A Review of Nanomaterials with Different Dimensions as Lubricant Additives

Abstract

:1. Introduction

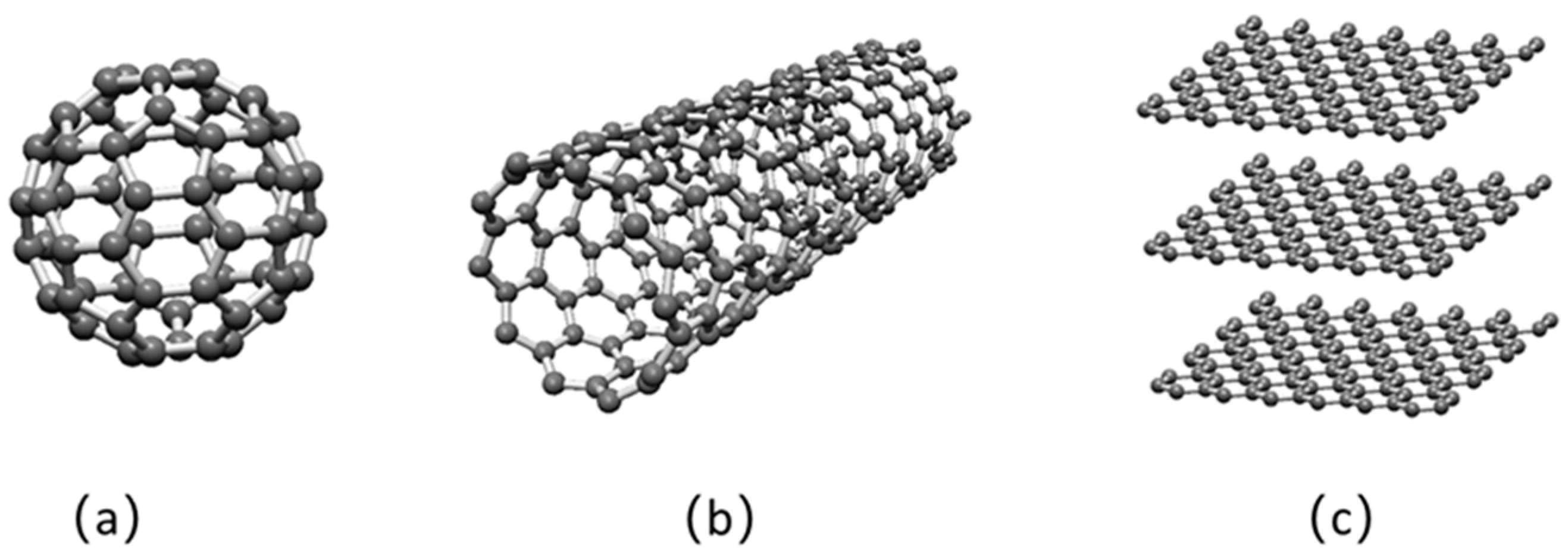

2. Single Nanoadditive

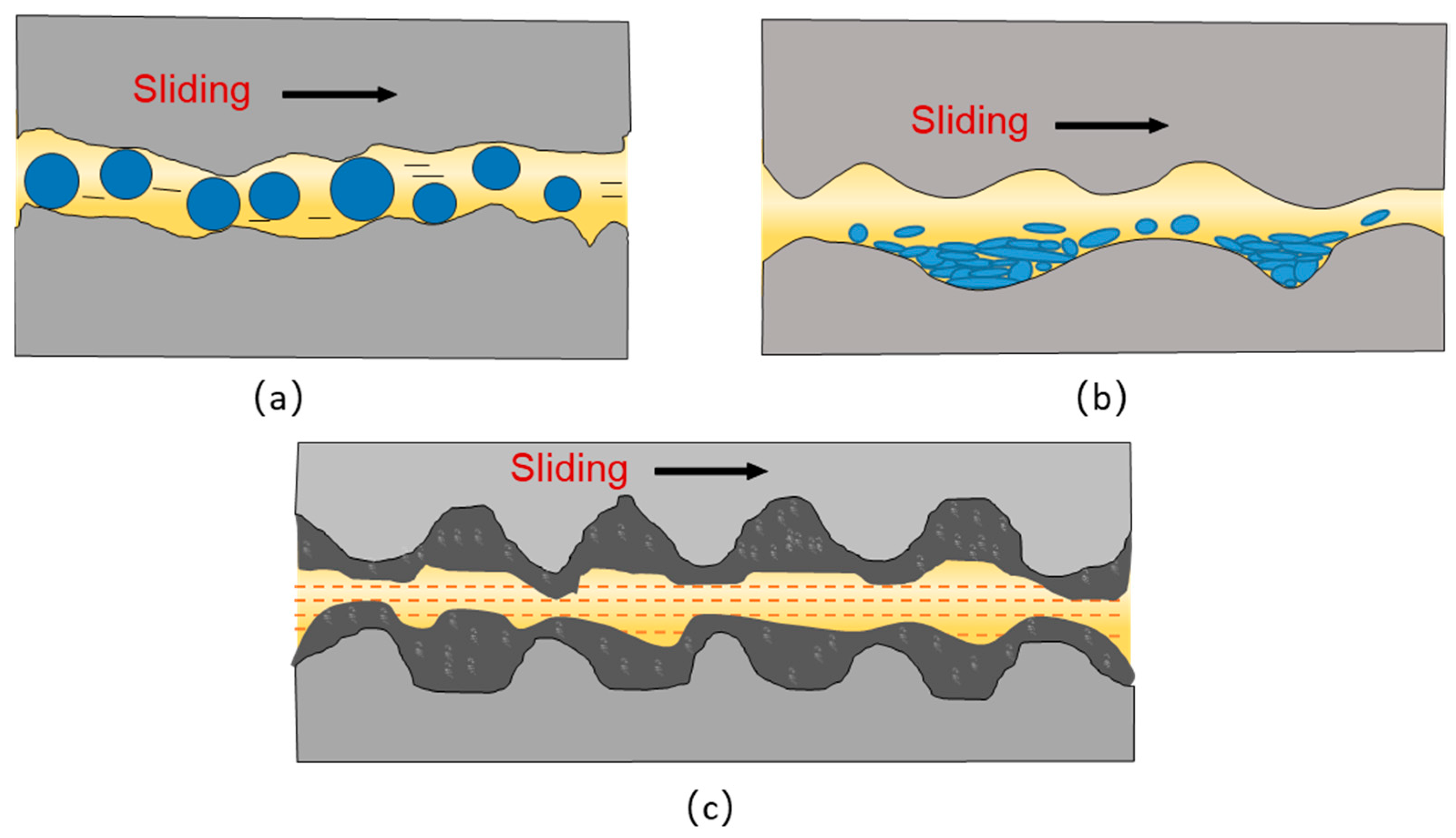

2.1. Zero-Dimensional Nanoadditive

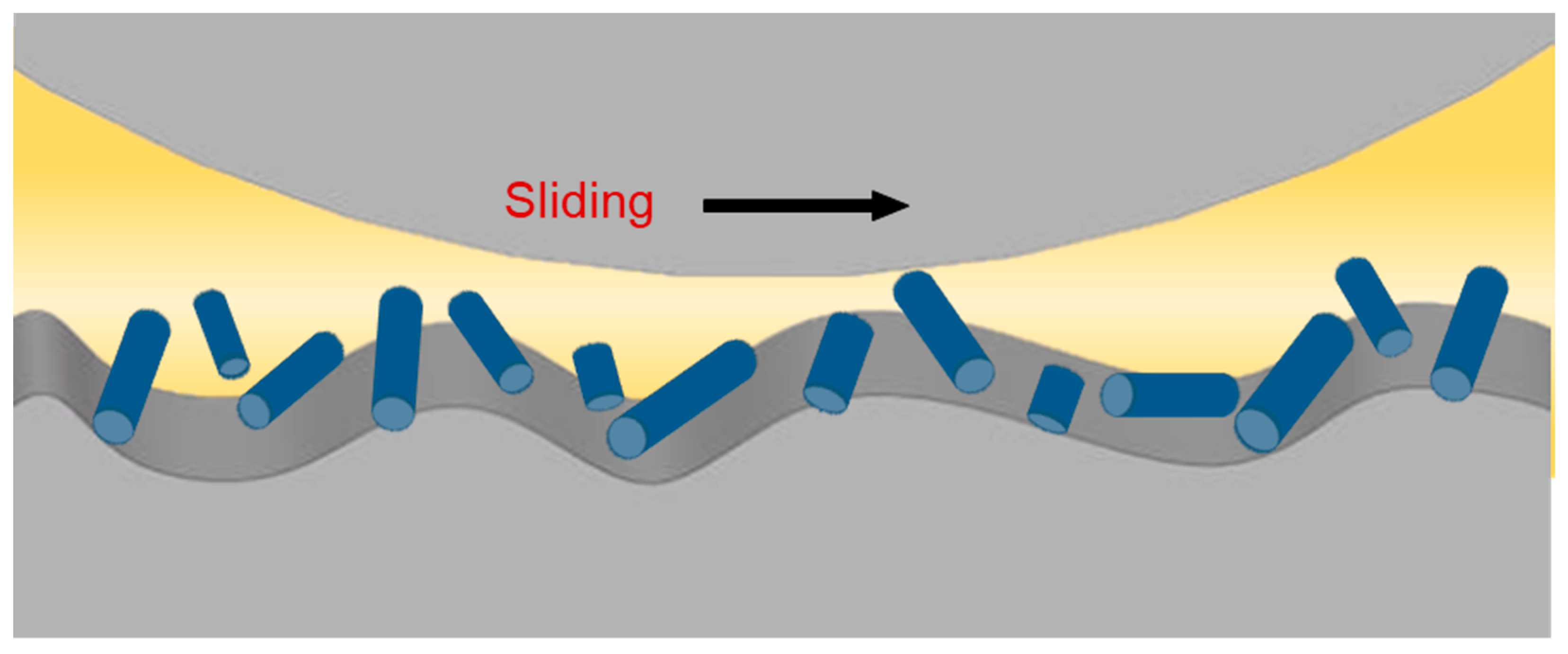

2.2. One-Dimensional Nanoadditives

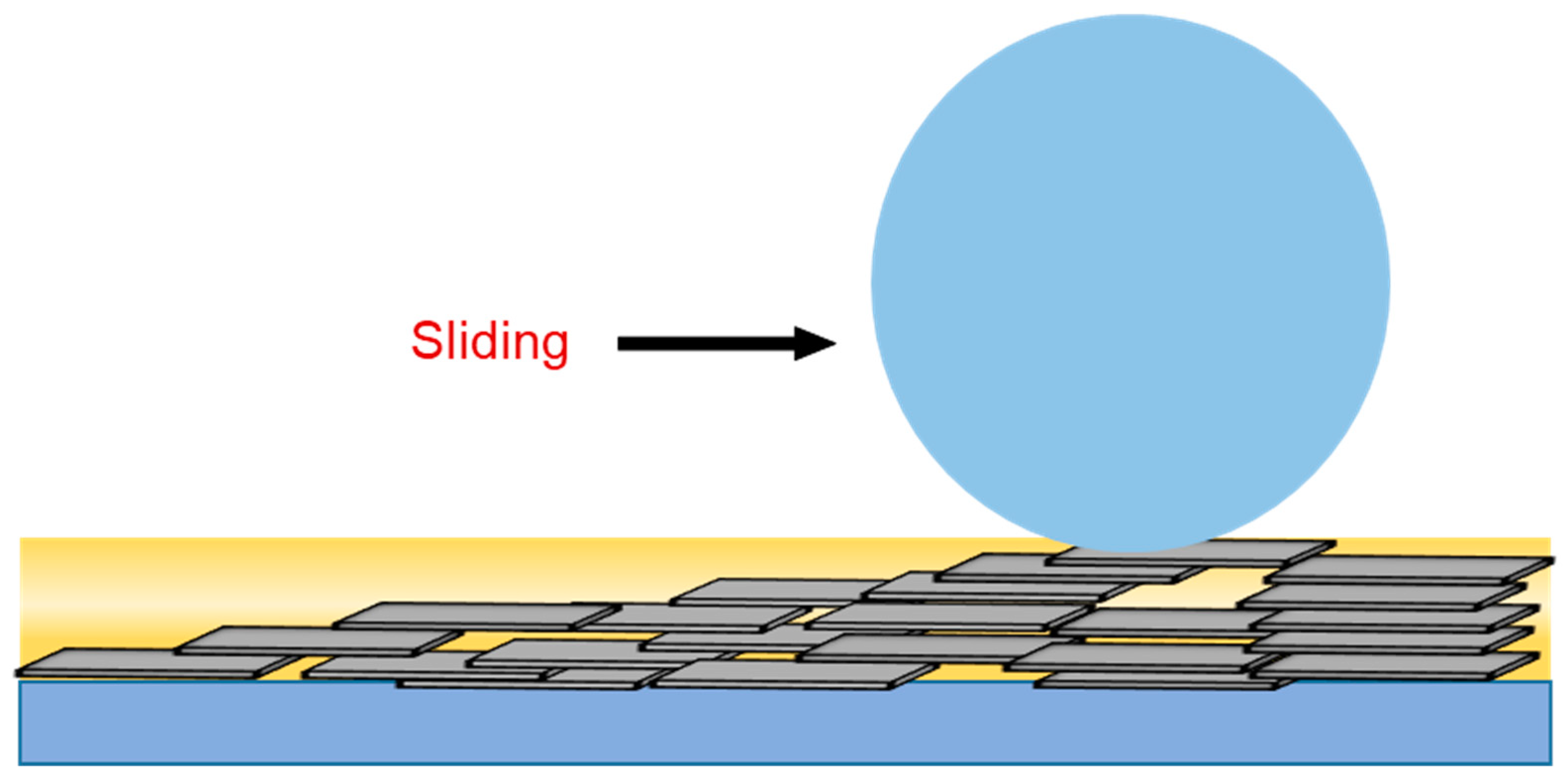

2.3. Two-Dimensional Nanoadditives

3. Composite Nanoadditives

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef] [Green Version]

- Luo, J.B. Investigation on the origin of friction and superlubricity. Chin. Sci. Bull. 2020, 65, 2966–2978. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8, 221–300. [Google Scholar] [CrossRef] [Green Version]

- Park, J.Y.; Salmeron, M. Fundamental aspects of energy dissipation in friction. Chem. Rev. 2014, 114, 677–711. [Google Scholar] [CrossRef]

- Huang, J.; Tan, J.; Fang, H.; Gong, F.; Wang, J. Tribological and wear performances of graphene-oil nanofluid under industrial high-speed rotation. Tribol. Int. 2019, 135, 112–120. [Google Scholar] [CrossRef]

- Mai, Y.J.; Chen, F.X.; Zhou, M.P.; Xiao, Q.N.; Cai, G.F.; Jie, X.H. Anchored graphene nanosheet films towards high performance solid lubricants. Mater. Des. 2018, 160, 861–869. [Google Scholar] [CrossRef]

