Mechanical and Optical Properties of Cr2O3 Thin Films Grown by Atomic Layer Deposition Method Using Cr(thd)3 and Ozone

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

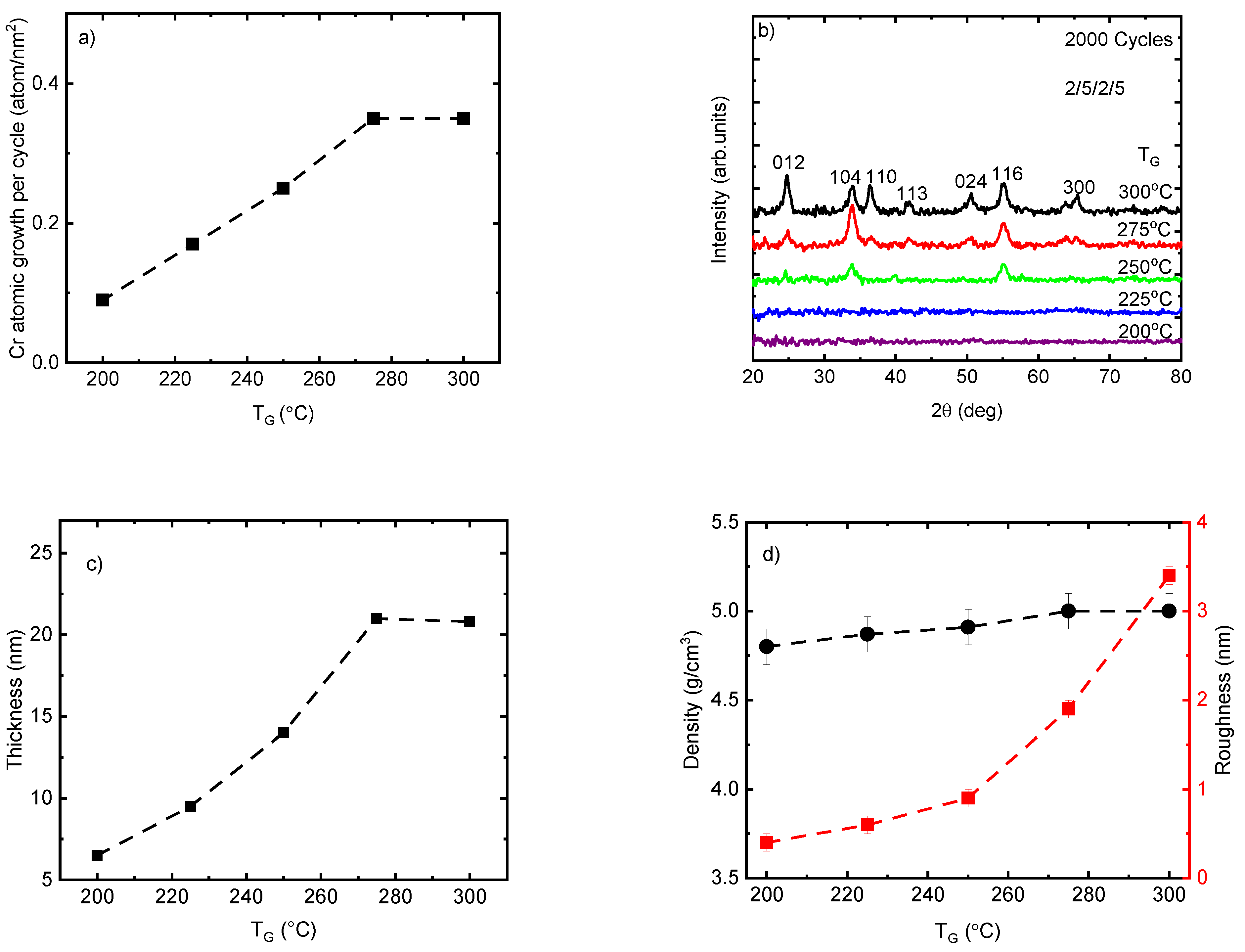

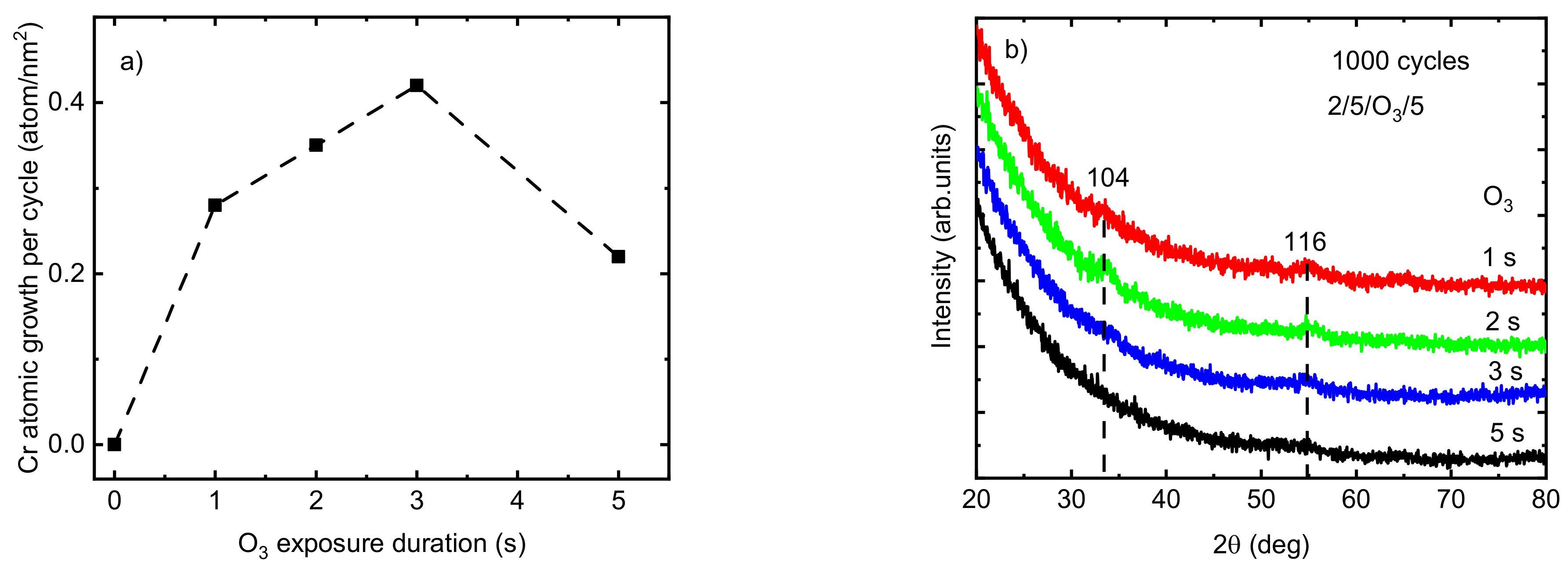

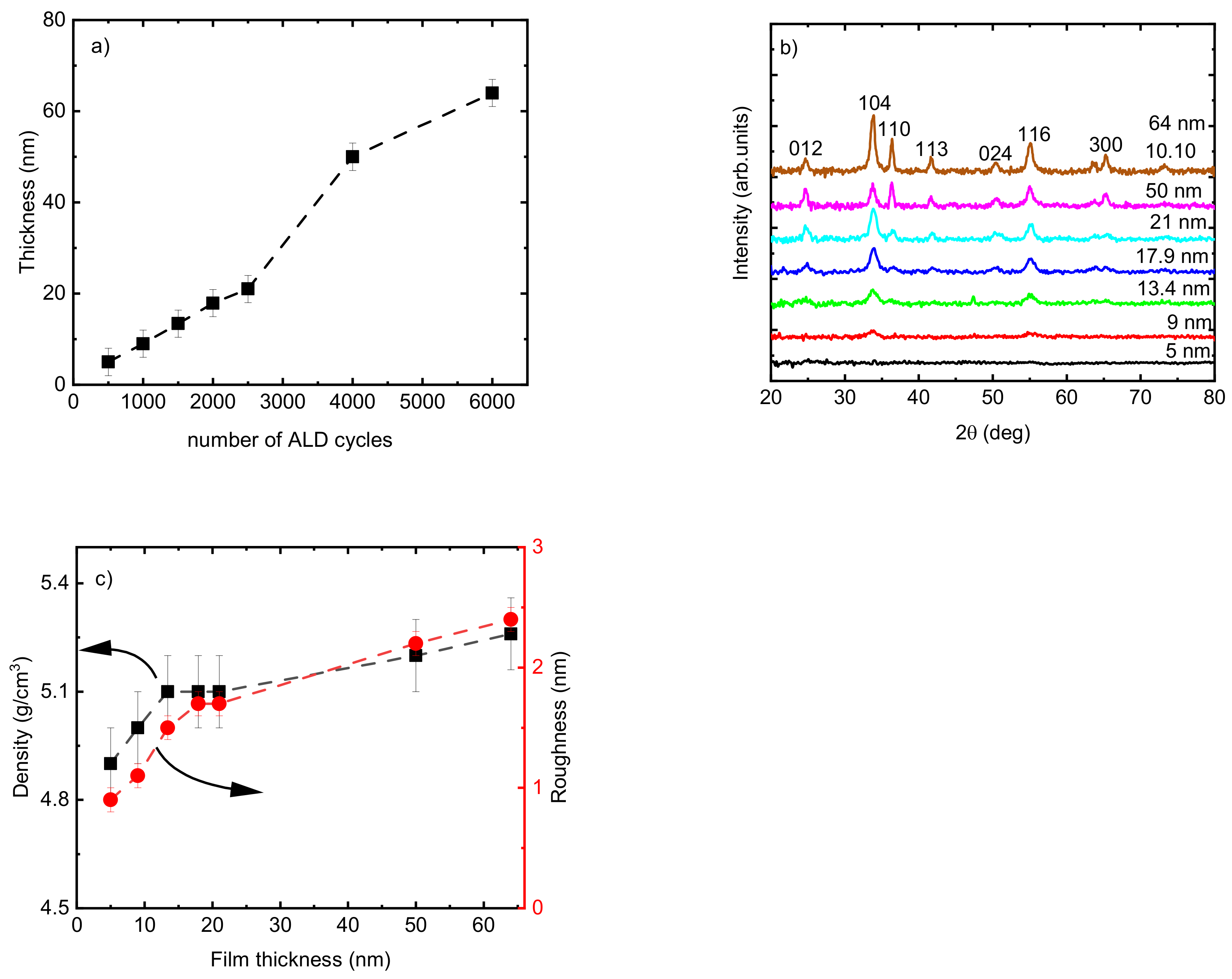

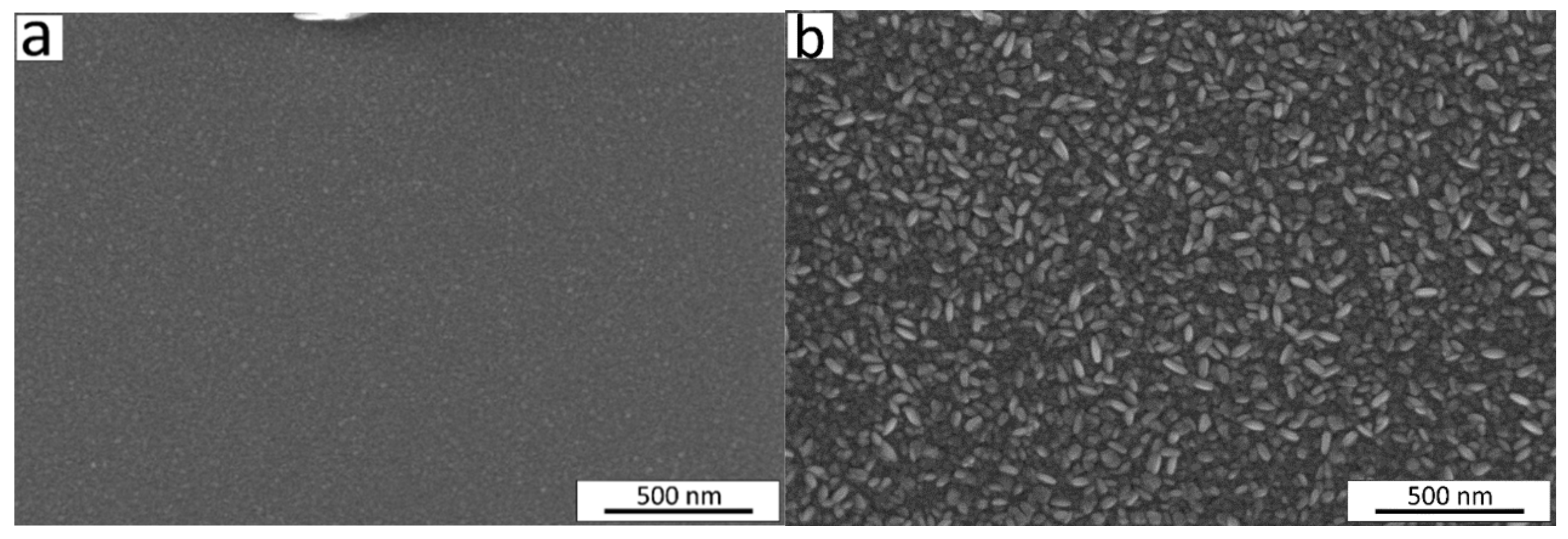

3.1. The Growth of Cr2O3

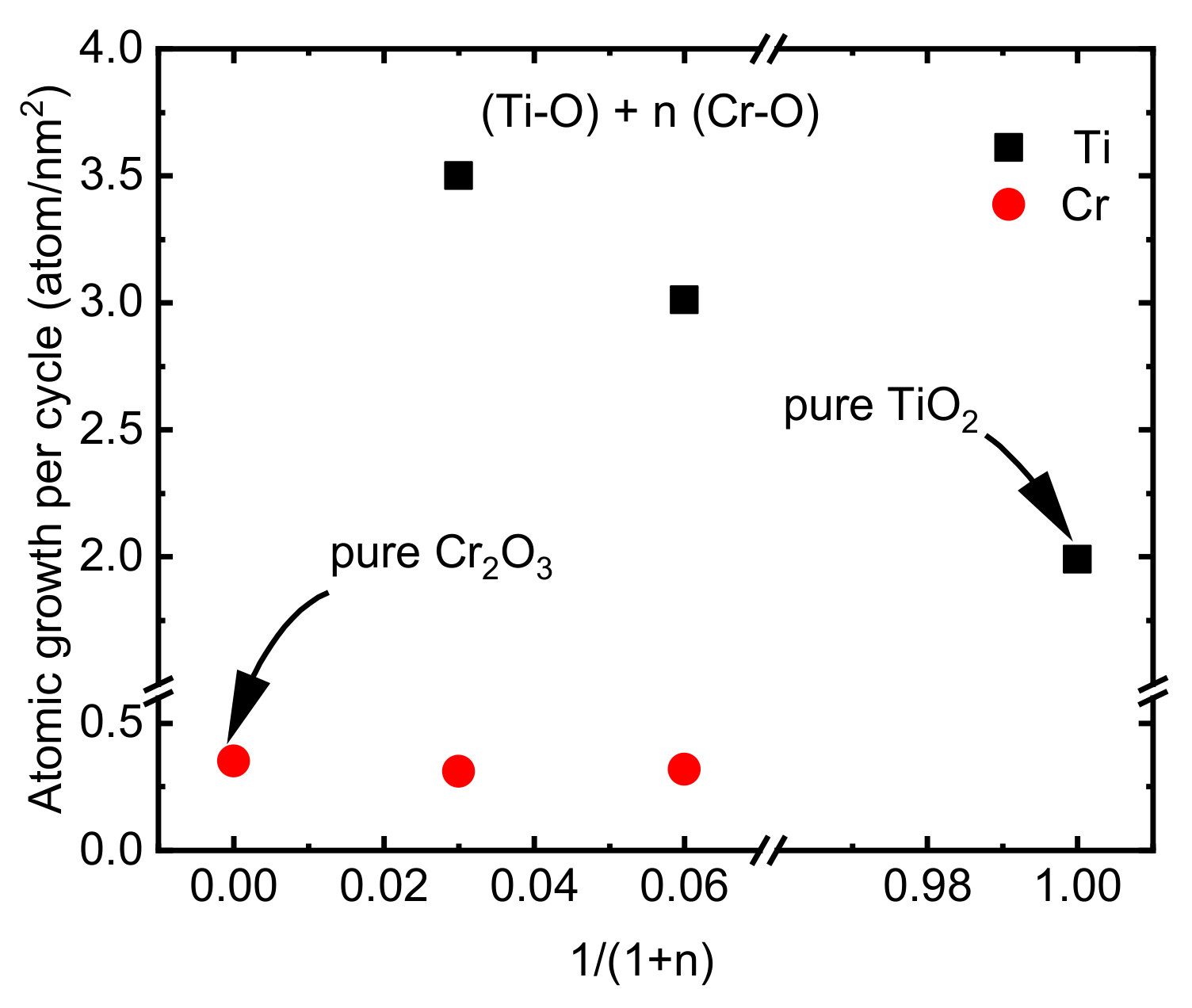

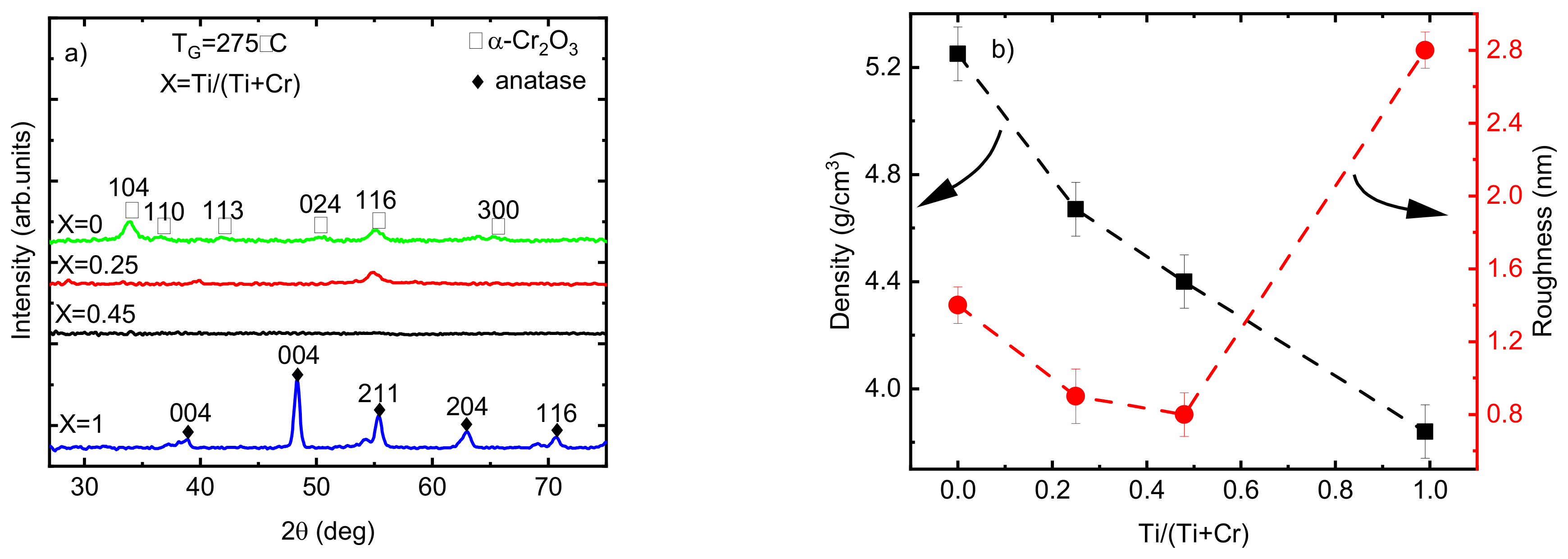

3.2. The Growth of CTO Films

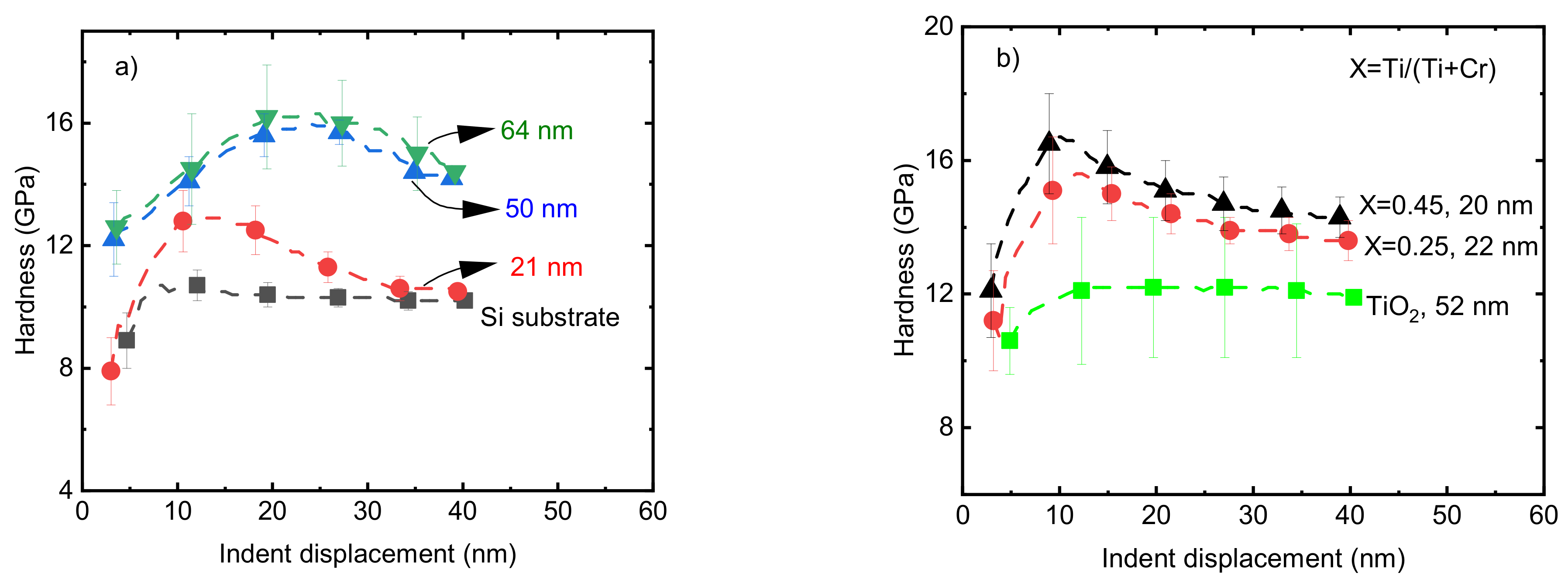

3.3. Mechanical Properties of the Films

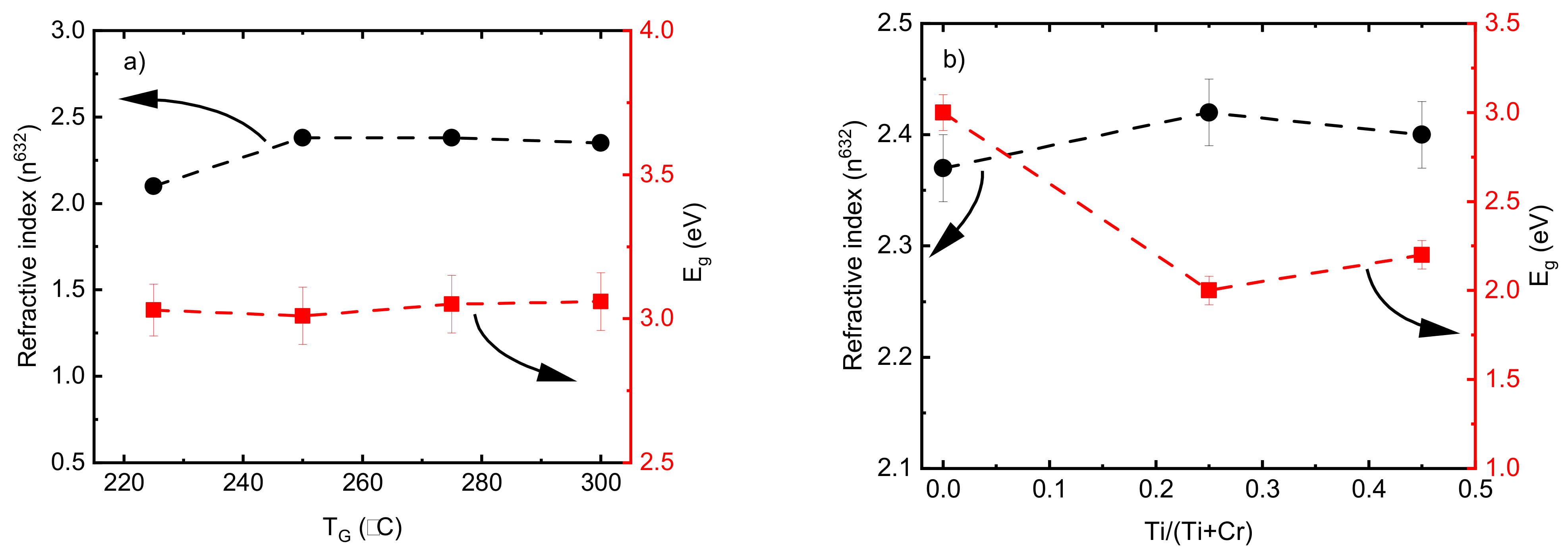

3.4. Optical Properties of Films

