Preparation and Characterization of Non-Crimping Laminated Textile Composites Reinforced with Electrospun Nanofibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

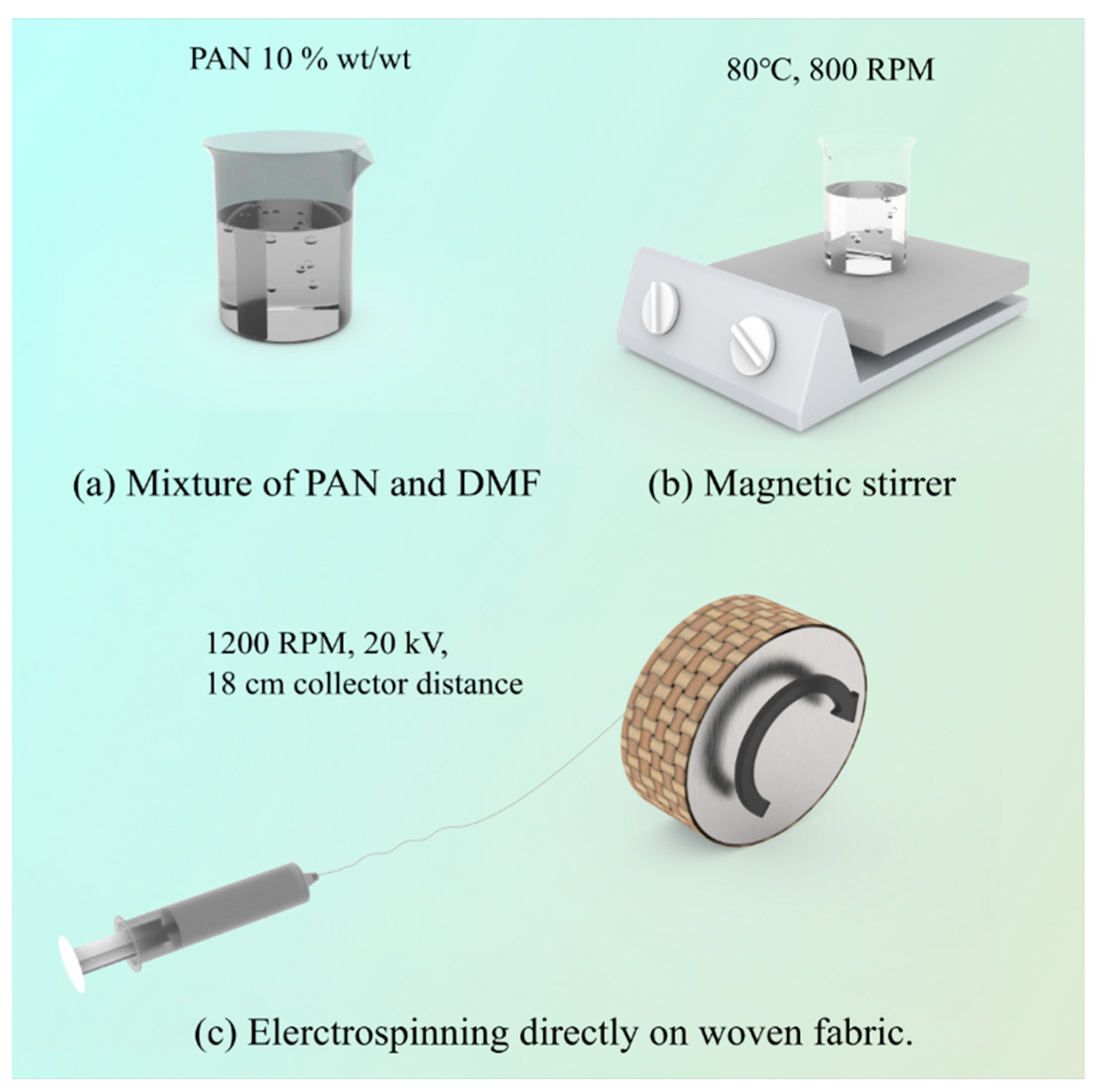

2.2. Fabrication of Nanofiber-Laminated Composite Fabrics

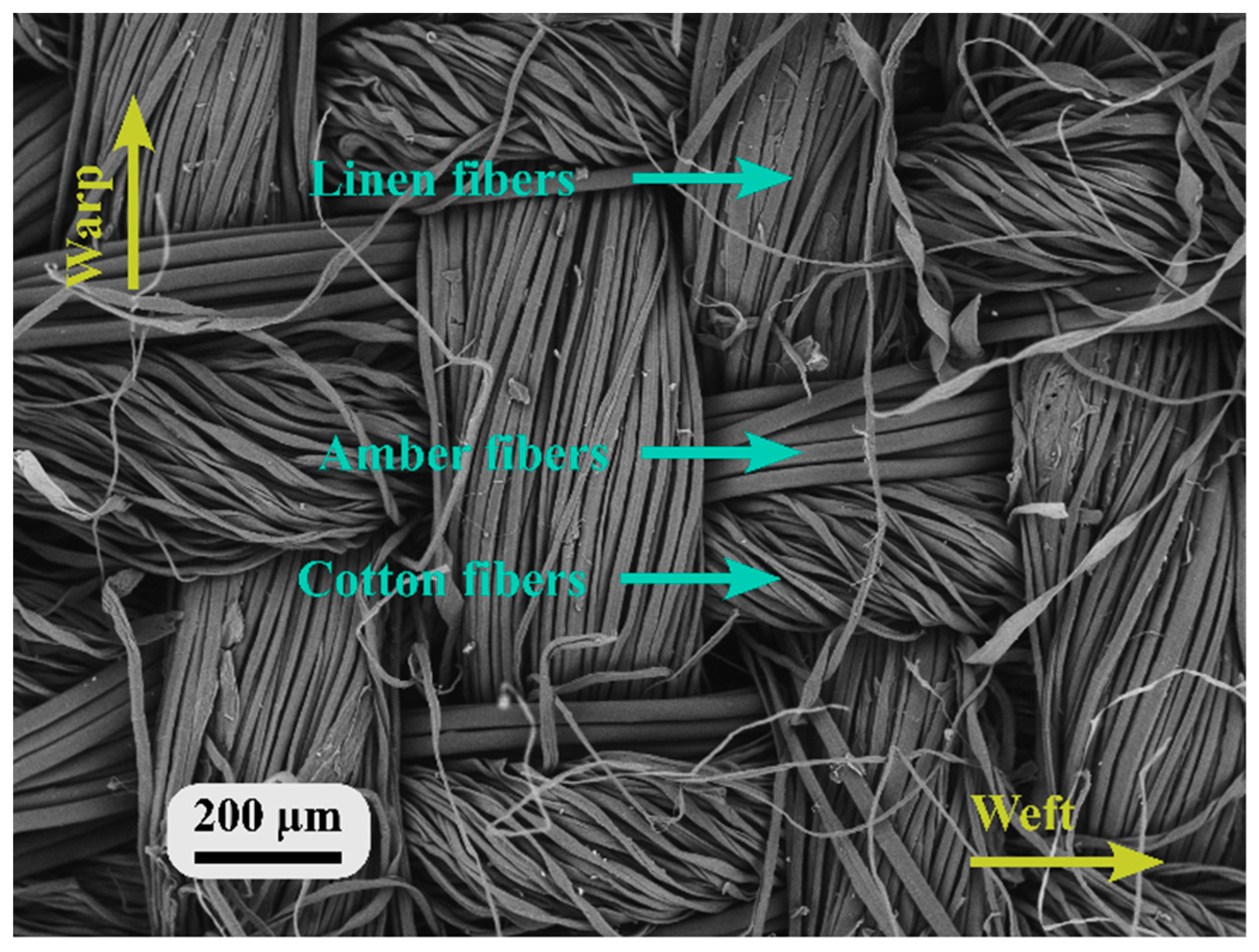

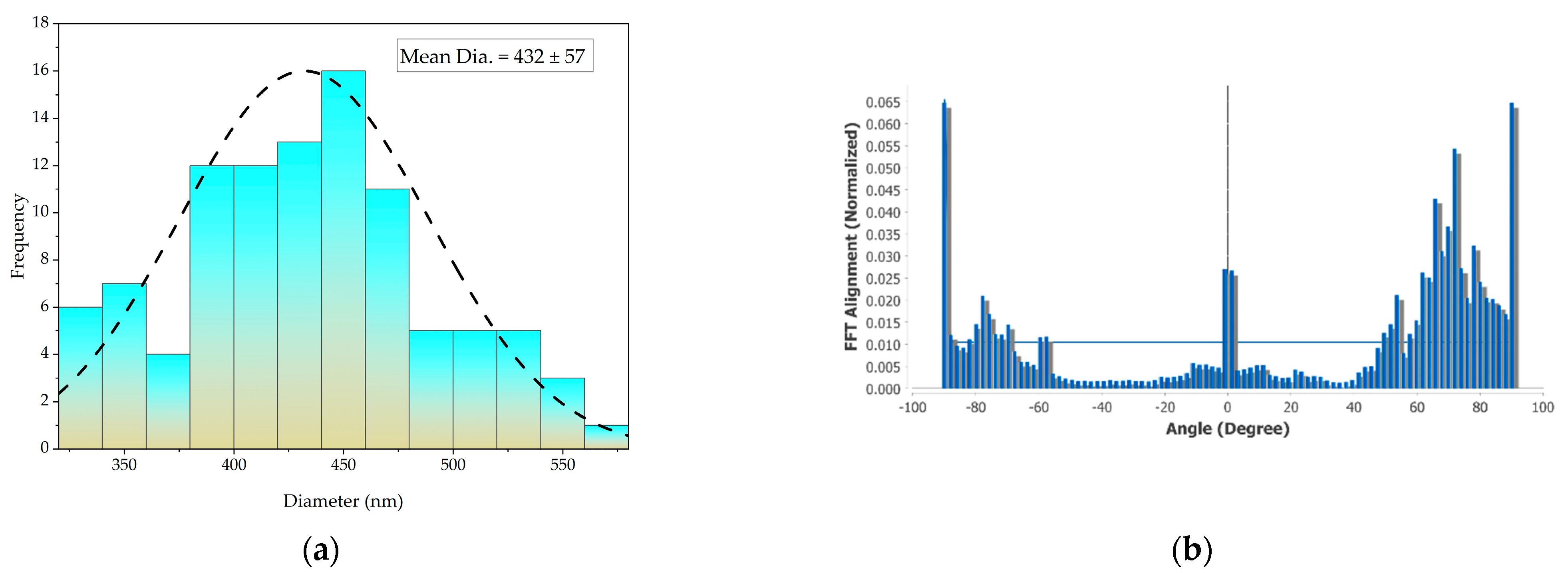

2.3. Morphology of the Composite Nanofiber-Laminated Textiles

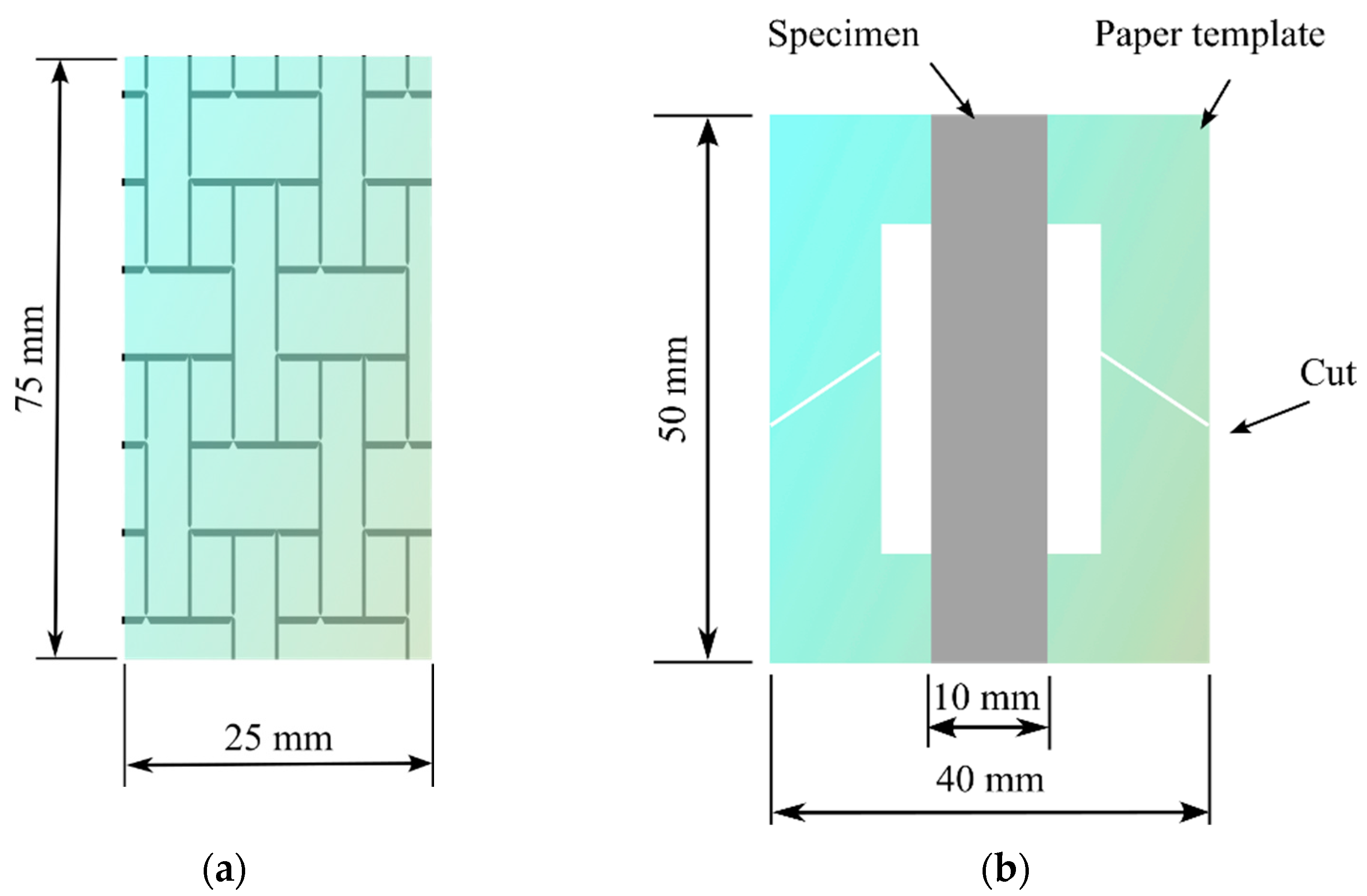

2.4. Tensile Properties

3. Results and Discussion

3.1. Morphology

