Innovative Variation in the Morphological Characteristics of Carbon Nanowalls Grown on a Molybdenum Disulfide Interlayer

Abstract

1. Introduction

2. Experimental Method

2.1. Preparation of Substrate

2.2. MoS2 Interlayer Synthesis and Annealing

2.3. Growth of the Carbon Nanowall

2.4. Characterization and Analysis of Materials

3. Results and Discussion

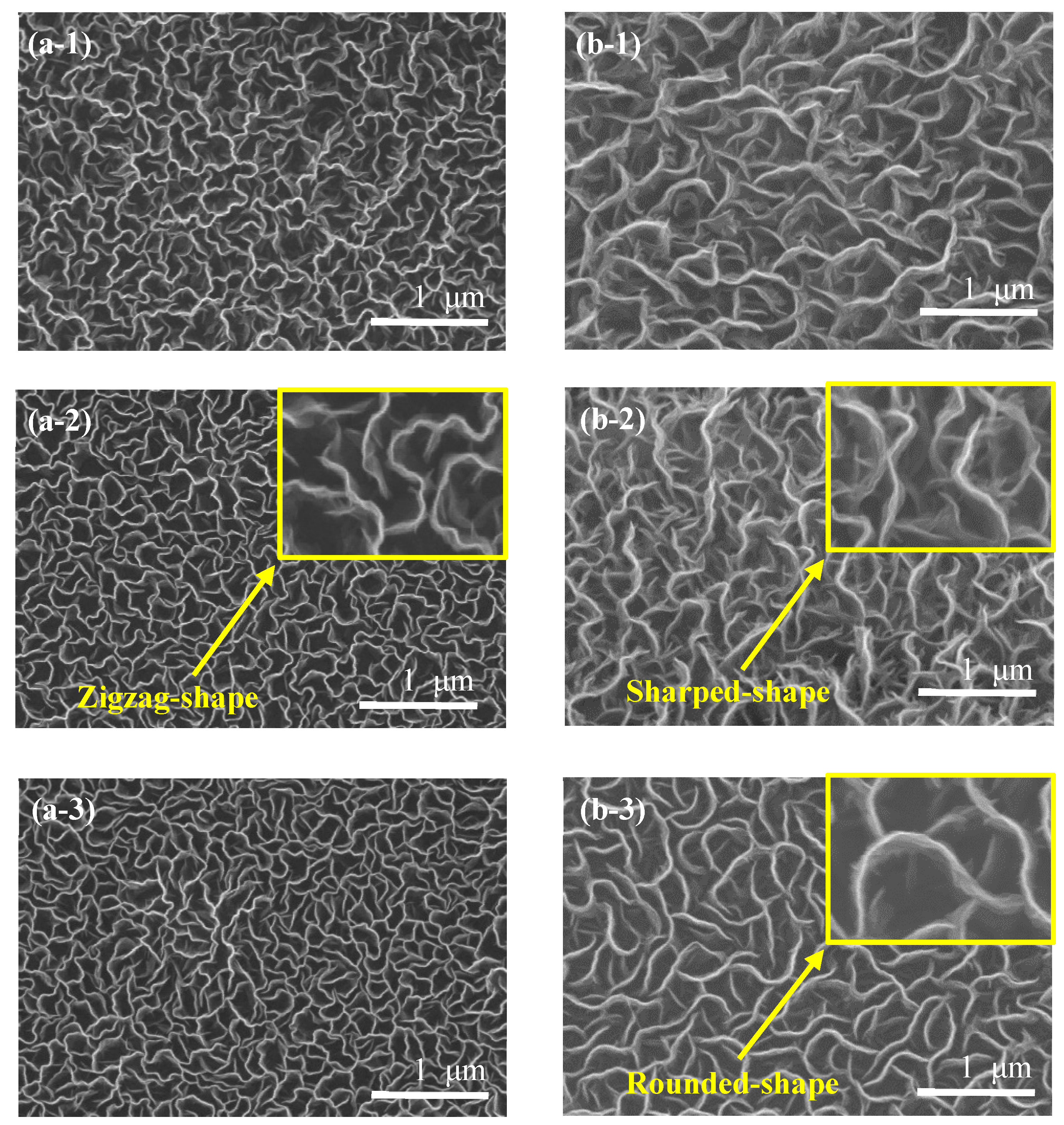

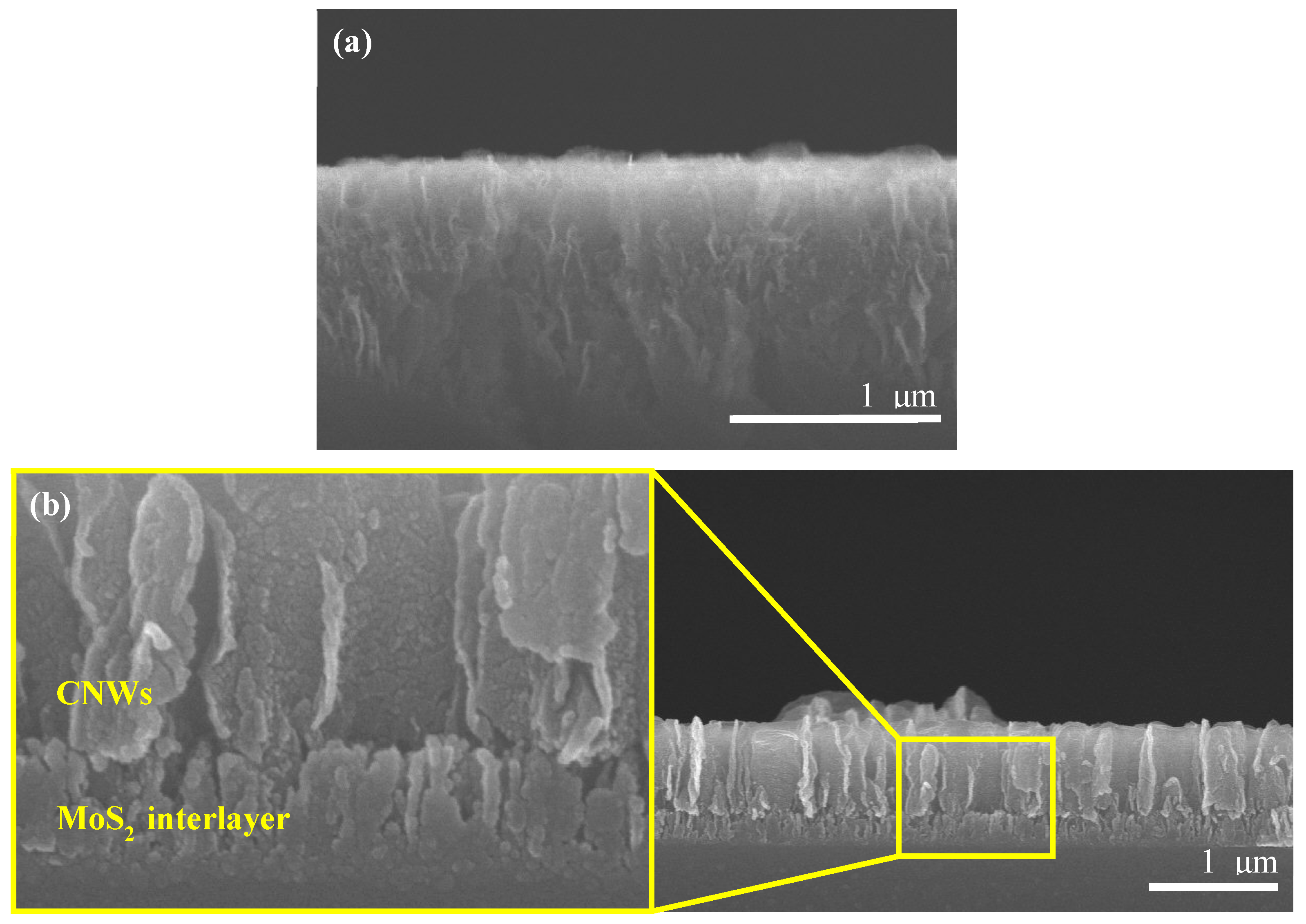

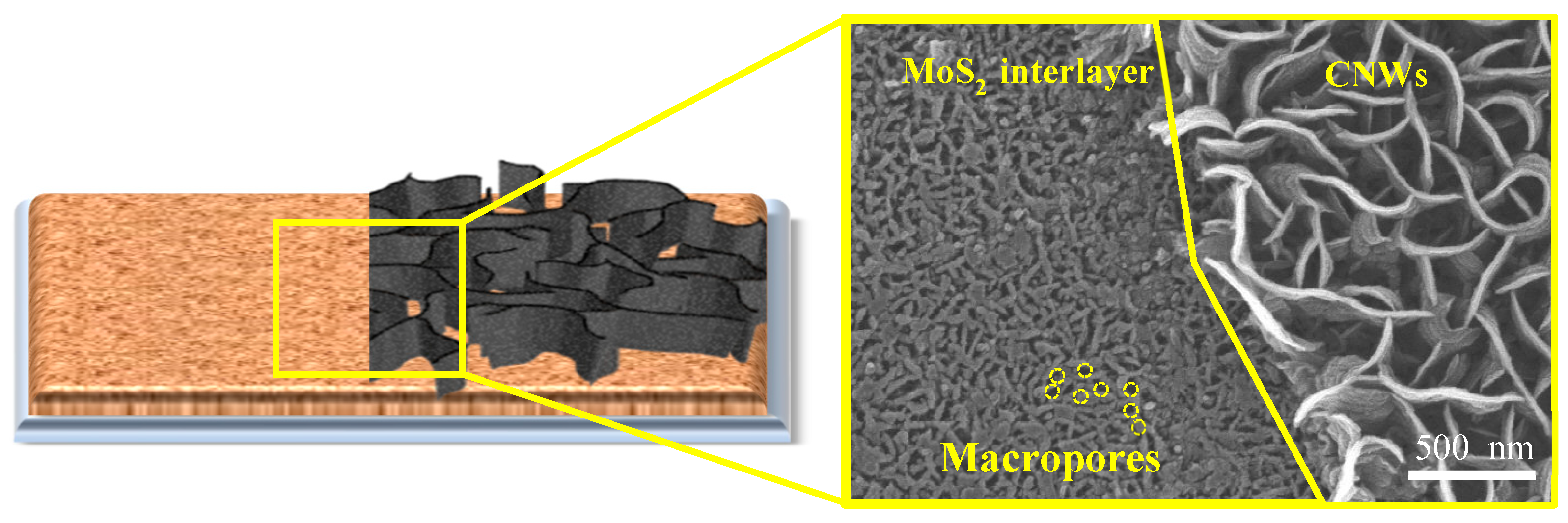

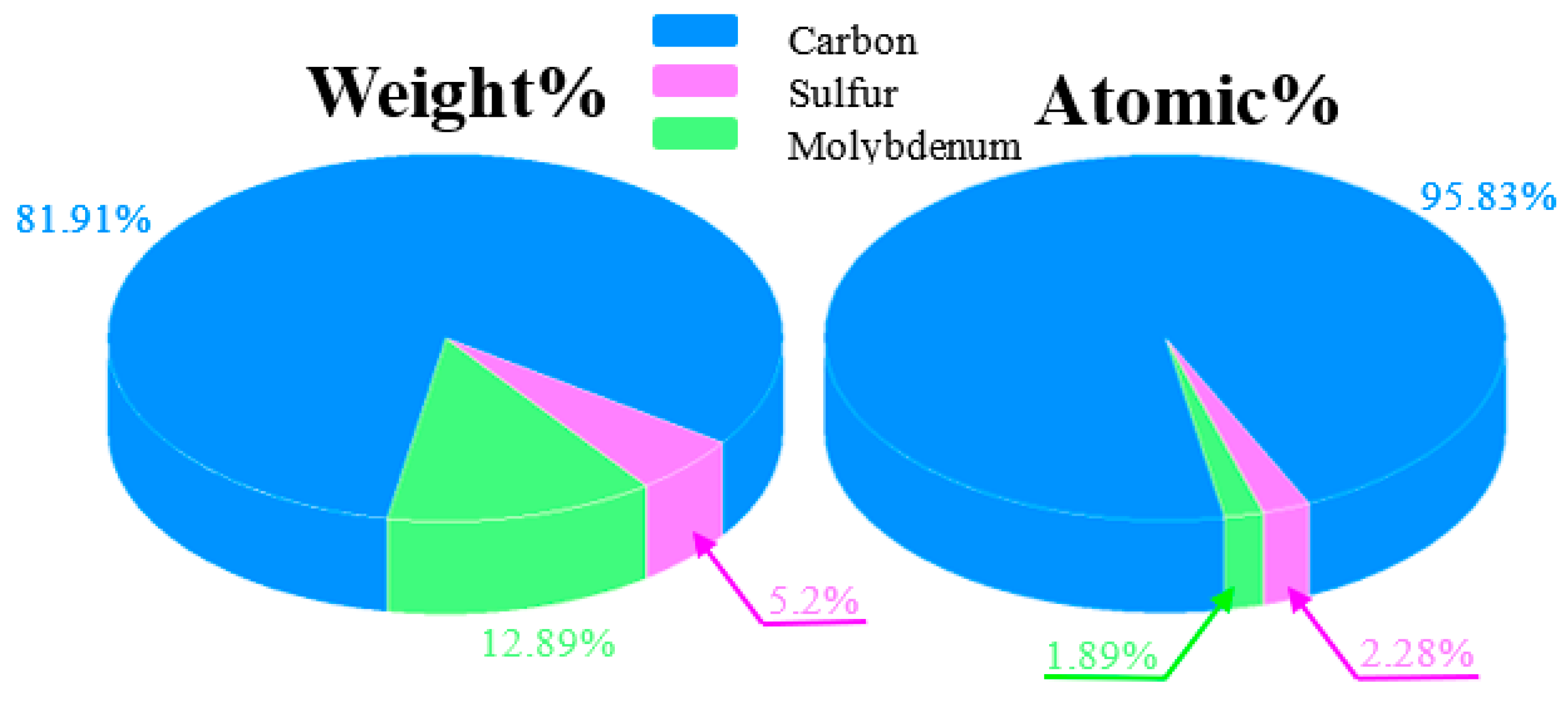

3.1. Molphological Characteristics of Carbon Nanowalls

3.2. Raman Spectra

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shi, H.; Wen, G.; Nie, Y.; Zhang, G.; Duan, H. Flexible 3D carbon cloth as a high performing electrode for energy storage and conversion. Nanoscale 2020, 12, 5261–5285. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Kwon, S.; Kim, K.; Kang, H.; Ko, J.M.; Choi, W. Preparation of Carbon nanowall and Carbon Nanotube for Anode Material of Lithium-Ion Battery. Molecules 2021, 26, 6950. [Google Scholar] [CrossRef] [PubMed]

- Mori, S.; Ueno, T.; Suzuki, M. Synthesis of carbon nanowalls by plasma-enhanced chemical vapor deposition in a CO/H2 microwave discharge system. Diam. Relat. Mater. 2011, 20, 1129–1132. [Google Scholar] [CrossRef]

