Temperature Dependence of Electron Leakage Current in InGaN Blue Light-Emitting Diode Structures

Abstract

:1. Introduction

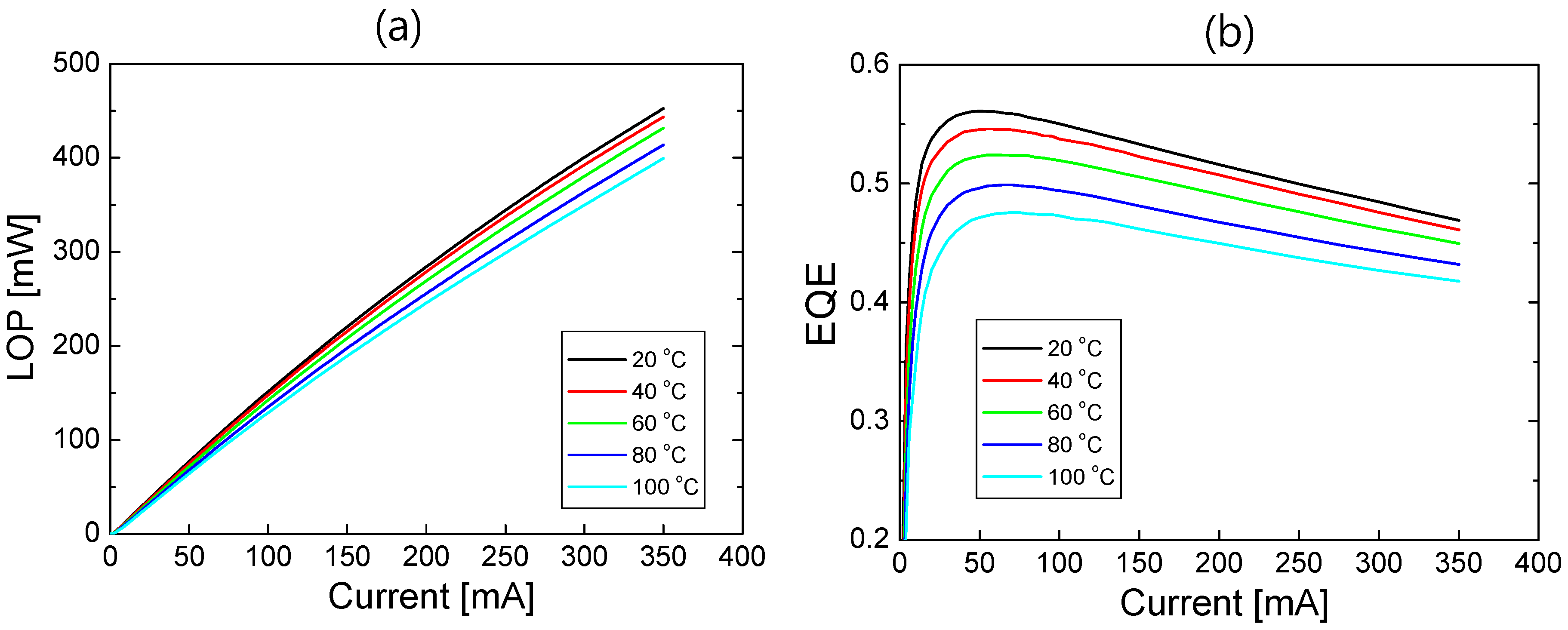

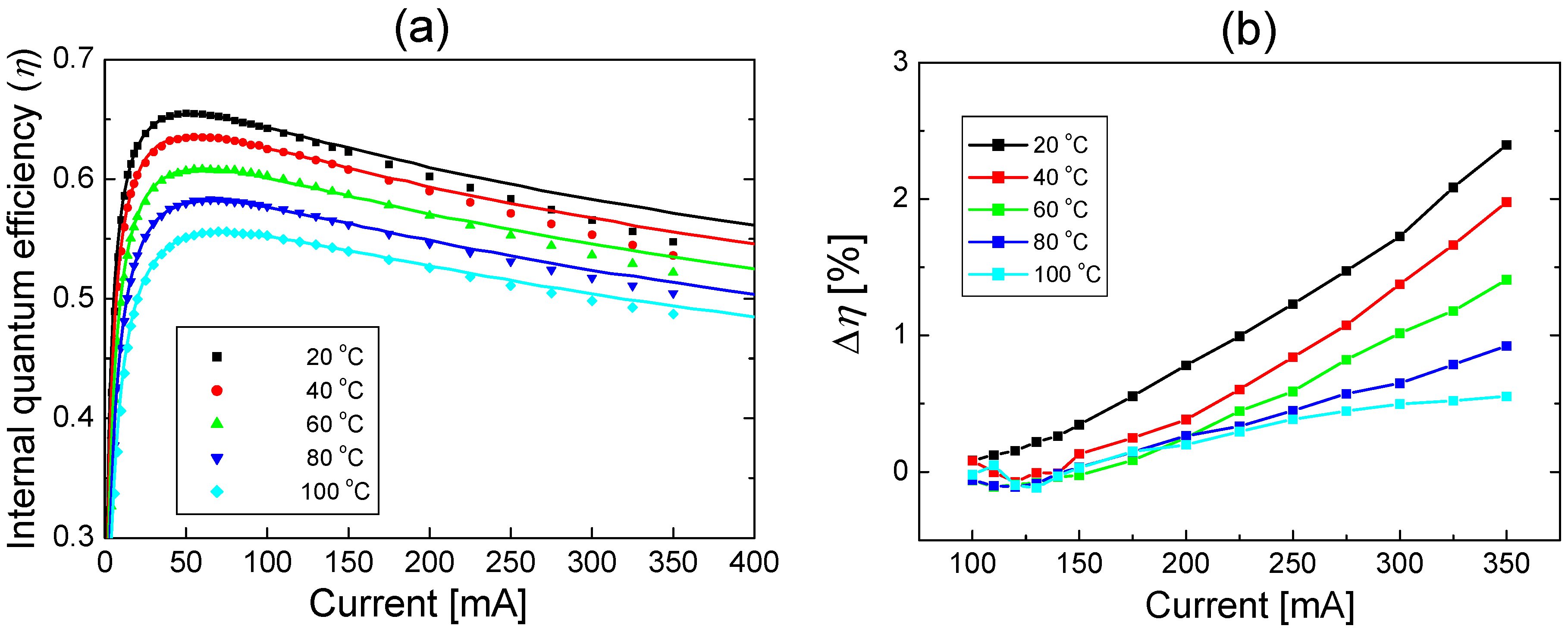

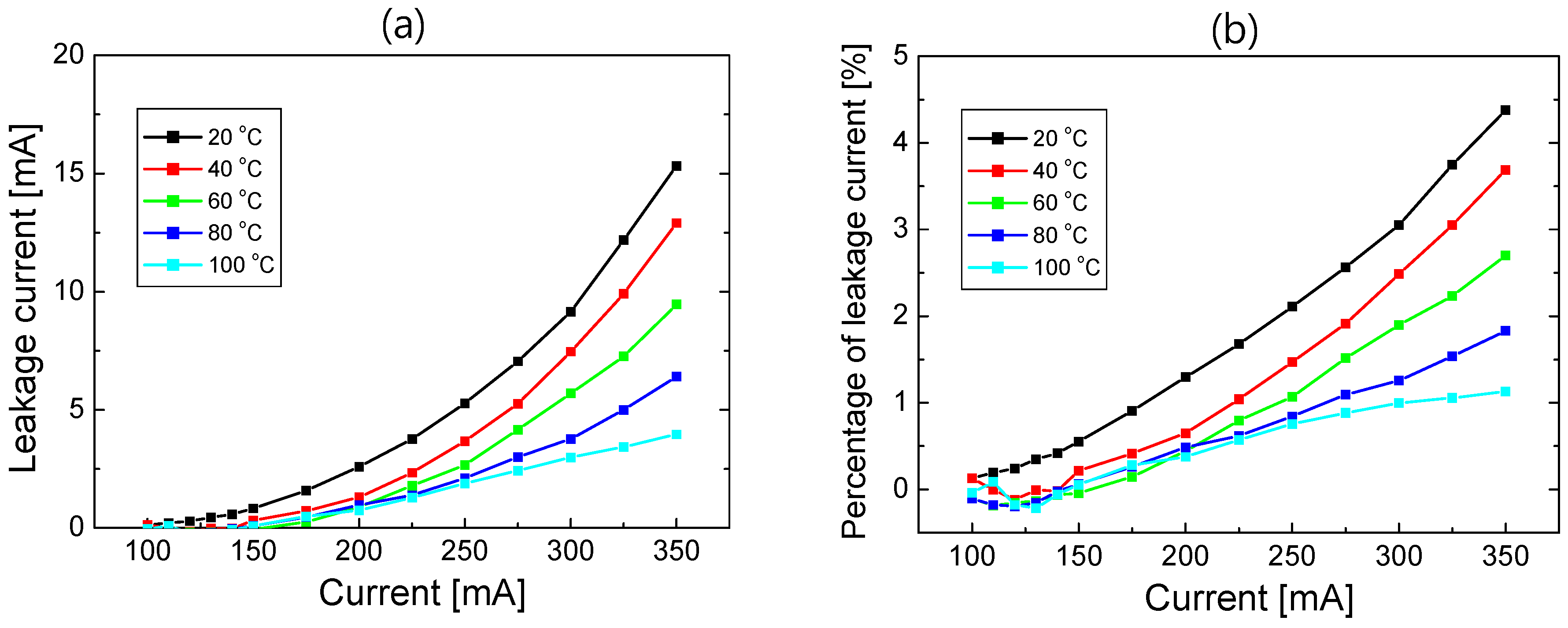

2. Experimental Results

2.1. Sample and Measurement

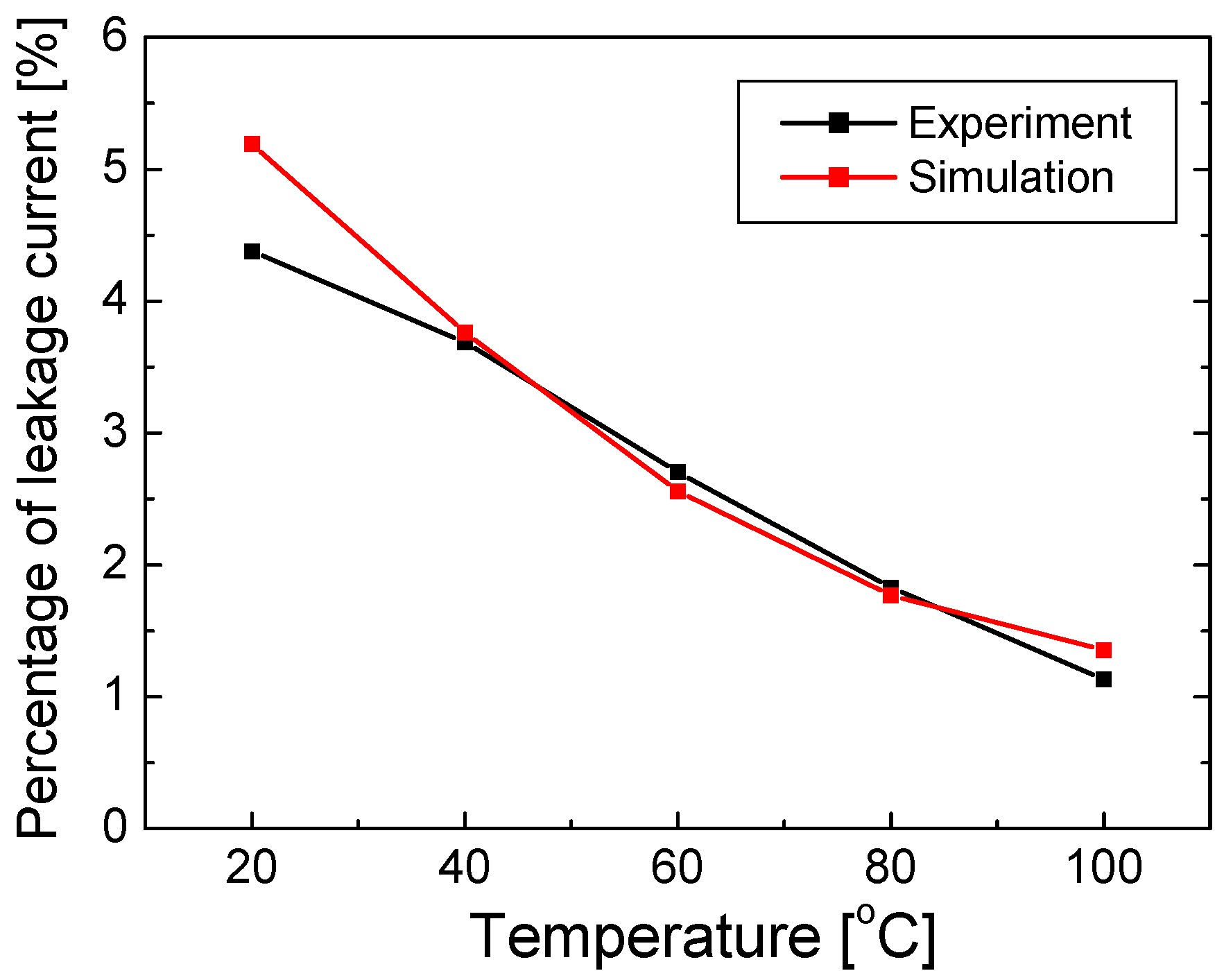

2.2. IQE Fitting and Leakage Current

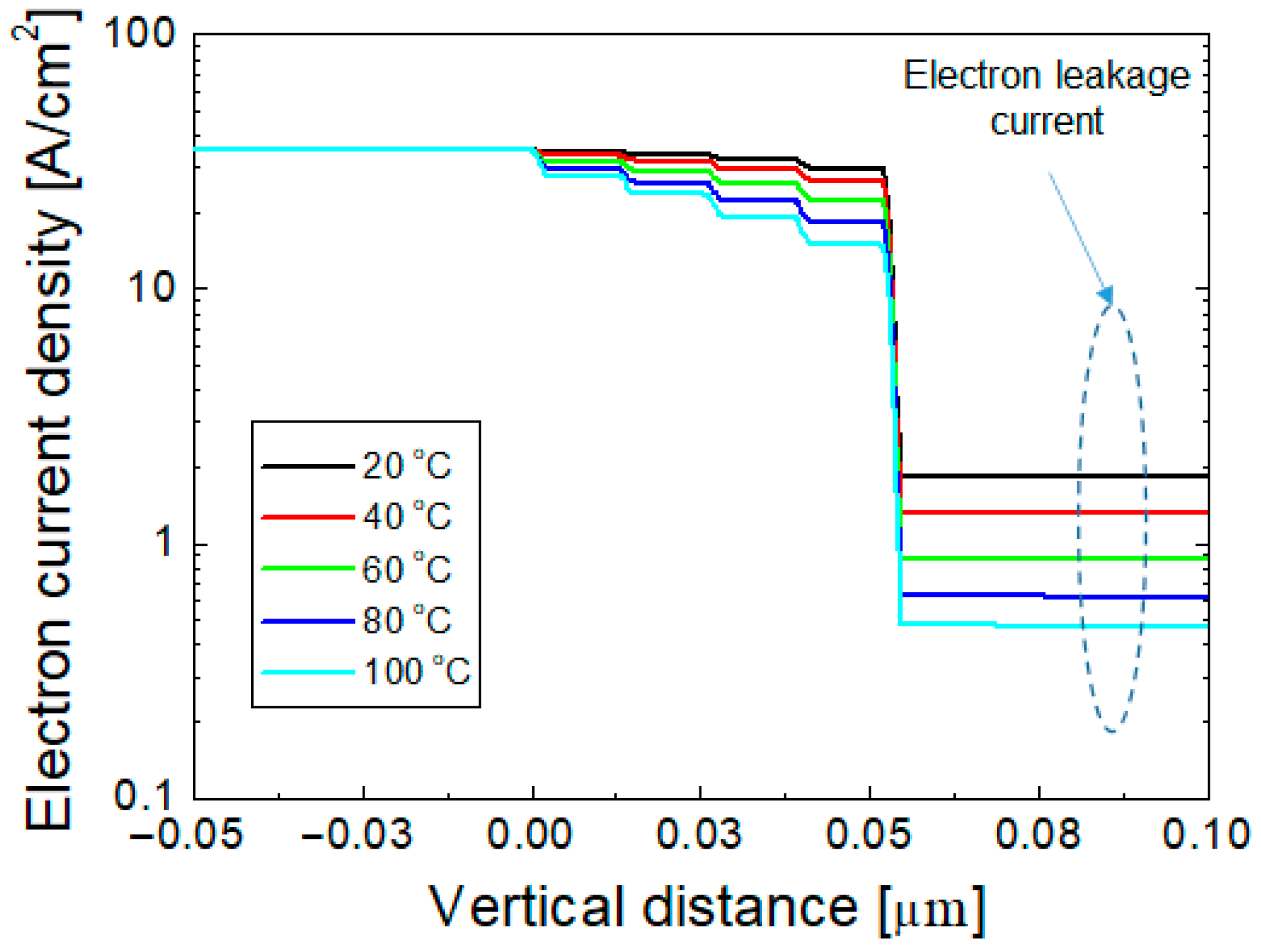

3. Simulation Results

3.1. Simulation Model

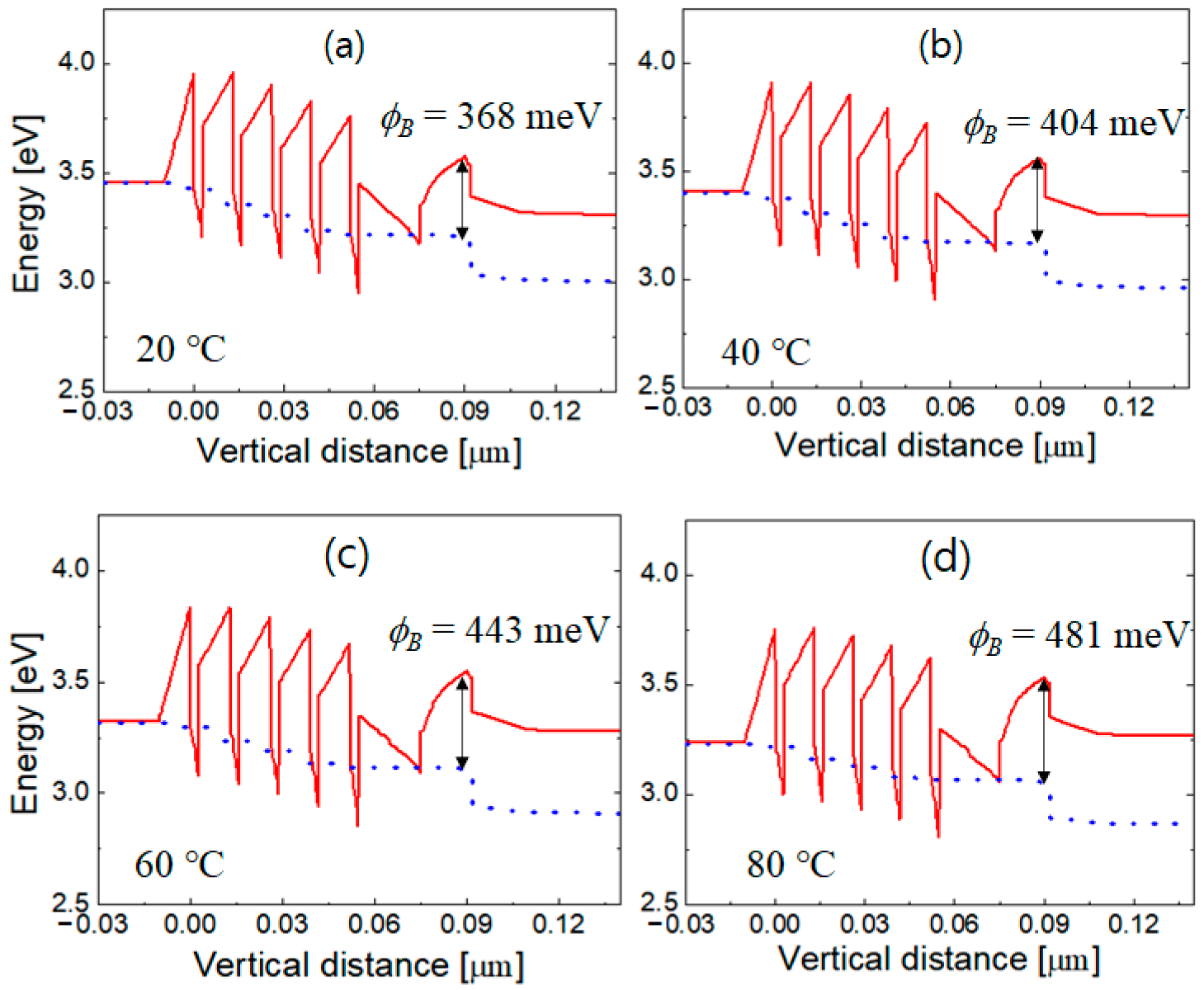

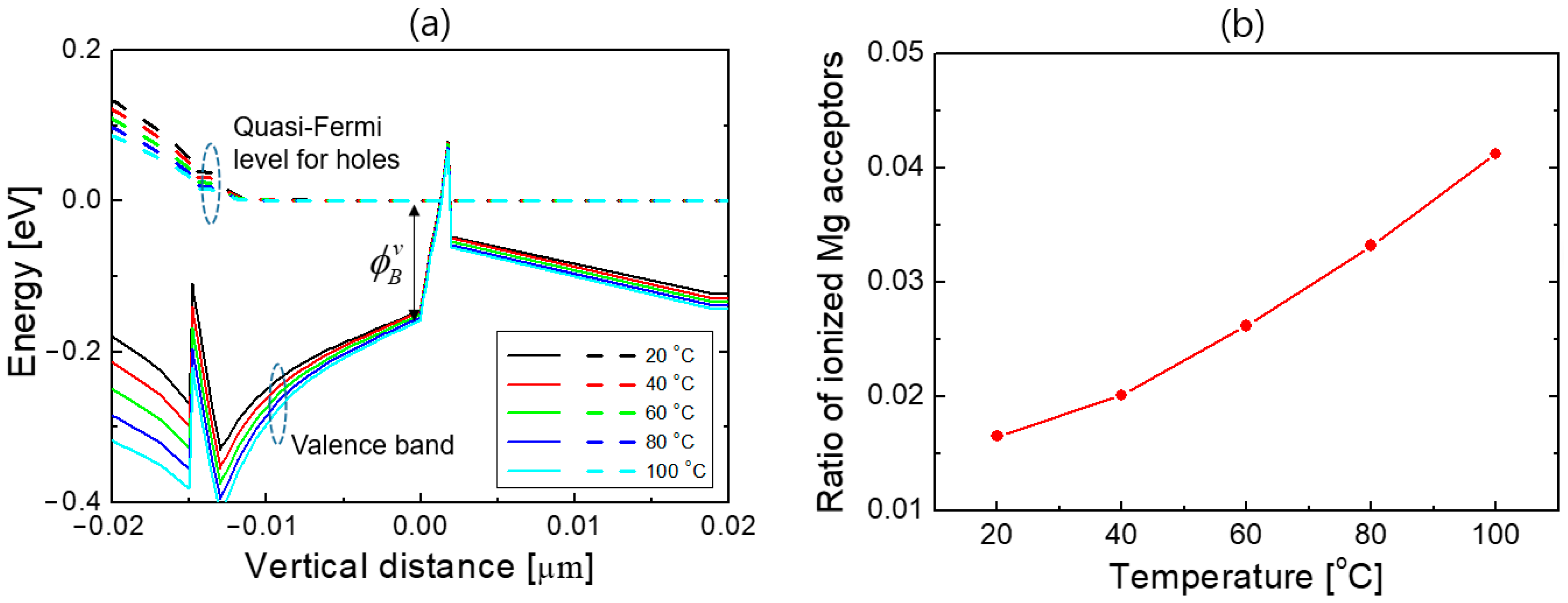

3.2. Simulation of Electron Leakage Current

