Magnetic Field Sensing Based on Whispering Gallery Mode with Nanostructured Magnetic Fluid-Infiltrated Photonic Crystal Fiber

Abstract

:1. Introduction

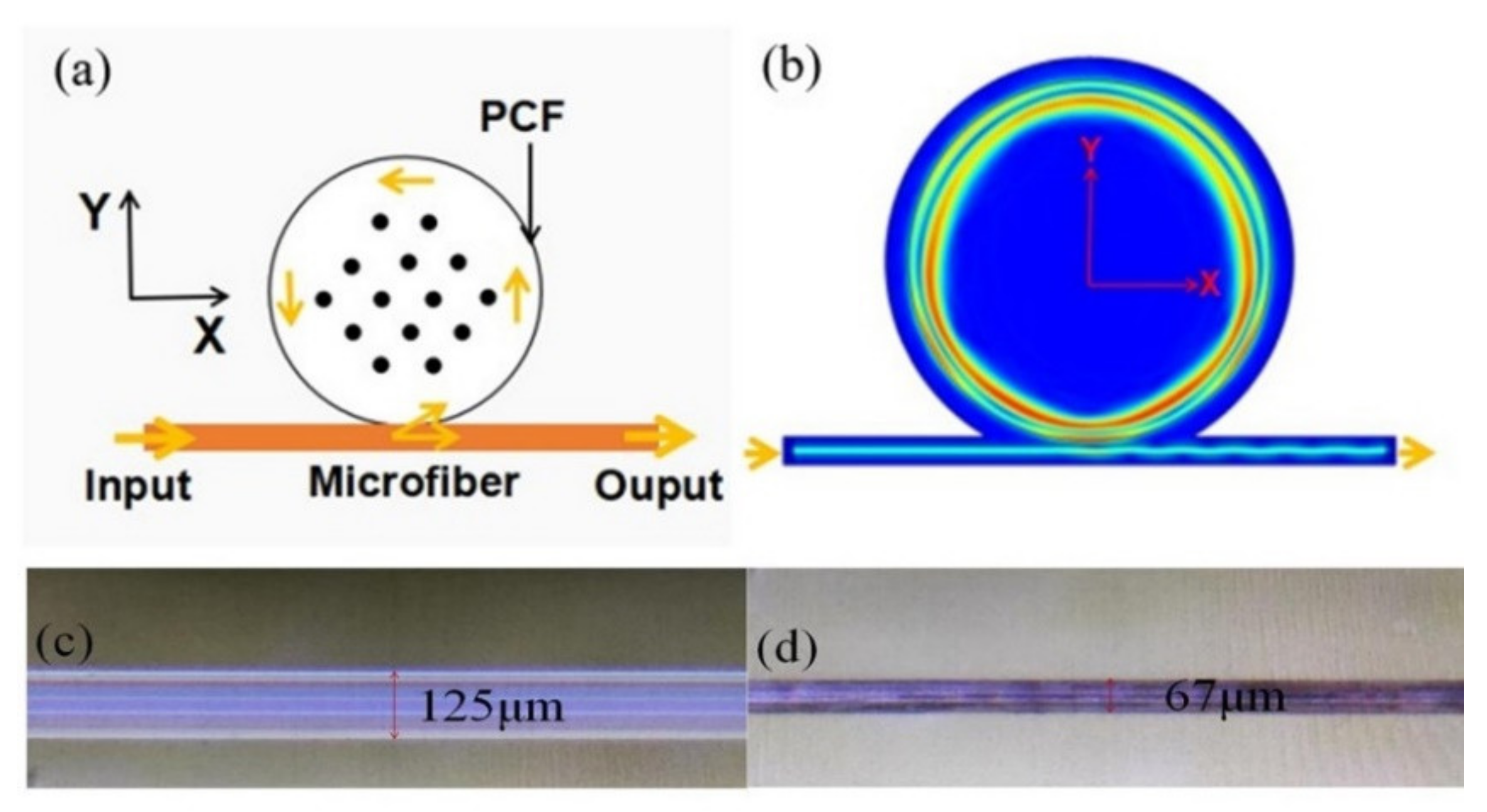

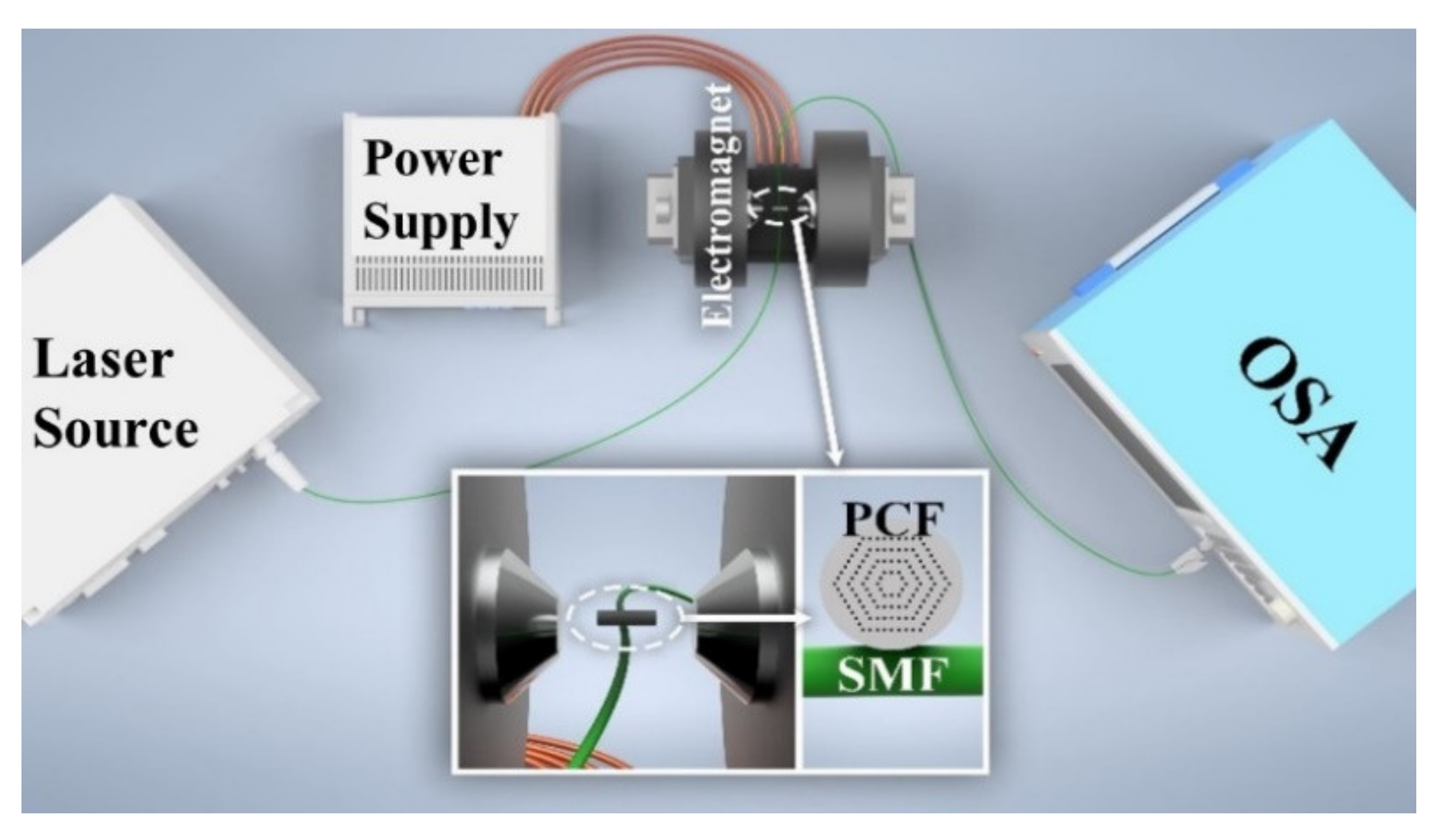

2. Fabrication and Experimental Details

