Preparation of Nickel Oxide Nanoflakes for Carrier Extraction and Transport in Perovskite Solar Cells

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

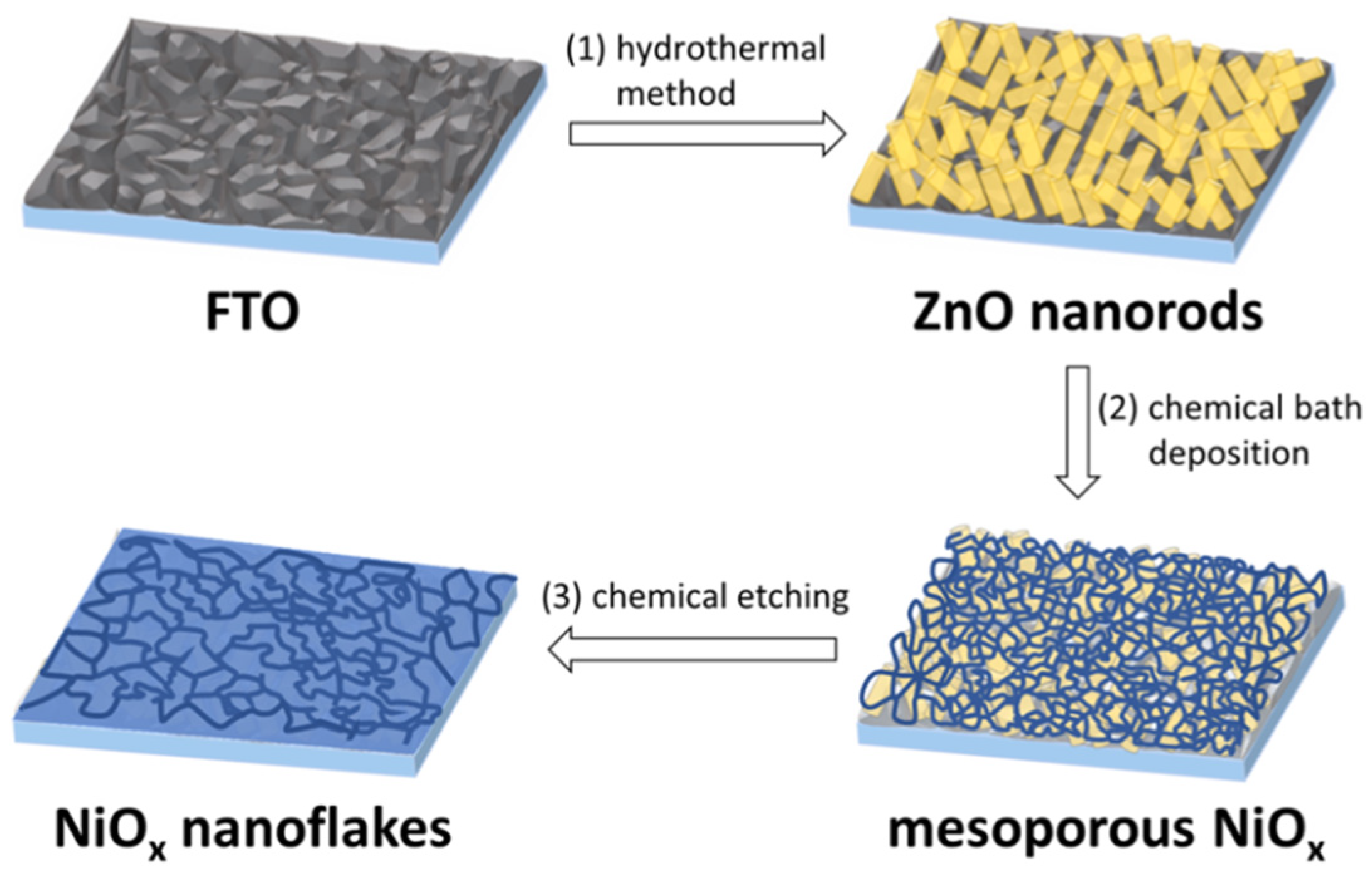

2.2. Preparation of NiOx Thin Films and Nanoflakes

2.3. Device Fabrication

2.4. Characterization Methods

3. Results and Discussion

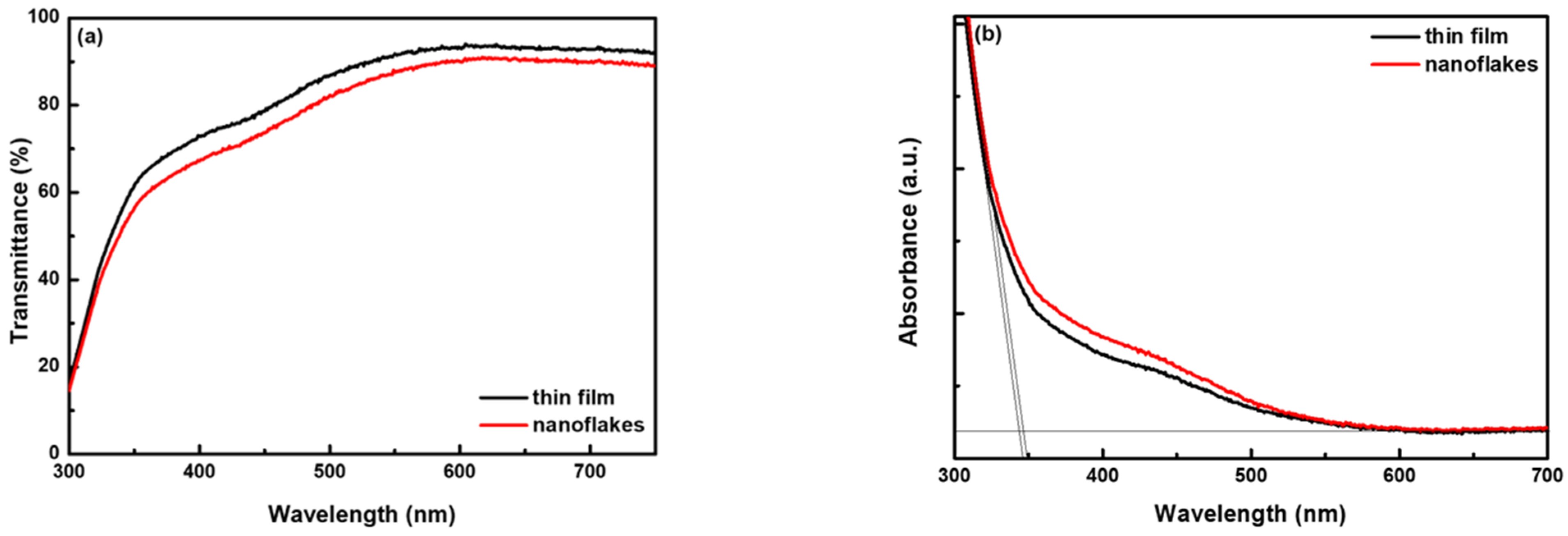

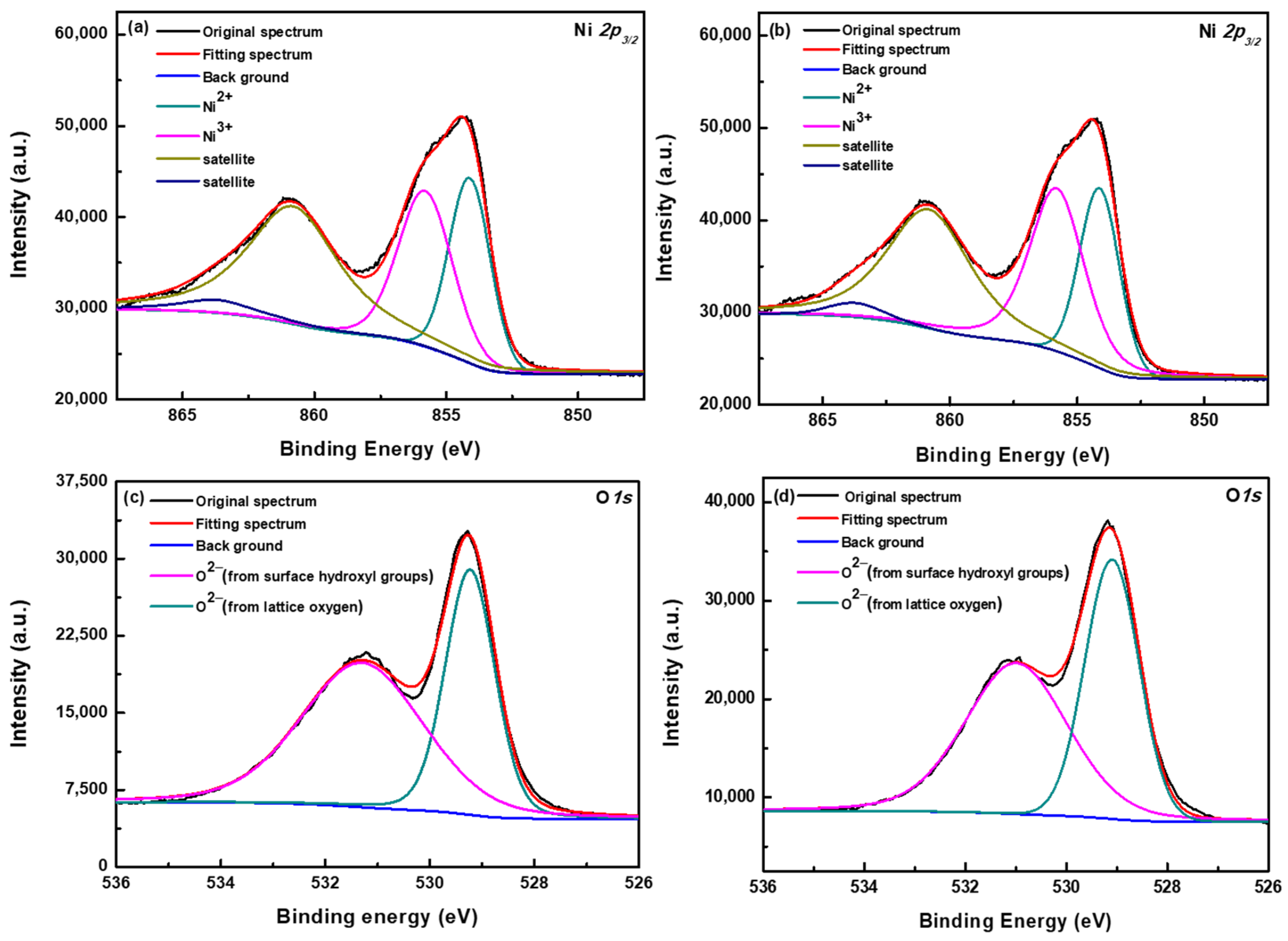

3.1. Characterization of NiOx Thin Film and Nanoflakes

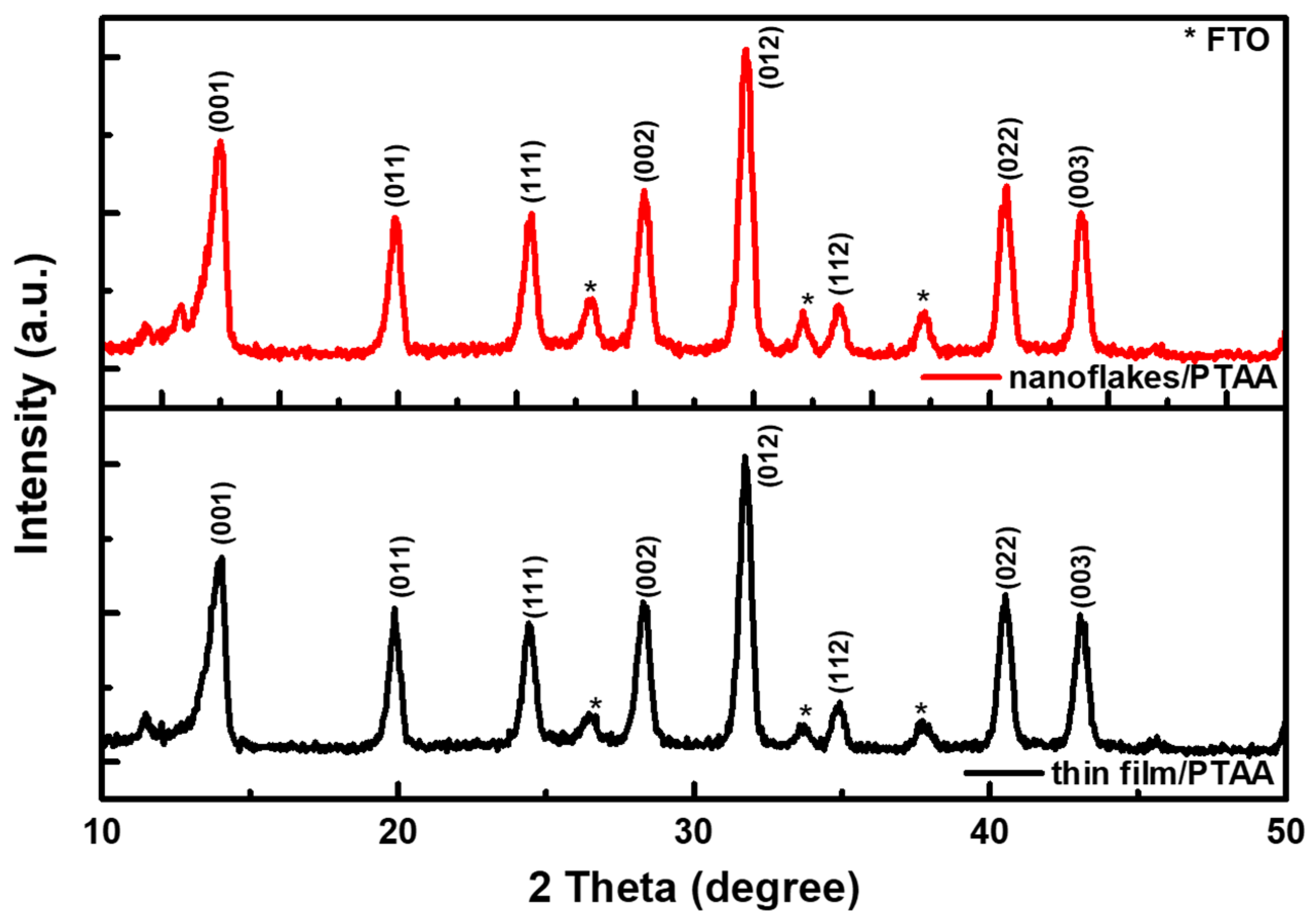

3.2. Characterization of Perovskite Layers on NiOx

3.3. Device Evaluation of PSCs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, S.; Wan, L.; Chen, L.; Deng, C.; Tao, L.; Lu, Z.; Zhang, W.; Fang, J.; Song, W. Self-Doping