- Xue, W.; Gao, S.; Duan, D.; Zheng, H.; Li, S. Investigation and simulation of the shear lip phenomenon observed in a high-speed abradable seal for use in aero-engines. Wear 2017, 386, 195–203. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, J.; Ge, S.; Zhang, D.; Shi, G. Mechanical behavior of hoisting rope in 2 km ultra deep coal mine. Eng. Fail. Anal. 2019, 106, 104185. [Google Scholar] [CrossRef]

- Stachowiak, G.; Batchelor, A.J.E.T. Lubricants and their composition. Eng. Tribol. 2006, 3, 51–101. [Google Scholar]

- Liu, G.; Li, X.; Qin, B.; Xing, D.; Guo, Y. Investigation of the mending effect and mechanism of copper nano-particles on a tribologically stressed surface. Tribol. Lett. 2004, 17, 961–966. [Google Scholar] [CrossRef]

- Battez, A.H.; Gonzalez, R.; Viesca, J.L. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 2008, 265, 422–428. [Google Scholar] [CrossRef]

- Chen, S.; Liu, W.; Yu, L. Preparation of DDP-coated PbS nanoparticles and investigation of the antiwear ability of the prepared nanoparticles as additive in liquid paraffin. Wear 1998, 218, 153–158. [Google Scholar] [CrossRef]

- Rapoport, L.; Feldman, Y.; Homyonfer, M.; Cohen, H.; Sloan, J.; Hutchison, J.L.; Tenne, R. Inorganic fullerene-like material as additives to lubricants: Structure–function relationship. Wear 1999, 225–229, 975–982. [Google Scholar] [CrossRef]

- Huang, H.D.; Tu, J.P.; Gan, L.P.; Li, C.Z. An investigation on tribological properties of graphite nanosheets as oil additive. Wear 2006, 261, 140–144. [Google Scholar] [CrossRef]

- Kumar, V.B.; Sahu, A.K.; Rao, K.B.S. Development of Doped Carbon Quantum Dot-Based Nanomaterials for Lubricant Additive Applications. Lubricants 2022, 10, 144. [Google Scholar] [CrossRef]

