Submicronic Filtering Media Based on Electrospun Recycled PET Nanofibers: Development, Characterization, and Method to Manufacture Surgical Masks

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

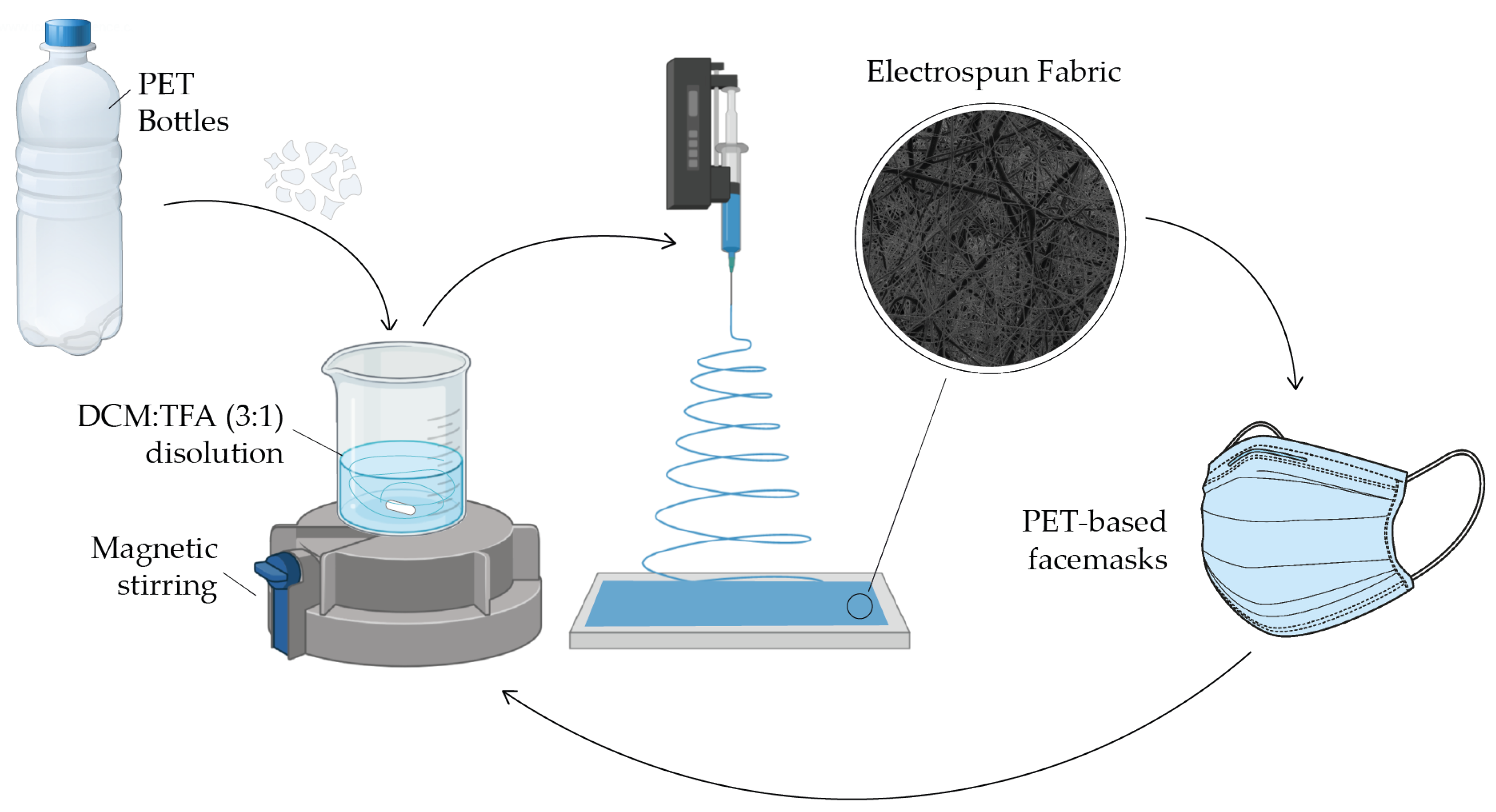

2.2. Electrospun PET Fibers

2.3. Microscopic Characterization

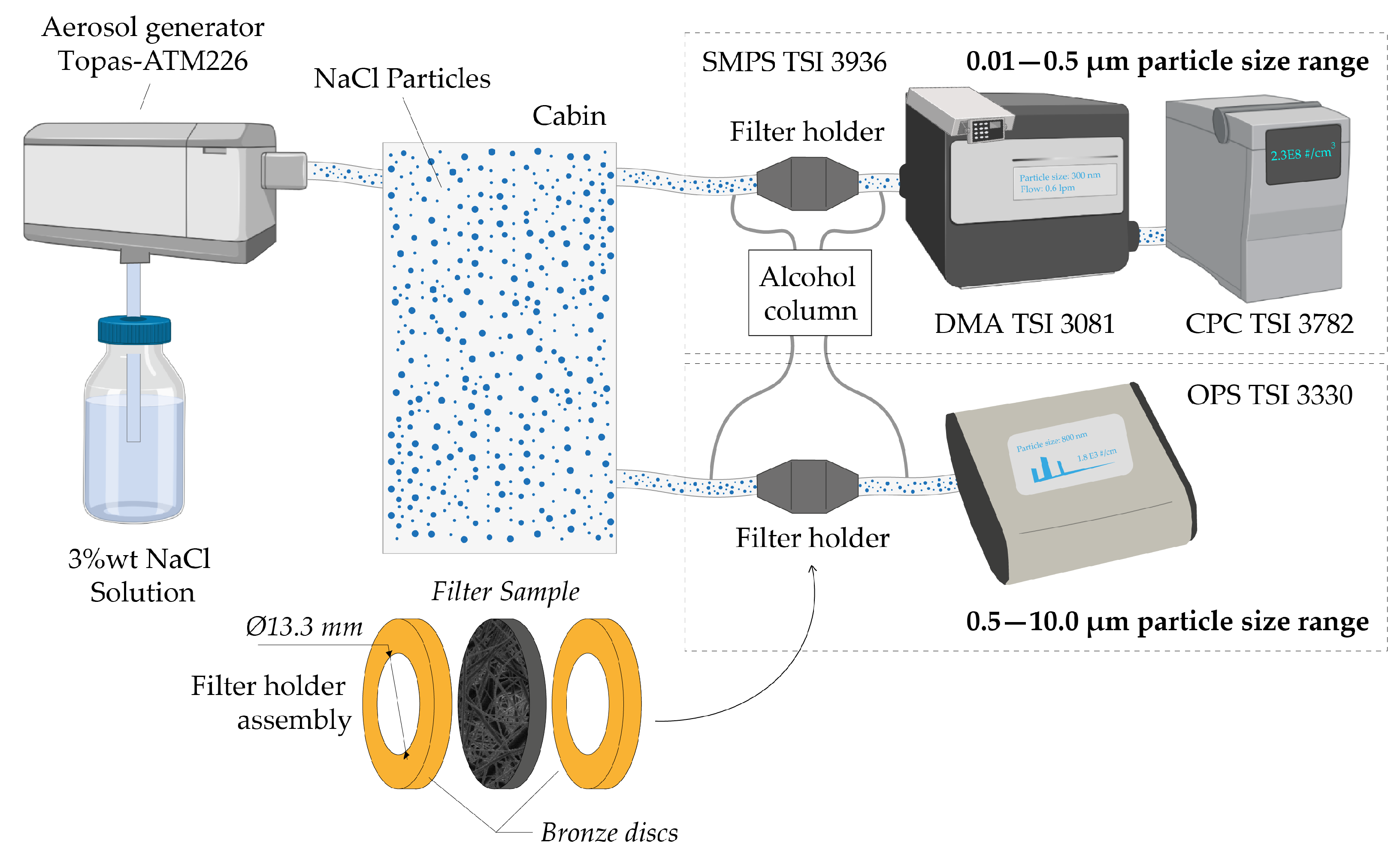