a Hole-Transporting Layer Based on a Conjugated Polyelectrolyte Enables Efficient and Stable Inverted Perovskite Solar Cells. ACS Appl. Energy Mater. 2020, 3, 11724–11731. [Google Scholar] [CrossRef]

- Yu, Z.; Sun, L. Recent Progress on Hole-Transporting Materials for Emerging Organometal Halide Perovskite Solar Cells. Adv. Energy Mater. 2015, 5, 1500213. [Google Scholar] [CrossRef]

- Chiang, C.-H.; Wu, C.-G. Bulk heterojunction perovskite–PCBM solar cells with high fill factor. Nat. Photonics 2016, 10, 196–200. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, K. Additive Engineering for Efficient and Stable Perovskite Solar Cells. Adv. Energy Mater. 2020, 10, 1902579. [Google Scholar] [CrossRef]

- Ng, C.H.; Ripolles, T.S.; Hamada, K.; Teo, S.H.; Lim, H.N.; Bisquert, J.; Hayase, S. Tunable Open Circuit Voltage by Engineering Inorganic Cesium Lead Bromide/Iodide Perovskite Solar Cells. Sci. Rep. 2018, 8, 2482. [Google Scholar] [CrossRef] [PubMed]

- Sajid, S.; Elseman, A.M.; Huang, H.; Ji, J.; Dou, S.; Jiang, H.; Liu, X.; Wei, D.; Cui, P.; Li, M. Breakthroughs in NiOx-HTMs towards stable, low-cost and efficient perovskite solar cells. Nano Energy 2018, 51, 408–424. [Google Scholar] [CrossRef]

- Wang, T.; Ding, D.; Zheng, H.; Wang, X.; Wang, J.; Liu, H.; Shen, W. Efficient Inverted Planar Perovskite Solar Cells Using Ultraviolet/Ozone-Treated NiOx as the Hole Transport Layer. Sol. RRL 2019, 3, 1900045. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL). Efficiency Chart. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 30 May 2022).

- Liu, M.; Johnston, M.B.; Snaith, H.J. Efficient planar heterojunction perovskite solar cells by vapour deposition. Nature 2013, 501, 395–398. [Google Scholar] [CrossRef]

- Ok, S.A.; Jo, B.; Somasundaram, S.; Woo, H.J.; Lee, D.W.; Li, Z.; Kim, B.-G.; Kim, J.H.; Song, Y.J.; Ahn, T.K.; et al. Management of transition dipoles in organic hole-transporting materials under solar irradiation for perovskite solar cells. Nat. Commun. 2018, 9, 4537. [Google Scholar] [CrossRef]

