Theoretical Optical Output Power Improvement of InGaN-Based Violet Laser Diode Using AlGaN/GaN Composite Last Quantum Barrier

Abstract

1. Introduction

2. Design Concept and Simulation Parameters

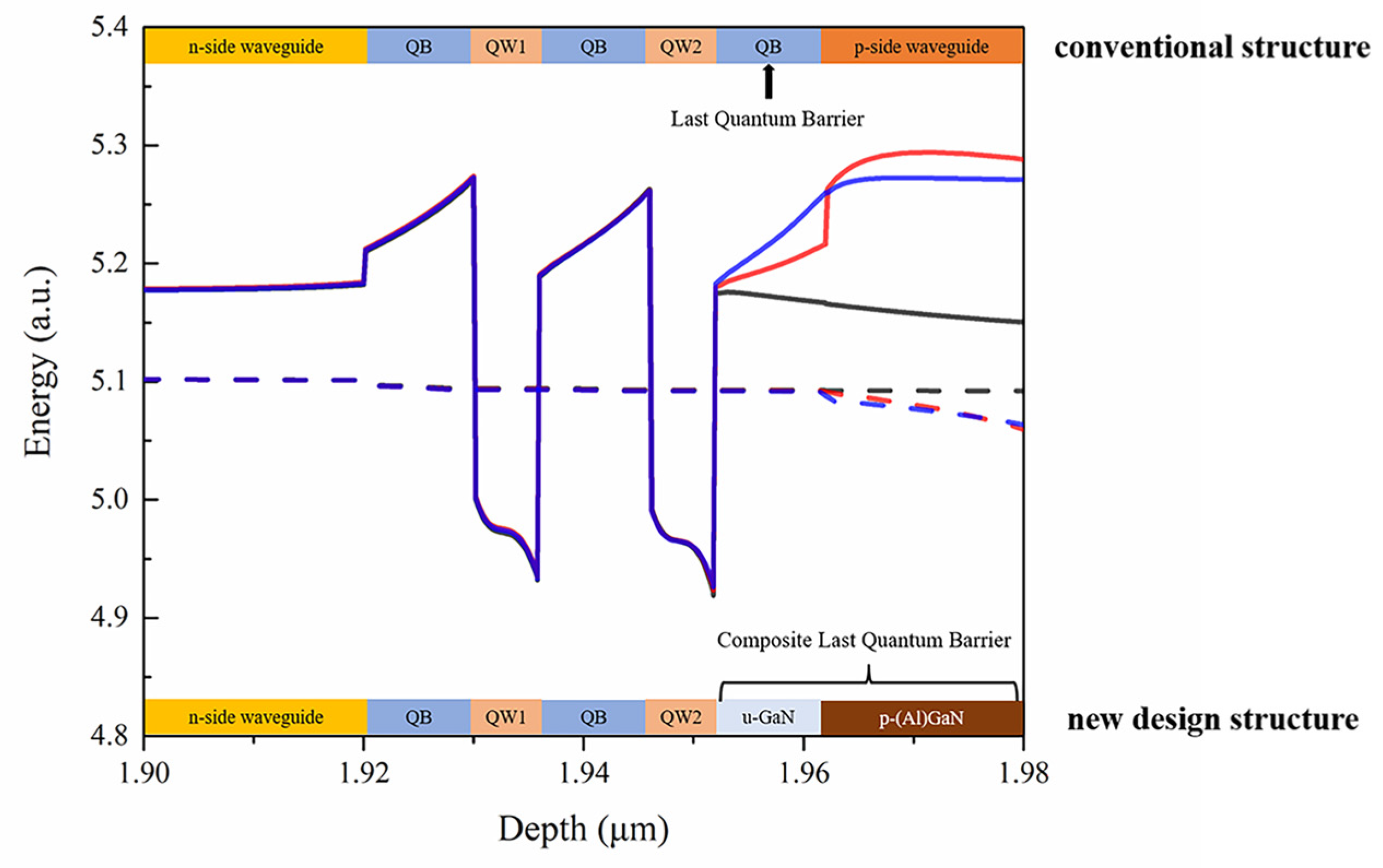

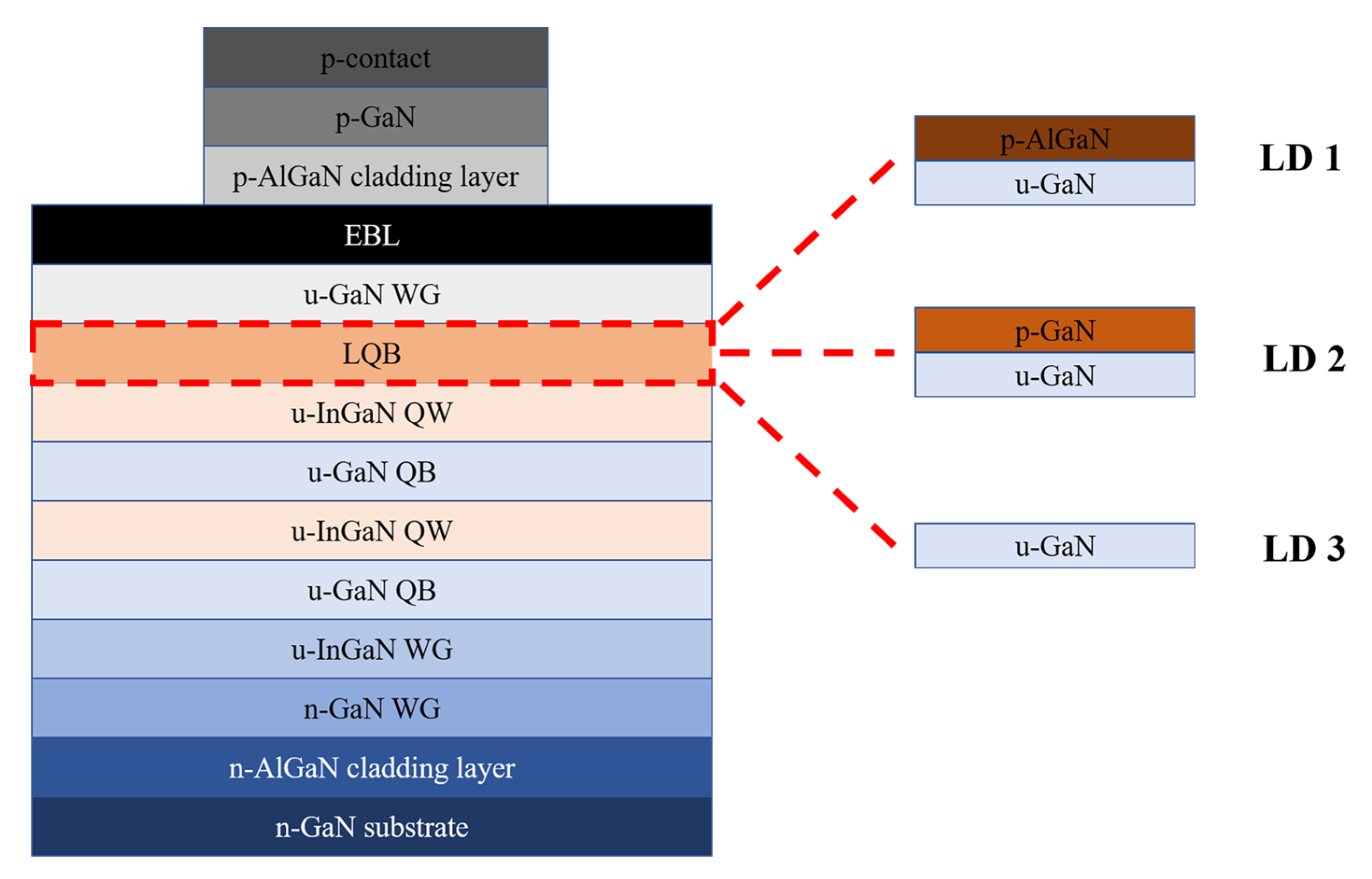