- Senatore, A.; Hong, H.; D’Urso, V.; Younes, H. Tribological Behavior of Novel CNTs-Based Lubricant Grease in Steady-State and Fretting Sliding Conditions. Lubricants 2021, 9, 107. [Google Scholar] [CrossRef]

- Zhang, B.S.; Xu, B.S.; Xu, Y.; Gao, F.; Shi, P.J.; Wu, Y.X. Cu nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel–steel contacts. Tribol. Int. 2011, 44, 878–886. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Tsui, W.C.; Liu, T.C. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Xia, R.; Lou, D.; Younes, H.; Haiston, J.; Chen, H.; Hong, H. Synergistic effect of hexagonal boron nitride and carbon nanofibers on tribological behavior of nanolubricant. Tribol. Int. 2022, 177, 107957. [Google Scholar] [CrossRef]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. C60:Buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Lopez, A.M.; Mateo-Alonso, A.; Prato, M. Materials chemistry of fullerene C60 derivatives. J. Mater. Chem. 2011, 21, 1305–1318. [Google Scholar] [CrossRef]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Liu, K.Q.; Gao, S.; Zheng, Z.; Deng, X.L.; Mukherjee, S.; Wang, S.S.; Xu, H.; Wang, J.Q.; Liu, J.F.; Zhai, T.Y.; et al. Spatially confined growth of fullerene to super-long crystalline fibers in supramolecular gels for high-performance photodetector. Adv. Mater. 2019, 31, 08254–08263. [Google Scholar] [CrossRef] [PubMed]

