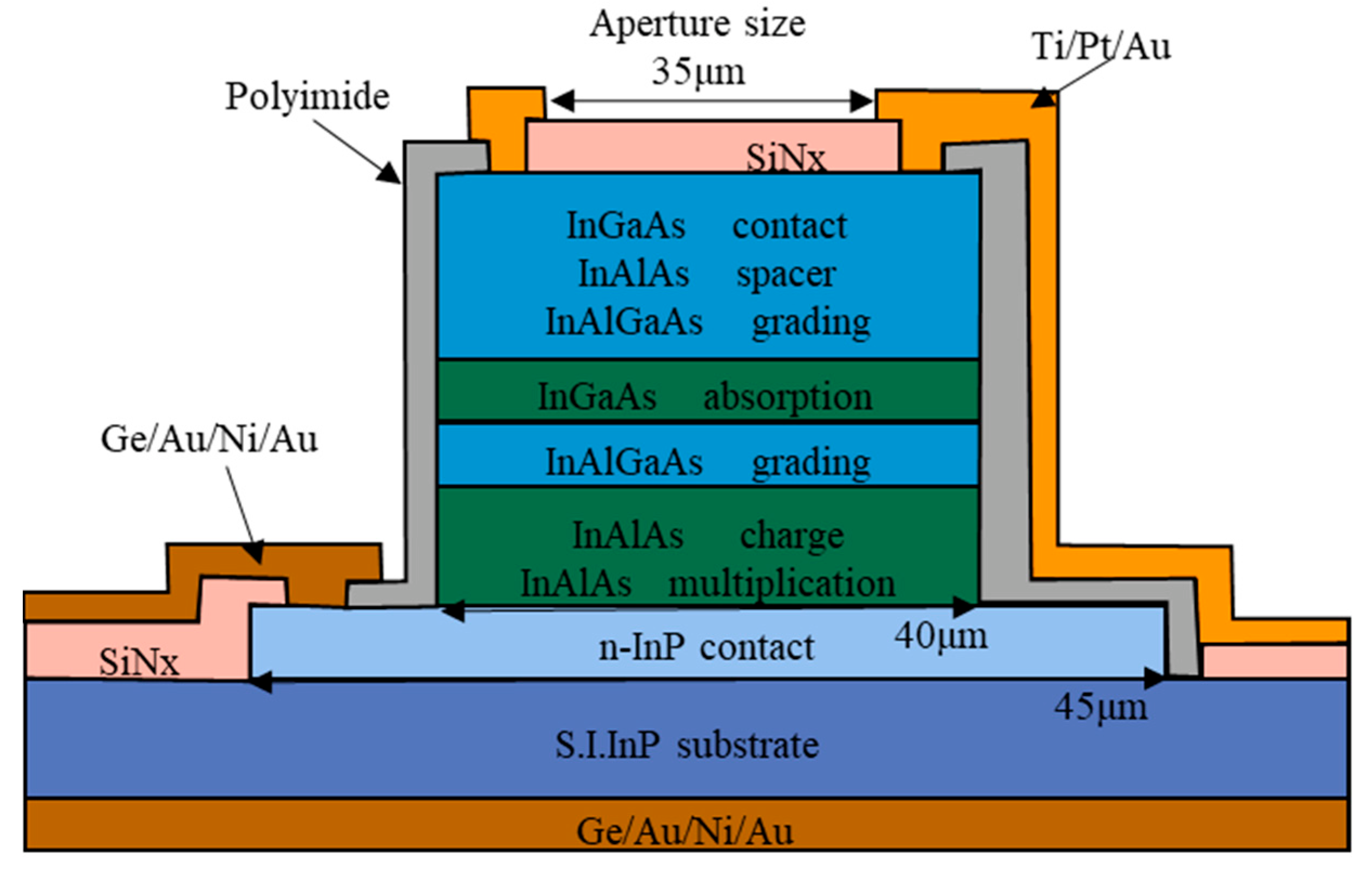

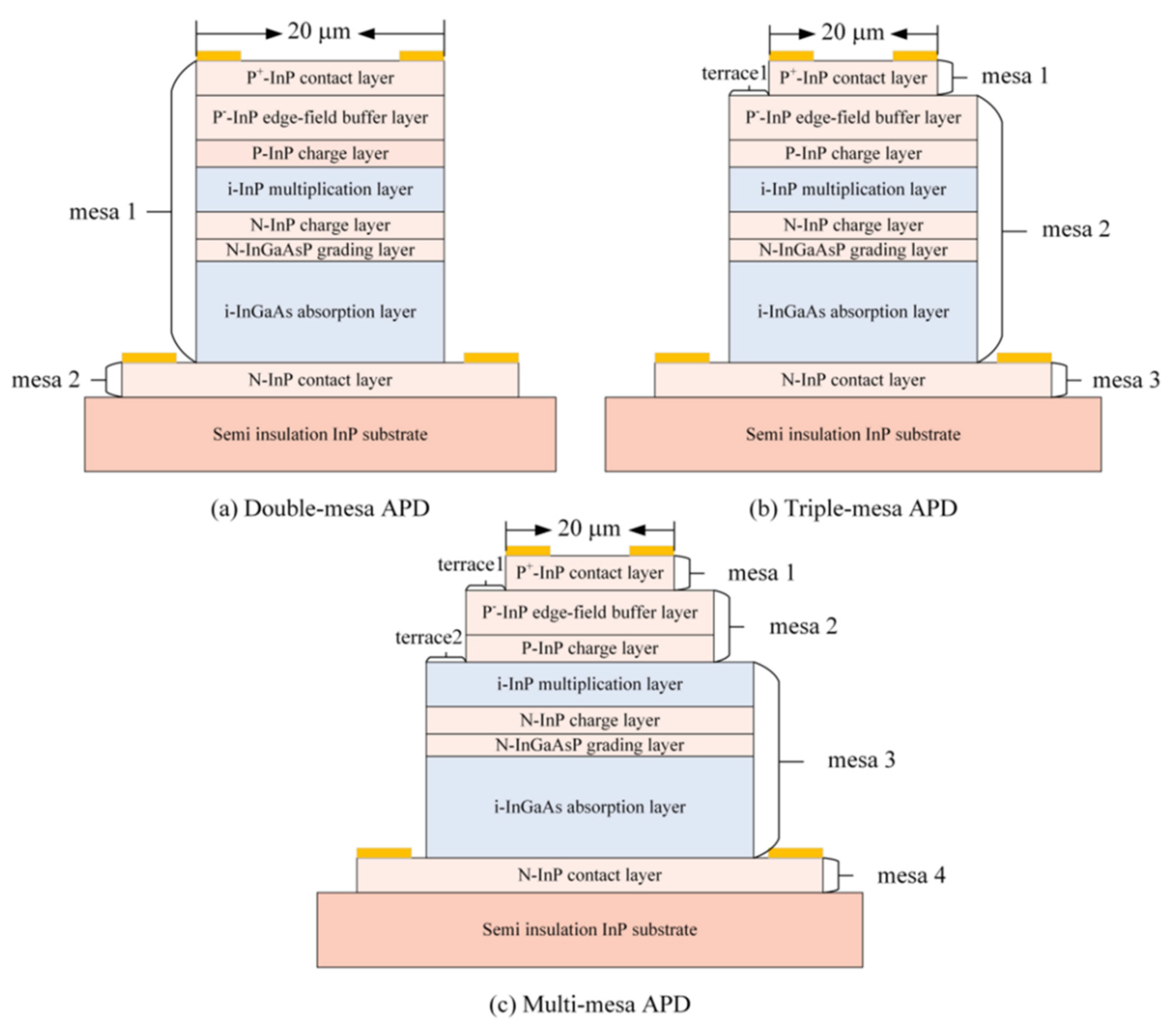

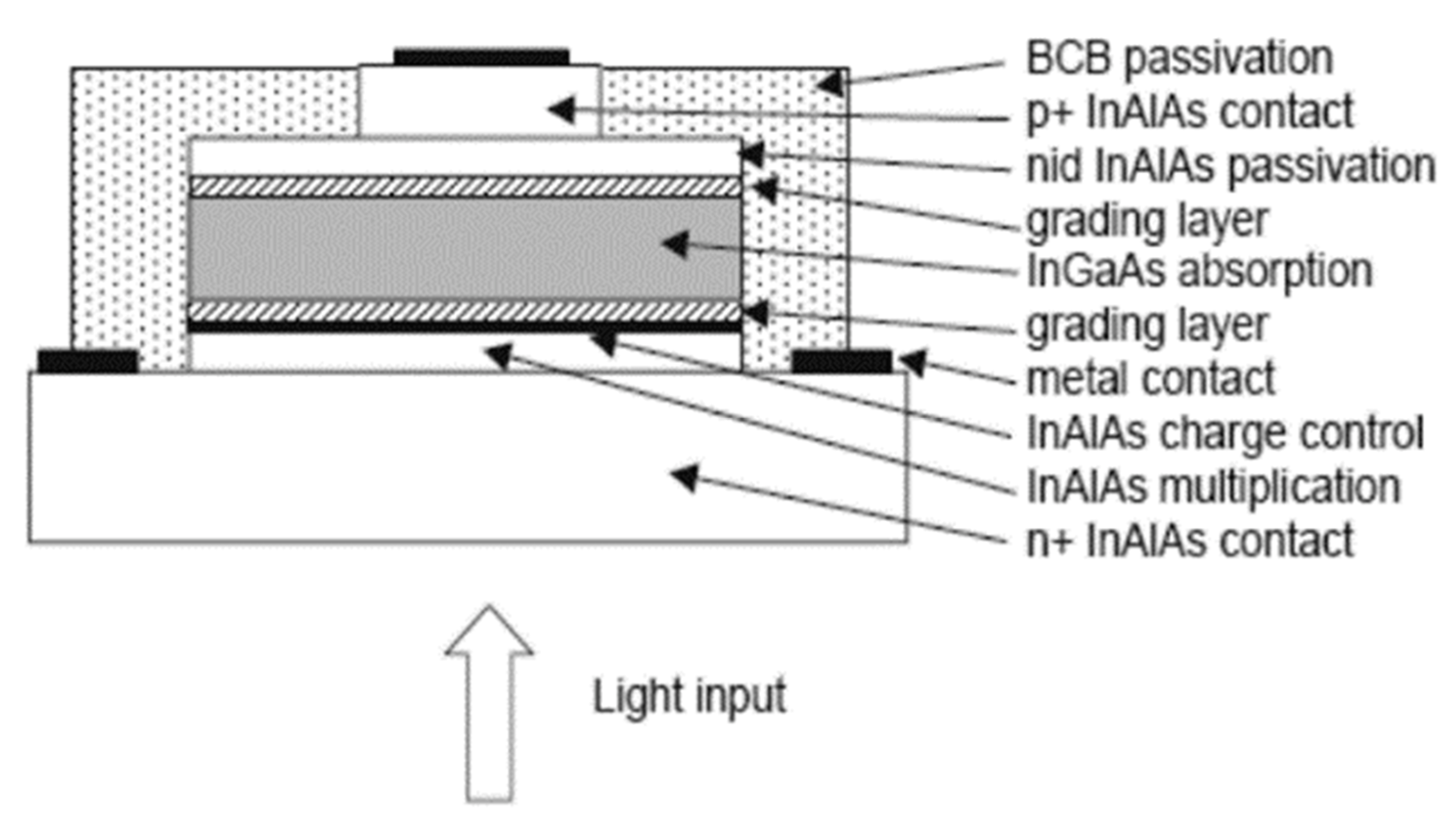

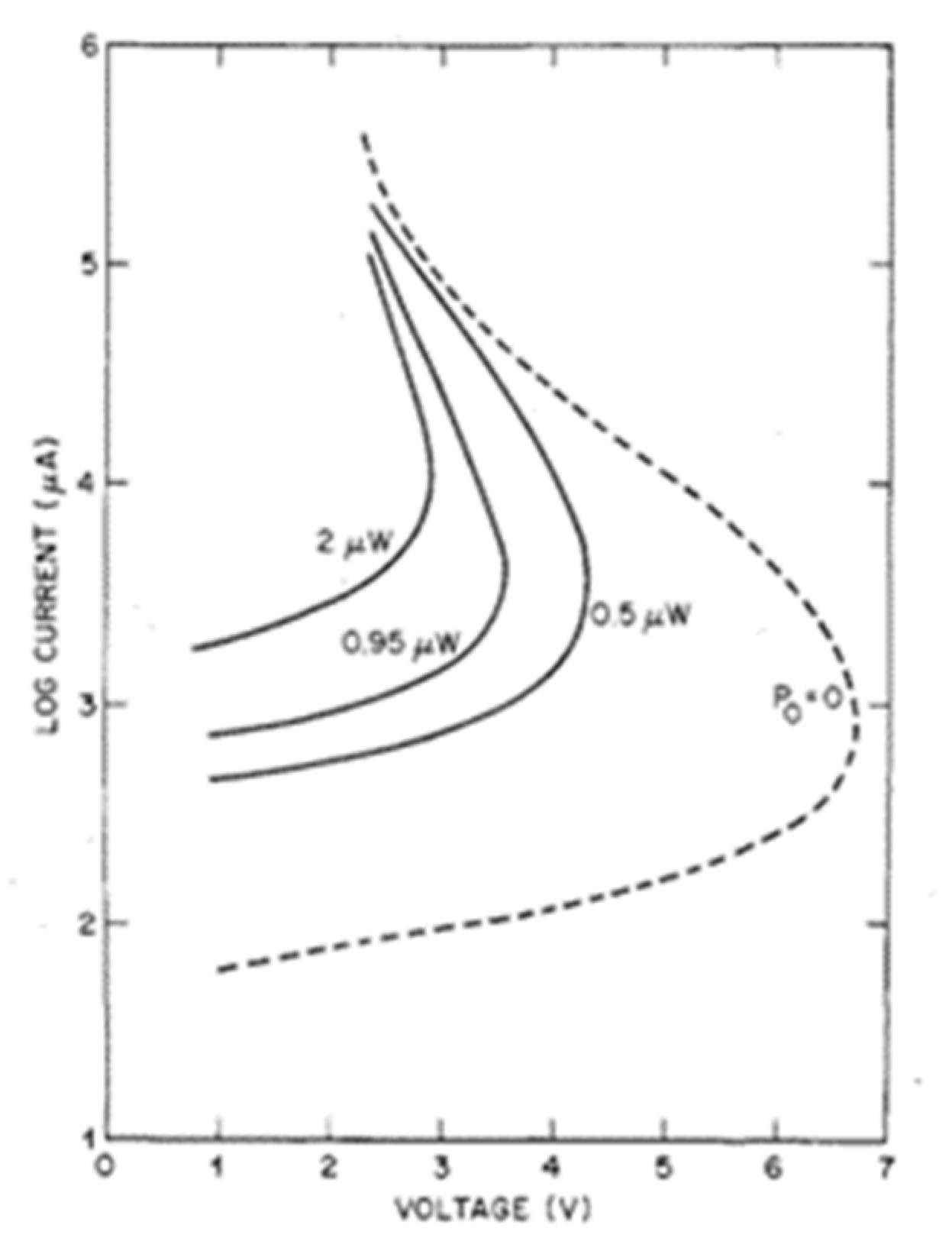

2.3.2. Mesa Geometry InGaAs/InP and InGaAs/InAlAs APDs

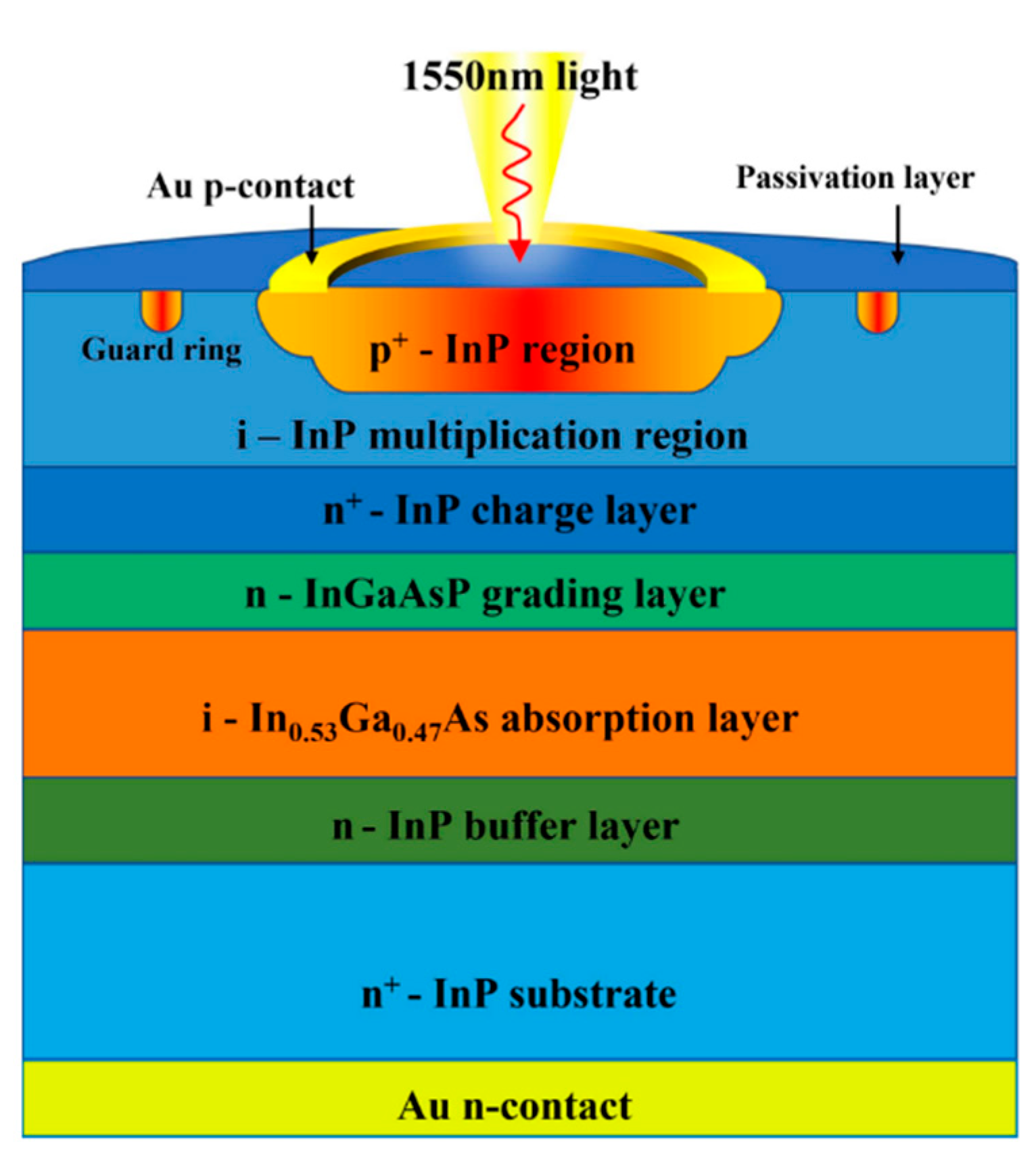

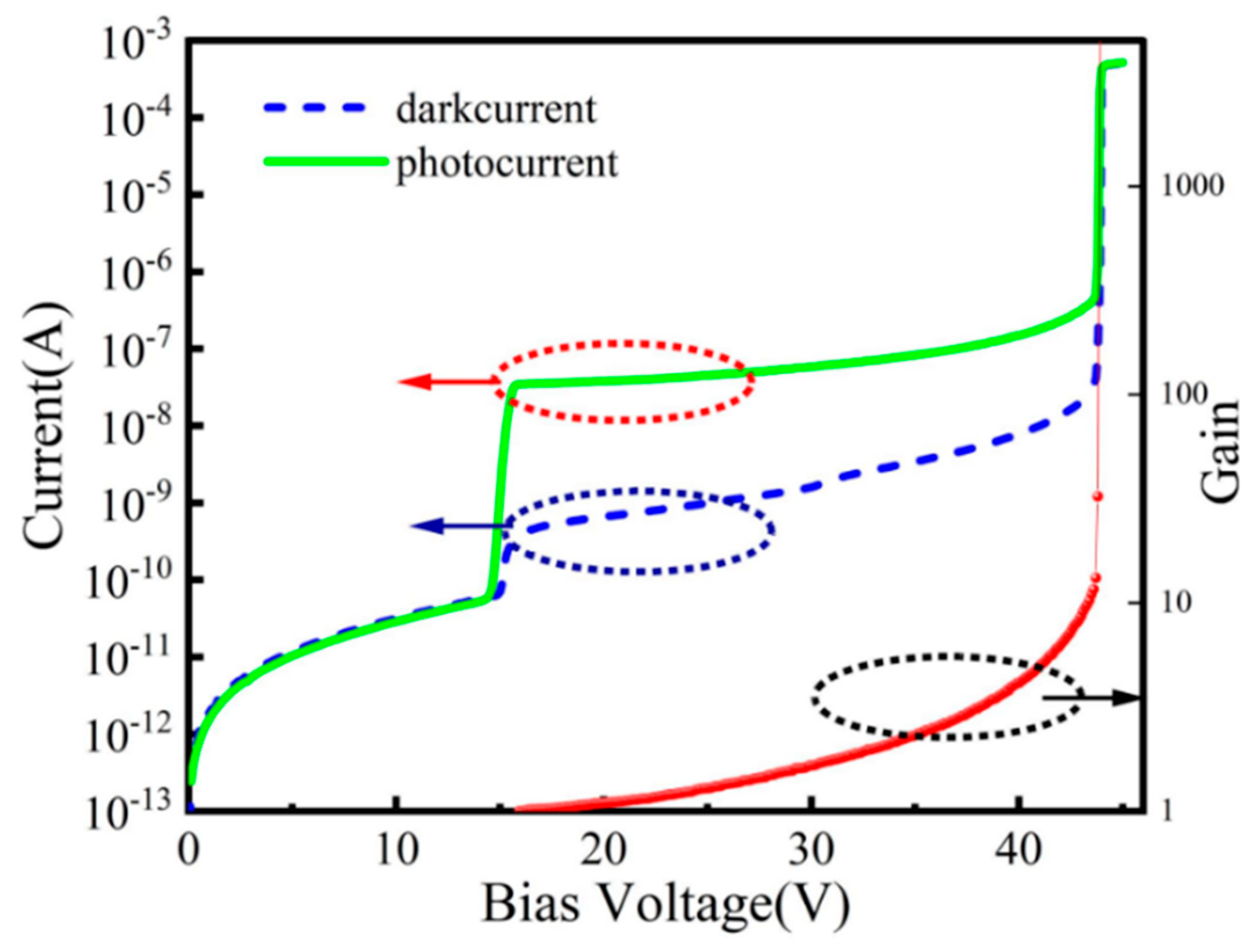

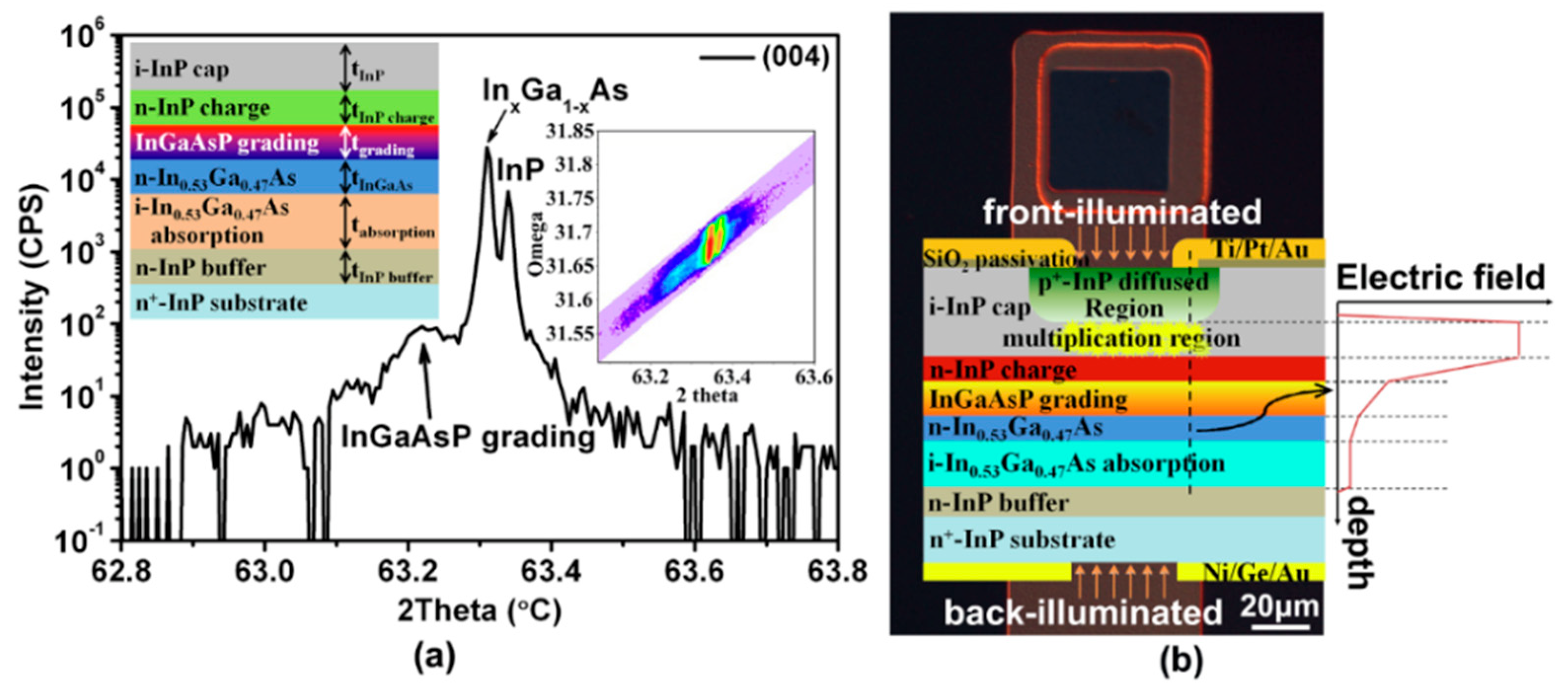

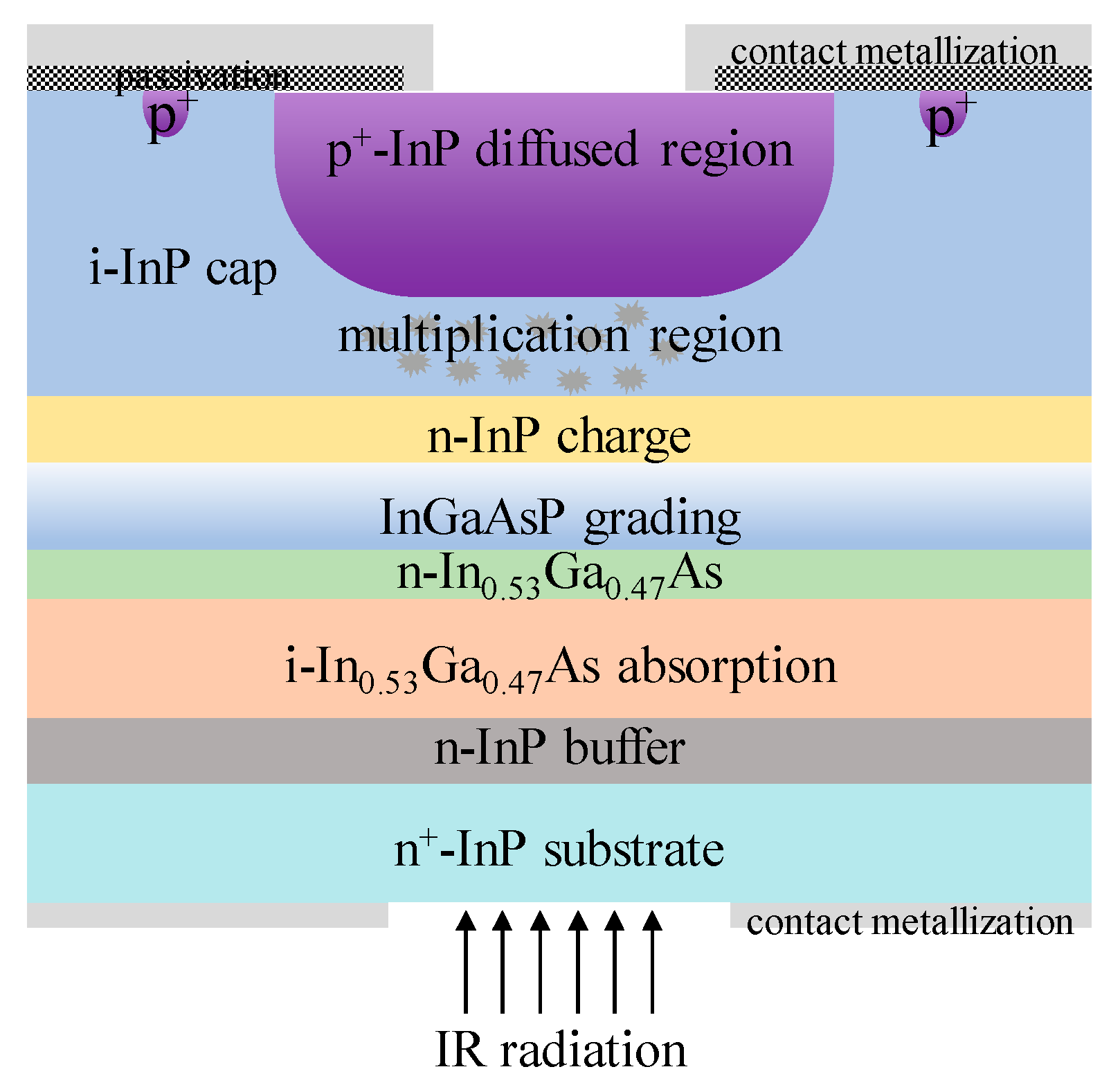

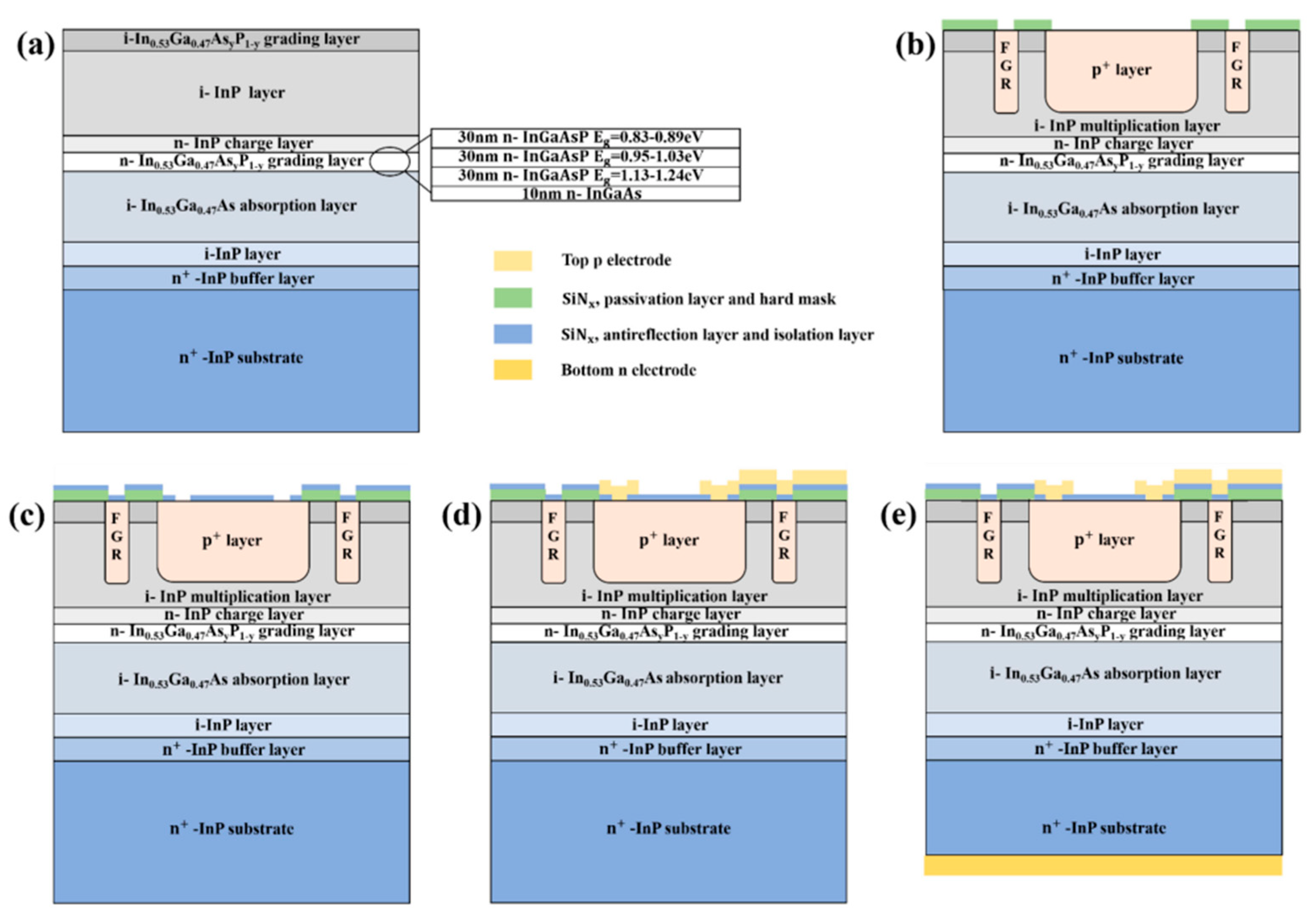

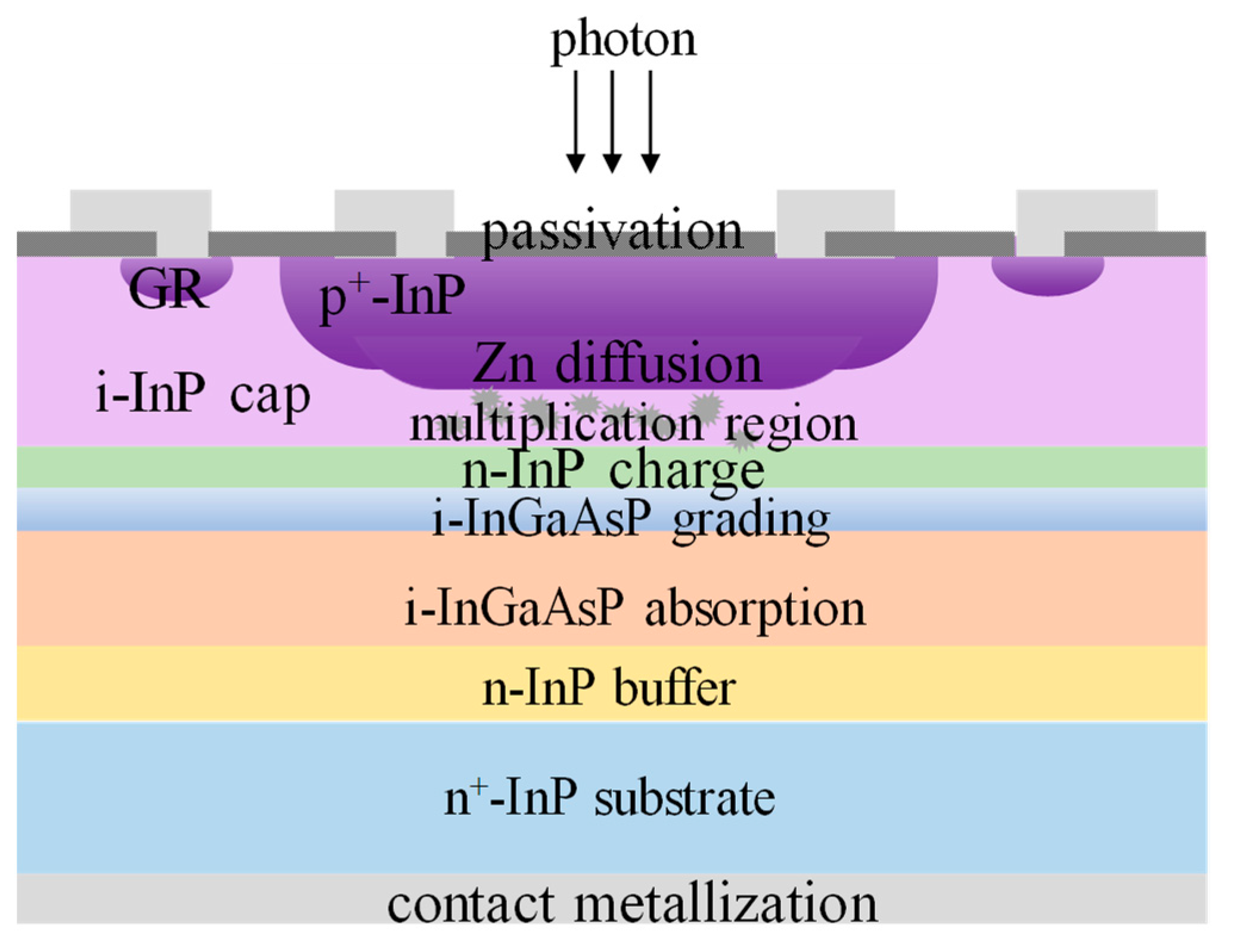

2.3.3. Planar Geometry InGaAs/InP and InGaAs/InAlAs APDs

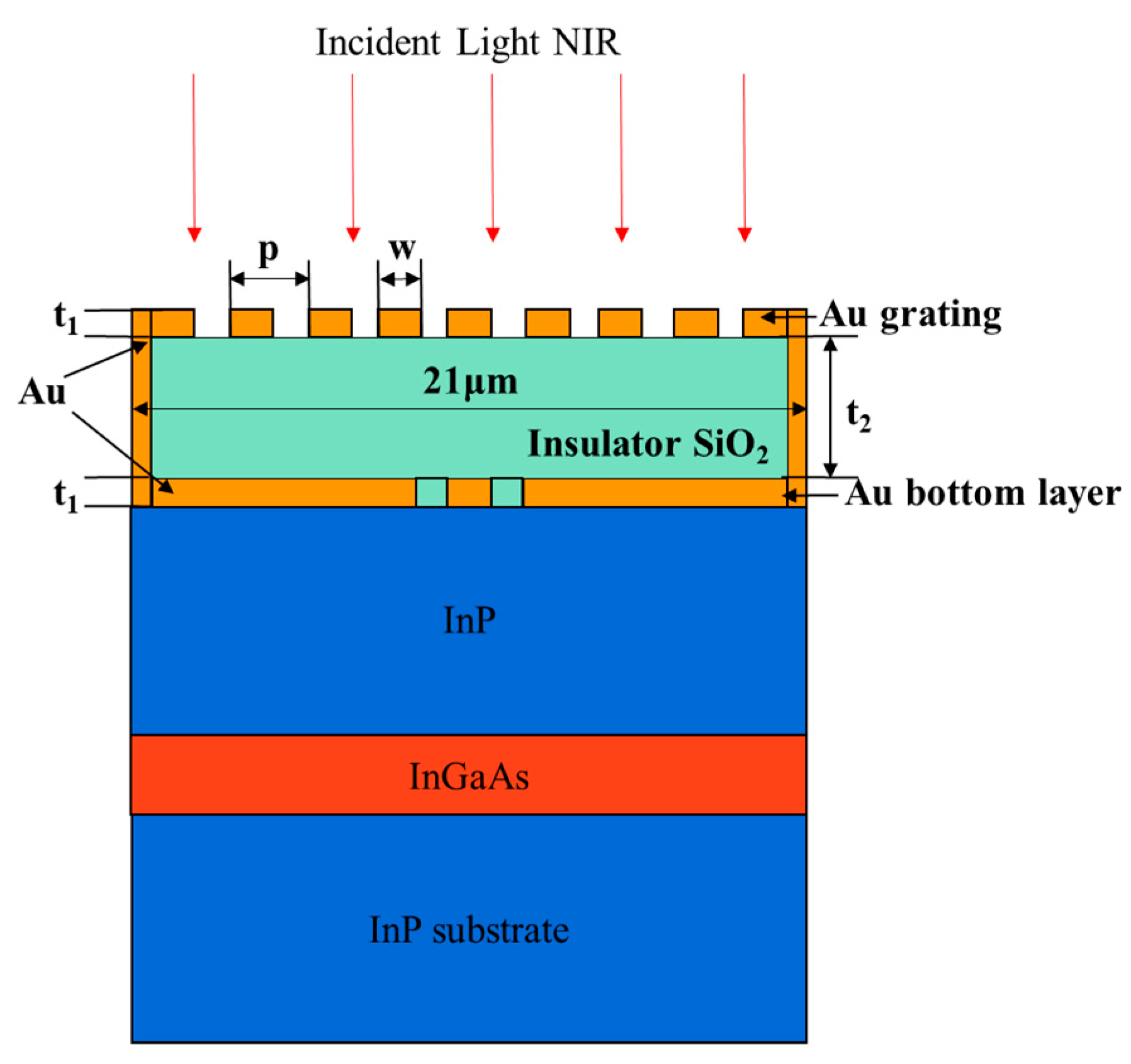

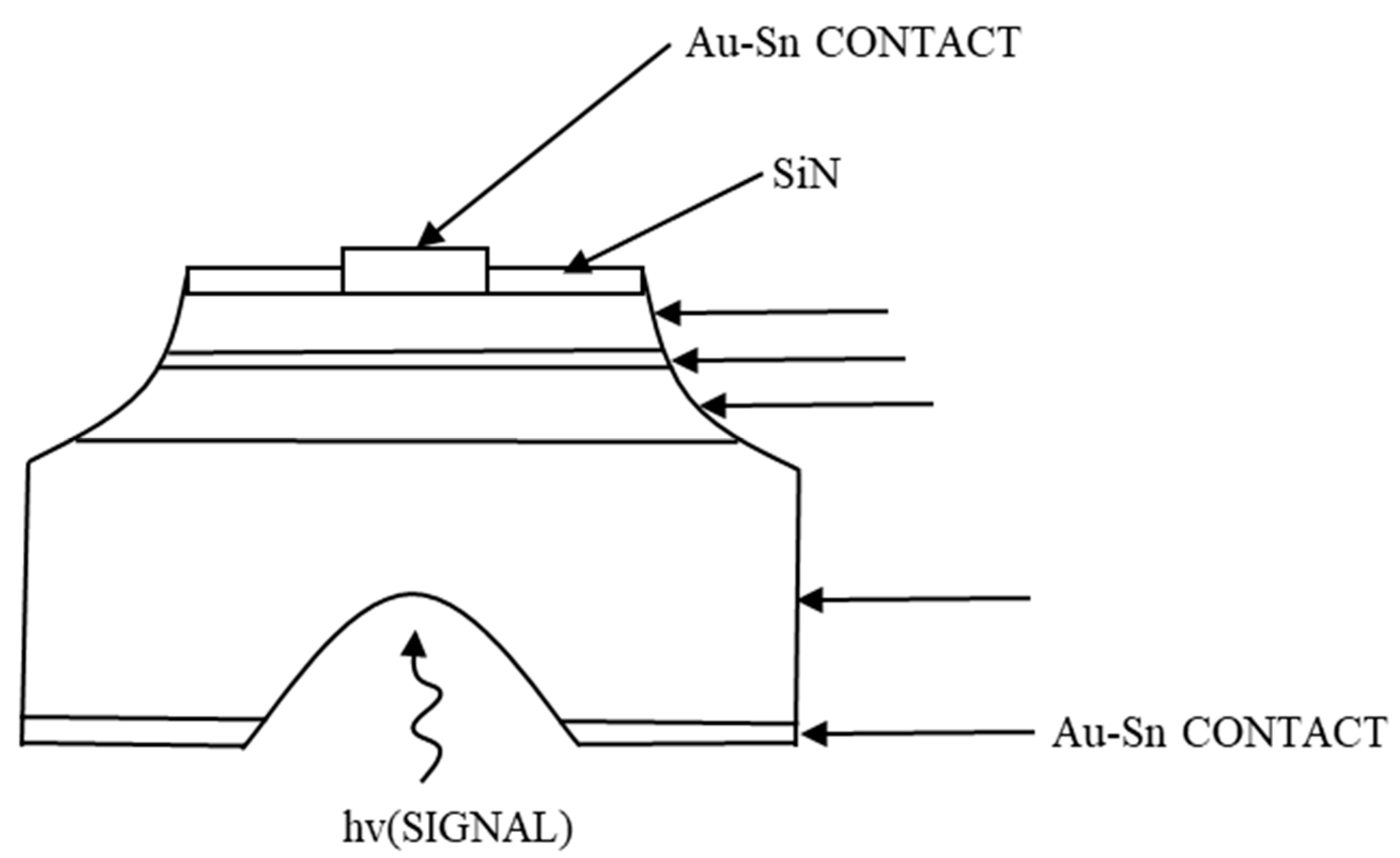

2.3.4. Other Novel InGaAs Avalanche Device Structures

3. SWIR APDs Focal Plane Arrays (FPAs)

3.1. Ge/Si APDs FPAs

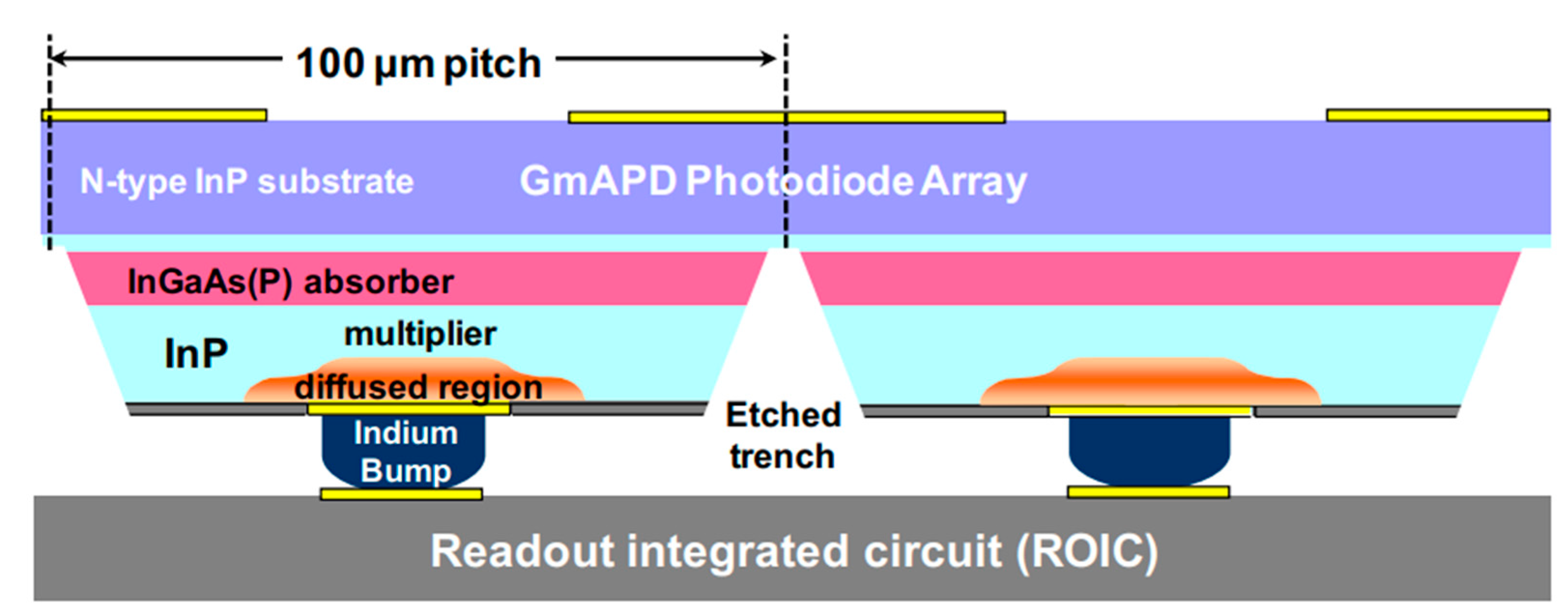

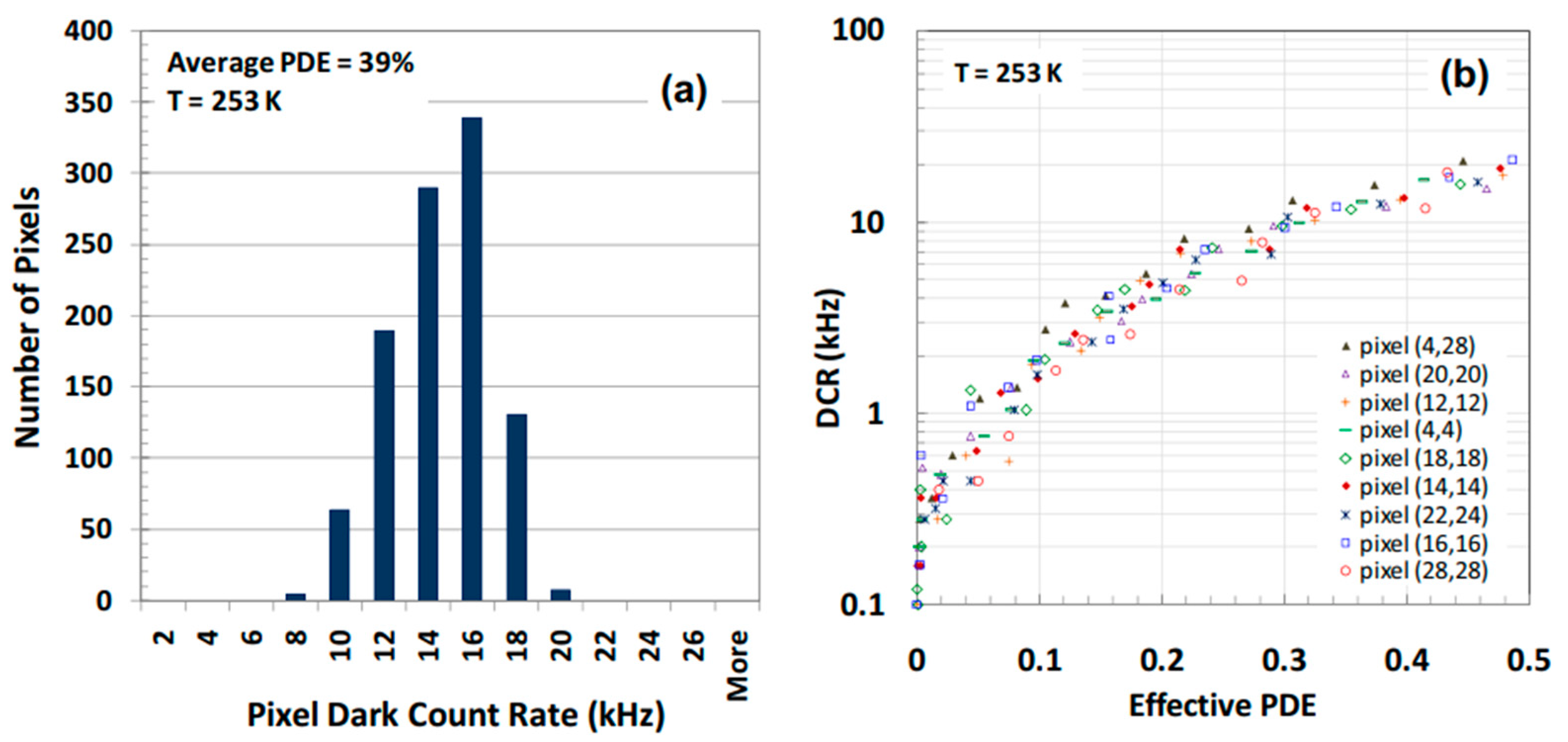

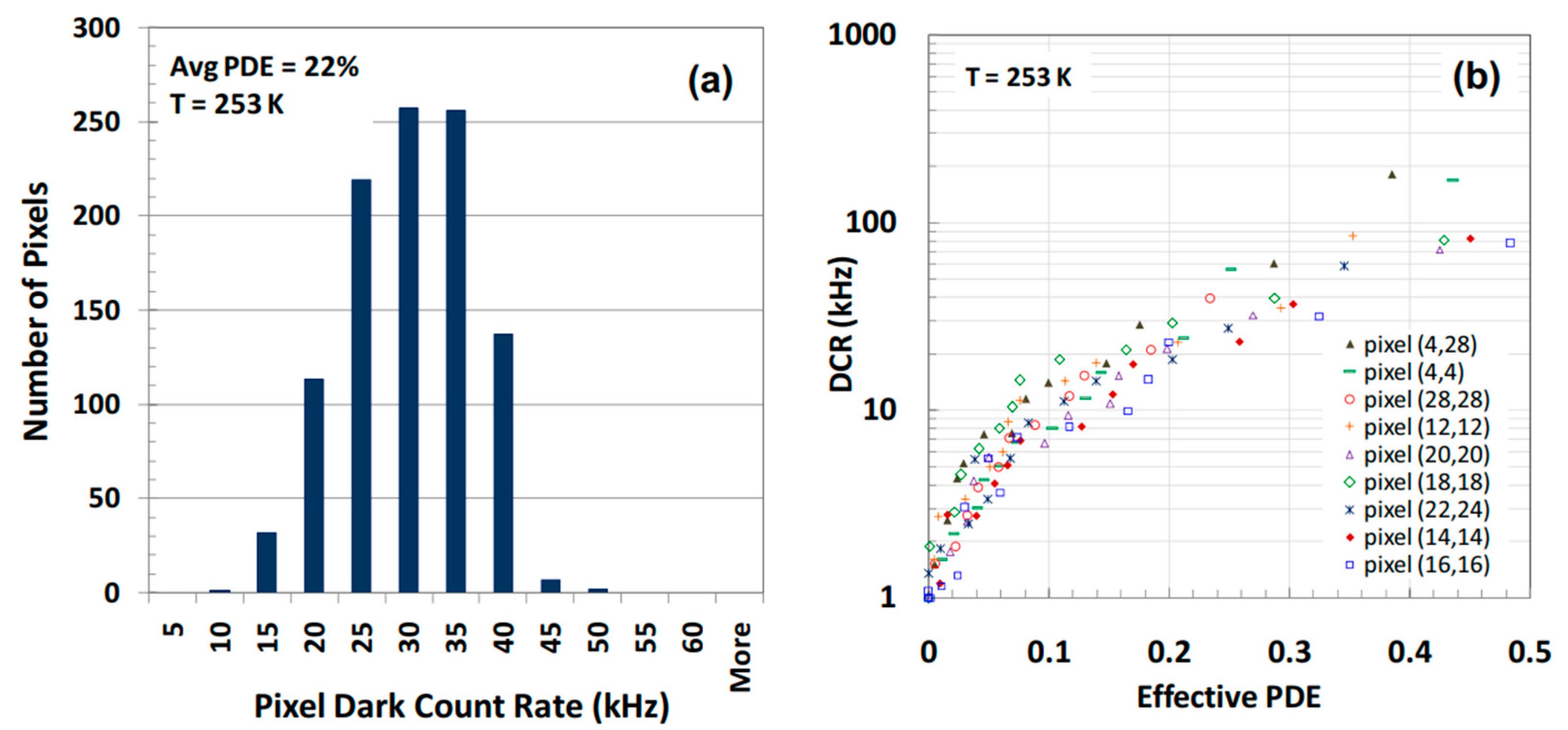

3.2. InGaAs APDs FPAs

3.3. Challenges

3.3.1. Challenges for Ge(GeSn)/Si APDs

3.3.2. Challenges for InGaAs/InP APDs and InGaAs/InAlAs APDs

4. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moeen, M.; Kolahdouz, M.; Salemi, A.; Abedin, A.; Östling, M.; Radamson, H.H. Improved designs of Si-based quantum wells and Schottky diodes for IR detection. Thin Solid Films 2016, 613, 19–23. [Google Scholar] [CrossRef]

- Conley, B.R.; Margetis, J.; Du, W.; Tran, H.; Mosleh, A.; Ghetmiri, S.A.; Tolle, J.; Soref, R.; Li, B.; Naseem, H.; et al. Si based GeSn photoconductors with a 1.63 A/W peak responsivity and a 2.4 μm long-wavelength cutoff. Appl. Phys. Lett. 2014, 105, 221117. [Google Scholar] [CrossRef]

- Zhao, X.; Moeen, M.; Toprak, M.S.; Wang, G.; Luo, J.; Ke, X.; Li, Z.; Liu, D.; Wang, W.; Zhao, C.; et al. Design impact on the performance of Ge PIN photodetectors. J. Mater. Sci. Mat. Electron. 2020, 31, 18–25. [Google Scholar] [CrossRef]

