Dispersion and Preparation of Nano-AlN/AA6061 Composites by Pressure Infiltration Method

Abstract

:1. Introduction

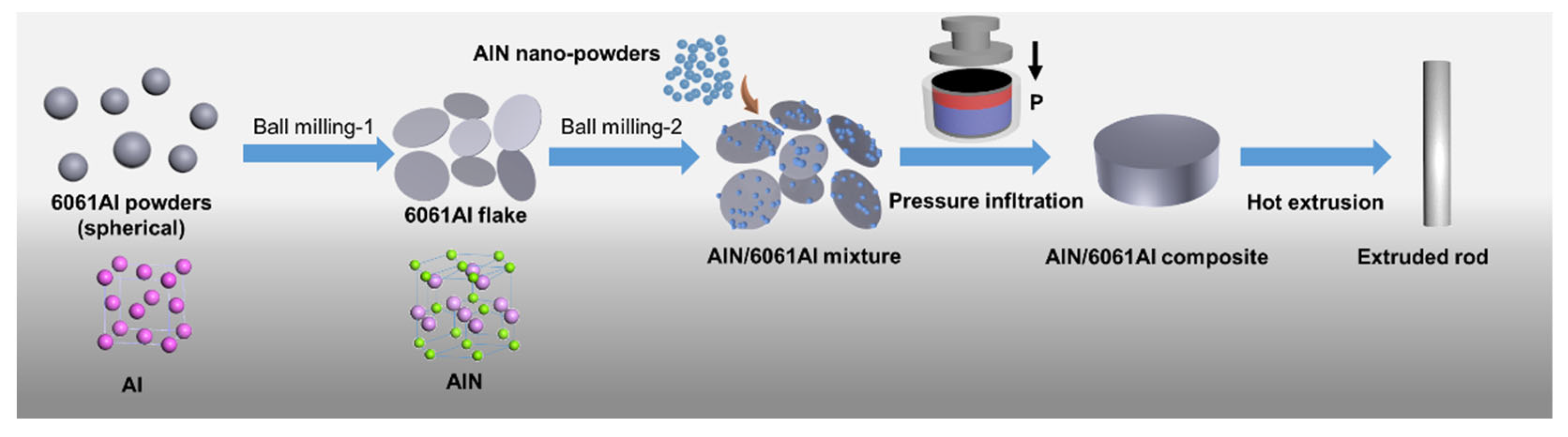

2. Materials and Methods

2.1. Materials and Praperation

2.2. Characterization Methods

3. Results and Discussion

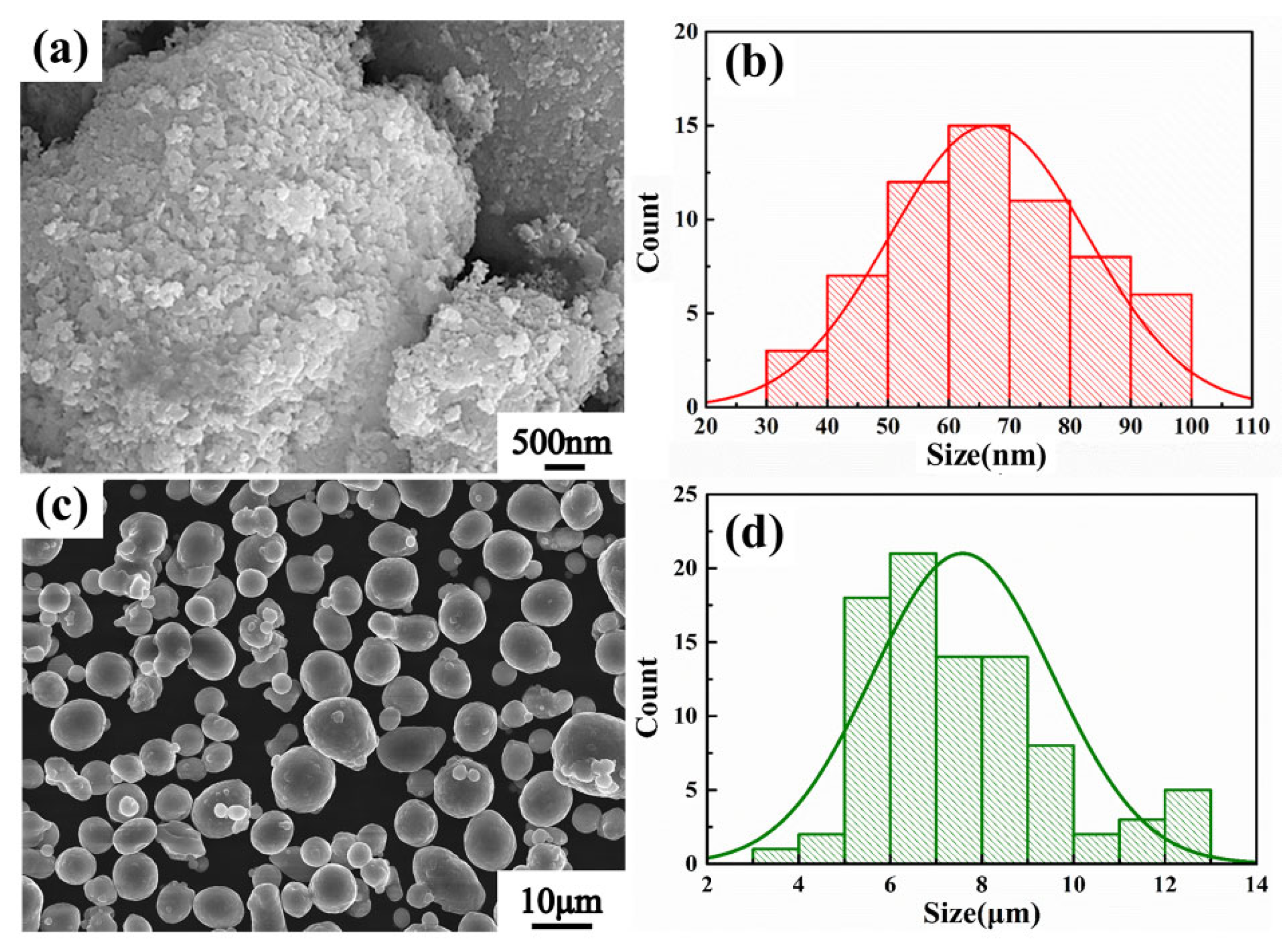

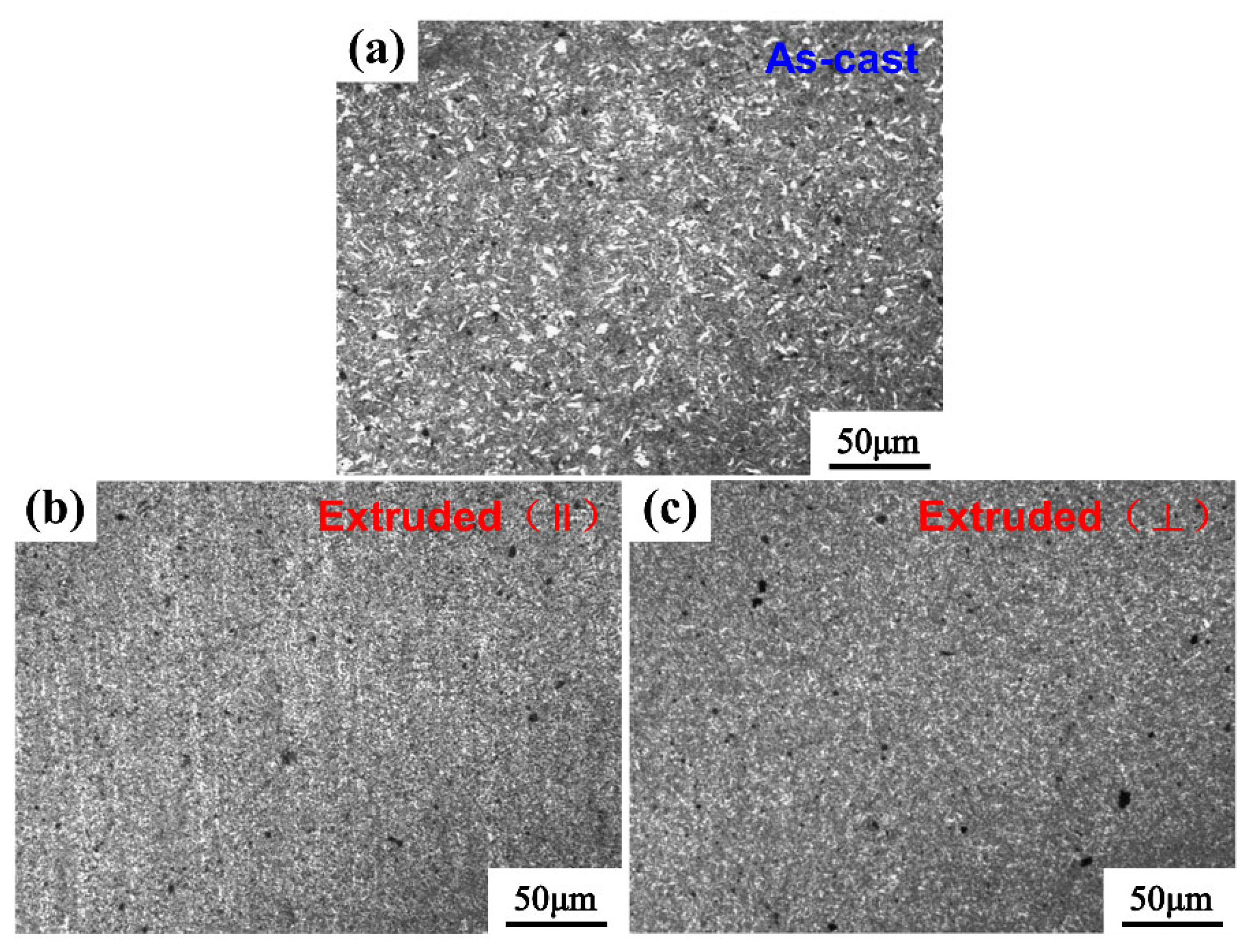

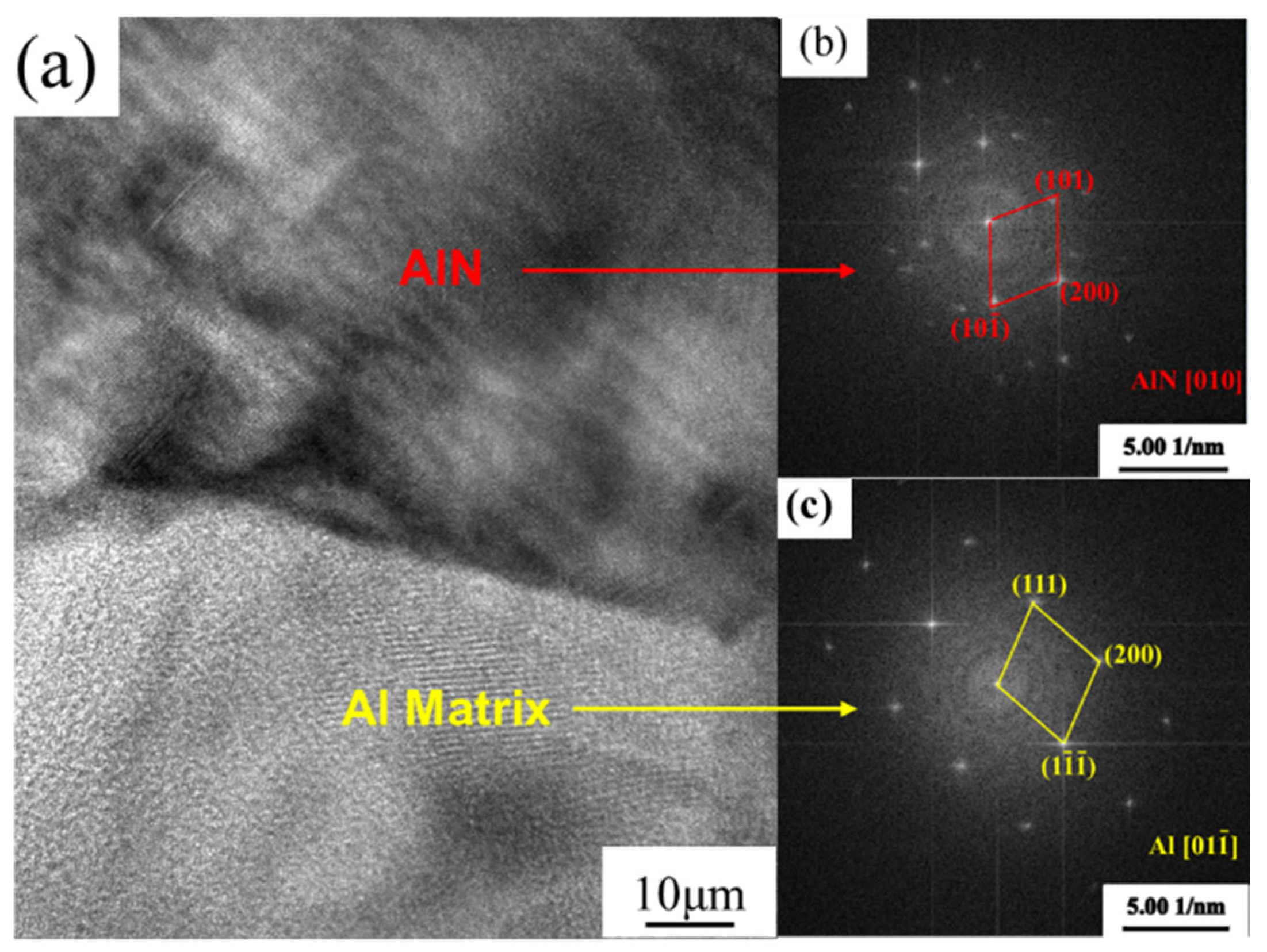

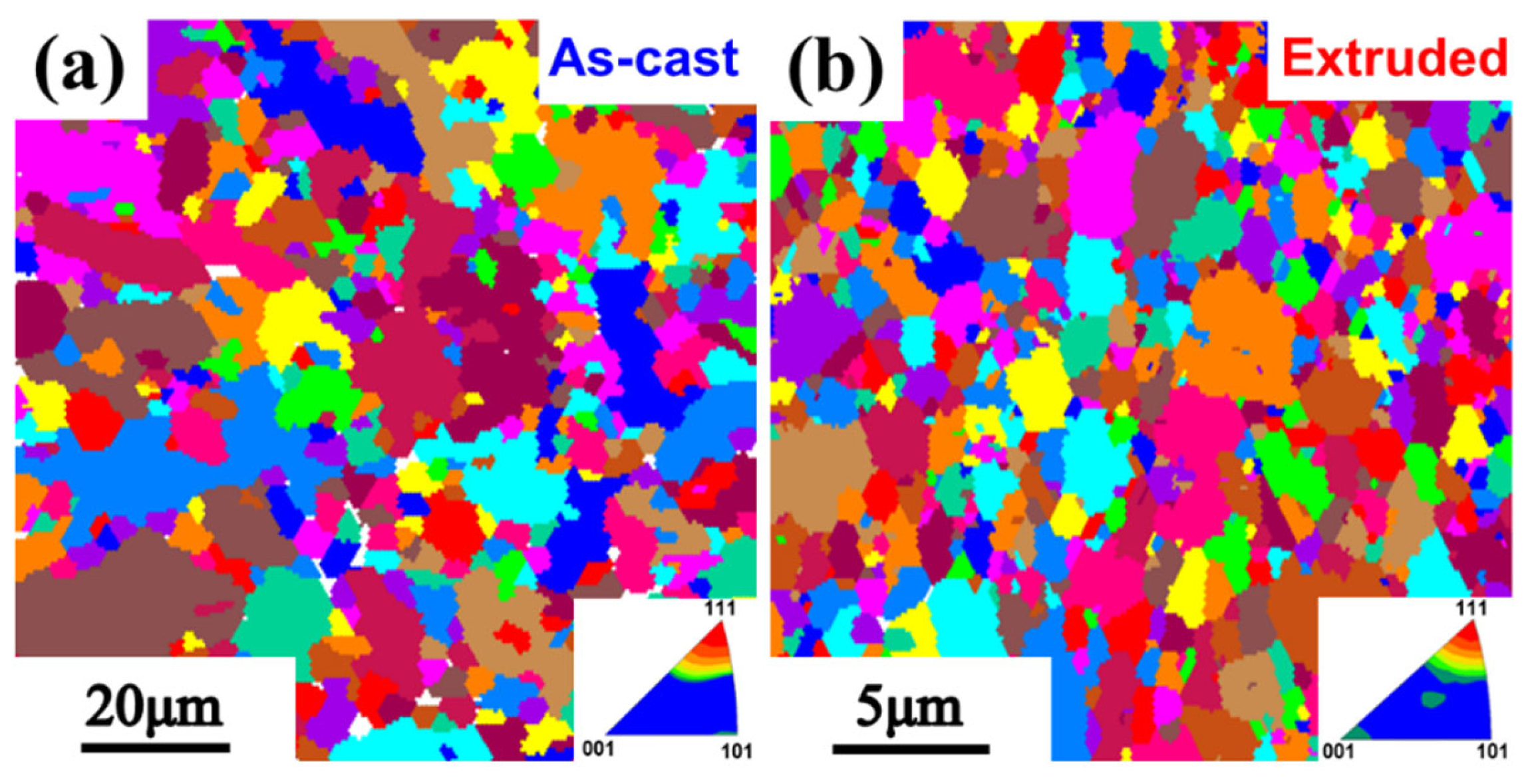

3.1. Microstructure of Nano-AlN/AA6061 Composites

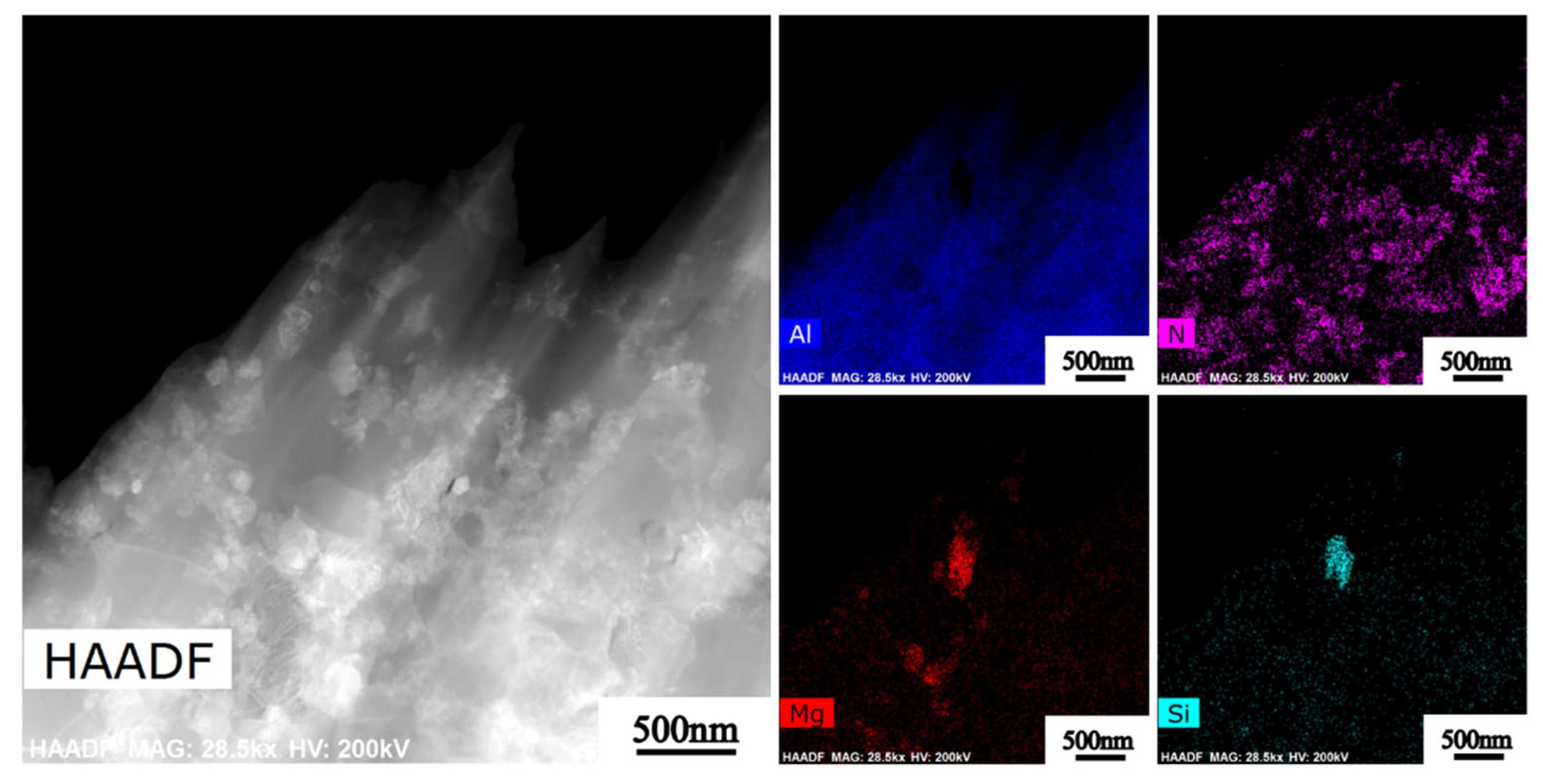

3.2. Distribution of Nano-AlN Particles

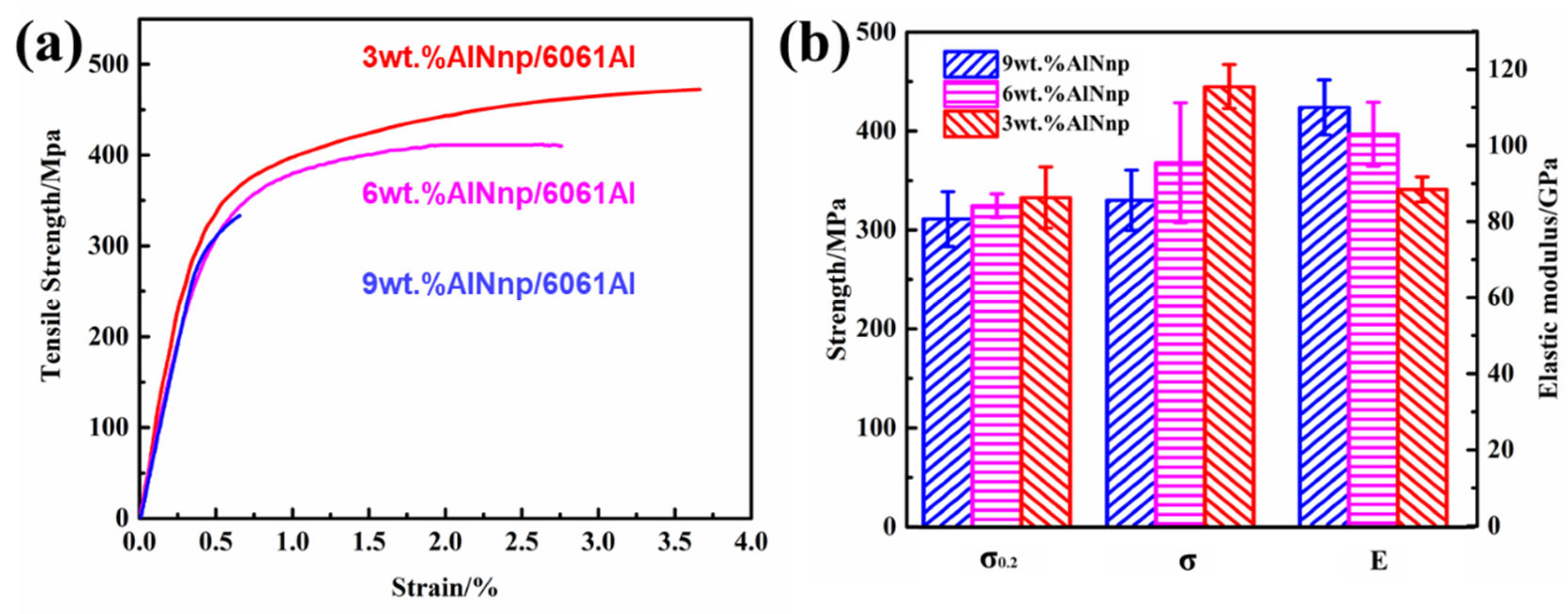

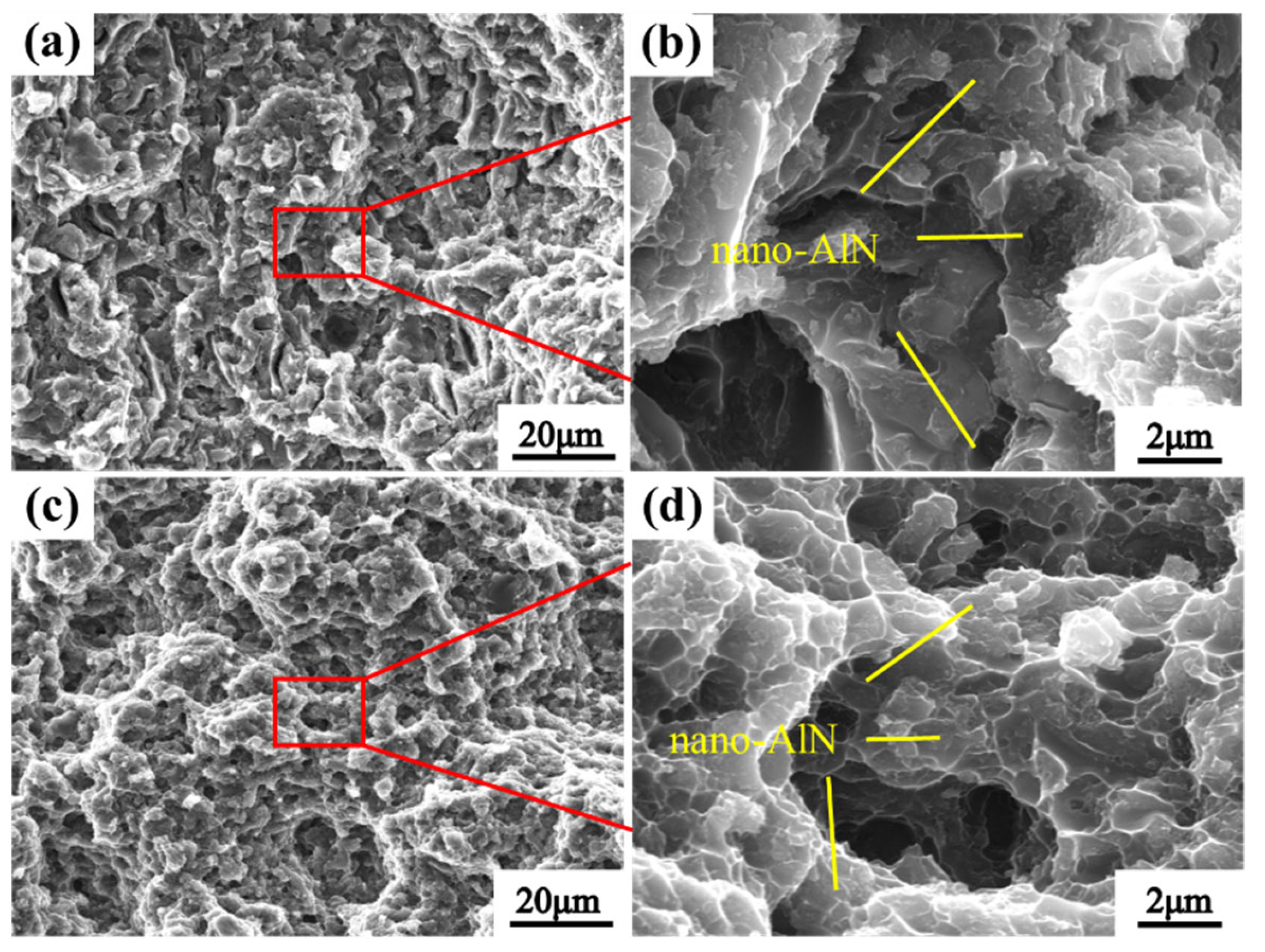

3.3. Machinal Properties of Nano-AlN/AA6061

3.4. Strengthening Mechanism of Nano-AlN/AA6061