- Gresham, R.M.J.T. Lubricant Additives: Chemistry and Applications. Tribol. Lubr. Technol. 2017, 73, 112. [Google Scholar]

- Kumara, C.; Luo, H.; Leonard, D.N.; Meyer, H.M.; Qu, J. Organic-Modified Silver Nanoparticles as Lubricant Additives. ACS Appl. Mater. Interfaces 2017, 9, 37227–37237. [Google Scholar] [CrossRef] [PubMed]

- Ku, B.C.; Han, Y.C.; Lee, J.E.; Lee, J.K.; Park, S.H.; Hwang, Y.J. Tribological effects of fullerene (C60) nanoparticles added in mineral lubricants according to its viscosity. Int. J. Precis. Eng. Man. 2010, 11, 607–611. [Google Scholar] [CrossRef]

- Lee, J.; Cho, S.; Hwang, Y.; Cho, H.J.; Lee, C.; Choi, Y.; Ku, B.C.; Lee, H.; Lee, B.; Kim, D.; et al. Application of fullerene-added nano-oil for lubrication enhancement in friction surfaces. Tribol. Int. 2009, 42, 440–447. [Google Scholar] [CrossRef]

- Guzman Borda, F.L.; Ribeiro de Oliveira, S.J.; Seabra Monteiro Lazaro, L.M.; Kalab Leiróz, A.J. Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, L.; Feng, D.; Wang, H. Anti-wear and friction-reduction mechanism of Sn and Fe nanoparticles as additives of multialkylated cyclopentanes under vacuum condition. Vacuum 2013, 87, 75–80. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Mai, L.; Qingping, C.; Turkson, R.F.; Bicheng, C. Improving the tribological characteristics of piston ring assembly in automotive engines using Al2O3 and TiO2 nanomaterials as nano-lubricant additives. Tribol. Int. 2016, 103, 540–554. [Google Scholar] [CrossRef]

- Ingole, S.; Charanpahari, A.; Kakade, A.; Umare, S.S.; Bhatt, D.V.; Menghani, J. Tribological behavior of nano TiO2 as an additive in base oil. Wear 2013, 301, 776–785. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Huang, X.; Huang, L.; Yang, F. Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceram. Int. 2014, 40, 7143–7149. [Google Scholar] [CrossRef]

- Oh, G.H.; Kim, B.S.; Song, Y.; Kim, S. Acid treatment to tune the optical properties of carbon quantum dots. Appl. Surf. Sci. 2022, 605, 154690. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, S.; Xu, Q.; Zhang, H. Carbon quantum dots: An innovative additive for water lubrication. Sci. China Technol. Sci. 2018, 62, 587–596. [Google Scholar] [CrossRef]

- Hu, J.T.; Odom, T.W.; Lieber, C.M. Chemistry and Physics in One Dimension: Synthesis and Properties of Nanowires and Nanotubes. Acc. Chem. Res. 1999, 32, 435–445. [Google Scholar] [CrossRef]

- Salah, N.; Abdel-Wahab, M.S.; Alshahrie, A.; Alharbi, N.D.; Khan, Z.H. Carbon nanotubes of oil fly ash as lubricant additives for different base oils and their tribology performance. RSC Adv. 2017, 7, 40295–40302. [Google Scholar] [CrossRef] [Green Version]

- Ye, X.; E, S.; Fan, M. The influences of functionalized carbon nanotubes as lubricating additives: Length and diameter. Diam. Relat. Mater. 2019, 100, 107548. [Google Scholar] [CrossRef]

- Christensen, G.; Younes, H.; Hong, G.; Lou, D.; Hong, H.; Widener, C.; Bailey, C.; Hrabe, R. Hydrogen bonding enhanced thermally conductive carbon nano grease. Synth. Met. 2020, 259, 116213. [Google Scholar] [CrossRef]

- Khalil, W.; Mohamed, A.; Bayoumi, M.; Osman, T.A. Tribological properties of dispersed carbon nanotubes in lubricant. Fuller. Nanotub. Carbon Nanostructures 2016, 24, 479–485. [Google Scholar] [CrossRef]

- Gong, K.; Wu, X.; Zhao, G.; Wang, X. Tribological properties of polymeric aryl phosphates grafted onto multi-walled carbon nanotubes as high-performances lubricant additive. Tribol. Int. 2017, 116, 172–179. [Google Scholar] [CrossRef]

- Cornelio, J.A.C.; Cuervo, P.A.; Hoyos-Palacio, L.M.; Lara-Romero, J.; Toro, A. Tribological properties of carbon nanotubes as lubricant additive in oil and water for a wheel–rail system. J. Mater. Res. Technol. 2016, 5, 68–76. [Google Scholar] [CrossRef] [Green Version]

- Kumar, H.; Harsha, A.P. Enhanced Lubrication Ability of Polyalphaolefin and Polypropylene Glycol by COOH-Functionalized Multiwalled Carbon Nanotubes as an Additive. J. Mater. Eng. Perform. 2021, 30, 1075–1089. [Google Scholar] [CrossRef]

- Zhang, L.L.; Tu, J.P.; Wu, H.M.; Yang, Y.Z. WS2 nanorods prepared by self-transformation process and their tribological properties as additive in base oil. Mater. Sci. Eng. A 2007, 454–455, 487–491. [Google Scholar] [CrossRef]

- Rajkumar, R.M.; Kiruthiga, K.; Induja, S.; Raghavan, P.S.; Shafee, M.; Pandiyan, P.; Sathyamurthy, R.; Sekhar, S.C.; Kabeel, A.E. Studies on tribological behaviour of ZnO nanorods suspended in SAE 20w 40 engine oil. Solid State Commun. 2021, 328, 114235. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, D. Preparation and tribological properties of unmodified and oleic acid-modified CuS nanorods as lubricating oil additives. Ceram. Int. 2017, 43, 4246–4251. [Google Scholar] [CrossRef]