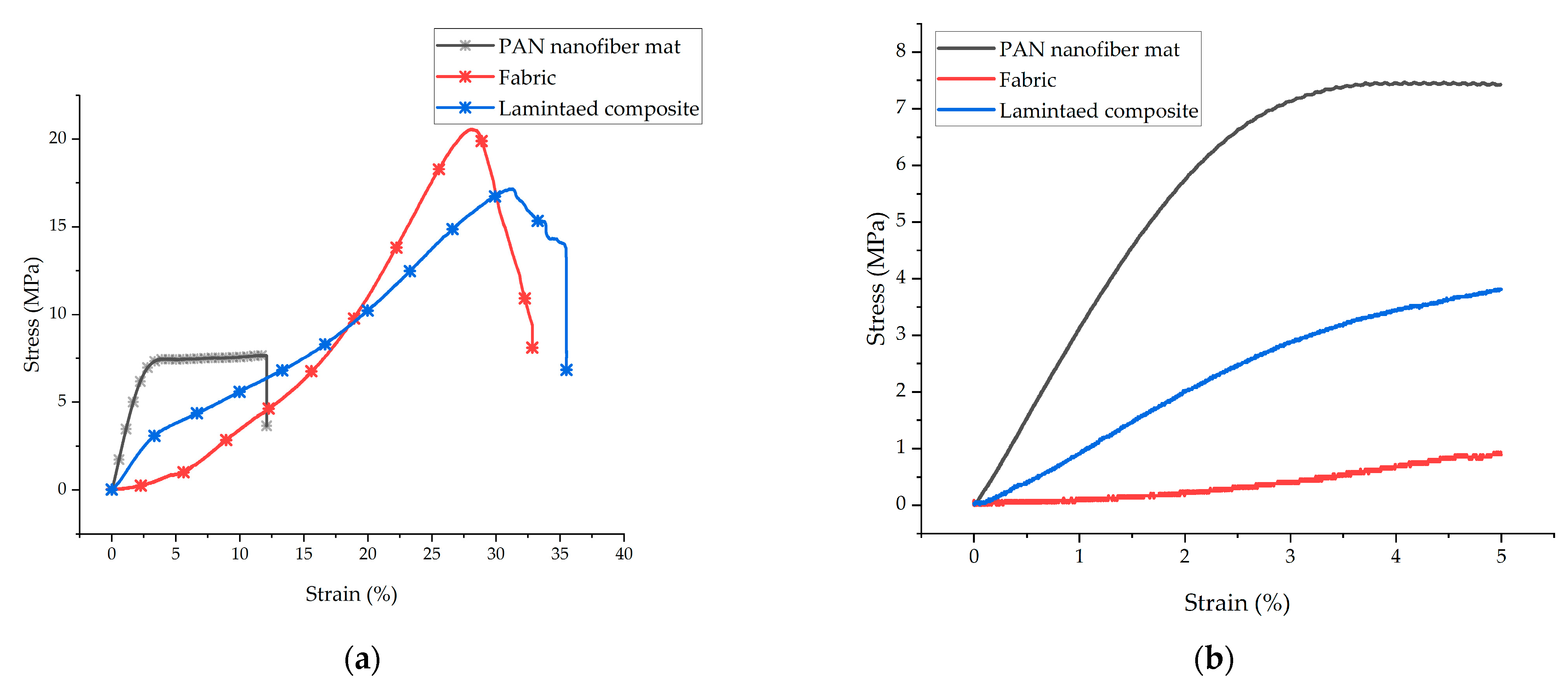

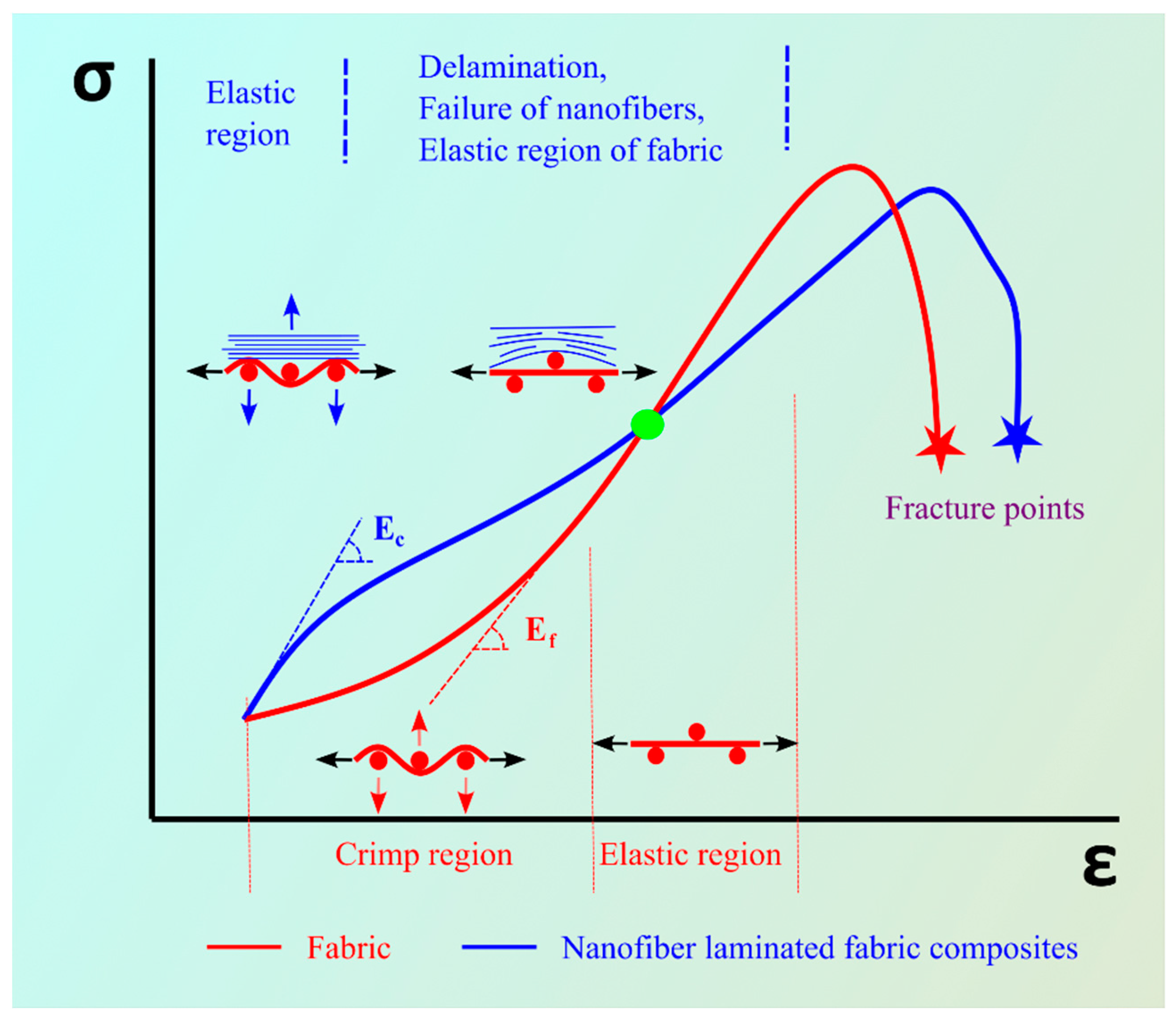

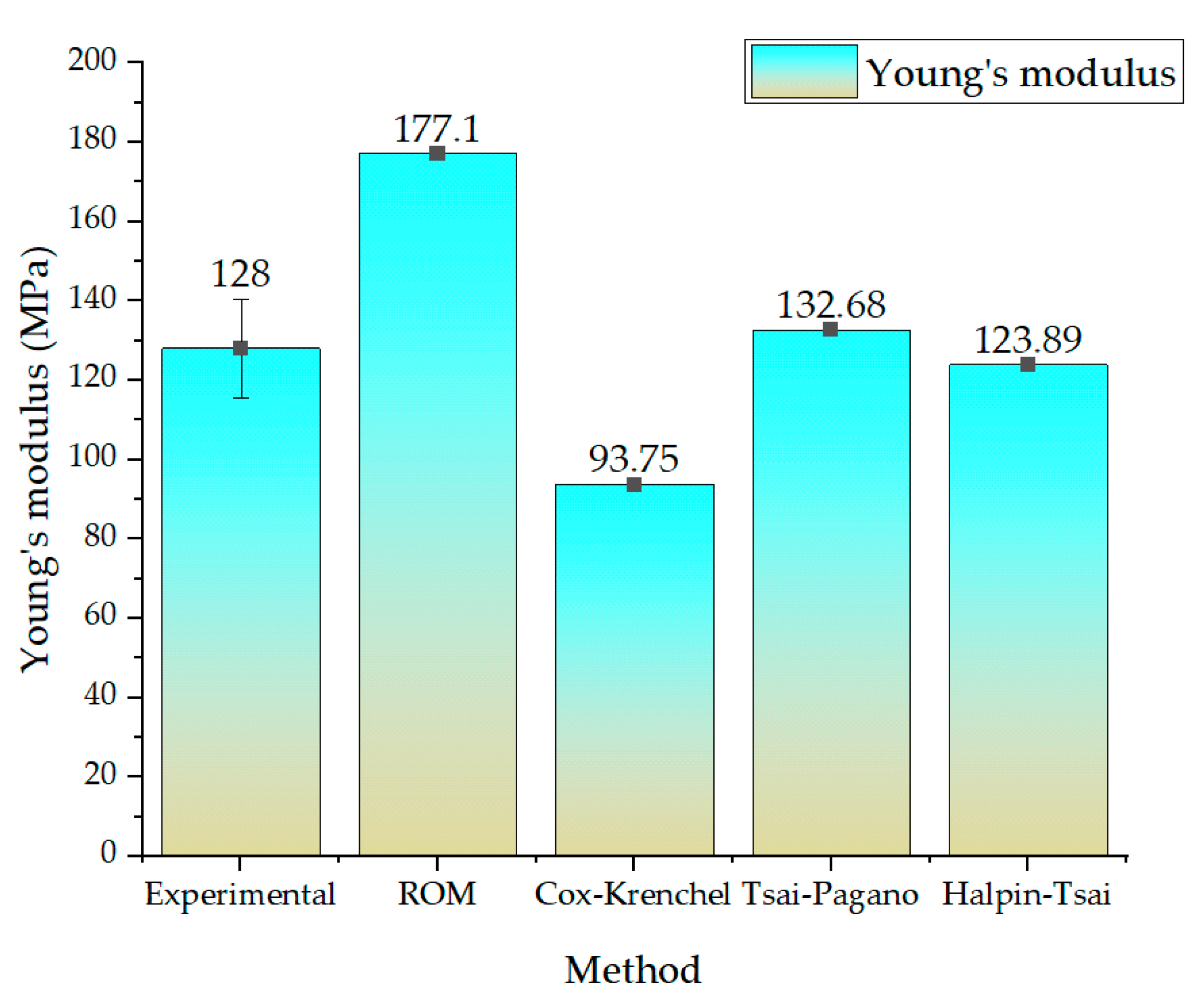

3.2. Tensile Tests

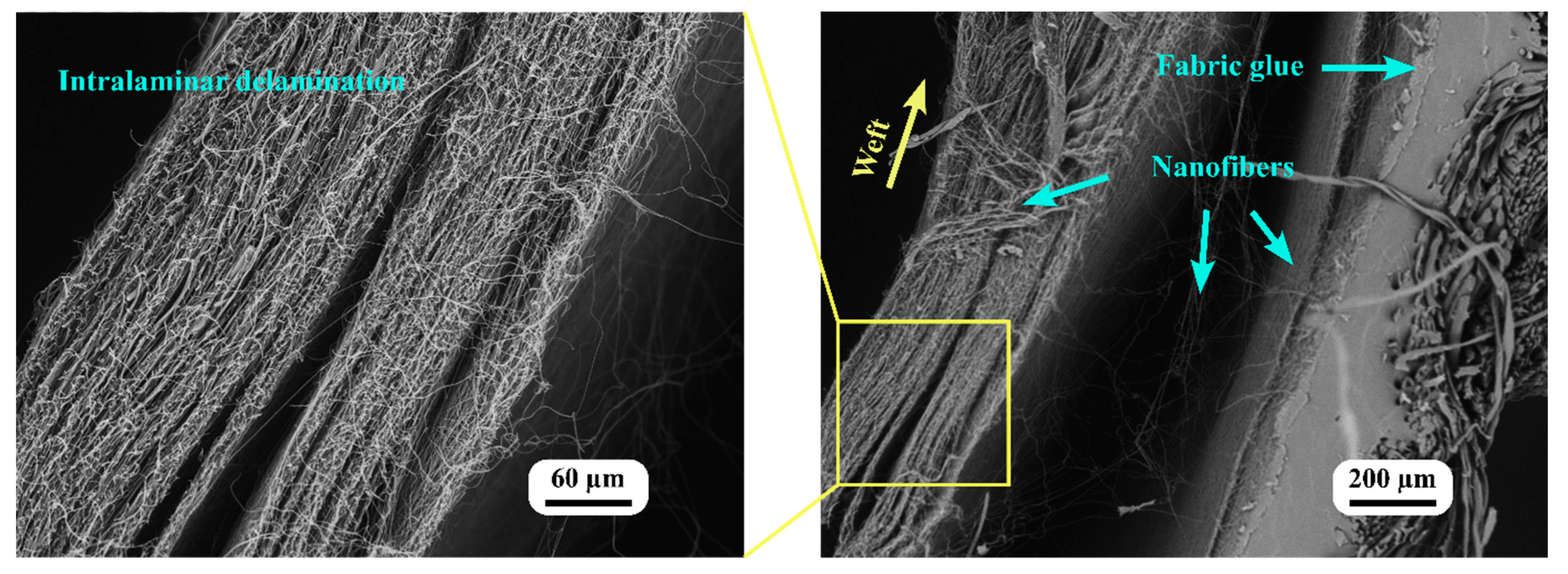

3.3. SEM Analysis after Tensile Testing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- You, X.; He, J.; Nan, N.; Sun, X.; Qi, K.; Zhou, Y.; Shao, W.; Liu, F.; Cui, S. Stretchable capacitive fabric electronic skin woven by electrospun nanofiber coated yarns for detecting tactile and multimodal mechanical stimuli. J. Mater. Chem. C 2018, 6, 12981–12991. [Google Scholar] [CrossRef]

