Light-Controlled Direction of Distributed Feedback Laser Emission by Photo-Mobile Polymer Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

Holographic Halolakanes/Acrylate-Based Mixture Preparation

2.3. PMP Mixture Preparation

2.4. Hologram Recording and Optical Characterization Set-Up

2.5. Sample Preparation

2.6. Pumping Set-Up (See Figure S2 in the Supporting Information Section)

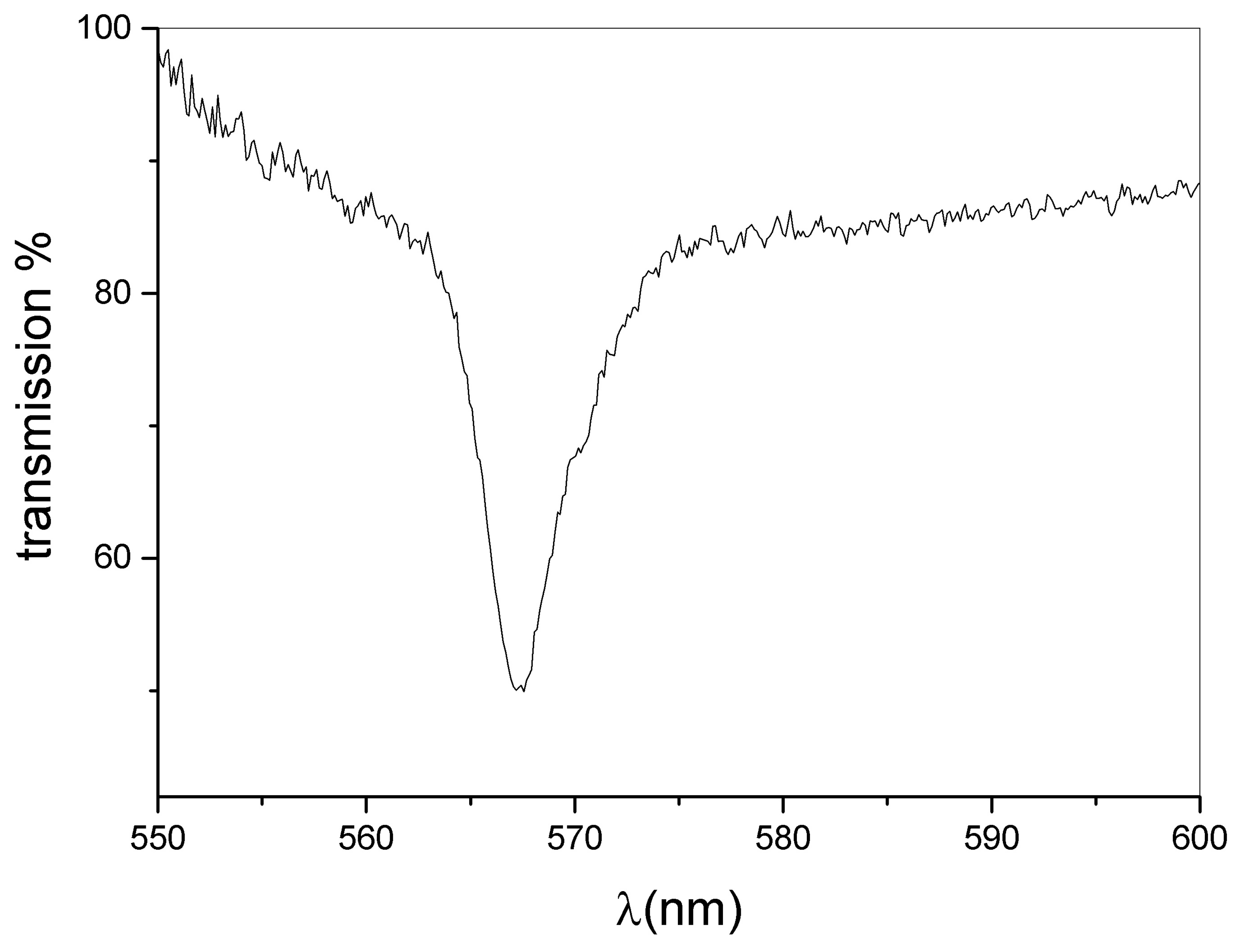

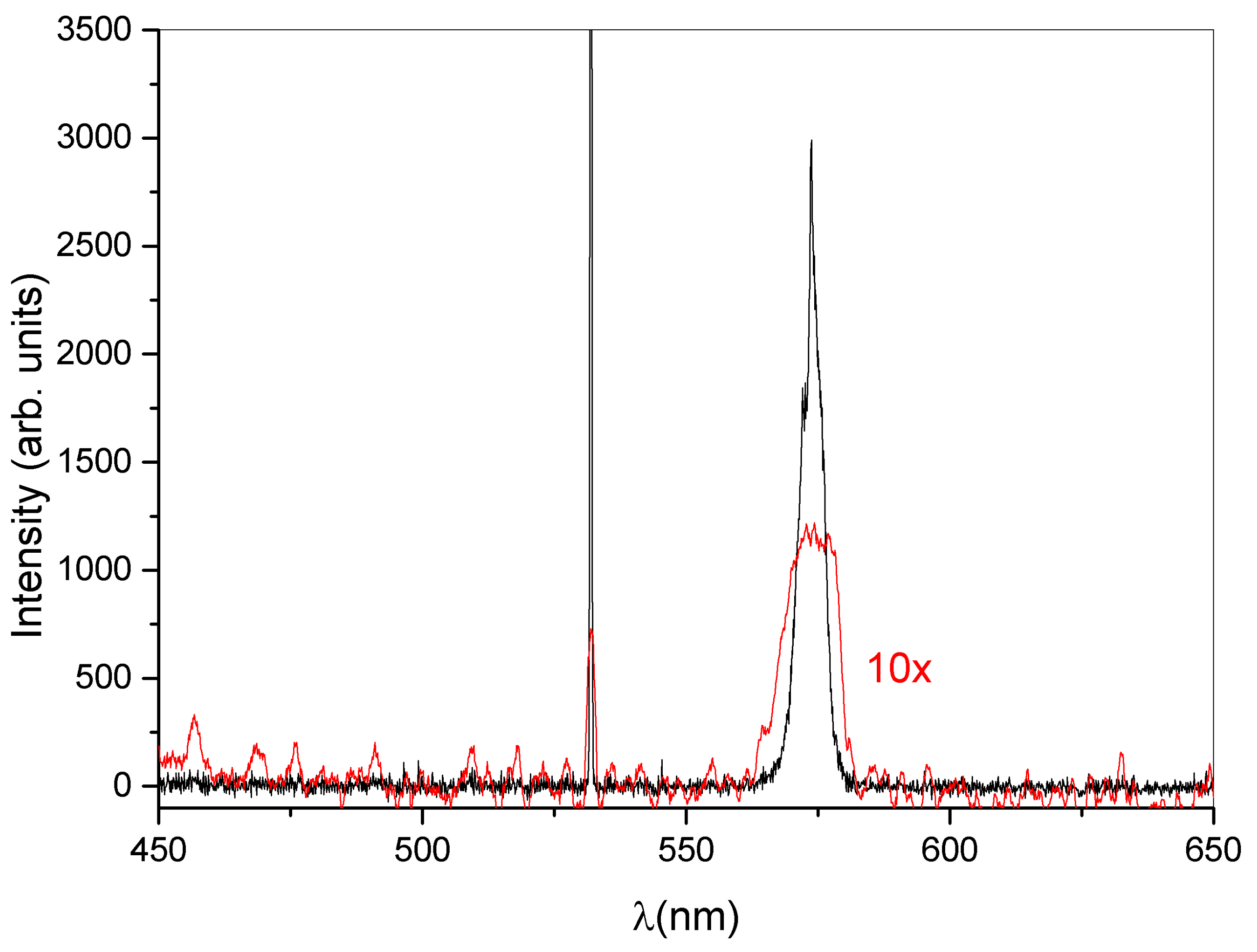

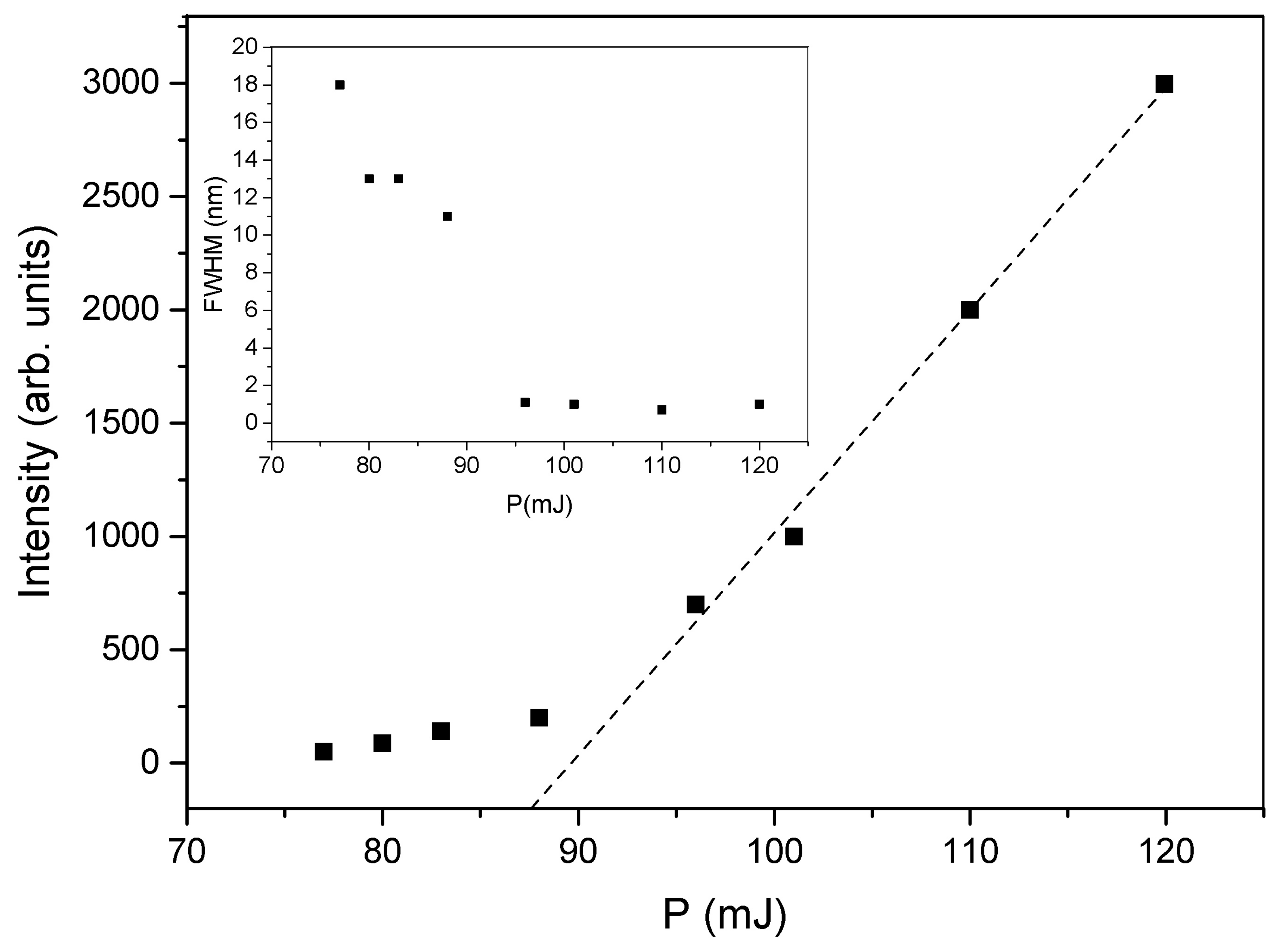

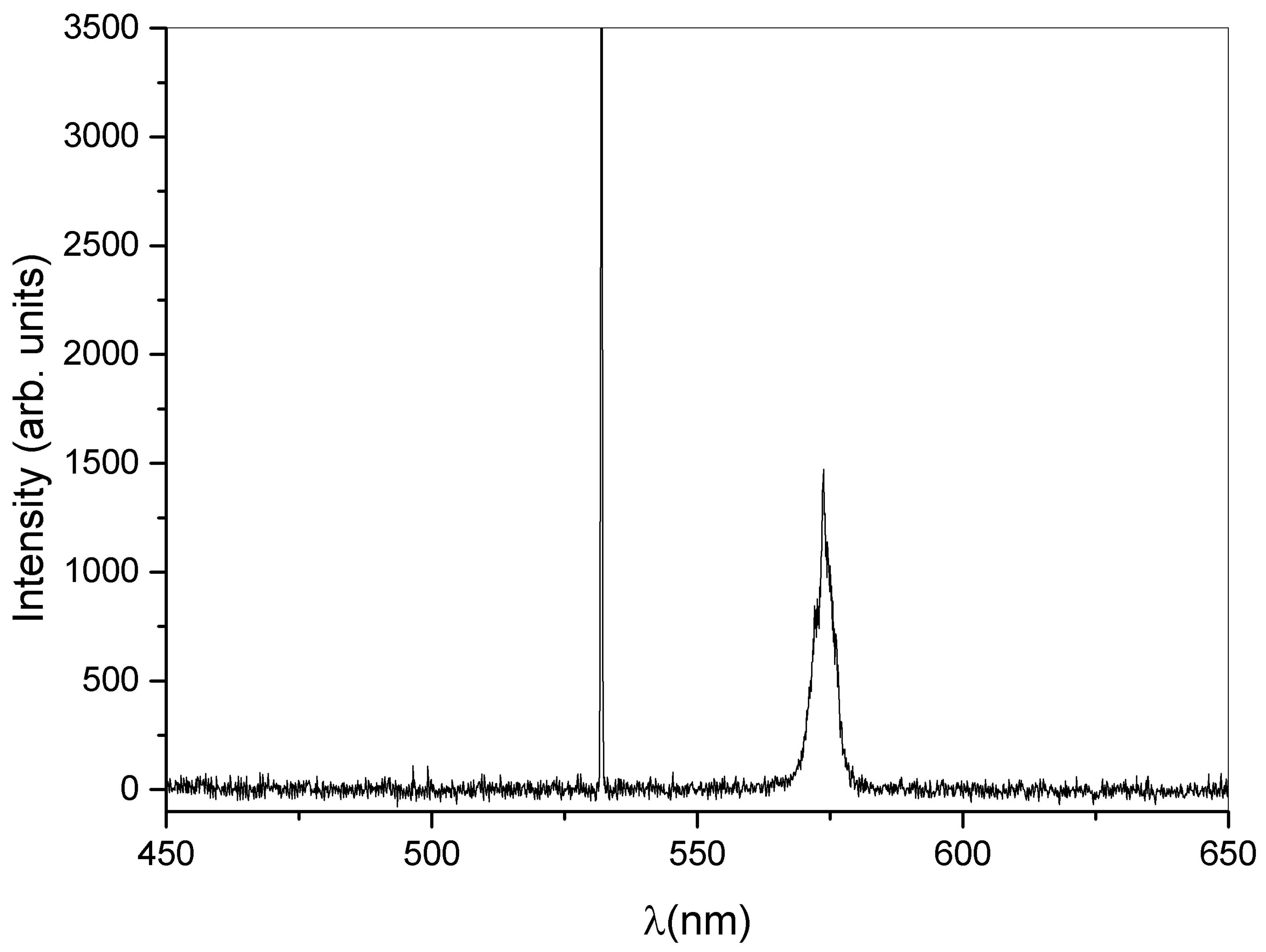

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trentler, T.J.; Boyd, J.E.; Colvin, V.L. Epoxy-photopolymer composites: Thick recording media for holographic data storage. In Proceedings of the Practical Holography XV and Holographic Materials VII, San Jose, CA, USA, 20 January 2001; SPIE: Bellingham, WA, USA, 2001; Volume 4296, pp. 259–266. [Google Scholar]

