Progress in the Study of Vortex Pinning Centers in High-Temperature Superconducting Films

Abstract

:1. Introduction

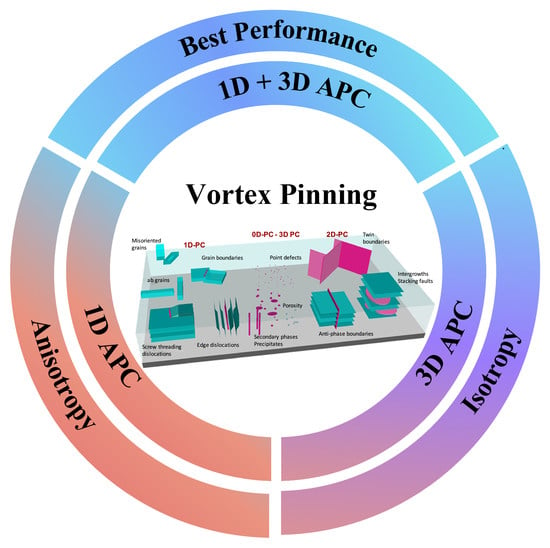

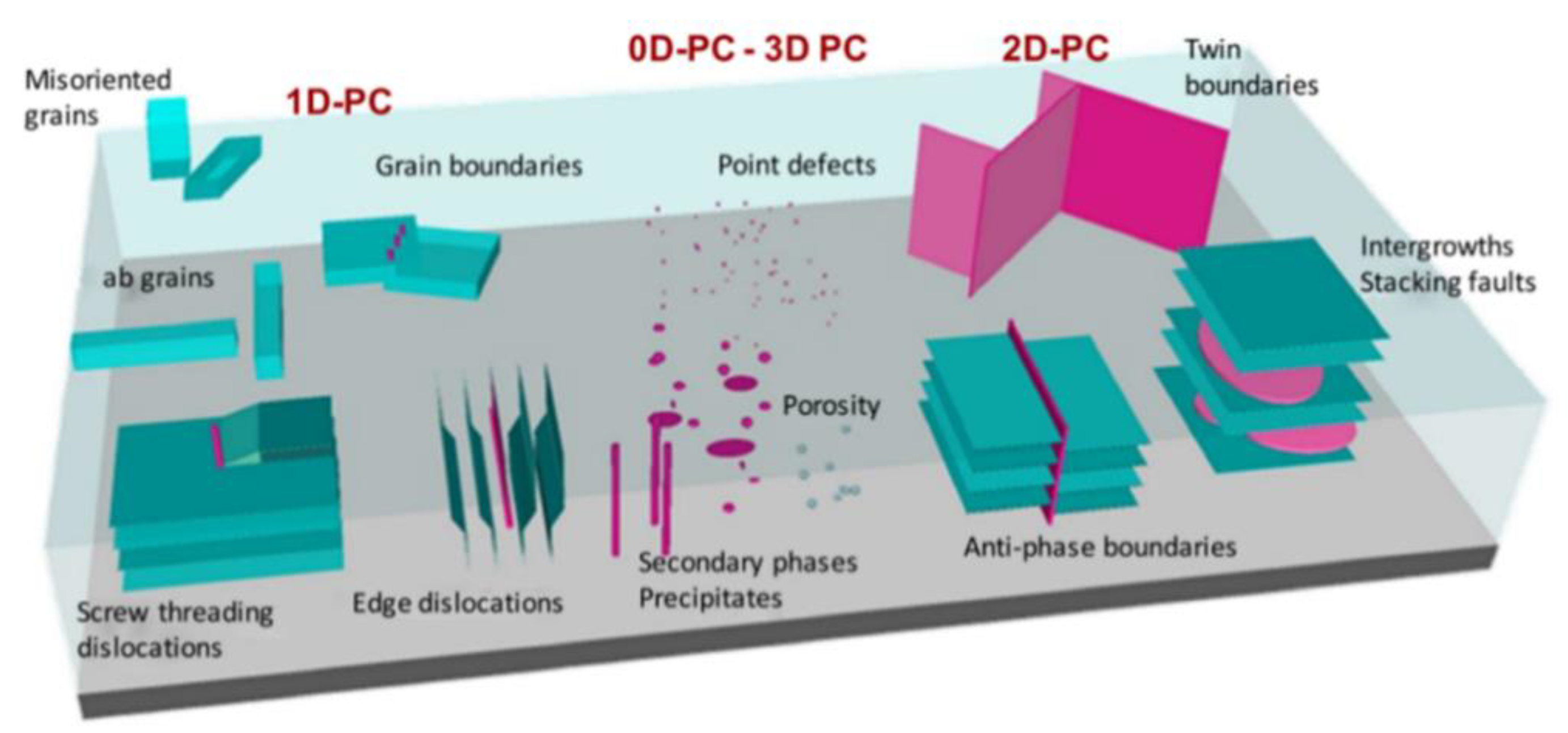

2. Natural Vortex Pinning Centers

3. Artificial Pinning Centers (APCs)

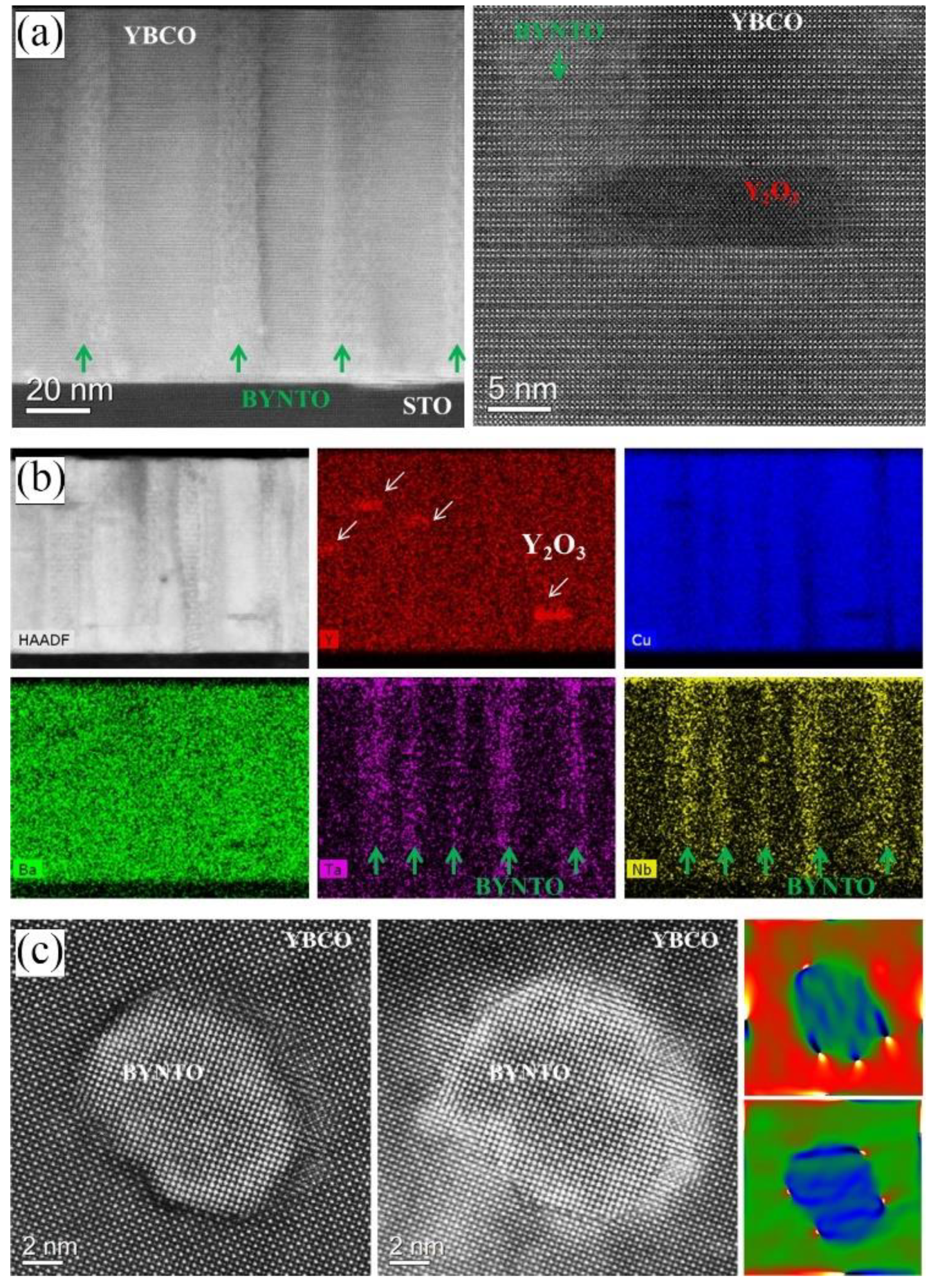

3.1. Zero-Dimensional APCs (0D APCs)

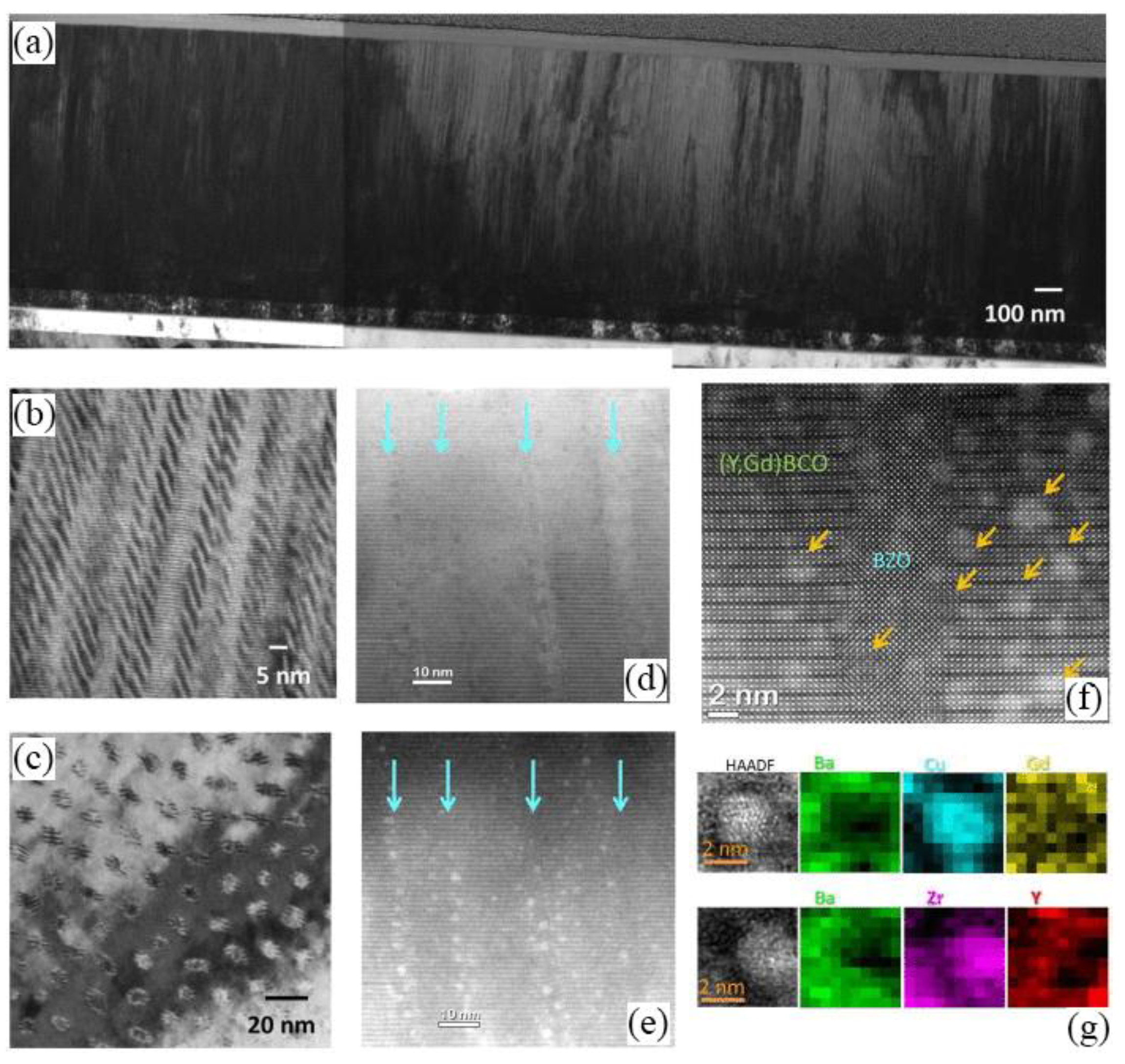

3.2. One-Dimensional APCs (1D APCs)

3.3. Two-Dimensional APCs (2D APCs)

3.4. Three-Dimensional APCs (3D APCs)

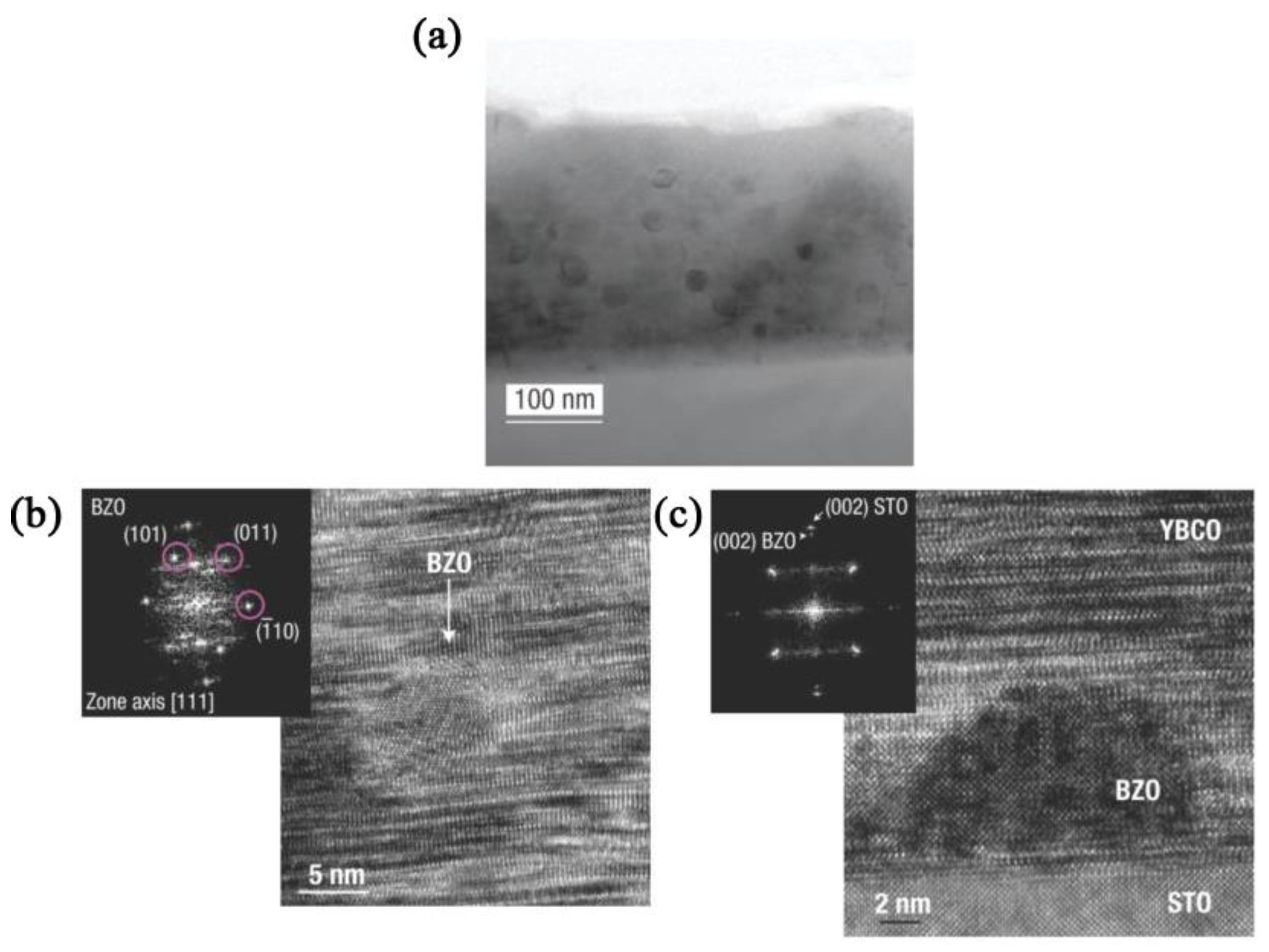

3.4.1. Introduction of 3D APCs by Vapor Deposition Methods

3.4.2. Introduction of 3D APCs by Liquid Phase Deposition Methods

3.4.3. Substrate Decoration by 3D APCs

3.5. Hybrid 1D + 3D APCs

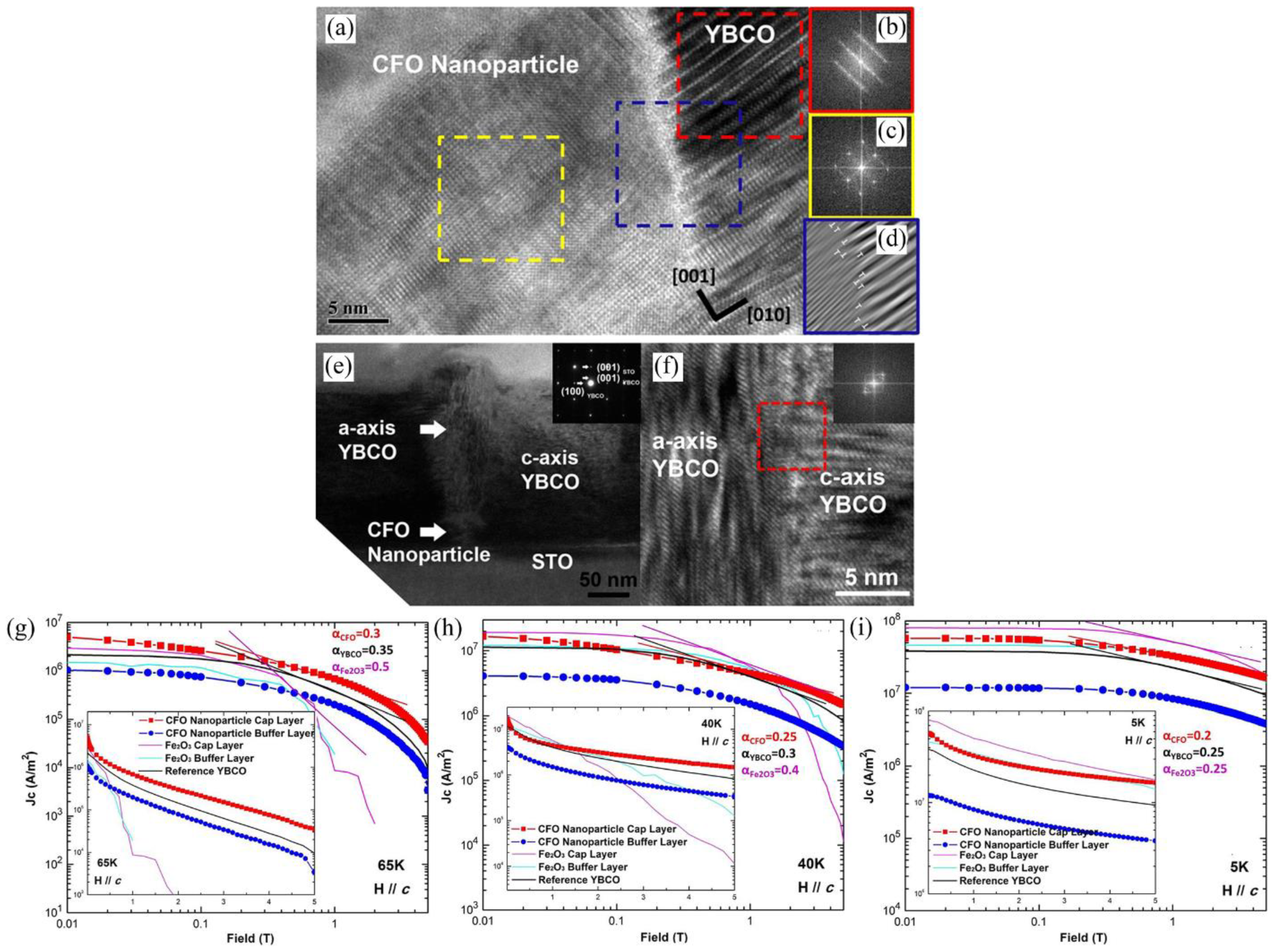

3.6. Ferromagnetic APCs

4. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Bednorz, J.G.; Müller, K.A. Possible high Tc superconductivity in the Ba-La-Cu-O system. Z. Für Phys. B Condens. Matter 1986, 64, 189–193. [Google Scholar] [CrossRef]

- Wu, M.K.; Ashburn, J.R.; Torng, C.J.; Hor, P.H.; Meng, R.L.; Gao, L.; Huang, Z.J.; Wang, Y.Q.; Chu, C.W. Superconductivity at 93 K in a new mixed-phase Y-Ba-Cu-O compound system at ambient pressure. Phys. Rev. Lett. 1987, 58, 908–910. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maeda, H.; Tanaka, Y.; Fukutomi, M.; Asano, T. A New High-Tc Oxide Superconductor without a Rare Earth Element. Jpn J. Appl. Phys. 1988, 27, L209–L210. [Google Scholar] [CrossRef] [Green Version]

- Parkin, S.S.P.; Lee, V.Y.; Engler, E.M.; Nazzal, A.I.; Huang, T.C.; Gorman, G.; Savoy, R.; Beyers, R. Bulk superconductivity at 125 K in Tl2Ca2Ba2Cu3Ox. Phys. Rev. Lett. 1988, 60, 2539–2542. [Google Scholar] [CrossRef]

- Schilling, A.; Cantoni, M.; Guo, J.D.; Ott, H.R. Superconductivity above 130 K in the Hg-Ba-Ca-Cu-O system. Nature 1993, 363, 56–58. [Google Scholar] [CrossRef]

- Yildiz, Y.; Nalbant, M. A review of cryogenic cooling in machining processes. Int. J. Mach. Tools Manuf. 2008, 48, 947–964. [Google Scholar] [CrossRef]

- Natsume, K.; Mito, T.; Yanagi, N.; Tamura, H.; Tamada, T.; Shikimachi, K.; Hirano, N.; Nagaya, S. Heat transfer performance of cryogenic oscillating heat pipes for effective cooling of superconducting magnets. Cryogenics 2011, 51, 309–314. [Google Scholar] [CrossRef]

- Paidpilli, M.; Selvamanickam, V. Development of RE-Ba-Cu-O superconductors in the U.S. for ultra-high field magnets. Supercond. Sci. Technol. 2022, 35, 043001. [Google Scholar] [CrossRef]

- Uglietti, D. A review of commercial high temperature superconducting materials for large magnets: From wires and tapes to cables and conductors. Supercond. Sci. Technol. 2019, 32, 053001. [Google Scholar] [CrossRef]