- Jin, H.; Nayeem, M.O.G.; Lee, S.; Matsuhisa, N.; Inoue, D.; Yokota, T.; Hashizume, D.; Someya, T. Highly durable nanofiber-reinforced elastic conductors for skin-tight electronic textiles. ACS Nano 2019, 13, 7905–7912. [Google Scholar] [CrossRef]

- Meena, J.S.; Choi, S.B.; Jung, S.-B.; Kim, J.-W. Electronic textiles: New age of wearable technology for healthcare and fitness solutions. Mater. Today Bio 2023, 19, 100565. [Google Scholar] [CrossRef]

- Georgopoulou, A.; Michel, S.; Clemens, F. Sensorized robotic skin based on piezoresistive sensor fiber composites produced with injection molding of liquid silicone. Polymers 2021, 13, 1226. [Google Scholar] [CrossRef]

- Sharma, S.; Chhetry, A.; Zhang, S.; Yoon, H.; Park, C.; Kim, H.; Sharifuzzaman, M.; Hui, X.; Park, J.Y. Hydrogen-Bond-Triggered hybrid nanofibrous membrane-based wearable pressure sensor with ultrahigh sensitivity over a broad pressure range. ACS Nano 2021, 15, 4380–4393. [Google Scholar] [CrossRef]