- Dong, L.; Yu, J.; Jia, R.; Hu, J.; Zhang, Y.; Sun, J. Self-powered MSM deep-ultraviolet β-Ga2O3 photodetector realized by an asymmetrical pair of Schottky contacts. Opt. Mater. Exp. 2019, 9, 1191–1199. [Google Scholar] [CrossRef]

- Kumar, H.; Basu, R. Effect of defects on the performance of Si-based GeSn/Ge mid-infrared phototransistors. IEEE Sens. J. 2020, 21, 5975–5982. [Google Scholar] [CrossRef]

- Chen, B.; Wan, Y.; Xie, Z.; Huang, J.; Zhang, N.; Shang, C.; Norman, J.; Li, Q.; Tong, Y.; Lau, K.; et al. Low dark current high gain InAs quantum dot avalanche photodiodes monolithically grown on Si. ACS Photonics 2020, 7, 528–533. [Google Scholar] [CrossRef]

- Craig, A.P.; Jain, M.; Meriggi, L.; Cann, T.; Niblett, A.; Collins, X.; Marshall, A.R.J. Extended short-wave infrared linear and Geiger mode avalanche photodiodes, based on 6.1 Å materials. Appl. Phys. Lett. 2019, 114, 053501. [Google Scholar] [CrossRef]

- Chapman, D.C.; Vineis, C.J.; Oakley, D.C.; Napoleone, A.; Smith, G.M.; Duerr, E.K.; Jensen, K.E.; Donnelly, J.P.; McIntosh, K.A.; Verghese, S. Growth and characterization of GaInAsP/InP-based Geiger-mode avalanche photodiodes. J. Cryst. Growth 2008, 310, 2365–2369. [Google Scholar] [CrossRef]

- Marshall, A.R. The InAs Electron Avalanche Photodiode. In Advances in Photodiodes; IntechOpen: London, UK, 2011. [Google Scholar]

- Manis-Levy, H.; Shikler, R.; Golan, Y.; Sarusi, G. High photoconductive gain in a GaAs/PbS heterojunction based SWIR detector. Appl. Phys. Lett. 2020, 117, 081107. [Google Scholar] [CrossRef]

- Pandey, A.K.; Basu, R.; Chang, G.E. Optimized Ge1−xSnx/Ge Multiple-Quantum-Well Heterojunction Phototransistors for High-Performance SWIR Photodetection. IEEE Sens. J. 2018, 18, 5842–5852. [Google Scholar] [CrossRef]

- Chen, B.; Jiang, W.; Yuan, J.; Holmes, A.L.; Onat, B.M. SWIR/MWIR InP-based pin photodiodes with InGaAs/GaAsSb type-II quantum wells. IEEE J. Sel. Top. Quantum Electron. 2011, 47, 1244–1250. [Google Scholar] [CrossRef]