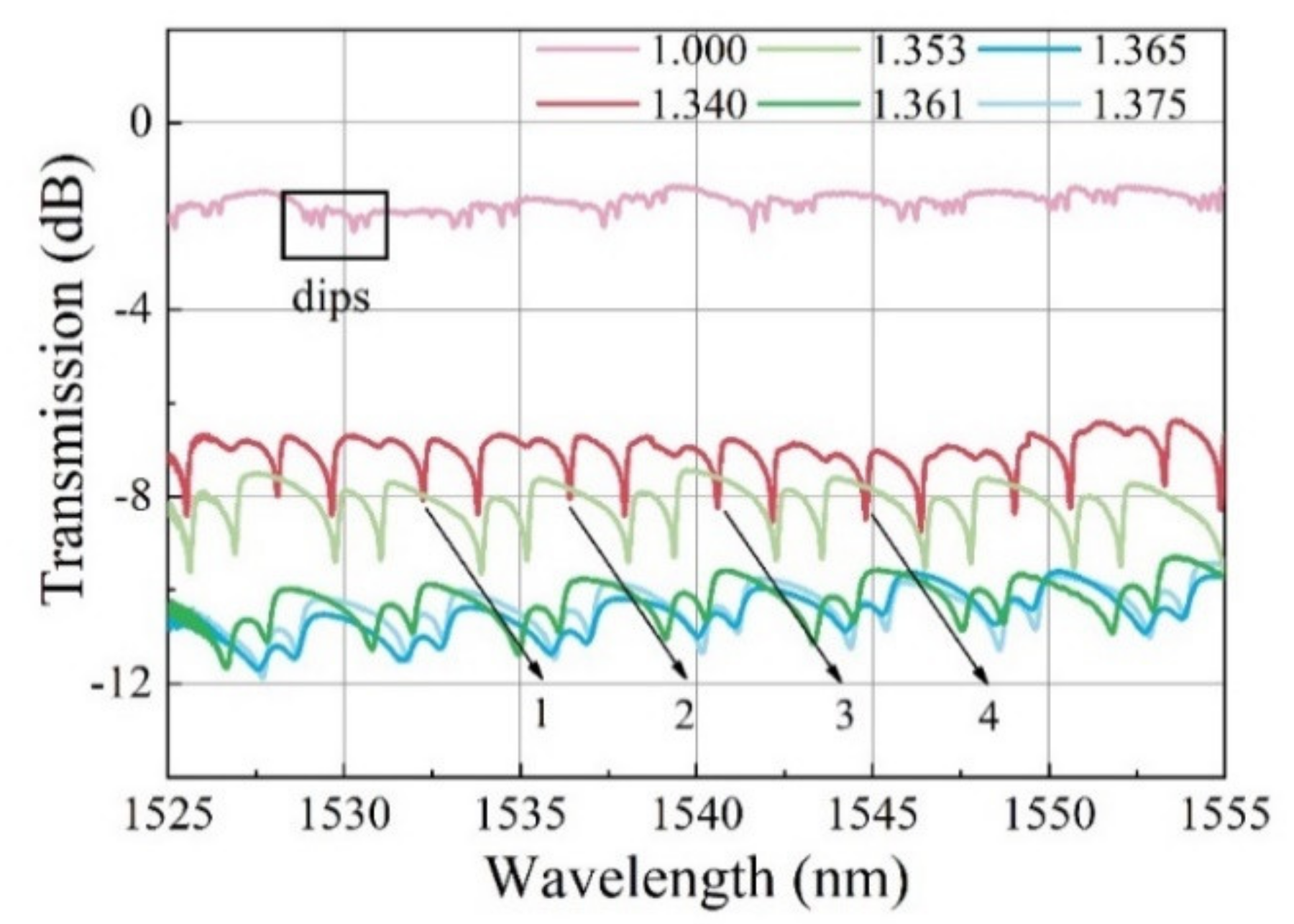

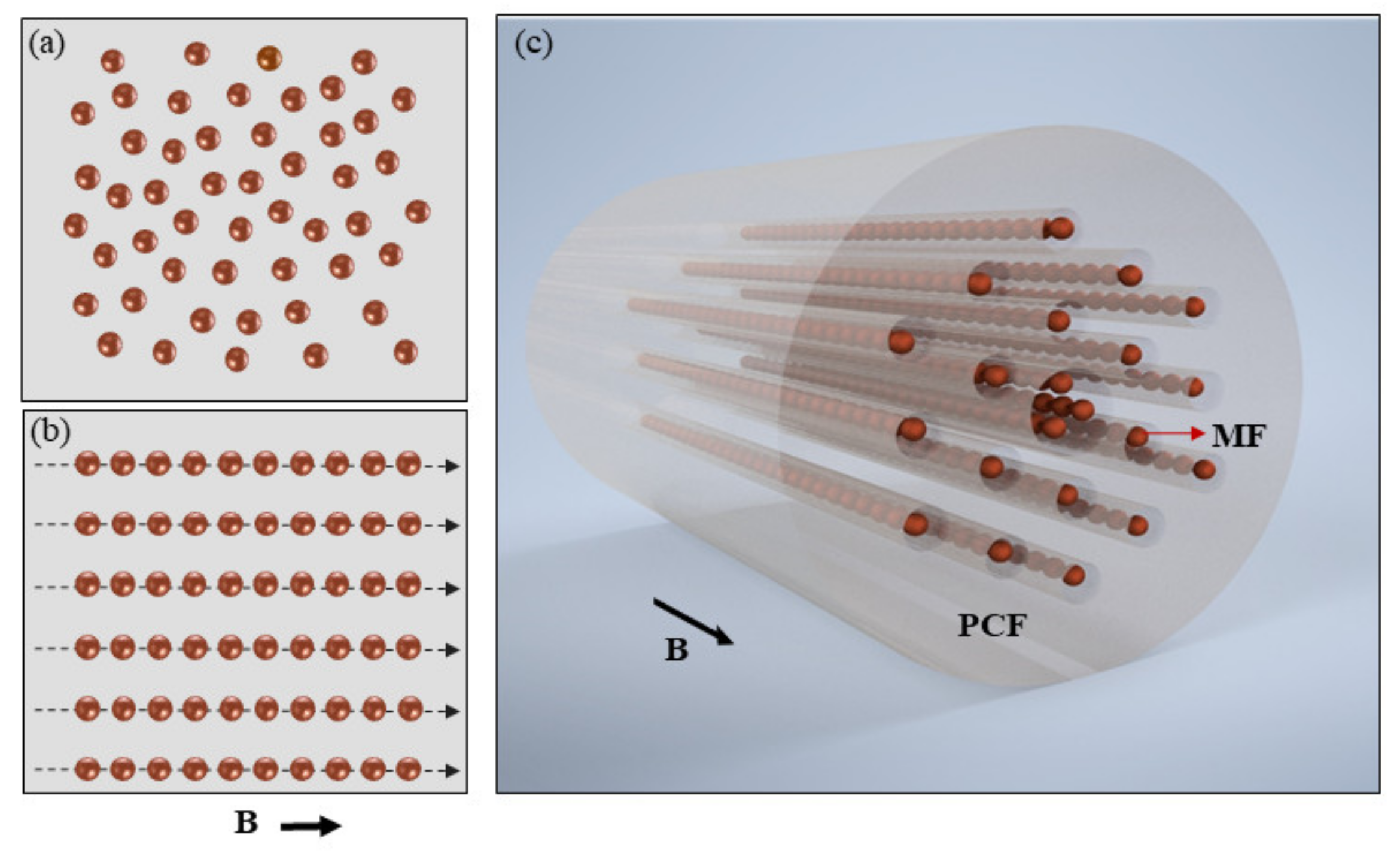

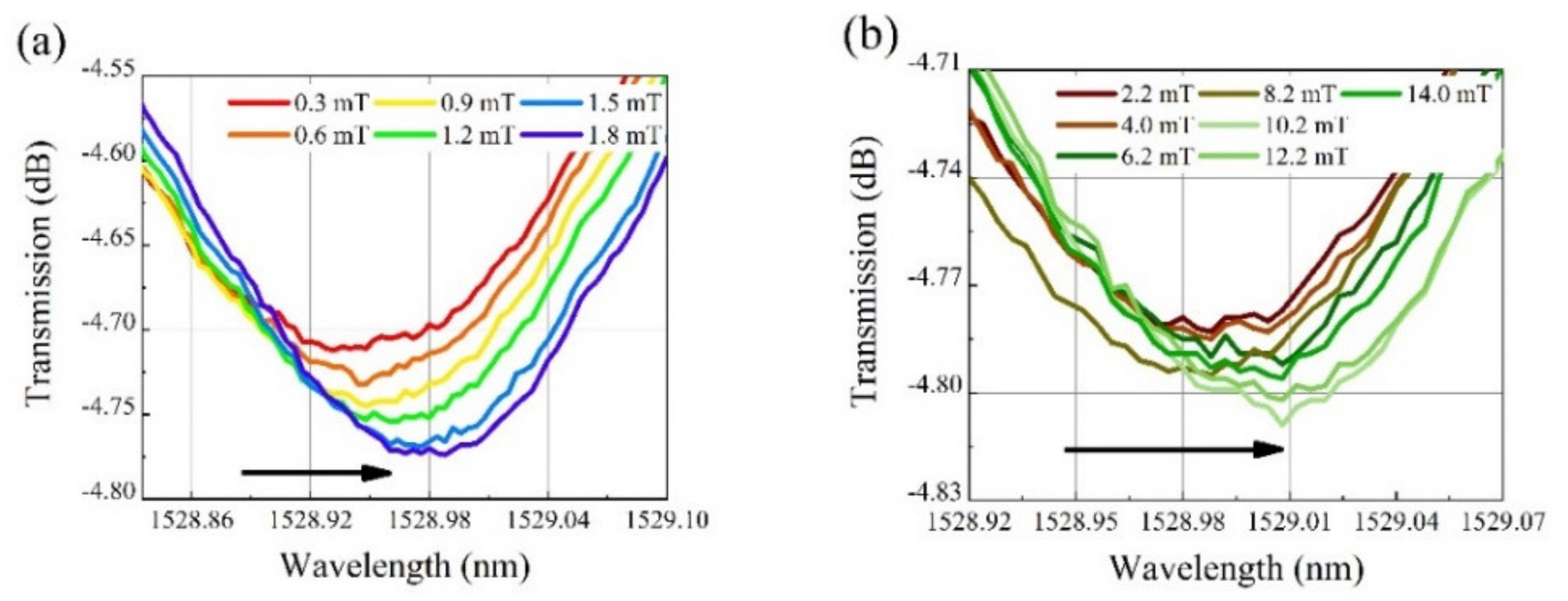

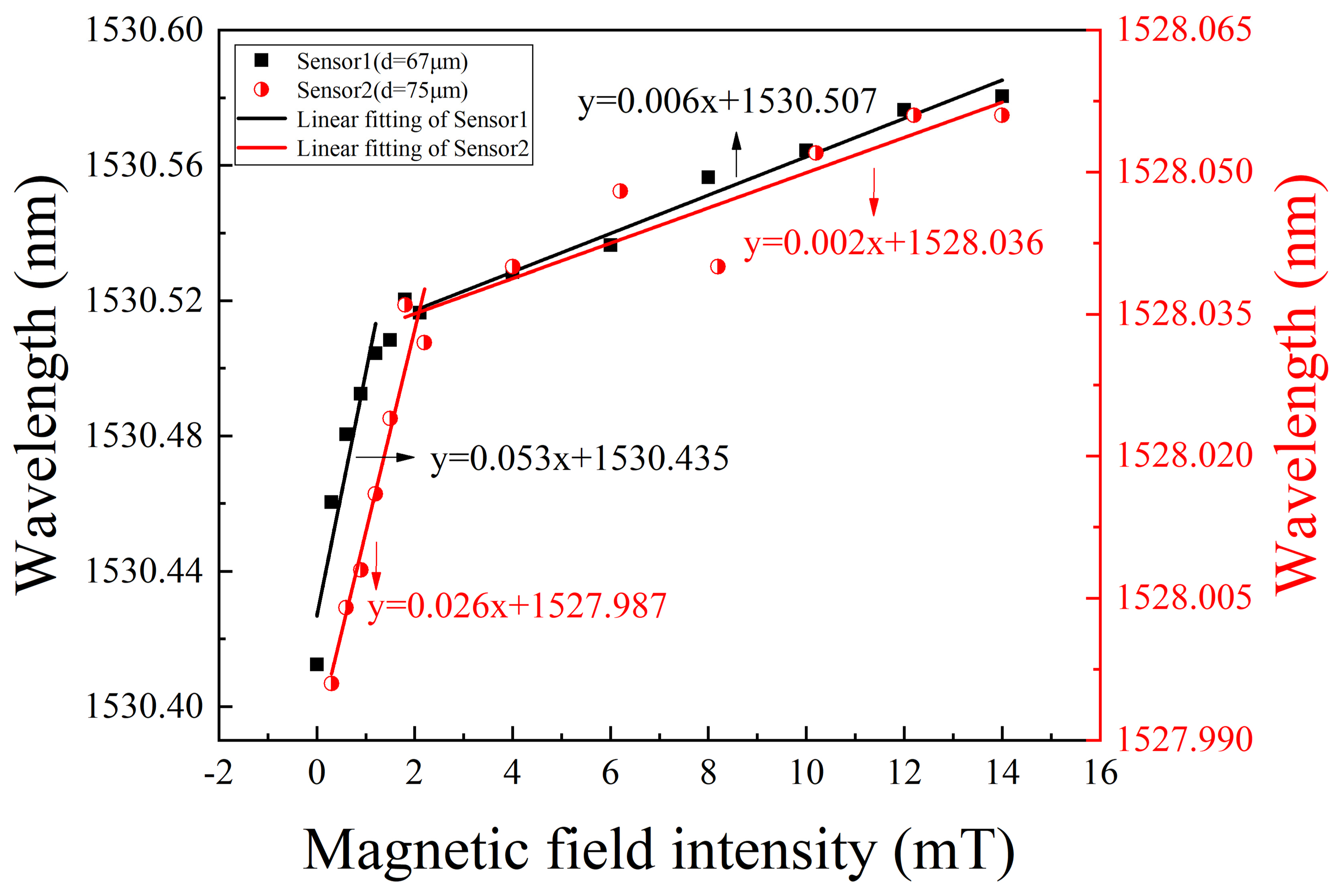

3. Sensing Principle and Experimental Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Tong, R.-J.; Xia, F.; Peng, Y. Current status of optical fiber biosensor based on surface plasmon resonance. Biosens. Bioelectron. 2019, 142, 111505. [Google Scholar] [CrossRef] [PubMed]