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tugirumubano, A.; Go, S.H.; Shin, H.J.; Kwac, L.K.; Kim, H.G. Magnetic, Electrical, and Mechanical Behavior of Fe-Al-MWCNT and Fe-Co-Al-MWCNT Magnetic Hybrid Nanocomposites Fabricated by Spark Plasma Sintering. Nanomaterials 2020, 10, 436. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, Y.; Fatemi, V.; Fang, S.; Watanabe, K.; Taniguchi, T.; Kaxiras, E.; Jarillo-Herrero, P. Unconventional superconductivity in magic-angle graphene superlattices. Nature 2018, 556, 43–50. [Google Scholar] [CrossRef]

- Wang, Z.J.; Zhou, S.J.; Shao, P.Z.; Sun, K.; Zhang, Q.; Xiu, Z.Y.; Xiao, H.Y.; Wu, G.H. Element diffusion behavior and mechanical properties of AlSiTiCrNiCu HEA particulates reinforced Al6061 composites by SPS and HPS process. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2022, 37, 1–12. [Google Scholar] [CrossRef]

- Wen, L.; Li, F.; Cheng, H.M. Carbon Nanotubes and Graphene for Flexible Electrochemical Energy Storage: From Materials to Devices. Adv. Mater. 2016, 28, 4306–4337. [Google Scholar] [CrossRef] [PubMed]