- Iiyama, K.; Takamatsu, H.; Maruyama, T. Hole-Injection-Type and Electron-Injection-Type Silicon Avalanche Photodiodes Fabricated by Standard 0.18-μm CMOS Process. IEEE Photonics Technol. Lett. 2010, 22, 932–934. [Google Scholar] [CrossRef]

- Baron, A.Q.; Kishimoto, S.; Morse, J.; Rigal, J.M. Silicon avalanche photodiodes for direct detection of X-rays. J. Synch. Radiat. 2006, 13, 131–142. [Google Scholar] [CrossRef]

- Menkara, H.M.; Wagner, B.K.; Summers, C.J. Gain properties of doped GaAs/AlGaAs multiple quantum well avalanche photodiode structures. Appl. Phys. Lett. 1995, 66, 1764–1766. [Google Scholar] [CrossRef]

- Saleh, M.A.; Hayat, M.M.; Saleh, B.E.; Teich, M.C. Dead-space-based theory correctly predicts excess noise factor for thin GaAs and AlGaAs avalanche photodiodes. IEEE Trans. Electron. Devices 2000, 47, 625–633. [Google Scholar] [CrossRef]

- Ribordy, G.; Gisin, N.; Guinnard, O.; Stuck, D.; Wegmuller, M.; Zbinden, H. Photon counting at telecom wavelengths with commercial InGaAs/InP avalanche photodiodes: Current performance. J. Modern Opt. 2004, 51, 1381–1398. [Google Scholar]

- Jung, J.; Kwon, Y.H.; Hyun, K.S.; Yun, I. Reliability of planar InP-InGaAs avalanche photodiodes with recess etching. IEEE Photonics Technol. Lett. 2002, 14, 1160–1162. [Google Scholar] [CrossRef]

- Sandall, I.C.; Zhang, S.; Tan, C.H. Linear array of InAs APDs operating at 2 µm. Opt. Express 2013, 21, 25780–25787. [Google Scholar] [CrossRef]

- Alimi, Y.; Pusino, V.; Steer, M.J.; Cumming, D.R.S. InSb avalanche photodiodes on GaAs substrates for mid-infrared detection. IEEE Trans. Electron. Devices 2019, 67, 179–184. [Google Scholar] [CrossRef]

- Shen, C.; Yang, L.; Guo, H.-J.; Yang, D.; Chen, L.; He, L. Numerical simulation of high-operating-temperature MWIR HgCdTe APD detectors. J. Infrared. Millimeter. Waves. 2021, 40, 576. [Google Scholar]