- Wu, P.R.; Liu, Z.; Cheng, Z.L. Growth of MoS2 Nanotubes Templated by Halloysite Nanotubes for the Reduction of Friction in Oil. ACS Omega 2018, 3, 15002–15008. [Google Scholar] [CrossRef] [Green Version]

- Jiang, L.; Dong, H.L.; Hu, W.P. Controlled growth and assembly of one-dimensional ordered nanostructures of organic functional materials. Soft. Matter 2011, 7, 1615–1630. [Google Scholar] [CrossRef]

- Bhaumik, S.; Maggirwar, R.; Datta, S.; Pathak, S.D. Analyses of anti-wear and extreme pressure properties of castor oil with zinc oxide nano friction modifiers. Appl. Surf. Sci. 2018, 449, 277–286. [Google Scholar] [CrossRef]

- Liu, N.; Tian, Y.M.; Yu, L.X.; Li, Q.J.; Meng, F.Y.; Zheng, Y.H.; Zhang, G.Y.; Liu, Z.H.; Li, J.; Jiang, F.M. Synthesis and surface modification of uniform barium borate nanorods for lubrication. J. Alloys Compd. 2008, 466, 11–14. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, S. 2D nanomaterials as lubricant additive: A review. Mater. Des. 2017, 135, 319–332. [Google Scholar] [CrossRef]

- Guo, Y.B.; Zhang, S.W. The Tribological Properties of Multi-Layered Graphene as Additives of PAO2 Oil in Steel–Steel Contacts. Lubricants 2016, 4, 30. [Google Scholar] [CrossRef] [Green Version]

- Azman, S.S.N.; Zulkifli, N.W.M.; Masjuki, H.; Gulzar, M.; Zahid, R. Study of tribological properties of lubricating oil blend added with graphene nanoplatelets. J. Mater. Res. 2016, 31, 1932–1938. [Google Scholar] [CrossRef]

- La, D.D.; Truong, T.N.; Pham, T.Q.; Vo, H.T.; Tran, N.T.; Nguyen, T.A.; Nadda, A.K.; Nguyen, T.T.; Chang, S.W.; Chung, W.J.; et al. Scalable Fabrication of Modified Graphene Nanoplatelets as an Effective Additive for Engine Lubricant Oil. Nanomaterials 2020, 10, 877. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Kim, S.H.; Cho, D.H. Tribological properties of chemical vapordeposited grapheme coating layer. J. Korean Inst. Met. Mater. 2012, 50, 206–211. [Google Scholar]

- Cho, D.H.; Kim, J.S.; Kwon, S.H.; Lee, C.; Lee, Y.Z. Evaluation of hexagonal boron nitride nano-sheets as a lubricant additive in water. Wear 2013, 302, 981–986. [Google Scholar] [CrossRef]

- Wang, Y.; Du, Y.; Deng, J.; Wang, Z. Friction reduction of water based lubricant with highly dispersed functional MoS2 nanosheets. Colloids Surf. A Physicochem. Eng. Asp. 2019, 562, 321–328. [Google Scholar] [CrossRef]

- Guo, J.; Wu, P.; Zeng, C.; Wu, W.; Zhao, X.; Liu, G.; Zhou, F.; Liu, W. Fluoropolymer grafted Ti3C2Tx MXene as an efficient lubricant additive for fluorine-containing lubricating oil. Tribol. Int. 2022, 170, 107500. [Google Scholar] [CrossRef]

- Ariharan, A.; Viswanathan, B.; Nandhakumar, V. Hydrogen storage on boron substituted carbon materials. Int. J. Hydrogen. Energy 2016, 41, 3527–3536. [Google Scholar] [CrossRef]

- Moore, A.W. Characterization of pyrolytic boron nitride for semiconductor materials processing. J. Cryst. Growth 1990, 106, 6–15. [Google Scholar] [CrossRef]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef]

- Peng, M.K.; Wang, L.; Li, L.B.; Tang, X.N.; Huang, B.Y.; Hu, T.; Yuan, K.; Chen, Y.W. Manipulating the Interlayer Spacing of 3D MXenes with Improved Stability and Zinc-Ion Storage Capability. Adv. Funct. Mater. 2022, 32, 2109524. [Google Scholar] [CrossRef]