2.1. Design Concept

2.2. Simulation Parameters

3. Results and Discussion

3.1. Effect of Al Composition in CLQB

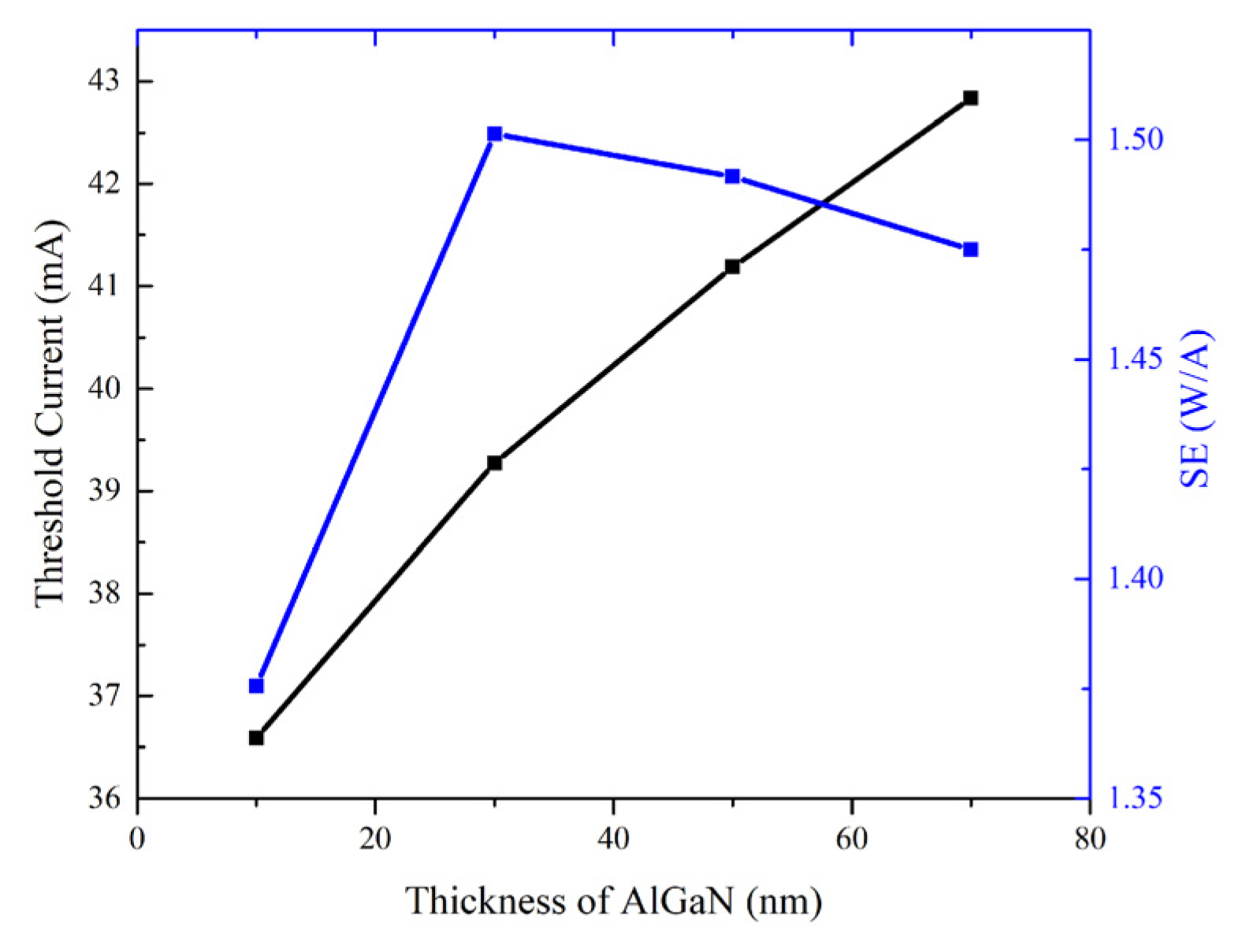

3.2. Effect of AlGaN Layer Thickness in CLQB

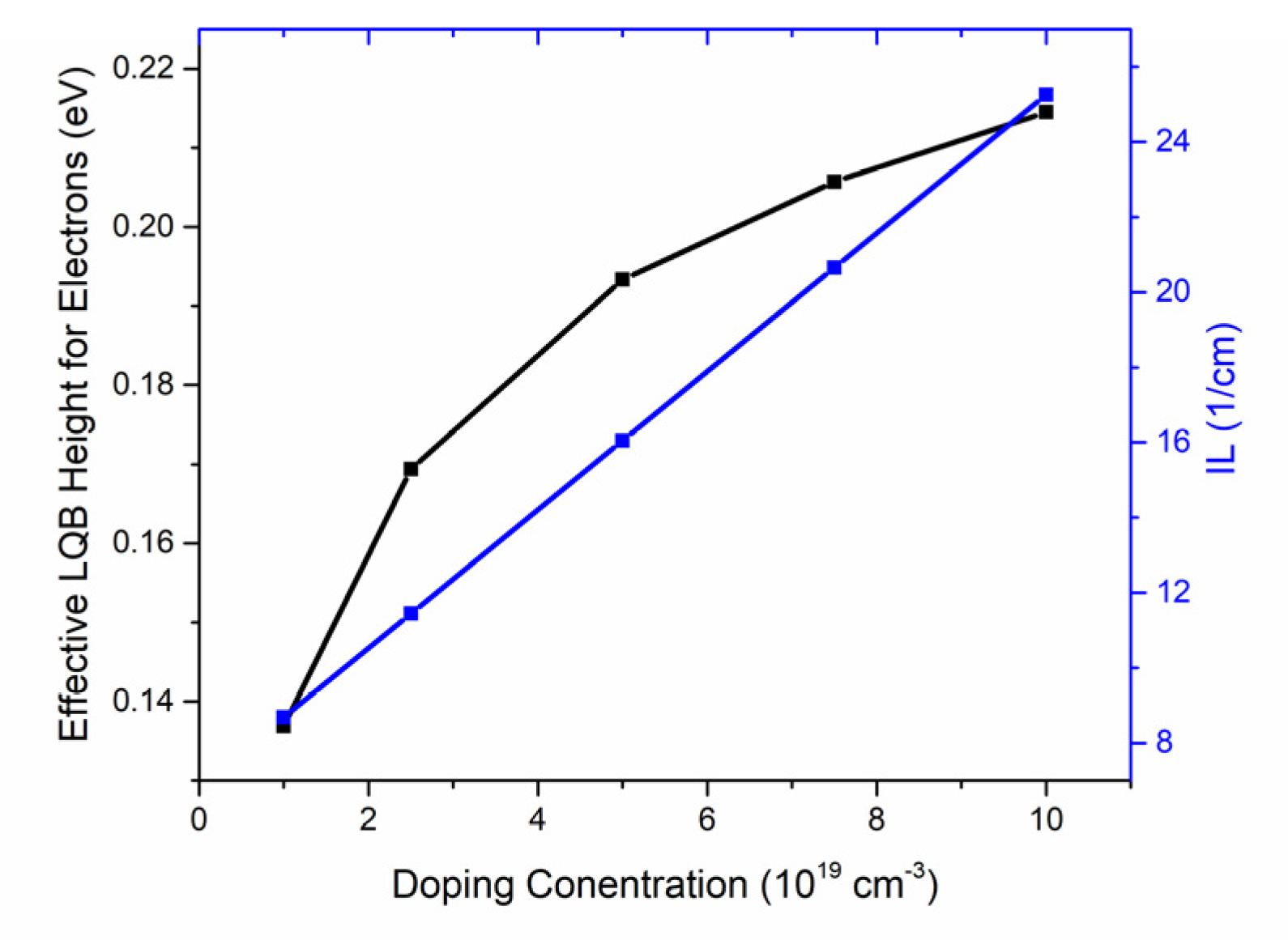

3.3. Effect of Acceptor Doping Level in CLQB

3.4. Comparison between LDs with Different LQB Structures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yamanaka, K.; Kato, R.; Oya, M.; Morimoto, K.; Samonji, K.; Okuyama, K. Optical light devices for next-generation automobile headlamp. Panasonic Technol. J. 2015, 61, 41. [Google Scholar]