- Tsybrii, Z.; Bezsmolnyy, Y.; Svezhentsova, K.; Vuichyk, M.; Lysiuk, I.; Apatska, M.; Smolii, M.; Dmytruk, N.; Bunchuk, S.; Andreeva, K.; et al. HgCdTe/CdZnTe LPE epitaxial layers: From material growth to applications in devices. J. Crys. Growth 2020, 529, 125295. [Google Scholar] [CrossRef]

- Shen, G.; Zheng, T.; Li, Z.; Wu, E.; Yang, L.; Tao, Y.; Wang, C.; Wu, G. High-speed airborne single-photon LiDAR with GHz-gated single-photon detector at 1550 nm. Opt. Laser. Technol. 2021, 141, 107109. [Google Scholar] [CrossRef]

- Spuler, S.M.; Mayor, S.D. Scanning eye-safe elastic backscatter lidar at 1.54 μ m. J. Atmospheric. Oceanic. Tech. 2005, 22, 696–703. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, G.; Lin, H.; Du, Y.; Luo, X.; Kong, Z.; Su, J.; Li, J.; Xiong, W.; Miao, Y.; et al. High performance pin photodetectors on Ge-on-insulator platform. Nanomaterials 2021, 11, 1125. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, G.; Kong, Z.; Xu, B.; Zhao, X.; Luo, X.; Lin, H.; Dong, Y.; Lu, B.; Dong, L.; et al. Review of Si-Based GeSn CVD Growth and Optoelectronic Applications. Nanomaterials 2021, 11, 2556. [Google Scholar] [CrossRef]

- Mathews, J.; Roucka, R.; Xie, J.; Yu, S.Q.; Menéndez, J.; Kouvetakis, J. Extended performance GeSn/Si (100) p-i-n photodetectors for full spectral range telecommunication applications. Appl. Phys. Lett. 2009, 95, 133506. [Google Scholar] [CrossRef]

- Tran, H.; Pham, T.; Du, W.; Zhang, Y.; Grant, P.C.; Grant, J.M.; Sun, G.; Soref, R.; Margetis, J.; Yu, S.Q.; et al. High performance Ge0. 89Sn0. 11 photodiodes for low-cost shortwave infrared imaging. J. Appl. Phys. 2018, 124, 013101. [Google Scholar] [CrossRef]

- Tran, H.; Pham, T.; Margetis, J.; Zhou, Y.; Dou, W.; Grant, P.C.; Grant, J.M.; Al-Kabi, S.; Sun, G.; Soref, R.A.; et al. Si-based GeSn photodetectors toward mid-infrared imaging applications. ACS Photonics 2019, 6, 2807–2815. [Google Scholar] [CrossRef]