- Lenz, J.; Edelstein, S. Magnetic sensors and their applications. IEEE Sens. J. 2006, 6, 631–649. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.; Lv, R.-Q.; Zhang, Y.-N.; Wang, Q. Review on optical fiber sensors based on the refractive index tunability of ferrofluid. J. Light. Technol. 2017, 35, 3406–3412. [Google Scholar] [CrossRef]

- Janssen, J.; Perenboom, J. Magneto-optical phenomena in magnetic fluids: The influence of orientation of anisotropic scatterers. J. Magn. Magn. Mater. 1989, 81, 14–24. [Google Scholar] [CrossRef]

- Hasmonay, E.; Dubois, E.; Bacri, J.-C.; Perzynski, R.; Raikher, Y.L.; Stepanov, V.I. Static magneto-optical birefringence of size-sorted γ-Fe2O3 nanoparticles. Eur. Phys. J. B 1998, 5, 859–867. [Google Scholar] [CrossRef]

- Taketomi, S. Magnetic fluid’s anomalous pseudo-cotton mouton effects about 107 times larger than that of nitrobenzene. Jpn. J. Appl. Phys. 1983, 22, 1137–1143. [Google Scholar] [CrossRef]

- Xu, M.; Ridler, P.J. Linear dichroism and birefringence effects in magnetic fluids. J. Appl. Phys. 1997, 82, 326–332. [Google Scholar] [CrossRef]

- Horng, H.; Hong, C.-Y.; Yang, S.Y.; Yang, H.C. Novel properties and applications in magnetic fluids. J. Phys. Chem. Solids 2001, 62, 1749–1764. [Google Scholar] [CrossRef]

- Gao, R.; Lu, D.-F.; Zhang, Q.; Xin, X.-J.; Tian, Q.-H.; Tian, F.; Wang, Y.-J. Temperature compensated three-dimension fiber optic vector magnetic field sensor based on an elliptical core micro fiber Bragg grating. Opt. Express 2020, 28, 7721–7733. [Google Scholar] [CrossRef] [PubMed]

- Yuan, M.; Pu, S.L.; Li, D.H.; Li, Y.X.; Hao, Z.J.; Zhang, Y.X.; Zhang, C.C.; Yan, S.K. Extremely high sensitivity magnetic field sensing based on birefringence-induced dispersion turning point characteristics of microfiber coupler. Results Phys. 2021, 29, 104743. [Google Scholar] [CrossRef]

- Li, X.-G.; Zhao, Y.; Cai, L.; Zhou, X. Measurement of magnetic field and temperature based on fiber-optic composite interferometer. IEEE Trans. Instrum. Meas. 2017, 66, 1906–1911. [Google Scholar] [CrossRef]

- Zhou, X.; Li, X.G.; Li, S.G.; An, G.-W.; Cheng, T.L. Magnetic field sensing based on SPR optical fiber sensor interacting with magnetic fluid. IEEE Trans. Instrum. Meas. 2019, 68, 234–239. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, D.; Lv, R.-Q.; Li, J. Magnetic field measurement based on the Sagnac interferometer with a ferrofluid-filled high-birefringence photonic crystal fiber. IEEE Trans. Instrum. Meas. 2016, 65, 1503–1507. [Google Scholar] [CrossRef]

- Sun, B.; Fang, F.; Zhang, Z.; Xu, J.; Zhang, L. High-sensitivity and low-temperature magnetic field sensor based on tapered two-mode fiber interference. Opt. Lett. 2018, 43, 1311–1314. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Guo, Z. Integrated sensor with a whispering-gallery mode and surface plasmonic resonance for the enhanced detection of viruses. J. Opt. Soc. Am. B 2021, 38, 2855–2862. [Google Scholar] [CrossRef]

- Guo, Z.; Qin, Y.; Chen, P.; Hu, J.; Zhou, Y.; Zhao, X.; Liu, Z.; Fei, Y.; Jiang, X.; Wu, X. Hyperboloid-drum microdisk laser biosensors for ultrasensitive detection of human IgG. Small 2020, 16, 2000239. [Google Scholar] [CrossRef]

- Swaim, J.D.; Knittel, J.; Bowen, W.P. Detection limits in whispering gallery biosensors with plasmonic enhancement. Appl. Phys. Lett. 2011, 99, 243109. [Google Scholar] [CrossRef] [Green Version]

- Liao, J.; Yang, L. Optical whispering-gallery mode barcodes for high-precision and wide-range temperature measurements. Light. Sci. Appl. 2021, 10, 32. [Google Scholar] [CrossRef] [PubMed]