- Arpaia, R.; Golubev, D.; Baghdadi, R.; Ciancio, R.; Dražić, G.; Orgiani, P.; Montemurro, D.; Bauch, T.; Lombardi, F. Transport properties of ultrathin YBa2Cu3O7−δ nanowires: A route to single-photon detection. Phys. Rev. B 2017, 96, 064525. [Google Scholar] [CrossRef]

- Trabaldo, E.; Pfeiffer, C.; Andersson, E.; Chukharkin, M.; Arpaia, R.; Montemurro, D.; Kalaboukhov, A.; Winkler, D.; Lombardi, F.; Bauch, T. SQUID Magnetometer Based on Grooved Dayem Nanobridges and a Flux Transformer. IEEE Trans. Appl. Supercond. 2020, 30, 1600904. [Google Scholar] [CrossRef]

- Arpaia, R.; Andersson, E.; Kalaboukhov, A.; Schröder, E.; Trabaldo, E.; Ciancio, R.; Dražić, G.; Orgiani, P.; Bauch, T.; Lombardi, F. Untwinned YBa2Cu3O7−δ thin films on MgO substrates: A platform to study strain effects on the local orders in cuprates. Phys. Rev. Mater. 2019, 3, 114804. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Wu, H.; Zhao, G.; Han, L.; Zhang, J. A Review on Strain Study of Cuprate Superconductors. Nanomaterials 2022, 12, 3340. [Google Scholar] [CrossRef] [PubMed]

- Bondarenko, S.I.; Koverya, V.P.; Krevsun, A.V.; Link, S.I. High-temperature superconductors of the family (RE)Ba2Cu3O7-δ and their application. Low Temp. Phys. 2017, 43, 1125–1151. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Wang, W.; Wang, N.; Wang, M.; Qi, Y. Atomic-resolution study on the interface structure and strain state reversion of the Bi2Sr2CuO6+δ/MgO heterostructure. J. Colloid Interf. Sci. 2021, 592, 291–295. [Google Scholar] [CrossRef]

- Chikumoto, N.; Lee, S.; Nakao, K.; Tanabe, K. Development of inside-plume PLD process for the fabrication of large Ic(B) REBCO tapes. Phys. C-Supercond. Its Appl. 2009, 469, 1303–1306. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, J.M.; Jiang, G.Y.; Chen, C.S.; Wu, W.; Zhang, Z.W.; Chen, S.K.; Hong, Y.M.; Hong, Z.Y.; Jin, Z.J.; et al. Progress in fabrication of second generation high temperature superconducting tape at Shanghai Superconductor Technology. Supercond. Sci. Technol. 2019, 32, 044004. [Google Scholar] [CrossRef]

- Prusseit, W.; Nemetschek, R.; Hoffmann, C.; Sigl, G.; Lumkemann, A.; Kinder, H. ISD process development for coated conductors. Phys. C-Supercond. Its Appl. 2005, 426, 866–871. [Google Scholar] [CrossRef]

- Feys, J.; Vermeir, P.; Lommens, P.; Hopkins, S.C.; Granados, X.; Glowacki, B.A.; Baecker, M.; Reich, E.; Ricard, S.; Holzapfel, B.; et al. Ink-jet printing of YBa2Cu3O7 superconducting coatings and patterns from aqueous solutions. J. Mater. Chem. 2012, 22, 3717–3726. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.J.; Zdun, K.; Hope, L.; Xie, J.; Corcoran, S.; Qiao, Y.; Reeves, J.; Lenseth, K.; Selvamanickam, V. Texture development and superconducting properties of YBCO thick films deposited on buffered metal substrates at various deposition rates. IEEE Trans. Appl. Supercond. 2003, 13, 2758–2761. [Google Scholar] [CrossRef]