- Tavakoli, M.M.; Yadav, P.; Tavakoli, R.; Kong, J. Surface Engineering of TiO2 ETL for Highly Efficient and Hysteresis-Less Planar Perovskite Solar Cell (21.4%) with Enhanced Open-Circuit Voltage and Stability. Adv. Energy Mater. 2018, 8, 1800794. [Google Scholar] [CrossRef]

- Xu, Y.; Gao, C.; Tang, S.; Zhang, J.; Chen, Y.; Zhu, Y.; Hu, Z. Comprehensive understanding of TiCl4 treatment on the compact TiO2 layer in planar perovskite solar cells with efficiencies over 20%. J. Alloys Compd. 2019, 787, 1082–1088. [Google Scholar] [CrossRef]

- Zhao, D.-W.; Yu, M.-Y.; Zheng, L.-L.; Li, M.; Dai, S.-J.; Chen, D.-C.; Lee, T.-C.; Yun, D.-Q. Enhanced Efficiency and Stability of Planar Perovskite Solar Cells Using a Dual Electron Transport Layer of Gold Nanoparticles Embedded in Anatase TiO2 Films. ACS Appl. Energy Mater. 2020, 3, 9568–9575. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-S.; Jang, I.-H.; Ahn, N.; Choi, M.; Guerrero, A.; Bisquert, J.; Park, N.-G. Control of I−V Hysteresis in CH3NH3PbI3 Perovskite Solar Cell. J. Phys. Chem. Lett. 2015, 6, 4633–4639. [Google Scholar] [CrossRef]

- Weber, S.A.L.; Hermes, I.M.; Turren-Cruz, S.-H.; Gort, C.; Bergmann, V.W.; Gilson, L.; Hagfeldt, A.; Graetzel, M.; Tress, W.; Berger, R. How the formation of interfacial charge causes hysteresis in perovskite solar cells. Energy Environ. Sci. 2018, 11, 2404–2413. [Google Scholar] [CrossRef]

- Bai, Y.; Chen, H.; Xiao, S.; Xue, Q.; Zhang, T.; Zhu, Z.; Li, Q.; Hu, C.; Yang, Y.; Hu, Z.; et al. Effects of a Molecular Monolayer Modification of NiO Nanocrystal Layer Surfaces on Perovskite Crystallization and Interface Contact toward Faster Hole Extraction and Higher Photovoltaic Performance. Adv. Funct. Mater. 2016, 26, 2950–2958. [Google Scholar] [CrossRef]

- Li, Z.; Jo, B.H.; Hwang, S.J.; Kim, T.H.; Somasundaram, S.; Kamaraj, E.; Bang, J.; Ahn, T.K.; Park, S.; Park, H.J. Bifacial Passivation of Organic Hole Transport Interlayer for NiOx-Based p-i-n Perovskite Solar Cells. Adv. Sci. 2019, 6, 1802163. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Chueh, C.-C.; Zhao, T.; Cheng, J.; Eslamian, M.; Choy, W.C.H.; Jen, A.K.-Y. Effects of Self-Assembled Monolayer Modification of Nickel Oxide Nanoparticles Layer on the Performance and Application of Inverted Perovskite Solar Cells. ChemSusChem 2017, 10, 3794–3803. [Google Scholar] [CrossRef]

- Yu, J.C.; Hong, J.A.; Jung, E.D.; Kim, D.B.; Baek, S.-M.; Lee, S.; Cho, S.; Park, S.S.; Choi, K.J.; Song, M.H. Highly efficient and stable inverted perovskite solar cell employing PEDOT:GO composite layer as a hole transport layer. Sci. Rep. 2018, 8, 1070. [Google Scholar] [CrossRef]

- Wang, M.; Li, W.; Wang, H.; Yang, K.; Hu, X.; Sun, K.; Lu, S.; Zang, Z. Small Molecule Modulator at the Interface for Efficient Perovskite Solar Cells with High Short-Circuit Current Density and Hysteresis Free. Adv. Electron. Mater. 2020, 6, 2000604. [Google Scholar] [CrossRef]

- Li, W.; Wang, H.; Hu, X.; Cai, W.; Zhang, C.; Wang, M.; Zang, Z. Sodium Benzenesulfonate Modified Poly (3,4-Ethylenedioxythiophene):Polystyrene Sulfonate with Improved Wettability and Work Function for Efficient and Stable Perovskite Solar Cells. Sol. RRL 2021, 5, 2000573. [Google Scholar] [CrossRef]