- Li, L.; Fourkas, J.T. Multiphoton polymerization. Mater. Today 2007, 10, 30–37. [Google Scholar] [CrossRef]

- Trentler, T.J.; Boyd, J.E.; Colvin, V.L. Epoxy resin- photopolymer composites for volume holography. Chem. Mater. 2000, 12, 1431–1438. [Google Scholar] [CrossRef]

- Jeong, Y.C.; Lee, S.; Park, J.K. Holographic diffraction gratings with enhanced sensitivity based on epoxy-resin photopolymers. Opt. Express 2007, 15, 1497–1504. [Google Scholar] [CrossRef]

- Waldman, D.A.; Butler, C.J.; Raguin, D.H. CROP holographic storage media for optical data storage greater than 100 bits/um2. In Organic Holographic Materials and Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 2003; Volume 5216, pp. 10–25. [Google Scholar]

- Waldman, D.; Li, H.; Horner, M. Volume shrinkage in slant fringe gratings of a cationic ring-opening holographic recording material. J. Imaging Sci. Technol. 1997, 41, 497–514. [Google Scholar]

- Lawrence, J.; O’Neill, F.; Sheridan, J. Photopolymer holographic recording material. Optik 2001, 112, 449–463. [Google Scholar] [CrossRef]

- Eichler, H.; Orlic, S.; Schulz, R.; Rübner, J. Holographic reflection gratings in azobenzene polymers. Opt. Lett. 2001, 26, 581–583. [Google Scholar] [CrossRef]

- Hesselink, L.; Orlov, S.S.; Bashaw, M.C. Holographic data storage systems. Proc. IEEE 2004, 92, 1231–1280. [Google Scholar] [CrossRef]

- McLeod, R.R.; Daiber, A.J.; McDonald, M.E.; Robertson, T.L.; Slagle, T.; Sochava, S.L.; Hesselink, L. Microholographic multilayer optical disk data storage. Appl. Opt. 2005, 44, 3197–3207. [Google Scholar] [CrossRef] [PubMed]

- Orlic, S.; Dietz, E.; Frohmann, S.; Mueller, C.; Schoen, R.; Trefzer, M.; Eichler, H.J. High-density multilayer recording of microgratings for optical data storage. In Organic Holographic Materials and Applications II; SPIE: Bellingham, WA, USA, 2004; Volume 5521, pp. 161–173. [Google Scholar]

- Ramírez, M.G.; Sirvent, D.; Morales-Vidal, M.; Ortu no, M.; Martínez-Guardiola, F.J.; Francés, J.; Pascual, I. LED-cured reflection gratings stored in an acrylate-based photopolymer. Polymers 2019, 11, 632. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Yao, L.; Zhang, R.; Zou, Z.; Liu, Y.; Liu, Y.; Xuan, L. Thermo-stability of acrylate based holographic polymer dispersed liquid crystal gratings. J. Phys. D Appl. Phys. 2009, 42, 115504. [Google Scholar] [CrossRef][Green Version]

- Shen, Z.; Weng, Y.; Zhang, Y.; Wang, C.; Liu, A.; Li, X. Holographic recording performance of acrylate-based photopolymer under different preparation conditions for waveguide display. Polymers 2021, 13, 936. [Google Scholar] [CrossRef]

- Abbate, G.; Vita, F.; Marino, A.; Tkachenko, V.; Slussarenko, S.; Sakhno, O.; Stumpe, J. New generation of holographic gratings based on polymer-LC composites: POLICRYPS and POLIPHEM. Mol. Cryst. Liq. Cryst. 2006, 453, 1–13. [Google Scholar] [CrossRef]