- Feng, S.; Guo, Q.; Li, Z.; Fan, G.; Li, Z.; Xiong, D.; Su, Y.; Tan, Z.; Zhang, J.; Zhang, D. Strengthening and toughening mechanisms in graphene-Al nanolaminated composite micro-pillars. Acta Mater. 2017, 125, 98–108. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.; Pan, B.; Pan, D.; Zhou, S.; Yang, S.; Jia, L.; Kondoh, K. A novel strengthening effect of in-situ nano Al2O3w on CNTs reinforced aluminum matrix nanocomposites and the matched strengthening mechanisms. J. Alloys Compd. 2018, 764, 279–288. [Google Scholar] [CrossRef]

- Zhao, Z.; Bai, P.; Misra, R.; Dong, M.; Guan, R.; Li, Y.; Zhang, J.; Tan, L.; Gao, J.; Ding, T.; et al. AlSi10Mg alloy nanocomposites reinforced with aluminum-coated graphene: Selective laser melting, interfacial microstructure and property analysis. J. Alloys Compd. 2019, 792, 203–214. [Google Scholar] [CrossRef]

- Wang, Y.; Sha, G.; Harlow, C.; Yazbeck, M.; Khafizov, M. Impact of nuclear reactor radiation on the performance of AlN/sapphire surface acoustic wave devices. Nuclear Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2020, 481, 35–41. [Google Scholar] [CrossRef]

- Bembalge, O.B.; Panigrahi, S.K. Development and strengthening mechanisms of bulk ultrafine grained AA6063/SiC composite sheets with varying reinforcement size ranging from nano to micro domain. J. Alloys Compd. 2018, 766, 355–372. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, Y.F.; Tian, W.J.; Qian, Z.; Chen, H.W.; Wu, Y.Y.; Liu, X.F. A novel Al matrix composite reinforced by nano-AlNp network. Sci. Rep. 2018, 6, 34919. [Google Scholar] [CrossRef] [Green Version]