- Morimoto, K.; Suzuki, N.; Yamanaka, K.; Yuri, M.; Milliez, J.; Liu, X. An advanced 405-nm laser diode crystallization method of a-Si film for fabricating microcrystalline-Si TFTs. IEICE Trans. Electron. 2011, 94, 1733–1738. [Google Scholar] [CrossRef]

- Wang, W.J.; Liao, M.L.; Yuan, J.; Luo, S.Y.; Huang, F. Enhancing performance of GaN-based LDs by using GaN/InGaN asymmetric lower waveguide layers. Chin. Phys. B 2022, 31, 074206. [Google Scholar] [CrossRef]

- Chellappan, K.V.; Erden, E.; Urey, H. Laser-based displays: A review. Appl. Opt. 2010, 49, F79–F98. [Google Scholar] [CrossRef] [PubMed]

- Kawaguchi, M.; Imafuji, O.; Nozaki, S.; Hagino, H.; Takigawa, S.; Katayama, T.; Tanaka, T. Optical-loss suppressed InGaN laser diodes using undoped thick waveguide structure. In Proceeding of the Conference on Gallium Nitride Materials and Devices XI, San Francisco, CA, USA, 15–18 February 2016. [Google Scholar]

- Han, D.P.; Shim, J.I.; Shin, D.S.; Kim, K.S. Effects of unbalanced carrier injection on the performance characteristics of InGaN light-emitting diodes. Appl. Phys. Express 2016, 9, 081002. [Google Scholar] [CrossRef]

- Lee, S.N.; Cho, S.Y.; Ryu, H.Y.; Son, J.K.; Paek, H.S.; Sakong, T.; Jang, T.; Choi, K.K.; Ha, K.H.; Yang, M.H.; et al. High-power GaN-based blue-violet laser diodes with AlGaN/GaN multiquantum barriers. Appl. Phys. Lett. 2006, 88, 111101. [Google Scholar] [CrossRef]

- Nakamura, S.; Senoh, M.; Nagahama, S.-i.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y.; Kozaki, T.; Umemoto, H. Violet InGaN/GaN/AlGaN-based laser diodes with an output power of 420 mW. Jpn. J. Appl. Phys. 1998, 37, L627. [Google Scholar] [CrossRef]

- Tojyo, T.; Asano, T.; Takeya, M.; Hino, T.; Kijima, S.; Goto, S.; Uchida, S.; Ikeda, M. GaN-based high power blue-violet laser diodes. Jpn. J. Appl. Phys. Part 1—Regul. Pap. Short Notes Rev. Pap. 2001, 40, 3206–3210. [Google Scholar] [CrossRef]

- Li-Qun, Z.; Shu-Ming, Z.; De-Sheng, J.; Hui, W.; Jian-Jun, Z.; De-Gang, Z.; Zong-Shun, L.; Hui, Y. GaN-based violet laser diodes grown on free-standing GaN substrate. Chin. Phys. B 2009, 18, 5350. [Google Scholar] [CrossRef]

- Liang, F.; Yang, J.; Zhao, D.; Liu, Z.; Zhu, J.; Chen, P.; Jiang, D.; Shi, Y.; Wang, H.; Duan, L.; et al. Room-temperature continuous-wave operation of GaN-based blue-violet laser diodes with a lifetime longer than 1000 h. J. Semicond. 2019, 40, 022801. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, D.G.; Zhu, J.J.; Liu, Z.S.; Jiang, D.S.; Chen, P.; Liang, F.; Liu, S.T.; Xing, Y. Effect of Mg doping concentration of electron blocking layer on the performance of GaN-based laser diodes. Appl. Phys. B Lasers Opt. 2019, 125, 235. [Google Scholar] [CrossRef]

- Yan Zhang, Y.; An Yin, Y. Performance enhancement of blue light-emitting diodes with a special designed AlGaN/GaN superlattice electron-blocking layer. Appl. Phys. Lett. 2011, 99, 221103. [Google Scholar]

- Wang, C.; Ke, C.; Lee, C.; Chang, S.; Chang, W.; Li, J.; Li, Z.; Yang, H.; Kuo, H.-C.; Lu, T. Hole injection and efficiency droop improvement in InGaN/GaN light-emitting diodes by band-engineered electron blocking layer. Appl. Phys. Lett. 2010, 97, 261103. [Google Scholar] [CrossRef]

- Svensk, O.; Torma, P.T.; Suihkonen, S.; Ali, M.; Lipsanen, H.; Sopanen, M.; Odnoblyudov, M.A.; Bougrov, V.E. Enhanced electroluminescence in 405 nm InGaN/GaN LEDs by optimized electron blocking layer. J. Cryst. Growth 2008, 310, 5154–5157. [Google Scholar]

- Asano, T.; Takeya, M.; Tojyo, T.; Mizuno, T.; Ikeda, S.; Shibuya, K.; Hino, T.; Uchida, S.; Ikeda, M. High-power 400-nm-band AlGaInN-based laser diodes with low aspect ratio. Appl. Phys. Lett. 2002, 80, 3497–3499. [Google Scholar]

