Predictions on the Phase Constitution of SmCo7−XMx Alloys by Data Mining

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Set Used in the Analysis

2.2. Feature Construction and Data Pre-Analysis

2.3. Machine Learning (ML) Algorithms

2.4. Feature Engineering

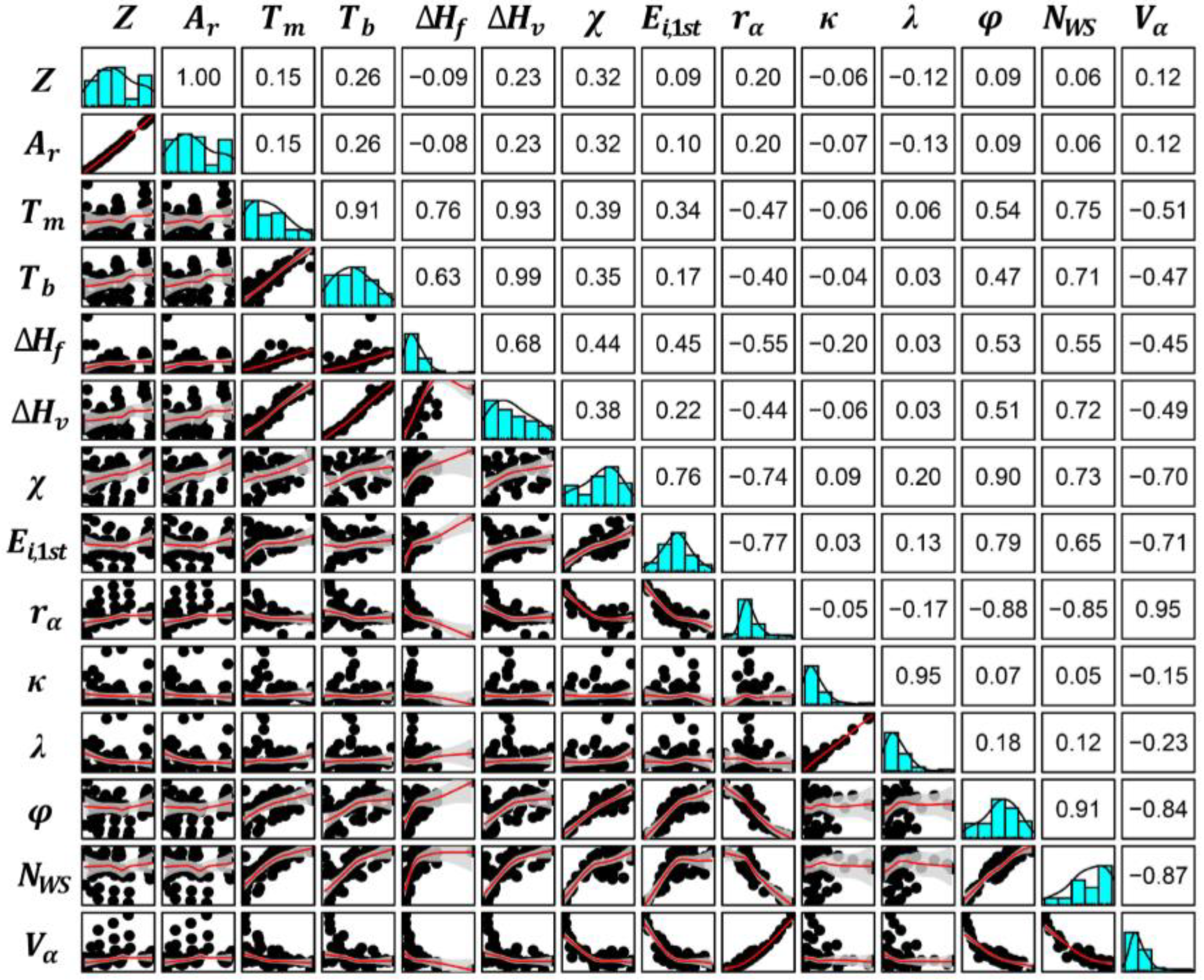

2.4.1. Feature Correlation Analysis

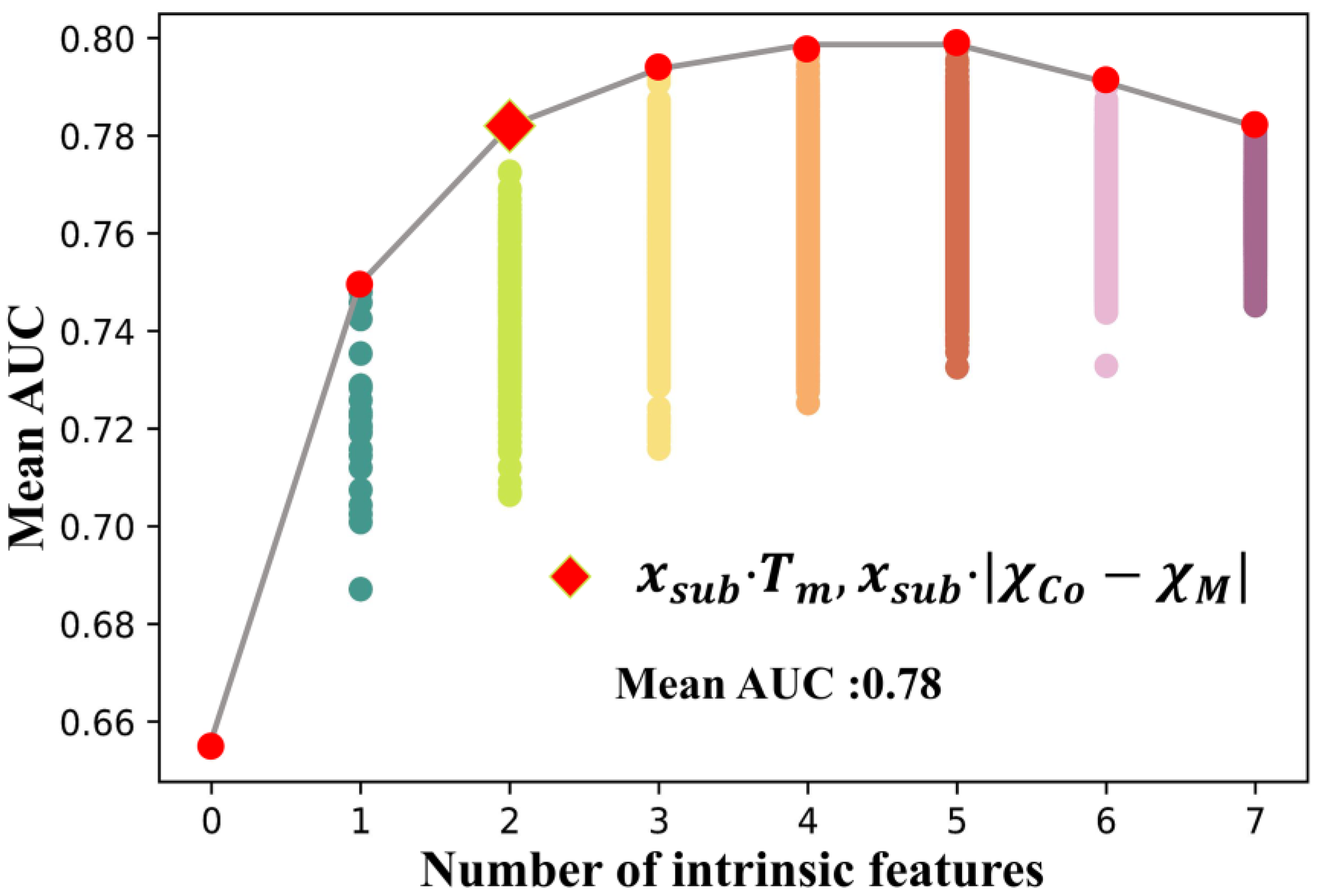

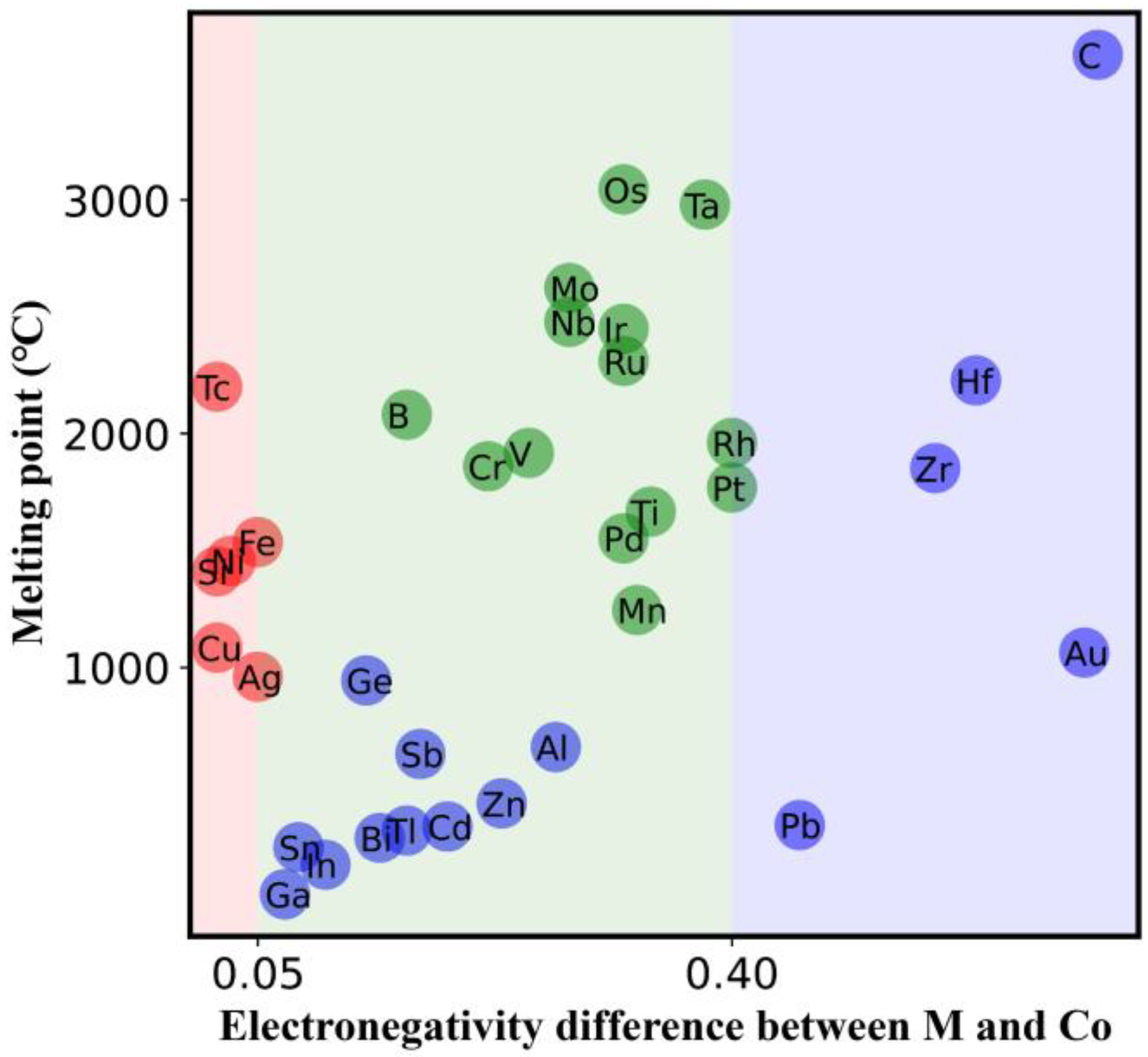

2.4.2. Evaluation for the Effect of Intrinsic Features on the Stability of the 1:7 H Phase

3. Results and Discussion