- Schindl, M.; Genoud, J.Y.; Suo, H.; Dhalle, M.; Walker, E.; Flukiger, R. Epitaxial growth of biaxially aligned Y-Ba-Cu-O superconductors by spray pyrolysis on textured Ag ribbons and single crystal substrates. IEEE Trans. Appl. Supercond. 2001, 11, 3313–3316. [Google Scholar] [CrossRef]

- Kim, H.S.; Oh, S.S.; Ha, H.S.; Youm, D.; Moon, S.H.; Kim, J.H.; Dou, S.X.; Heo, Y.U.; Wee, S.H.; Goyal, A. Ultra-High Performance, High-Temperature Superconducting Wires via Cost-effective, Scalable, Co-evaporation Process. Sci. Rep. 2014, 4, 4744. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maroni, V.A.; Li, Y.; Feldmann, D.M.; Jia, Q.X. Correlation between cation disorder and flux pinning in the YBa2Cu3O7 coated conductor. J. Appl. Phys. 2007, 102, 113909. [Google Scholar] [CrossRef]

- Haugan, T.J.; Campbell, T.A.; Pierce, N.A.; Locke, M.F.; Maartense, I.; Barnes, P.N. Microstructural and superconducting properties of (Y1-xEux)Ba2Cu3O7-δ thin films: x = 0 − 1. Supercond. Sci. Technol. 2008, 21, 025014. [Google Scholar] [CrossRef]

- Agassi, D.; Christen, D.K.; Pennycook, S.J. Flux pinning and critical currents at low-angle grain boundaries in high-temperature superconductors. Appl. Phys. Lett. 2002, 81, 2803–2805. [Google Scholar] [CrossRef]

- Pan, V.; Cherpak, Y.; Komashko, V.; Pozigun, S.; Tretiatchenko, C.; Semenov, A.; Pashitskii, E.; Pan, A.V. Supercurrent transport in YBa2Cu3O7-δ epitaxial thin films in a dc magnetic field. Phys. Rev. B 2006, 73, 054508. [Google Scholar] [CrossRef] [Green Version]

- Jooss, C.; Warthmann, R.; Kronmuller, H. Pinning mechanism of vortices at antiphase boundaries in YBa2Cu3O7-δ. Physical Review B 2000, 61, 12433–12446. [Google Scholar] [CrossRef]

- Miura, M.; Baily, S.A.; Maiorov, B.; Civale, L.; Willis, J.O.; Marken, K.; Izumi, T.; Tanabe, K.; Shiohara, Y. Vortex liquid-glass transition up to 60 T in nanoengineered coated conductors grown by metal organic deposition. Appl. Phys. Lett. 2010, 96, 072506. [Google Scholar] [CrossRef]

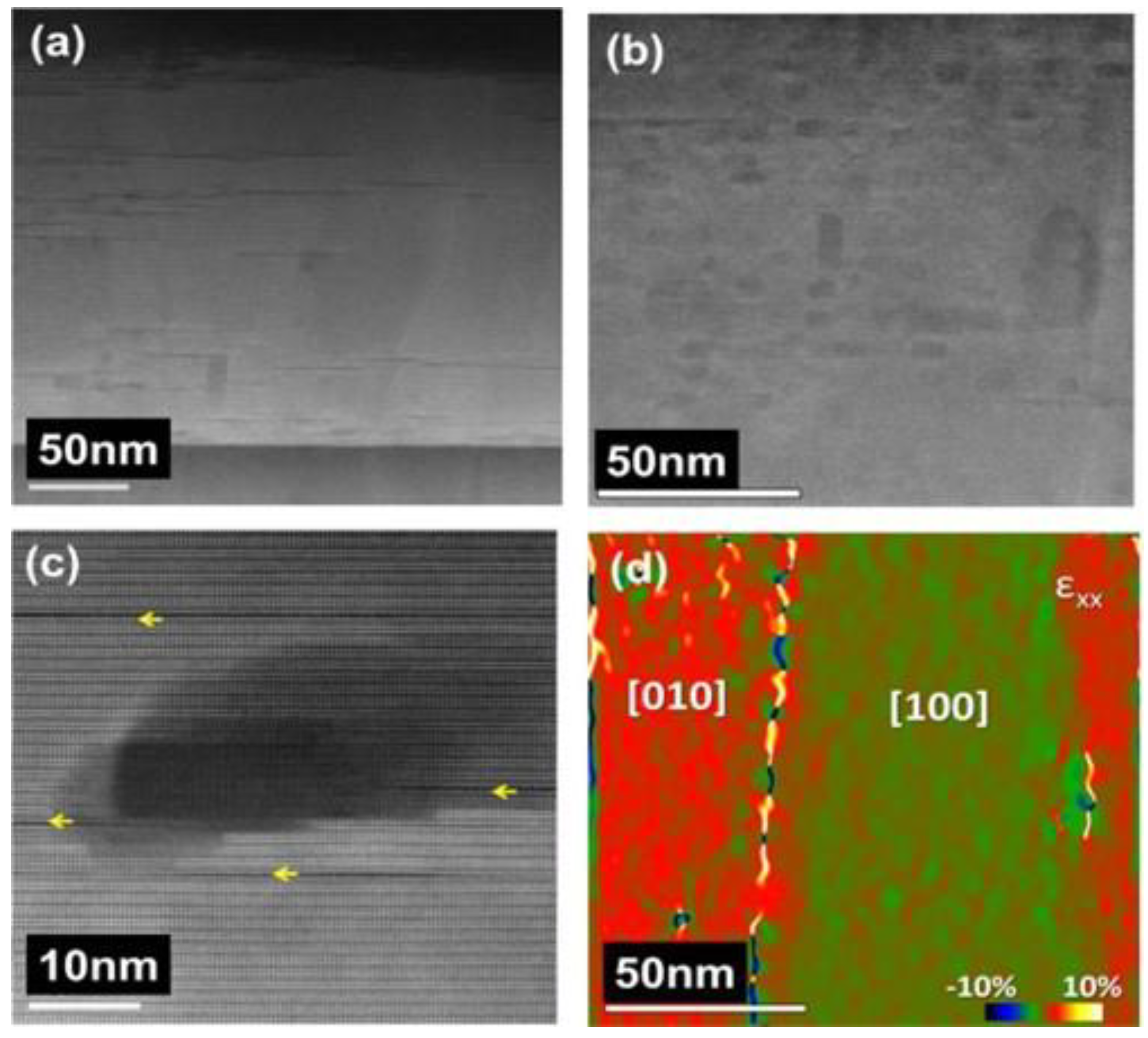

- Guzman, R.; Gazquez, J.; Rouco, V.; Palau, A.; Magen, C.; Varela, M.; Arbiol, J.; Obradors, X.; Puig, T. Strain-driven broken twin boundary coherence in YBa2Cu3O7−δ nanocomposite thin films. Appl. Phys. Lett. 2013, 102, 081906. [Google Scholar] [CrossRef] [Green Version]

- Gutiérrez, J.; Maiorov, B.; Puig, T.; Gázquez, J.; Romà, N.; Wang, H.; Sandiumenge, F.; Obradors, X. The role of stacking faults in the critical current density of MOD films through a thickness dependence study. Supercond. Sci. Technol. 2009, 22, 015022. [Google Scholar] [CrossRef]

- Dam, B.; Huijbregtse, J.M.; Klaassen, F.C.; Geest, R.C.F.v.d.; Doornbos, G.; Rector, J.H.; Testa, A.M.; Freisem, S.; Martinez, J.C.; Griessen, R. Origin of high critical currents in YBa2Cu3O7-δ superconducting thin films. Nature 1999, 399, 439–442. [Google Scholar] [CrossRef]

- Huijbregtse, J.M.; Klaassen, F.C.; Szepielow, A.; Rector, J.H.; Dam, B.; Griessen, R.; Kooi, B.J.; de Hosson, J.T.M. Vortex pinning by natural defects in thin films of YBa2Cu3O7-δ. Supercond. Sci. Technol. 2002, 15, 395–404. [Google Scholar] [CrossRef] [Green Version]

- Palau, A.; Vallès, F.; Rouco, V.; Coll, M.; Li, Z.; Pop, C.; Mundet, B.; Gàzquez, J.; Guzman, R.; Gutierrez, J.; et al. Disentangling vortex pinning landscape in chemical solution deposited superconducting YBa2Cu3O7−x films and nanocomposites. Supercond. Sci. Technol. 2018, 31, 034004. [Google Scholar] [CrossRef]

- Lin, J.G.; Huang, C.Y.; Xue, Y.Y.; Chu, C.W.; Cao, X.W.; Ho, J.C. Origin of the R-ion effect on Tc in YBa2Cu3O7. Phys. Rev. B 1995, 51, 12900–12903. [Google Scholar] [CrossRef] [PubMed]

- Jia, Q.X.; Maiorov, B.; Wang, H.; Lin, Y.; Foltyn, S.R.; Civale, L.; MacManus-Driscoll, J.L. Comparative study of REBa2Cu3O7 films for coated conductors. IEEE Trans. Appl. Supercond. 2005, 15, 2723–2726. [Google Scholar] [CrossRef]

- Wee, S.H.; Goyal, A.; Martin, P.M.; Heatherly, L. High in-field critical current densities in epitaxial NdBa2Cu3O7-d films on RABiTS by pulsed laser deposition. Supercond. Sci. Technol. 2006, 19, 865–868. [Google Scholar] [CrossRef]

- Konishi, M.; Takahashi, K.; Ibi, A.; Muroga, T.; Miyata, S.; Kobayashi, H.; Yamada, Y.; Shiohara, Y. Jc-B characteristics of RE-Ba-Cu-O (RE = Sm, Er and [Gd, Er]) films on PLD-CeO2/IBAD-GZO/metal substrates. Phys. C-Supercond. Its Appl. 2006, 445, 633–636. [Google Scholar] [CrossRef]

- Cai, C.; Holzapfel, B.; Hanisch, J.; Fernandez, L.; Schultz, L. Magnetotransport and flux pinning characteristics in RBa2Cu3O7-d (R=Gd,Eu,Nd) and (Gd1/3Eu1/3Nd1/3)Ba2Cu3O7-d high-Tc superconducting thin films on SrTiO3(100). Phys. Rev. B 2004, 69, 104531. [Google Scholar] [CrossRef]

- Devi, A.R.; Bai, V.S.; Patanjali, P.V.; Pinto, R.; Kumar, N.H.; Malik, S.K. Enhanced critical current density due to flux pinning from lattice defects in pulsed laser ablated Y1-xDyxBa2Cu3O7-δ thin films. Supercond. Sci. Technol. 2000, 13, 935–939. [Google Scholar] [CrossRef]

- Barnes, P.N.; Kell, J.W.; Harrison, B.C.; Haugan, T.J.; Varanasi, C.V.; Rane, M.; Ramos, F. Minute doping with deleterious rare earths in YBa2Cu3O7-δ films for flux pinning enhancements. Appl. Phys. Lett. 2006, 89, 012503. [Google Scholar] [CrossRef]

- Horii, S.; Ichinose, A.; Ichino, Y.; Ozaki, T.; Yoshida, Y.; Matsumoto, K.; Mukaida, M.; Shimoyama, J.; Kishio, K. Critical current properties and microstructures in impurity-doped ErBa2Cu3Oy films. Phys. C-Supercond. Its Appl. 2007, 463, 922–926. [Google Scholar] [CrossRef]

- Zhou, H.; Maiorov, B.; Wang, H.; MacManus-Driscoll, J.L.; Holesinger, T.G.; Civale, L.; Jia, Q.X.; Foltyn, S.R. Improved microstructure and enhanced low-field Jc in (Y0.67Eu0.33)Ba2Cu3O7-d films. Supercond. Sci. Technol. 2008, 21, 025001. [Google Scholar] [CrossRef]

- Shi, J.J.; Wu, J.Z. Micromechanical model for self-organized secondary phase oxide nanorod arrays in epitaxial YBa2Cu3O7-δ films. Philos. Mag. A 2012, 92, 2911–2922. [Google Scholar] [CrossRef] [Green Version]

- Miu, L.; Ivan, I.; Miu, D.; Mele, P.; Matsumoto, K.; Mikheenko, P.; Dang, V.S.; Crisan, A. High vortex depinning temperatures in YBCO films with BZO nanorods. J. Supercond. Nov. Magn. 2012, 26, 1167–1173. [Google Scholar] [CrossRef]

- Shi, J.J.; Wu, J.Z. Influence of the lattice strain decay on the diameter of self assembled secondary phase nanorod array in epitaxial films. J. Appl. Phys. 2015, 118, 164301. [Google Scholar] [CrossRef]

- Wu, J.Z.; Shi, J.J.; Baca, F.J.; Emergo, R.; Wilt, J.; Haugan, T.J. Controlling BaZrO3 nanostructure orientation in YBa2Cu3O7-δ films for a three-dimensional pinning landscape. Supercond. Sci. Technol. 2015, 28, 125009. [Google Scholar] [CrossRef]

- Shi, J.J.; Wu, J.Z. Structural transition of secondary phase oxide nanorods in epitaxial YBa2Cu3O7-δ films on vicinal substrates. Philos. Mag. A 2012, 92, 4205–4214. [Google Scholar] [CrossRef]