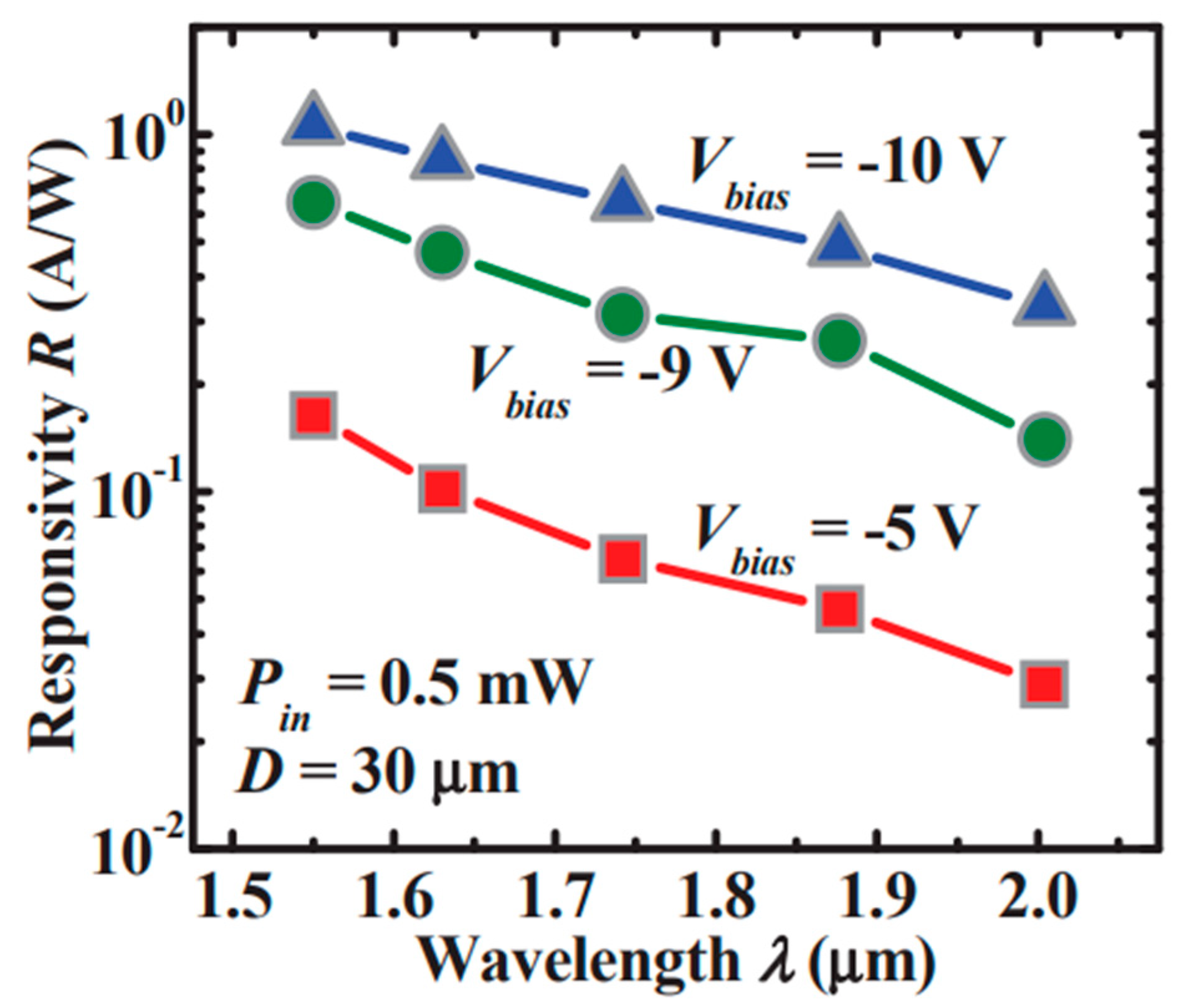

- Zhou, H.; Xu, S.; Wu, S.; Huang, Y.C.; Zhao, P.; Tong, J.; Son, B.; Guo, X.; Zhang, D.; Gong, X.; et al. Photo detection and modulation from 1,550 to 2,000 nm realized by a GeSn/Ge multiple-quantum-well photodiode on a 300-mm Si substrate. Opt. Express 2020, 28, 34772–34786. [Google Scholar] [CrossRef]

- Bowers, J.E.; Ramaswamy, A.; Dai, D.; Zaoui, W.S.; Kang, Y.; Yin, T.; Morse, M. Recent advances in Ge/Si PIN and APD photodetectors. Phys. Status Solidi C 2010, 7, 2526–2531. [Google Scholar] [CrossRef]

- Stokoe, J.C.D.; Putland, P.A.; Sutherland, R.R. A review of reliability evaluation techniques applied to InGaAs PIN photodiodes, Germanium APDs and InGaAs APDs. Qual. Reliab. Eng. Int. 1989, 5, 319–329. [Google Scholar] [CrossRef]

- Liang, Y.; Lin, G.; Su, X.; Zhang, X.; Feng, S.; Xu, Y.; Li, C. A review on III-V compound semiconductor short wave infrared avalanche photodiodes. Nanotechnology 2022, 33, 222003. [Google Scholar] [CrossRef]

- Izhnin, I.I.; Lozovoy, K.A.; Kokhanenko, A.P.; Khomyakova, K.I.; Douhan, R.M.; Dirko, V.V.; Akimenko, N.Y. Single-photon avalanche diode detectors based on group IV materials. Appl. Nano 2022, 12, 253–263. [Google Scholar] [CrossRef]

- Xie, S. Design and Characterisation of InGaAs High Speed Photodiodes, InGaAs/InAlAs Avalanche Photodiodes and Novel AlAsSb Based Avalanche Photodiodes. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2012. [Google Scholar]

- Huang, M.; Li, S.; Cai, P.; Hou, G.; Su, T.I.; Chen, W.; Pan, D. Germanium on silicon avalanche photodiode. IEEE J. Sel. Top. Quantum Electron. 2017, 24, 1–11. [Google Scholar] [CrossRef]

- Xiang, J.; Zhao, Y. Comparison of waveguide avalanche photodiodes with InP and InAlAs multiplication layer for 25 Gb/s operation. Opt. Eng. 2014, 53, 046106. [Google Scholar] [CrossRef]

- Cai, H.; Qian, K.; An, Y.; Lin, G.; Wu, S.; Ding, H.; Huang, W.; Chen, Y.; Wang, Y.; Li, C. Thickness-dependent behavior of strain relaxation and Sn segregation of GeSn epilayer during rapid thermal annealing. J. Alloys Compd. 2022, 904, 164068. [Google Scholar] [CrossRef]

- Ni, W.X.; Ekberg, J.O.; Joelsson, K.B.; Radamson, H.H.; Henry, A.; Shen, G.D.; Hansson, G.V. A silicon molecular beam epitaxy system dedicated to device-oriented material research. J. Crys. Growth 1995, 157, 285–294. [Google Scholar] [CrossRef]

- Gurdal, O.; Hasan, M.A.; Sardela, M.R., Jr.; Greene, J.E.; Radamson, H.H.; Sundgren, J.E.; Hansson, G.V. Growth of metastable Ge1−xSnx/Ge strained layer superlattices on Ge (001) 2×1 by temperature-modulated molecular beam epitaxy. Appl. Phy. Lett. 1995, 67, 956–958. [Google Scholar] [CrossRef]

- Wan, F.; Xu, C.; Wang, X.; Xu, G.; Cheng, B.; Xue, C. Study of strain evolution mechanism in Ge1−xSnx materials grown by low temperature molecular beam epitaxy. J. Crys. Growth. 2022, 577, 126399. [Google Scholar] [CrossRef]

- Yang, J.; Hu, H.; Miao, Y.; Dong, L.; Wang, B.; Wang, W.; Su, H.; Xuan, R.; Zhang, H. High-quality GeSn Layer with Sn Composition up to 7% Grown by Low-Temperature Magnetron Sputtering for Optoelectronic Application. Materials 2019, 12, 2662. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, Z.; Zhang, Y.; Zuo, Y.; Li, C.; Xue, C.; Cheng, B.; Wang, Q. Growth of high-Sn content (28%) GeSn alloy films by sputtering epitaxy. J. Crys. Growth 2018, 492, 29–34. [Google Scholar] [CrossRef]

- Radamson, H.H.; Noroozi, M.; Jamshidi, A.; Thompson, P.E.; Östling, M. Strain engineering in GeSnSi materials. ECS Trans. 2013, 50, 527. [Google Scholar] [CrossRef]

- Grant, P.C.; Margetis, J.; Zhou, Y.; Dou, W.; Abernathy, G.; Kuchuk, A.; Du, W.; Li, B.L.; Tolle, J.; Yu, S.Q.; et al. Direct bandgap type-I GeSn/GeSn quantum well on a GeSn-and Ge-buffered Si substrate. AIP Adv. 2018, 8, 025104. [Google Scholar] [CrossRef]

- Polak, M.P.; Scharoch, P.; Kudrawiec, R. The electronic band structure of Ge1−xSnx in the full composition range: Indirect, direct, and inverted gaps regimes, band offsets, and the Burstein–Moss effect. J. Phys. D: Appl. Phys. 2017, 50, 195103. [Google Scholar] [CrossRef]

- Cohen, M.L.; Chelikowsky, J.R. Electronic Structure and Optical Properties of Semiconductors; Springer Science Business Media: Berlin, Germany, 2012; Volume 75. [Google Scholar]

- Jenkins, D.W.; Dow, J.D. Electronic properties of metastable GexSn1−x alloys. Phys. Rev. B 1987, 36, 7994. [Google Scholar] [CrossRef]

- Mäder, K.A.; Baldereschi, A.; Von Känel, H. Band structure and instability of Ge1−xSnx alloys. Solid State Commun. 1989, 69, 1123–1126. [Google Scholar] [CrossRef]

- Pandey, R.; Rérat, M.; Causa, M. First-principles study of stability, band structure, and optical properties of the ordered Ge0.50Sn0.50 alloy. Appl. Phys. Lett. 1999, 75, 4127–4129. [Google Scholar] [CrossRef]

- Moontragoon, P.; Ikonić, Z.; Harrison, P. Band structure calculations of Si–Ge–Sn alloys: Achieving direct band gap materials. Semi. Sci. Tech. 2007, 22, 742. [Google Scholar] [CrossRef]

- Yin, W.J.; Gong, X.G.; Wei, S.H. Origin of the unusually large band-gap bowing and the breakdown of the band-edge distribution rule in the SnxGe1−x alloys. Phys. Rev. B 2008, 78, 161203. [Google Scholar] [CrossRef]

- Gupta, S.; Chen, R.; Magyari-Kope, B.; Lin, H.; Yang, B.; Nainani, A.; Nishi, Y.; Harris, J.; Saraswat, K.C. GeSn technology: Extending the Ge electronics roadmap. In Proceedings of the 2011 International Electron Devices Meeting, IEEE Conference, Washington, DC, USA, 5–7 December 2011; p. 16-6. [Google Scholar]

- Lu Low, K.; Yang, Y.; Han, G.; Fan, W.; Yeo, Y.C. Electronic band structure and effective mass parameters of Ge1−xSnx alloys. J. Appl. Phys. 2012, 112, 103715. [Google Scholar] [CrossRef]

- Zhang, X.; Ying, C.; Li, Z.; Shi, G. First-principles calculations of structural stability, elastic, dynamical and thermodynamic properties of SiGe, SiSn, GeSn. Superlattices Microstruct. 2012, 52, 459–469. [Google Scholar] [CrossRef]

- Gupta, S.; Magyari-Köpe, B.; Nishi, Y.; Saraswat, K.C. Achieving direct band gap in germanium through integration of Sn alloying and external strain. J. Appl. Phys. 2013, 113, 073707. [Google Scholar] [CrossRef]

- Sant, S.; Schenk, A. Pseudopotential calculations of strained-GeSn/SiGeSn hetero-structures. Appl. Phys. Lett. 2014, 105, 162101. [Google Scholar] [CrossRef]

- Huang, W.; Cheng, B.; Xue, C.; Liu, Z. Comparative studies of band structures for biaxial (100)-,(110)-, and (111)-strained GeSn: A first-principles calculation with GGA+ U approach. J. Appl. Phys. 2015, 118, 165704. [Google Scholar] [CrossRef]

- Kirwan, A.C.; O’Halloran, E.; Broderick, C.A.; Schulz, S.; O’Reilly, E.P. Towards Direct Gap Emission in GeSn and GeC: A Hybrid Functional DFT Analysis. In Proceedings of the 2018 IEEE 18th International Conference on Nanotechnology (IEEE-NANO), IEEE Conference, Cork, Ireland, 23–26 July 2018; pp. 1–2. [Google Scholar]

- Liu, S.Q.; Yen, S.T. Extraction of eight-band k⋅p parameters from empirical pseudopotentials for GeSn. J. Appl. Phys. 2019, 125, 245701. [Google Scholar] [CrossRef]

- Song, Z.; Fan, W.; Tan, C.S.; Wang, Q.; Nam, D.; Zhang, D.H.; Sun, G. Band structure of Ge1−xSnx alloy: A full-zone 30-band k· p model. New J. Phys. 2019, 21, 073037. [Google Scholar] [CrossRef]

- Cao, B.; Chen, S.; Jin, X.; Liu, J.; Li, T. Short-range order in GeSn alloy. ACS Appl. Mater. Inter. 2020, 12, 57245–57253. [Google Scholar] [CrossRef]

- Zhao, C.Z.; Sun, S.Y.; Zhu, M.M.; Guo, Y. First-principle calculation of the band structure of Ge1−xSnx alloy by screened-exchange local-density approximation theory. Appl. Phys. A 2020, 126, 131. [Google Scholar] [CrossRef]

- O’Donnell, C.; Sanchez-Soares, A.; Broderick, C.A.; Greer, J.C. Impact of stoichiometry and strain on Ge1−xSnx alloys from first principles calculations. J. Phys. D Appl. Phys. 2021, 54, 245103. [Google Scholar] [CrossRef]

- Xu, S. Germanium-Tin Photo Detectors for Applications in the Two Micron Wavelength Range. Ph.D. Thesis, National University of Singapore, Singapore, 2019. [Google Scholar]

- Kang, Y.; Zadka, M.; Litski, S.; Sarid, G.; Morse, M.; Paniccia, M.J.; Kuo, Y.H.; Bowers, J.; Beling, A.; Liu, H.D.; et al. Epitaxially-grown Ge/Si avalanche photodiodes for 1.3 µm light detection. Opt. Express 2008, 16, 9365–9371. [Google Scholar] [CrossRef]

- Lu, Z.; Kang, Y.; Hu, C.; Zhou, Q.; Liu, H.D.; Campbell, J.C. Geiger-mode operation of Ge-on-Si avalanche photodiodes. IEEE J. Quantum Electron. 2011, 47, 731–735. [Google Scholar] [CrossRef]

- Warburton, R.E.; Intermite, G.; Myronov, M.; Allred, P.; Leadley, D.R.; Gallacher, K.; Paul, D.J.; Pilgrim, N.J.; Lever, L.J.; Ikonic, Z.; et al. Ge-on-Si single-photon avalanche diode detectors: Design, modeling, fabrication, and characterization at wavelengths 1310 and 1550 nm. IEEE Trans. Electron. Devices 2013, 60, 3807–3813. [Google Scholar] [CrossRef]

- Duan, N.; Liow, T.Y.; Lim, A.E.J.; Ding, L.; Lo, G.Q. 310 GHz gain-bandwidth product Ge/Si avalanche photodetector for 1550 nm light detection. Opt. Express 2012, 20, 11031–11036. [Google Scholar] [CrossRef] [PubMed]

- Kolahdouz, M.; Hållstedt, J.; Khatibi, A.; Östling, M.; Wise, R.; Riley, D.J.; Radamson, H. Comprehensive evaluation and study of pattern dependency behavior in selective epitaxial growth of B-doped SiGe layers. IEEE Trans. Nanotechnol. 2008, 8, 291–297. [Google Scholar] [CrossRef]