- Yang, D.; Sano, T.; Yaguchi, Y.; Sun, H.; Sasabe, H.; Kido, J. Achieving 20% Efficiency for Low-Temperature-Processed Inverted Perovskite Solar Cells. Adv. Funct. Mater. 2019, 29, 1807556. [Google Scholar] [CrossRef]

- Bagheri, Z.; Matteocci, F.; Lamanna, E.; Di Girolamo, D.; Marrani, A.G.; Zanoni, R.; Di Carlo, A.; Moshaii, A. Light-induced improvement of dopant-free PTAA on performance of inverted perovskite solar cells. Sol. Energy Mater. Sol. Cells 2020, 215, 110606. [Google Scholar] [CrossRef]

- Yan, X.; Zheng, J.; Zheng, L.; Lin, G.; Lin, H.; Chen, G.; Du, B.; Zhang, F. Optimization of sputtering NiOx films for perovskite solar cell applications. Mater. Res. Bull. 2018, 103, 150–157. [Google Scholar] [CrossRef]

- Yuan, X.; Li, H.; Fan, J.; Zhang, L.; Ran, F.; Feng, M.; Li, P.; Kong, W.; Chen, S.; Zang, Z.; et al. Enhanced p Type Conductivity of NiOx Films with Divalent Cd Ion Doping for Efficient Inverted Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 17434–17443. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Peng, S.; Choy, W.C.H. Inorganic top electron transport layer for high performance inverted perovskite solar cells. EcoMat 2021, 3, 12127. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Zhang, H.; Lv, H.; Hu, R.; Liu, W.; Wang, S.; Jiang, M.; Chu, L.; Zhang, J.; et al. Effective carrier transport tuning of CuOx quantum dots hole interfacial layer for high-performance inverted perovskite solar cell. Appl. Surf. Sci. 2021, 547, 149117. [Google Scholar] [CrossRef]

- Ye, S.; Sun, W.; Li, Y.; Yan, W.; Peng, H.; Bian, Z.; Liu, Z.; Huang, C. CuSCN-Based Inverted Planar Perovskite Solar Cell with an Average PCE of 15.6%. Nano Lett. 2015, 15, 3723–3728. [Google Scholar] [CrossRef]

- Chandrasekhar, P.S.; Seo, Y.-H.; Noh, Y.-J.; Na, S.-I. Room temperature solution-processed Fe doped NiOx as a novel hole transport layer for high efficient perovskite solar cells. Appl. Surf. Sci. 2019, 481, 588–596. [Google Scholar] [CrossRef]

- Zhang, J.; Mao, W.; Hou, X.; Duan, J.; Zhou, J.; Huang, S.; Ou-Yang, W.; Zhang, X.; Sun, Z.; Chen, X. Solution-processed Sr-doped NiOx as hole transport layer for efficient and stable perovskite solar cells. Sol. Energy 2018, 174, 1133–1141. [Google Scholar] [CrossRef]

- Chen, W.; Liu, F.-Z.; Feng, X.-Y.; Djurišić, A.B.; Chan, W.K.; He, Z.-B. Cesium Doped NiOx as an Efficient Hole Extraction Layer for Inverted Planar Perovskite Solar Cells. Adv. Energy Mater. 2017, 7, 1700722. [Google Scholar] [CrossRef]

- Xu, L.; Chen, X.; Jin, J.; Liu, W.; Dong, B.; Bai, X.; Song, H.; Reiss, P. Inverted perovskite solar cells employing doped NiO hole transport layers: A review. Nano Energy 2019, 63, 103860. [Google Scholar] [CrossRef]

- Yin, X.; Liu, J.; Ma, J.; Zhang, C.; Chen, P.; Que, M.; Yang, Y.; Que, W.; Niu, C.; Shao, J. Solvothermal derived crystalline NiOx nanoparticles for high performance perovskite solar cells. J. Power Sources 2016, 329, 398–405. [Google Scholar] [CrossRef]

- Yin, X.; Zhai, J.; Song, L.; Du, P.; Li, N.; Yang, Y.; Xiong, J.; Ko, F. Novel NiO Nanoforest Architecture for Efficient Inverted Mesoporous Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2019, 11, 44308–44314. [Google Scholar] [CrossRef] [PubMed]

- Yin, X.; Zhai, J.; Du, P.; Li, N.; Song, L.; Xiong, J.; Ko, F. 3D NiO Nanowall Hole-Transporting Layer for the Passivation of Interfacial Contact in Inverted Perovskite Solar Cells. ChemSusChem 2020, 13, 1006–1012. [Google Scholar] [CrossRef]