- Kang, M.; Kim, J.; Jang, B.; Chae, Y.; Kim, J.H.; Ahn, J.H. Graphene-based three-dimensional capacitive touch sensor for wearable electronics. ACS Nano 2017, 11, 7950–7957. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, B.; Ma, P. Advances in mechanical properties of flexible textile composites. Compos. Struct. 2023, 303, 116350. [Google Scholar] [CrossRef]

- Qiu, Q.; Chen, S.; Li, Y.; Yang, Y.; Zhang, H.; Quan, Z.; Qin, X.; Wang, R.; Yu, J. Functional nanofibers embedded into textiles for durable antibacterial properties. Chem. Eng. J. 2020, 384, 123241. [Google Scholar] [CrossRef]

- Lasenko, I.; Grauda, D.; Butkauskas, D.; Sanchaniya, J.V.; Viluma-Gudmona, A.; Lusis, V. Testing the physical and mechanical properties of polyacrylonitrile nanofibers reinforced with succinite and silicon dioxide nanoparticles. Textiles 2022, 2, 162–173. [Google Scholar] [CrossRef]

- Viluma-Gudmona, A.; Lasenko, I.; Sanchaniya, J.V.; Podgornovs, A. Electro-resistant biotextile development based on fiber reinforcement with nano particles. In Proceedings of the 20th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021; pp. 804–812. [Google Scholar]