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bijker, M.D.; Bastiaens, J.J.J.; Draaisma, E.A.; de Jong, L.A.M.; Sourty, E.; Saied, S.O.; Sullivan, J.L. The Development of a Thin Cr2O3 Wear Protective Coating for the Advanced Digital Recording System. Tribol. Int. 2003, 36, 227–233. [Google Scholar] [CrossRef]

- Kaleel, S.G.; Suhail, M.H.; Kamil, H. Effect of Thermal Annealing on the Electrical Properties and Gas Sensing for Pulsed Laser Deposition Cr2O3 Thin Films. J. Phys. Conf. Ser. 2021, 1829, 012020. [Google Scholar] [CrossRef]

- Khelifa, A.B.; Khamlich, S.; Nuru, Z.Y.; Kotsedi, L.; Mebrahtu, A.; Balgouthi, M.; Guizani, A.A.; Dimassi, W.; Maaza, M. Growth and Characterization of Spectrally Selective Cr2O3/Cr/Cr2O3 Multilayered Solar Absorber by e-Beam Evaporation. J. Alloys Compd. 2018, 734, 204–209. [Google Scholar] [CrossRef]

- Oje, A.M.; Ogwu, A.A. Chromium Oxide Coatings with the Potential for Eliminating the Risk of Chromium Ion Release in Orthopaedic Implants. R. Soc. Open Sci. 2017, 4, 170218. [Google Scholar] [CrossRef]

- Ye, S. Magnetoelectric Switching Energy of Antiferromagnetic Cr2O3 Used for Spintronic Logic Devices and Memory. Phys. Status Solidi RRL Rapid Res. Lett. 2022, 16, 2100396. [Google Scholar] [CrossRef]

- Singh, J.; Verma, V.; Kumar, R. Preparation and Structural, Optical Studies of Al Substituted Chromium Oxide(Cr2O3) Nanoparticles. Vacuum 2019, 159, 282–286. [Google Scholar] [CrossRef]