- Liu, J.H.; Wu, F.T. Holographic gratings in photosensitive acrylic polymers with high refractive index diphenyl sulfide. J. Polym. Res. 2004, 11, 43–51. [Google Scholar] [CrossRef]

- Tomlin, D.; Natarajan, L.; Tondiglia, V.; Sutherland, R.; Bunning, T. Morphology of Holographic Polymer Dispersed Liquid Crystal Reflection Gratings Written in Thiol-ene and Acrylate Polymer Hosts: Part I-Grating Formation. Microsc. Microanal. 2003, 9, 382–383. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Y.; Diao, Z.; Yang, C.; Yao, L.; Ma, J.; Xuan, L. Theory and characteristics of holographic polymer dispersed liquid crystal transmission grating with scaffolding morphology. Appl. Opt. 2012, 51, 4013–4020. [Google Scholar] [CrossRef]

- Rippa, M.; Castagna, R.; Tkachenko, V.; Zhou, J.; Petti, L. Engineered nanopatterned substrates for high-sensitive localized surface plasmon resonance: An assay on biomacromolecules. J. Mater. Chem. B 2017, 5, 5473–5478. [Google Scholar] [CrossRef]

- Rippa, M.; Castagna, R.; Brandi, S.; Fusco, G.; Monini, M.; Chen, D.; Zhou, J.; Zyss, J.; Petti, L. Octupolar Plasmonic Nanosensor Based on Ordered Arrays of Triangular Au Nanopillars for Selective Rotavirus Detection. ACS Appl. Nano Mater. 2020, 3, 4837–4844. [Google Scholar] [CrossRef]

- Zhao, Y.; Peng, H.; Zhou, X.; Li, Z.; Xie, X. Interfacial AIE for Orthogonal Integration of Holographic and Fluorescent Dual-Thermosensitive Images. Adv. Sci. 2022, 9, 2105903. [Google Scholar] [CrossRef]

- Shishova, M.; Zherdev, A.; Odinokov, S.; Venediktov, V.; Lushnikov, D.; Kim, Y. Selective Couplers Based on Multiplexed Volume Holographic Gratings for Waveguide Displays. Photonics 2021, 8, 232. [Google Scholar] [CrossRef]

- Castagna, R.; Lucchetta, D.E.; Vita, F.; Criante, L.; Simoni, F. At a glance determination of laser light polarization state. Appl. Phys. Lett. 2008, 92, 041115. [Google Scholar] [CrossRef]

- Liu, H.; Wang, R.; Yu, D.; Luo, S.; Li, L.; Wang, W.; Song, Q. Direct light written holographic volume grating as a novel optical platform for sensing characterization of solution. Opt. Laser Technol. 2019, 109, 510–517. [Google Scholar] [CrossRef]

- Tong, X.; Wang, G.; Yavrian, A.; Galstian, T.; Zhao, Y. Dual-Mode Switching of Diffraction Gratings Based on Azobenzene-Polymer-Stabilized Liquid Crystals. Adv. Mater. 2005, 17, 370–374. [Google Scholar] [CrossRef]

- Bunning, T.J.; Natarajan, L.V.; Tondiglia, V.P.; Sutherland, R.L. Holographic Polymer-Dispersed Liquid Crystals (H-PDLCs). Annu. Rev. Mater. Sci. 2000, 30, 83–115. [Google Scholar] [CrossRef]

- Lucchetta, D.; Vita, F.; Francescangeli, D.; Francescangeli, O.; Simoni, F. Optical measurement of flow rate in a microfluidic channel. Microfluid. Nanofluid. 2016, 20, 9. [Google Scholar] [CrossRef]

- Zhao, W.; de Haan, L.T.; Broer, D.J.; Zhang, Y.; Lv, P.; Zhou, G. Photopolymerization-enforced stratification in liquid crystal materials. Prog. Polym. Sci. 2021, 114, 101365. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, X.; Li, M.D.; Li, Z.; Peng, H.; Xie, X. Crosstalk-Free Patterning of Cooperative-Thermoresponse Images by the Synergy of the AIEgen with the Liquid Crystal. Angew. Chem. Int. Ed. 2020, 59, 10066–10072. [Google Scholar] [CrossRef]

- Lee, K.M.; Tondiglia, V.P.; Godman, N.P.; White, T.J.; Bunning, T.J.; McConney, M.E. Reconfigurable Reflective Colors in Holographically Patterned Liquid Crystal Gels. ACS Photonics 2020, 7, 1978–1982. [Google Scholar] [CrossRef]

- Castagna, R.; Lucchetta, D.E.; Rippa, M.; Xu, J.H.; Donato, A.D. Near-frequency photons Y-splitter. Appl. Mater. Today 2020, 19, 100636. [Google Scholar] [CrossRef]

- Shalit, A.; Lucchetta, D.; Piazza, V.; Simoni, F.; Bizzarri, R.; Castagna, R. Polarization-dependent laser-light structured directionality with polymer composite materials. Mater. Lett. 2012, 81, 232–234. [Google Scholar] [CrossRef]