- Munir, M.U.; Mayer-Gall, T.; Gutmann, J.S.; Ali, W.; Etemad-Parishanzadeh, O.; Khanzada, H.; Mikučioniene, D. Development of carbon-nanodot-loaded PLA nanofibers and study of their barrier performance for medical applications. Nanomaterials 2023, 13, 1195. [Google Scholar] [CrossRef]

- Ambekar, R.S.; Kandasubramanian, B. Advancements in nanofibers for wound dressing: A review. Eur. Polym. J. 2019, 117, 304–336. [Google Scholar] [CrossRef]

- Homaeigohar, S.; Boccaccini, A.R. Antibacterial biohybrid nanofibers for wound dressings. Acta Biomater. 2020, 107, 25–49. [Google Scholar] [CrossRef]

- Arun, A.; Malrautu, P.; Laha, A.; Ramakrishna, S. Gelatin nanofibers in drug delivery systems and tissue engineering. Eng. Sci. 2021, 16, 71–81. [Google Scholar] [CrossRef]

- Nemati, S.; Kim, S.J.; Shin, Y.M.; Shin, H. Current progress in application of polymeric nanofibers to tissue engineering. Nano Converg. 2019, 6, 36. [Google Scholar] [CrossRef] [PubMed]

- Hanumantharao, S.N.; Rao, S. Multi-functional electrospun nanofibers from polymer blends for scaffold tissue engineering. Fibers 2019, 7, 66. [Google Scholar] [CrossRef]

- Lusis, V.; Kononova, O.; Macanovskis, A.; Stonys, R.; Lasenko, I.; Krasnikovs, A. Experimental investigation and modelling of the layered concrete with different concentration of short fibers in the layers. Fibers Spec. Issue Mech. Fiber Reinf. Cem. Compos. 2021, 9, 76. [Google Scholar] [CrossRef]

- Lusis, V.; Annamaneni, K.K.; Kononova, O.; Korjakins, A.; Lasenko, I.; Karunamoorthy, R.K.; Krasnikovs, A. Experimental study and modelling on the structural response of fiber reinforced concrete beams. Appl. Sci. 2022, 12, 9492. [Google Scholar] [CrossRef]

- Lasenko, I.; Sanchaniya, J.V.; Kanukuntla, S.P.; Ladani, Y.; Viluma-gudmona, A.; Kononova, O.; Lusis, V.; Tipans, I.; Selga, T. The mechanical properties of nanocomposites reinforced with PA6 electrospun nanofibers. Multidiscip. Digit. Publ. Inst. 2023, 15, 673. [Google Scholar] [CrossRef]

- Lasenko, I.; Sanchaniya, J.V.; Kanukuntala, S.-P.; Smogor, H.; Viluma-Gudmona, A.; Krasnikovs, A.; Gobins, V.; Tipans, I. Mechanical and thermal characteristics of annealed-oriented PAN nanofibers. Polymers 2023. Unpublished work. [Google Scholar]

- Wang, W.B.S.; Clapper, J.C. Antibacterial activity of electrospun polyacrylonitrile copper nanoparticle nanofibers on antibiotic resistant pathogens and methicillin resistant staphylococcus aureus (MRSA). Nanomaterials 2022, 12, 2139. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, A.; Guo, H.; Li, Y.; He, X.; Chen, L.; Zhang, Y. Covalent organic framework/polyacrylonitrile electrospun nanofiber for dispersive solid-phase extraction of trace quinolones in food samples. Nanomaterials 2022, 12, 2482. [Google Scholar] [CrossRef]

- Jalalah, M.; Ahmad, A.; Saleem, A.; Qadir, M.B.; Khaliq, Z.; Khan, M.Q.; Nazir, A.; Faisal, M.; Alsaiari, M.; Irfan, M.; et al. Electrospun nanofiber/textile supported composite membranes with improved mechanical performance for biomedical applications. Membranes 2022, 12, 1158. [Google Scholar] [CrossRef] [PubMed]

- Guan, X.; Xu, B.; Wu, M.; Jing, T.; Yang, Y.; Gao, Y. Breathable, washable and wearable woven-structured triboelectric nanogenerators utilizing electrospun nanofibers for biomechanical energy harvesting and self-powered sensing. Nano Energy 2021, 80, 105549. [Google Scholar] [CrossRef]

- Chen, J.; Chen, W.; Wang, M.; Ding, Y.; Zhou, H.; Zhao, B.; Fan, J. Mechanical behaviors and elastic parameters of laminated fabric URETEK3216LV subjected to uniaxial and biaxial loading. Appl. Compos. Mater. 2017, 24, 1107–1136. [Google Scholar] [CrossRef]

- Kucukali-Ozturk, M.; Ozden-Yenigun, E.; Nergis, B.; Candan, C. Nanofiber-enhanced lightweight composite textiles for acoustic applications. J. Ind. Text. 2017, 46, 1498–1510. [Google Scholar] [CrossRef]

- Hahn, L.; Rittner, S.; Bauer, C.; Cherif, C. Development of alternative bondings for the production of stitch-free non-crimp fabrics made of multiple carbon fiber heavy tows for construction industry. J. Ind. Text. 2018, 48, 660–681. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Kam, K.K.C.; Perrotey, P.; Joshi, S.C. Effect of fixation stitches on out-of-plane response of textile non-crimp fabric composites. J. Ind. Text. 2019, 48, 1151–1166. [Google Scholar] [CrossRef]