- Wang, E.; Cheng, P.; Li, J.; Cheng, Q.; Zhou, X.; Jiang, H. High-sensitivity temperature and magnetic sensor based on magnetic fluid and liquid ethanol filled micro-structured optical fiber. Opt. Fiber Technol. 2020, 55, 102161. [Google Scholar] [CrossRef]

- Wang, Z.; Mallik, A.K.; Wei, F.; Wang, Z.; Rout, A.; Wu, Q.; Semenova, Y. Thermo-optic tuning of a nematic liquid crystal-filled capillary whispering gallery mode resonator. Opt. Express 2021, 29, 23569–23581. [Google Scholar] [CrossRef]

- Li, H.Y.; Sun, B.; Yuan, Y.G.; Yang, J. Guanidine derivative polymer coated microbubble resonator for high sensitivity detection of CO2 gas concentration. Opt. Express 2019, 27, 1991–2000. [Google Scholar] [CrossRef] [PubMed]

- Reinis, P.K.; Milgrave, L.; Draguns, K.; Brice, I.; Alnis, J.; Atvars, A. High-sensitivity whispering gallery mode humidity sensor based on glycerol microdroplet volumetric expansion. Sensors 2021, 21, 1746. [Google Scholar] [CrossRef]

- Yan, J.; Wang, D.N.; Li, X. An erbium-doped whispering-gallery-mode microlaser for sensing. J. Light. Technol. 2021, 39, 5177–5182. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Y.D.; Sun, H.Y.; Zhu, F.X.; Yi, G.; Wang, J.F. Magnetic-field tuning whispering gallery mode based on hollow microbubble resonator with Terfenol-D-fixed. Appl. Opt. 2019, 58, 8889–8893. [Google Scholar] [CrossRef]

- Freeman, E.; Wang, C.-Y.; Sumaria, V.; Schiff, S.J.; Liu, Z.W.; Tadigadapa, S. Chip-scale high Q-factor glassblown microspherical shells for magnetic sensing. AIP Adv. 2018, 8, 065214. [Google Scholar] [CrossRef]

- Xia, J.; Wang, F.Y.; Xiong, S.D.; Zhou, G.Y.; Hu, Y.M.; Yao, Q. Novel magnetometer basedon magnetic fluid coated whispering gallery ode resonator. In Proceedings of the 2019 18th International Conference on Optical Communications and Networks, Huangshan, China, 5–8 August 2019; pp. 1–3. [Google Scholar]

- Liu, Y.L.; Zhang, H.; Fan, M.S.; Liang, C.Z.; Lei, J. Bidirectional tuning of whispering gallery modes in a silica microbubble infiltrated with magnetic fluids. Appl. Opt. 2020, 59, 1–8. [Google Scholar] [CrossRef]

- Liu, W.; Li, W.Y.; Wang, R.; Xing, E.B.; Jing, N.; Zhou, Y.R.; Tang, J.; Liu, J. Magnetic sensor based on WGM hollow microbubble resonator filled with magnetic fluid. Opt. Commun. 2021, 497, 127148. [Google Scholar] [CrossRef]

- Mahmood, A.; Kavungal, V.; Ahmed, S.S.; Kopcansky, P.; Zavisova, V.; Farrell, G.; Semenova, Y. Magnetic field sensing using whispering-gallery modes in a cylindrical microresonator infiltrated with ferronematic liquid crystal. Opt. Express 2017, 25, 12195–12202. [Google Scholar] [CrossRef]

- Zhu, S.; Shi, L.; Liu, N.Y.; Xu, X.B.; Zhang, X.L. Magnetic field sensing using magnetic-fluid-filled optofluidic ring resonator. Microfluid. Nanofluid. 2017, 21, 156. [Google Scholar] [CrossRef]

- Hou, F.Y.; Zhang, X.B.; Wang, Z.J.; Yang, L.; Sun, W.; Yang, Y.; Dong, Y.H.; Huang, Y.; Wang, T.Y. Magnetic fluid infiltrated microbottle resonator sensor with axial confined mode. IEEE Photon. J. 2020, 12, 1–9. [Google Scholar] [CrossRef]

- Huang, H.M.; Yu, Y.; Zhou, L.J.; Tao, Y.Y.; Yang, J.B.; Zhang, Z.R. Whispering gallery modes in a microsphere attached to a side-polished fiber and their application for magnetic field sensing. Opt. Commun. 2020, 478, 126366. [Google Scholar] [CrossRef]