- Kim, S.U.; Choi, W.S.; Lee, J.H.; Hong, B.U. Substrate temperature effect on the growth of carbon nanowalls synthesized via microwave PECVD. Mater. Res. Bull. 2014, 58, 112–116. [Google Scholar] [CrossRef]

- Zhang, L.X.; Sun, Z.; Qi, J.L.; Shi, J.M.; Hao, T.D.; Feng, J.C. Understanding the growth mechanism of vertically aligned graphene and control of its wettability. Carbon 2016, 103, 339–345. [Google Scholar] [CrossRef]

- Wu, Y.; Qiao, P.; Chong, T.; Shen, Z. Carbon Nanowalls Grown by Microwave Plasma Enhanced Chemical Vapor Deposition. Adv. Mater. 2022, 14, 64–67. [Google Scholar] [CrossRef]

- Choi, H.; Kwon, S.H.; Kang, H.; Kim, J.H.; Choi, W. Zinc-oxide-deposited Carbon Nanowalls for Acetone Sensing. Thin Solid Films 2020, 700, 137887. [Google Scholar] [CrossRef]

- Zhanga, J.; Khatria, I.; Kishia, N.; Mominuzzamanb, S.M.; Sogaa, T.; Jimbo, T. Low substrate temperature synthesis of carbon nanowalls by ultrasonic spray pyrolysis. Thin Solid Films 2011, 519, 4162–4165. [Google Scholar] [CrossRef]

- Kim, S.Y.; Lee, s.; Choi, W.; Jung, Y.H.; Lim, D.G. Growth and Resistance Properties of Carbon Nanowall According to the Variation of Reaction Gas. J. KIEEME 2014, 27, 217–220. [Google Scholar]

- Thi, M.T.; Kwon, S.; Kang, H.; Kim, J.H.; Yoon, Y.K.; Choi, W. Growth Properties of Carbon Nanowalls on Nickel and Titanium Interlayers. Molecules 2022, 27, 406. [Google Scholar]

- Wang, Q.H.; Zadeh, K.K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Kumar, S.; Mishra, A.; Tripathi, M.N.; Tripathi, A. Study of structural and electronic properties of few-layer MoS2 film. Mater. Today Proc. 2022, 57, 100–105. [Google Scholar] [CrossRef]

- Shin, J.H.; Choi, Y.S.; Park, H.J. Remote Plasma-Induced Synthesis of Self-Assembled MoS2/Carbon Nanowall Nanocomposites and Their Application as High-Performance Active Materials for Supercapacitors. Nanomaterials 2022, 12, 1338. [Google Scholar] [CrossRef] [PubMed]

- Akikubo, K.; Kurahashi, T.; Kawaguchi, S.; Tachibana, M. Thermal expansion measurements of nano-graphite using high-temperature X-ray diffraction. Carbon 2020, 169, 307–311. [Google Scholar] [CrossRef]

- Davami, K.; Shaygan, M.; Kheirabi, N.; Zhao, J.; Kovalenko, D.A.; Rummeli, M.H.; Opitz, J.; Cuniberti, G.; Lee, J.S.; Meyyappan, M. Synthesis and characterization of carbon nanowalls on different substrates by radio frequency plasma enhanced chemical vapor deposition. Carbon 2014, 72, 372–380. [Google Scholar] [CrossRef]

- Quinlan, R.A.; Cai, M.; Outlaw, R.A.; Butler, S.M.; Miller, J.R.; Mansour, A.N. Investigation of defects generated in vertically oriented graphene. Carbon 2013, 64, 92–100. [Google Scholar] [CrossRef]

- Serra, E.B.; Avetisyan, A.M.; Chaitoglou, S.; Rovira, R.A.; Alshaikh, I.; Suárez, F.P.; Bella, J.L.A.; Jawhari, T.; Pino, A.P.; Gyorgye, E. Temperature-modulated synthesis of vertically oriented atomic bilayer graphene nanowalls grown on stainless steel by inductively coupled plasma chemical vapor deposition. Appl. Surf. Sci. 2023, 610, 155530. [Google Scholar] [CrossRef]