2.4. Retention Efficiency and Pressure Drop Determination

3. Results and Discussion

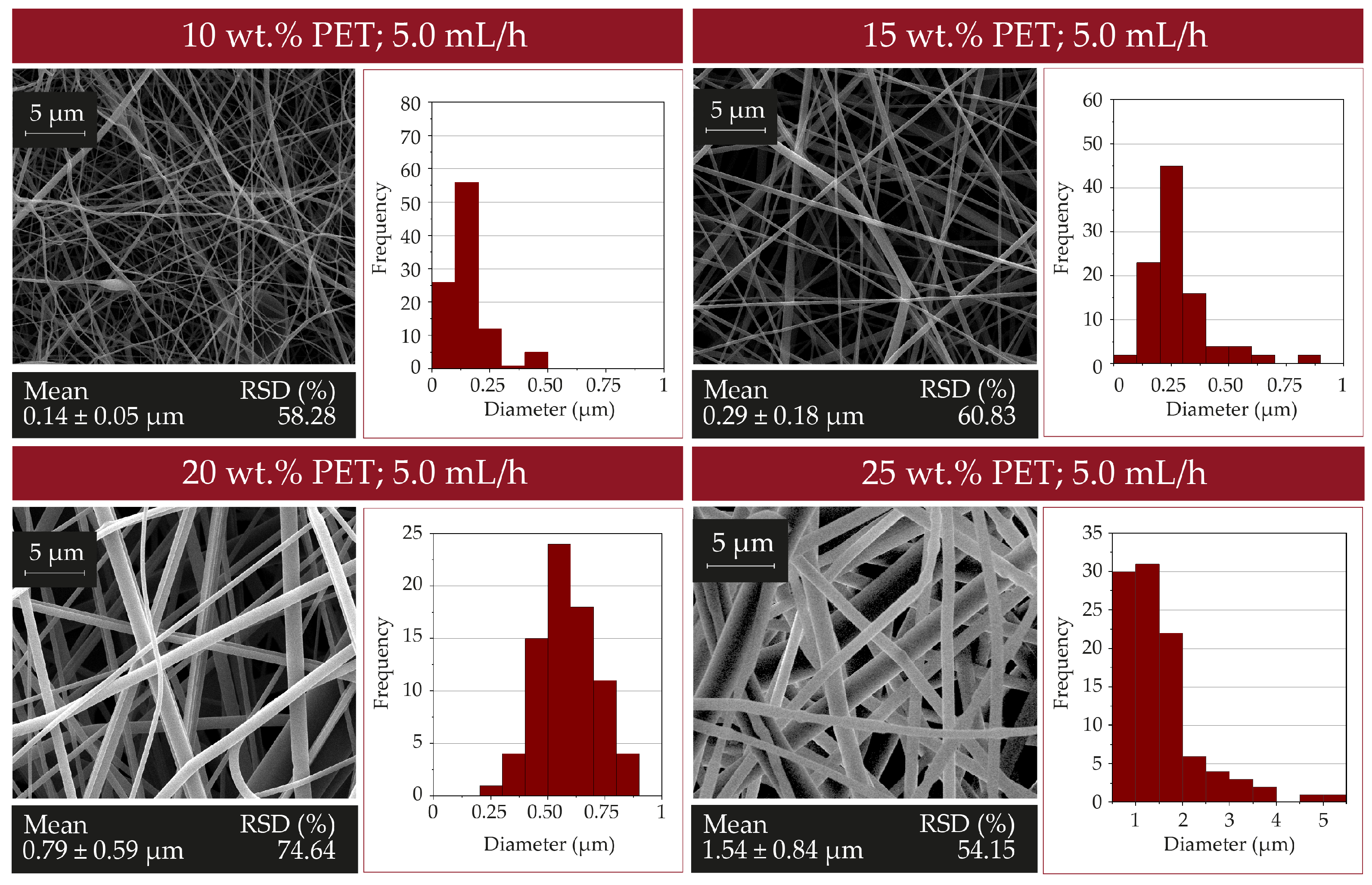

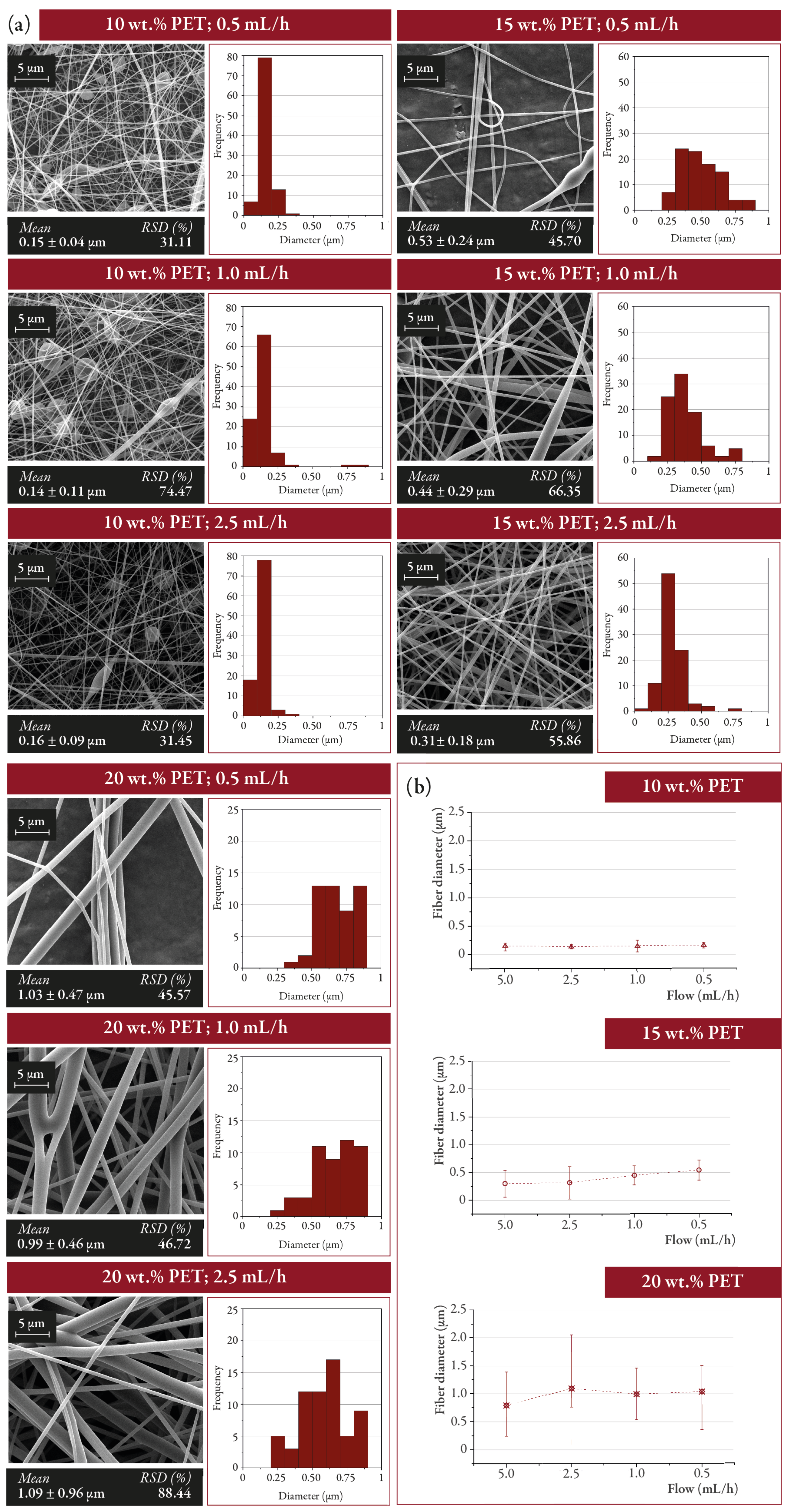

3.1. Fiber Diameter Control

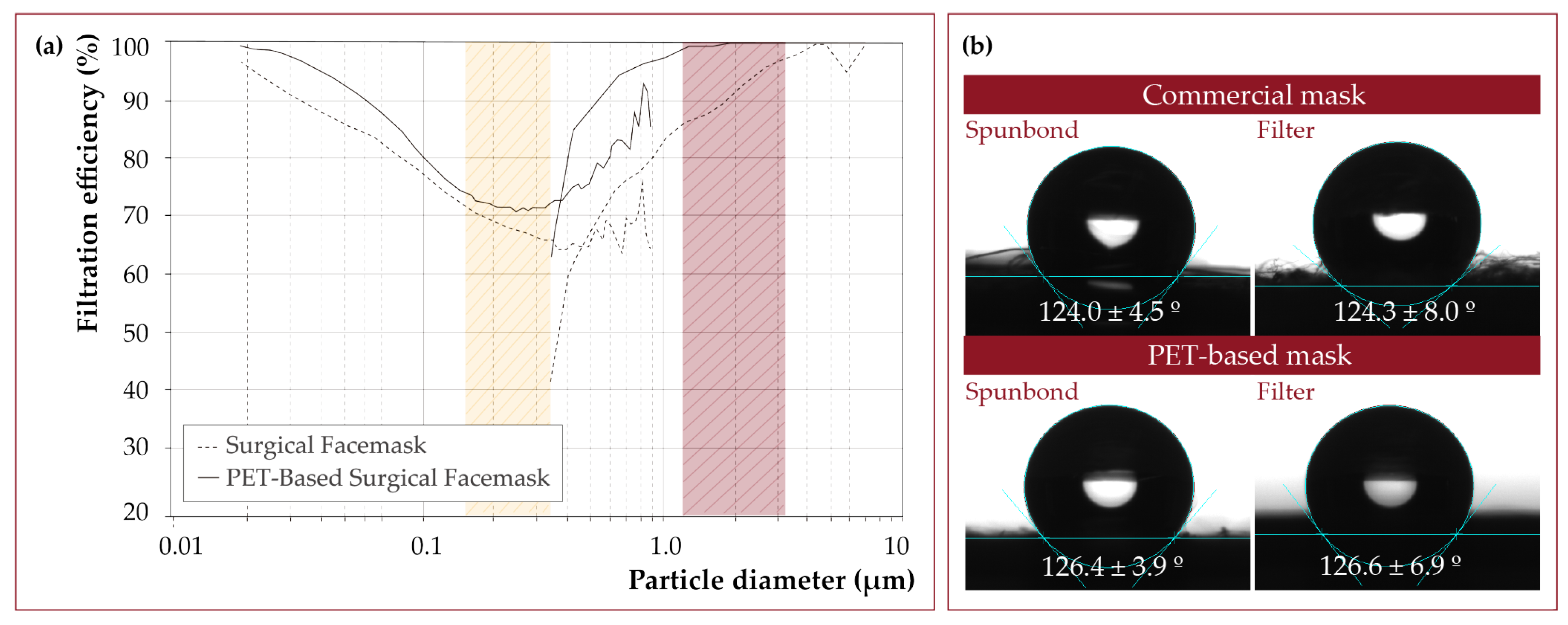

3.2. Contact Angle Measurement

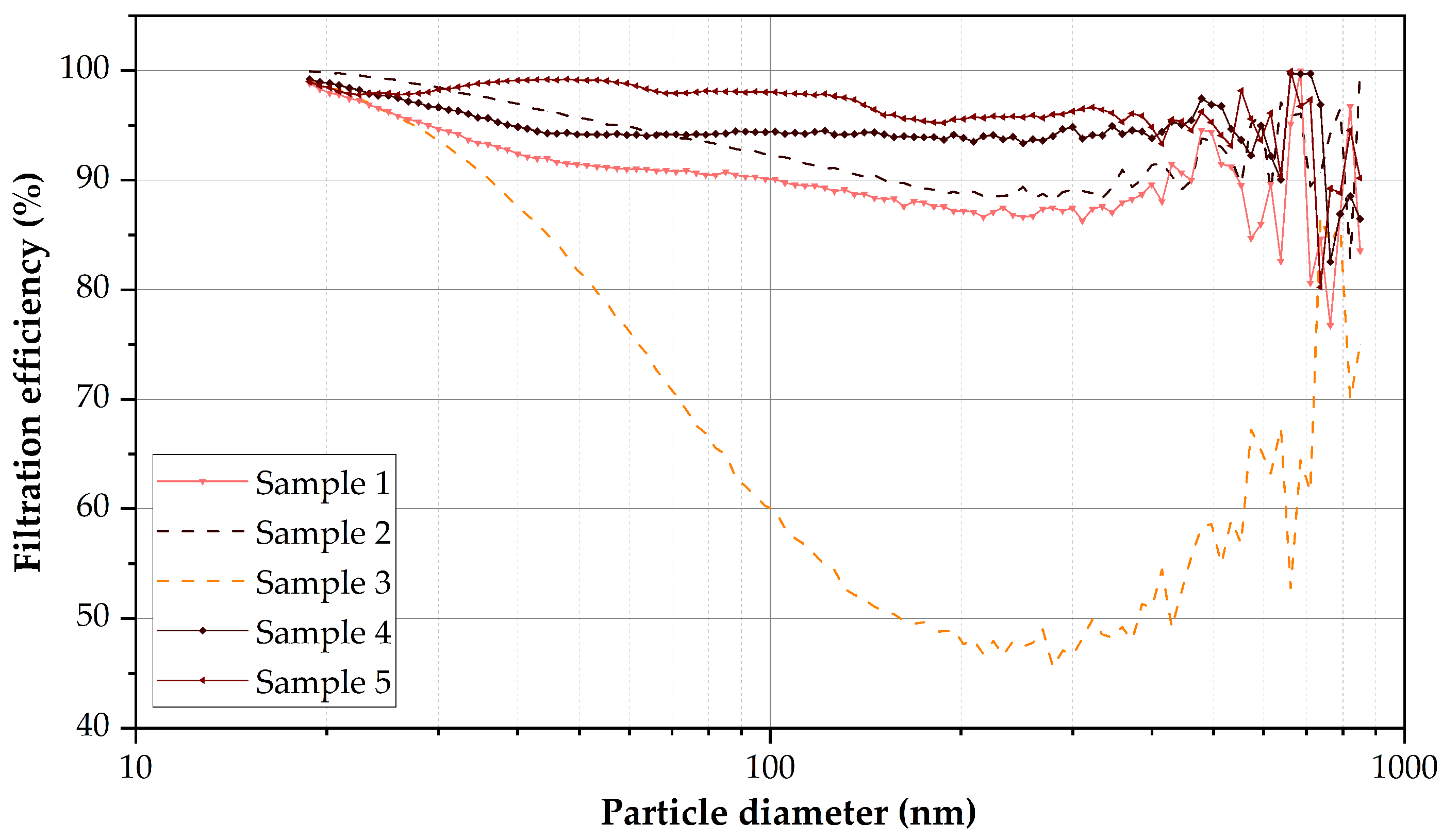