- Xiu, Z.; Yang, W.; Dong, R.; Hussain, M.; Jiang, L.; Liu, Y.; Wu, G. Microstructure and Mechanical Properties of 45 vol.% SiCp/7075Al Composite. J. Mater. Sci. Technol. 2015, 31, 930–934. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Li, C.J.; Li, K.R.; Yi, J.H.; Tang, J.J.; Zhang, Q.X.; Liu, X.Q.; Bao, R.; Li, X. Carbon nanotube-reinforced aluminum matrix composites enhanced by grain refinement and in situ precipitation. J. Mater. Sci. 2019, 54, 8655–8664. [Google Scholar] [CrossRef]

- Geng, R.; Qiu, F.; Jiang, Q. Reinforcement in Al Matrix Composites: A Review of Strengthening Behavior of Nano-Sized Particles. Adv. Eng. Mater. 2018, 20, 201701089. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, P.; Zhang, B.; Tang, S.; Yang, Z.; Chen, Y.; Yang, W. Preparation and characterization of reduced graphene oxide/copper composites incorporated with nano-SiO2 particles. J. Alloys Compd. 2016, 671, 465–472. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, N.; He, C. The superior mechanical and physical properties of nanocarbon reinforced bulk composites achieved by architecture design—A review. Prog. Mater. Sci. 2020, 113, 100672. [Google Scholar] [CrossRef]

- Zhang, D.; Zhan, Z. Strengthening effect of graphene derivatives in copper matrix composites. J. Alloys Compd. 2016, 654, 226–233. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Xiong, D.; Fan, G.; Guo, Q.; Zhang, J.; Su, Y.; Li, Z.; Zhang, D. Balanced strength and ductility in CNT/Al composites achieved by flake powder metallurgy via shift-speed ball milling. Compos. Part A Appl. Sci. Manuf. 2017, 96, 57–66. [Google Scholar] [CrossRef]

- Hwang, J.; Yoon, T.; Jin, S.H.; Lee, J.; Kim, T.S.; Hong, S.H.; Jeon, S. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process. Adv. Mater. 2013, 25, 6724–6729. [Google Scholar] [CrossRef]