- Wu, J.; Shi, J. Interactive modeling-synthesis-characterization approach towards controllable in situ self-assembly of artificial pinning centers in RE-123 films. Supercond. Sci. Technol. 2017, 30, 103002. [Google Scholar] [CrossRef]

- Matsumoto, K.; Mele, P. Artificial pinning center technology to enhance vortex pinning in YBCO coated conductors. Supercond. Sci. Technol. 2010, 23, 014001. [Google Scholar] [CrossRef]

- Matsushita, T. Flux pinning in superconducting 123 materials. Supercond. Sci. Technol. 2000, 13, 730–737. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.L.; Foltyn, S.R.; Jia, Q.X.; Wang, H.; Serquis, A.; Civale, L.; Maiorov, B.; Hawley, M.E.; Maley, M.P.; Peterson, D.E. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7–x+BaZrO3. Nat. Mater. 2004, 3, 439–443. [Google Scholar] [CrossRef] [PubMed]

- Yamada, Y.; Takahashi, K.; Kobayashi, H.; Konishi, M.; Watanabe, T.; Ibi, A.; Muroga, T.; Miyata, S.; Kato, T.; Hirayama, T.; et al. Epitaxial nanostructure and defects effective for pinning in Y(RE)Ba2Cu3O7-x coated conductors. Appl. Phys. Lett. 2005, 87, 132502. [Google Scholar] [CrossRef]

- Shchukin, V.A.; Bimberg, D. Spontaneous ordering of nanostructures on crystal surfaces. Rev. Mod. Phys. 1999, 71, 1125–1171. [Google Scholar] [CrossRef]

- Goyal, A.; Kang, S.; Leonard, K.J.; Martin, P.M.; Gapud, A.A.; Varela, M.; Paranthaman, M.; Ijaduola, A.O.; Specht, E.D.; Thompson, J.R.; et al. Irradiation-free, columnar defects comprised of self-assembled nanodots and nanorods resulting in strongly enhanced flux-pinning in YBa2Cu3O7−δ films. Supercond. Sci. Technol. 2005, 18, 1533–1538. [Google Scholar] [CrossRef]

- Cantoni, C.; Gao, Y.; Wee, S.H.; Specht, E.D.; Gazquez, J.; Meng, J.; Pennycook, S.J.; Goyal, A. Strain-driven oxygen deficiency in self-assembled, nanostructured, composite oxide films. Acs. Nano 2011, 5, 4783–4789. [Google Scholar] [CrossRef] [PubMed]

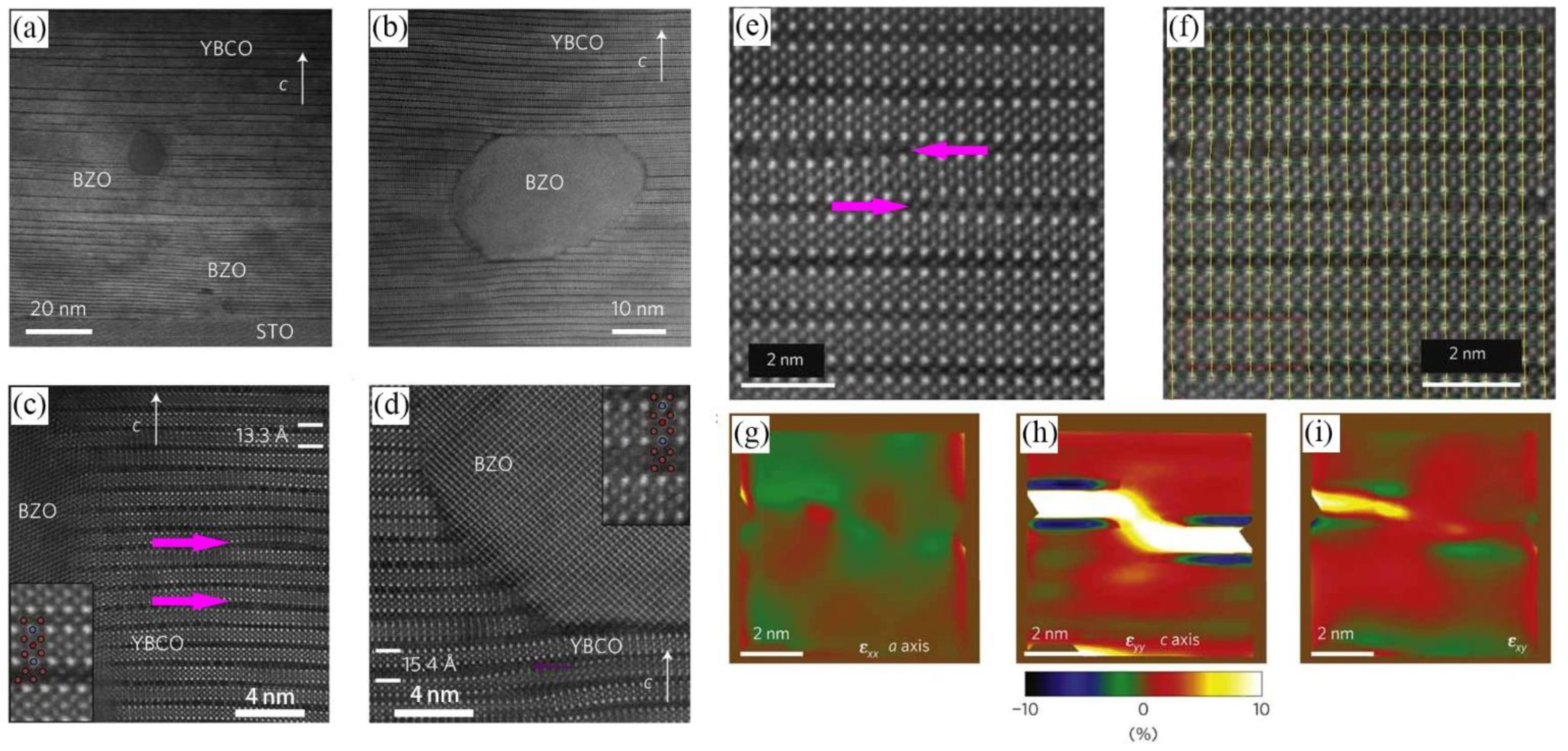

- Horide, T.; Kametani, F.; Yoshioka, S.; Kitamura, T.; Matsumoto, K. Structural evolution induced by interfacial lattice mismatch in self-organized YBa2Cu3O7−δ nanocomposite film. Acs. Nano 2017, 11, 1780–1788. [Google Scholar] [CrossRef]

- Xu, A.; Delgado, L.; Khatri, N.; Liu, Y.; Selvamanickam, V.; Abraimov, D.; Jaroszynski, J.; Kametani, F.; Larbalestier, D.C. Strongly enhanced vortex pinning from 4 to 77 K in magnetic fields up to 31 T in 15 mol.% Zr-added (Gd, Y)-Ba-Cu-O superconducting tapes. Apl. Mater. 2014, 2, 046111. [Google Scholar] [CrossRef] [Green Version]

- Selvamanickam, V.; Gharahcheshmeh, M.H.; Xu, A.; Zhang, Y.; Galstyan, E. Critical current density above 15MA cm-2 at 30K, 3T in 2.2 μm thick heavily-doped (Gd,Y)Ba2Cu3Ox superconductor tapes. Supercond. Sci. Technol. 2015, 28, 072002. [Google Scholar] [CrossRef]

- Selvamanickam, V.; Gharahcheshmeh, M.H.; Xu, A.; Galstyan, E.; Delgado, L.; Cantoni, C. High critical currents in heavily doped (Gd,Y)Ba2Cu3Ox superconductor tapes. Appl. Phys. Lett. 2015, 106, 032601. [Google Scholar] [CrossRef]

- Xu, A.; Delgado, L.; Gharahcheshmeh, M.H.; Khatri, N.; Liu, Y.; Selvamanickam, V. Strong correlation between Jc(T, H parallel to c) and Jc 77 K, 3 T parallel to c in Zr-added (Gd, Y)BaCuO coated conductors at temperatures from 77 down to 20 K and fields up to 9 T. Supercond. Sci. Technol. 2015, 28, 082001. [Google Scholar] [CrossRef]

- Selvamanickam, V.; Gharahcheshmeh, M.H.; Xu, A.; Zhang, Y.; Galstyan, E. Requirements to achieve high in-field critical current density at 30 K in heavily-doped (Gd,Y)Ba2Cu3Ox superconductor tapes. Supercond. Sci. Technol. 2015, 28, 104003. [Google Scholar] [CrossRef]

- Xu, A.; Zhang, Y.; Gharahcheshmeh, M.H.; Yao, Y.; Galstyan, E.; Abraimov, D.; Kametani, F.; Polyanskii, A.; Jaroszynski, J.; Griffin, V.; et al. Je(4.2 K, 31.2 T) beyond 1 kA/mm2 of a similar to 3.2 μm thick, 20 mol% Zr-added MOCVD REBCO coated conductor. Sci. Rep. 2017, 7, 6853. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Horide, T.; Nagao, S.; Lzutsu, R.; Ishimaru, M.; Kita, R.; Matsumoto, K. Geometric and compositional factors on critical current density in YBa2Cu3O7-d films containing nanorods. Supercond. Sci. Technol. 2018, 31, 065012. [Google Scholar] [CrossRef]

- Horide, T.; Kawamura, T.; Matsumoto, K.; Ichinose, A.; Yoshizumi, M.; Izumi, T.; Shiohara, Y.J. Improvement by double artificial pinning centers of BaSnO3 nanorods and Y2O3 nanoparticles in YBa2Cu3O7 coated conductors. Supercond. Sci. Technol. 2013, 26, 075019. [Google Scholar] [CrossRef]

- Jha, A.K.; Matsumoto, K.; Horide, T.; Saini, S.; Mele, P.; Ichinose, A.; Yoshida, Y.; Awaji, S. Tailoring the vortex pinning strength of YBCO thin films by systematic incorporation of hybrid artificial pinning centers. Supercond. Sci. Technol. 2015, 28, 114004. [Google Scholar] [CrossRef] [Green Version]

- Matsumoto, K.; Horide, T.; Jha, A.K.; Mele, P.; Yoshida, Y.; Awaji, S. Irreversibility fields and critical current densities in strongly pinned YBa2Cu3O7-x films with artificial pinning centers. IEEE Trans. Appl. Supercond. 2015, 25, 8001106. [Google Scholar] [CrossRef]

- Mele, P.; Matsumoto, K.; Horide, T.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S.; Kita, R. Ultra-high flux pinning properties of BaMO3-doped YBa2Cu3O7-x thin films (M = Zr, Sn). Supercond. Sci. Technol. 2008, 21, 032002. [Google Scholar] [CrossRef]

- Mele, P.; Matsumoto, K.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S.; Kita, R. Systematic study of BaSnO3 doped YBa2Cu3O7-x films. Phys. C-Supercond. Its Appl. 2009, 469, 1380–1383. [Google Scholar] [CrossRef]

- Varanasi, C.V.; Burke, J.; Wang, H.; Lee, J.H.; Barnes, P.N. Thick YBa2Cu3O7-x+BaSnO3 films with enhanced critical current density at high magnetic fields. Appl. Phys. Lett. 2008, 93, 092501. [Google Scholar] [CrossRef]

- Varanasi, C.; Burke, J.; Brunke, L.; Wang, H.; Sumption, M.; Barnes, P. Enhancement and angular dependence of transport critical current density in pulsed laser deposited YBa2Cu3O7−x+BaSnO3 films in applied magnetic fields. J. Appl. Phys. 2007, 102, 063909. [Google Scholar] [CrossRef]

- Mele, P.; Matsumoto, K.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S.; Kita, R. Systematic study of the BaSnO3 insertion effect on the properties of YBa2Cu3O7-x films prepared by pulsed laser ablation. Supercond. Sci. Technol. 2008, 21, 125017. [Google Scholar] [CrossRef]

- Jha, A.K.; Khare, N.; Pinto, R. Enhanced flux pinning in pulsed laser deposited YBa2Cu3O7-d:BaTiO3 nanocomposite thin films. Solid State Commun. 2011, 151, 1447–1451. [Google Scholar] [CrossRef]

- Gautam, B.; Sebastian, M.A.; Chen, S.; Misra, S.; Huang, J.; Javier Baca, F.; Emergo, R.; Haugan, T.; Xing, Z.; Wang, H.; et al. Probing the effect of interface on vortex pinning efficiency of one-dimensional BaZrO3 and BaHfO3 artificial pinning centers in YBa2Cu3O7-x thin films. Appl. Phys. Lett. 2018, 113, 212602. [Google Scholar] [CrossRef]

- Miura, S.; Tsuchiya, Y.; Yoshida, Y.; Ichino, Y.; Awaji, S.; Ichinose, A.; Matsumoto, K.; Ibi, A.; Izumi, T.; Iwakuma, M. Improved Flux Pinning for High-Field Applications in BaHfO3-Doped SmBa2Cu3Oy-Coated Conductors With High Density of Random Pinning Centers Induced by BaHfO3 Nanorods. IEEE Trans. Appl. Supercond. 2018, 28, 1–6. [Google Scholar] [CrossRef]

- Miura, S.; Yoshida, Y.; Ichino, Y.; Tsuruta, A.; Matsumoto, K.; Ichinose, A.; Awaji, S. Vortex pinning at low temperature under high magnetic field in SmBa2Cu3Oy superconducting films with high number density and small size of BaHfO3 nano-rods. Supercond. Sci. Technol. 2015, 28, 114006. [Google Scholar] [CrossRef]

