Structural-Functional Changes in a Ti50Ni45Cu5 Alloy Caused by Training Procedures Based on Free-Recovery and Work-Generating Shape Memory Effect

Abstract

:1. Introduction

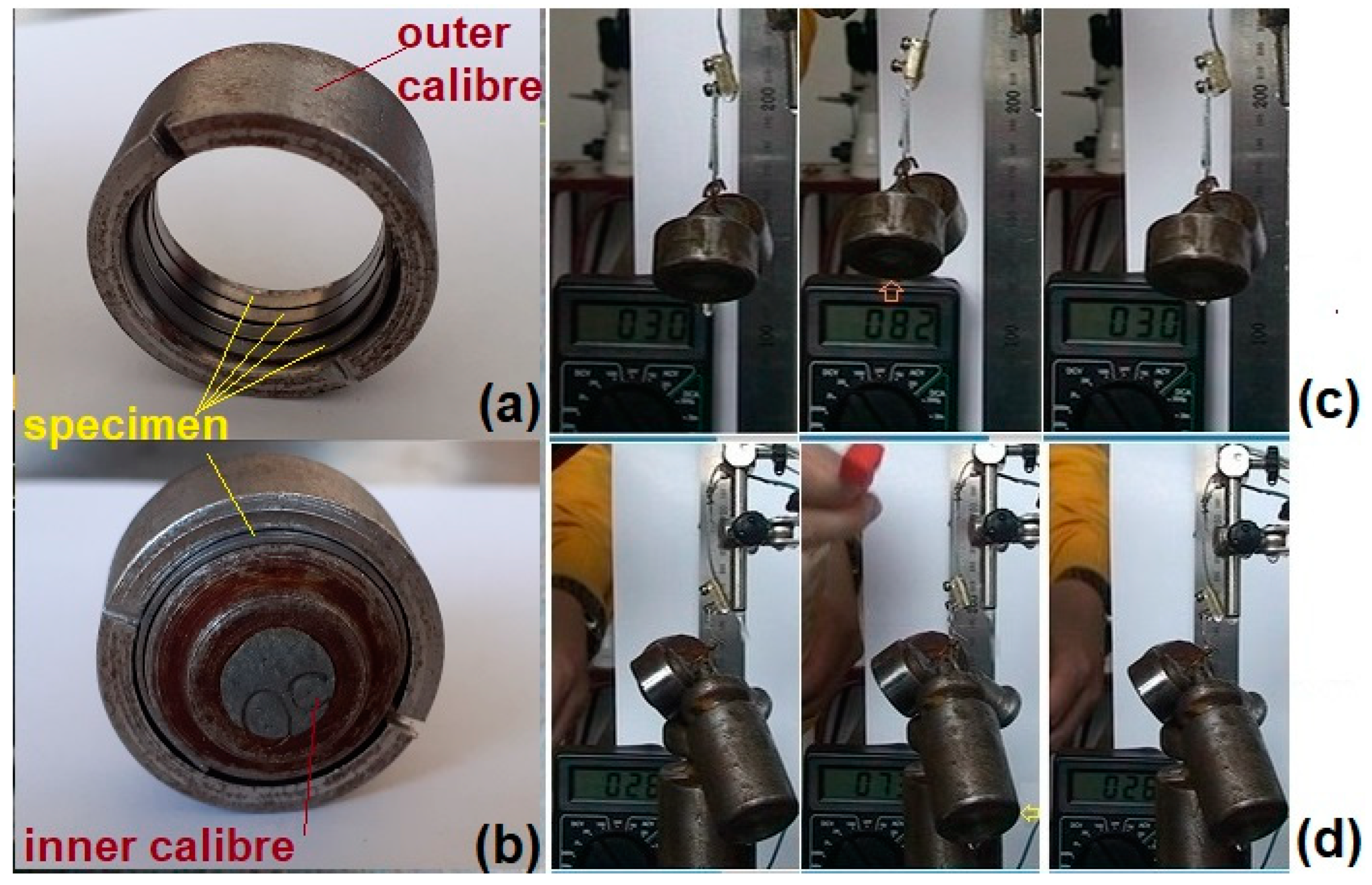

2. Materials and Methods

3. Results and Discussion

3.1. Evolution of Specimens’ Profile during Training

3.2. Tensile Testing (TENS)

3.3. Differential Scanning Calorimetry (DSC)

- Heating rate increasing, from 5 to 10 °C/min, caused higher values for both Δhendo (in absolute value) and A50, in good agreement with previous results reported by some of the present authors, in the case of a Cu-Zn-Al SMA [28];