- Jiang, L.; Li, Z.; Fan, G.; Cao, L.; Zhang, D. The use of flake powder metallurgy to produce carbon nanotube (CNT)/aluminum composites with a homogenous CNT distribution. Carbon 2012, 50, 1993–1998. [Google Scholar] [CrossRef]

- Chen, J.; Bao, C.; Chen, F. Evolutions of microstructure and mechanical properties for Mg-Al/AlN composites under hot extrusion. Mater. Sci. Eng. A 2016, 667, 426–434. [Google Scholar] [CrossRef]

- Caballero, E.; Cintas, J.; Cuevas, F.; Montes, J.; Ternero, F.; Reina, F. Synthesis and characterization of in situ-reinforced Al-AlN composites produced by mechanical alloying. J. Alloys Compd. 2017, 728, 640–644. [Google Scholar] [CrossRef]

- Sethi, J.; Das, S.; Das, K. Study on thermal and mechanical properties of yttrium tungstate-aluminium nitride reinforced aluminium matrix hybrid composites. J. Alloys Compd. 2019, 774, 848–855. [Google Scholar] [CrossRef]

- Bellucci, S.; Popov, A.I.; Balasubramanian, C.; Cinque, G.; Marcelli, A.; Karbovnyk, I.; Savchyn, V.; Krutyak, N. Luminescence, vibrational and XANES studies of AlN nanomaterials. Radiat. Meas. 2007, 42, 708–711. [Google Scholar] [CrossRef]

- Steinman, A.; Corthay, S.; Firestein, K.; Kvashnin, D.; Kovalskii, A.; Matveev, A.; Sorokin, P.; Golberg, D.; Shtansky, D. Al-based composites reinforced with AlB2, AlN and BN phases: Experimental and theoretical studies. Mater. Des. 2018, 141, 88–98. [Google Scholar] [CrossRef]

- Fale, S.; Likhite, A.; Bhatt, J. Nanoindentation studies of ex situ AlN/Al metal matrix nanocomposites. J. Alloys Compd. 2014, 615, S392–S396. [Google Scholar] [CrossRef]

- Jia, L.; Kondoh, K.; Imai, H.; Onishi, M.; Chen, B.; Li, S. Nano-scale AlN powders and AlN/Al composites by full and partial direct nitridation of aluminum in solid-state. J. Alloys Compd. 2015, 629, 184–187. [Google Scholar] [CrossRef]

- Wang, J.; Yi, D.; Su, X.; Yin, F.; Li, H. Properties of submicron AlN particulate reinforced aluminum matrix composite. Mater. Des. 2009, 30, 78–81. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, Y.; Sun, C.; Cong, H. AlN nanowires for Al-based composites with high strength and low thermal expansion. J. Mater. Res. 2007, 22, 2711–2718. [Google Scholar] [CrossRef]

- Xu, Q.; Ma, X.; Hu, K.; Gao, T.; Liu, X. A novel (AlN + Si3N4)/Al composite with well-balanced strength and ductility. Mater. Sci. Eng. A 2018, 726, 113–119. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, C.; Li, H.; Sun, Y.; Yan, Y.; Zhao, T.; Li, X.; Liu, F. Achieving high strength-ductility combination and negligible yield asymmetry in extruded AlN/AZ91 composite rods. Mater. Sci. Eng. A 2020, 773, 138842. [Google Scholar] [CrossRef]

- Gostariani, R.; Bagherpour, E.; Rifai, M.; Ebrahimi, R.; Miyamoto, H. Fabrication of Al/AlN in-situ nanocomposite through planetary ball milling and hot extrusion of Al/BN: Microstructural evaluation and mechanical behavior. J. Alloys Compd. 2018, 768, 29–339. [Google Scholar] [CrossRef]

- Chen, B.; Kondoh, K.; Umeda, J.; Li, S.; Jia, L.; Li, J. Interfacial in-situ Al2O3 nanoparticles enhance load transfer in carbon nanotube (CNT)-reinforced aluminum matrix composites. J. Alloys Compd. 2019, 789, 25–29. [Google Scholar] [CrossRef]

- Shao, P.; Chen, G.; Ju, B.; Yang, W.; Zhang, Q.; Wang, Z.; Tan, X.; Pei, Y.; Zhong, S.; Hussain, M.; et al. Effect of hot extrusion temperature on graphene nanoplatelets reinforced Al6061 composite fabricated by pressure infiltration method. Carbon 2020, 162, 455–464. [Google Scholar] [CrossRef]

- Bhoi, N.K.; Singh, H.; Pratap, S. Developments in the aluminum metal matrix composites reinforced by micro/nano particles—A review. J. Compos. Mater. 2019, 54, 813–833. [Google Scholar] [CrossRef]

- Chen, B.; Kondoh, K.; Li, J.S.; Qian, M. Extraordinary reinforcing effect of carbon nanotubes in aluminium matrix composites assisted by in-situ alumina nanoparticles. Compos. Part B Eng. 2020, 183, 107961. [Google Scholar] [CrossRef]

- Xia, M.; Liu, A.; Wang, H.; Lin, Y.; Li, N.; Man, Z.; Ding, H. Microstructure evolution and its effect on mechanical response of the multi-phase reinforced Ti-based composites by laser powder-bed fusion. J. Alloys Compd. 2018, 782, 506–515. [Google Scholar] [CrossRef]

- Wu, Y.; Zhan, K.; Yang, Z.; Sun, W.; Zhao, B.; Yan, Y.; Yang, J. Graphene oxide/Al composites with enhanced mechanical properties fabricated by simple electrostatic interaction and powder metallurgy. J. Alloys Compd. 2019, 775, 233–240. [Google Scholar] [CrossRef]

- Afifeh, M.; Hosseinipour, S.J.; Jamaati, R. High-strength and high-conductivity nanograined copper fabricated by partial homogenization and asymmetric rolling. Mater. Sci. Eng. A 2019, 768, 138451. [Google Scholar] [CrossRef]