- Sieger, M.; Pahlke, P.; Hanisch, J.; Sparing, M.; Bianchetti, M.; MacManus-Driscoll, J.; Lao, M.; Eisterer, M.; Meledin, A.; Van Tendeloo, G.; et al. Ba2Y(Nb/Ta)O6-Doped YBCO Films on Biaxially Textured Ni-5at.% W Substrates. IEEE Trans. Appl. Supercond. 2016, 26, 7500305. [Google Scholar] [CrossRef]

- Feldmann, D.M.; Holesinger, T.G.; Maiorov, B.; Foltyn, S.R.; Coulter, J.Y.; Apodaca, I. Improved flux pinning in YBa2Cu3O7 with nanorods of the double perovskite Ba2YNbO6. Supercond. Sci. Technol. 2010, 23, 095004. [Google Scholar] [CrossRef]

- Opherden, L.; Sieger, M.; Pahlke, P.; Huhne, R.; Schultz, L.; Meledin, A.; Van Tendeloo, G.; Nast, R.; Holzapfel, B.; Bianchetti, M.; et al. Large pinning forces and matching effects in YBa2Cu3O7-δ thin films with Ba2Y(Nb/Ta)O6 nano-precipitates. Sci. Rep. 2016, 6, 21188. [Google Scholar] [CrossRef] [Green Version]

- Wee, S.H.; Goyal, A.; Zuev, Y.L.; Cantoni, C.; Selvamanickam, V.; Specht, E.D. Formation of Self-Assembled, Double-Perovskite, Ba2YNbO6 Nanocolumns and Their Contribution to Flux-Pinning and Jc in Nb-Doped YBa2Cu3O7-d Films. Appl. Phys. Express. 2010, 3, 023101. [Google Scholar] [CrossRef]

- Wee, S.H.; Zuev, Y.L.; Cantoni, C.; Goyal, A. Engineering nanocolumnar defect configurations for optimized vortex pinning in high temperature superconducting nanocomposite wires. Sci. Rep. 2013, 3, 2749. [Google Scholar] [CrossRef] [Green Version]

- Ercolano, G.; Harrington, S.A.; Wang, H.; Tsai, C.F.; MacManus-Driscoll, J.L. Enhanced flux pinning in YBa2Cu3O7-d thin films using Nb-based double perovskite additions. Supercond. Sci. Technol. 2010, 23, 022003. [Google Scholar] [CrossRef]

- Jha, A.K.; Matsumoto, K.; Horide, T.; Saini, S.; Mele, P.; Yoshida, Y.; Awaji, S. Tuning the microstructure and vortex pinning properties of YBCO-based superconducting nanocomposite films by controlling the target rotation speed. Supercond. Sci. Technol. 2014, 27, 025009. [Google Scholar] [CrossRef]

- Harrington, S.A.; Durrell, J.H.; Maiorov, B.; Wang, H.; Wimbush, S.C.; Kursumovic, A.; Lee, J.H.; MacManus-Driscoll, J.L. Self-assembled, rare earth tantalate pyrochlore nanoparticles for superior flux pinning in YBa2Cu3O7-δ films. Supercond. Sci. Technol. 2009, 22, 022001. [Google Scholar] [CrossRef]

- Wee, S.H.; Goyal, A.; Specht, E.D.; Cantoni, C.; Zuev, Y.L.; Selvamanickam, V.; Cook, S. Enhanced flux pinning and critical current density via incorporation of self-assembled rare-earth barium tantalate nanocolumns within YBa2Cu3O7-δ films. Phys. Rev. B 2010, 81, 140503. [Google Scholar] [CrossRef]

- Tobita, H.; Notoh, K.; Higashikawa, K.; Inoue, M.; Kiss, T.; Kato, T.; Hirayama, T.; Yoshizumi, M.; Izumi, T.; Shiohara, Y. Fabrication of BaHfO3 doped Gd1Ba2Cu3O7-δ coated conductors with the high Ic of 85 A/cm-w under 3 T at liquid nitrogen temperature (77 K). Supercond. Sci. Technol. 2012, 25, 062002. [Google Scholar] [CrossRef]

- Tsuruta, A.; Watanabe, S.; Ichino, Y.; Yoshida, Y. Enhancement of critical current density in the force-free sate of BaHfO3-doped multilayered SmBa2Cu3Oy film. Jpn J. Appl. Phys 2014, 53, 078003. [Google Scholar] [CrossRef]

- Tsuruta, A.; Yoshida, Y.; Ichino, Y.; Ichinose, A.; Matsumoto, K.; Awaji, S. The influence of the geometric characteristics of nanorods on the flux pinning in high-performance BaMO3-doped SmBa2Cu3Oy films (M = Hf, Sn). Supercond. Sci. Technol. 2014, 27, 065001. [Google Scholar] [CrossRef]

- Miura, S.; Yoshida, Y.; Ichino, Y.; Matsumoto, K.; Ichinose, A.; Awaji, S. Characteristics of high-performance BaHfO3-doped SmBa2Cu3Oy superconducting films fabricated with a seed layer and low-temperature growth. Supercond. Sci. Technol. 2015, 28, 065013. [Google Scholar] [CrossRef]

- Miura, S.; Yoshida, Y.; Ichino, Y.; Tsuruta, A.; Matsumoto, K.; Ichinose, A.; Awaji, S. Flux pinning properties and microstructures of a SmBa2Cu3Oy film with high number density of BaHfO3 nanorods deposited by using low-temperature growth technique. Jpn J. Appl. Phys. 2014, 53, 090304. [Google Scholar] [CrossRef]

- Awaji, S.; Yoshida, Y.; Suzuki, T.; Watanabe, K.; Hikawa, K.; Ichino, Y.; Izumi, T. High-performance irreversibility field and flux pinning force density in BaHfO3-doped GdBa2Cu3Oy tape prepared by pulsed laser deposition. Appl. Phys. Express. 2015, 8, 023101. [Google Scholar] [CrossRef]

- Engel, S.; Thersleff, T.; Hühne, R.; Schultz, L.; Holzapfel, B.; Engel, S.; Thersleff, T.; Schultz, L.; Holzapfel, B.; Schultz, L. Enhanced flux pinning in YBa2Cu3O7 layers by the formation of nanosized BaHfO3 precipitates using the chemical deposition method. Appl. Phys. Lett. 2007, 90, 3. [Google Scholar] [CrossRef]

- Cayado, P.; Erbe, M.; Kauffmann-Weiss, S.; Buhler, C.; Jung, A.; Hanisch, J.; Holzapfel, B. Large critical current densities and pinning forces in CSD-grown superconducting GdBa2Cu3O7-δ-BaHfO3 nanocomposite films. Supercond. Sci. Technol. 2017, 30, 094007. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Llordés, A.; Gázquez, J.; Gibert, M.; Romà, N.; Ricart, S.; Pomar, A.; Sandiumenge, F.; Mestres, N.; Puig, T.; et al. Strong isotropic flux pinning in solution-derived YBa2Cu3O7-x nanocomposite superconductor films. Nat. Mater. 2007, 6, 367–373. [Google Scholar] [CrossRef]

- Li, Z.; Coll, M.; Mundet, B.; Chamorro, N.; Valles, F.; Palau, A.; Gazquez, J.; Ricart, S.; Puig, T.; Obradors, X. Control of nanostructure and pinning properties in solution deposited YBa2Cu3O7-x nanocomposites with preformed perovskite nanoparticles. Sci. Rep. 2019, 9, 5828. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Puig, T.; Gutiérrez, J.; Pomar, A.; Llordés, A.; Gázquez, J.; Ricart, S.; Sandiumenge, F.; Obradors, X. Vortex pinning in chemical solution nanostructured YBCO films. Supercond. Sci. Technol. 2008, 21, 034008. [Google Scholar] [CrossRef]

- Palau, A.; Bartolomé, E.; Llordés, A.; Puig, T.; Obradors, X. Isotropic and anisotropic pinning in TFA-grown YBa2Cu3O7−x films with BaZrO3 nanoparticles. Supercond. Sci. Technol. 2011, 24, 125010. [Google Scholar] [CrossRef]

- Crisan, A.; Dang, V.S.; Mikheenko, P. Nano-engineered pinning centres in YBCO superconducting films. Phys. C Supercond. Its Appl. 2017, 533, 118–132. [Google Scholar] [CrossRef]

- Sarkar, A.; Mikheenko, P.; Dang, V.S.; Awang Kechik, M.M.; Abell, J.S.; Crisan, A. Improved Critical Current Densities in YBa2Cu3O7−δ Multilayer Films Interspaced with Palladium Nano-dots. J. Supercond. Nov. Magn. 2010, 24, 173–177. [Google Scholar] [CrossRef]

- Gapud, A.A.; Kumar, D.; Viswanathan, S.K.; Cantoni, C.; Varela, M.; Abiade, J.; Pennycook, S.J.; Christen, D.K. Enhancement of flux pinning in YBa2Cu3O7-d thin films embedded with epitaxially grown Y2O3 nanostructures using a multi-layering process. Supercond. Sci. Technol. 2005, 18, 1502–1505. [Google Scholar] [CrossRef]

- Cai, C.; Hanisch, J.; Huhne, R.; Stehr, V.; Mickel, C.; Gemming, T.; Holzapfel, B. Structural and magnetotransport properties of YBa2Cu3O7-δ/Y2O3 quasimultilayers. J. Appl. Phys. 2005, 98, 123906. [Google Scholar] [CrossRef]

- Cai, C.B.; Zhang, J.C.; Cao, S.X.; Hänisch, J.; Hühne, R.; Holzapfel, B. Growth-controlled precipitates for flux pinning enhancement in YBa2Cu3O7−δ films and coated conductors. Phys. C Supercond. 2007, 460–462, 1355–1356. [Google Scholar] [CrossRef]

- Kiessling, A.; Hanisch, J.; Thersleff, T.; Reich, E.; Weigand, M.; Huhne, R.; Sparing, M.; Holzapfel, B.; Durrell, J.H.; Schultz, L. Nanocolumns in YBa2Cu3O7-δ/BaZrO3 quasi-multilayers: Formation and influence on superconducting properties. Supercond. Sci. Technol. 2011, 24, 055018. [Google Scholar] [CrossRef]

- Huhtinen, H.; Schlesier, K.; Paturi, P. Growth andc-axis flux pinning of nanostructured YBCO/BZO multilayers. Supercond. Sci. Technol. 2009, 22, 075019. [Google Scholar] [CrossRef]

- Cai, C.; Liu, J.; Liu, Z.; Ying, L.; Gao, B.; Peng, L.; Chen, C. Heteroperovskite phase formation and magnetotransport properties of YBa2Cu3O7−x/SrRuO3 quasimultilayers. J. Appl. Phys. 2008, 104, 023913. [Google Scholar] [CrossRef]

- Petrov, P.K.; Ivanov, Z.G.; Gevorgyan, S.S. X-ray study of SrTiO3 thin films in multilayer structures. Mater. Sci. Eng. A 2000, 288, 231–234. [Google Scholar] [CrossRef]

- Mukaida, M.; Miyazawa, S. In-plane alignment ofa-axis oriented YBa2Cu3Ox thin films. Appl. Phys. Lett. 1993, 63, 999–1001. [Google Scholar] [CrossRef]

- Peng, L.; Cai, C.; Chen, C.; Liu, Z.; Hühne, R.; Holzapfel, B. Angular-dependent vortex pinning mechanism in YBa2Cu3O7−δ/YSZ quasi-multilayer. J. Appl. Phys. 2008, 104, 033920. [Google Scholar] [CrossRef]

- Haugan, T.; Barnes, P.N.; Maartense, I.; Cobb, C.B.; Lee, E.J.; Sumption, M. Island growth of Y2BaCuO5 nanoparticles in (211∼1.5 nm/123∼10 nm)×N composite multilayer structures to enhance flux pinning of YBa2Cu3O7−δ films. J. Mater. Res. 2011, 18, 2618–2623. [Google Scholar] [CrossRef] [Green Version]

- Crisan, A.; Dang, V.S.; Mikheenko, P.; Tse, Y.Y.; Sarkar, A.; Bowen, J.; Abell, J.S. Pinning potential in thick PrBa2Cu3Ox/YBa2Cu3O7−δ quasi-multilayers. Phys. C Supercond. 2010, 470, 55–60. [Google Scholar] [CrossRef]

- Hanisch, J.; Cai, C.; Huhne, R.; Schultz, L.; Holzapfel, B. Formation of nanosized BaIrO3 precipitates and their contribution to flux pinning in Ir-doped YBa2Cu3O7-δ quasi-multilayers. Appl. Phys. Lett. 2005, 86, 122508. [Google Scholar] [CrossRef]

- Hanisch, J.; Cai, C.; Stehr, V.; Huhne, R.; Lyubina, J.; Nenkov, K.; Fuchs, G.; Schultz, L.; Holzapfel, B. Formation and pinning properties of growth-controlled nanoscale precipitates in YBa2Cu3O7−δ/transition metal quasi-multilayers. Supercond. Sci. Technol. 2006, 19, 534–540. [Google Scholar] [CrossRef]

- Develos-Bagarinao, K.; Yamasaki, H.; Ohki, K.; Nakagawa, Y. Multilayered structures of (RE = rare earth)Ba2Cu3Ox films: An approach for the growth of superior quality large-area superconducting films on sapphire substrates. Supercond. Sci. Technol. 2007, 20, L25–L29. [Google Scholar] [CrossRef]