- A50 values had a general decreasing tendency with increasing the number of cycles;

- Δhendo values have a general decreasing trend (in absolute values) with the increase in the number of training cycles.

3.4. Dynamic Mechanical Analysis (DMA)

3.5. X-ray Diffraction (XRD)

3.6. AFM Observations

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of Low-Temperature Phase Changes on the Mechanical Properties of Alloys near Composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Melton, K.N. Ni-Ti based shape memory alloys. In Engineering Aspects of Shape Memory Alloys; Duerig, T.W., Melton, K.N., Stockel, D., Wayman, C.M., Eds.; Butterworth-Heinemann: Oxford UK, 1990; pp. 21–35. [Google Scholar]

- Matsumoto, O.; Miyazaki, S.; Otsuka, K.; Tamura, H. Crystallography of martensitic transformation in Ti-Ni single crystals. Acta Met. 1987, 35, 2137–2144. [Google Scholar] [CrossRef]

- Wollants, P.; Roos, J.R.; Delaey, L. Thermally- and stress-induced thermoelastic martensitic transformations in the reference frame of equilibrium thermodynamics. Prog. Mater. Sci. 1993, 37, 227–288. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Duerig, T.W.; Stöckel, D.; Keeley, A. Actuator and work production devices. In Engineering Aspects of Shape Memory Alloys; Duerig, T.W., Melton, K.N., Stockel, D., Wayman, C.M., Eds.; Butterworth-Heinemann: Oxford UK, 1990; pp. 181–194. [Google Scholar]

- van Humbeeck, J.; Stalmans, R. Characteristics of Shape Memory Alloys. In Shape Memory Materials; Otsuka, K., Wayman, C.M., Eds.; University Press: Cambridge, UK, 1998; pp. 149–183. [Google Scholar]

- Furuya, Y.; Shimada, H. Shape memory actuators for robotic applications. In Engineering Aspects of Shape Memory Alloys; Duerig, T.W., Melton, K.N., Stockel, D., Wayman, C.M., Eds.; Butterworth-Heinemann: Cambridge, UK, 1990; pp. 338–355. [Google Scholar]

- Ohkata, I.; Suzuki, Y. The design of shape memory alloy actuators and their applications. In Shape Memory Materials; Otsuka, K., Wayman, C.M., Eds.; University Press: Cambridge, UK, 1998; pp. 240–266. [Google Scholar]

- Gao, Z.; Shi, Q.; Fukuda, T.; Li, C.; Huang, Q. An overview of biomimetic robots with animal behaviors. Neurocomputing 2019, 332, 339–350. [Google Scholar] [CrossRef]

- Motzki, P.; Seelecke, S. Industrial applications for shape memory alloys. In Encyclopedia of Smart Materials; Olabi, A.-G., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; Volume 4, pp. 254–266. [Google Scholar] [CrossRef]

- Moberlyt, W.J.; Melton, K.N. Ni-Ti-Cu shape memory alloys. In Engineering Aspects of Shape Memory Alloys; Duerig, T.W., Melton, K.N., Stockel, D., Wayman, C.M., Eds.; Butterworth-Heinemann: Oxford UK, 1990; pp. 46–57. [Google Scholar]

- Nam, T.H.; Saburi, T.; Shimizu, K. Cu-content dependence of shape memory characteristics in Ti-Ni-Cu alloys. Mater. Trans. JIM 1990, 31, 959–967. [Google Scholar] [CrossRef] [Green Version]