- Mohammadtaheri, M.; Li, Y.; Yang, Q. Hard Cr2O3 Coatings on SS316L Substrates Prepared by Reactive Magnetron Sputtering Technique: A Potential Candidate for Orthopedic Implants. Environ. Sci. Pollut. Res. 2021, 28, 25146–25154. [Google Scholar] [CrossRef] [PubMed]

- Mittal, A.; Albertsson, G.J.; Gupta, G.S.; Seetharaman, S.; Subramanian, S. Some Thermodynamic Aspects of the Oxides of Chromium. Metall. Mater. Trans. B 2014, 45, 338–344. [Google Scholar] [CrossRef]

- Sammelselg, V.; Netšipailo, I.; Aidla, A.; Tarre, A.; Aarik, L.; Asari, J.; Ritslaid, P.; Aarik, J. Chemical Resistance of Thin Film Materials Based on Metal Oxides Grown by Atomic Layer Deposition. Thin Solid Films. 2013, 542, 219–224. [Google Scholar] [CrossRef]

- Borisov, P.; Hochstrat, A.; Shvartsman, V.V.; Kleemann, W.; Hauck, P.M. Magnetoelectric Cr2O3 for spintronic applications. Integr. Ferroelectr. 2008, 99, 69–76. [Google Scholar] [CrossRef]

- Almodóvar, P.; Santos, F.; González, J.; Ramírez-Castellanos, J.; González-Calbet, J.M.; Díaz-Guerra, C.; Fernández Romero, A.J. Study of Cr2O3 Nanoparticles Supported on Carbonaceous Materials as Catalysts for O2 Reduction Reaction. J. Electroanal. Chem. 2021, 895, 115441. [Google Scholar] [CrossRef]

- Zekaik, A.; Benhebal, H.; Benrabah, B.; Chibout, A.; Tayebi, N.; Kharroubi, A.; Ammari, A.; Dalache, C. Sol–Gel Synthesis of Nickel-Doped Cr2O3 Thin Films. J. Mol. Eng. Mater. 2017, 5, 1750012. [Google Scholar] [CrossRef]