- Tzeng, Y.; Chen, W.L.; Wu, C.; Lo, J.Y.; Li, C.Y. The synthesis of graphene nanowalls on a diamond film on a silicon substrate by direct-current plasma chemical vapor deposition. Carbon 2013, 53, 120–129. [Google Scholar] [CrossRef]

- Feng, J.; Fan, Y.; Zhao, H.; Zhang, Y. The First Principles Calculation on the Raman Spectrum and Optical Properties of the Defect Monolayer MoS2. Braz. J. Phys. 2021, 51, 493–498. [Google Scholar] [CrossRef]

- Cicily Rigia, V.J.; Jayaraj, M.K.; Saji, K.J. Envisaging radio frequency magnetron sputtering as an efficient method for large scale deposition of homogeneous two dimensional MoS2. Appl. Surf. Sci. 2020, 529, 147158. [Google Scholar] [CrossRef]

- Nong, J.; Wei, W.; Song, X.; Tang, L.; Yang, J.; Sun, T.; Yu, L.; Luo, W.; Li, C.; Wei, D. Direct growth of graphene nanowalls on silica for high-performance photo-electrochemical anode. Surf. Coat. Technol. 2022, 624, 423–432. [Google Scholar] [CrossRef]

- Cancado, L.G.; Jorio, A.; Pimenta, M.A. Measuring the absolute Raman cross section of nanographites as a function of laser energy and clystallite size. Phys. Rev. B 2007, 76, 064304. [Google Scholar] [CrossRef]

- Cancado, L.G.; Takai, K.; Endo, E.; Kim, Y.A.; Mizusaki, N.L.; Jorio, A.; Pimenta, M.A. Measuring the degree of stacking order in graphite by Raman spectroscopy. Carbon 2008, 46, 272–275. [Google Scholar] [CrossRef]

| Parameters | MoS2 |

|---|---|

| RF Power | 200 W |

| Base Pressure | 10−6 Torr |

| Working Pressure | 1.5 × 10−2 Torr |

| Temperature | Room Temperature |

| Synthesis Time | 10 min |

| Parameters | CNW |

|---|---|

| Microwave Power | 1300 W |

| Reaction Gas | H2 40 sccm and CH4 20 sccm |

| Base pressure | 10−6 Torr |

| Working Pressure | 4 × 10−2 Torr |

| Temperature | 600 °C |

| Growth Time | 5, 10 and 15 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.; Kim, K.; Kwon, S.; Kang, H.; Hong, B.; Choi, W. Innovative Variation in the Morphological Characteristics of Carbon Nanowalls Grown on a Molybdenum Disulfide Interlayer. Nanomaterials 2022, 12, 4334. https://doi.org/10.3390/nano12234334

Kim C, Kim K, Kwon S, Kang H, Hong B, Choi W. Innovative Variation in the Morphological Characteristics of Carbon Nanowalls Grown on a Molybdenum Disulfide Interlayer. Nanomaterials. 2022; 12(23):4334. https://doi.org/10.3390/nano12234334

Chicago/Turabian StyleKim, Chulsoo, Kangmin Kim, Seokhun Kwon, Hyunil Kang, Byungyou Hong, and Wonseok Choi. 2022. "Innovative Variation in the Morphological Characteristics of Carbon Nanowalls Grown on a Molybdenum Disulfide Interlayer" Nanomaterials 12, no. 23: 4334. https://doi.org/10.3390/nano12234334

APA StyleKim, C., Kim, K., Kwon, S., Kang, H., Hong, B., & Choi, W. (2022). Innovative Variation in the Morphological Characteristics of Carbon Nanowalls Grown on a Molybdenum Disulfide Interlayer. Nanomaterials, 12(23), 4334. https://doi.org/10.3390/nano12234334