- Wu, S.-K.; Lin, H.; Lin, T. Electrical resistivity of Ti–Ni binary and Ti–Ni–X (X = Fe, Cu) ternary shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 536–539. [Google Scholar] [CrossRef]

- Harikrishnan, K.; Chandra, K.; Misra, P.S.; Agarwala Vinod, S. B19 orthorhombic martensitic transformations in aged TiNiCu shape memory alloys. In ESOMAT 2009, Proceedings of the 8th European Symposium on Martensitic Transformations, Prague, Czech Republic, 7–11 September 2009; Šittner, P., Heller, L., Paidar, V., Eds.; EDP Sciences: Les Ulis, France, 2009; p. 02020. [Google Scholar] [CrossRef] [Green Version]

- Perkins, J.; Hodson, D. The two-way shape memory effect, In Engineering Aspects of Shape Memory Alloys; Duerig, T.W., Melton, K.N., Stockel, D., Wayman, C.M., Eds.; Butterworth-Heinemann: Cambridge, UK, 1990; pp. 195–206. [Google Scholar]

- Kireeva, I.V.; Pobedennaya, Z.V.; Chumlyakov, Y.I.; Marchenko, E.S. Superelasticity and two-way shape memory effect in [0 0 1]-oriented TiNiCu single crystals under compression. Mater. Lett. 2020, 281, 128646. [Google Scholar] [CrossRef]

- Zhou, X.; Huang, Z.; Chen, F.; Tian, B.; Li, L.; Tong, Y. Two-way shape memory effect with excellent cycling stability in TiNiCuNb alloy. Mater. Lett. 2022, 308, 131256. [Google Scholar] [CrossRef]

- Wang, Z.G.; Zu, X.T.; You, L.P.; Feng, X.D.; Zhang, C.F. Investigation on the two-way shape memory effect and alternating current electrothermal driving characteristics of TiNiCu shape memory alloy. J. Mater. Sci. 2004, 39, 3391–3395. [Google Scholar] [CrossRef]

- Chen, L.P.; Si, N.C. Influence of thermomechanical training deformations on TWSME in TiNiCu alloy spring. J. Alloys Compd. 2008, 448, 219–222. [Google Scholar] [CrossRef]

- Bujoreanu, L.-G.; Lohan, N.M.; Pricop, B.; Cimpoeşu, N. On role of atomic migration in amnesia occurrence during complex thermal cycling of Cu–Zn–Al shape memory alloy. Mater. Sci. Technol. 2012, 28, 658–667. [Google Scholar] [CrossRef]

- Vitel, G.; Paraschiv, A.L.; Suru, M.G.; Cimpoesu, N.; Bujoreanu, L.-G. New calorimetric-structural aspects of temperature memory effect in hot rolled Cu-Zn-Al SMAs. Optoelectron. Adv. Mater.-Rapid Commun. 2011, 5, 858–862. [Google Scholar]

- Ye, Z.; Li, C.; Zheng, M.; Zhang, X.; Yang, X.; Gu, J. In situ EBSD/DIC-based investigation of deformation and fracture mechanism in FCC- and L12-structured FeCoNiV high-entropy alloys. Int. J. Plast. 2022, 152, 103247. [Google Scholar] [CrossRef]

- Duerig, T.W.; Zadno, R. An engineer’s perspective of pseudoelasticity. In Engineering Aspects of Shape Memory Alloys; Duerig, T.W., Melton, K.N., Stockel, D., Wayman, C.M., Eds.; Butterworth-Heinemann: Cambridge, UK, 1990; pp. 369–393. [Google Scholar]

- Mihalache, E.; Pricop, B.; Comăneci, R.I.; Suru, M.-G.; Lohan, N.-M.; Mocanu, M.; Ozkal, B.; Bujoreanu, L.-G. Structural Effects of Thermomechanical Processing on the Static and Dynamic Responses of Powder Metallurgy Fe-Mn-Si Based Shape Memory Alloys. Adv. Sci. Technol. 2017, 97, 153–158. [Google Scholar]