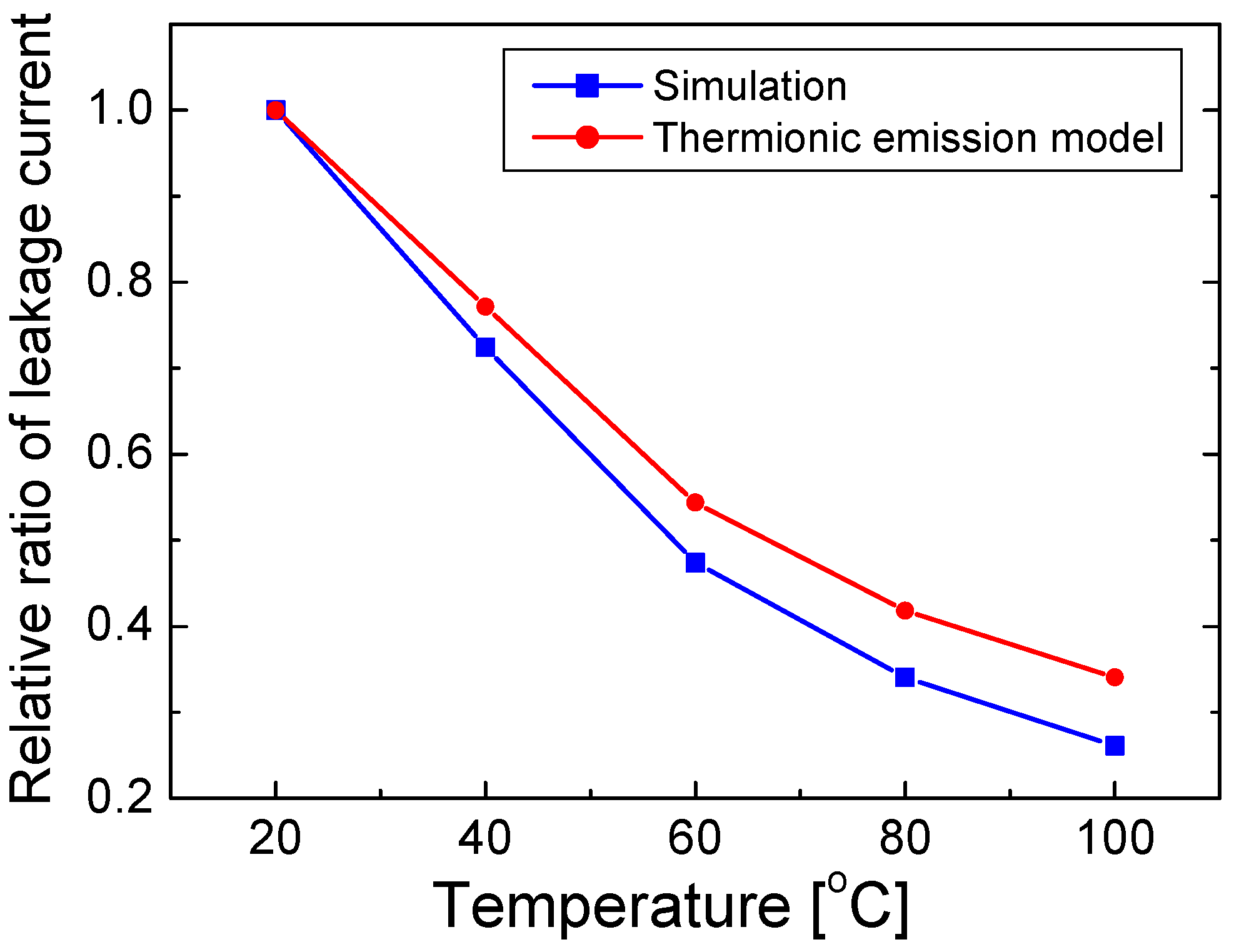

3.3. Analysis Uising Thermionic Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pust, P.; Schmidt, P.J.; Schnick, W. A revolution in lighting. Nat. Mater. 2015, 14, 454–458. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, J.; Cesaratto, J.M.; Wildeson, I.H.; Choy, H.; Tandon, A.; Soer, W.A.; Schmidt, P.J.; Spinger, B.; Deb, P.; Shchekin, O.B.; et al. Progress in high-luminance LED technology for solid-state lighting. Phys. Status Solidi A 2017, 214, 1600826. [Google Scholar] [CrossRef]

- Cho, J.; Park, J.H.; Kim, J.K.; Schubert, E.F. White light-emitting diodes: History, progress, and future. Laser Photon. Rev. 2017, 11, 1600147. [Google Scholar] [CrossRef]