- Yang, H.; Gao, T.; Wu, Y.; Zhang, H.; Nie, J.; Liu, X. Microstructure and mechanical properties at both room and high temperature of insitu TiC reinforced Al–4.5Cu matrix nanocomposite. J. Alloys Compd. 2018, 767, 606–616. [Google Scholar] [CrossRef]

- Chen, B.; Li, S.; Imai, H.; Jia, L.; Umeda, J. Carbon nanotube induced microstructural characteristics in powder metallurgy Al matrix composites and their effects on mechanical and conductive properties. J. Alloys Compd. 2015, 651, 608–615. [Google Scholar] [CrossRef]

- George, R.; Kashyap, K.T.; Rahul, R.; Yamdagni, S. Strengthening in carbon nanotube/aluminium (CNT/Al) composites. Scr. Mater. 2005, 53, 1159–1163. [Google Scholar] [CrossRef]

- Nam, D.H.; Cha, S.I.; Lim, B.K.; Park, H.M.; Han, D.S.; Hong, S.H. Synergistic strengthening by load transfer mechanism and grain refinement of CNT/Al-Cu composites. Carbon 2012, 20, 2417–2423. [Google Scholar] [CrossRef]

- Yang, Z.Y.W.; Zhou, C.; Zhang, N.; Chao, Z.; Liu, H.; Cao, Y.; Sun, Y.; Shao, P.; Wu, G. Effect of ball milling time on graphene nanosheets reinforced Al6063 composite fabricated by pressure infiltration method. Carbon 2019, 141, 25–39. [Google Scholar]

- Wyrzykowski, J.W.; Grabski, M.W. The Hall–Petch relation in aluminium and its dependence on the grain boundary structure. Philos. Mag. A 1986, 53, 505–520. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch relation and boundary strengthening. Scr. Mater. 2004, 8, 801–806. [Google Scholar] [CrossRef]

- Deutschman, A.D.; Michels, W.A.; Wilson, C.E. Machine Design: Theory and Practice. In Machinery’s Handbook, 27th ed.; MacMillan: London, UK, 1975. [Google Scholar]

- Tan, X.; Zhang, B.; Liu, K. Microstructure and mechanical property of the 2024Al matrix hybrid composite reinforced with recycled SiCp/2024Al composite particles. J. Alloys Compd. 2019, 815, 152330. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, D.L. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength. Scr. Mater. 2006, 54, 1321–1326. [Google Scholar] [CrossRef]

- Park, J.G.; Keum, D.H.; Lee, Y.H. Strengthening mechanisms in carbon nanotube-reinforced aluminum composites. Carbon 2015, 95, 690–698. [Google Scholar] [CrossRef]

- Ashok, K.B.; Murugan, N. Metallurgical and Mechanical Characterization of Stir Cast AA6061-T6–AlNp Composite. Mater. Des. 2012, 40, 52–58. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, Y.F.; Zhao, X.J. Influence Mechanisms of Cu or Fe on the Microstructures and Tensile Properties at 350 °C of Network AlNp Reinforced Al Composites. J. Alloys Compd. 2018, 740, 452–460. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, W.; Xie, K.; Liu, X. Microstructure Evolution and High Temperature Tensile Properties of AlNp/Al–Fe Composites Induced by Microalloying. J. Alloys Compd. 2019, 786, 1005–1012. [Google Scholar] [CrossRef]

| Element | Mg | Si | Cu | Fe | Zn | Al |

|---|---|---|---|---|---|---|

| Wt.% | 1.12 | 0.8 | 0.3 | 0.7 | 0.25 | Bal. |

| Materials | Status | Density (g cm−3) | Relative Density (%) |

|---|---|---|---|

| 3 wt.%nano-AlN/AA6061 | As cast | 2.40 | 88.1 |

| Heat extruded | 2.60 | 95.4 | |

| 6 wt.%nano-AlN/AA6061 | As cast | 2.34 | 85.2 |

| Heat extruded | 2.53 | 92.1 | |

| 9 wt.%nano-AlN/AA6061 | As cast | 2.26 | 81.5 |

| Heat extruded | 2.49 | 89.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, K.; Zhu, P.; Zhang, P.; Zhang, Q.; Shao, P.; Wang, Z.; Yang, W.; Zhao, D.; Balog, M.; Krizik, P.; et al. Dispersion and Preparation of Nano-AlN/AA6061 Composites by Pressure Infiltration Method. Nanomaterials 2022, 12, 2258. https://doi.org/10.3390/nano12132258

Sun K, Zhu P, Zhang P, Zhang Q, Shao P, Wang Z, Yang W, Zhao D, Balog M, Krizik P, et al. Dispersion and Preparation of Nano-AlN/AA6061 Composites by Pressure Infiltration Method. Nanomaterials. 2022; 12(13):2258. https://doi.org/10.3390/nano12132258

Chicago/Turabian StyleSun, Kai, Ping Zhu, Pinliang Zhang, Qiang Zhang, Puzhen Shao, Zhijun Wang, Wenshu Yang, Dashuai Zhao, Martin Balog, Peter Krizik, and et al. 2022. "Dispersion and Preparation of Nano-AlN/AA6061 Composites by Pressure Infiltration Method" Nanomaterials 12, no. 13: 2258. https://doi.org/10.3390/nano12132258

APA StyleSun, K., Zhu, P., Zhang, P., Zhang, Q., Shao, P., Wang, Z., Yang, W., Zhao, D., Balog, M., Krizik, P., & Wu, G. (2022). Dispersion and Preparation of Nano-AlN/AA6061 Composites by Pressure Infiltration Method. Nanomaterials, 12(13), 2258. https://doi.org/10.3390/nano12132258