Metallic On-Chip Light Concentrators Fabricated by In Situ Plasmonic Etching Technique

Abstract

1. Introduction

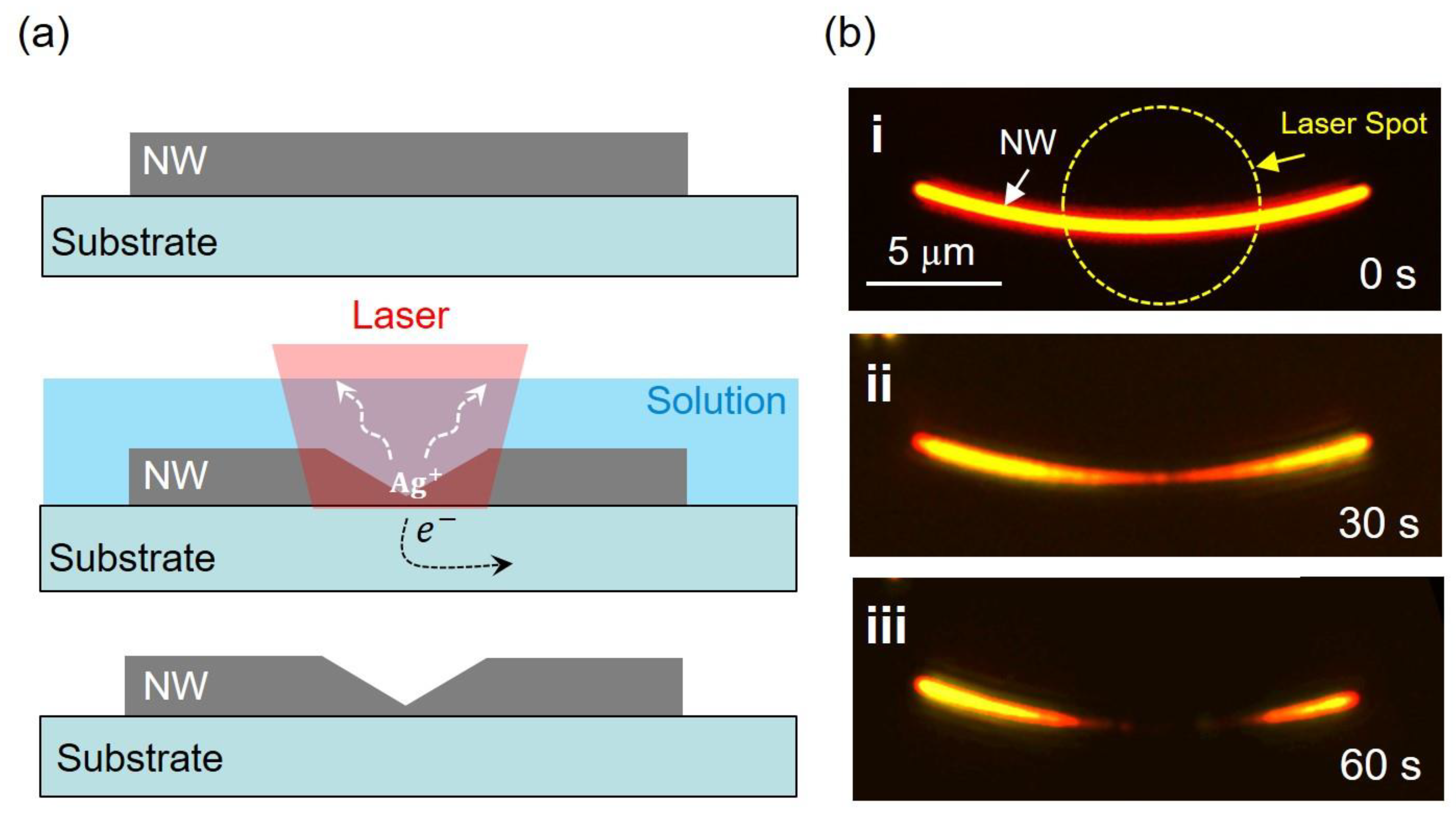