- Hassan, H.B.; Hamid, Z.A. Electrodeposited Ni–Cr2O3 Nanocomposite Anodes for Ethanol Electrooxidation. Int. J. Hydrogen Energy 2011, 36, 5117–5127. [Google Scholar] [CrossRef]

- Yang, X.; Zeng, J.; Zhang, H.; Wang, J.; Sun, J.; Dong, S.; Jiang, J.; Deng, L.; Zhou, X.; Cao, X. Correlation between Microstructure, Chemical Components and Tribological Properties of Plasma-Sprayed Cr2O3-Based Coatings. Ceram. Int. 2018, 44, 10154–10168. [Google Scholar] [CrossRef]

- Kadari, A.; Schemme, T.; Kadri, D.; Wollschläger, J. XPS and Morphological Properties of Cr2O3 Thin Films Grown by Thermal Evaporation Method. Results Phys. 2017, 7, 3124–3129. [Google Scholar] [CrossRef]

- Chambers, S.A.; Williams, J.R.; Henderson, M.A.; Joly, A.G.; Varela, M.; Pennycook, S.J. Structure, Band Offsets and Photochemistry at Epitaxial α-Cr2O3/α-Fe2O3 Heterojunctions. Surf. Sci. 2005, 587, L197–L207. [Google Scholar] [CrossRef]

- Zhu, M.; Li, F.; Zhou, G.; Jin, X.; Wang, X.; Wang, L.; Song, F. Microstructures and Electrical Properties of Nanostructured Cr2O3 Thin Films Deposited by Dual-Target Reactive High-Power Impulse Magnetron Sputtering. Vacuum 2019, 164, 293–299. [Google Scholar] [CrossRef]

- Popovici, N.; Paramês, M.L.; Da Silva, R.C.; Monnereau, O.; Sousa, P.M.; Silvestre, A.J.; Conde, O. KrF Pulsed Laser Deposition of Chromium Oxide Thin Films from Cr8O21 Targets. Appl. Phys. A 2004, 79, 1409–1411. [Google Scholar] [CrossRef]

- Wang, J.; Gupta, A.; Klein, T.M. Plasma Enhanced Chemical Vapor Deposition of Cr2O3 Thin Films Using Chromium Hexacarbonyl(Cr(CO)6) Precursor. Thin Solid Film. 2008, 516, 7366–7372. [Google Scholar] [CrossRef]

- Tarre, A.; Aarik, J.; Mändar, H.; Niilisk, A.; Pärna, R.; Rammula, R.; Uustare, T.; Rosental, A.; Sammelselg, V. Atomic Layer Deposition of Cr2O3 Thin Films: Effect of Crystallization on Growth and Properties. Appl. Surf. Sci. 2008, 254, 5149–5156. [Google Scholar] [CrossRef]

- Ponraj, J.S.; Attolini, G.; Bosi, M. Review on Atomic Layer Deposition and Applications of Oxide Thin Films. Crit. Rev. Solid State Mater. Sci. 2013, 38, 203–233. [Google Scholar] [CrossRef]

- Cremers, V.; Puurunen, R.L.; Dendooven, J. Conformality in Atomic Layer Deposition: Current Status Overview of Analysis and Modelling. Appl. Phys. Rev. 2019, 6, 021302. [Google Scholar] [CrossRef]

- Ezhovskii, Y.K.; Kholkin, V.Y. The Preparation and Properties of Chromium Oxide Nanolayers on Semiconducting Matrices. Russ. J. Phys. Chem. A 2008, 82, 1154–1158. [Google Scholar] [CrossRef]

- Tripathi, T.S.; Niemelä, J.-P.; Karppinen, M. Atomic Layer Deposition of Transparent Semiconducting Oxide CuCrO2 Thin Films. J. Mater. Chem. C 2015, 3, 8364–8371. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kang, J.-C. The Chromium Accumulation and Its Physiological Effects in Juvenile Rockfish, Sebastes Schlegelii, Exposed to Different Levels of Dietary Chromium(Cr6+) Concentrations. Environ. Toxicol. Pharmacol. 2016, 41, 152–158. [Google Scholar] [CrossRef]

- Paiva, L.B.; de Oliveira, J.G.; Azevedo, R.A.; Ribeiro, D.R.; da Silva, M.G.; Vitória, A.P. Ecophysiological Responses of Water Hyacinth Exposed to Cr3+ and Cr6+. Environ. Exp. Bot. 2009, 65, 403–409. [Google Scholar] [CrossRef]

- Mandol, B.; Mahuli, N.; Ohno, K.; Scudder, L.; Sarkar, S.K. Atomic Layer Deposition of Chromium Oxide—An Interplay between Deposition and Etching. J. Vac. Sci. Technol. A 2021, 39, 032414. [Google Scholar] [CrossRef]

- Aarik, L.; Mändar, H.; Ritslaid, P.; Tarre, A.; Kozlova, J.; Aarik, J. Low-Temperature Atomic Layer Deposition of α-Al2O3 Thin Films. Cryst. Growth Des. 2021, 21, 4220–4229. [Google Scholar] [CrossRef]

- Mohammadtaheri, M.; Li, Y.; Corona-Gomez, J.; Yang, Q. An Investigation on Synthesis and Characterization of Superhard Cr-Zr-O Coatings. Surf. Coat. Technol. 2019, 375, 694–700. [Google Scholar] [CrossRef]

- Liu, H.D.; Wan, Q.; Lin, B.Z.; Wang, L.L.; Yang, X.F.; Wang, R.Y.; Gong, D.Q.; Wang, Y.B.; Ren, F.; Chen, Y.M.; et al. The Spectral Properties and Thermal Stability of CrAlO-Based Solar Selective Absorbing Nanocomposite Coating. Sol. Energy Mater. Sol. Cells 2014, 122, 226–232. [Google Scholar] [CrossRef]