- Vita, F.; Lucchetta, D.E.; Castagna, R.; Criante, L.; Simoni, F. Effects of resin addition on holographic polymer dispersed liquid crystals. J. Opt. Pure Appl. Opt. 2009, 11, 024021. [Google Scholar] [CrossRef]

- Blanche, P.A.; Gailly, P.; Habraken, S.L.; Lemaire, P.C.; Jamar, C.A.J. Volume phase holographic gratings: Large size and high diffraction efficiency. Opt. Eng. 2004, 43, 2603–2612. [Google Scholar] [CrossRef]

- Dhar, L. High-performance polymer recording materials for holographic data storage. MRS Bull. 2006, 31, 324–328. [Google Scholar] [CrossRef]

- Ramos, G.; Álvarez-Herrero, A.; Belenguer, T.; del Monte, F.; Levy, D. Shrinkage control in a photopolymerizable hybrid solgel material for holographic recording. Appl. Opt. 2004, 43, 4018–4024. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y.H.; Shin, C.W.; Kim, N.; Kim, B.K.; Kawakami, Y. High-performance transmission holographic gratings via different polymerization rates of dipentaerythritol acrylates and siloxane-containing epoxides. Chem. Mater. 2005, 17, 6263–6271. [Google Scholar] [CrossRef]

- Castagna, R.; Lucchetta, D.; Vita, F.; Criante, L.; Greci, L.; Simoni, F. Haloalkane-based polymeric mixtures for high density optical data storage. Opt. Mater. 2008, 30, 1878–1882. [Google Scholar] [CrossRef]

- Castagna, R.; Vita, F.; Lucchetta, D.E.; Criante, L.; Simoni, F. Superior-Performance Polymeric Composite Materials for High-Density Optical Data Storage. Adv. Mater. 2009, 21, 589–592. [Google Scholar] [CrossRef]

- Lucchetta, D.; Spegni, P.; Di Donato, A.; Simoni, F.; Castagna, R. Hybrid surface-relief/volume one dimensional holographic gratings. Opt. Mater. 2015, 42, 366–369. [Google Scholar] [CrossRef]

- Kneubühl, F. Theories on Distributed Feedback Lasers. In Handbook of Laser Science and Technology; Harwood Academic Publishers: Reading, UK, 1993. [Google Scholar]

- Fu, Y.; Zhai, T. Distributed feedback organic lasing in photonic crystals. Front. Optoelectron. 2020, 13, 18–34. [Google Scholar] [CrossRef]

- Zhai, T.; Ma, X.; Han, L.; Zhang, S.; Ge, K.; Xu, Y.; Xu, Z.; Cui, L. Self-Aligned Emission of Distributed Feedback Lasers on Optical Fiber Sidewall. Nanomaterials 2021, 11, 2381. [Google Scholar] [CrossRef]

- Lucchetta, D.; Vita, F.; Castagna, R.; Francescangeli, O.; Simoni, F. Laser emission based on first order reflection by novel composite polymeric gratings. Photonics Nanostruct. Fundam. Appl. 2012, 10, 140–145. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Criante, L.; Francescangeli, O.; Simoni, F. Light amplification by dye-doped holographic polymer dispersed liquid crystals. Appl. Phys. Lett. 2004, 84, 4893–4895. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Di Donato, A.; Singh, G.; Castagna, R. Lasing in Haloalkanes-based polymeric mixtures. Opt. Mater. 2022, 131, 112614. [Google Scholar] [CrossRef]

- Lucchetta, D.; Simoni, F.; Hernandez, R.; Mazzulla, A.; Cipparrone, G. Lasing from chiral doped nematic liquid crystal droplets generated in a microfluidic device. Mol. Cryst. Liq. Cryst. 2017, 649, 11–19. [Google Scholar] [CrossRef]

- Yu, Y.; Nakano, M.; Ikeda, T. Directed bending of a polymer film by light. Nature 2003, 425, 145. [Google Scholar] [CrossRef]

- Yamada, M.; Kondo, M.; Mamiya, J.i.; Yu, Y.; Kinoshita, M.; Barrett, C.; Ikeda, T. Photomobile Polymer Materials: Towards Light-Driven Plastic Motors. Angew. Chem. Int. Ed. 2008, 47, 4986–4988. [Google Scholar] [CrossRef]

- Castagna, R.; Donato, A.D.; Strangi, G.; Lucchetta, D.E. Light controlled bending of a holographic transmission phase grating. Smart Mater. Struct. 2022, 31, 03LT02. [Google Scholar] [CrossRef]

- Castagna, R.; Nucara, L.; Simoni, F.; Greci, L.; Rippa, M.; Petti, L.; Lucchetta, D.E. An Unconventional Approach to Photomobile Composite Polymer Films. Adv. Mater. 2017, 29, 1604800. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Di Donato, A.; Paturzo, M.; Singh, G.; Castagna, R. Light-Induced Dynamic Holography. Micromachines 2022, 13, 297. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Castagna, R.; Singh, G.; Riminesi, C.; Di Donato, A. Spectral, Morphological and Dynamical Analysis of a Holographic Grating Recorded in a Photo-Mobile Composite Polymer Mixture. Nanomaterials 2021, 11, 2925. [Google Scholar] [CrossRef]