- Li, Y.X.; Pu, S.L.; Zhao, Y.L.; Zhang, R.; Jia, Z.X.; Yao, J.L. All-fiber-optic vector magnetic field sensor based on side-polished fiber and magnetic fluid. Opt. Express 2019, 27, 35182–35188. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.-N.; Zhu, N.; Gao, P.; Zhao, Y. Magnetic field sensor based on ring WGM resonator infiltrated with magnetic fluid. J. Magn. Magn. Mater. 2020, 493, 165701. [Google Scholar] [CrossRef]

- Vega, F.; Torres, C.; Mattos, L. Method of producing tapered fibers. In Proceedings of the 22nd Congress of the International Commission for Optics: Light for the Development of the World, Puebla, Mexico, 15–19 August 2011. [Google Scholar]

- Suter, J.D.; Fan, X. Overview of the optofluidic ring resonator: A versatile platform for label-free biological and chemical sensing. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Minneapolis, MN, USA, 3–6 September 2009; pp. 1042–1044. [Google Scholar] [CrossRef]

- Yin, J.; Yan, P.; Chen, H.; Yu, L.; Jiang, J.; Zhang, M.; Ruan, S. All-fiber-optic vector magnetometer based on anisotropic magnetism-manipulation of ferromagnetism nanoparticles. Appl. Phys. Lett. 2017, 110, 231104. [Google Scholar] [CrossRef]

- Bertoni, G.; Torre, B.; Falqui, A.; Fragouli, D.; Athanassiou, A.; Cingolani, R. Nanochains formation of superparamagnetic nanoparticles. J. Phys. Chem. C 2011, 115, 7249–7254. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, T.; Zhang, X.-J.; Xu, J.; Xie, W.-P.; Nie, M.; Wu, Q.; Guan, B.-O.; Albert, J. Plasmonic fiber-optic vector magnetometer. Appl. Phys. Lett. 2016, 108, 101105. [Google Scholar] [CrossRef]

- Hong, C.Y.; Horng, H.E.; Yang, S.Y. Tunable refractive index of magnetic fluids and its applications. Phys. Status Solid. C 2004, 1, 1604–1609. [Google Scholar] [CrossRef]

| Sensing Structure | Fabrication Method | Maximum Sensitivity | Ref. |

|---|---|---|---|

| Hollow microbubble | Fuse-and-blow technique | 0.081 pm/mT | [24] |

| Borosilicate glass | HF etching + silicon nitride ceramic heating + glassblowing method | 4.0 pm/mT | [25] |

| Microsphere | HF etching + fusing + electrode discharging method | 5.036 pm/mT | [26] |

| Silica microbubble | Fusing + discharging method | 15.1 pm/mT | [27] |

| Hollow microbottle | Pressure-assisted air discharging + HF etching method | 25.21 pm/mT | [28] |

| PCF | Tapering method | −61.86 pm/mT | [29] |

| Silica microcapillary | Hydrogen flame heating + air-pumped swelling method | 75.7 pm/mT | [30] |

| Silica capillary | Fuse-discharging + increasing gas pressure + heated and soften method | 8.45 pm/Gs (84.5 pm/mT) | [31] |

| SiO2 microsphere | Side-polishing method | 0.0108 nm/Oe (108 pm/mT) | [32] |

| PCF | HF etching method | 53 pm/mT | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Pu, S.; Hao, Z.; Wang, B.; Yuan, M.; Zhang, Y. Magnetic Field Sensing Based on Whispering Gallery Mode with Nanostructured Magnetic Fluid-Infiltrated Photonic Crystal Fiber. Nanomaterials 2022, 12, 862. https://doi.org/10.3390/nano12050862

Zhang C, Pu S, Hao Z, Wang B, Yuan M, Zhang Y. Magnetic Field Sensing Based on Whispering Gallery Mode with Nanostructured Magnetic Fluid-Infiltrated Photonic Crystal Fiber. Nanomaterials. 2022; 12(5):862. https://doi.org/10.3390/nano12050862

Chicago/Turabian StyleZhang, Chencheng, Shengli Pu, Zijian Hao, Boyu Wang, Min Yuan, and Yuxiu Zhang. 2022. "Magnetic Field Sensing Based on Whispering Gallery Mode with Nanostructured Magnetic Fluid-Infiltrated Photonic Crystal Fiber" Nanomaterials 12, no. 5: 862. https://doi.org/10.3390/nano12050862

APA StyleZhang, C., Pu, S., Hao, Z., Wang, B., Yuan, M., & Zhang, Y. (2022). Magnetic Field Sensing Based on Whispering Gallery Mode with Nanostructured Magnetic Fluid-Infiltrated Photonic Crystal Fiber. Nanomaterials, 12(5), 862. https://doi.org/10.3390/nano12050862