- Zekaik, A.; Benhebal, H.; Benrabah, B. Synthesis and Characterization of Cu Doped Chromium Oxide(Cr2O3) Thin Films. High Temp. Mater. Process. 2019, 38, 806–812. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; He, T. The Doping Mechanism of Cr into TiO2 and Its Influence on the Photocatalytic Performance. Phys.Chem. Chem. Phys. 2013, 15, 20037–20045. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Kumar, E.S.; Rao, M.R. Microstructural, Optical and Electrical Properties of Cr-Doped ZnO. Scr. Mater. 2008, 58, 866–869. [Google Scholar] [CrossRef]

- Bahrami, A.; Delgado, A.; Onofre, C.; Muhl, S.; Rodil, S.E. Structure, Mechanical Properties and Corrosion Resistance of Amorphous Ti-Cr-O Coatings. Surf. Coat. Technol. 2019, 374, 690–699. [Google Scholar] [CrossRef]

- Baraskar, P.; Chouhan, R.; Agrawal, A.; Choudhary, R.J.; Sen, P. Weak Ferromagnetism at Room Temperature in Ti Incorporated Cr2O3 Thin Film. Phys. B Condens. Matter. 2019, 571, 36–40. [Google Scholar] [CrossRef]

- Nagai, H.; Ohbayashi, K. Effect of TiO2 on the Sintering and the Electrical Conductivity of Cr2O3. J. Am. Ceram. Soc. 1989, 72, 400–403. [Google Scholar] [CrossRef]

- Arroval, T.; Aarik, L.; Rammula, R.; Kruusla, V.; Aarik, J. Effect of Substrate-Enhanced and Inhibited Growth on Atomic Layer Deposition and Properties of Aluminum-Titanium Oxide Films. Thin Solid Films 2016, 600, 119–125. [Google Scholar] [CrossRef]

- Langford, J.I.; Wilson, A.J.C. Scherrer after Sixty Years: A Survey and Some New Results in the Determination of Crystallite Size. J. Appl. Cryst. 1978, 11, 102–113. [Google Scholar] [CrossRef]

- Barrett, C.S.; Massalski, T.B. Structure of Metals, Third Edition: Crystallographic Methods, Principles and Data; Pergamon Press: Oxford, UK, 1980; 654p, ISBN 10-0080261728. [Google Scholar]

- Putkonen, M.; Nieminen, M.; Niinistö, J.; Niinistö, L.; Sajavaara, T. Surface-Controlled Deposition of Sc2O3 Thin Films by Atomic Layer Epitaxy Using β-Diketonate and Organometallic Precursors. Chem. Mater. 2001, 13, 4701–4707. [Google Scholar] [CrossRef]

- Aarik, J.; Kukli, K.; Aidla, A.; Pung, L. Mechanisms of Suboxide Growth and Etching in Atomic Layer Deposition of Tantalum Oxide from TaCl5 and H2O. Appl. Surf. Sci. 1996, 103, 331–341. [Google Scholar] [CrossRef]

- Li, W.; Gibbs, G.V.; Oyama, S.T. Mechanism of Ozone Decomposition on a Manganese Oxide Catalyst. 1. In Situ Raman Spectroscopy and Ab Initio Molecular Orbital Calculations. J. Am. Chem. Soc. 1998, 120, 9041–9046. [Google Scholar] [CrossRef]

- Imamura, S.; Ikebata, M.; Ito, T.; Ogita, T. Decomposition of Ozone on a Silver Catalyst. Ind. Eng. Chem. Res. 1991, 30, 217–221. [Google Scholar] [CrossRef]

- Yuan, G.; Wang, N.; Huang, S.; Liu, J. A Brief Overview of Atomic Layer Deposition and Etching in the Semiconductor Processing. In Proceedings of the 2016 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; pp. 1365–1368. [Google Scholar] [CrossRef]

- Kanarik, K.J.; Tan, S.; Gottscho, R.A. Atomic Layer Etching: Rethinking the Art of Etch. J. Phys. Chem. Let. 2018, 9, 4814–4821. [Google Scholar] [CrossRef]

- Ohba, T.; Yang, W.; Tan, S.; Kanarik, K.J.; Nojiri, K. Atomic Layer Etching of GaN and AlGaN Using Directional Plasma-Enhanced Approach. Jpn. J. Appl. Phys. 2017, 56, 06HB06. [Google Scholar] [CrossRef]

- Eklund, P.; Sridharan, M.; Sillassen, M.; Böttiger, J. α-Cr2O3 Template-Texture Effect on α-Al2O3 Thin-Film Growth. Thin Solid Films 2008, 516, 7447–7450. [Google Scholar] [CrossRef]

- Jõgiaas, T.; Tarre, A.; Mändar, H.; Kozlova, J.; Tamm, A. Nanoindentation of Chromium Oxide Possessing Superior Hardness among Atomic-Layer-Deposited Oxides. Nanomaterials 2021, 12, 82. [Google Scholar] [CrossRef]

- Aarik, J.; Arroval, T.; Aarik, L.; Rammula, R.; Kasikov, A.; Mändar, H.; Hudec, B.; Hušeková, K.; Fröhlich, K. Atomic Layer Deposition of Rutile-Phase TiO2 on RuO2 from TiCl4 and O3: Growth of High-Permittivity Dielectrics with Low Leakage Current. J. Cryst. Growth 2013, 382, 61–66. [Google Scholar] [CrossRef]

- Martinez, G.; Shutthanandan, V.; Thevuthasan, S.; Chessa, J.F.; Ramana, C.V. Effect of Thickness on the Structure, Composition and Properties of Titanium Nitride Nano-Coatings. Ceram. Int. 2014, 40, 5757–5764. [Google Scholar] [CrossRef]

- Chen, S.; Liu, L.; Wang, T. Investigation of the Mechanical Properties of Thin Films by Nanoindentation, Considering the Effects of Thickness and Different Coating–Substrate Combinations. Surf. Coat. Technol. 2005, 191, 25–32. [Google Scholar] [CrossRef]

- Weertman, J.R. Hall-Petch Strengthening in Nanocrystalline Metals. Mater. Sci. Eng. A 1993, 166, 161–167. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, G.; Wood, R.J.K.; Wang, S.C.; Xue, Q. Fabrication of CrAlN Nanocomposite Films with High Hardness and Excellent Anti-Wear Performance for Gear Application. Surf. Coat. Technol. 2010, 204, 3517–3524. [Google Scholar] [CrossRef]