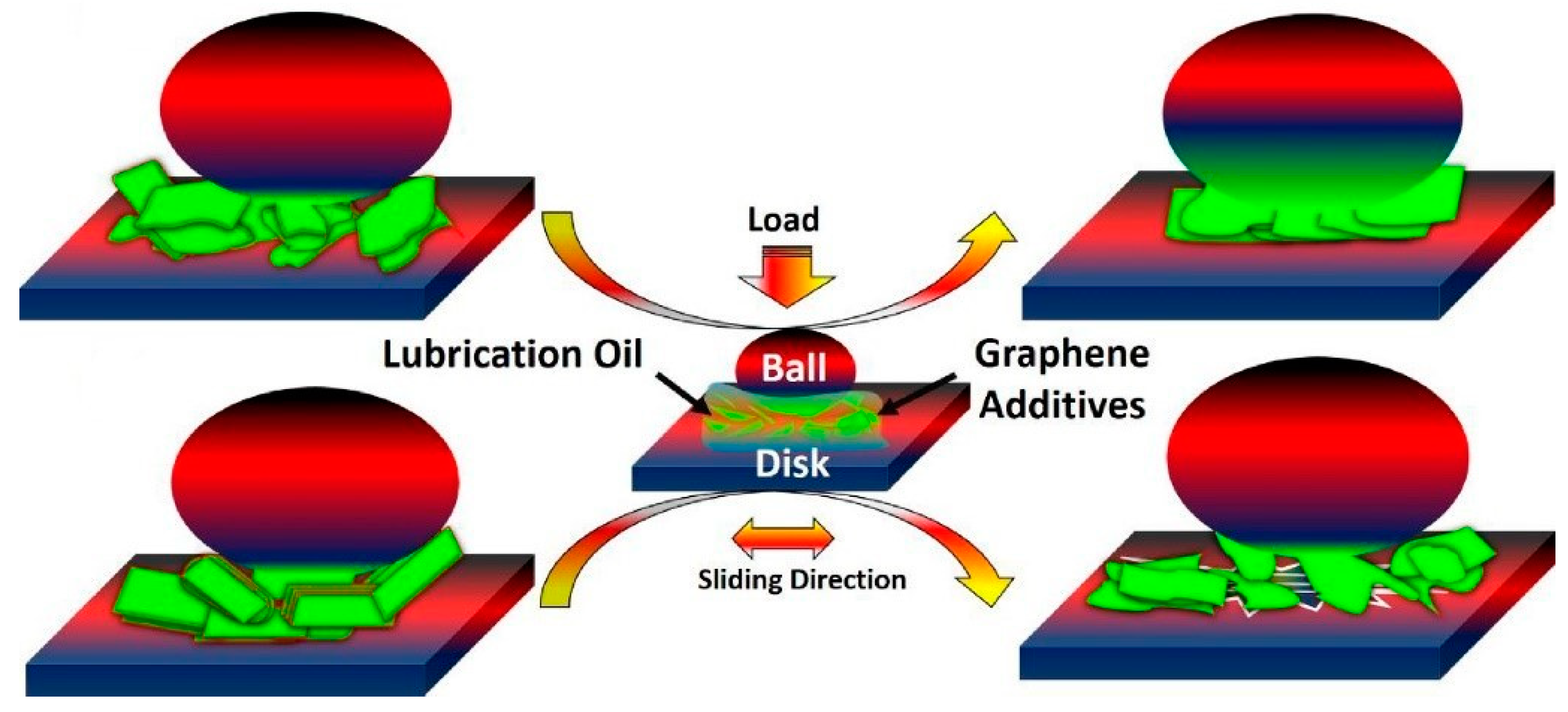

- Zhao, J.; Mao, J.; Li, Y.; He, Y.; Luo, J. Friction-induced nano-structural evolution of graphene as a lubrication additive. Appl. Surf. Sci. 2018, 434, 21–27. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Wang, Y.; Mao, J.; He, Y.; Luo, J. Mild thermal reduction of graphene oxide as a lubrication additive for friction and wear reduction. RSC Adv. 2017, 7, 1766–1770. [Google Scholar] [CrossRef]

- Gan, C.; Liang, T.; Li, X.; Li, W.; Li, H.; Fan, X.; Zhu, M. Ultra-dispersive monolayer graphene oxide as water-based lubricant additive: Preparation, characterization and lubricating mechanisms. Tribol. Int. 2021, 155, 106768. [Google Scholar] [CrossRef]

- Cheng, Z.L.; Li, W.; Wu, P.R.; Liu, Z. Study on structure-activity relationship between size and tribological properties of graphene oxide nanosheets in oil. J. Alloys Compd. 2017, 722, 778–784. [Google Scholar] [CrossRef]

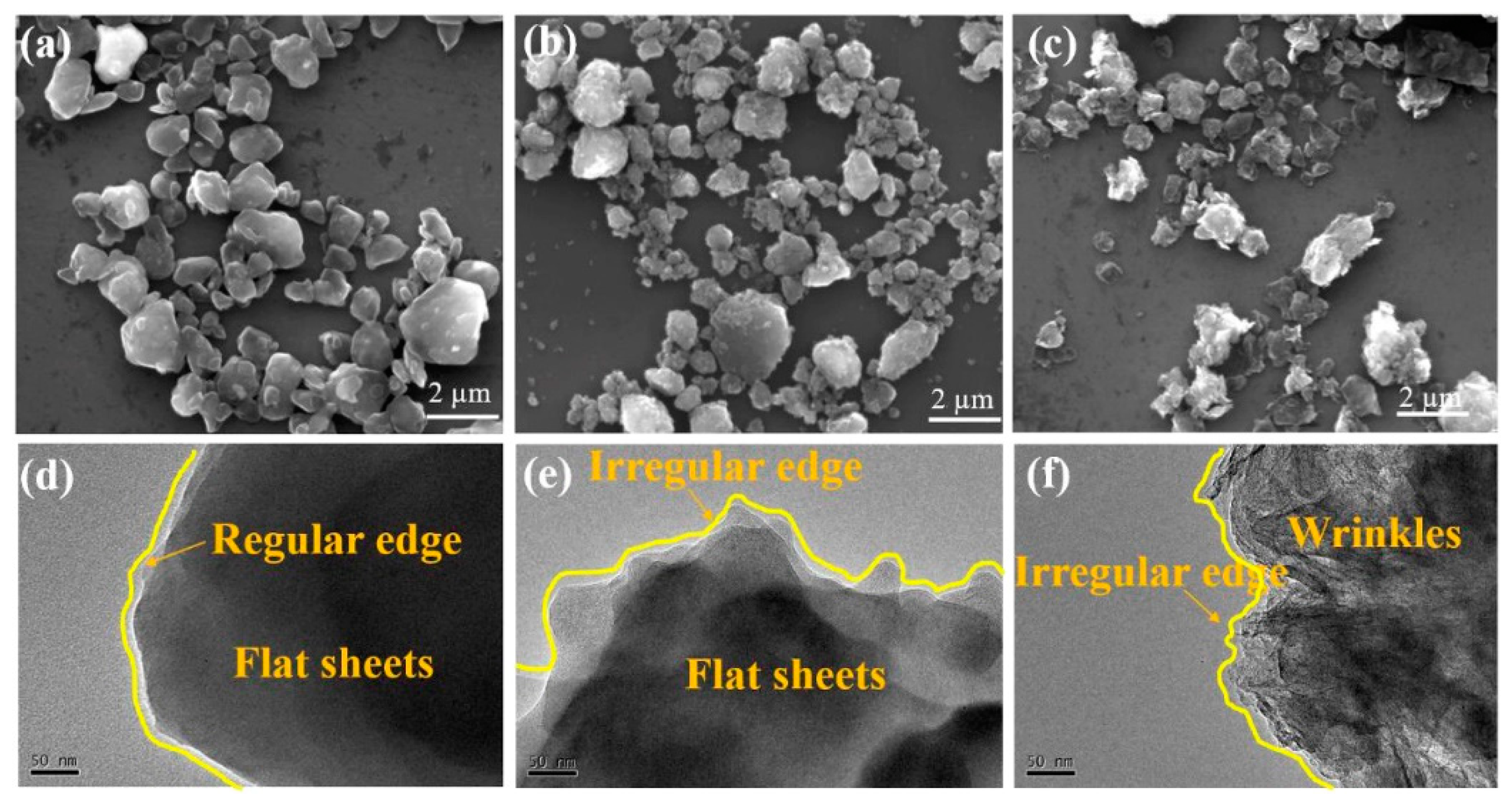

- Mao, J.; Zhao, J.; Wang, W.; He, Y.; Luo, J. Influence of the micromorphology of reduced graphene oxide sheets on lubrication properties as a lubrication additive. Tribol. Int. 2018, 119, 614–621. [Google Scholar] [CrossRef]