3.3. Influence of Electrospinning Parameters on Filtration

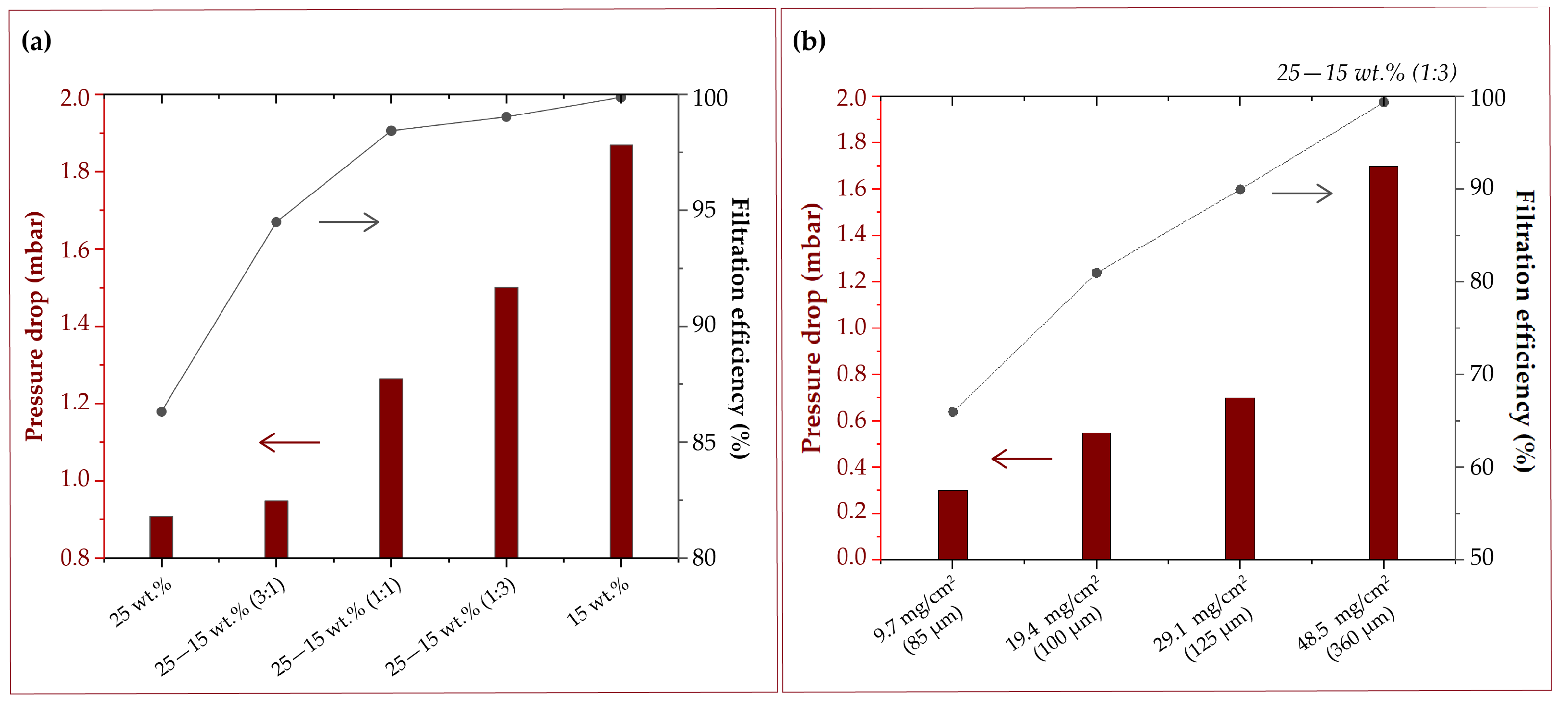

3.4. Fiber Diameter and Filtration Efficiency

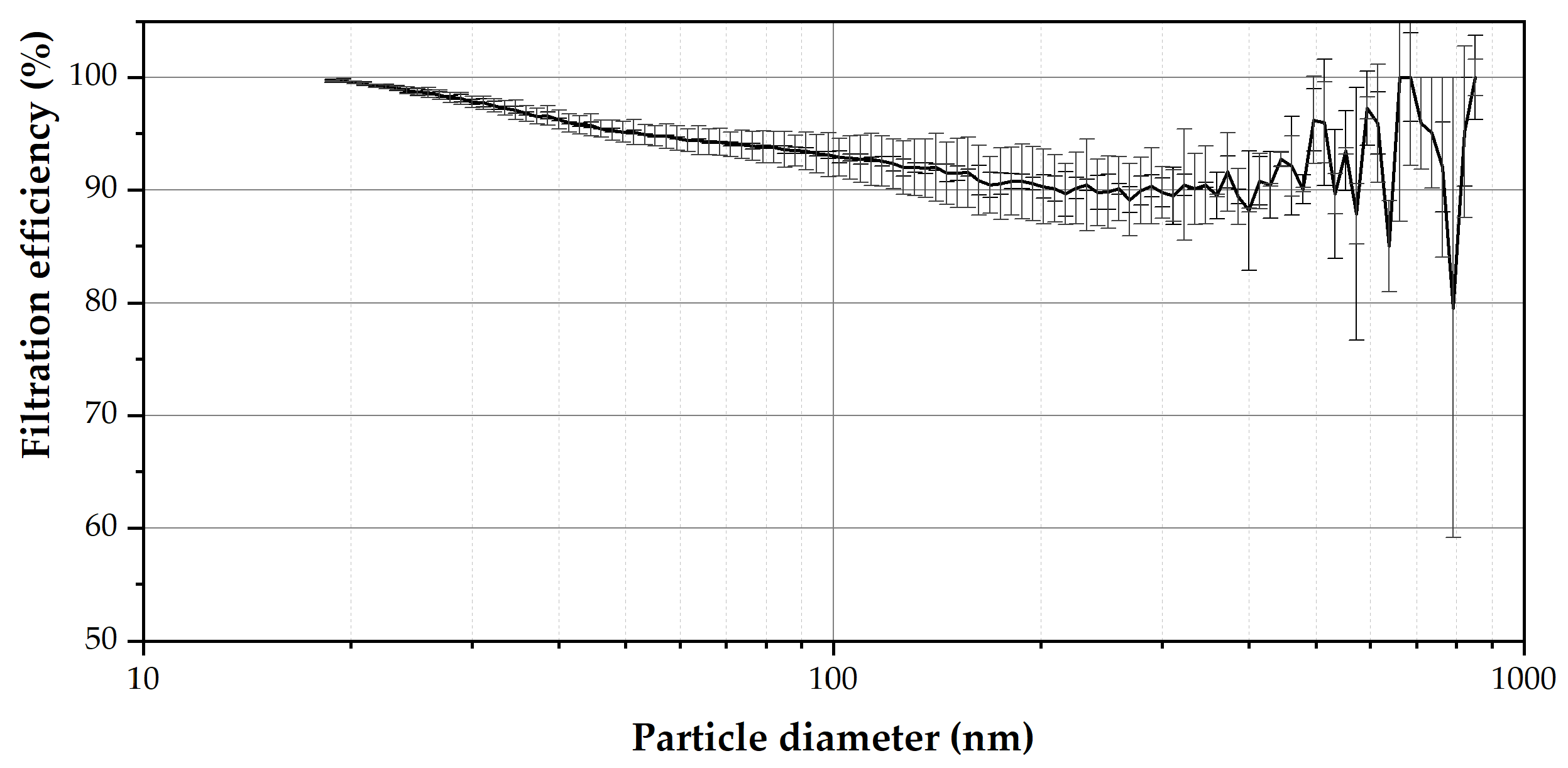

3.5. Homogeneity across the Fabric

3.6. Reproducibility

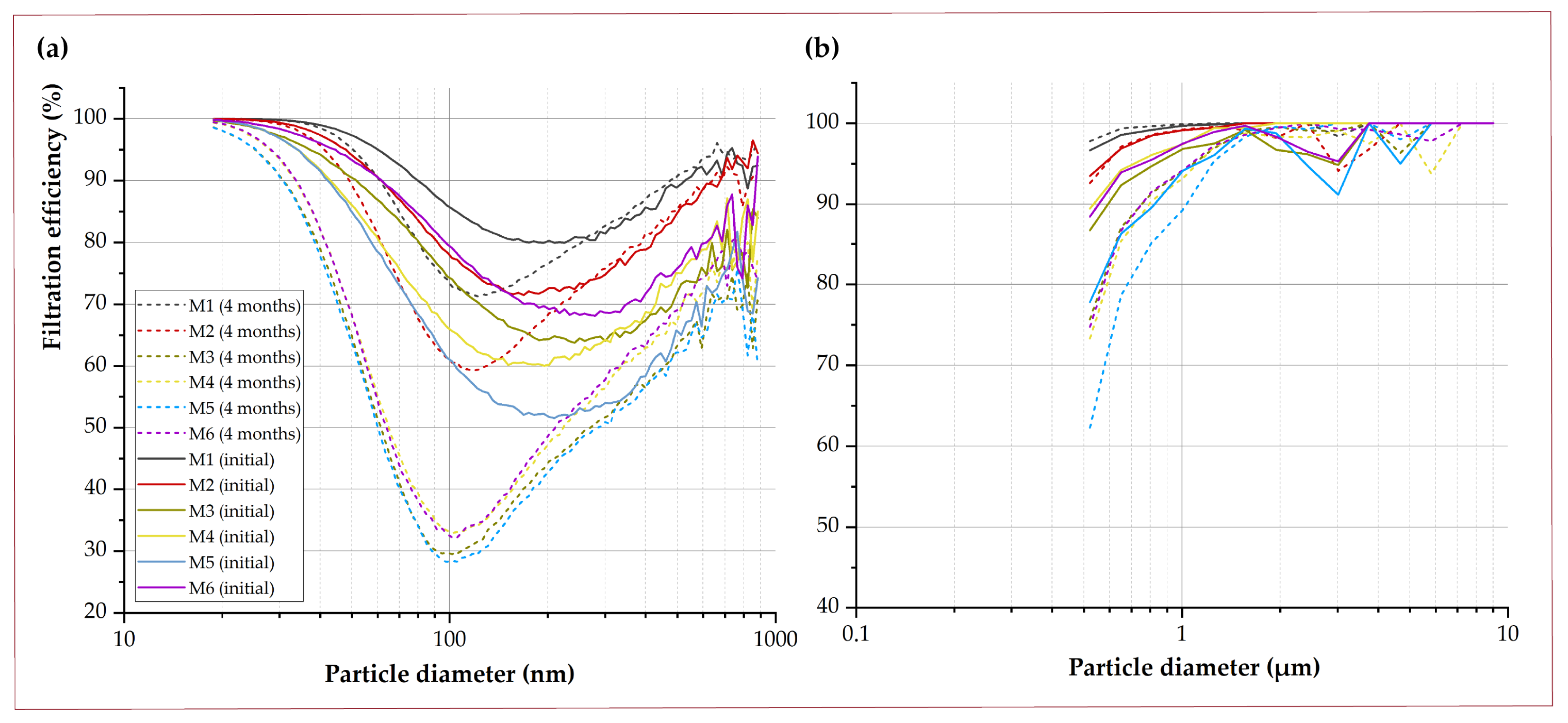

3.7. Evaluation of the Retention Efficiency over Time