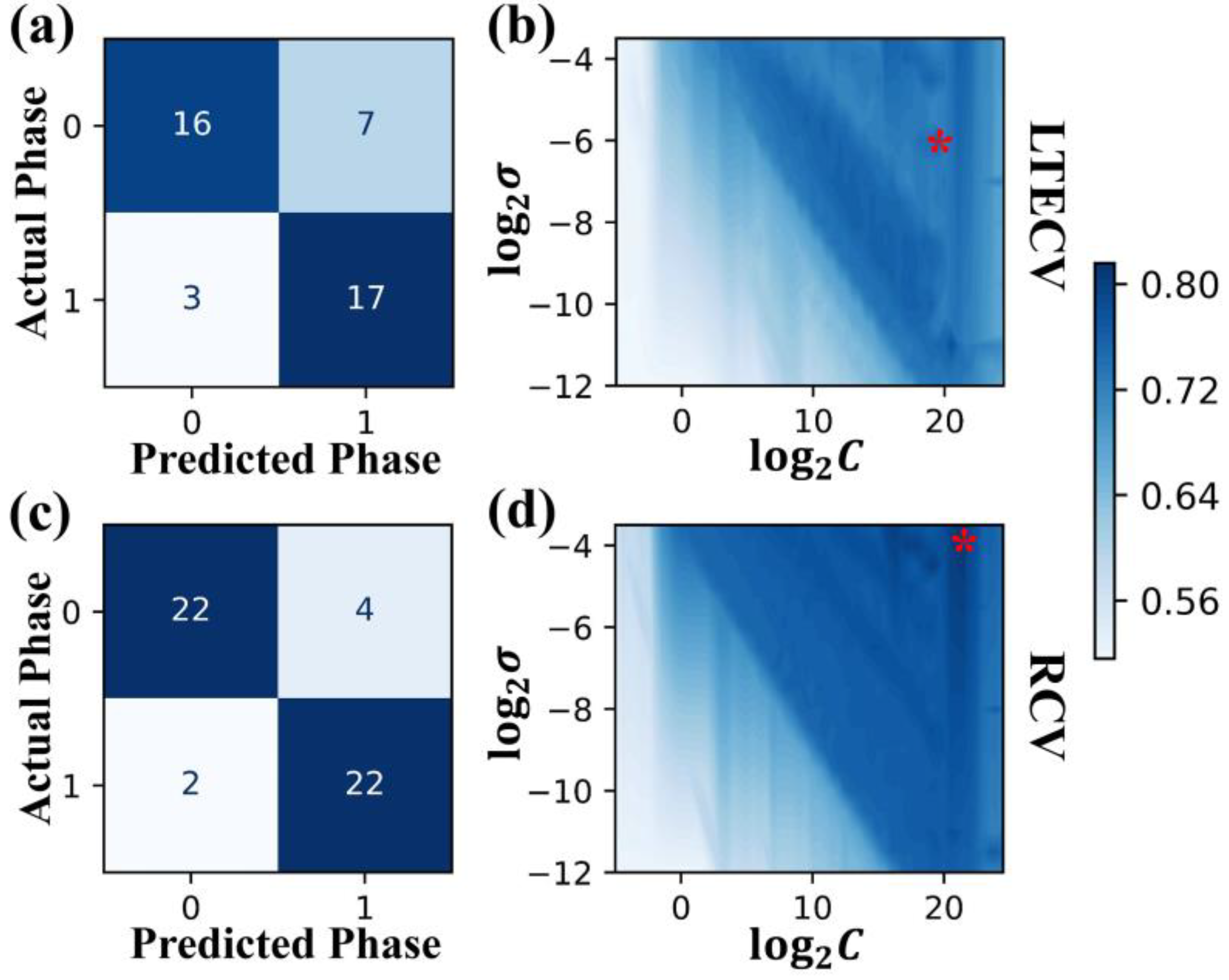

3.1. A More Suitable Cross-Validation Method Developed for Predicting “Unknown Elements”

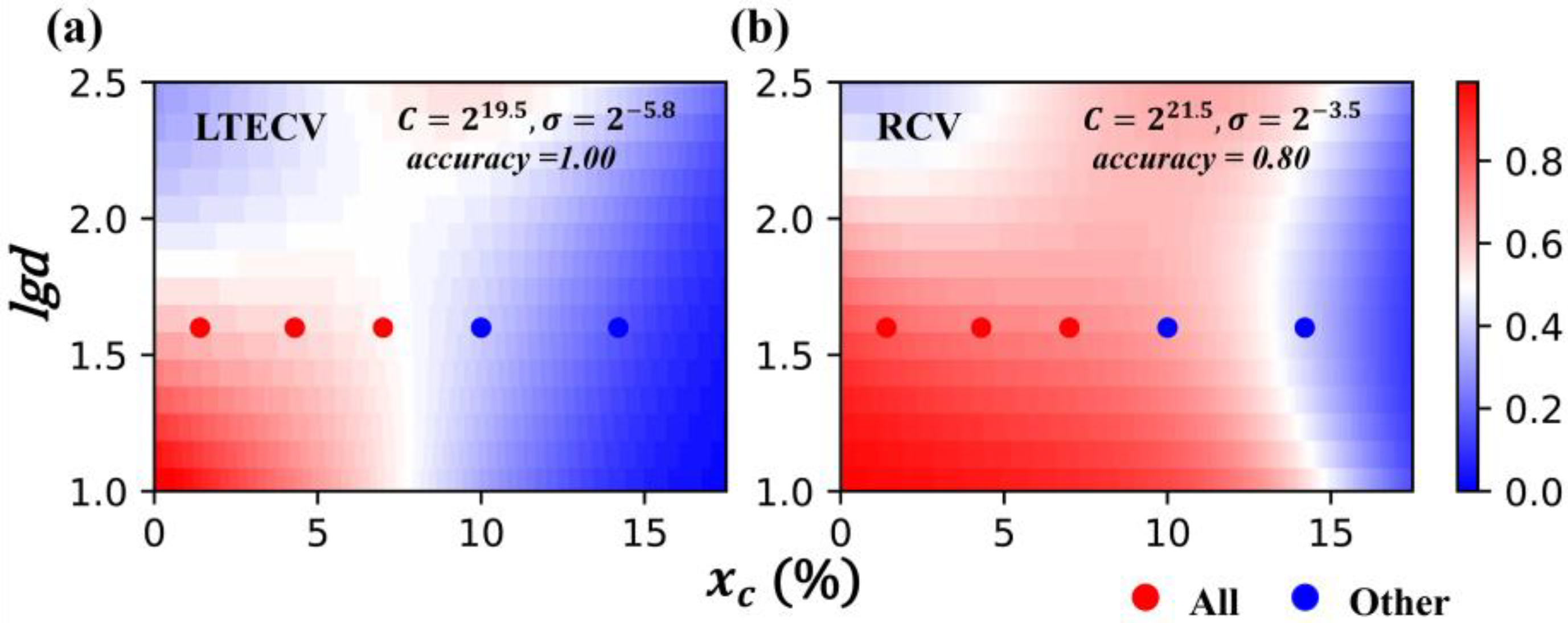

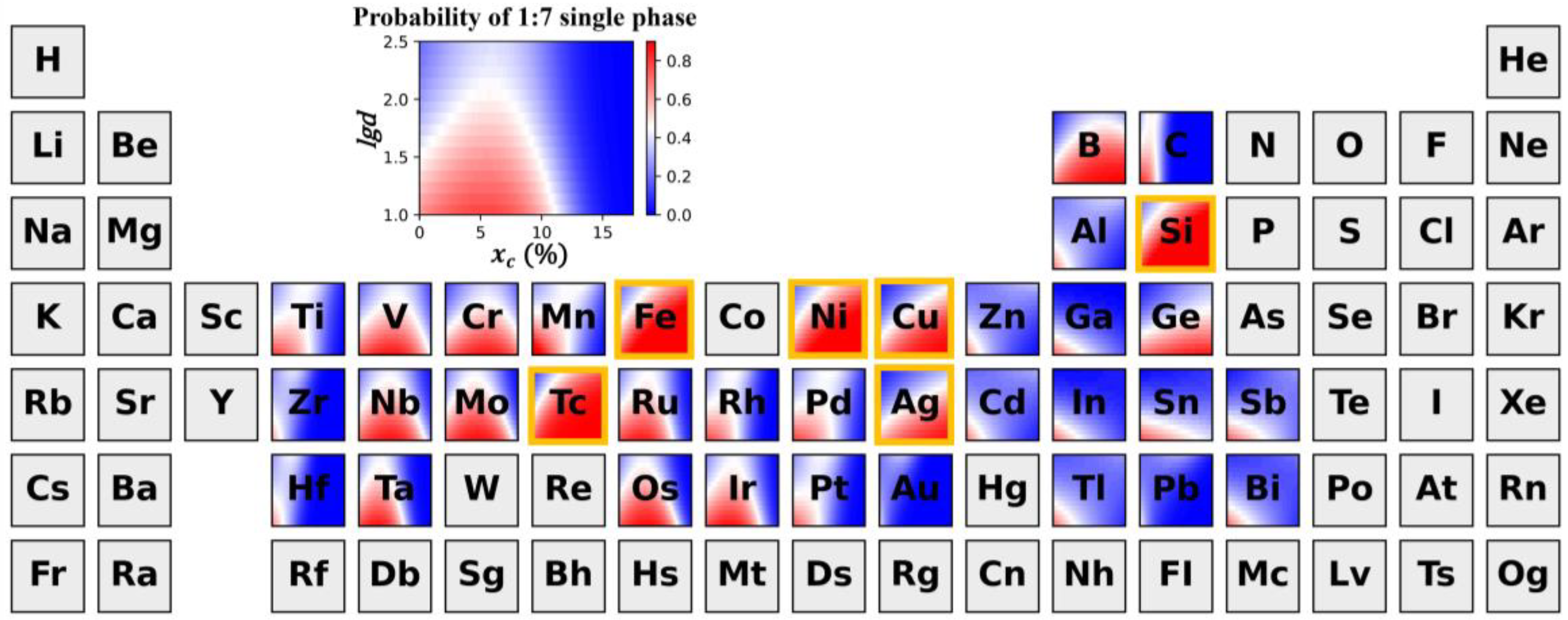

3.2. High-Throughput Prediction for the Phase Constitution of Sm-Co-Based Alloys

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.F.; Zhang, Y.; Dimitrov, D.; Hadjipanayis, G.C. Microstructure and high temperature magnetic properties of Sm(Co,Cu,Fe,Zr)z (z = 6.7–9.1) permanent magnets. J. Appl. Phys. 1999, 85, 2800–2804. [Google Scholar] [CrossRef]