- Sanchaniya, J.-V.; Kanukuntla, S.-P.; Modappathi, P.; Macanovskis, A. Mechanical behaviour numerical investigation of composite structure, consisting of polymeric nanocomposite mat and textile. 21st Int. Sci. Conf. Eng. Rural Dev. Proc. 2022, 21, 720–726. [Google Scholar] [CrossRef]

- Rezakhaniha, R.; Agianniotis, A.; Schrauwen, J.T.C.; Griffa, A.; Sage, D.; Bouten, C.V.C.; Van De Vosse, F.N.; Unser, M.; Stergiopulos, N. Experimental investigation of collagen waviness and orientation in the arterial adventitia using confocal laser scanning microscopy. Biomech. Model. Mechanobiol. 2012, 11, 461–473. [Google Scholar] [CrossRef]

- Püspöki, Z.; Storath, M.; Sage, D.; Unser, M. Transforms and operators for directional bioimage analysis: A survey. Adv. Anat. Embryol. Cell Biol. 2016, 219, 69–93. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Magazzù, A.; Marcuello, C. Investigation of soft matter nanomechanics by atomic force microscopy and optical tweezers: A comprehensive review. Nanomaterials 2023, 13, 963. [Google Scholar] [CrossRef] [PubMed]

- Krenchel, H. Theoretical and Practical Investigation of the Elasticity and Strength of Fiber-Reinforced Materials; Akademisk Forlag: Copenhagen, Denmasrk, 1964. [Google Scholar]

- Agarwal, B.D.; Broutman, L.J.; Chandrasekhara, K. Analysis and Performance of Fiber Composites; John Wiley & Sons: Hoboken, NJ, USA, 2017; Volume 151, ISBN 1119389984. [Google Scholar]

- Landel, R.F.; Nielsen, L.E. Mechanical Properties of Polymers and Composites; CRC Press: Boca Raton, FL, USA, 1993; ISBN 1482277433. [Google Scholar]

- Adams, D.F.; Doner, D.R. Longitudinal shear loading of a unidirectional composite. J. Compos. Mater. 1967, 1, 4–17. [Google Scholar] [CrossRef]

- Ayres, C.E.; Jha, B.S.; Meredith, H.; Bowman, J.R.; Bowlin, G.L.; Henderson, S.C.; Simpson, D.G. Measuring fiber alignment in electrospun scaffolds: A user’s guide to the 2D fast Fourier transform approach. J. Biomater. Sci. Polym. Ed. 2008, 19, 603–621. [Google Scholar] [CrossRef] [PubMed]

- Pham, L.Q.; Uspenskaya, M.V.; Olekhnovich, R.O.; Baranov, M.A. The mechanical properties of PVC nanofiber mats obtained by electrospinning. Fibers 2021, 9, 2. [Google Scholar] [CrossRef]

- Sridhara, P.K.; Masso, F.; Olsén, P.; Vilaseca, F. Strong polyamide-6 nanocomposites with cellulose nanofibers mediated by green solvent mixtures. Nanomaterials 2021, 11, 2127. [Google Scholar] [CrossRef]

- Marcuello, C.; Chabbert, B.; Berzin, F.; Bercu, N.B.; Molinari, M.; Aguié-Béghin, V. Influence of Surface Chemistry of Fiber and Lignocellulosic Materials on Adhesion Properties with Polybutylene Succinate at Nanoscale. Materials 2023, 16, 2440. [Google Scholar] [CrossRef]

| Materials | Thickness, t (µm) | Ultimate Tensile Strength, σ (MPa) | Young’s Modulus, E (MPa) | Elongation at Breaking, ε (%) |

|---|---|---|---|---|

| Fabric | 301 ± 12 | 18.9 ± 2 | 72.9 ± 3 | 31.2 ± 2 |

| PAN nanofiber mat | 147.8 ± 7 | 10.2 ± 2 | 333.4 ± 32 | 18 ± 4 |

| Laminated composite | 565 ± 13 | 17.2 ± 1 | 128 ± 12.5 | 37.5 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchaniya, J.V.; Lasenko, I.; Kanukuntla, S.P.; Mannodi, A.; Viluma-Gudmona, A.; Gobins, V. Preparation and Characterization of Non-Crimping Laminated Textile Composites Reinforced with Electrospun Nanofibers. Nanomaterials 2023, 13, 1949. https://doi.org/10.3390/nano13131949

Sanchaniya JV, Lasenko I, Kanukuntla SP, Mannodi A, Viluma-Gudmona A, Gobins V. Preparation and Characterization of Non-Crimping Laminated Textile Composites Reinforced with Electrospun Nanofibers. Nanomaterials. 2023; 13(13):1949. https://doi.org/10.3390/nano13131949

Chicago/Turabian StyleSanchaniya, Jaymin Vrajlal, Inga Lasenko, Sai Pavan Kanukuntla, Anunand Mannodi, Arta Viluma-Gudmona, and Valters Gobins. 2023. "Preparation and Characterization of Non-Crimping Laminated Textile Composites Reinforced with Electrospun Nanofibers" Nanomaterials 13, no. 13: 1949. https://doi.org/10.3390/nano13131949

APA StyleSanchaniya, J. V., Lasenko, I., Kanukuntla, S. P., Mannodi, A., Viluma-Gudmona, A., & Gobins, V. (2023). Preparation and Characterization of Non-Crimping Laminated Textile Composites Reinforced with Electrospun Nanofibers. Nanomaterials, 13(13), 1949. https://doi.org/10.3390/nano13131949