- Wang, W.J.; Liao, M.L.; Yuan, J.; Luo, S.Y. Effects of Composition-graded AlGaN/GaN/AlGaN Electron Blocking Layer on Photoelectric Performance in InGaN Laser Diodes. In Proceedings of the Applied Optics and Photonics China (AOPC) Conference—Optoelectronics and Nanophotonics and Quantum Information Technology, Beijing, China, 30 November–2 December 2020. [Google Scholar]

- Sandhu, H.K.; Sharma, A.; Jain, A.; Das, S. Efficiency enhancement in InGaN-based laser diodes using an optimized Al0.12Ga0.88N electron blocking layer. Semicond. Sci. Technol. 2020, 35, 105017. [Google Scholar]

- Le, L.; Zhao, D.; Jiang, D.; Chen, P.; Liu, Z.; Zhu, J.; Yang, J.; Li, X.; He, X.; Liu, J. Utilization of polarization-inverted AlInGaN or relatively thinner AlGaN electron blocking layer in InGaN-based blue–violet laser diodes. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2015, 33, 011209. [Google Scholar]

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y. InGaN-based multi-quantum-well-structure laser diodes. Jpn. J. Appl. Phys. Part 2—Lett. Express Lett. 1996, 35, L74–L76. [Google Scholar]

- Bin, Y.; Zhi-You, G.; Nan, X.; Pan-Jun, Z.; Jing, L.; Fang-Zheng, L.; Hong, L.; Huan, Z.; Jin-Xin, C. A GaN–AlGaN–InGaN last quantum barrier in an InGaN/GaN multiple-quantum-well blue LED. Chin. Physics. B 2014, 23, 048502. [Google Scholar]

- Liang, F.; Zhao, D.G.; Jiang, D.S.; Liu, Z.S.; Zhu, J.J.; Chen, P.; Yang, J.; Liu, W.; Liu, S.T.; Xing, Y.; et al. Performance enhancement of the GaN-based laser diode by using an unintentionally doped GaN upper waveguide. Jpn J. Appl. Phys. 2018, 57, 070307. [Google Scholar]

- Chen, P.; Zhao, D.G.; Jiang, D.S.; Zhu, J.J.; Liu, Z.S.; Le, L.C.; Yang, J.; Li, X.; Zhang, L.Q.; Liu, J.P.; et al. The effect of composite GaN/InGaN last barrier layer on electron leakage current and modal gain of InGaN-based multiple quantum well laser diodes. Phys. Status Solidi. A 2015, 212, 2936–2943. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.G.; Jiang, D.S.; Liu, Z.S.; Zhu, J.J.; Chen, P.; Yang, J.; Liu, W.; Liu, S.T.; Xing, Y.; et al. Output light power of InGaN-based violet laser diodes improved by using a u-InGaN/GaN/AlGaN multiple upper waveguide. Chin. Phys. B 2017, 26, 124210. [Google Scholar]

- Hou, Y.; Zhao, D.; Chen, P.; Liang, F.; Liu, Z.; Yang, J. Stepped upper waveguide layer for higher hole injection efficiency in GaN-based laser diodes. Opt. Express 2021, 29, 33992–34001. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Wang, B.B.; Zhao, D.G.; Liu, Z.S.; Liang, F.; Chen, P.; Zhang, Y.H.; Zhang, Z.Z. Realization of 366 nm GaN/AlGaN single quantum well ultraviolet laser diodes with a reduction of carrier loss in the waveguide layers. J. Appl. Phys. 2021, 130, 173105. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.G.; Jiang, D.S.; Wang, W.J.; Liu, Z.S.; Zhu, J.J.; Chen, P.; Yang, J.; Zhang, L.Q. Performance deterioration of GaN-based laser diode by V-pits in the upper waveguide layer. Nanophotonics 2020, 9, 667–674. [Google Scholar] [CrossRef]

- Alahyarizadeh, G.; Hassan, Z.; Thahab, S.M.; Yam, F.K.; Ghazai, A.J. Performance characteristics of deep violet InGaN DQW laser diodes with InGaN/GaN superlattice waveguide layers. Optik 2014, 125, 341–344. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for nonlinear macroscopic polarization in III-V nitride alloy heterostructures. Appl. Phys. Lett. 2002, 80, 1204–1206. [Google Scholar] [CrossRef]

- Piprek, J.; Nakamura, S. Physics of high-power InGaN/GaN lasers. Iee Proc.-Optoelectron. 2002, 149, 145–151. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, Y.-D.; Tyagi, A.; Chakraborty, A.; Ohta, H.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. Optical waveguide simulations for the optimization of InGaN-based green laser diodes. J. Appl. Phys. 2010, 107, 023101. [Google Scholar] [CrossRef]

- Zhang, L.Q.; Jiang, D.S.; Zhu, J.J.; Zhao, D.G.; Liu, Z.S.; Zhang, S.M.; Yang, H. Confinement factor and absorption loss of AlInGaN based laser diodes emitting from ultraviolet to green. J. Appl. Phys. 2009, 105, 023104. [Google Scholar]