- Huang, Z.-W.; Yang, S.-H.; Wu, Z.-Y.; Hsu, H.-C. Performance Comparison between the Nanoporous NiOx Layer and NiOx Thin Film for Inverted Perovskite Solar Cells with Long-Term Stability. ACS Omega 2021, 6, 15855–15866. [Google Scholar] [CrossRef] [PubMed]

- Mali, S.S.; Kim, H.; Shim, S.E.; Hong, C.K. A solution processed nanostructured p-type NiO electrode for efficient inverted perovskite solar cells. Nanoscale 2016, 8, 19189–19194. [Google Scholar] [CrossRef]

- Mali, S.S.; Kim, H.; Kim, H.H.; Shim, S.E.; Hong, C.K. Nanoporous p-type NiOx electrode for p-i-n inverted perovskite solar cell toward air stability. Mater. Today 2017, 5, 483–500. [Google Scholar] [CrossRef]

- Chen, W.-C.; Chen, P.-Y.; Yang, S.-H. Solution-processed hybrid light emitting and photovoltaic devices comprising zinc oxide nanorod arrays and tungsten trioxide layers. AIMS Mater. Sci. 2017, 4, 551–560. [Google Scholar] [CrossRef]

- Chen, P.-C.; Yang, S.-H. Potassium-Doped Nickel Oxide as the Hole Transport Layer for Efficient and Stable Inverted Perovskite Solar Cells. ACS Appl. Energy Mater. 2019, 2, 6705–6713. [Google Scholar] [CrossRef]

- Kartikay, P.; Sadhukhan, D.; Yella, A.; Mallick, S. Enhanced charge transport in low temperature carbon-based n-i-p perovskite solar cells with NiOx-CNT hole transport material. Sol. Energy Mater. Sol. Cells 2021, 230, 111241. [Google Scholar] [CrossRef]

- Saki, Z.; Sveinbjörnsson, K.; Boschloo, G.; Taghavinia, N. The Effect of Lithium Doping in Solution-Processed Nickel Oxide Films for Perovskite Solar Cells. ChemPhysChem 2019, 20, 3322–3327. [Google Scholar] [CrossRef] [PubMed]

- Seo, S.; Park, I.J.; Kim, M.; Lee, S.; Bae, C.; Jung, H.S.; Park, N.-G.; Kim, J.Y.; Shin, H. An ultra-thin, un-doped NiO hole transporting layer of highly efficient (16.4%) organic-inorganic hybrid perovskite solar cells. Nanoscale 2016, 8, 11403–11412. [Google Scholar] [CrossRef] [PubMed]

- Zheng, G.; Zhu, C.; Ma, J.; Zhang, X.; Tang, G.; Li, R.; Chen, Y.; Li, L.; Hu, J.; Hong, J.; et al. Manipulation of facet orientation in hybrid perovskite polycrystalline films by cation cascade. Nat. Commun. 2018, 9, 2793. [Google Scholar] [CrossRef] [PubMed]

- Matsui, T.; Seo, J.-Y.; Saliba, M.; Zakeeruddin, S.M.; Grätzel, M. Room-Temperature Formation of Highly Crystalline Multication Perovskites for Efficient, Low-Cost Solar Cells. Adv. Mater. 2017, 29, 1606258. [Google Scholar] [CrossRef]

- Du, Q.; Shen, Z.; Chen, C.; Li, F.; Jin, M.; Li, H.; Dong, C.; Zheng, J.; Ji, M.; Wang, M. Spiro-OMeTAD:Sb2S3 Hole Transport Layer with Triple Functions of Overcoming Lithium Salt Aggregation, Long-Term High Conductivity, and Defect Passivation for Perovskite Solar Cells. Sol. RRL 2021, 5, 2100622. [Google Scholar] [CrossRef]

- Cho, S.; Pandey, P.; Park, J.; Lee, T.-W.; Kang, D.-W. Mixed Solvent Engineering for Morphology Optimization of the Electron Transport Layer in Perovskite Photovoltaics. ACS Appl. Energy Mater. 2022, 5, 387–396. [Google Scholar] [CrossRef]

- Yan, P.-R.; Huang, W.-J.; Yang, S.-H. Incorporation of quaternary ammonium salts containing different counterions to improve the performance of inverted perovskite solar cells. Chem. Phys. Lett. 2017, 669, 143–149. [Google Scholar] [CrossRef]