- Saito, H.; Takahashi, M.; Wakiyama, T.; Kido, G.; Nakagawa, H. Magnetocrystalline Anisotropy for Sm2(Co-Mn)17 Compound with TbCu7 Type Disordered Structure. J. Magn. Magn. Mater. 1989, 82, 322–326. [Google Scholar] [CrossRef]

- Jiang, C.B.; An, S.Z. Recent progress in high temperature permanent magnetic materials. Rare Met. 2013, 32, 431–440. [Google Scholar] [CrossRef]

- Khan, Y. On the crystal structures of the Cointermetallic compounds. Acta Cryst. 2001, B29, 2502–2507. [Google Scholar] [CrossRef]

- Yang, J.; Mao, O.; Altounian, Z. Structure and magnetic properties of mechanically alloyed SmCo7 compound. IEEE Trans. Magn. 1996, 32, 4380–4382. [Google Scholar] [CrossRef]

- Song, X.Y.; Xu, W.W.; Zhang, Z.X. Nanoscale stabilization of metastable phase: Thermodynamic model and experimental studies. Acta Phys. Sin. 2012, 61, 200510. (In Chinese) [Google Scholar] [CrossRef]

- Al-Omari, I.A.; Yeshurun, Y.; Zhou, J.; Sellmyer, D.J. Magnetic and structural properties of SmCo7−xCux alloys. J. Appl. Phys. 2000, 87, 6710–6712. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.B.; Venkatesan, M.; Gallagher, K.; Coey, J.M.D. Magnetic and structural properties of SmCo7−xTix magnets. J. Magn. Magn. Mater. 2001, 236, 49–55. [Google Scholar] [CrossRef]

- You, C.Y.; Zhang, Z.D.; Sun, X.K.; Liu, W.; Zhao, X.G.; Geng, D.Y. Phase transformation and magnetic properties of SmCo7−xBx alloys prepared by mechanical alloying. J. Magn. Magn. Mater. 2001, 234, 395–400. [Google Scholar] [CrossRef]

- Liu, T.; Li, W.; Li, X.M.; Feng, W.C.; Guo, Y.Q. Crystal structure and magnetic properties of SmCo7−xAgx. J. Magn. Magn. Mater. 2007, 310, E632–E634. [Google Scholar] [CrossRef]