- Parbrook, P.J.; Corbett, B.; Han, J.; Seong, T.Y.; Amano, H. Micro-light emitting diode: From chips to applications. Laser Photon. Rev. 2021, 15, 2000133. [Google Scholar] [CrossRef]

- Hurni, A.; David, A.; Cich, M.J.; Aldaz, R.I.; Ellis, B.; Huang, K.; Tyagi, A.; DeLille, R.A.; Craven, M.D.; Steranka, F.M. Bulk GaN flip-chip violet light-emitting diodes with optimized efficiency for high-power operation. Appl. Phys. Lett. 2015, 106, 031101. [Google Scholar] [CrossRef]

- Kuritzky, L.Y.; Weisbuch, C.; Speck, J.S. Prospects for 100% wall-plug efficiency III-nitride LEDs. Opt. Express 2018, 26, 16600–16608. [Google Scholar] [CrossRef] [PubMed]

- Shim, J.I.; Shin, D.S. Measuring the internal quantum efficiency of light-emitting diodes: Towards accurate and reliable room-temperature characterization. Nanophotonics 2018, 7, 1601–1615. [Google Scholar] [CrossRef]

- David, A.; Young, N.G.; Lund, C.; Craven, M.D. Review—The physics of recombinations in III-nitride emitters. ECS J. Solid State Sci. Technol. 2020, 9, 016021. [Google Scholar] [CrossRef]

- Cho, J.; Schubert, E.F.; Kim, J.K. Efficiency droop in light-emitting diodes: Challenges and countermeasures. Laser Photon. Rev. 2013, 7, 408–421. [Google Scholar] [CrossRef]