- Leszczynski, M.; Czernecki, R.; Krukowski, S.; Krysko, M.; Targowski, G.; Prystawko, P.; Plesiewicz, J.; Perlin, P.; Suski, T. Indium incorporation into InGaN and InAlN layers grown by metalorganic vapor phase epitaxy. J. Cryst. Growth 2011, 318, 496–499. [Google Scholar] [CrossRef]

- Czernecki, R.; Kret, S.; Kempisty, P.; Grzanka, E.; Plesiewicz, J.; Targowski, G.; Grzanka, S.; Bilska, M.; Smalc-Koziorowska, J.; Krukowski, S.; et al. Influence of hydrogen and TMIn on indium incorporation in MOVPE growth of InGaN layers. J. Cryst. Growth 2014, 402, 330–336. [Google Scholar]

- Hardy, M.T.; Feezell, D.F.; DenBaars, S.P.; Nakamura, S. Group III-nitride lasers: A materials perspective. Mater. Today 2011, 14, 408–415. [Google Scholar] [CrossRef]

- Tian, A.Q.; Hu, L.; Zhang, L.Q.; Liu, J.P.; Yang, H. Design and growth of GaN-based blue and green laser diodes. Sci. China-Mater. 2020, 63, 1348–1363. [Google Scholar] [CrossRef]

- Nozaki, S.; Kawaguchi, M.; Morimoto, K.; Takigawa, S.; Katayama, T.; Tanaka, T. High-power Blue-violet InGaN Laser Diodes for White Spot Lighting Systems. J. Sci. Technol. Light. 2018, 41, 77–84. [Google Scholar] [CrossRef]

- Sze, S.M.; Li, Y.; Ng, K.K. Physics of Semiconductor Devices; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

| Layers in LD Structure | Al or In Composition (%) | Layer Thickness (nm) | Doping Type | Doping Concentration (cm−3) | Dopant |