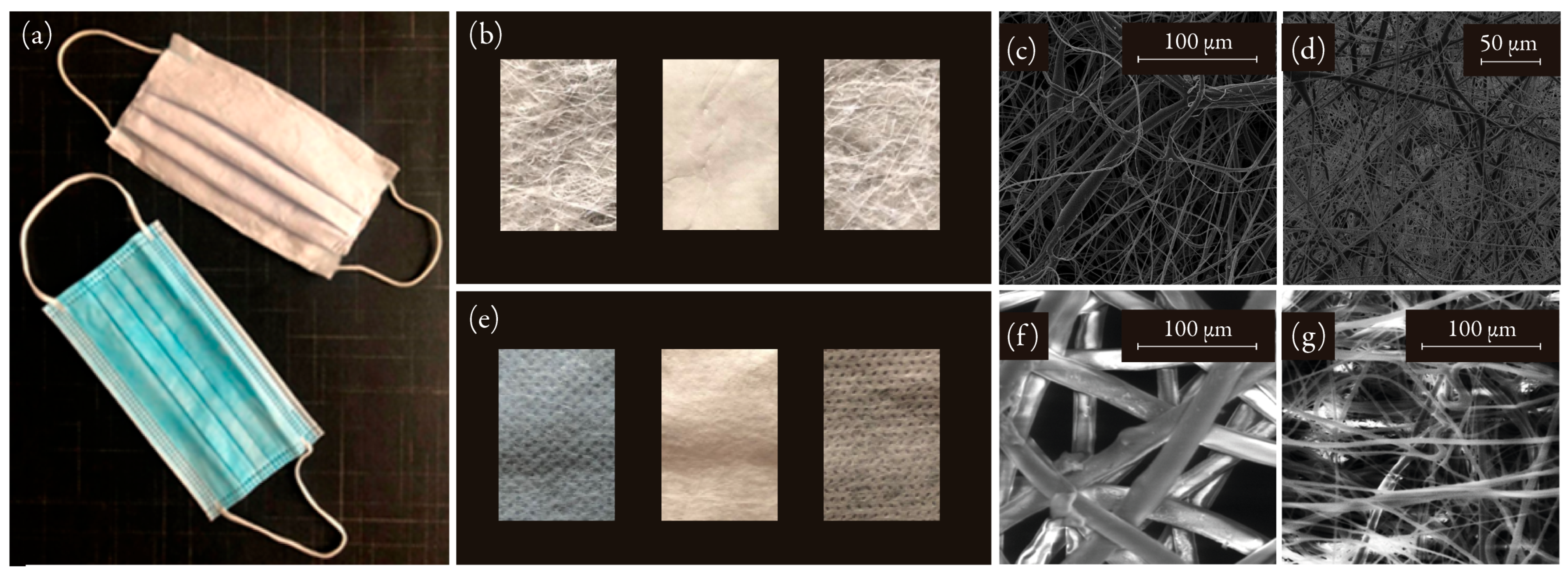

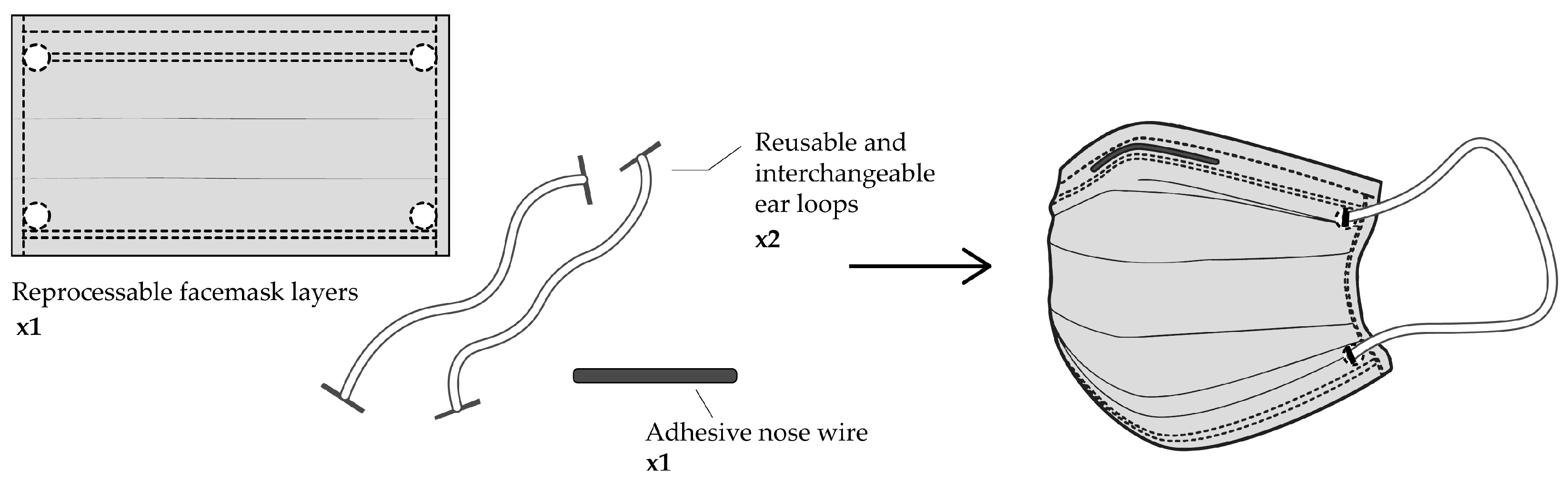

3.8. Development of a Surgical Mask

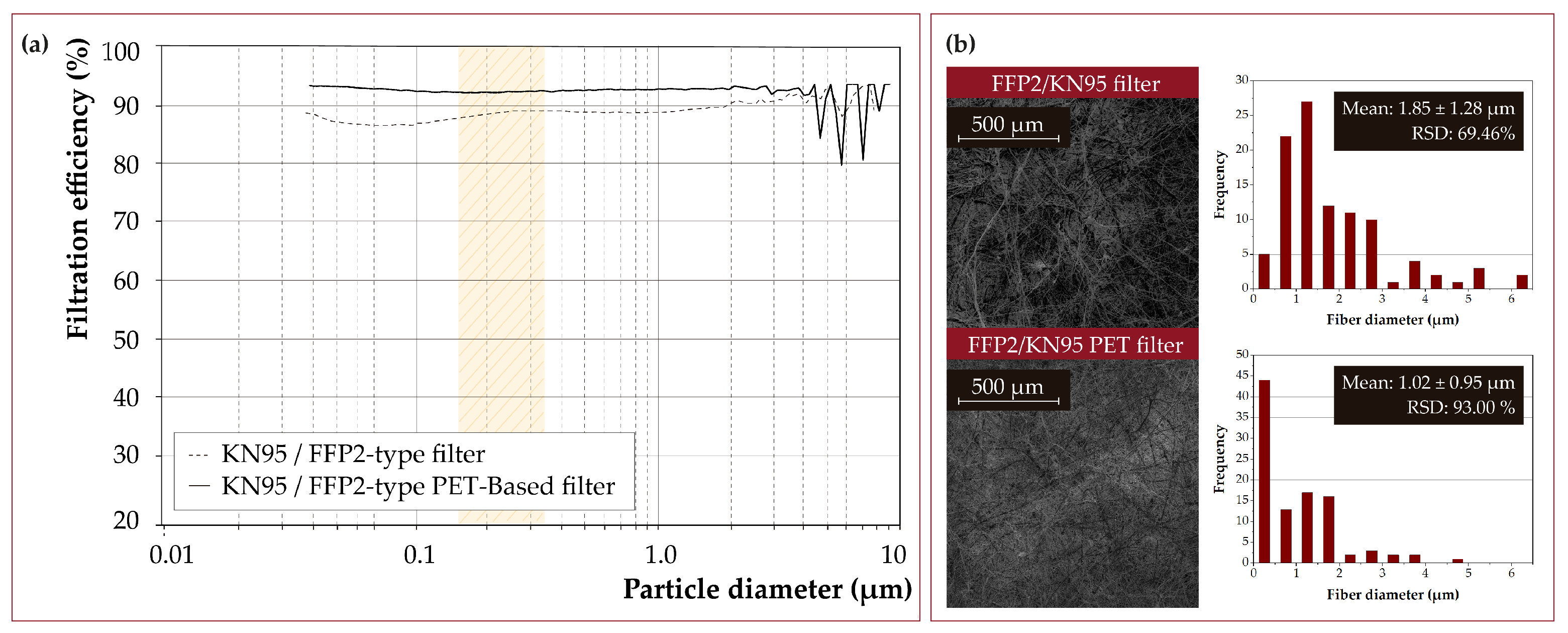

3.9. Exploring FFP2/KN95-Type Filters

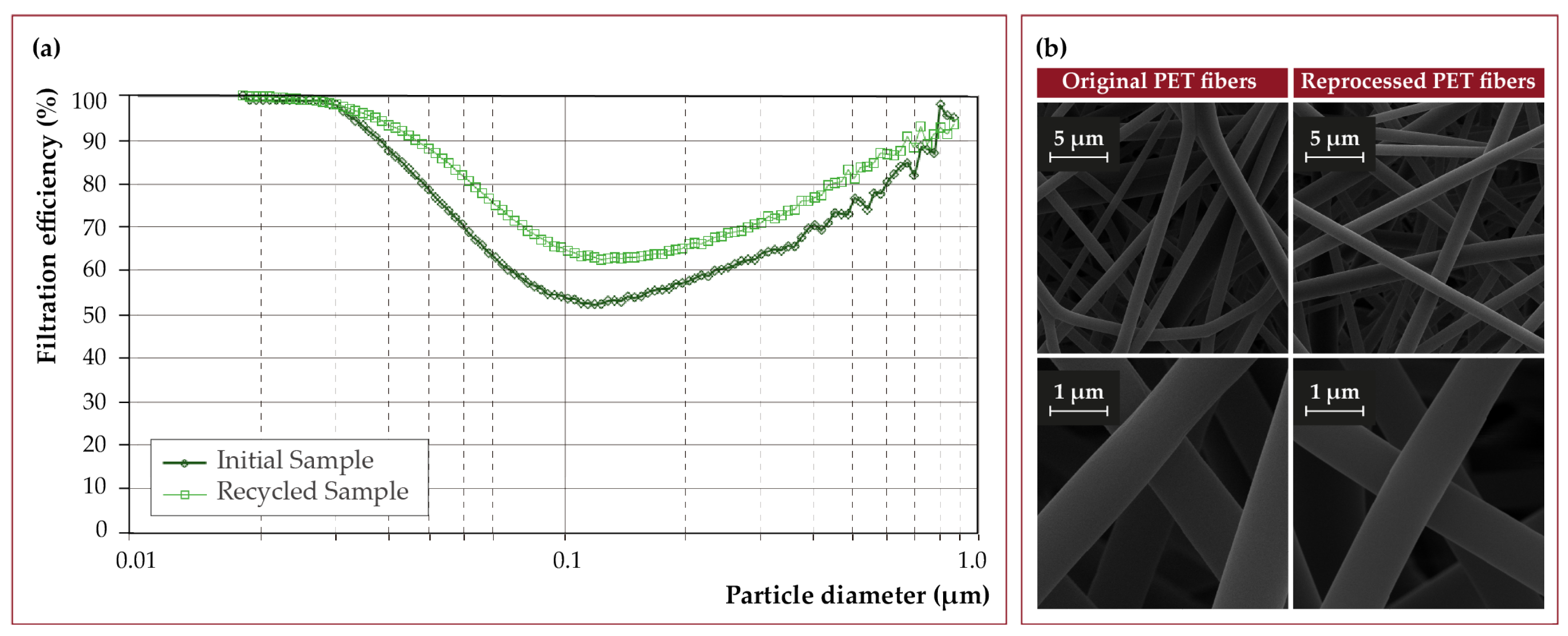

3.10. Reprocessing of PET Masks

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Graulich, K.; Köhler, A.; Low, C.; Sutter, J.; Watson, D.; Mehlhart, G.; Egebae, K.K.; Bilsen, V.; Bley, F. Impact of COVID-19 on Single-Use Plastics and the Environment in Europe; European Environment Agency: Boeretang, Belgium, 2021; Volume 10, pp. 142–149. Available online: http://europa.eu (accessed on 17 February 2022).