- Hopkins, M.A.; Allsopp, D.W.E.; Kappers, M.J.; Oliver, R.A.; Humphreys, C.J. The ABC model of recombination reinterpreted: Impact on understanding carrier transport and efficiency droop in InGaN/GaN light emitting diodes. J. Appl. Phys. 2017, 122, 234505. [Google Scholar] [CrossRef]

- Zhao, Y.; Fu, H.; Wang, G.T.; Nakamura, S. Toward ultimate efficiency: Progress and prospects on planar and 3D nanostructured nonpolar and semipolar InGaN light-emitting diodes. Adv. Opt. Photon. 2018, 10, 246–308. [Google Scholar] [CrossRef]

- Piprek, J. Efficiency models for GaN-based light-emitting diodes: Status and challenges. Materials 2020, 13, 5174. [Google Scholar] [CrossRef] [PubMed]

- Meyaard, D.S.; Shan, Q.; Cho, J.; Schubert, E.F.; Han, S.H.; Kim, M.H.; Sone, C.; Oh, S.J.; Kim, J.K. Temperature dependent efficiency droop in GaInN light-emitting diodes with different current densities. Appl. Phys. Lett. 2012, 100, 081106. [Google Scholar] [CrossRef] [Green Version]

- Park, S.H.; Moon, Y.T. Temperature droop characteristics of internal efficiency in InxGa1-xN/GaN quantum well light-emitting diodes. IEEE Photon. J. 2014, 6, 1600209. [Google Scholar]