|---|---|---|---|---|---|

| p-contact | 0 | 20 | p | 1 × 1020 | Mg |

| p-GaN | 0 | 50 | p | 1 × 1019 | Mg |

| p-AlGaN cladding layer | 7 | 600 | p | 5 × 1018 | Mg |

| p-AlGaN EBL | 20 | 20 | p | 1 × 1019 | Mg |

| p-side GaN WG | 0 | 100 | n | 5 × 1016 | u * |

| AlGaN/GaN CLQB | 5 | 30 | p | 2.5 × 1019 | Mg |

| /0 | /10 | /n | /5 × 1016 | /u | |

| InGaN QW | 10 | 6 | n | 5 × 1016 | u |

| GaN QB | 0 | 10 | n | 5 × 1016 | u |

| InGaN QW | 10 | 6 | n | 5 × 1016 | u |

| GaN QB | 0 | 10 | n | 5 × 1016 | u |

| n-side InGaN/GaN WG | 1 | 40 | n | 5 × 1016 | u |

| /0 | /80 | /n | /2 × 1017 | /Si | |

| n-AlGaN cladding layer | 7 | 800 | n | 5 × 1018 | Si |

| n-GaN substrate | 0 | 1000 | n | 1.5 × 1018 | u |

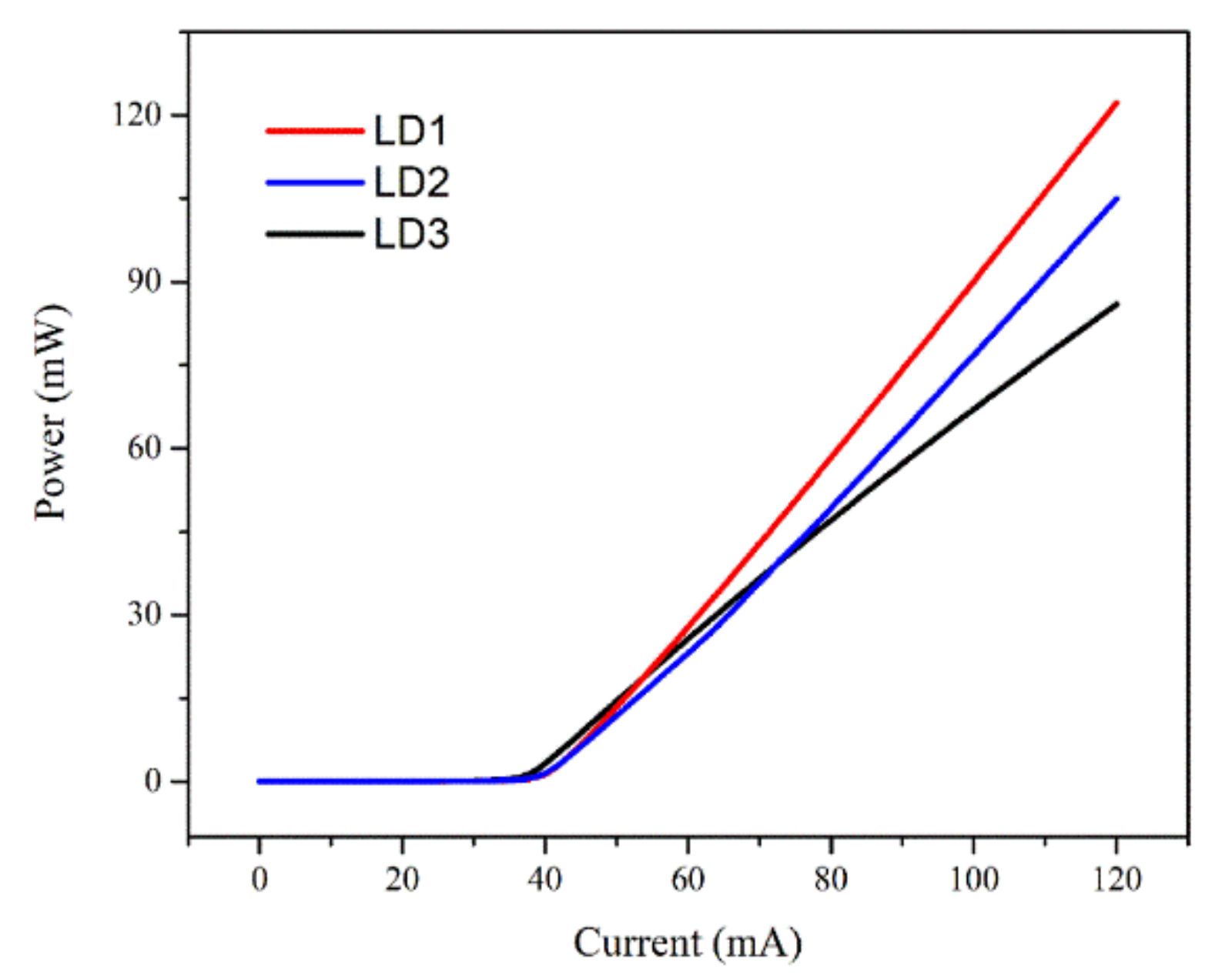

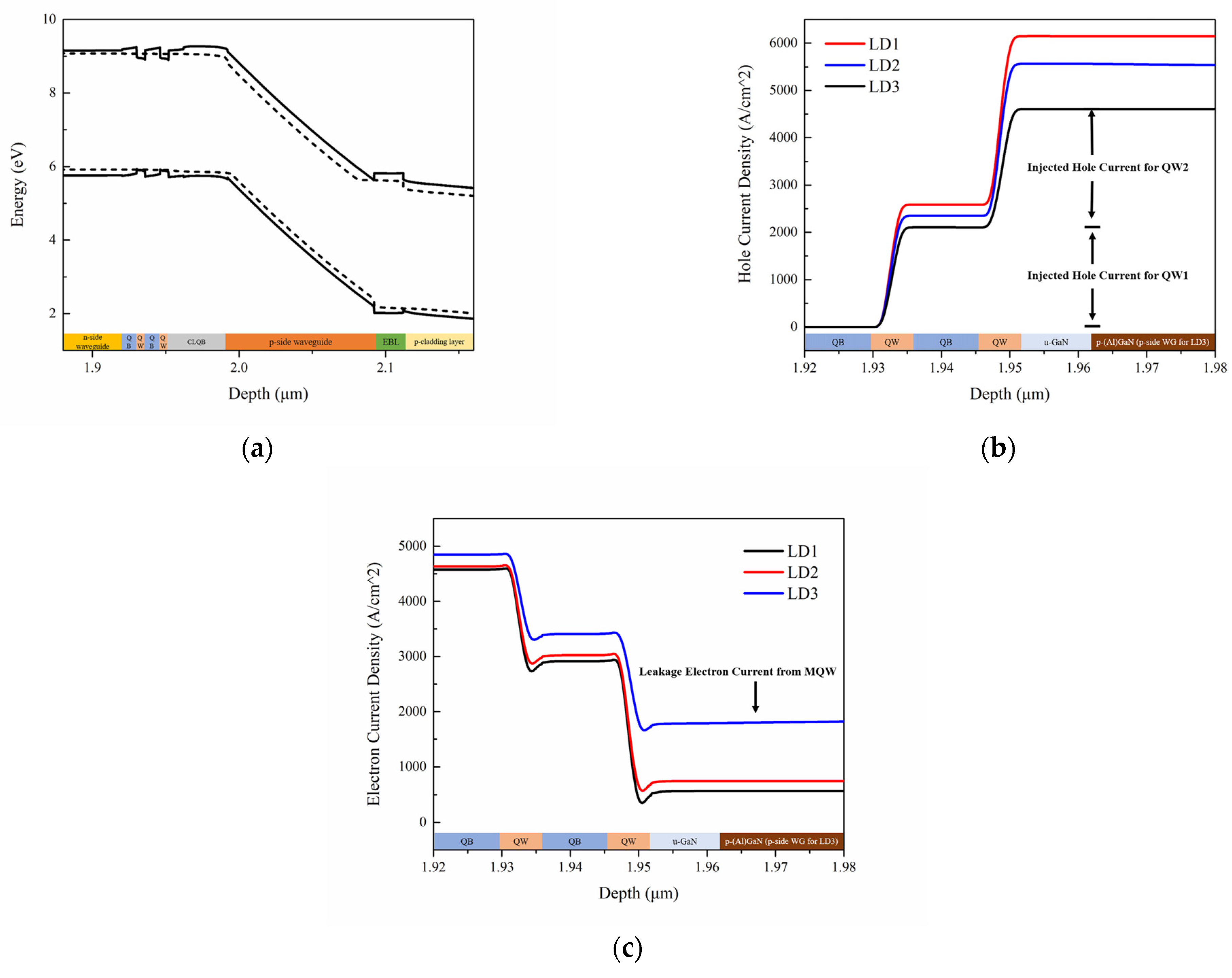

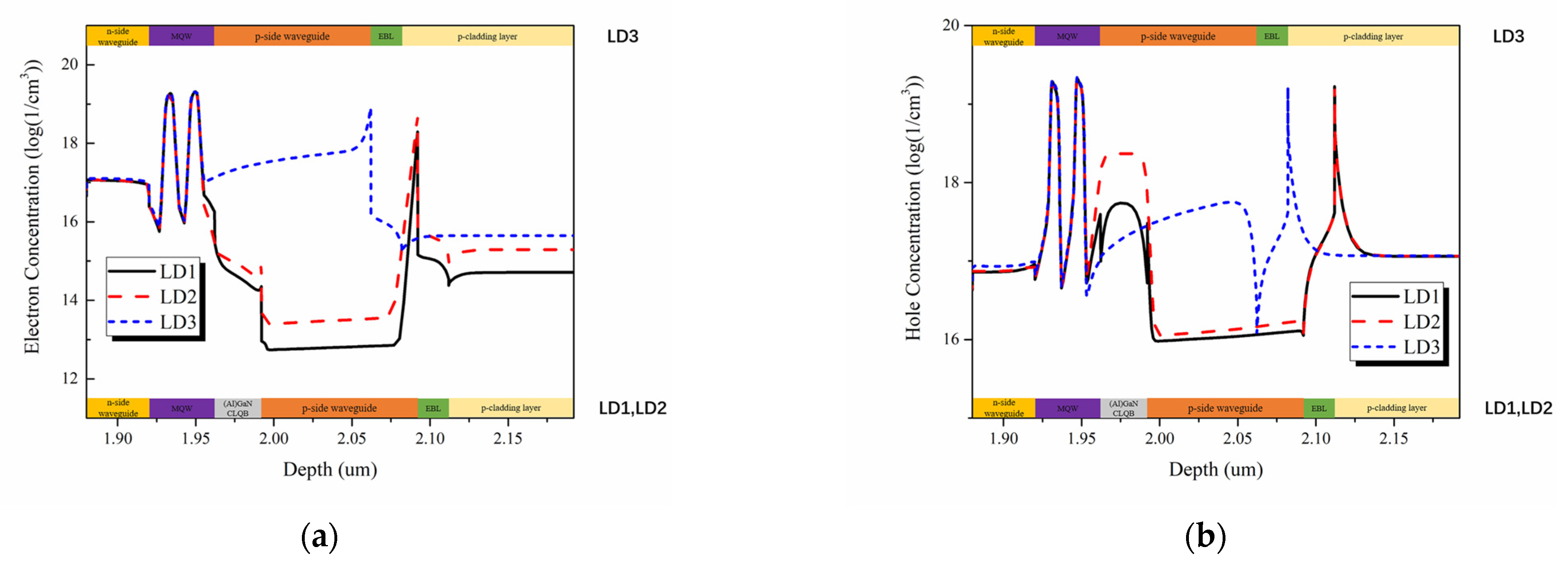

| LD1 | LD2 | LD3 | ||

|---|---|---|---|---|

| CLQB Structure Parameter | Structure | p-Al0.05Ga0.95N /u-GaN | p-GaN/ u-GaN | u-GaN |

| p-type Doping Concentration (1019 cm−3) | 2.5 | 50 | - | |

| Thickness of p-type Layer (nm) | 30 | 30 | - | |

| Performance | Power@120 mA (mW) | 128.8 | 105.0 | 85.9 |

| Threshold Current (mA) | 36.6 | 39.0 | 36.9 | |

| SE (W/A) | 1.53 | 1.28 | 1.02 | |