- Badillo-Goicoechea, E.; Chang, T.H.; Kim, E.; LaRocca, S.; Morris, K.; Deng, X.; Chiu, S.; Bradford, A.; Garcia, A.; Kern, C.; et al. Global trends and predictors of face mask usage during the COVID-19 pandemic. BMC Public Health 2021, 21, 2099. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.G.; Jin, P.; English, A.S. Collectivism predicts mask use during COVID-19. Proc. Natl. Acad. Sci. USA 2021, 118, e2021793118. [Google Scholar] [CrossRef] [PubMed]

- Chattopadhyay, S.; Hatton, T.A.; Rutledge, G.C. Aerosol filtration using electrospun cellulose acetate fibers. J. Mat. Sci. 2015, 51, 204–217. [Google Scholar] [CrossRef]

- Shen, H.; Zhou, Z.; Wang, H.; Zhang, M.; Han, M.; Durkin, D.P.; Shuai, D.; Shen, Y. Development of Electrospun Nanofibrous Filters for Controlling Coronavirus Aerosols. Environ. Sci. Technol. Lett. 2021, 8, 545–550. [Google Scholar] [CrossRef]

- Mamun, A.; Blachowicz, T.; Sabantina, L. Electrospun nanofiber mats for filtering applications technology, structure and materials. Polymers 2021, 13, 1368. [Google Scholar] [CrossRef] [PubMed]

- Payen, J.; Vroman, P.; Lewandowski, M.; Perwuelz, A.; Callé-Chazelet, S.; Thomas, D. Influence of fiber diameter, fiber combinations and solid volume fraction on air filtration properties in nonwovens. Text. Res. J. 2012, 82, 1948–1959. [Google Scholar] [CrossRef]

- Al-Attabi, R.; Dumée, L.F.; Schütz, J.A.; Morsi, Y. Pore engineering towards highly efficient electrospun nanofibrous membranes for aerosol particle removal. Sci. Total Environ. 2018, 625, 706–715. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y. Electrospinning of nanofibers: Reinventing the wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Matulevicius, J.; Kliucininkas, L.; Prasauskas, T.; Buivydiene, D.; Martuzevicius, D. The comparative study of aerosol filtration by electrospun polyamide, polyvinyl acetate, polyacrylonitrile and cellulose acetate nanofiber media. J. Aerosol. Sci. 2016, 92, 27–37. [Google Scholar] [CrossRef]

- Teo, W.E.; Ramakrishna, S. A review on electrospinning design and nanofibre assemblies. Nanotechnology 2006, 17, r89. [Google Scholar] [CrossRef]

- Thavasi, V.; Singh, G.; Ramakrishna, S. Electrospun nanofibers in energy and environmental applications. Energy Environ. Sci. 2008, 1, 205–221. [Google Scholar] [CrossRef]

- Pardo-Figuerez, M.; Chiva-Flor, A.; Figueroa-Lopez, K.; Prieto, C.; Lagaron, J.M. Antimicrobial nanofiber based filters for high filtration efficiency respirators. Nanomaterials 2021, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, R.; Rodrigues, B.; Santos, D.; Campana-Filho, S.; Ruvolo-Filho, A.C.; Frollini, E. Electrospun recycled PET-based mats: Tuning the properties by addition of cellulose and/or lignin. Polym. Test. 2017, 60, 422–431. [Google Scholar] [CrossRef]

- Strain, I.N.; Wu, Q.; Pourrahimi, A.M.; Hedenqvist, M.S.; Olsson, R.T.; Andersson, R.L. Electrospinning of recycled PET to generate tough mesomorphic fibre membranes for smoke filtration. J. Mater. Chem. A 2015, 3, 1632–1640. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Sweetser, D. Recycled PET nanofibers for water filtration applications. Materials 2016, 9, 247. [Google Scholar] [CrossRef] [PubMed]

- Bonfim, D.; Cruz, F.; Bretas, R.; Guerra, V.G. A Sustainable Recycling Alternative: Electrospun. Polymers 2021, 13, 1166. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Xia, Y. Aerosol filtraton by fibrous filters. I: Theoretical. J. Aerosol. Sci. 1974, 5, 191–204. [Google Scholar]

- Li, D.; Xia, Y. Aerosol filtraton by fibrous filters. II: Experimental. J. Aerosol. Sci. 1974, 5, 205–217. [Google Scholar]

- Olmedo, C.G.; Aragón, E.Q.; Torrent, J.G.; Pejic, L.M.; Ramon, C.F. Study of porosity and permeability of air filter material in respiratory protection filters. In Proceedings of the 8th International Scientific Conference of Modern Management of Mine Producing (SGEM 2008), Albena, Bulgaria, 16–20 June 2008; Volume 1, pp. 231–240. [Google Scholar]

- Walsh, D.; Stenhouse, J.; Scurrah, K.; Graef, A. The effect of solid and liquid particles loading on fibrous filter material perfromances. J. Aerosol. Sci. 1996, 27, s617–s618. [Google Scholar] [CrossRef]

- Essa, W.K.; Yasin, S.A.; Saeed, I.A.; Ali, G.A.M. Nanofiber-based face masks and respirators as covid-19 protection: A review. Membranes 2021, 11, 250. [Google Scholar] [CrossRef]

- Tebyetekerwa, M.; Xu, Z.; Yang, S.; Ramakrishna, S. Electrospun Nanofibers-Based Face Masks. Adv. Fiber. Mater. 2020, 2, 161–166. [Google Scholar] [CrossRef]

- Liao, M.; Liu, H.; Wang, X.; Hu, X.; Huang, Y.; Liu, X.; Brenan, K.; Mecha, J.; Nirmalan, M.; Lu, J.R. A technical review of face mask wearing in preventing respiratory COVID-19 transmission. Curr. Opin. Colloid Interface Sci. 2021, 52, 101417. [Google Scholar] [CrossRef] [PubMed]

- Kulkarni, P.; Baron, P.A.; Willeke, K. Fundamentals of Single Particle Transport. In Aerosol Measurements: Principles, Techniques, and Applications, 3rd ed.; Kulkarni, P., Baron, P.A., Willeke, K., Eds.; John Wiley & Sons, Inc.: New Jersey, NJ, USA, 2011; pp. 15–30. [Google Scholar]

- Bian, Y.; Wang, S.; Zhang, L.; Chen, C. Influence of fiber diameter, filter thickness, and packing density on PM2.5 removal efficiency of electrospun nanofiber air filters for indoor applications. Build Environ. 2020, 170, 106628. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, Y.S.; Tian, G.J.; Wang, H.; Zhang, H.L.; Xie, W. Influence of Fiber diameter on filtration performance of polyester fibers. Therm. Sci. 2019, 23, 2291–2296. [Google Scholar] [CrossRef]

- Charvet, A.; Pacault, S.; Bourrous, S.; Thomas, D. Association of fibrous filters for aerosol filtration in predominant Brownian diffusion conditions. Sep. Purif. Technol. 2018, 207, 420–426. [Google Scholar] [CrossRef]

- Gustafsson, O. Nanoparticle Removal and Brownian Diffusion by Virus Removal Filters: Theoretical and Experimental Study. Ph.D. Thesis, Uppsala University, Uppsala, Sweden, November 2017. [Google Scholar]

- Lamb, G.E.; Costanza, P.; Miller, B. Influences of Fiber Geometry on the Performance of Nonwoven Air Filters. Tex Res. J. 1975, 45, 452–463. [Google Scholar] [CrossRef]

- Zhu, C.; Lin, H.; Cheung, C.S. Inertial impaction-dominated fibrous filtration with rectangular or cylindrical fibers. Powder Technol. 2000, 112, 149–162. [Google Scholar] [CrossRef]

- Wang, K.; Zhao, H. The influence of fiber geometry and orientation angle on filtration performance. Aerosol. Sci. Technol. 2015, 49, 75–85. [Google Scholar] [CrossRef]

- Stepanyan, R.; Lebouille, J.G.J.L.; Slot, J.J.M.; Tuinier, R.; Stuart, M.A.C. Controlled nanoparticle formation by diffusion limited coalescence. Phys. Rev. Lett. 2012, 109, 1–5. [Google Scholar] [CrossRef]