- Loo, R.; Wang, G.; Souriau, L.; Lin, J.C.; Takeuchi, S.; Brammertz, G.; Caymax, M. Epitaxial Ge on standard STI patterned Si wafers: High quality virtual substrates for Ge pMOS and III/V nMOS. ECS Trans. 2009, 25, 335. [Google Scholar] [CrossRef]

- Menon, C.; Bentzen, A.; Radamson, H.H. Loading effect in SiGe layers grown by dichlorosilane-and silane-based epitaxy. J. Appl. Phys. 2001, 90, 4805–4809. [Google Scholar] [CrossRef]

- Liu, J.P.; Chew, H.G.; See, A.; Zhou, M.S.; Hsia, L.C. Loading effect of selective epitaxial growth of silicon germanium in submicrometer-scale Silicon (001) windows. Electrochem. Solid-State Lett. 2008, 12, H58. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, W.; Xu, X.; Gong, X.; Lei, D.; Zhou, Q.; Xu, Z.; Loke, W.; Yoon, S.; Liang, G.; et al. Germanium-tin on silicon avalanche photodiode for short-wave infrared imaging. In Proceedings of the 2014 Symposium on VLSI Technology (VLSI-Technology): Digest of Technical Papers, Honolulu, HI, USA, 9–12 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–2. [Google Scholar]

- Dong, Y.; Wang, W.; Lee, S.Y.; Lei, D.; Gong, X.; Loke, W.K.; Yoon, S.; Liang, G.; Yeo, Y.C. Avalanche photodiode featuring Germanium-tin multiple quantum wells on silicon: Extending photodetection to wavelengths of 2 and beyond. In Proceedings of the 2015 IEEE International Electron Devices Meeting (IEDM), IEEE Conference, Washington, DC, USA, 7–9 December 2015; pp. 30–35. [Google Scholar]

- Chen, Q.; Wu, S.; Zhang, L.; Fan, W.; Tan, C.S. Simulation of High-Efficiency Resonant-Cavity-Enhanced GeSn Single-Photon Avalanche Photodiodes for Sensing and Optical Quantum Applications. IEEE Sens. J. 2021, 21, 14789–14798. [Google Scholar] [CrossRef]

- Kuzmenko, K. Semiconductor Photodetectors for Photon-Starved Applications in the Short-Wavelength Infrared Spectral Region. Ph.D. Thesis, Heriot-Watt University, Edinburgh, UK, 2019. [Google Scholar]

- Vines, P.; Kuzmenko, K.; Kirdoda, J.; Dumas, D.; Mirza, M.M.; Millar, R.W.; Paul, D.; Buller, G.S. High performance planar germanium-on-silicon single-photon avalanche diode detectors. Nat. Commun. 2019, 10, 1086. [Google Scholar] [CrossRef]

- Millar, R.W.; Kirdoda, J.; Thorburn, F.; Yi, X.; Greener, Z.M.; Huddleston, L.; Benakaprasad, B.; Watson, S.; Coughlan, C.; Buller, G.; et al. Pseudo-planar Ge-on-Si single photon avalanche diode detector with record low noise-equivalent power. In Proceedings of the Quantum Technology: Driving Commercialisation of an Enabling Science II SPIE Conference, Glasgow, UK, 6 October 2021; Volume 11881, pp. 45–52. [Google Scholar]

- Kolahdouz, M.; Xu, B.; Nasiri, A.F.; Fathollahzadeh, M.; Manian, M.; Aghababa, H.; Radamson, H.H. Carbon-related materials: Graphene and carbon nanotubes in semiconductor applications and design. Micromachines 2022, 13, 1257. [Google Scholar] [CrossRef]

- Radamson, H.H. Graphene. In Springer Handbook of Electronic and Photonic Materials; Springer Handbooks; Kasap, S., Capper, P., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar]

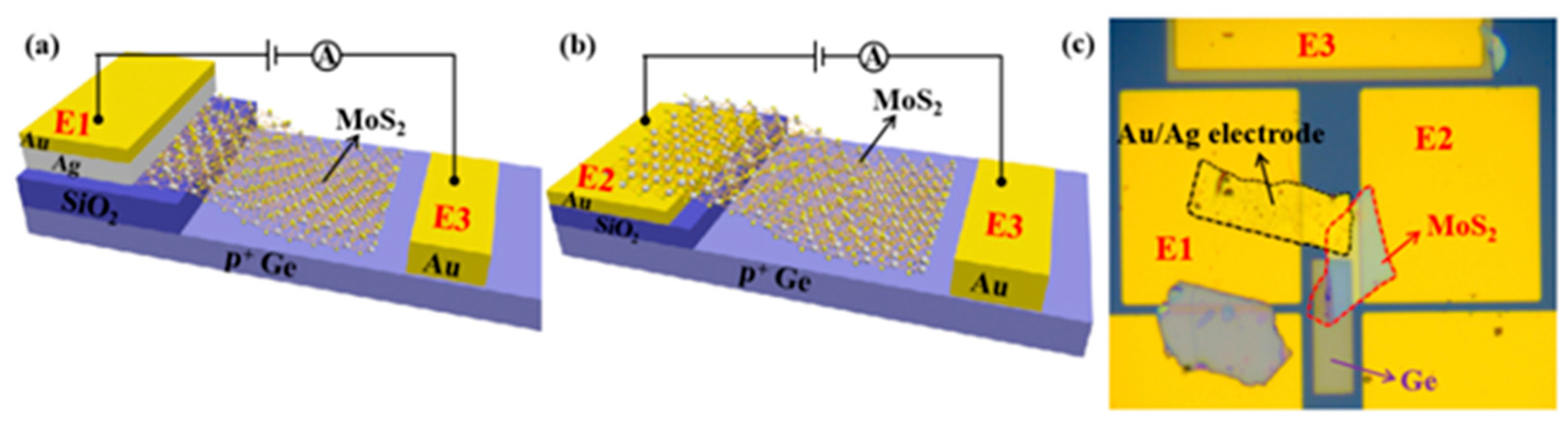

- Yuan, X.; Zhang, N.; Zhang, T.; Meng, L.; Zhang, J.; Shao, J.; Wang, L. Influence of metal-semiconductor junction on the performances of mixed-dimensional MoS2/Ge heterostructure avalanche photodetector. Opt. Express 2022, 30, 20250–20260. [Google Scholar] [CrossRef]

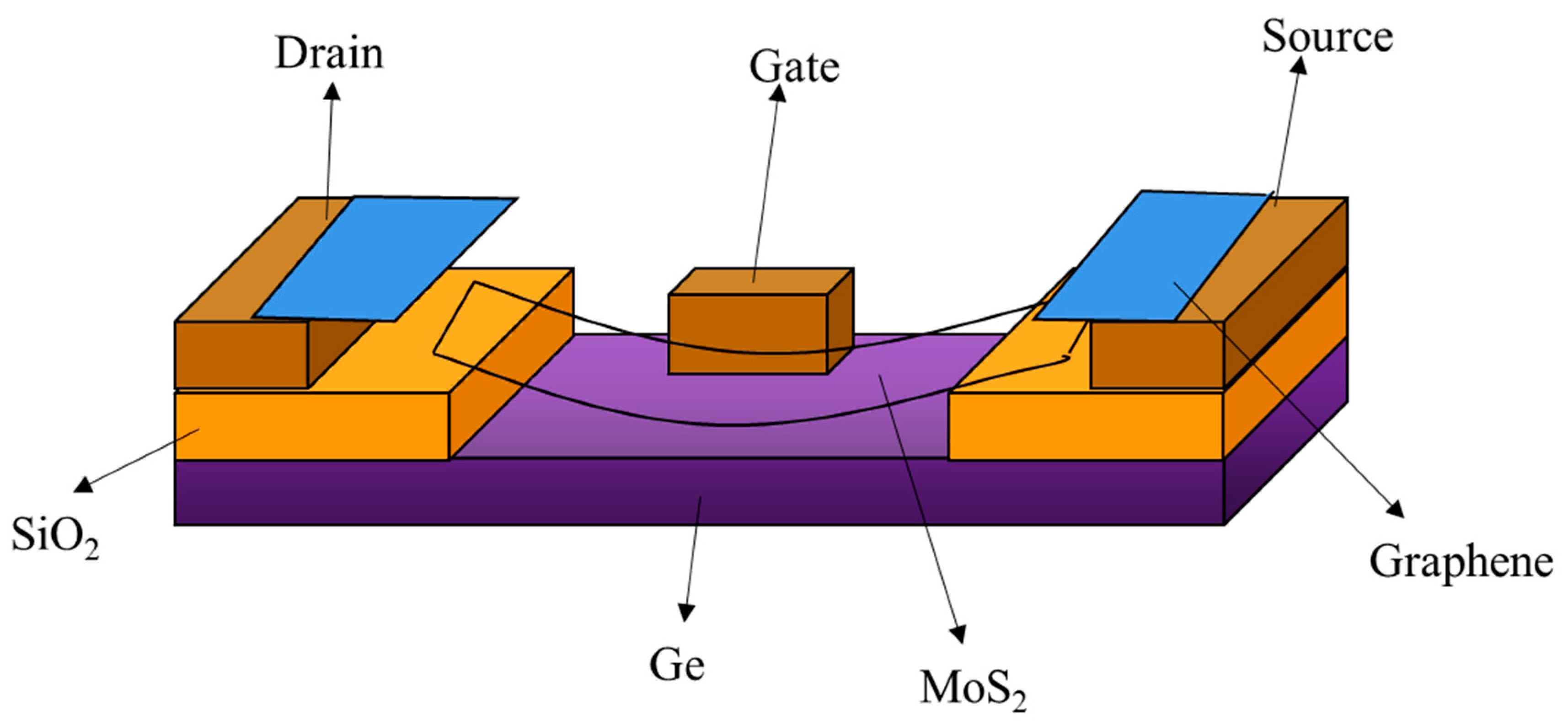

- Wang, B.; Wang, L.; Zhang, Y.; Yang, M.; Lin, D.; Zhang, N.; Hu, H. Mixed-Dimensional MoS2/Ge Heterostructure Junction Field-Effect Transistors for Logic Operation and Photodetection. Adv. Funct. Mater. 2022, 32, 2110181. [Google Scholar] [CrossRef]

- Ang, K.W.; Yu, M.B.; Lo, G.Q.; Kwong, D.L. Low-voltage and high-responsivity germanium bipolar phototransistor for optical detections in the near-infrared regime. IEEE Electron Device Lett. 2008, 29, 1124–1127. [Google Scholar] [CrossRef]

- Basu, R.; Chakraborty, V.; Mukhopadhyay, B.; Basu, P.K. Predicted performance of Ge/GeSn hetero-phototransistors on Si substrate at 1.55 μm. Opt. Quant. Electron. 2015, 47, 387–399. [Google Scholar] [CrossRef]

- Shulyak, V. Low-Photon Detection Using InGaAs/InAlAs and InAs Avalanche Photodiodes. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2020. [Google Scholar]

- Kleinow, P.; Rutz, F.; Aidam, R.; Bronner, W.; Heussen, H.; Walther, M. Charge-layer design considerations in SAGCM InGaAs/InAlAs avalanche photodiodes. Phys. Status Solidi A 2016, 213, 925–929. [Google Scholar] [CrossRef]

- Sim, J.S.; Kim, K.; Song, M.; Kim, S.; Song, M. Optimization of charge and multiplication layers of 20-Gbps InGaAs/InAlAs avalanche photodiode. ETRI J. 2021, 43, 916–922. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, A.; Xing, H.; Yang, Y. Study on surface leakage current at sidewall in InP-based avalanche photodiodes with mesa structure. AIP Adv. 2022, 12, 035336. [Google Scholar] [CrossRef]

- Han, H.; Zhu, Y.; Guo, Z.; Li, Z.; Qu, H.; Gao, W.; Wang, W. High performance InGaAs/InP avalanche photodiode integrated with metal-insulator-metal microcavity. Opt. Quant. Electron. 2021, 53, 1–9. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, W.; Li, Y.; Qu, H.; Fan, L.; Chen, X.; Lu, W. Material Defects and Dark Currents in InGaAs/InP Avalanche Photodiode Devices. IEEE Trans. Electron Devices 2022, 69, 4944–4949. [Google Scholar] [CrossRef]

- Levine, B.F.; Sacks, R.N.; Ko, J.; Jazwiecki, M.; Valdmanis, J.A.; Gunther, D.; Meier, J. A new planar InGaAs–InAlAs avalanche photodiode. IEEE Photonic. Tech. Lett. 2006, 18, 1898–1900. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Z.; Miao, G.; Jiang, H.; Song, H. A comparative study of front-and back-illuminated planar InGaAs/InP avalanche photodiodes. Mater. Lett. 2022, 308, 131144. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Z.; Miao, G.; Jiang, H.; Song, H. Optimized Selective-Area p-Type Diffusion for the Back-Illuminated Planar InGaAs/InP Avalanche Photodiodes by a Single Diffusion Process. Phys. Status Solidi A 2022, 219, 2100577. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Du, C.; Jiang, Y.; Ma, Z.; Chen, H.; Deng, Z. Experimental Demonstration of the Impact of the Parameters of Floating Guard Ring on Planar InP/InGaAs-Based Avalanche Photodiodes’ Performance and Its Optimization. IEEE Photonics J. 2022, 14, 1–6. [Google Scholar] [CrossRef]

- Signorelli, F.; Telesca, F.; Conca, E.; Della Frera, A.; Ruggeri, A.; Giudice, A.; Tosi, A. InGaAs/InP SPAD detecting single photons at 1550 nm with up to 50% efficiency and low noise. In Proceedings of the 2021 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–16 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 20–23. [Google Scholar]

- Metz, S. The avalanche phototransistor—A novel type of radiation detector and its potential use in optical communication systems. IEEE Trans. Electron Devices 1975, 22, 617–619. [Google Scholar] [CrossRef]

- Chen, C.W.; Gustafson, T.K. Characteristics of an avalanche phototransistor fabricated on a Si surface. Appl. Phys. Lett. 1981, 39, 161–163. [Google Scholar] [CrossRef]

- Campbell, J.; Dentai, A.; Qua, G.; Ferguson, J. Avalanche InP/InGaAs heterojunction phototransistor. IEEE J. Quant. Electron. 1983, 19, 1134–1138. [Google Scholar] [CrossRef]

- Campbell, J.C.; Qua, G.J.; Dentai, A.G. Optical comparator: A new application for avalanche phototransistors. IEEE Trans. Electron Devices 1983, 30, 408–411. [Google Scholar] [CrossRef]

- Shi, J.W.; Wu, Y.S.; Hong, F.C.; Chiu, W.Y. Separate absorption-charge multiplication heterojunction phototransistors with the bandwidth-enhancement effect and ultrahigh gain-bandwidth product under near avalanche operation. IEEE Electron Device Lett. 2008, 29, 714–717. [Google Scholar] [CrossRef]

- Sammak, A.; Aminian, M.; Nanver, L.K.; Charbon, E. CMOS-compatible PureGaB Ge-on-Si APD pixel arrays. IEEE Trans. Electron Devices 2015, 63, 92–99. [Google Scholar] [CrossRef]

- Kuzmenko, K.; Vines, P.; Halimi, A.; Collins, R.J.; Maccarone, A.; McCarthy, A.; Greener, Z.; Kirdoda, J.; Dumas, D.; Llin, L.; et al. 3D LIDAR imaging using Ge-on-Si single–photon avalanche diode detectors. Opt. Express 2020, 28, 1330–1344. [Google Scholar] [CrossRef]

- Tan, C.; Kong, W.; Huang, G.; Hou, J.; Luo, Y.; Chen, T.; Shu, R. Long-Range Daytime 3D Imaging Lidar With Short Acquisition Time Based on 64× 64 Gm-APD Array. IEEE Photonics J. 2022, 14, 1–7. [Google Scholar] [CrossRef]

- Yang, R. Optical system design of 64 × 64 InGaAs/InP single photon avalanche diode (SPAD) focal plane arrays. In Proceedings of the Seventh Asia Pacific Conference on Optics Manufacture and 2021 International Forum of Young Scientists on Advanced Optical Manufacturing (APCOM and YSAOM 2021), Hong Kong, China, 13–16 August 2021; SPIE: Bellingham, WA, USA, 2022; Volume 12166, pp. 271–276. [Google Scholar]