- Develos-Bagarinao, K.; Yamasaki, H.; Ohki, K. Flux pinning properties of YBCO/DyBCO multilayers. J. Appl. Phys. 2008, 104. [Google Scholar] [CrossRef]

- Kang, S.; Leonard, K.J.; Martin, P.M.; Li, J.; Goyal, A. Strong enhancement of flux pinning in YBa2Cu3O7−δ multilayers with columnar defects comprised of self-assembled BaZrO3 nanodots. Supercond. Sci. Technol. 2007, 20, 11–15. [Google Scholar] [CrossRef]

- Haugan, T.; Barnes, P.N.; Wheeler, R.; Meisenkothen, F.; Sumption, M. Addition of nanoparticle dispersions to enhance flux pinning of the YBa2Cu3O7-x superconductor. Nature 2004, 430, 867–870. [Google Scholar] [CrossRef] [PubMed]

- Barnes, P.N.; Haugan, T.J.; Sumption, M.D.; Harrison, B.C. Pinning enhancement of YBa2Cu3O7-δ thin films with Y2BaCuO5 nanoparticulates. IEEE Trans. Appl. Supercond. 2005, 15, 3766–3769. [Google Scholar] [CrossRef]

- Jha, A.K.; Matsumoto, K.; Horide, T.; Saini, S.; Mele, P.; Ichinose, A.; Yoshida, Y.; Awaji, S. Isotropic enhancement in the critical current density of YBCO thin films incorporating nanoscale Y2BaCuO5 inclusions. J. Appl. Phys. 2017, 122, 093905. [Google Scholar] [CrossRef]

- Mele, P.; Matsumoto, K.; Horide, T.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S. Insertion of nanoparticulate artificial pinning centres in YBa2Cu3O7-x films by laser ablation of a Y2O3 surface modified target. Supercond. Sci. Technol. 2007, 20, 616–620. [Google Scholar] [CrossRef]

- Kim, S.I.; Kametani, F.; Chen, Z.; Gurevich, A.; Larbalestier, D.C.; Haugan, T.; Barnes, P. On the through-thickness critical current density of an YBa2Cu3O7−x film containing a high density of insulating, vortex-pinning nanoprecipitates. Appl. Phys. Lett. 2007, 90, 252502. [Google Scholar] [CrossRef] [Green Version]

- Campbell, T.A.; Haugan, T.J.; Maartense, I.; Murphy, J.; Brunke, L.; Barnes, P.N. Flux pinning effects of Y2O3 nanoparticulate dispersions in multilayered YBCO thin films. Phys. C Supercond. 2005, 423, 1–8. [Google Scholar] [CrossRef]

- Solovyov, V.F.; Wiesmann, H.J.; Wu, L.; Li, Q.; Cooley, L.D.; Suenaga, M.; Maiorov, B.; Civale, L. High critical currents by isotropic magnetic-flux-pinning centres in a 3 μm-thick YBa2Cu3O7 superconducting coated conductor. Supercond. Sci. Technol. 2007, 20, L20–L23. [Google Scholar] [CrossRef]

- Yamasaki, H.; Ohki, K.; Yamada, H.; Nakagawa, Y.; Mawatari, Y. Strong flux pinning in YBa2Cu3O7−δ thin films due to nanometer-sized precipitates. Supercond. Sci. Technol. 2008, 21, 125011. [Google Scholar] [CrossRef]

- Viswanathan, S.K.; Gapud, A.A.; Varela, M.; Abiade, J.T.; Christen, D.K.; Pennycook, S.J.; Kumar, D. Enhancement of critical current density of YBa2Cu3O7−δ thin films by self-assembly of Y2O3 nanoparticulates. Thin. Solid Films. 2007, 515, 6452–6455. [Google Scholar] [CrossRef]

- Varanasi, C.; Barnes, P.N.; Burke, J.; Carpenter, J.; Haugan, T.J. Controlled introduction of flux pinning centers in YBa2Cu3O7−x films during pulsed-laser deposition. Appl. Phys. Lett. 2005, 87, 262510. [Google Scholar] [CrossRef]

- Sumption, M.D.; Haugan, T.J.; Barnes, P.N.; Campbell, T.A.; Pierce, N.A.; Varanasi, C. Magnetization creep and decay inYBa2Cu3O7−x thin films with artificial nanostructure pinning. Phys. Rev. B 2008, 77, 094506. [Google Scholar] [CrossRef]

- Horide, T.; Matsumoto, K.; Adachi, H.; Takahara, D.; Osamura, K.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S. Evaluation of metallic nanoparticles in REBa2Cu3O7−δ (RE=Y, Gd) thin films by small angle X-ray scattering. Phys. C Supercond. Its Appl. 2006, 445-448, 652–655. [Google Scholar] [CrossRef]

- Roma, N.; Morlens, S.; Ricart, S.; Zalamova, K.; Moreto, J.M.; Pomar, A.; Puig, T.; Obradors, X. Acid anhydrides: A simple route to highly pure organometallic solutions for superconducting films. Supercond. Sci. Technol. 2006, 19, 521–527. [Google Scholar] [CrossRef]

- Mele, P.; Guzman, R.; Gazquez, J.; Puig, T.; Obradors, X.; Saini, S.; Yoshida, Y.; Mukaida, M.; Ichinose, A.; Matsumoto, K.; et al. High pinning performance of YBa2Cu3O7−x films added with Y2O3 nanoparticulate defects. Supercond. Sci. Technol. 2015, 28, 024002. [Google Scholar] [CrossRef] [Green Version]

- Miura, M.; Yoshida, Y.; Ichino, Y.; Takai, Y.; Matsumoto, K.; Ichinose, A.; Horii, S.; Mukaida, M. Enhancement of flux-pinning in epitaxial Sm1+xBa2-xCu3Oy films by introduction of Low-Tc nanoparticles. Jpn J. Appl. Phys. 2006, 45, L11–L13. [Google Scholar] [CrossRef]

- Pinto, V.; Vannozzi, A.; Armenio, A.A.; Celentano, G.; De Angelis, M.; Rizzo, F.; Carcione, R.; Domenici, F.; Palmieri, D.; Politi, S.; et al. Nanodiamond addition to chemical solution deposited YBa2Cu3O7-δ film: Effect on structural and superconducting properties. Thin. Solid Films. 2020, 693, 137696. [Google Scholar] [CrossRef]

- Llordés, A.; Palau, A.; Gázquez, J.; Coll, M.; Vlad, R.; Pomar, A.; Arbiol, J.; Guzmán, R.; Ye, S.; Rouco, V.; et al. Nanoscale strain-induced pair suppression as a vortex-pinning mechanism in high-temperature superconductors. Nat. Mater. 2012, 11, 329–336. [Google Scholar] [CrossRef] [PubMed]

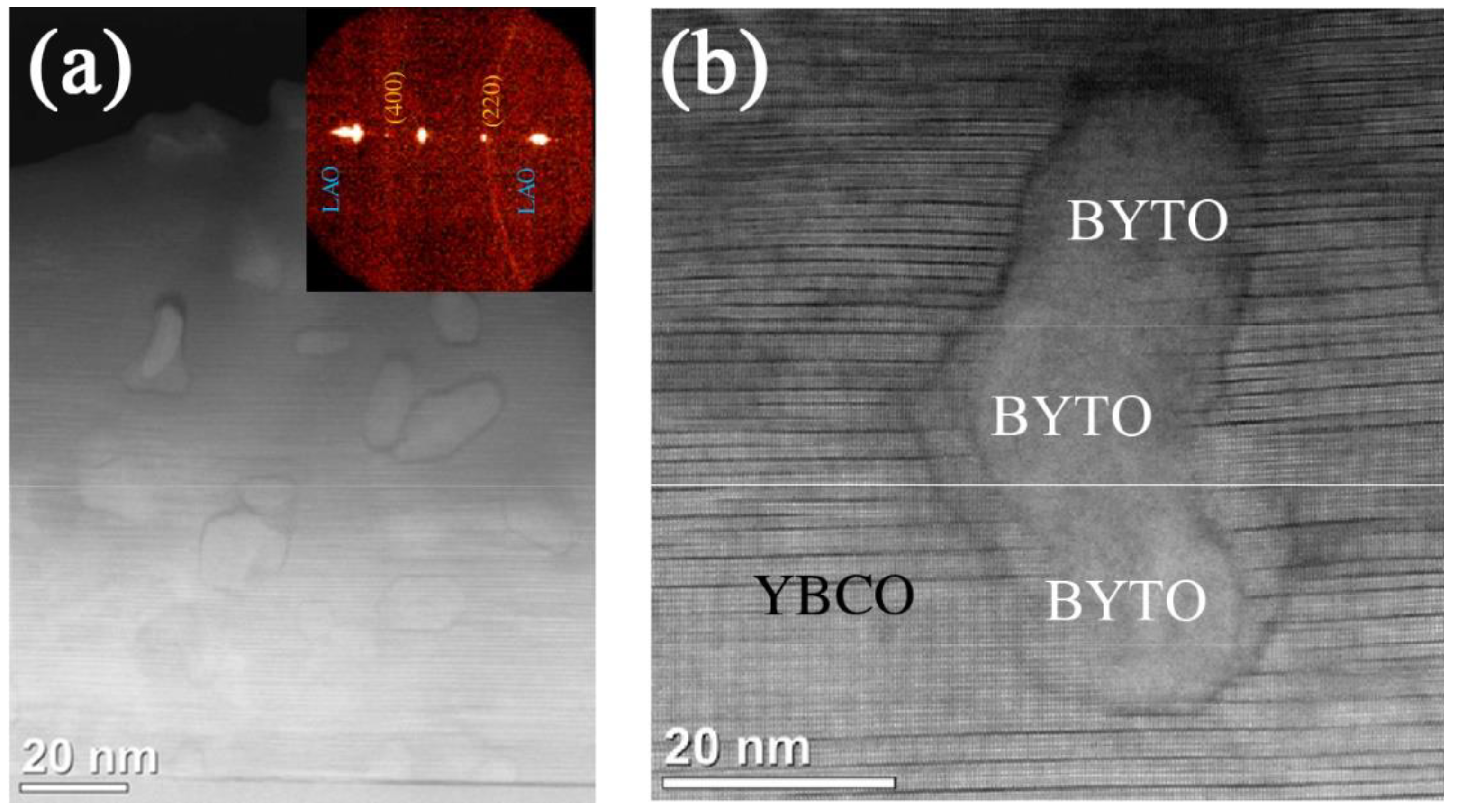

- Coll, M.; Ye, S.; Rouco, V.; Palau, A.; Guzman, R.; Gazquez, J.; Arbiol, J.; Suo, H.; Puig, T.; Obradors, X. Solution-derived YBa2Cu3O7 nanocomposite films with a Ba2YTaO6 secondary phase for improved superconducting properties. Supercond. Sci. Technol. 2013, 26, 015001. [Google Scholar] [CrossRef]

- Tang, X.; Zhao, Y.; Wu, W.; Grivel, J.C. Effect of BaZrO3/Ag hybrid doping to the microstructure and performance of fluorine-free MOD method derived YBa2Cu3O7−x superconducting thin films. J. Mater. Sci. Mater. Electron. 2014, 26, 1806–1811. [Google Scholar] [CrossRef]

- Abd-Shukor, R.; Jannah, A.N. Advances in superconductivity and Co3O4 nanoparticles as flux pinning center in (Bi, Pb)-2223/Ag superconductor tapes. AIP Conf. Proc. 2017, 1877, 020003. [Google Scholar]

- Miura, M.; Maiorov, B.; Sato, M.; Kanai, M.; Kato, T.; Kato, T.; Izumi, T.; Awaji, S.; Mele, P.; Kiuchi, M.; et al. Tuning nanoparticle size for enhanced functionality in perovskite thin films deposited by metal organic deposition. Npg Asia. Mater. 2017, 9, e477. [Google Scholar] [CrossRef] [Green Version]

- Miura, M.; Maiorov, B.; Willis, J.O.; Kato, T.; Sato, M.; Izumi, T.; Shiohara, Y.; Civale, L. The effects of density and size of BaMO3(M=Zr, Nb, Sn) nanoparticles on the vortex glassy and liquid phase in (Y,Gd)Ba2Cu3Oy coated conductors. Supercond. Sci. Technol. 2013, 26, 035008. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, W.; Wang, T.; Jiang, L.; Wang, N.; Sun, D.; Zhao, X.; Wang, M.; Qi, Y. Nanoscale characterization of the doped SrZrO3 nanoparticles distribution and its influence on the microstructure of Bi2Sr2CaCu2O8+δ film. J. Alloy Compd. 2020, 157650. [Google Scholar] [CrossRef]

- Bian, W.; Chen, Y.; Yin, X.; Tang, X.; Feng, Y.; Zhang, K.; Wu, H.; Li, L.; Hong, F.; Zhao, G.; et al. Manipulation of YBCO film properties by the introduction of perovskite BaTiO3 nanodots as substrate decorations. J. Eur. Ceram Soc. 2016, 36, 3417–3422. [Google Scholar] [CrossRef]