- Dehghan, S.F.; Golbabaei, F.; de Bozorgmehr, M.; Latifi, K.; Pezeshk, H.; Hasanzadeh, M.; Akbar-Khanzadeh, F. Optimization of electrospinning parameters for polyacrylonitrile-MgO nanofibers applied in air filtration. J. Air Waste Manag. Assoc. 2016, 66, 912–921. [Google Scholar] [CrossRef]

- Megelski, S.; Stephens, J.S.; Bruce Chase, D.; Rabolt, J.F. Micro- and nanostructured surface morphology on electrospun polymer fibers. Macromolecules 2002, 35, 8456–8466. [Google Scholar] [CrossRef]

- Zargham, S.; Bazgir, S.; Tavakoli, A.; Rashidi, S.A.; Damerchely, R. The effect of flow rate on morphology and deposition area of electrospun nylon 6 nanofiber. J. Eng. Fiber Fabr. 2012, 7, 42–49. [Google Scholar] [CrossRef]

- Duque, D.; Rodriguez, L.; López, M. Electrospinning: The Nanofibers Age. Rev. Iberoam Pol. 2014, 14, 10–27. [Google Scholar]

- Fong, H.; Chun, I.; Reneker, D. Beaded nanofibers formed during electrospinning. Polymer 1999, 40, 4585–4592. [Google Scholar] [CrossRef]

- Higashi, S.; Hirai, T.; Matsubara, M.; Yoshida, H.; Beniya, A. Dynamic viscosity recovery of electrospinning solution for stabilizing elongated ultrafine polymer nanofiber by TEMPO-CNF. Sci. Rep. 2020, 10, 13427. [Google Scholar] [CrossRef] [PubMed]

- Korycka, P.; Mirek, A.; Kramek-Romanowska, K.; Grzeczkowicz, M.; Lewinska, D. Effect of electrospinning process variables on the size of polymer fibers and bead-on-string structures established with a 23 factorial design. J. Nanotechnol. 2018, 9, 2466–2478. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Li, X.; Xin, B.; Meng, N.; Helian, X. Effects of surface morphology of electrospun polystyrene fiber on its air filtration performance. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Deitzel, J.; Kleinmeyer, D.; Harris, N.; Tan, B. The effect of processing variables on the morphology of electrospun nanofibers and textiles. Polymer 2001, 42, 261–272. [Google Scholar] [CrossRef]

- Li, D.; Wang, Y.; Xia, Y. Electrospinning Nanofibers as Uniaxially Aligned Arrays and Layer-by-Layer Stacked Films. Adv. Mater. 2004, 16, 361–366. [Google Scholar] [CrossRef]

- Buchko, C.J.; Chen, L.C.; Shen, Y.; Martin, D.C. Processing and microstructural characterization of porous biocompatible protein polymer thin films. Polymer 1999, 40, 7397–7407. [Google Scholar] [CrossRef]

- Nazir, A.; Khenoussi, N.; Hussain, T.; Abid, S.; Schacher, L.; Adolphe, D.; Zahir, A.; Bilal Qadir, M.; Khaliq, Z.; Shahzad, A. Enhanced filtration and comfort properties of nonwoven filtering facepiece respirator by the incorporation of polymeric nanoweb. Polymer Bul. 2020, 77, 5155–5173. [Google Scholar] [CrossRef]

- Nam, C.; Lee, S.; Ryu, M.; Lee, J.; Lee, H. Electrospun nanofiber filters for highly efficient PM2.5 capture. Korean J. Chem. Eng. 2019, 36, 1565–1574. [Google Scholar] [CrossRef]

- Khandaker, M.; Progri, H.; Arasu, D.T.; Nikfarjam, S.; Shamim, N. Use of polycaprolactone electrospun nanofiber mesh in a face mask. Materials 2021, 14, 4272. [Google Scholar] [CrossRef] [PubMed]

- De Vrieze, S.; Van Camp, T.; Nelvig, A.; Hagström, B.; Westbroek, P.; de Clerck, K. The effect of temperature and humidity on electrospinning. J. Mater Sci. 2009, 44, 1357–1362. [Google Scholar] [CrossRef]

- Raksa, A.; Numpaisal, P.O.; Ruksakulpiwat, Y. The effect of humidity during electrospinning on morphology and mechanical properties of SF/PVA nanofibers. Mater Today Proc. 2021, 47, 3458–3461. [Google Scholar] [CrossRef]

- Sang, T.; Wallis, C.J.; Hill, G.; Britovsek, G.J.P. Polyethylene terephthalate degradation under natural and accelerated weathering conditions. Eur. Polym. J. 2020, 136, 109873. [Google Scholar] [CrossRef]

- Webb, H.K.; Arnott, J.; Crawford, R.J.; Ivanova, E.P. Plastic degradation and its environmental implications with special reference to poly(ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef]

- Edge, M.; Hayes, M.; Mohammadian, M.; Allen, N.S.; Jewitt, T.S.; Brems, K.; Jones, K. Aspects of poly(ethylene terephthalate) degradation for archival life and environmental degradation. Polym. Degrad. Stab. 1991, 32, 131–153. [Google Scholar] [CrossRef]

- Sammon, C.; Yarwood, J.; Everall, N. An FT–IR study of the effect of hydrolytic degradation on the structure of thin PET films. Polymer Degradation and Stability. Adv. Mater. Polym. Degrad. Stab. 2000, 67, 149–158. [Google Scholar] [CrossRef]

- EN 14683:2019+AC:2019; Medical Face Masks—Requirements and Test Methods. European Committee for Standarization: Brussels, Belgium, 2019.

- O’Kelly, E.; Arora, A.; Pirog, S.; Ward, K.; Clarkson, P.J. Comparing the fit of N95, KN95, surgical, and cloth face masks and assessing the accuracy of fit checking. PLoS ONE 2021, 16, e0245688. [Google Scholar] [CrossRef] [PubMed]

- Persano, L.; Camposeo, A.; Tekmen, C.; Pisignano, D. Industrial upscaling of electrospinning and applications of polymer nanofibers: A review. Macromol. Mater. Eng. 2003, 298, 504–520. [Google Scholar] [CrossRef]

- Omer, S.; Forgách, L.; Zelkó, R.; Sebe, I. Scale-up of electrospinning: Market overview of products and devices for pharmaceutical and biomedical purposes. Pharmaceutics 2021, 13, 286. [Google Scholar] [CrossRef] [PubMed]

- Valipouri, A. Production Scale Up of Nanofibers: A Review. J. Text. Polym. 2017, 5, 8–16. [Google Scholar]

- Park, J. Electric Spinning Apparatus for Mass-Production of Nano-Fiber. U.S. Patent 7,980,838, 19 July 2011. [Google Scholar]

- Pardo-Figuerez, M.; Chiva-Flor, A.; CSIC-Bioinicia. Filtro Multicapa con Propiedades Antimicrobianas y su uso en Aplicaciones de Respiradores y Mascarillas Protectoras. Spanish Patent ES2765374A1, 20 April 2020. [Google Scholar]

- Ultra-Web Media Technology. Available online: https://www.donaldson.com/en-be/industrial-dust-fume-mist/technicalarticles/ultra-web-media-technology/ (accessed on 27 February 2022).

- Kara, Y.; Molnár, K. A review of processing strategies to generate melt-blown nano/microfiber mats for high-efficiency filtration applications. J. Ind. Text. 2021. [Google Scholar] [CrossRef]

- EN 149:2001+A1:2009; Respiratory Protective Devices. Filtering Half Masks to Protect against Particles. Requirements, Testing, Marking. European Committee for Standarization: Brussels, Belgium, 2009.

- EN 13274-7:2020; Respiratory Protective Devices—Methods of Test—Part 7: Determination of Particle Filter Penetration. European Committee for Standarization: Brussels, Belgium, 2020.