- Mihalache, E.; Pricop, B.; Lohan, N.-M.; Suru, M.-G.; Ozkal, B.; Bujoreanu, L.-G. Internal friction evaluation in mechanically alloyed-powder metallurgy Fe-Mn-Si-Cr-Ni shape memory alloys. Int. J. Mod. Manuf. Technol. 2016, VIII, 61–68. [Google Scholar]

- Santosh, S. Synthesis, Hot Deformation Behavior and Biocompatibility of Some NiTi-Based Ternary Shape Memory Alloys. Ph.D. Thesis, Indian Institute of Technology Madras, Chennai, India, 2020. [Google Scholar]

- Lohan, N.M.; Pricop, B.; Bujoreanu, L.-G.; Cimpoeşu, N. Heating rate effects on reverse martensitic transformation in a Cu-Zn-Al shape memory alloy. Int. J. Mater. Res. 2011, 102, 1345–1351. [Google Scholar] [CrossRef]

- Kajiwara, S.; Kikuchi, T. Dislocation structures produced by diverse martensitic transformation in a Cu-Zn alloy. Acta Metall. 1982, 30, 589–598. [Google Scholar] [CrossRef]

- Liu, T.-W.; Zheng, Y.-J.; Cui, L.-S. Transformation Sequence Rule of Martensite Plates and Temperature Memory Effect in Shape Memory Alloys. Acta Met. Sin. 2015, 28, 1286–1290. [Google Scholar] [CrossRef] [Green Version]

- Khangholi, S.N.; Javidani, M.; Maltais, A.; Chen, X.-G. Effect of Ag and Cu addition on the strength and electrical conductivity of Al-Mg-Si alloys using conventional and modified thermomechanical treatments. J. Alloys Compd. 2022, 914, 165242. [Google Scholar] [CrossRef]

- Kireeva, I.V.; Pobedennaya, Z.V.; Chumlyakov, Y.I.; Marchenko, E.S. Effect of stress-induced martensite ageing on the one-way and two-way shape memory effect of [0 1 1]-oriented TiNiCu crystals under tension. Mater. Lett. 2021, 305, 130773. [Google Scholar] [CrossRef]

- Yoshida, I.; Otsuka, K. Effect of Heat Treatments on the Damping Characteristics of TiNi-Based Shape Memory Alloys. Key Eng. Mater. 2006, 319, 33–38. [Google Scholar] [CrossRef]

- Yoshida, I.; Ono, T.; Asai, M. Internal friction of Ti–Ni alloy. J. Alloys Compd. 2000, 310, 339–343. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Damping capacity of thermoelastic martensite in shape memory alloys. J. Alloys Compd. 2003, 355, 58–64. [Google Scholar] [CrossRef]

- Chien, C.; Wu, S.-K.; Chang, S.-H. Damping Characteristics of Ti50Ni50−xCux (x = 0~30 at.%) Shape Memory Alloys at a Low Frequency. Materials 2014, 7, 4574–4586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fabregat-Sanjuan, A.; Guirado, F.G.; Ferrando, F.; De la Flor, S. Identifying the effects of heat treatment temperatures on the Ti50Ni45Cu5 alloy using dynamic mechanical analysis combined with microstructural analysis. Mater. Sci. Eng. A 2018, 712, 281–291. [Google Scholar] [CrossRef]

- Juan, J.S.; No, M.L. Damping behavior during martensitic transformation in shape memory alloys. J. Alloys Compd. 2003, 355, 35565–35571. [Google Scholar] [CrossRef]

- Chien, C.; Wu, S.-K.; Chang, S.-H. Damping Capacities of Ti50Ni50−xCux Shape Memory Alloys Measured under Temperature, Strain, and Frequency Sweeps. Mater. Trans. 2015, 56, 193–199. [Google Scholar] [CrossRef] [Green Version]

- Bujoreanu, L.-G.; Young, M.L.; Gollerthan, S.; Somsen, C.; Eggeler, G. Influence of heat treatment and microstructure on the tensile pseudoelastic response of an Ni-rich NiTi shape memory alloy. Int. J. Mater. Res. 2010, 101, 623–630. [Google Scholar] [CrossRef]