- Buchsteiner, A.; Lerf, A.; Pieper, J. Water Dynamics in Graphite Oxide Investigated with Neutron Scattering. J. Phys. Chem. B 2006, 110, 22328–22338. [Google Scholar] [CrossRef]

- Hou, K.M.; Gong, P.W.; Wang, J.Q.; Yang, Z.G.; Wang, Z.F.; Yang, S.R. Structural and tribological characterization of fluorinated graphene with various fluorine contents prepared by liquid-phase exfoliation. RSC Adv. 2014, 4, 56543–56551. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, E.; Zhong, H.; Wang, J.; Subedi, A.; Hu, K.; Hu, X. Characterization and Tribological Performances of Graphene and Fluorinated Graphene Particles in PAO. Nanomaterials 2021, 11, 2126. [Google Scholar] [CrossRef]

- Li, Y.R.; Zhao, J.; Tang, C.; He, Y.Y.; Wang, Y.F.; Chen, J.; Mao, J.Y.; Zhou, Q.Q.; Wang, B.Y.; Wei, F.; et al. Highly Exfoliated Reduced Graphite Oxide Powders as Efficient Lubricant Oil Additives. Adv. Mater. Interfaces 2016, 3, 1600700. [Google Scholar] [CrossRef]

- Yu, B.; Wang, K.; Pang, X.; Wu, G.; Pu, J.; Zhao, H. Tribological properties of alkylated reduced graphene oxide as lubricant additive. Tribol. Int. 2022, 165, 107273. [Google Scholar] [CrossRef]

- Wu, P.; Chen, X.; Zhang, C.; Zhang, J.; Luo, J.; Zhang, J. Modified graphene as novel lubricating additive with high dispersion stability in oil. Friction 2020, 9, 143–154. [Google Scholar] [CrossRef] [Green Version]

- Song, I.; Park, C.; Choi, H.C. Synthesis and properties of molybdenum disulphide: From bulk to atomic layers. RSC Adv. 2015, 5, 7495–7514. [Google Scholar] [CrossRef]

- Donnet, C.; Martin, J.M.; LeMogne, T.; Belin, M. Super-low friction of MoS2 coatings in various environments. Tribol. Int. 1996, 29, 123–128. [Google Scholar] [CrossRef]

- Zhao, J.; He, Y.; Wang, Y.; Wang, W.; Yan, L.; Luo, J. An investigation on the tribological properties of multilayer graphene and MoS2 nanosheets as additives used in hydraulic applications. Tribol. Int. 2016, 97, 14–20. [Google Scholar] [CrossRef]

- Scharf, T.; Prasad, S. Solid lubricants: A review. Mater. Sci. 2013, 48, 511–531. [Google Scholar] [CrossRef]

- Falvo, M.R.; Clary, G.J.; Taylor, R.M., II; Chi, V.; Brooks, F.P., Jr.; Washburn, S.; Superfine, R. Bending and buckling of carbon nanotubes under large strain. Nature 1997, 389, 582–584. [Google Scholar] [CrossRef]

- Bin Abdollah, M.F.; Amiruddin, H.; Alif Azmi, M.; Mat Tahir, N.A. Lubrication mechanisms of hexagonal boron nitride nano-additives water-based lubricant for steel–steel contact. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 1038–1046. [Google Scholar] [CrossRef]

- Ma, Z.S.; Ding, H.L.; Liu, Z.; Cheng, Z.L. Preparation and tribological properties of hydrothermally exfoliated ultrathin hexagonal boron nitride nanosheets (BNNSs) in mixed NaOH/KOH solution. J. Alloys Compd. 2019, 784, 807–815. [Google Scholar] [CrossRef]

- Yi, S.; Li, J.; Liu, Y.; Ge, X.; Zhang, J.; Luo, J. In-situ formation of tribofilm with Ti3C2Tx MXene nanoflakes triggers macroscale superlubricity. Tribol. Int. 2021, 154, 106695. [Google Scholar] [CrossRef]

- Zhou, X.; Guo, Y.; Wang, D.; Xu, Q. Nano friction and adhesion properties on Ti3C2 and Nb2C MXene studied by AFM. Tribol. Int. 2021, 153, 106646. [Google Scholar] [CrossRef]

- Yi, S.; Guo, Y.; Li, J.; Zhang, Y.; Zhou, A.; Luo, J. Two-dimensional molybdenum carbide (MXene) as an efficient nanoadditive for achieving superlubricity under ultrahigh pressure. Friction 2022. [Google Scholar] [CrossRef]

- Shin, Y.J.; Stromberg, R.; Nay, R.; Huang, H.; Wee, A.T.S.; Yang, H.; Bhatia, C.S. Frictional characteristics of exfoliated and epitaxial graphene. Carbon 2011, 49, 4070–4073. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of Nanoparticles in Lubricating Oil: A Critical Review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.G.; Yun, T.; Chae, J.; Yang, G.G.; Lee, G.S.; Kim, I.H.; Jung, H.J.; Hwang, H.S.; Kim, J.T.; Choi, S.Q.; et al. Molecular-Level Lubrication Effect of 0D Nanodiamonds for Highly Bendable Graphene Liquid Crystalline Fibers. ACS Appl. Mater. Interfaces 2022, 14, 13601–13610. [Google Scholar] [CrossRef]