- Yao, Z.; Jiang, C.B. Structural and Magnetic Properties of TbCu7-type SmCo7−xNix Magnets Produced by Mechanical Milling. IEEE Trans. Magn. 2008, 44, 4578–4581. [Google Scholar] [CrossRef]

- Chang, H.W.; Hsieh, C.C.; Guo, Z.H.; Huang, S.T.; Chang, W.C. Magnetic properties and crystal structure of melt spun Sm(Co,M)7 ribbons (M = Hf, V, Nb, and Ta). Mod. Phys. Lett. B 2009, 23, 3707–3716. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Chang, H.W.; Chang, C.W.; Guo, Z.H.; Yang, C.C.; Chang, W.C. Crystal structure and magnetic properties of melt spun Sm(Co, V)7 ribbons. J. Appl. Phys. 2009, 105, 07A705. [Google Scholar] [CrossRef]

- Yao, Z.; Li, P.P.; Jiang, C.B. Structural and magnetic properties of SmCo7−xMox alloys. J. Magn. Magn. Mater. 2009, 321, 203–206. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Chang, H.W.; Guo, Z.H.; Chang, C.W.; Zhao, X.G.; Chang, W.C. Crystal structure and magnetic properties of melt spun SmCo7−xMx (M = Ta, Cr, and Mo; x = 0–0.6) ribbons. J. Appl. Phys. 2010, 107, 09A738. [Google Scholar] [CrossRef]

- Sun, J.B.; Han, D.; Cui, C.X.; Yang, W.; Li, L.; Yang, F.; Yang, L.G. Effects of Hf and CNTs on structure and magnetic properties of TbCu7-type Sm-Co magnets. Intermetallics 2010, 18, 599–605. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Hsieh, C.C.; Lo, S.C.; Chang, W.C.; Chang, H.W.; Chiou, S.H.; Ouyang, H. The effect of doping element Zr on anisotropy and microstructure of SmCo7−xZrx. J. Appl. Phys. 2011, 109, 07A748. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Chang, H.W.; Sun, A.C.; Chang, W.C.; Guo, P. Magnetic Properties and Crystal Structure of Melt Spun SmCo7−xSnx (x = 0–0.6) Ribbons. IEEE Trans. Magn. 2011, 47, 3332–3335. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Chang, H.W.; Zhao, X.G.; Sun, A.C.; Chang, W.C. Effect of Ge on the magnetic properties and crystal structure of melt spun SmCo7−xGex ribbons. J. Appl. Phys. 2011, 109, 07A730. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Shih, C.W.; Liu, Z.; Chang, W.C.; Chang, H.W.; Sun, A.C.; Shaw, C.C. Magnetic properties and crystal structure of melt-spun Sm(Co, M)7 (M = Al and Si) ribbons. J. Appl. Phys. 2012, 111, 07E306. [Google Scholar] [CrossRef]

- Liu, L.L.; Jiang, C.B. Oxidation Resistance and Magnetic Properties of SmCo7−xSix Permanent Magnetic Alloys. J. Supercond Nov. Magn. 2012, 25, 131–135. [Google Scholar] [CrossRef]

- Sun, J.B.; Bu, S.J.; Yang, W.; Ding, H.W.; Cui, C.X.; Zheng, H.X. Structure and magnetic properties of SmCo7−xGax (0 ≤ x ≤ 1.2) alloys. J. Alloys Compd. 2014, 583, 554–559. [Google Scholar] [CrossRef]

- Li, T.Y.; Chiou, S.H.; Chang, H.W.; Lo, S.C.; Hsieh, C.C.; Chang, W.C.; van Lierop, J.; Hsiao, C.H.; Hsu, Y.W.; Ouyang, H. Origins of the significant improvement in nanocrystalline Samarium-Cobalt’s magnetic properties when doping with Niobium. J. Alloys Compd. 2015, 622, 262–268. [Google Scholar] [CrossRef]

- Hua, G.; Song, X.Y.; Liu, D.; Wang, D.X.; Wang, H.B.; Liu, X.M. Effects of Hf on phase structure and magnetic performance of nanocrystalline SmCo7-type alloy. J. Mater. Sci. 2016, 51, 3390–3397. [Google Scholar] [CrossRef]

- Guo, K.; Lu, H.; Mao, F.; Liu, D.; Tang, F.W.; Wang, H.B.; Song, X.Y. How non-ferromagnetic Mn enhances the magnetization of SmCo7 based alloys. Nanoscale 2020, 12, 5567–5577. [Google Scholar] [CrossRef] [PubMed]

- Song, X.Y.; Guo, K.; Lu, H.; Liu, D.; Tang, F.W. Modelling of phase stability: From computational materials science to materials informatics. J. Mater. Inform. 2021, 1, 7–32. [Google Scholar] [CrossRef]

- Zhai, X.Y.; Chen, M.T.; Lu, W.C. Accelerated search for perovskite materials with higher Curie temperature based on the machine learning methods. Comp. Mater. Sci. 2018, 151, 41–48. [Google Scholar] [CrossRef]