- Zhao, G.; Chen, J.; Ding, C.; Fang, D.; Huang, C.; Ye, X. Effect of Yttrium on the microstructure, phase transformation and superelasticity of a Ti–Ni–Cu shape memory alloy. Vacuum 2020, 177, 109381. [Google Scholar] [CrossRef]

- Bumke, L.; Wolff, N.; Chluba, C.; Dankwort, T.; Kienle, L.; Quandt, E. Coherent Precipitates as a Condition for Ultra-Low Fatigue in Cu-Rich Ti53.7Ni24.7Cu21.6 Shape Memory Alloys. Shape Mem. Superelasticity 2021, 7, 526–540. [Google Scholar] [CrossRef]

- Sun, K.; Yi, X.; Sun, B.; Gao, W.; Wang, H.; Meng, X.; Cai, W.; Zhao, L. The effect of Hf on the microstructure, transformation behaviors and the mechanical properties of Ti-Ni-Cu shape memory alloys. J. Alloys Compd. 2019, 772, 603–611. [Google Scholar] [CrossRef]

- Haq, I.U.; Khan, M.I.; Karim, R.A.; Raza, S.A.; Wadood, A.; Hassan, M. Effect of Various Thermal Treatments and Cu Contents on Precipitation Mechanism, Martensitic Growth, and Cold Workability of Ti50Ni50-xCux Ternary Shape Memory Alloys. J. Eng. Mater. Perform. 2021, 30, 451–466. [Google Scholar] [CrossRef]

- Suru, M.-G.; Paraschiv, A.-L.; Lohan, N.M.; Pricop, B.; Ozkal, B.; Bujoreanu, L.-G. Loading Mode and Environment Effects on Surface Profile Characteristics of Martensite Plates in Cu-Based SMAs. J. Mater. Eng. Perform. 2014, 23, 2669–2676. [Google Scholar] [CrossRef]

- Suru, M.-G.; Morosanu, C.; Bujoreanu, L.-G. Variation tendencies of shape memory alloys surface relief as a function of training-cycling parameters. J. Optoelectron. Adv. Mater. 2014, 16, 394–400. [Google Scholar]

- Jones, N.; Dye, D. Influence of applied stress on the transformation behaviour and martensite evolution of a Ti-Ni-Cu shape memory alloy. Intermetallics 2013, 32, 239–249. [Google Scholar] [CrossRef]

- Shiva, S.; Yadaiah, N.; Palani, I.; Paul, C.; Bindra, K. Thermo mechanical analyses and characterizations of TiNiCu shape memory alloy structures developed by laser additive manufacturing. J. Manuf. Process. 2019, 48, 98–109. [Google Scholar] [CrossRef]

- Pushin, V.G.; Kuranova, N.N.; Pushin, A.V. Structure and mechanical properties of shape-memory alloys of the Ti-Ni-Cu system. Met. Sci. Heat Treat. 2016, 57, 739–745. [Google Scholar] [CrossRef]

- Curtis, S.M.; Wolff, N.; Dengiz, D.; Lewitz, H.; Jetter, J.; Bumke, L.; Hayes, P.; Yarar, E.; Thormählen, L.; Kienle, L.; et al. Integration of AlN piezoelectric thin films on ultralow fatigue TiNiCu shape memory alloys. J. Mater. Res. 2020, 35, 1298–1306. [Google Scholar] [CrossRef]

- Li, J.; Yi, X.; Sun, K.; Sun, B.; Gao, W.; Wang, H.; Meng, X.; Song, W. The effect of Zr on the transformation behaviors, microstructure and the mechanical properties of Ti-Ni-Cu shape memory alloys. J. Alloys Compd. 2018, 747, 348–353. [Google Scholar] [CrossRef]