- David, A.; Young, N.G.; Lund, C.; Craven, M.D. Thermal droop in high-quality InGaN LEDs. Appl. Phys. Lett. 2019, 115, 223502. [Google Scholar] [CrossRef]

- Meneghini, M.; De Santi, C.; Tibaldi, A.; Vallone, M.; Bertazzi, F.; Meneghesso, G.; Zanoni, E.; Goano, M. Thermal droop in III-nitride based light-emitting diodes: Physical origin and perspectives. J. Appl. Phys. 2020, 127, 211102. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Y.; Huang, J.; Deng, H.; Wang, M.; Yin, H. The effects of temperature on optical properties of InGaN/GaN multiple quantum well light-emitting diodes. J. Appl. Phys. 2017, 121, 053105. [Google Scholar] [CrossRef]

- Zhao, L.; Yan, D.; Zhang, Z.; Hua, B.; Yang, G.; Cao, Y.; Zhang, E.X.; Gu, X.; Fleetwood, D.M. Temperature-dependent efficiency droop in GaN-based blue LEDs. IEEE Electr. Dev. Lett. 2018, 39, 528–531. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Ryu, G.H.; Onwukaeme, C.; Ma, B. Temperature dependence of the Auger recombination coefficient in InGaN/GaN multiple-quantum-well light-emitting diodes. Opt. Express 2020, 28, 27459–27472. [Google Scholar] [CrossRef]

- Kim, M.H.; Schubert, M.F.; Dai, Q.; Kim, J.K.; Schubert, E.F.; Piprek, J.; Park, Y. Origin of efficiency droop in GaN-based light-emitting diodes. Appl. Phys. Lett. 2007, 91, 183507. [Google Scholar] [CrossRef] [Green Version]

- Rozhansky, I.V.; Zakheim, D.A. Analysis of processes limiting quantum efficiency of AlGaInN LEDs at high pumping. Phys. Stat. Solidi A 2007, 204, 227–230. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Z.; Yi, X.; Guo, Y.; Wu, S.; Yuan, G.; Wang, J.; Wang, G.; Li, J. Overshoot effects of electron on efficiency droop in InGaN/GaN MQW light-emitting diodes. AIP Adv. 2016, 6, 045219. [Google Scholar] [CrossRef] [Green Version]

- Ryu, H.Y.; Jeon, K.S.; Kang, M.G.; Yuh, H.K.; Choi, Y.H.; Lee, J.S. A comparative study of efficiency droop and internal electric field for InGaN blue light-emitting diodes on silicon and sapphire substrates. Sci. Rep. 2017, 7, 44814. [Google Scholar] [CrossRef]

- Xia, C.S.; Li, Z.M.S.; Sheng, Y. On the importance of AlGaN electron blocking layer design for GaN-based light-emitting diodes. Appl. Phys. Lett. 2013, 103, 233505. [Google Scholar]

- Tzou, A.J.; Lin, D.W.; Yu, C.R.; Li, Z.Y.; Liao, Y.K.; Lin, B.C.; Huang, J.K.; Lin, C.C.; Kao, T.S.; Kuo, H.C.; et al. High-performance InGaN-based green light-emitting diodes with quaternary InAlGaN/GaN superlattice electron blocking layer. Opt. Express. 2016, 24, 11387–11395. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Yin, Y.A. Performance enhancement of blue light-emitting diodes with a special designed AlGaN/GaN superlattice electron-blocking layer. Appl. Phys. Lett. 2011, 99, 221103. [Google Scholar] [CrossRef]

- Kim, J.; Ji, M.H.; Detchprohm, T.; Dupuis, R.D.; Shervin, S.; Ryou, J.H. Effect of lattice-matched InAlGaN electron-blocking layer on hole transport and distribution in InGaN/GaN multiple quantum wells of visible light-emitting diodes. Phys. Status Solidi A 2015, 213, 1296–1301. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, S.W.H.; Chu, C.; Tian, K.; Fang, M.; Zhang, Y.; Bi, W.; Kuo, H.C. Nearly efficiency-droop-free AlGaN-based ultraviolet light-emitting diodes with a specifically designed superlattice p-type electron blocking layer for high Mg doping efficiency. Nanoscale Res. Lett. 2018, 13, 122. [Google Scholar] [CrossRef] [Green Version]

- Yan, G.; Hyun, B.R.; Jiang, F.; Kuo, H.C.; Liu, Z. Exploring superlattice DBR effect on a micro-LED as an electron blocking layer. Opt. Express 2021, 29, 26255–26264. [Google Scholar] [CrossRef]

- Meyaard, D.S.; Shan, Q.; Dai, Q.; Cho, J.; Schubert, E.F.; Kim, M.H.; Sone, C. On the temperature dependence of electron leakage from the active region of GaInN/GaN light-emitting diodes. Appl. Phys. Lett. 2011, 99, 041112. [Google Scholar] [CrossRef] [Green Version]

- Prajoon, P.; Nirmal, D.; Menokey, M.A.; Pravin, J.C. Temperature-dependent efficiency droop analysis of InGaN MQW light-emitting diode with modified ABC model. J. Comput. Electron. 2016, 15, 1511–1520. [Google Scholar] [CrossRef]

- Shen, Y.C.; Mueller, G.O.; Watanabe, S.; Gardner, N.F.; Munkholm, A.; Krames, M.R. Auger recombination in InGaN measured by photoluminescence. Appl. Phys. Lett. 2007, 91, 141101. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Kim, H.S.; Shim, J.I. Rate equation analysis of efficiency droop in InGaN light-emitting diodes. Appl. Phys. Lett. 2009, 95, 081114. [Google Scholar] [CrossRef]