- He, J.; Zhao, Y.; Zhao, Y. Photoinduced bending of a coumarin-containing supramolecular polymer. Soft Matter 2009, 5, 308–310. [Google Scholar] [CrossRef]

- Kondo, M.; Matsuda, T.; Fukae, R.; Kawatsuki, N. Photoinduced Deformation of Polymer Fibers with Anthracene Side Groups. Chem. Lett. 2010, 39, 234–235. [Google Scholar] [CrossRef]

- Kondo, M.; Takemoto, M.; Matsuda, T.; Fukae, R.; Kawatsuki, N. Preparation and Macroscopic Deformation of Liquid-Crystalline Polymer Fibers Crosslinked with Anthracene Side Chains. Mol. Cryst. Liq. Cryst. 2011, 550, 98–104. [Google Scholar] [CrossRef]

- Gao, J.; He, Y.; Liu, F.; Zhang, X.; Wang, Z.; Wang, X. Azobenzene-Containing Supramolecular Side-Chain Polymer Films for Laser-Induced Surface Relief Gratings. Chem. Mater. 2007, 19, 3877–3881. [Google Scholar] [CrossRef]

- Kondo, M.; Takemoto, M.; Fukae, R.; Kawatsuki, N. Photomobile polymers from commercially available compounds: Photoinduced deformation of side-chain polymers containing hydrogen-bonded photoreactive compounds. Polym. J. 2012, 44, 410–414. [Google Scholar] [CrossRef]

- Ube, T.; Ikeda, T. Photomobile Polymer Materials with Crosslinked Liquid-Crystalline Structures: Molecular Design, Fabrication, and Functions. Angew. Chem. Int. Ed. 2014, 53, 10290–10299. [Google Scholar] [CrossRef]

- Mamiya, J.i.; Kuriyama, A.; Yokota, N.; Yamada, M.; Ikeda, T. Photomobile Polymer Materials: Photoresponsive Behavior of Cross-Linked Liquid-Crystalline Polymers with Mesomorphic Diarylethenes. Chem. Eur. J. 2015, 21, 3174–3177. [Google Scholar] [CrossRef]

- Ube, T.; Takado, K.; Ikeda, T. Photomobile materials with interpenetrating polymer networks composed of liquid-crystalline and amorphous polymers. J. Mater. Chem. C 2015, 3, 8006–8009. [Google Scholar] [CrossRef]

- Ube, T.; Ikeda, T. Photomobile Polymer Materials with Complex 3D Deformation, Continuous Motions, Self-Regulation, and Enhanced Processability. Adv. Opt. Mater. 2019, 7, 1900380. [Google Scholar] [CrossRef]

- Ikeda, T.; Ube, T. Photomobile polymer materials: From nano to macro. Mater. Today 2011, 14, 480–487. [Google Scholar] [CrossRef]

- White, T.J.; Tabiryan, N.V.; Serak, S.V.; Hrozhyk, U.A.; Tondiglia, V.P.; Koerner, H.; Vaia, R.A.; Bunning, T.J. A high frequency photodriven polymer oscillator. Soft Matter 2008, 4, 1796–1798. [Google Scholar] [CrossRef]

- De Gennes, P. Possibilites offertes par la reticulation de polymeres en presence d’un cristal liquide. Phys. Lett. A 1969, 28, 725–726. [Google Scholar] [CrossRef]

- Cheng, Z.; Ma, S.; Zhang, Y.; Huang, S.; Chen, Y.; Yu, H. Photomechanical Motion of Liquid-Crystalline Fibers Bending Away from a Light Source. Macromolecules 2017, 50, 8317–8324. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, Z.; Wang, C.; Zarrouk, D.; Seo, J.W.T.; Cheng, J.C.; Buchan, A.D.; Takei, K.; Zhao, Y.; Ager, J.W.; et al. Photoactuators and motors based on carbon nanotubes with selective chirality distributions. Nat. Commun. 2014, 5, 2983. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, G.; Lan, T.; Zhao, J.; Liu, Y.; Chen, W. A Graphene-Based Bimorph Structure for Design of High Performance Photoactuators. Adv. Mater. 2015, 27, 7867–7873. [Google Scholar] [CrossRef]

- Lucchetta, D.E.; Castagna, R.; Simoni, F. Light-actuated contactless macro motors exploiting Bénard–Marangoni convection. Opt. Express 2019, 27, 13574–13580. [Google Scholar] [CrossRef]

- Angeloni, A.S.; Caretti, D.; Carlini, C.; Chiellini, E.; Galli, G.; Altomare, A.; Solaro, R.; Laus, M. Photochromic liquid-crystalline polymers. Main chain and side chain polymers containing azobenzene mesogens. Liq. Cryst. 1989, 4, 513–527. [Google Scholar] [CrossRef]