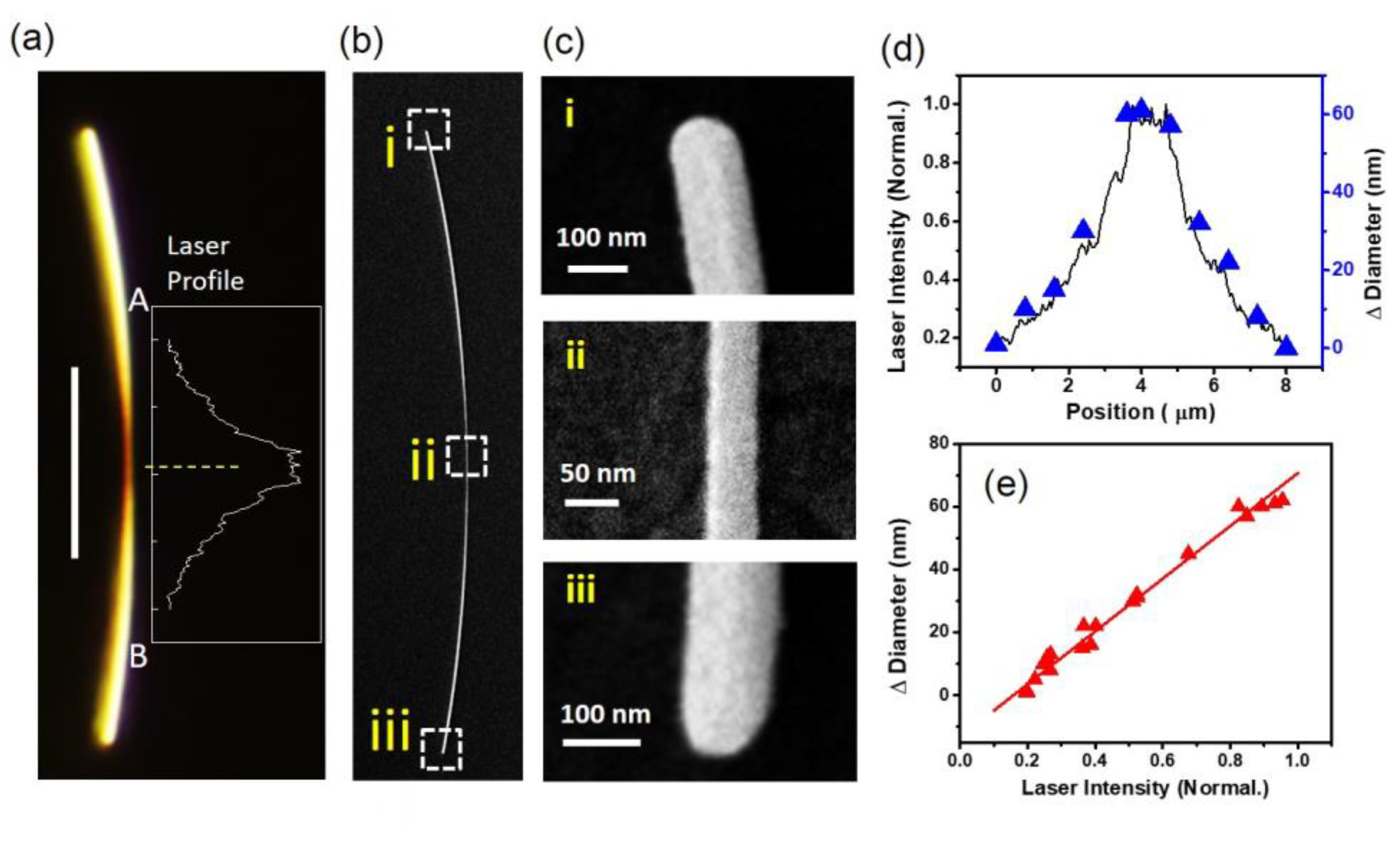

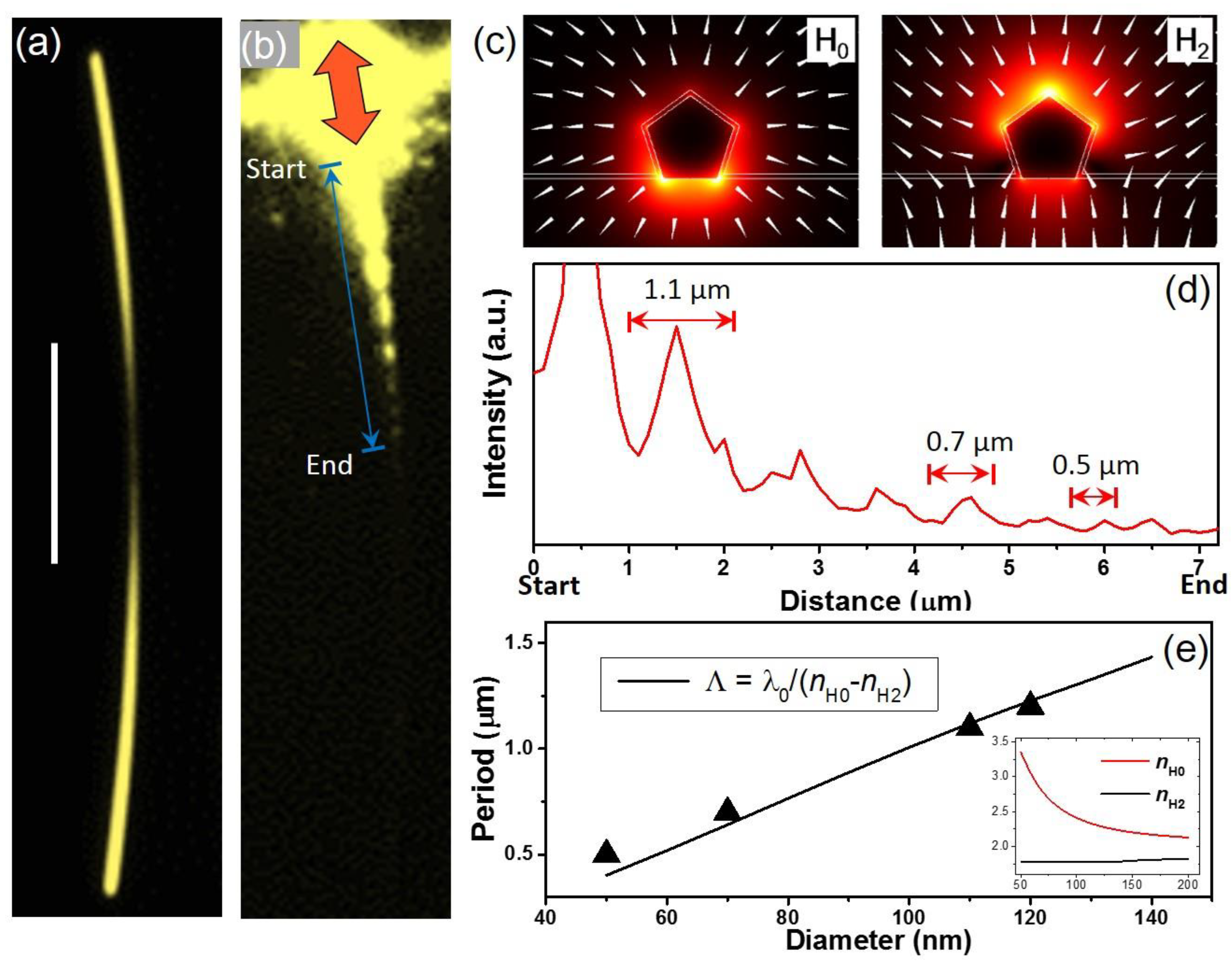

2. Experimental Setup

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang, Y.; Sun, M. Nanoplasmonic Waveguides: Towards Applications in Integrated Nanophotonic Circuits. Light Sci. Appl. 2015, 4, e294. [Google Scholar] [CrossRef]