- Diserens, M.; Patscheider, J.; Levy, F. Mechanical Properties and Oxidation Resistance of Nanocomposite TiN–SiNx Physical-Vapor-Deposited Thin Films. Surf. Coat. Technol. 1999, 120, 158–165. [Google Scholar] [CrossRef]

- Spitz, S.; Stüber, M.; Leiste, H.; Ulrich, S.; Seifert, H.J. Microstructure and Hardness of Reactively r.f. Magnetron Sputtered Cr-V-O Thin Films in Dependence on Composition and Substrate Bias. Surf. Coat. Technol. 2014, 257, 355–362. [Google Scholar] [CrossRef]

- Li, N.; Li, G.; Wang, H.; Kang, J.; Dong, T.; Wang, H. Influence of TiO2 Content on the Mechanical and Tribological Properties of Cr2O3-Based Coating. Mater. Des. 2015, 88, 906–914. [Google Scholar] [CrossRef]

- Huang, H.; Winchester, K.J.; Suvorova, A.; Lawn, B.R.; Liu, Y.; Hu, X.Z.; Dell, J.M.; Faraone, L. Effect of Deposition Conditions on Mechanical Properties of Low-Temperature PECVD Silicon Nitride Films. Mater. Sci. Eng. A 2006, 435–436, 453–459. [Google Scholar] [CrossRef]

- Patsalas, P.; Charitidis, C.; Logothetidis, S. The Effect of Substrate Temperature and Biasing on the Mechanical Properties and Structure of Sputtered Titanium Nitride Thin Films. Surf. Coat. Technol. 2000, 125, 335–340. [Google Scholar] [CrossRef]

- Kasikov, A.; Tarre, A.; Vinuesa, G. Inhomogeneous HfO2 Layer Growth at Atomic Layer Deposition. J. Electr. Eng. 2023, 74, 246–255. [Google Scholar] [CrossRef]

- Haryński, Ł.; Olejnik, A.; Grochowska, K.; Siuzdak, K. A Facile Method for Tauc Exponent and Corresponding Electronic Transitions Determination in Semiconductors Directly from UV–Vis Spectroscopy Data. Opt. Mater. 2022, 127, 112205. [Google Scholar] [CrossRef]

- Bhardwaj, P.; Singh, J.; Kumar, R.; Kumar, R.; Verma, V. Structural, Optical and Magnetic Characterization of Ni2+ Ions Doped Chromium Oxide(Cr2O3) Nanoparticles. Solid State Sci. 2021, 115, 106581. [Google Scholar] [CrossRef]

- Aarik, L.; Arroval, T.; Rammula, R.; Mändar, H.; Sammelselg, V.; Aarik, J. Atomic layer deposition of TiO2 from TiCl4 and O3. Thin Solid Film. 2013, 542, 100–107. [Google Scholar] [CrossRef]

| hkl | 275 °C | 300 °C |

|---|---|---|

| 012 | 0.9 ± 0.09 | 1.4 ± 0.14 |

| 104 | 1.6 ± 0.16 | 0.7 ± 0.07 |

| 110 | 0.3 ± 0.03 | 0.8 ± 0.08 |

| 116 | 1.0 ± 0.1 | 0.9 ± 0.1 |

| STD | 0.46 | 0.27 |

| ALD Formula | Number of Super Cycles | Film Thickness (nm) | Ti (atm%) | Cr (atm%) | O (atm%) | Cl (atm%) | Ti/(Ti+Cr) |

|---|---|---|---|---|---|---|---|

| Cr2O3 | 2000 | 18 | 0 | 42 | 58 | 0.0 | 0 |

| (Cr—O) + (Ti—O) | 500 | 33 | 32 | 1 | 66 | 0.04 | 0.97 |

| (Cr—O) + 5(Ti—O) | 140 | 38 | 33 | 0.2 | 66 | 0.06 | 0.99 |

| (Cr—O) + 30 (Ti—O) | 137 | 48 | 34 | 0 | 65 | 0.06 | 1 |

| 15 (Cr—O) + (Ti—O) | 80 | 20 | 19 | 20 | 61 | 0.04 | 0.45 |

| 30 (Cr—O) + (Ti—O) | 45 | 22 | 10 | 29 | 60 | 0.03 | 0.25 |

| TiO2 | 1000 | 52 | 33 | 0 | 65 | 0.08 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salari Mehr, M.; Aarik, L.; Jõgiaas, T.; Kasikov, A.; Damerchi, E.; Mändar, H. Mechanical and Optical Properties of Cr2O3 Thin Films Grown by Atomic Layer Deposition Method Using Cr(thd)3 and Ozone. Nanomaterials 2023, 13, 2702. https://doi.org/10.3390/nano13192702

Salari Mehr M, Aarik L, Jõgiaas T, Kasikov A, Damerchi E, Mändar H. Mechanical and Optical Properties of Cr2O3 Thin Films Grown by Atomic Layer Deposition Method Using Cr(thd)3 and Ozone. Nanomaterials. 2023; 13(19):2702. https://doi.org/10.3390/nano13192702

Chicago/Turabian StyleSalari Mehr, Mahtab, Lauri Aarik, Taivo Jõgiaas, Aarne Kasikov, Elyad Damerchi, and Hugo Mändar. 2023. "Mechanical and Optical Properties of Cr2O3 Thin Films Grown by Atomic Layer Deposition Method Using Cr(thd)3 and Ozone" Nanomaterials 13, no. 19: 2702. https://doi.org/10.3390/nano13192702

APA StyleSalari Mehr, M., Aarik, L., Jõgiaas, T., Kasikov, A., Damerchi, E., & Mändar, H. (2023). Mechanical and Optical Properties of Cr2O3 Thin Films Grown by Atomic Layer Deposition Method Using Cr(thd)3 and Ozone. Nanomaterials, 13(19), 2702. https://doi.org/10.3390/nano13192702