- Tsutsumi, O.; Shiono, T.; Ikeda, T.; Galli, G. Photochemical Phase Transition Behavior of Nematic Liquid Crystals with Azobenzene Moieties as Both Mesogens and Photosensitive Chromophores. J. Phys. Chem. B 1997, 101, 1332–1337. [Google Scholar] [CrossRef]

- Zettsu, N.; Ogasawara, T.; Arakawa, R.; Nagano, S.; Ubukata, T.; Seki, T. Highly Photosensitive Surface Relief Gratings Formation in a Liquid Crystalline Azobenzene Polymer: New Implications for the Migration Process. Macromolecules 2007, 40, 4607–4613. [Google Scholar] [CrossRef]

- Young Kim, J.; Ho Kim, T.; Kimura, T.; Fukuda, T.; Matsuda, H. Surface relief grating and liquid crystal alignment on azobenzene functionalized polymers. Opt. Mater. 2003, 21, 627–631. [Google Scholar] [CrossRef]

- Ubukata, T.; Hara, M.; Seki, T. Photogeneration of Surface Relief Gratings in Azobenzene Polymer/Liquid Crystal Hybrid Films. Mol. Cryst. Liq. Cryst. 2002, 377, 173–176. [Google Scholar] [CrossRef]

- Wyatt, P.J.M.; Bailey, J.; Nagaraj, M.; Jones, J.C. A self-healing ferroelectric liquid crystal electro-optic shutter based on vertical surface-relief grating alignment. Nat. Commun. 2021, 12, 4717. [Google Scholar] [CrossRef] [PubMed]

- Kawatsuki, N.; Hasegawa, T.; Ono, H.; Tamoto, T. Formation of Polarization Gratings and Surface Relief Gratings in Photocrosslinkable Polymer Liquid Crystals by Polarization Holography. Adv. Mater. 2003, 15, 991–994. [Google Scholar] [CrossRef]

- Lucchetta, D.; Di Donato, A.; Singh, G.; Tombesi, A.; Castagna, R. Optically tunable diffraction efficiency by photo-mobile holographic composite polymer material. Opt. Mater. 2021, 121, 111612. [Google Scholar] [CrossRef]

- Sutherland, R.L.; Natarajan, L.V.; Tondiglia, V.P.; Bunning, T.J. Bragg gratings in an acrylate polymer consisting of periodic polymer-dispersed liquid-crystal planes. Chem. Mater. 1993, 5, 1533–1538. [Google Scholar] [CrossRef]

- Castagna, R.; Rippa, M.; Simoni, F.; Villani, F.; Nenna, G.; Petti, L. Plasmonic Photomobile Polymer Films. Crystals 2020, 10, 660. [Google Scholar] [CrossRef]

- Lucchetta, D.; Castagna, R.; Vita, F.; Gianni, A.; Simoni, F. Microfluidic transport of photopolymerizable species for laser source integration in lab-on-a-chip photonic devices. Photonics Nanostruct. Fundam. Appl. 2012, 10, 575–580. [Google Scholar] [CrossRef]

- Criante, L.; Vita, F.; Castagna, R.; Lucchetta, D.E.; Simoni, F. Characterization of Blue Sensitive Holographic Polymer Dispersed Liquid Crystal for Microholographic Data Storage. Mol. Cryst. Liq. Cryst. 2007, 465, 203–215. [Google Scholar] [CrossRef]

- Criante, L.; Beev, K.; Lucchetta, D.E.; Simoni, F.; Frohmann, S.; Orlic, S. Characterization of polymeric materials for microholographic data storage. In Organic Holographic Materials and Applications III; Meerholz, K., Ed.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2005; Volume 5939, pp. 61–69. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lucchetta, D.E.; Di Donato, A.; Francescangeli, O.; Singh, G.; Castagna, R. Light-Controlled Direction of Distributed Feedback Laser Emission by Photo-Mobile Polymer Films. Nanomaterials 2022, 12, 2890. https://doi.org/10.3390/nano12172890

Lucchetta DE, Di Donato A, Francescangeli O, Singh G, Castagna R. Light-Controlled Direction of Distributed Feedback Laser Emission by Photo-Mobile Polymer Films. Nanomaterials. 2022; 12(17):2890. https://doi.org/10.3390/nano12172890

Chicago/Turabian StyleLucchetta, Daniele Eugenio, Andrea Di Donato, Oriano Francescangeli, Gautam Singh, and Riccardo Castagna. 2022. "Light-Controlled Direction of Distributed Feedback Laser Emission by Photo-Mobile Polymer Films" Nanomaterials 12, no. 17: 2890. https://doi.org/10.3390/nano12172890

APA StyleLucchetta, D. E., Di Donato, A., Francescangeli, O., Singh, G., & Castagna, R. (2022). Light-Controlled Direction of Distributed Feedback Laser Emission by Photo-Mobile Polymer Films. Nanomaterials, 12(17), 2890. https://doi.org/10.3390/nano12172890