- Selvaranjan, K.; Navaratnam, S.; Rajeev, P.; Ravintherakumaran, N. Environmental challenges induced by extensive use of face masks during COVID-19: A review and potential solutions. Environ. Challenges 2021, 3, 100039. [Google Scholar] [CrossRef]

- Allison, A.L.; Ambrose-Dempster, E.; Aparsi, D.T.; Bawn, M.; Casas Arredondo, M.; Chau, C.; Chandler, K.; Dobrijevic, D.; Hailes, H.; Lettieri, P. The Environmental Dangers of Employing Single-Use Face Masks as Part of a COVID-19 Exit Strategy; University College London: London, UK, 2020. [Google Scholar]

- Battegazzore, D.; Cravero, F.; Frache, A. Is it possible to mechanical recycle the materials of the disposable filtering masks? Polymers 2020, 12, 2726. [Google Scholar] [CrossRef] [PubMed]

- Leonas, K.K.; Jones, C.R.; Hall, D. The relationship of fabric properties and bacterial filtration efficiency for selected surgical face masks. JTATM 2003, 3, 1–8. [Google Scholar]

- Teesing, G.R.; van Straten, B.; de Man, P.; Horeman-Franse, T. Is there an adequate alternative to commercially manufactured face masks? A comparison of various materials and forms. J. Hosp. Infect. 2020, 106, 246–253. [Google Scholar] [CrossRef] [PubMed]

- Mueller, A.V.; Eden, M.J.; Oakes, J.M.; Bellini, C.; Fernandez, L.A. Quantitative method for comparative assessment of particle removal efficiency of fabric masks as alternatives to standard surgical masks for PPE. Matter 2020, 3, 950–962. [Google Scholar] [CrossRef] [PubMed]

- Côrtes, M.F.; Espinoza, E.P.; Noguera, S.L.; Silva, A.A.; de Medeiros, M.E.; Boas, L.S.; Ferreira, N.E.; Tozetto-Mendoza, T.R.; Morais, F.G.; de Queiroz, R.S.; et al. Decontamination and re-use of surgical masks and respirators during the COVID-19 pandemic. Int. J. Infect. Dis. 2021, 104, 320–328. [Google Scholar] [CrossRef] [PubMed]

- Juang, P.S.C.; Tsai, P. N95 respirator cleaning and reuse methods proposed by the inventor of the N95 mask material. J. Emerg. Med. 2020, 58, 817–820. [Google Scholar] [CrossRef] [PubMed]

- Crespo, C.; Ibarz, G.; Sáenz, C.; Gonzalez, P.; Roche, S. Study of Recycling Potential of FFP2 Face Masks and Characterization of the Plastic Mix-Material Obtained. A Way of Reducing Waste in Times of Covid-19. Waste Biomass Valorization 2021, 12, 6423–6432. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Zhu, H.; Yao, Y.; Nian, X.; Fan, X. Analysis of the Mask Price Change from the Perspective of Economics. Financ. Forum. 2021, 9, 185. [Google Scholar] [CrossRef]

- van Straten, B.; Ligtelijn, S.; Droog, L.; Putman, E.; Dankelman, J.; Weil, N.H.; Horeman, T. A life cycle assessment of reprocessing face masks during the Covid-19 pandemic. Sci. Rep. 2021, 11, 17680. [Google Scholar] [CrossRef] [PubMed]

- McGain, F.; Story, D.; Lim, T.; McAlister, S. Financial and environmental costs of reusable and single-use anaesthetic equipment. Br. J. Anaesth. 2017, 118, 862–869. [Google Scholar] [CrossRef] [PubMed]

- Raghuvanshi, R.S.; Goyal, S.; Singh, O.; Panda, A.K. Stabilization of dichloromethane-induced protein denaturation during microencapsulation. Pharm. Dev. Technol. 1998, 3, 269–276. [Google Scholar] [CrossRef] [PubMed]

- Leisinger, T.; Braus-Stromeyer, S.A. Bacterial growth with chlorinated methanes. Environ. Health Perspect 1995, 103, 33–36. [Google Scholar]

- Byers, H.K.; Sly, L.I. Toxic effects of dichloromethane on the growth of methanotrophic bacteria. FEMS Microbiol. Ecol. 1993, 12, 35–38. [Google Scholar] [CrossRef][Green Version]

| Sample | PET (wt.%) | Flow (mL/h) | Voltage (kV) | Needle to Collector Distance (cm) | Needle Velocity (mm/s) | Filtration Efficiency (%) | Pressure Drop (mbar) |

|---|---|---|---|---|---|---|---|

| Sample 1 | 25 | 9.9 | +10.5/−3.9 | 20 | 25()/2() | 91.7 | 0.24 |

| Sample 2 | 25 | 9.9 | +10.5/−3.9 | 20 | 50()/2() | 95.2 | 0.39 |

| Sample 3 | 25 | 9.9 | +5.5/−3.9 | 20 | 25()/2() | 77.8 | 0.23 |

| Sample 4 | 25 | 9.9 | +10.5/−3.9 | 25 | 25()/2() | 95.1 | 0.19 |

| Sample 5 | 25 | 6.0 | +10.5/−3.9 | 20 | 25()/2() | 98.3 | 0.25 |

| Particle Diameter Range 0.01–1.0 m | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample | Thickness (m) | Filtration Efficiency (%) 1 | Pressure Drop (mbar) 1 | Filtration Efficiency (%) 2 | Pressure Drop (mbar) 2 | Loss of Efficiency (%) 2 | Filtration Efficiency (%) 3 | Pressure Drop (mbar) 3 | Loss of Efficiency (%) 3 |

| M1 | 230 | 89.9 | 0.80 | 87.8 | 0.86 | 2.4 | 87.4 | 0.88 | 2.9 |

| M2 | 210 | 85.5 | 0.64 | 85.1 | 0.76 | 0.5 | 80.9 | 0.68 | 5.4 |

| M3 | 110 | 78.85 | 0.40 | 77.1 | 0.52 | 2.2 | 59.3 | 0.66 | 24.8 |

| M4 | 110 | 76.6 | 0.42 | 65.0 | 0.36 | 15.0 | 63.1 | 0.70 | 17.5 |

| M5 | 100 | 71.2 | 0.40 | 67.7 | 0.42 | 4.9 | 58.3 | 0.64 | 18.1 |

| M6 | 190 | 82.5 | 0.46 | 70.0 | 0.46 | 15.2 | 63.5 | 0.70 | 23.0 |

| Particle Diameter Range 0.5–1.0 m Particle Diameter Range 1–10 m | |||||||

|---|---|---|---|---|---|---|---|

| Sample | Thickness (m) | Filtration Efficiency (%) 1 | Filtration Efficiency (%) 2 | Loss of Efficiency (%) 2 | Filtration Efficiency (%) 1 | Filtration Efficiency (%) 2 | Loss of Efficiency (%) 2 |

| M1 | 230 | 98.1 | 96.3 | 1.7 | 99.9 | 99.8 | 0.1 |

| M2 | 210 | 96.5 | 92.5 | 4.0 | 99.9 | 99.8 | 1.1 |

| M3 | 110 | 93.1 | 86.1 | 7.0 | 98.3 | 98.5 | 0.0 |

| M4 | 110 | 95.2 | 82.4 | 12.8 | 99.7 | 97.8 | 1.9 |

| M5 | 100 | 89.5 | 85.5 | 4.0 | 97.2 | 98.2 | 0.0 |

| M6 | 190 | 93.9 | 82.5 | 8.5 | 98.8 | 98.6 | 0.2 |

| Parameters | Filter | External Layers |

|---|---|---|

| PET concentration | 25 wt.% | 25 wt.% |

| Voltage | ∼△15 kV | ∼△25 kV |

| Needle distance | 25 cm | 15 cm |

| Solution flow rate | 9.9 mL/h | 9.9 mL/h |

| Electrospinning Process | Traditional Meltblown/Spunbond Process | |

|---|---|---|

| Advantages | ||

| Single production equipment can manufacture the outer layers and the mask’s filter. | Two different types of equipment are required to manufacture the meltblown (filter), and the spunbond (external layers) since the change in fiber diameter requires different techniques. | |

| Electrospun fabrics do not require heat-sealing processes to ensure the bonding of the fibers in the outer layers, although they do require fusing one layer with another. | The spunbond material requires a heat-sealing process to bond the fibers obtained and to form the fabric. | |

| Electrospinning parameters can be easily manipulated to obtain different fabrics with variable filtration performance. | It is more expensive and complex to manipulate the parameters to obtain different types of filter fabric. | |

| It offers versatility to functionalize fabrics (e.g., incorporating antimicrobial materials). | The versatility of the process is limited. | |

| Disadvantages | ||

| Toxic solvents are used that must be handled in controlled environments. | It is not necessary to have controlled environments for handling the materials. | |

| Reduced production rate. | High production rate. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baselga-Lahoz, M.; Yus, C.; Arruebo, M.; Sebastián, V.; Irusta, S.; Jiménez, S. Submicronic Filtering Media Based on Electrospun Recycled PET Nanofibers: Development, Characterization, and Method to Manufacture Surgical Masks. Nanomaterials 2022, 12, 925. https://doi.org/10.3390/nano12060925

Baselga-Lahoz M, Yus C, Arruebo M, Sebastián V, Irusta S, Jiménez S. Submicronic Filtering Media Based on Electrospun Recycled PET Nanofibers: Development, Characterization, and Method to Manufacture Surgical Masks. Nanomaterials. 2022; 12(6):925. https://doi.org/10.3390/nano12060925

Chicago/Turabian StyleBaselga-Lahoz, Marta, Cristina Yus, Manuel Arruebo, Víctor Sebastián, Silvia Irusta, and Santiago Jiménez. 2022. "Submicronic Filtering Media Based on Electrospun Recycled PET Nanofibers: Development, Characterization, and Method to Manufacture Surgical Masks" Nanomaterials 12, no. 6: 925. https://doi.org/10.3390/nano12060925

APA StyleBaselga-Lahoz, M., Yus, C., Arruebo, M., Sebastián, V., Irusta, S., & Jiménez, S. (2022). Submicronic Filtering Media Based on Electrospun Recycled PET Nanofibers: Development, Characterization, and Method to Manufacture Surgical Masks. Nanomaterials, 12(6), 925. https://doi.org/10.3390/nano12060925