| LQB Barrier Height for Electron(meV) | 169.4 | 182.2 | 79.9 | |

| EOR (%) | 7.9 | 15.7 | 36.6 | |

| Average Injected Hole Current (A/cm2) | 2949 | 2785 | 2306 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Yang, J.; Zhao, D.; Liang, F.; Chen, P.; Liu, Z. Theoretical Optical Output Power Improvement of InGaN-Based Violet Laser Diode Using AlGaN/GaN Composite Last Quantum Barrier. Nanomaterials 2022, 12, 3990. https://doi.org/10.3390/nano12223990

Zhang Z, Yang J, Zhao D, Liang F, Chen P, Liu Z. Theoretical Optical Output Power Improvement of InGaN-Based Violet Laser Diode Using AlGaN/GaN Composite Last Quantum Barrier. Nanomaterials. 2022; 12(22):3990. https://doi.org/10.3390/nano12223990

Chicago/Turabian StyleZhang, Zhenzhuo, Jing Yang, Degang Zhao, Feng Liang, Ping Chen, and Zongshun Liu. 2022. "Theoretical Optical Output Power Improvement of InGaN-Based Violet Laser Diode Using AlGaN/GaN Composite Last Quantum Barrier" Nanomaterials 12, no. 22: 3990. https://doi.org/10.3390/nano12223990

APA StyleZhang, Z., Yang, J., Zhao, D., Liang, F., Chen, P., & Liu, Z. (2022). Theoretical Optical Output Power Improvement of InGaN-Based Violet Laser Diode Using AlGaN/GaN Composite Last Quantum Barrier. Nanomaterials, 12(22), 3990. https://doi.org/10.3390/nano12223990