- Rijckaert, H.; Cayado, P.; Nast, R.; Diez Sierra, J.; Erbe, M.; Lopez Dominguez, P.; Haenisch, J.; De Buysser, K.; Holzapfel, B.; Van Driessche, I. Superconducting HfO2-YBa2Cu3O7-δ Nanocomposite Films Deposited Using Ink-Jet Printing of Colloidal Solutions. Coatings 2020, 10, 17. [Google Scholar] [CrossRef] [Green Version]

- Diez-Sierra, J.; Lopez-Dominguez, P.; Rijckaert, H.; Rikel, M.; Hanisch, J.; Khan, M.Z.; Falter, M.; Bennewitz, J.; Huhtinen, H.; Schafer, S.; et al. High Critical Current Density and Enhanced Pinning in Superconducting Films of YBa2Cu3O7-δ Nanocomposites with Embedded BaZrO3, BaHfO3, BaTiO3, and SrZrO3 Nanocrystals. ACS Appl. Nano Mater. 2020, 3, 5542–5553. [Google Scholar] [CrossRef]

- De Keukeleere, K.; Cayado, P.; Meledin, A.; Valles, F.; De Roo, J.; Rijckaert, H.; Pollefeyt, G.; Bruneel, E.; Palau, A.; Coll, M.; et al. Superconducting YBa2Cu3O7-δ Nanocomposites Using Preformed ZrO2 Nanocrystals: Growth Mechanisms and Vortex Pinning Properties. Adv. Electron. Mater. 2016, 2, 1600161. [Google Scholar] [CrossRef]

- Bartolome, E.; Cayado, P.; Solano, E.; Mocuta, C.; Ricart, S.; Mundet, B.; Coll, M.; Gazquez, J.; Meledin, A.; van Tendeloo, G.; et al. Hybrid YBa2Cu3O7 Superconducting-Ferromagnetic Nanocomposite Thin Films Prepared from Colloidal Chemical Solutions. Adv. Electron. Mater. 2017, 3, 1700037. [Google Scholar] [CrossRef]

- Gondo, M.; Yoshida, M.; Yoshida, Y.; Ishimaru, M.; Horide, T.; Matsumoto, K.; Kita, R. Nanostructures and flux pinning properties in YBa2Cu3O7−y thin films with double perovskite Ba2LuNbO6 nanorods. J. Appl. Phys. 2021, 129, 195301. [Google Scholar] [CrossRef]

- Horide, T.; Matsukida, N.; Ishimaru, M.; Kita, R.; Awaji, S.; Matsumoto, K. Pin potential effect on vortex pinning in YBa2Cu3O7-δ films containing nanorods: Pin size effect and mixed pinning. Appl. Phys. Lett. 2017, 110, 052601. [Google Scholar] [CrossRef]

- Ercolano, G.; Bianchetti, M.; Sahonta, S.L.; Kursumovic, A.; Lee, J.H.; Wang, H.; MacManus-Driscoll, J.L. Strong correlated pinning at high growth rates in YBa2Cu3O7−x thin films with Ba2YNbO6 additions. J. Appl. Phys. 2014, 116, 033915. [Google Scholar] [CrossRef]

- Rizzo, F.; Augieri, A.; Angrisani Armenio, A.; Galluzzi, V.; Mancini, A.; Pinto, V.; Rufoloni, A.; Vannozzi, A.; Bianchetti, M.; Kursumovic, A.; et al. Enhanced 77 K vortex-pinning in YBa2Cu3O7−x films with Ba2YTaO6 and mixed Ba2YTaO6+Ba2YNbO6 nano-columnar inclusions with irreversibility field to 11 T. Apl. Mater. 2016, 4, 061101. [Google Scholar] [CrossRef] [Green Version]

- Ogunjimi, V.; Sebastian, M.A.; Zhang, D.; Gautam, B.; Jian, J.; Huang, J.; Zhang, Y.; Haugan, T.; Wang, H.; Wu, J. Enhancing magnetic pinning by BaZrO3 nanorods forming coherent interface by strain-directed Ca-doping in YBa2Cu3O7−x nanocomposite films. Supercond. Sci. Technol. 2021, 34, 104002. [Google Scholar] [CrossRef]

- Celentano, G.; Rizzo, F.; Augieri, A.; Mancini, A.; Pinto, V.; Rufoloni, A.; Vannozzi, A.; MacManus-Driscoll, J.L.; Feighan, J.; Kursumovic, A.; et al. YBa2Cu3O7-δ films with Ba2Y(Nb,Ta)O6 nanoinclusions for high-field applications. Supercond. Sci. Technol. 2020, 33, 044010. [Google Scholar] [CrossRef]

- Jha, A.K.; Matsumoto, K.; Horide, T.; Saini, S.; Mele, P.; Ichinose, A.; Yoshida, Y.; Awaji, S. Controlling the critical current anisotropy of YBCO superconducting films by incorporating hybrid artificial pinning centers. IEEE Trans. Appl. Supercond. 2016, 26, 8000404. [Google Scholar] [CrossRef] [Green Version]

- Malmivirta, M.; Rijckaert, H.; Paasonen, V.; Huhtinen, H.; Hynninen, T.; Jha, R.; Awana, V.S.; Van Driessche, I.; Paturi, P. Enhanced flux pinning in YBCO multilayer films with BCO nanodots and segmented BZO nanorods. Sci. Rep. 2017, 7, 14682. [Google Scholar] [CrossRef] [Green Version]

- Coll, M.; Guzman, R.; Garces, P.; Gazquez, J.; Rouco, V.; Palau, A.; Ye, S.; Magen, C.; Suo, H.; Castro, H.; et al. Size-controlled spontaneously segregated Ba2YTaO6 nanoparticles in YBa2Cu3O7 nanocomposites obtained by chemical solution deposition. Supercond. Sci. Technol. 2014, 27, 044008. [Google Scholar] [CrossRef]

- Mele, P.; Matsumoto, K.; Horide, T.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S.; Kita, R. Incorporation of double artificial pinning centers in YBa2Cu3O7-δ films. Supercond. Sci. Technol. 2008, 21, 015019. [Google Scholar] [CrossRef]

- Rouco, V.; Bartolomé, E.; Palau, A.; Coll, M.; Obradors, X.; Puig, T. Nanostrain induced pinning in YBa2Cu3O7−x nanocomposites even close to the irreversibility line. Supercond. Sci. Technol. 2012, 25, 122001. [Google Scholar] [CrossRef]

- Rizzo, F.; Augieri, A.; Kursumovic, A.; Bianchetti, M.; Opherden, L.; Sieger, M.; Huhne, R.; Hanisch, J.; Meledin, A.; Van Tendeloo, G.; et al. Pushing the limits of applicability of REBCO coated conductor films through fine chemical tuning and nanoengineering of inclusions. Nanoscale 2018, 10, 8187–8195. [Google Scholar] [CrossRef] [PubMed]

- Crisan, A.; Fujiwara, S.; Nie, J.C.; Sundaresan, A.; Ihara, H. Sputtered nanodots: A costless method for inducing effective pinning centers in superconducting thin films. Appl. Phys. Lett. 2001, 79, 4547–4549. [Google Scholar] [CrossRef]

- Aytug, T.; Paranthaman, M.; Gapud, A.A.; Kang, S.; Christen, H.M.; Leonard, K.J.; Martin, P.M.; Thompson, J.R.; Christen, D.K.; Meng, R.; et al. Enhancement of flux pinning and critical currents inYBa2Cu3O7-d films by nanoscale iridium pretreatment of substrate surfaces. J. Appl. Phys. 2005, 98, 114309. [Google Scholar] [CrossRef]

- Crisan, A.; Dang, V.S.; Mikheenko, P.; Ionescu, A.M.; Ivan, I.; Miu, L. Synergetic pinning centres in BaZrO3-doped YBa2Cu3O7-δ films induced by SrTiO3 nano-layers. Supercond. Sci. Technol. 2017, 30, 045012. [Google Scholar] [CrossRef] [Green Version]

- Mikheenko, P.; Dang, V.S.; Tse, Y.Y.; Kechik, M.M.A.; Paturi, P.; Huhtinen, H.; Wang, Y.; Sarkar, A.; Abell, J.S.; Crisan, A. Integrated nanotechnology of pinning centers in YBa2Cu3Ox films. Supercond. Sci. Technol. 2010, 23, 125007. [Google Scholar] [CrossRef]

- Matsumoto, K.; Horide, T.; Osamura, K.; Mukaida, M.; Yoshida, Y.; Ichinose, A.; Horii, S. Enhancement of critical current density of YBCO films by introduction of artificial pinning centers due to the distributed nano-scaled Y2O3 islands on substrates. Phys. C-Supercond. Its Appl. 2004, 412, 1267–1271. [Google Scholar] [CrossRef]

- Mele, P.; Matsumoto, K.; Horide, T.; Miura, O.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S. Critical current enhancement in PLD YBa2Cu3O7-x films using artificial pinning centers. Phys. C-Supercond. Its Appl. 2006, 445, 648–651. [Google Scholar] [CrossRef]

- Nie, J.C.; Yamasaki, H.; Yamada, H.; Nakagawa, Y.; Develos-Bagarinao, K.; Mawatari, Y. Evidence for c-axis correlated vortex pinning in YBa2Cu3O7-δ films on sapphire buffered with an atomically flat CeO2 layer having a high density of nanodots. Supercond. Sci. Technol. 2004, 17, 845–852. [Google Scholar] [CrossRef]

- Maiorov, B.; Wang, H.; Foltyn, S.R.; Li, Y.; DePaula, R.; Stan, L.; Arendt, P.N.; Civale, L. Influence of naturally grown nanoparticles at the buffer layer in the flux pinning in YBa2Cu3O7 coated conductors. Supercond. Sci. Technol. 2006, 19, 891–895. [Google Scholar] [CrossRef]

- Aytug, T.; Paranthaman, M.; Leonard, K.J.; Kang, S.; Martin, P.M.; Heatherly, L.; Goyal, A.; Ijaduola, A.O.; Thompson, J.R.; Christen, D.K.; et al. Analysis of flux pinning in YBa2Cu3O7-d films by nanoparticle-modified substrate surfaces. Phys. Rev. B 2006, 74, 184505. [Google Scholar] [CrossRef]

- Aytug, T.; Paranthaman, M.; Leonard, K.J.; Kim, K.; Ijaduola, A.O.; Zhang, Y.; Tuncer, E.; Thompson, J.R.; Christen, D.K. Enhanced flux pinning and critical currents in YBa2Cu3O7-d films by nanoparticle surface decoration: Extension to coated conductor templates. J. Appl. Phys. 2008, 104, 043906. [Google Scholar] [CrossRef]

- Jha, A.K.; Khare, N.; Pinto, R. Interface engineering using ferromagnetic nanoparticles for enhancing pinning in YBa2Cu3O7-δ thin film. J. Appl. Phys. 2011, 110, 113920. [Google Scholar] [CrossRef]

- Gutierrez, J.; Puig, T.; Gibert, M.; Moreno, C.; Romà, N.; Pomar, A.; Obradors, X. Anisotropic c-axis pinning in interfacial self-assembled nanostructured trifluoracetate-YBa2Cu3O7−x films. Appl. Phys. Lett. 2009, 94, 172513. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, M.; Suo, H.L.; Ye, S.; Wu, Z.P.; Mao, L. An effective substrate surface decoration to YBCO films by multiphase nanoparticles. Phys. C-Supercond. Its Appl. 2013, 495, 187–191. [Google Scholar] [CrossRef]

- Piperno, L.; Armenio, A.A.; Vannozzi, A.; Mancini, A.; Rizzo, F.; Augieri, A.; Pinto, V.; Rufoloni, A.; Mos, R.B.; Ciontea, L.; et al. Polymer-assisted surface decoration for critical current enhancement in YBa2Cu3O7-x films. Appl. Surf. Sci. 2019, 484, 237–244. [Google Scholar] [CrossRef]