- Li, Y.; Guo, W.L. Machine-learning model for predicting phase formations of high-entropy alloys. Phys. Rev. Mater. 2019, 3, 095005. [Google Scholar] [CrossRef]

- Frey, N.C.; Horton, M.K.; Munro, J.M.; Griffin, S.M.; Persson, K.A.; Shenoy, V.B. High-throughput search for magnetic and topological order in transition metal oxides. Sci. Adv. 2020, 6, eabd1076. [Google Scholar] [CrossRef]

- Katsikas, G.; Sarafidis, C.; Kioseoglou, J. Machine Learning in Magnetic Materials. Phys. Status Solidi B-Basic Solid State Phys. 2021, 258, 2000600. [Google Scholar] [CrossRef]

- Huang, M.Q.; Wallace, W.E.; McHenry, M.; Chen, Q.; Ma, B.M. Structure and magnetic properties of SmCo7−xZrx alloys (x = 0–0.8). J. Appl. Phys. 1998, 83, 6718–6720. [Google Scholar] [CrossRef]

- Gjoka, M.; Kalogirou, O.; Sarafidis, C.; Niarchos, D.; Hadjipanayis, G.C. Structure and magnetic properties of RCo7−xMnx alloys (R = Sm, Gd; x = 0.1–1.4). J. Magn. Magn. Mater. 2002, 242, 844–846. [Google Scholar] [CrossRef]

- Venkatesan, M.; Jiang, C.; Coey, J.M.D. 1:7-type magnets produced by mechanical milling. J. Magn. Magn. Mater. 2002, 242, 1350–1352. [Google Scholar] [CrossRef]

- Luo, J.; Liang, J.K.; Guo, Y.Q.; Liu, Q.L.; Yang, L.T.; Liu, F.S.; Rao, G.H. Crystal structure and magnetic properties of SmCo5.85Si0.90 compound. Appl. Phys. Lett. 2004, 84, 3094–3096. [Google Scholar] [CrossRef]

- Luo, J.; Liang, J.K.; Guo, Y.Q.; Yang, L.T.; Liu, F.S.; Zhang, Y.; Liu, Q.L.; Rao, G.H. Crystal structure and magnetic properties of SmCo7−xHfx compounds. Appl. Phys. Lett. 2004, 85, 5299–5301. [Google Scholar] [CrossRef]

- Guo, Y.Q.; Li, W.; Feng, W.C.; Luo, J.; Liang, J.K.; He, Q.J.; Yu, X.J. Structural stability and magnetic properties of SmCo7−xGax. Appl. Phys. Lett. 2005, 86, 192513. [Google Scholar] [CrossRef]

- Yao, Q.; Liu, W.; Zhao, X.G.; Li, D.; Zhang, Z.D. Structure, phase transformation, and magnetic properties of SmCo7−xCrx magnets. J. Appl. Phys. 2006, 99, 053905. [Google Scholar] [CrossRef]

- Chang, H.W.; Huang, S.T.; Chang, C.W.; Chiu, C.H.; Chen, I.W.; Chang, W.C.; Sun, A.C.; Yao, Y.D. Comparison on the magnetic properties and phase evolution of melt-spun SmCo7 ribbons with Zr and Hf substitution. Scr. Mater. 2007, 56, 1099–1102. [Google Scholar] [CrossRef]

- Yue, M.; Zhang, J.X.; Zhang, D.T.; Pan, L.J.; Liu, X.B.; Altounian, Z. Structure and magnetic properties of bulk nanocrystalline SmCo6.6Nb0.4 permanent magnets. Appl. Phys. Lett. 2007, 90, 242506. [Google Scholar] [CrossRef]

- Yao, Z.; Jiang, C.B. Structure and magnetic properties of SmCoxTi0.4–1:7 ribbons. J. Magn. Magn. Mater. 2008, 320, 1073–1077. [Google Scholar] [CrossRef]

- Guo, Z.H.; Chang, H.W.; Chang, C.W.; Hsieh, C.C.; Sun, A.C.; Chang, W.C.; Pan, W.; Li, W. Magnetic properties, phase evolution, and structure of melt spun SmCo7−xNbx (x = 0–0.6) ribbons. J. Appl. Phys. 2009, 105, 07A731. [Google Scholar] [CrossRef]

- Chang, H.W.; Guo, C.S.; Hsieh, C.C.; Guo, Z.H.; Zhao, X.G.; Chang, W.C. Magnetic properties, phase evolution, and microstructure of melt spun Sm(Co, M)xCy (M = Hf and Zr; x = 5–9; y = 0–0.15) ribbons. J. Appl. Phys. 2010, 107, 09A710. [Google Scholar] [CrossRef]

- Guo, Z.H.; Hsieh, C.C.; Chang, H.W.; Zhu, M.G.; Pan, W.; Li, A.H.; Chang, W.C.; Li, W. Enhancement of coercivity for melt-spun SmCo7−xTax ribbons with Ta addition. J. Appl. Phys. 2010, 107, 09A705. [Google Scholar] [CrossRef]