- Lim, K.-G.; Ahn, S.; Lee, T.-W. Energy level alignment of dipolar interface layer in organic and hybrid perovskite solar cells. J. Mater. Chem. C 2018, 6, 2915–2924. [Google Scholar] [CrossRef]

- Wang, M.; Wang, H.; Li, W.; Hu, X.; Sun, K.; Zang, Z. Defect passivation using ultrathin PTAA layers for efficient and stable perovskite solar cells with a high fill factor and eliminated hysteresis. J. Mater. Chem. A 2019, 7, 26421–26428. [Google Scholar] [CrossRef]

- Du, Y.; Xin, C.; Huang, W.; Shi, B.; Ding, Y.; Wei, C.; Zhao, Y.; Li, Y.; Zhang, X. Polymeric Surface Modification of NiOx-Based Inverted Planar Perovskite Solar Cells with Enhanced Performance. ACS Sustain. Chem. Eng. 2018, 6, 16806–16812. [Google Scholar] [CrossRef]

- Wang, C.; Yang, H.; Xia, X.; Wang, X.; Li, F. Suppressing interfacial defect formation derived from in-situ-generated polyethylenimine-based 2D perovskites to boost the efficiency and stability NiOx-based inverted planar perovskite solar cells. Appl. Surf. Sci. 2021, 548, 149276. [Google Scholar] [CrossRef]

- Habisreutinger, S.N.; Noel, N.K.; Snaith, H.J. Hysteresis Index: A Figure without Merit for Quantifying Hysteresis in Perovskite Solar Cells. ACS Energy Lett. 2018, 3, 2472–2476. [Google Scholar] [CrossRef]

- Wang, A.; Cao, Z.; Wang, J.; Wang, S.; Li, C.; Li, N.; Xie, L.; Xiang, Y.; Li, T.; Niu, X.; et al. Vacancy defect modulation in hot-casted NiOx film for efficient inverted planar perovskite solar cells. J. Energy Chem. 2020, 48, 426–434. [Google Scholar] [CrossRef]

- Di Girolamo, D.; Matteocci, F.; Piccinni, M.; Di Carlo, A.; Dini, D. Anodically electrodeposited NiO nanoflakes as hole selective contact in efficient air processed p-i-n perovskite solar cells. Sol. Energy Mater. Sol. Cells 2020, 205, 110288. [Google Scholar] [CrossRef]

| NiOx HTL | Scan Direction | JSC a (mA/cm2) | VOC a (V) | FF a (%) | Best PCE a (%) | Avg PCE b (%) | RS a (Ω·cm2) | RSh a (kΩ·cm2) |

|---|---|---|---|---|---|---|---|---|

| thin film | Forward | 18.4 | 0.93 | 64 | 10.96 | 10.4 | 7.42 | 0.67 |

| (σ = 0.3) | ||||||||

| Reverse | 19.1 | 0.94 | 66 | 11.88 | 11.4 | 7.24 | 0.78 | |

| (σ = 0.33) | ||||||||

| nanoflakes | Forward | 20.5 | 0.99 | 68 | 13.96 | 13.7 | 5.85 | 1.36 |

| (σ = 0.15) | ||||||||

| Reverse | 20.8 | 0.99 | 69 | 14.21 | 13.9 | 5.67 | 1.53 | |

| (σ = 0.17) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, C.-Y.; Wu, Y.-W.; Yang, S.-H.; Abdulhalim, I. Preparation of Nickel Oxide Nanoflakes for Carrier Extraction and Transport in Perovskite Solar Cells. Nanomaterials 2022, 12, 3336. https://doi.org/10.3390/nano12193336

Chang C-Y, Wu Y-W, Yang S-H, Abdulhalim I. Preparation of Nickel Oxide Nanoflakes for Carrier Extraction and Transport in Perovskite Solar Cells. Nanomaterials. 2022; 12(19):3336. https://doi.org/10.3390/nano12193336

Chicago/Turabian StyleChang, Chih-Yu, You-Wei Wu, Sheng-Hsiung Yang, and Ibrahim Abdulhalim. 2022. "Preparation of Nickel Oxide Nanoflakes for Carrier Extraction and Transport in Perovskite Solar Cells" Nanomaterials 12, no. 19: 3336. https://doi.org/10.3390/nano12193336

APA StyleChang, C.-Y., Wu, Y.-W., Yang, S.-H., & Abdulhalim, I. (2022). Preparation of Nickel Oxide Nanoflakes for Carrier Extraction and Transport in Perovskite Solar Cells. Nanomaterials, 12(19), 3336. https://doi.org/10.3390/nano12193336