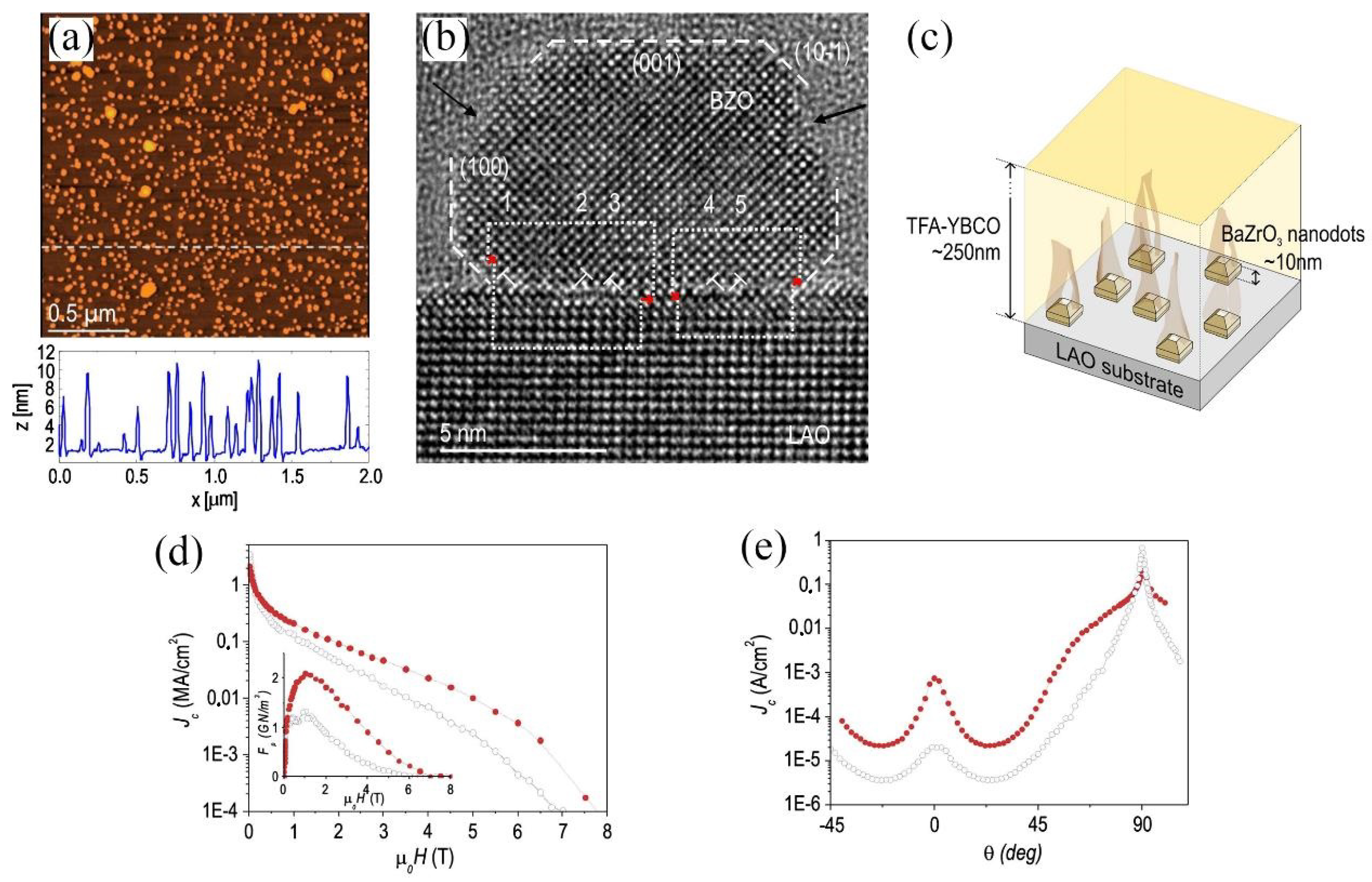

- Abellán, P.; Sandiumenge, F.; Casanove, M.-J.; Gibert, M.; Palau, A.; Puig, T.; Obradors, X. Interaction between solution derived BaZrO3 nanodot interfacial templates and YBa2Cu3O7 films leading to enhanced critical currents. Acta Mater. 2011, 59, 2075–2082. [Google Scholar] [CrossRef]

- Matsumoto, K.; Horide, T.; Ichinose, A.; Horii, S.; Yoshida, Y.; Mukaida, M. Critical Current Control in YBa2Cu3O7-δ Films Using Artificial Pinning Centers. Jpn J. Appl. Phys. 2005, 44, L246–L248. [Google Scholar] [CrossRef]

- Crisan, A.; Badica, P.; Fujiwara, S.; Nie, J.C.; Sundaresan, A.; Tanaka, Y.; Ihara, H. Strong reduction of thermally activated flux jump rate in superconducting thin films by nanodot-induced pinning centers. Appl. Phys. Lett. 2002, 80, 3566–3568. [Google Scholar] [CrossRef]

- Ionescu, M.; Li, A.H.; Zhao, Y.; Liu, H.K.; Crisan, A. Enhancement of critical current density in YBa2Cu3O7-δ thin films grown using PLD on YSZ (001) surface modified with Ag nano-dots. J. Phys. D Appl. Phys. 2004, 37, 1824–1828. [Google Scholar] [CrossRef]

- Maiorov, B.; Baily, S.A.; Zhou, H.; Ugurlu, O.; Kennison, J.A.; Dowden, P.C.; Holesinger, T.G.; Foltyn, S.R.; Civale, L. Synergetic combination of different types of defect to optimize pinning landscape using BaZrO3-doped YBa2Cu3O7. Nat. Mater. 2009, 8, 398–404. [Google Scholar] [CrossRef] [PubMed]

- Ding, F.Z.; Gu, H.W.; Zhang, T.; Wang, H.Y.; Qu, F.; Dai, S.T.; Peng, X.Y.; Cao, J.L. Enhanced flux pinning in MOD-YBCO films with co-doping of BaZrO3 and Y2O3 nanoparticles. J. Alloy Compd. 2012, 513, 277–281. [Google Scholar] [CrossRef]

- Jha, A.K.; Matsumoto, K.; Horide, T.; Saini, S.; Mele, P.; Yoshida, Y.; Awaji, S. Systematic variation of hybrid APCs Into YBCO thin films for improving the vortex pinning properties. IEEE Trans. Appl. Supercond. 2015, 25, 8000505. [Google Scholar] [CrossRef] [Green Version]

- Gautam, B.; Sebastian, M.A.; Chen, S.; Haugan, T.; Zhang, W.; Huang, J.; Wang, H.; Wu, J.Z. Microscopic adaptation of BaHfO3 and Y2O3 artificial pinning centers for strong and isotropic pinning landscape in YBa2Cu3O7–x thin films. Supercond. Sci. Technol. 2018, 31, 025008. [Google Scholar] [CrossRef]

- Wang, J.; Tsai, C.F.; Bi, Z.X.; Naugle, D.G.; Wang, H.Y. Microstructural and Pinning Properties of YBa2Cu3O7-δ Thin Films Doped With Magnetic Nanoparticles. IEEE Trans. Appl. Supercond. 2009, 19, 3503–3506. [Google Scholar] [CrossRef]

- Tsai, C.F.; Zhu, Y.Y.; Chen, L.; Wang, H.Y. Flux Pinning Properties in YBCO Thin Films With Self-Aligned Magnetic Nanoparticles. IEEE Trans. Appl. Supercond. 2011, 21, 2749–2752. [Google Scholar] [CrossRef]

- Wimbush, S.C.; Durrell, J.H.; Tsai, C.F.; Wang, H.; Jia, Q.X.; Blamire, M.G.; MacManus-Driscoll, J.L. Enhanced critical current in YBa2Cu3O7-δ thin films through pinning by ferromagnetic YFeO3 nanoparticles. Supercond. Sci. Technol. 2010, 23, 045019. [Google Scholar] [CrossRef]

- Tsai, C.F.; Chen, L.; Chen, A.P.; Khatkhatay, F.; Zhang, W.R.; Wang, H.Y. Enhanced Flux Pinning Properties in Self-Assembled Magnetic CoFe2O4 Nanoparticles Doped YBa2Cu3O7-δ Thin Films. IEEE Trans. Appl. Supercond. 2013, 23, 8001204. [Google Scholar] [CrossRef]

- Wimbush, S.C.; Durrell, J.H.; Bali, R.; Yu, R.; Wang, H.Y.; Harrington, S.A.; MacManus-Driscoll, J.L. Practical Magnetic Pinning in YBCO. IEEE Trans. Appl. Supercond. 2009, 19, 3148–3151. [Google Scholar] [CrossRef]

- Blamire, M.G.; Dinner, R.B.; Wimbush, S.C.; MacManus-Driscoll, J.L. Critical current enhancement by Lorentz force reduction in superconductor-ferromagnet nanocomposites. Supercond. Sci. Technol. 2009, 22, 025017. [Google Scholar] [CrossRef]

- Huang, J.; Fan, M.; Wang, H.; Chen, L.; Tsai, C.-F.; Li, L.; Wang, H. Enhanced superconducting properties of YBa2Cu3O7−δ thin film with magnetic nanolayer additions. Ceram. Int. 2016, 42, 12202–12209. [Google Scholar] [CrossRef]

| APC | Film | Method | Dimension | Film Thickness (nm) | Jc (MA/cm2) | Tc (K) | Fpmax (GN m−3) | References |

|---|---|---|---|---|---|---|---|---|

| HfO2 | YBCO | ex situ Ink-Jet Printing | 3D | 450–500 | 3.1 (77 K, 0 T) | — | 6.8 (77 K, 0 T) | [139] |

| Nanodiamond | YBCO | ex situ MOD | 3D | 75 | 4 (77 K, 0 T) | 90.4 ± 0.2 | — | [130] |

| BaZrO3 | YBCO | ex situ MOD | 3D | 260 | 4.7 (77 K, 0 T) | 91.3 | 4.1 (77 K, 1 T) | [140] |

| SrZrO3 | YBCO | ex situ MOD | 3D | 290 | 2.7 (77 K, 0 T) | 90.2 | 2.0 (77 K, 1 T) | [140] |

| BaHfO3 | YBCO | ex situ MOD | 3D | 240 | 4.5 (77 K, 0 T) | 90.7 | 5.9 (77 K, 1 T) | [140] |

| BaTiO3 | YBCO | ex situ MOD | 3D | 300 | 4.6 (77 K, 0 T) | 92.3 | 1.5 (77 K, 1 T) | [140] |

| ZrO2 | YBCO | ex situ CSD | 3D | 180 | 5 (77 K, 0 T) | 89.6 | 6 (77 K, 0 T) | [141] |

| MnFe2O4 | YBCO | ex situ CSD | 3D | 150 ± 10 | 2 (5 K, 0 T) | 76 | — | [142] |

| BaZrO3 | YBCO | in situ MOD | 3D | 200–270 | 2.2 (77 K, 1 T) | 91 | 21 (77 K, 2 T) | [93] |

| Ba2YTaO6 | YBCO | in situ CSD | 3D | 250 | 4–5 (77 K, 0 T) | 89–90 | 6 (77 K, 1 T) | [132] |

| Y2O3 | YBCO | in situ PLD | 3D | — | 2.62 (44 K, 0 T) | 89.26 | 7.8 (77 K, 2 T) | [118] |

| Ba2LuNbO6 | YBCO | in situ PLD | 1D | 160 | 0.76 (77 K, 2 T) | 89.5 | 17.5 (77 K, 1.5 T) | [143] |

| BaHfO3 | YBCO | in situ PLD | 1D | 190 | 0.61 (77 K, 0 T) | 89.0 | 15.9 (77 K, 3 T) | [144] |

| BaSnO3 | YBCO | in situ PLD | 1D | 220 | 0.64 (77 K, 1 T) | 89.6 | 13.4 (77 K, 2 T) | [144] |

| BaSnO3 | YBCO | in situ PLD | 1D | 271–310 | 0.38 (77 K, 5 T) | 88.6 | 28.3 (77 K, 2 T) | [71] |

| Ba2YNbO6 | YBCO | in situ PLD | 1D | 500–1000 | 4.5 (75.6 K, 0 T) | 92.0–92.5 | 32.3 (75.5 K, 0 T) | [77] |

| Ba2Y(Nb/Ta)O6 | YBCO | in situ PLD | 1D | 250 | 1.18 (77 K, 2 T) | 90.5–90.8 | 21.5 (77 K, 1.7 T) | [78] |

| Ba2YNbO6 | YBCO | in situ PLD | 1D | 400 | 1.6 (77K, 0 T) | 88–91 | 6 (77 K, 1.4 T) | [145] |

| Ba2YTaO6 | YBCO | in situ PLD | 1D | 215–230 | 1.6 (77K, 0 T) | — | 9.1 (77 K, 3 T) | [146] |

| Ba2Y(Nb/Ta)O6 | YBCO | in situ PLD | 1D | 215–230 | 3.2 (77 K, 1 T) | — | 11.5 (77 K, 4.4 T) | [146] |

| Ba2YNbO6 | YBCO | in situ PLD | 1D | 200–800 | 4.1 (77 K, 0 T) | 87.4–88.3 | — | [79] |

| BaZrO3 | (YCa)BCO | in situ PLD | 1D | 160–170 | 4.39 (77 K, 1 T) | 87.5 | 98 (65 K, 0 T) | [147] |

| Ba2YTaO6 + Ba2YNbO6 | YBCO | In situ PLD | 1D + 3D | 150–230 | 7.5 (10 K, 0 T) | 89.9 | 900 (10 K, 12 T) | [148] |

| BaSnO3 + Y2BaCuO5 | YBCO | In situ PLD | 1D + 3D | — | 3.4 (77 K, 0 T) | — | 9.65 (77 K, 0 T) 44.7 (77 K, 0 T) | [149] |

| BaZrO3 + BaCeO3 | YBCO | In situ PLD | 1D + 3D | 310–380 | 4.5 (77 K, 8 T) | 87.7–88.9 | — | [150] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wu, H.; Zhao, G.; Han, L.; Zhang, J. Progress in the Study of Vortex Pinning Centers in High-Temperature Superconducting Films. Nanomaterials 2022, 12, 4000. https://doi.org/10.3390/nano12224000

Zhang J, Wu H, Zhao G, Han L, Zhang J. Progress in the Study of Vortex Pinning Centers in High-Temperature Superconducting Films. Nanomaterials. 2022; 12(22):4000. https://doi.org/10.3390/nano12224000

Chicago/Turabian StyleZhang, Jian, Haiyan Wu, Guangzhen Zhao, Lu Han, and Jun Zhang. 2022. "Progress in the Study of Vortex Pinning Centers in High-Temperature Superconducting Films" Nanomaterials 12, no. 22: 4000. https://doi.org/10.3390/nano12224000

APA StyleZhang, J., Wu, H., Zhao, G., Han, L., & Zhang, J. (2022). Progress in the Study of Vortex Pinning Centers in High-Temperature Superconducting Films. Nanomaterials, 12(22), 4000. https://doi.org/10.3390/nano12224000