- Guo, X.; Ma, Y.G.; Wang, Y.P.; Tong, L.M. Nanowire Plasmonic Waveguides, Circuits and Devices. Laser Photonics Rev. 2013, 7, 855–881. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Halas, N.; Nordlander, P.; Xu, H. Coherent Modulation of Propagating Plasmons in Silver-Nanowire-Based Structures. Small 2011, 7, 593. [Google Scholar] [CrossRef] [PubMed]

- Lal, S.; Hafner, J.H.; Halas, N.J.; Link, S.; Nordlander, P. Noble Metal Nanowires: From Plasmon Waveguides to Passive and Active Devices. Acc. Chem. Res. 2012, 45, 1887–1895. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Wang, Z.; Tian, X.; Käll, M.; Xu, H. Cascaded Logic Gates in Nanophotonic Plasmon Networks. Nat. Commun. 2011, 2, 387. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; De Keersmaecker, H.; Su, L.; Kenens, B.; Rocha, S.; Fron, E.; Chen, C.; Van Dorpe, P.; Mizuno, H.; Hofkens, J.; et al. Live-Cell Sers Endoscopy Using Plasmonic Nanowire Waveguides. Adv. Mater. 2014, 26, 5124. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.Z.; Fang, Y.R.; Zhang, Z.L.; Zhu, L.; Sun, M.T. Nanowire-Supported Plasmonic Waveguide for Remote Excitation of Surface-Enhanced Raman Scattering. Light Sci. Appl. 2014, 3, e199. [Google Scholar] [CrossRef]

- Liu, Y.T.; Ma, Y.G. One-Dimensional Plasmonic Sensors. Front. Phys. 2020, 8, 312. [Google Scholar] [CrossRef]

- Yang, L.K.; Li, P.; Wang, H.C.; Li, Z.P. Surface Plasmon Polariton Waveguides with Subwavelength Confinement. Chin. Phys. B 2018, 27, 094216. [Google Scholar] [CrossRef]

- Stockman, M.I. Nanofocusing of Optical Energy in Tapered Plasmonic Waveguides. Phys. Rev. Lett. 2004, 93, 137404. [Google Scholar] [CrossRef]

- Groß, P.; Esmann, M.; Becker, S.F.; Vogelsang, J.; Talebi, N.; Lienau, C. Plasmonic Nanofocusing–Grey Holes for Light. Adv. Phys. X 2016, 1, 297–330. [Google Scholar] [CrossRef]

- Gramotnev, D.K.; Bozhevolnyi, S.I. Nanofocusing of Electromagnetic Radiation. Nat. Photon. 2014, 8, 13–22. [Google Scholar] [CrossRef]

- Huang, J.S.; Callegari, V.; Geisler, P.; Brüning, C.; Kern, J.; Prangsma, J.C.; Wu, X.F.; Feichtner, T.; Ziegler, J.; Weinmann, P.; et al. Atomically Flat Single-Crystalline Gold Nanostructures for Plasmonic Nanocircuitry. Nat. Commun. 2010, 1, 150. [Google Scholar] [CrossRef] [PubMed]

- Saito, K.; Tanabe, I.; Tatsuma, T. Site-Selective Plasmonic Etching of Silver Nanocubes. J. Phys. Chem. Lett. 2016, 7, 4363–4368. [Google Scholar] [CrossRef] [PubMed]