- Wang, S.; Ye, H.; Geng, L.; Lu, Z.; Xiao, F.; Xiao, F.; Han, Q. Design, Fabrication, and Characteristic Analysis of 64× 64 InGaAs/InP Single-Photon Avalanche Diode Array. J. Electron. Mater. 2022, 51, 2692–2697. [Google Scholar] [CrossRef]

- Itzler, M.A.; Entwistle, M.; Owens, M.; Patel, K.; Jiang, X.; Slomkowski, K.; Ferraro, J. Geiger-mode avalanche photodiode focal plane arrays for three-dimensional imaging LADAR. In Proceedings of the Infrared Remote Sensing and Instrumentation XVIII, San Diego, CA, USA, 1–5 August 2010; SPIE: Bellingham, WA, USA, 2010; Volume 7808, pp. 75–88. [Google Scholar]

- Chen, D.; Zhang, M.; Xue, Z.; Wang, G.; Guo, Q.; Mu, Z.; Liu, S. Ultrasmooth epitaxial Ge grown on (001) Si utilizing a thin B-doped SiGe buffer layer. Appl. Phys. Express 2014, 7, 111301. [Google Scholar] [CrossRef]

- Lee, K.H.; Bao, S.; Wang, B.; Wang, C.; Yoon, S.F.; Michel, J.; Tan, C.S. Reduction of threading dislocation density in Ge/Si using a heavily As-doped Ge seed layer. AIP Adv. 2016, 6, 025028. [Google Scholar] [CrossRef]

- Kuo, W.C.; Lee, M.J.; Wu, M.L.; Lee, C.C.; Tsao, I.Y.; Chang, J.Y. Low temperature growth of heavy boron-doped hydrogenated Ge epilayers and its application in Ge/Si photodetectors. Solid State Electron. 2017, 130, 41–44. [Google Scholar] [CrossRef]

- Loo, R.; Souriau, L.; Ong, P.; Kenis, K.; Rip, J.; Storck, P.; Vorderwestner, M. Smooth and high quality epitaxial strained Ge grown on SiGe strain relaxed buffers with 70–85% Ge. J. Cryst. Growth 2011, 324, 15–21. [Google Scholar] [CrossRef]

- Chen, D.; Wei, X.; Xue, Z.; Bian, J.; Wang, G.; Zhang, M.; Liu, S. Ultrathin low temperature Si0. 75Ge0. 25/Si buffer layer for the growth of high quality Ge epilayer on Si (100) by RPCVD. J. Cryst. Growth 2014, 386, 38–42. [Google Scholar] [CrossRef]

- Chen, D.; Guo, Q.; Zhang, N.; Xu, A.; Wang, B.; Li, Y.; Wang, G. High quality Ge epilayer on Si (1 0 0) with an ultrathin Si1−xGex/Si buffer layer by RPCVD. Mater. Res. Express 2017, 4, 076407. [Google Scholar] [CrossRef]

- Halpin, J.E.; Rhead, S.D.; Sanchez, A.M.; Myronov, M.; Leadley, D.R. Growth of complex SiGe/Ge superlattices by reduced pressure chemical vapour deposition at low temperature. Semicond. Sci. Tech. 2015, 30, 114009. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Corley, C.; Schubert, M.A.; Zöllner, M.; Tillack, B. Threading Dislocation Reduction of Ge by Introducing a SiGe/Ge Superlattice. ECS Trans. 2020, 98, 185. [Google Scholar] [CrossRef]

- Miao, Y.H.; Hu, H.Y.; Li, X.; Song, J.J.; Xuan, R.X.; Zhang, H.M. Evaluation of threading dislocation density of strained Ge epitaxial layer by high resolution x-ray diffraction. Chin. Phys. B 2017, 26, 127309. [Google Scholar] [CrossRef]

- Du, Y.; Kong, Z.; Toprak, M.S.; Wang, G.; Miao, Y.; Xu, B.; Yu, J.; Li, B.; Lin, H.; Han, J.; et al. Investigation of the heteroepitaxial process optimization of Ge layers on Si (001) by RPCVD. Nanomaterials 2021, 11, 928. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, Y.; Zaumseil, P.; Shubert, M.A.; Tillack, B. Influence of Annealing Condition on Threading Dislocation Density of Ge Grown by RPCVD. ECS Trans. 2019, 93, 87. [Google Scholar] [CrossRef]

- Chen, D.; Xue, Z.; Wei, X.; Wang, G.; Ye, L.; Zhang, M.; Liu, S. Ultralow temperature ramping rate of LT to HT for the growth of high quality Ge epilayer on Si (1 0 0) by RPCVD. Appl. Surf. Sci. 2014, 299, 1–5. [Google Scholar] [CrossRef]

- Tan, Y.H.; Bergkvist, M.; Tan, C.S. Investigation of Growth Kinetics, Inter-Diffusion and Quality of Ge-on-Si Epitaxial Film by a Three-Step Growth Approach. ECS J. Solid State Sci. Tech. 2012, 1, P117. [Google Scholar] [CrossRef]

- Du, Y.; Wang, G.; Miao, Y.; Xu, B.; Li, B.; Kong, Z.; Yu, J.; Zhao, X.; Lin, H.; Su, J.; et al. Strain Modulation of Selectively and/or Globally Grown Ge Layers. Nanomaterials 2021, 11, 1421. [Google Scholar] [CrossRef]

- Abedin, A. Germanium Layer Transfer and Device Fabrication for Monolithic 3D Integration. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2021. [Google Scholar]

- Xu, B.; Du, Y.; Wang, G.; Xiong, W.; Kong, Z.; Zhao, X.; Radamson, H.H. Dual-Step Selective Homoepitaxy of Ge with Low Defect Density and Modulated Strain Based on Optimized Ge/Si Virtual Substrate. Materials 2022, 15, 3594. [Google Scholar] [CrossRef]

- Ke, S.; Lin, S.; Li, X.; Li, J.; Xu, J.; Li, C.; Chen, S. Voltage sharing effect and interface state calculation of a wafer-bonding Ge/Si avalanche photodiode with an interfacial GeO2 insulator layer. Opt. Express 2016, 24, 1943–1952. [Google Scholar] [CrossRef]

- Son, B. High-Performance GE/GESN Photodetectors in Near-and Mid-Infrared Range. Ph.D. Thesis, Nanyang Technological University, Singapore, 2021. [Google Scholar]

- Miyasaka, Y.; Hiraki, T.; Okazaki, K.; Takeda, K.; Tsuchizawa, T.; Yamada, K.; Wada, K.; Ishikawa, Y. Ge/graded-SiGe multiplication layers for low-voltage and low-noise Ge avalanche photodiodes on Si. Jpn. J. Appl. Phys. 2016, 55, 04EH10. [Google Scholar] [CrossRef]

- Miao, Y.; Wang, Y.; Hu, H.; Liu, X.; Su, H.; Zhang, J.; Zhang, H. Characterization of crystalline GeSn layer on tensile-strained Ge buffer deposited by magnetron sputtering. Mat. Sci. Semicon. Proc. 2018, 85, 134–140. [Google Scholar] [CrossRef]

- Kong, Z.; Wang, G.; Liang, R.; Su, J.; Xun, M.; Miao, Y.; Radamson, H.H. Growth and Strain Modulation of GeSn Alloys for Photonic and Electronic Applications. Nanomaterials 2022, 12, 981. [Google Scholar] [CrossRef]

- Zhou, Y.; Miao, Y.; Ojo, S.; Tran, H.; Abernathy, G.; Grant, J.M.; Yu, S.Q. Electrically injected GeSn lasers on Si operating up to 100 K. Optica 2020, 7, 924–928. [Google Scholar] [CrossRef]

- Zhou, Y.; Ojo, S.; Wu, C.W.; Miao, Y.; Tran, H.; Grant, J.M.; Yu, S.Q. Electrically injected GeSn lasers with peak wavelength up to 2.7 μm. Photonics Res. 2022, 10, 222–229. [Google Scholar] [CrossRef]

- Abernathy, G.; Zhou, Y.; Ojo, S.; Miao, Y.; Du, W.; Sun, G.; Yu, S.Q. Study of gain for SiGeSn/GeSn/SiGeSn multiple quantum well lasers. In Proceedings of the 2020 Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 10–15 May 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–2. [Google Scholar]

- Zhou, Y.; Miao, Y.; Ojo, S.; Abernathy, G.; Du, W.; Sun, G.; Yu, S.Q. Direct bandgap electroluminescence from SiGeSn/GeSn double-heterostructure monolithically grown on Si. In Proceedings of the 2020 Conference on Lasers and Electro-Optics (CLEO), San Jose, CA, USA, 10–15 May 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–2. [Google Scholar]

- Dou, W.; Benamara, M.; Mosleh, A.; Margetis, J.; Grant, P.; Zhou, Y.; Yu, S.Q. Investigation of GeSn strain relaxation and spontaneous composition gradient for low-defect and high-Sn alloy growth. Sci. Rep. 2018, 8, 5640. [Google Scholar] [CrossRef]

- Grant, J.; Abernathy, G.; Olorunsola, O.; Ojo, S.; Amoah, S.; Wanglia, E.; Yu, S.Q. Growth of Pseudomorphic GeSn at Low Pressure with Sn Composition of 16.7%. Materials 2021, 14, 7637. [Google Scholar] [CrossRef]

- Miao, Y.H.; Hu, H.Y.; Song, J.J.; Xuan, R.X.; Zhang, H.M. Effects of rapid thermal annealing on crystallinity and Sn surface segregation of Ge1−xSnx films on Si (100) and Si (111). Chin. Phys. B 2017, 26, 127306. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Y.; Wu, Y.; Liu, T.; Miao, Y.; Meng, L.; Hu, H. Effects of Annealing on the Behavior of Sn in GeSn Alloy and GeSn-Based Photodetectors. IEEE Trans. Electron Devices 2020, 67, 3229–3234. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Hirose, N.; Kasamatsu, A.; Mimura, T.; Matsui, T.; Suda, Y. Investigation of Sn surface segregation during GeSn epitaxial growth by Auger electron spectroscopy and energy dispersive x-ray spectroscopy. Appl. Phys. Lett. 2015, 106, 052103. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Hirose, N.; Kasamatsu, A.; Matsui, T.; Suda, Y. Effects of Low-Temperature GeSn Buffer Layers on Sn Surface Segregation During GeSn Epitaxial Growth. Electr. Mater. Lett. 2020, 16, 9–13. [Google Scholar] [CrossRef]

- Li, H.; Cui, Y.X.; Wu, K.Y.; Tseng, W.K.; Cheng, H.H.; Chen, H. Strain relaxation and Sn segregation in GeSn epilayers under thermal treatment. Appl. Phys. Lett. 2013, 102, 251907. [Google Scholar] [CrossRef]

- Li, H.; Chang, C.; Chen, T.P.; Cheng, H.H.; Shi, Z.W.; Chen, H. Characteristics of Sn segregation in Ge/GeSn heterostructures. Appl. Phys. Lett. 2014, 105, 151906. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Hirose, N.; Kasamatsu, A.; Mimura, T.; Matsui, T.; Suda, Y. Formation of GeSn layers on Si (001) substrates at high growth temperature and high deposition rate by sputter epitaxy method. J. Mater. Sci. 2015, 50, 4366–4370. [Google Scholar] [CrossRef]

- Radamson, H.H.; Joelsson, K.B.; Ni, W.-X.; Hultman, L.; Hansson, G.V. Characterization of highly boron-doped Si, Si1-xGex and Ge layers by high-resolution transmission electron microscopy. J. Crys. Growth 1995, 157, 8. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Yan, J.; Zhang, C.; Hao, Y.; Han, G. Theoretical investigation of tensile strained GeSn waveguide with Si3N4 liner stressor for mid-infrared detector and modulator applications. Opt. Express 2015, 23, 7924–7932. [Google Scholar] [CrossRef] [PubMed]

- Kumar, H.; Pandey, A.K. GeSn-Based Multiple-Quantum-Well Photodetectors for Mid-Infrared Sensing Applications. IEEE Trans. NanoBiosci. 2021, 21, 175–183. [Google Scholar] [CrossRef]

- Kumar, D.V.; Pandey, A.K.; Basu, R.; Sharma, A.K. Simulated characteristics of a heterojunction phototransistor with Ge1-xSnx alloy as base. Optic. Eng. 2016, 55, 127103. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Yan, J.; Zhang, C.; Hao, Y.; Han, G. Simulation investigation of tensile strained GeSn fin photodetector with Si 3 N 4 liner stressor for extension of absorption wavelength. Opt. Express 2015, 23, 739–746. [Google Scholar] [CrossRef]

- Kumar, H.; Basu, R. Comprehensive Study and Noise Analysis of GeSn-based pnp Heterojunction Phototransistors for Efficient Detection. In Proceedings of the 2018 International Conference on Numerical Simulation of Optoelectronic Devices (NUSOD), Hong Kong, China, 5–9 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 11–12. [Google Scholar]

- Pandey, A.K.; Basu, R. Characteristics of GeSn-based multiple quantum well heterojunction phototransistors: A simulation-based analysis. IET Optoelectron. 2018, 12, 144–149. [Google Scholar] [CrossRef]

- Liu, T.; Miao, Y.; Wang, L.; Zhu, G.; Hu, H.; Zhong, Z.; Jiang, Z. Temperature dependence of Raman scattering in GeSn films. J. Raman. Spectrosc. 2020, 51, 1092–1099. [Google Scholar] [CrossRef]

- Noroozi, M.; Abedin, A.; Moeen, M.; Östling, M.; Radamson, H.H. CVD growth of GeSnSiC alloys using disilane, digermane, Tin Tetrachloride and methylsilane. ECS Trans. 2014, 64, 703. [Google Scholar] [CrossRef]

- Jamshidi, A.; Noroozi, M.; Moeen, M.; Hallén, A.; Hamawandi, B.; Lu, J.; Hultman, L.; Östling, M.; Radamson, H. Growth of GeSnSiC layers for photonic applications. Surf. Coat. Tech. 2013, 230, 106–110. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, J.; Li, X.; Liu, Z.; Zuo, Y.; Xue, C.; Cheng, B. Study of GePb photodetectors for shortwave infrared detection. Opt. Express 2019, 27, 18038–18043. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, J.; Zhou, L.; Liu, Z.; Zuo, Y.; Xue, C.; Cheng, B. Growth of single crystalline GePb film on Ge substrate by magnetron sputtering epitaxy. J. Alloys Comp. 2019, 785, 228–231. [Google Scholar] [CrossRef]

- Yang, J.; Hu, H.; Miao, Y.; Wang, B.; Wang, W.; Su, H.; Ma, Y. Single-crystalline GePb alloys formed by rapid thermal annealing-induced epitaxy. J. Phys. D Appl. Phys. 2020, 53, 265105. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, J.; Li, M.; Peng, L.; Wang, N.; Li, X.; Zuo, Y.; Liu, Z.; Xue, C.; Cheng, B. Epitaxial growth and characterization of Ge1-x-ySnxPby ternary alloys. J. Alloys Comp. 2020, 829, 154505. [Google Scholar] [CrossRef]

- Radamson, H.; Thylén, L. Monolithic Nanoscale Photonics-Electronics Integration in Silicon and Other Group IV Elements; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Kolahdouz, M.; Östling, M.; Radamson, H.H. High performance infra-red detectors based on Si/SiGe multilayers quantum structure. Mater. Sci. Eng. B 2012, 177, 1563–1566. [Google Scholar] [CrossRef]

- Moeen, M.; Salemi, A.; Kolahdouz, M.; Östling, M.; Radamson, H.H. Characterization of SiGe/Si multi-quantum wells for infrared sensing. Appl. Phys. Lett. 2013, 103, 251609. [Google Scholar] [CrossRef]

- Kolahdouz, M.; Farniya, A.A.; Di Benedetto, L.; Radamson, H.H. Improvement of infrared detection using Ge quantum dots multilayer structure. Appl. Phys. Lett. 2010, 96, 213516. [Google Scholar] [CrossRef]

- Kolahdouz, M.; Farniya, A.A.; Östling, M.; Radamson, H.H. The performance improvement evaluation for SiGe-based IR detectors. Solid State Electron 2011, 62, 72–76. [Google Scholar] [CrossRef]

- Radamson, H.H.; Wang, G. Silicon Nanodevices. Nanomaterials 2022, 12, 1980. [Google Scholar] [CrossRef]