| Cycle No. | αc, ° | αh, ° | SRD, % |

|---|---|---|---|

| 1 | 71 | 139 | 62.4 |

| 2 | 48.5 | 130 | 62 |

| 4 | 55 | 113 | 46.4 |

| 8 | 43 | 111.5 | 50 |

| 16 | 43.5 | 89 | 33.3 |

| Cycle No. | Heating Rate °C/min | Δhendo J/g | A50 °C |

|---|---|---|---|

| l | 5 | −21.65 | 60.85 |

| 10 | −28.25 | 62.1 | |

| 2 | 5 | −7.675 | 63.6 |

| 10 | −10.6 | 65.4 | |

| 4 | 5 | −11.655 | 60.7 |

| 10 | −25.195 | 61.3 | |

| 8 | 5 | −8.17 | 59 |

| 10 | −8.78 | 60.55 | |

| 16 | 5 | −9.45 | 57.5 |

| 10 | −9.62 | 58.05 |

| Specimen | Δhendo J/g | A50 °C | Δhexo J/g | M50 °C |

|---|---|---|---|---|

| hot rolled | −29.18 | 60.4 | 31.71 | 37.7 |

| 6 cycles | −30.29 | 47.4 | 34.71 | 24.5 |

| 50 cycles | −29.28 | 60.5 | 37.99 | 33.5 |

| a (nm) | b (nm) | c (nm) | |

|---|---|---|---|

| I (nm) | 0.28379 ± 0.00266 | 0.46041 ± 8.21888 × 10−4 | 0.42281 ± 0.00367 |

| s (nm/cycle) | (3.35385 ± 3.23116) × 10−4 | (6.15111 ± 9.96685) × 10−5 | (−8.82543 ± 4.45373) × 10−4 |

| Residual Sum of Squares | 5.01 × 10−5 | 4.77 × 10−6 | 9.52 × 10−5 |

| Pearson’s r | 0.51404 | 0.33565 | −0.75292 |

| R-Square (COD) | 0.26423 | 0.11266 | 0.56689 |

| Adj. R-Square | 0.01898 | −0.18312 | 0.42252 |

| Convex Surface | Concave Surface | |||

|---|---|---|---|---|

| 1st Cycle | 16th Cycle | 1st Cycle | 16th Cycle | |

| Width (nm) | 300 | 265 | 152 | 200 |

| Height (nm) | 106 | 17 | 300 | 39 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popa, M.; Lohan, N.-M.; Pricop, B.; Cimpoeșu, N.; Porcescu, M.; Comăneci, R.I.; Cazacu, M.; Borza, F.; Bujoreanu, L.-G. Structural-Functional Changes in a Ti50Ni45Cu5 Alloy Caused by Training Procedures Based on Free-Recovery and Work-Generating Shape Memory Effect. Nanomaterials 2022, 12, 2088. https://doi.org/10.3390/nano12122088

Popa M, Lohan N-M, Pricop B, Cimpoeșu N, Porcescu M, Comăneci RI, Cazacu M, Borza F, Bujoreanu L-G. Structural-Functional Changes in a Ti50Ni45Cu5 Alloy Caused by Training Procedures Based on Free-Recovery and Work-Generating Shape Memory Effect. Nanomaterials. 2022; 12(12):2088. https://doi.org/10.3390/nano12122088

Chicago/Turabian StylePopa, Mihai, Nicoleta-Monica Lohan, Bogdan Pricop, Nicanor Cimpoeșu, Marieta Porcescu, Radu Ioachim Comăneci, Maria Cazacu, Firuța Borza, and Leandru-Gheorghe Bujoreanu. 2022. "Structural-Functional Changes in a Ti50Ni45Cu5 Alloy Caused by Training Procedures Based on Free-Recovery and Work-Generating Shape Memory Effect" Nanomaterials 12, no. 12: 2088. https://doi.org/10.3390/nano12122088

APA StylePopa, M., Lohan, N.-M., Pricop, B., Cimpoeșu, N., Porcescu, M., Comăneci, R. I., Cazacu, M., Borza, F., & Bujoreanu, L.-G. (2022). Structural-Functional Changes in a Ti50Ni45Cu5 Alloy Caused by Training Procedures Based on Free-Recovery and Work-Generating Shape Memory Effect. Nanomaterials, 12(12), 2088. https://doi.org/10.3390/nano12122088