- Dai, Q.; Shan, Q.; Wang, J.; Chhajed, S.; Cho, J.; Schubert, E.F.; Crawford, M.H.; Koleske, D.D.; Kim, M.H.; Park, Y. Carrier recombination mechanisms and efficiency droop in GaInN/GaN light-emitting diodes. Appl. Phys. Lett. 2010, 97, 133507. [Google Scholar] [CrossRef] [Green Version]

- Piprek, J.; Römer, F.; Witzigmann, B. On the uncertainty of the Auger recombination coefficient extracted from InGaN/GaN light-emitting diode efficiency droop measurements. Appl. Phys. Lett. 2015, 106, 101101. [Google Scholar] [CrossRef] [Green Version]

- Nippert, F.; Karpov, S.; Pietzonka, I.; Galler, B.; Wilm, A.; Kure, T.; Nenstiel, C.; Callsen, G.; Straßburg, M.; Lugauer, H.; et al. Determination of recombination coefficients in InGaN quantum-well light-emitting diodes by small-signal time-resolved photoluminescence. Jpn. J. Appl. Phys. 2016, 55, 05FJ01. [Google Scholar] [CrossRef] [Green Version]

- Lin, G.B.; Meyaard, D.; Cho, J.; Schubert, E.F.; Shim, H.; Sone, C. Analytic model for the efficiency droop in semiconductors with asymmetric carrier-transport properties based on drift-induced reduction of injection efficiency. Appl. Phys. Lett. 2012, 100, 161106. [Google Scholar] [CrossRef] [Green Version]

- APSYS by Crosslight Software, Inc., Burnaby, Canada. Available online: http://www.crosslight.com (accessed on 1 June 2022).

- Piprek, J.; Li, Z.M.S. Sensitivity analysis of electron leakage in III-nitride light-emitting diodes. Appl. Phys. Lett. 2013, 102, 131103. [Google Scholar] [CrossRef] [Green Version]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for nonlinear macroscopic polarization in III-V nitride alloy heterostructures. Appl. Phys. Lett. 2002, 80, 1204–1206. [Google Scholar] [CrossRef]

- Feng, M.X.; Liu, J.P.; Zhang, S.M.; Jiang, D.S.; Li, Z.C.; Zhou, K.; Li, D.Y.; Zhang, L.Q.; Wang, F.; Wang, H.; et al. High efficient GaN-based laser diodes with tunnel junction. Appl. Phys. Lett. 2013, 103, 043508. [Google Scholar] [CrossRef]

- Piprek, J. Comparative efficiency analysis of GaN-based light-emitting diodes and laser diodes. Appl. Phys. Lett. 2016, 109, 021104. [Google Scholar] [CrossRef]

- Farahmand, M.; Garetto, C.; Bellotti, E.; Brennan, K.F.; Goano, M.; Ghillino, E.; Ghione, G.; Albrecht, J.D.; Ruden, P.P. Monte Carlo simulation of electron transport in the III-nitride wurtzite phase materials system: Binaries and ternaries. IEEE Trans. Electron Dev. 2001, 48, 535–542. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.R.; Wu, Y.C.; Ling, S.C.; Ko, T.S.; Lu, T.C.; Kuo, H.C.; Kuo, Y.K.; Wang, S.C. Investigation of wavelength-dependent efficiency droop in InGaN light-emitting diodes. Appl. Phys. B 2010, 98, 779–789. [Google Scholar] [CrossRef]

- Piprek, J. Semiconductor Optoelectronic Devices; Academic Press: Cambridge, MA, USA, 2003; Chapter 9. [Google Scholar]

- Horio, K.; Yanai, H. Numerical modeling of heterojunctions including the thermionic emission mechanism at the heterojunction interface. IEEE Trans. Electron Dev. 1990, 37, 1093–1098. [Google Scholar] [CrossRef]

- Onwukaeme, C.; Ryu, H.Y. Investigation of the optimum Mg doping concentration in p-type-doped layers of InGaN blue laser diode structures. Crystals 2021, 11, 1335. [Google Scholar] [CrossRef]

- Neamen, D.A. Semiconductor Physics and Devices, 4th ed.; McGraw Hill: New York, NY, USA, 2012; pp. 131–135. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onwukaeme, C.; Lee, B.; Ryu, H.-Y. Temperature Dependence of Electron Leakage Current in InGaN Blue Light-Emitting Diode Structures. Nanomaterials 2022, 12, 2405. https://doi.org/10.3390/nano12142405

Onwukaeme C, Lee B, Ryu H-Y. Temperature Dependence of Electron Leakage Current in InGaN Blue Light-Emitting Diode Structures. Nanomaterials. 2022; 12(14):2405. https://doi.org/10.3390/nano12142405

Chicago/Turabian StyleOnwukaeme, Chibuzo, Bohae Lee, and Han-Youl Ryu. 2022. "Temperature Dependence of Electron Leakage Current in InGaN Blue Light-Emitting Diode Structures" Nanomaterials 12, no. 14: 2405. https://doi.org/10.3390/nano12142405

APA StyleOnwukaeme, C., Lee, B., & Ryu, H.-Y. (2022). Temperature Dependence of Electron Leakage Current in InGaN Blue Light-Emitting Diode Structures. Nanomaterials, 12(14), 2405. https://doi.org/10.3390/nano12142405