- Radamson, H.H.; Thylén, L. (Eds.) Chapter 4—Moore’s Law for Photonics and Electronics. In Monolithic Nanoscale Photonics–Electronics Integration in Silicon and Other Group IV Elements; Elsevier: Amsterdam, The Netherlands, 2015; pp. 121–150. [Google Scholar]

- Radamson, H.; Simoen, E.; Luo, J.; Zhao, C. CMOS Past, Present and Future; Woodhead Publishing: Sawston, UK, 2018. [Google Scholar]

- Hållstedt, J.; Blomqvist, M.; Persson, P.Å.; Hultman, L.; Radamson, H.H. The effect of carbon and germanium on phase transformation of nickel on Si1−x−yGexCy epitaxial layers. J. Appl. Phys. 2004, 95, 2397–2402. [Google Scholar] [CrossRef]

- Radamson, H.H.; Kolahdouz, M.; Shayestehaminzadeh, S.; Farniya, A.A.; Wissmar, S. Carbon-doped single-crystalline SiGe/Si thermistor with high temperature coefficient of resistance and low noise level. Appl. Phys. Lett. 2010, 97, 223507. [Google Scholar] [CrossRef]

- Nur, O.; Willander, M.; Hultman, L.; Radamson, H.H.; Hansson, G.V.; Sardela, M.R., Jr.; Greene, J.E. CoSi2/Si1−xGex/Si (001) heterostructures formed through different reaction routes: Silicidation-induced strain relaxation, defect formation, and interlayer diffusion. J. Appl. Phys. 1995, 78, 7063–7069. [Google Scholar] [CrossRef]

- Hu, C.; Xu, P.; Fu, C.; Zhu, Z.; Gao, X.; Jamshidi, A.; Zhang, S.L. Characterization of Ni (Si, Ge) films on epitaxial SiGe (100) formed by microwave annealing. Appl. Phys. Lett. 2012, 101, 092101. [Google Scholar] [CrossRef]

- Duan, N.; Luo, J.; Wang, G.; Liu, J.; Simoen, E.; Mao, S.; Ye, T. Reduction of NiGe/n-and p-Ge specific contact resistivity by enhanced dopant segregation in the presence of carbon during nickel germanidation. IEEE Trans. Electron. Devices 2016, 63, 4546–4549. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, G.; Guo, Y.; Ke, X.; Radamson, H.; Liu, H.; Luo, J. Effects of carbon pre-germanidation implant into Ge on the thermal stability of NiGe films. Microelectron. Eng. 2015, 133, 6–10. [Google Scholar] [CrossRef]

- Noroozi, M.; Moeen, M.; Abedin, A.; Toprak, M.S.; Radamson, H.H. Effect of Strain on Ni-(GeSn) x Contact Formation to GeSn Nanowires; MRS Online Proceedings Library (OPL); Cambridge University Press: Cambridge, UK, 2014; p. 1707. [Google Scholar]

- Nur, O.; Willander, M.; Hultman, L.; Radamson, H.H.; Hansson, G.V.; Sardela, M.R., Jr.; Greene, J.E. Strain characterization of CoSi2/n-Si0.9 Ge0.1/p-Si heterostructures. Appl. Phys. Lett. 1994, 64, 440–442. [Google Scholar] [CrossRef]

- Du, Y.; Xu, B.; Wang, G.; Gu, S.; Li, B.; Kong, Z.; Radamson, H.H. Growth of high-quality epitaxy of GaAs on Si with engineered Ge buffer using MOCVD. J. Mater. Sci. Mater. Electron. 2021, 32, 6425–6437. [Google Scholar] [CrossRef]

- Du, Y.; Xu, B.; Wang, G.; Miao, Y.; Li, B.; Kong, Z.; Radamson, H.H. Review of Highly Mismatched III-V Heteroepitaxy Growth on (001) Silicon. Nanomaterials 2022, 12, 741. [Google Scholar] [CrossRef]

- Du, Y.; Wei, W.; Xu, B.; Wang, G.; Li, B.; Miao, Y.; Radamson, H.H. Reduced Dislocation of GaAs Layer Grown on Ge-Buffered Si (001) Substrate Using Dislocation Filter Layers for an O-Band InAs/GaAs Quantum Dot Narrow-Ridge Laser. Micromachines 2022, 13, 1579. [Google Scholar] [CrossRef]

- Xu, B.; Wang, G.; Du, Y.; Miao, Y.; Li, B.; Zhao, X.; Lin, H.; Yu, J.; Su, J.; Dong, Y.; et al. Monolithic Integration of O-Band InAs Quantum Dot Lasers with Engineered GaAs Virtual Substrate Based on Silicon. Nanomaterials 2022, 12, 2704. [Google Scholar] [CrossRef]

- Shi, B.; Klamkin, J. Defect engineering for high quality InP epitaxially grown on on-axis (001) Si. J. Appl. Phys. 2020, 127, 033102. [Google Scholar] [CrossRef]

- Schneble, O.D.; Neumann, A.N.; Mangum, J.S.; Norman, A.G.; Warren, E.L.; Zimmerman, J.D. Application of templated vapor-liquid-solid growth to heteroepitaxy of InP on Si. J. Vac. Sci. Technol. A Vac. Surf. Film. 2021, 39, 013404. [Google Scholar] [CrossRef]

- Lee, S.M.; Cho, Y.J.; Park, J.B.; Shin, K.W.; Hwang, E.; Lee, S.; Yoon, E. Effects of growth temperature on surface morphology of InP grown on patterned Si (0 0 1) substrates. J. Crys. Growth 2015, 416, 113–117. [Google Scholar] [CrossRef]

- Park, J.S.; Tang, M.; Chen, S.; Liu, H. Heteroepitaxial growth of iii-v semiconductors on silicon. Crystals 2020, 10, 1163. [Google Scholar] [CrossRef]

- Kang, Y.; Mages, P.; Clawson, A.R.; Yu, P.K.L.; Bitter, M.; Pan, Z.; Lo, Y.H. Fused InGaAs-Si avalanche photodiodes with low-noise performances. IEEE Photonics Technol. Lett. 2002, 14, 1593–1595. [Google Scholar] [CrossRef]

- Kang, Y.; Lo, Y.H.; Bitter, M.; Kristjansson, S.; Pan, Z.; Pauchard, A. InGaAs-on-Si single photon avalanche Photodetectors. Appl. Phys. Lett. 2004, 85, 1668–1670. [Google Scholar] [CrossRef]

- Zhang, H.; Tian, Y.; Li, Q.; Ding, W.; Yu, X.; Lin, Z.; Zhao, Y. Photon-Trapping Microstructure for InGaAs/Si Avalanche Photodiodes Operating at 1.31 μm. Sensors 2022, 22, 7724. [Google Scholar] [CrossRef]

- Wu, W.; Hawkins, A.R.; Bowers, J.E. Design of InGaAs/Si avalanche photodetectors for 400-GHz gain-bandwidth product. In Proceedings of the Optoelectronic Integrated Circuits, San Jose, CA, USA, 8–14 February 1997; SPIE: Bellingham, WA, USA, 1997; Volume 3006, pp. 38–47. [Google Scholar]

- Pan, Z.; Bitter, M.; Pauchard, A.; Hummel, S.; Feng, T.; Kang, Y.; Mages, P.; Paul, K.L.; Lo, Y.H. InGaAs-Si avalanche photodiodes fabricated by wafer bonding. In Materials and Devices for Optical and Wireless Communications; SPIE: Bellingham, WA, USA, 2002; Volume 4905, pp. 322–325. [Google Scholar]

- Peng, H.; Qu, H.; Zheng, W. A promising low noise and high gain InGaAs/Si avalanche photodiode. In Proceedings of the AOPC 2020: Optoelectronics and Nanophotonics; and Quantum Information Technology, Beijing, China, 30 November–2 December 2020; SPIE: Bellingham, WA, USA, 2020; Volume 11564, pp. 38–43. [Google Scholar]

- Ke, S.; Xiao, X.; Jiao, J.; Chen, X.; Huang, Z.; Zhou, J.; Chen, S. Theoretical Achievement of THz Gain-Bandwidth Product of Wafer-Bonded InGaAs/Si Avalanche Photodiodes With Poly-Si Bonding Layer. IEEE Trans. Electron Devices 2022, 69, 1123–1128. [Google Scholar] [CrossRef]

- Zhang, W.; Evans, M.J.; Huang, W.; Morales, M.; Wang, D.; Gustus, W.J.; Houlihan, S. Mesa pixel isolation with low dark current for improved MTF performance in SWIR photodiode array applications. In Proceedings of the Infrared Technology and Applications XLV, Baltimore, ML, USA, 14–18 April 2019; SPIE: Bellingham, WA, USA, 2019; Volume 11002, pp. 209–221. [Google Scholar]

- Skrimshire, C.P.; Farr, J.R.; Sloan, D.F.; Robertson, M.J.; Putland, P.A.; Stokoe, J.C.D.; Sutherland, R.R. Reliability of mesa and planar InGaAs PIN photodiodes. IEE Proc. J. (Optoelectron) 1990, 137, 74–78. [Google Scholar] [CrossRef]

- Verdun, M.; Beaudoin, G.; Portier, B.; Bardou, N.; Dupuis, C.; Sagnes, I.; Pelouard, J.L. Dark current investigation in thin PiN InGaAs photodiodes for nano-resonators. J. Appl. Phys. 2016, 120, 084501. [Google Scholar] [CrossRef]

- Klem, J.F.; Kim, J.K.; Cich, M.J.; Keeler, G.A.; Hawkins, S.D.; Fortune, T.R. Mesa-isolated InGaAs photodetectors with low dark current. Appl. Phys. Lett. 2009, 95, 031112. [Google Scholar] [CrossRef]

- Sun, J.; Rickert, K.A.; Redwing, J.M.; Ellis, A.B.; Himpsel, F.J.; Kuech, T.F. p-GaN surface treatments for metal contacts. Appl. Phys. Lett. 2000, 76, 415–417. [Google Scholar] [CrossRef]

- Kim, J.K.; Lee, J.L.; Lee, J.W.; Eoi Shin, H.; Jo Park, Y.; Kim, T. Low resistance Pd/Au ohmic contacts to p-type GaN using surface treatment. Appl. Phys. Lett. 1998, 73, 2953–2955. [Google Scholar] [CrossRef]

- Liu, J.J.; Ho, W.J.; Chen, J.Y.; Lin, J.N.; Teng, C.J.; Yu, C.C.; Chang, M.J. The fabrication and characterization of InAlAs/InGaAs APDs based on a mesa-structure with polyimide passivation. Sensors 2019, 19, 3399. [Google Scholar] [CrossRef]

- Lin, J.; Lee, S.; Oh, H.J.; Yang, W.; Lo, G.Q.; Kwong, D.L.; Chi, D.Z. Plasma PH 3-passivated high mobility inversion InGaAs MOSFET fabricated with self-aligned gate-first process and HfO2/TaN gate stack. In Proceedings of the 2008 IEEE International Electron Devices Meeting, San Francisco, CA, USA, 15–17 December 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 1–4. [Google Scholar]

- Jevasuwan, W.; Urabe, Y.; Maeda, T.; Miyata, N.; Yasuda, T.; Yamada, H.; Takagi, S. Initial Processes of Atomic Layer Deposition of Al2O3 on InGaAs: Interface Formation Mechanisms and Impact on Metal-Insulator-Semiconductor Device Performance. Materials 2012, 5, 404–414. [Google Scholar] [CrossRef]

- Driad, R.; Lu, Z.H.; Laframboise, S.; Scansen, D.; McKinnon, W.R.; McAlister, S.P. Surface passivation of InGaAs/InP beterostructures using UV-irradiation and ozone. In Proceedings of the 1998 International Conference on Indium Phosphide and Related Materials (Cat. No. 98CH36129), Tsukuba, Japan, 11–15 May 1998; IEEE: Piscataway, NJ, USA, 1998; pp. 459–462. [Google Scholar]

- Circir, K.; Dolas, M.H.; Kocaman, S. Optimization of in-device depleted passivation layer for InGaAs photodetectors. Infrared Phys. Technol. 2019, 97, 360–364. [Google Scholar] [CrossRef]

- Yeats, R.; Von Dessonneck, K. Polyimide passivation of In0.53Ga0.47As, InP, and InGaAsP/InP p-n junction structures. Appl. Phys. Lett. 1984, 44, 145–147. [Google Scholar] [CrossRef]

- Katz, A.; Thomas, P.M.; Chu, S.N.G.; Dautremont-Smith, W.C.; Sobers, R.G.; Napholtz, S.G. Pt/Ti Ohmic contact to p++-InGaAsP (1.3 μm) formed by rapid thermal processing. J. Appl. Phys. 1990, 67, 884–889. [Google Scholar] [CrossRef]

- Thorburn, F.; Yi, X.; Greener, Z.M.; Kirdoda, J.; Millar, R.W.; Huddleston, L.L. Ge-on-si single-photon avalanche diode detectors for short-wave infrared wavelengths. J. Phys. Photonics 2022, 4, 012001. [Google Scholar] [CrossRef]

- Yuan, Y.; Tossoun, B.; Huang, Z.; Zeng, X.; Kurczveil, G.; Fiorentino, M.; Liang, D.; Beausoleil, R.G. Avalanche photodiodes on silicon photonics. J. Semi. 2022, 43, 021301. [Google Scholar] [CrossRef]

| Diameter (μm) | Temperature (K) | SPDE (%) | DCRs | Jitter (ps) | NEP (WHz−1/2) |

|---|---|---|---|---|---|

| 100 | 125 | 38 | A vast improvement when compared to previous Ge-on-Si work, staying below 100 kcps for an excess bias of up to 6.5% | 310 | 1.9 × 10−16@78 K |

| 100 | 26 | ||||

| 80 | 22 | ||||

| 50 | 125 | 29 | Approximately 4 times greater than the 26 µm device at each excess bias level recorded (380 kcps) | 210 ± 10 | 1.6 × 10−16 |

| 26 | 125 | 28 | DCRs observed from the 26 µm device were extremely low (86 kcps) | 157 ± 10 | 9.8 × 10−17 |

| Index | Ge (GeSn) APDs | InGaAs APDs |

|---|---|---|

| Growth technology | MBE, RPCVD | MBE, MOCVD |

| Substrate | Si | InP |

| Device structure | SACM | SAGCM |

| Multiplication region | Si | InAlAs or InP |

| Absorption region | Ge (GeSn) | InGaAs |

| Wafer size | 8–12 inch available | 2–4 inch |

| Price | Low | High |

| Wavelength range | 1.1–3 μm | 1–2.5 μm |

| Technology Maturity | Research and Development | Commercialization |

| Product | No | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, Y.; Lin, H.; Li, B.; Dong, T.; He, C.; Du, J.; Zhao, X.; Zhou, Z.; Su, J.; Wang, H.; et al. Review of Ge(GeSn) and InGaAs Avalanche Diodes Operating in the SWIR Spectral Region. Nanomaterials 2023, 13, 606. https://doi.org/10.3390/nano13030606

Miao Y, Lin H, Li B, Dong T, He C, Du J, Zhao X, Zhou Z, Su J, Wang H, et al. Review of Ge(GeSn) and InGaAs Avalanche Diodes Operating in the SWIR Spectral Region. Nanomaterials. 2023; 13(3):606. https://doi.org/10.3390/nano13030606

Chicago/Turabian StyleMiao, Yuanhao, Hongxiao Lin, Ben Li, Tianyu Dong, Chuangqi He, Junhao Du, Xuewei Zhao, Ziwei Zhou, Jiale Su, He Wang, and et al. 2023. "Review of Ge(GeSn) and InGaAs Avalanche Diodes Operating in the SWIR Spectral Region" Nanomaterials 13, no. 3: 606. https://doi.org/10.3390/nano13030606

APA StyleMiao, Y., Lin, H., Li, B., Dong, T., He, C., Du, J., Zhao, X., Zhou, Z., Su, J., Wang, H., Dong, Y., Lu, B., Dong, L., & Radamson, H. H. (2023). Review of Ge(GeSn) and InGaAs Avalanche Diodes Operating in the SWIR Spectral Region. Nanomaterials, 13(3), 606. https://doi.org/10.3390/nano13030606