- Wang, J.; Zhuang, W.; Yan, T.; Liang, W.; Li, T.; Zhang, L.; Wei, X. Tribological performances of copper perrhenate/graphene nanocomposite as lubricating additive under various temperatures. J. Ind. Eng. Chem. 2021, 100, 296–309. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Effective lubricant additive of nano-Ag/MWCNTs nanocomposite produced by supercritical CO2 synthesis. Tribol. Int. 2018, 118, 180–188. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Deng, Y.; Chen, S.; Liang, W.; Zhang, L.; Wei, X.; Gao, S.; Wan, Y. Carbon quantum dots doped with silver as lubricating oil additive for enhancing tribological performance at various temperatures. Appl. Surf. Sci. 2022, 599, 154029. [Google Scholar] [CrossRef]

- Kumari, S.; Chouhan, A.; Siva Kumar Konathala, L.N.; Sharma, O.P.; Ray, S.S.; Ray, A.; Khatri, O.P. Chemically functionalized 2D/2D hexagonal boron Nitride/Molybdenum disulfide heterostructure for enhancement of lubrication properties. Appl. Surf. Sci. 2022, 579, 152157. [Google Scholar] [CrossRef]

| Two-Dimensional Nanomaterials | Layer Spacing | Reference |

|---|---|---|

| Graphene | About 0.335 nm | [58] |

| Hexagonal boron nitride | About 0.333 nm | [59] |

| Molybdenum disulfide | About 0.65 nm | [60] |

| MXene | About 1.23–1.40 nm | [61] |

| Dimensions of Nanoadditives | Nanomaterials | Lubricant | Optimal Concentration (wt%) | Operating Condition | Effect | Major Mechanism | Reference | |

|---|---|---|---|---|---|---|---|---|

| Antiwear | Friction Reduction | |||||||

| Zero dimension | C60 | Refrigerant oil | 0.1 | 1000 rpm; 1200 N; GC200 disk-on-GC200 disk | - | 33% | “Rolling bearing” effect; film-formation mechanism | [26] |

| Cu | Paraffinic mineral | 0.3 | 0.6 m/s; 588 N; AISI 1020 pin-on-AISI 52100 disk | 64% | 60% | Film-formation mechanism; mending or self-repairing effect | [28] | |

| Ag | PAO base oil | 0.38 | 0.5 m/s; 100 N; AISI 52100 steel ball-on-A2 tool steel disk | 85% | 35% | Film-formation mechanism; “rolling bearing” effect | [25] | |

| Fe | MAC | 0.2 | 1450 r/min; 300 N; AISI 52100 four-balls | - | 25% | Film-formation mechanism; mending or self-repairing effect | [29] | |

| Al2O3 | Base oil | 0.1 | 1450 r/min; 147 N; GCr15 four-balls | 41.75% | 23.92% | Film-formation mechanism; “rolling bearing” effect | [32] | |

| CQDs | Deionized water | 0.25 | 1.5 m/min; 2 N; Si3N4 ball-on-Si3N4 disk | - | 30% | “Rolling bearing” effect; film-formation mechanism | [34] | |

| One dimension | CNTs | PAG | 0.08 | 3 m/min; 50 N; AISI 52100 ball-on-AISI 52100 disk | - | 57% | Film-formation mechanism | [40] |

| ZnO nanorod | SAE(20W-40) | 0.02 | 1200 rpm; 400 N; AISI E52100 four-balls | - | 27.6% | “rolling bearing” effect | [44] | |

| CuS nanorod | Liquid paraffin | 2 | 300 rpm; 300 N; Pig iron pin-on-bearing steel disk | 10% | 50% | Film-formation mechanism | [45] | |

| MoS2 nanorod | 150 SN base oil | 0.08 | 1200 rpm; 100N; GCr15 four-balls | 35% | 39.2% | “Rolling bearing” effect; film-formation mechanism | [46] | |

| Two dimension | Graphene | PAO6 | 0.5 | 0.144 m/min; 2 N; AISI 52100 ball-on-AISI 52100 disk | - | 50% | Interlayer sliding | [62] |

| RGO | PAO6 | 0.5 | 0.144 m/min; 2 N; GCr15 ball-on-GCr15 disk | - | 30% | Interlayer sliding; film-formation mechanism | [63] | |

| F-Gr | PAO6 | 1 | 10 mm/s; 50 N; bearing steel ball-on-GCr15 steel disks | 12.30% | 87% | Film-formation mechanism | [69] | |

| MoS2 | Hydraulic oil | 0.1 | 2.4 mm/s; 3 N; GCr 15 ball-on-H62 brass disk | _ | 82% | Film-formation mechanism | [75] | |

| h-BN | Mineral lube | 0.06 | 1200 rpm; 100 N; four-balls | 35.20% | 35.70% | Interlayer sliding; film-formation mechanism | [79] | |

| MXene | Lithium hexafluorophosphate-based ionic liquid | 0.166 | 1200 rpm; 392 N; AISI 52100 four balls | - | 92% | Film-formation mechanism | [82] | |

| Dimensions of Nanoadditives | Lubrication Mechanisms | |

|---|---|---|

| Zero dimension | “Ball roller bearing” effect | Film-formation mechanism and mending or self-repairing effect |

| One dimension | “Cylindrical roller bearing” effect | |

| Two dimension | Interlayer sliding | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Qiao, X.; Liu, S.; Chen, P. A Review of Nanomaterials with Different Dimensions as Lubricant Additives. Nanomaterials 2022, 12, 3780. https://doi.org/10.3390/nano12213780

Liu W, Qiao X, Liu S, Chen P. A Review of Nanomaterials with Different Dimensions as Lubricant Additives. Nanomaterials. 2022; 12(21):3780. https://doi.org/10.3390/nano12213780

Chicago/Turabian StyleLiu, Wenwen, Xiaoxi Qiao, Shida Liu, and Ping Chen. 2022. "A Review of Nanomaterials with Different Dimensions as Lubricant Additives" Nanomaterials 12, no. 21: 3780. https://doi.org/10.3390/nano12213780

APA StyleLiu, W., Qiao, X., Liu, S., & Chen, P. (2022). A Review of Nanomaterials with Different Dimensions as Lubricant Additives. Nanomaterials, 12(21), 3780. https://doi.org/10.3390/nano12213780