- Matsubara, K.; Kelly, K.L.; Sakai, N.; Tatsuma, T. Effects of Adsorbed Water on Plasmon-Based Dissolution, Redeposition and Resulting Spectral Changes of Ag Nanoparticles on Single-Crystalline Tio2. Phys. Chem. Chem. Phys. 2008, 10, 2263–2269. [Google Scholar] [CrossRef] [PubMed]

- Tanabe, I.; Tatsuma, T. Plasmonic Manipulation of Color and Morphology of Single Silver Nanospheres. Nano Lett. 2012, 12, 5418–5421. [Google Scholar] [CrossRef]

- Tatsuma, T.; Nishi, H.; Ishida, T. Plasmon-Induced Charge Separation: Chemistry and Wide Applications. Chem. Sci. 2017, 8, 3325–3337. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Tatsuma, T. Mechanisms and Applications of Plasmon-Induced Charge Separation at Tio2 Films Loaded with Gold Nanoparticles. J. Am. Chem. Soc. 2005, 127, 7632–7637. [Google Scholar] [CrossRef]

- Gonzalez-Rubio, G.; Gonzalez-Izquierdo, J.; Banares, L.; Tardajos, G.; Rivera, A.; Altantzis, T.; Bals, S.; Pena-Rodriguez, O.; Guerrero-Martinez, A.; Liz-Marzan, L.M. Femtosecond Laser-Controlled Tip-to-Tip Assembly and Welding of Gold Nanorods. Nano Lett. 2015, 15, 8282–8288. [Google Scholar] [CrossRef]

- Babynina, A.; Fedoruk, M.; Kuehler, P.; Meledin, A.; Doeblinger, M.; Lohmueller, T. Bending Gold Nanorods with Light. Nano Lett. 2016, 16, 6485–6490. [Google Scholar] [CrossRef]

- Johnson, P.B.; Christy, R.W. Optical Constants of the Noble Metals. Phys. Rev. B 1972, 6, 4370–4379. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Y.N.; Zhang, L.S.; Fang, Y.; Wang, P.J. Polarization-Dependent Surface Plasmon-Driven Catalytic Reaction on a Single Nanowire Monitored by Sers. Nanoscale 2018, 10, 18720–18727. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.; Pan, D.; Zhang, S.P.; Li, Z.P.; Li, Q.; Liu, N.; Wang, W.H.; Xu, H.X. Plasmon Waveguiding in Nanowires. Chem. Rev. 2018, 118, 2882–2926. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Pan, D.; Yang, L.K.; Wei, H.; He, S.L.; Xu, H.X.; Li, Z.P. Silver Nano-Needles: Focused Optical Field Induced Solution Synthesis and Application in Remote-Excitation Nanofocusing Sers. Nanoscale 2019, 11, 2153–2161. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.G.; Xia, Y.N. Large-scale synthesis of uniform silver nanowires through a soft, self-seeding, polyol process. Adv. Mater. 2002, 14, 833–837. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cha, L.; Li, P. Metallic On-Chip Light Concentrators Fabricated by In Situ Plasmonic Etching Technique. Nanomaterials 2022, 12, 4195. https://doi.org/10.3390/nano12234195

Cha L, Li P. Metallic On-Chip Light Concentrators Fabricated by In Situ Plasmonic Etching Technique. Nanomaterials. 2022; 12(23):4195. https://doi.org/10.3390/nano12234195

Chicago/Turabian StyleCha, Lihua, and Pan Li. 2022. "Metallic On-Chip Light Concentrators Fabricated by In Situ Plasmonic Etching Technique" Nanomaterials 12, no. 23: 4195. https://doi.org/10.3390/nano12234195

APA StyleCha, L., & Li, P. (2022). Metallic On-Chip Light Concentrators Fabricated by In Situ Plasmonic Etching Technique. Nanomaterials, 12(23), 4195. https://doi.org/10.3390/nano12234195