- Song, X.Y.; Zhang, Z.X.; Lu, N.D.; Liang, H.N.; Li, D.P.; Yan, X.Q.; Zhang, J.X. Crystal structures and magnetic performance of nanocrystalline Sm-Co compounds. Front. Mater. Sci. 2012, 6, 207–215. [Google Scholar] [CrossRef]

- An, S.Z.; Zheng, L.; Zhang, T.L.; Jiang, C.B. Bulk anisotropic nanocrystalline SmCo6.6Ti0.4 permanent magnets. Scr. Mater. 2013, 68, 432–435. [Google Scholar] [CrossRef]

- Hsieh, C.C.; Huang, S.T.; Guo, J.S.; Shih, C.W.; Chang, W.C.; Chang, H.W.; Shaw, C.C. Effect of a carbon additive on the TbCu7-type melt-spun Sm(Co, M)7 (M = Ti, Zr, Hf, V and Ge) ribbons. J. Korean Phys. Soc. 2013, 63, 401–404. [Google Scholar] [CrossRef]

- Sun, J.B.; Bu, S.J.; Ding, H.W.; Cui, C.X.; Yang, W.; Zhang, L. The effects of CNTs and/or Si additions on the structure and magnetic properties of SmCo7-based alloys. J. Alloys Compd. 2013, 563, 91–98. [Google Scholar] [CrossRef]

- Feng, D.Y.; Liu, Z.W.; Wang, G.; Zheng, Z.G.; Zeng, D.C.; Li, Z.; Zhang, G.Q. Zr and Si co-substitution for SmCo7 alloy with enhanced magnetic properties and improved oxidation and corrosion resistances. J. Alloys Compd. 2014, 610, 341–346. [Google Scholar] [CrossRef]

- Li, Y.Q.; Yue, M.; Wu, Q.; Liu, W.Q.; Liu, Y.Q.; Zhang, D.T.; Zhang, J.X.; Hadjipanayis, G.C. Magnetic hardening mechanism of SmCo6.6Nb0.4 nanoflakes prepared by surfactant-assisted ball milling method. J. Appl. Phys. 2014, 115, 7A713. [Google Scholar] [CrossRef]

- Awad, M.; Khanna, R. Support Vector Machines for Classification. In Support Vector Machines; Springer: New York, NY, USA, 2008; pp. 285–329. [Google Scholar]

- Tang, J.; Alelyani, S.; Liu, H. Feature selection for classifcation: A review. In Data Classifcation: Algorithms and Applications; CRC Press: Boca Raton, FL, USA, 2014; pp. 37–64. [Google Scholar] [CrossRef]

- Jin, H.; Ling, C.X. Using AUC and accuracy in evaluating learning algorithms. IEEE Trans. Knowl. Data Eng. 2005, 17, 299–310. [Google Scholar] [CrossRef] [Green Version]

- Varma, S.; Simon, R. Bias in error estimation when using cross-validation for model selection. BMC Bioinform. 2006, 7, 91. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, D.; Guo, K.; Tang, F.W.; Mao, F.; Liu, X.M.; Hou, C.; Wang, H.B.; Lu, H.; Song, X.Y. Selecting Doping Elements by Data Mining for Advanced Magnets. Chem. Mater. 2019, 31, 10117–10125. [Google Scholar] [CrossRef]

| Name | Symbol | Feature Selection |

|---|---|---|

| Atomic number | Z | |

| Atomic radius | √ | |

| The first ionization energy | √ | |

| Standard atomic weight | √ | |

| Melting point | √ | |

| Boiling point | ||

| Electronegativity | √ | |

| Electrical conductivity | κ | √ |

| Heat of fusion | √ | |

| Heat of vaporization | ||

| Thermal conductivity | λ | |

| Work function | φ | |

| Electron density | ||

| Electron volume |

| Function | Implication |

|---|---|

| The product of doping amount and element features | |

| Interaction between doping element and Co | |

| | | Interaction between doping element and Sm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Lu, H.; Guo, K.; Tang, F.; Song, X. Predictions on the Phase Constitution of SmCo7−XMx Alloys by Data Mining. Nanomaterials 2022, 12, 1452. https://doi.org/10.3390/nano12091452

Xu G, Lu H, Guo K, Tang F, Song X. Predictions on the Phase Constitution of SmCo7−XMx Alloys by Data Mining. Nanomaterials. 2022; 12(9):1452. https://doi.org/10.3390/nano12091452

Chicago/Turabian StyleXu, Guojing, Hao Lu, Kai Guo, Fawei Tang, and Xiaoyan Song. 2022. "Predictions on the Phase Constitution of SmCo7−XMx Alloys by Data Mining" Nanomaterials 12, no. 9: 1452. https://doi.org/10.3390/nano12091452

APA StyleXu, G., Lu, H., Guo, K., Tang, F., & Song, X. (2022). Predictions on the Phase Constitution of SmCo7−XMx Alloys by Data Mining. Nanomaterials, 12(9), 1452. https://doi.org/10.3390/nano12091452