Improving the Stability of Lithium Aluminum Germanium Phosphate with Lithium Metal by Interface Engineering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

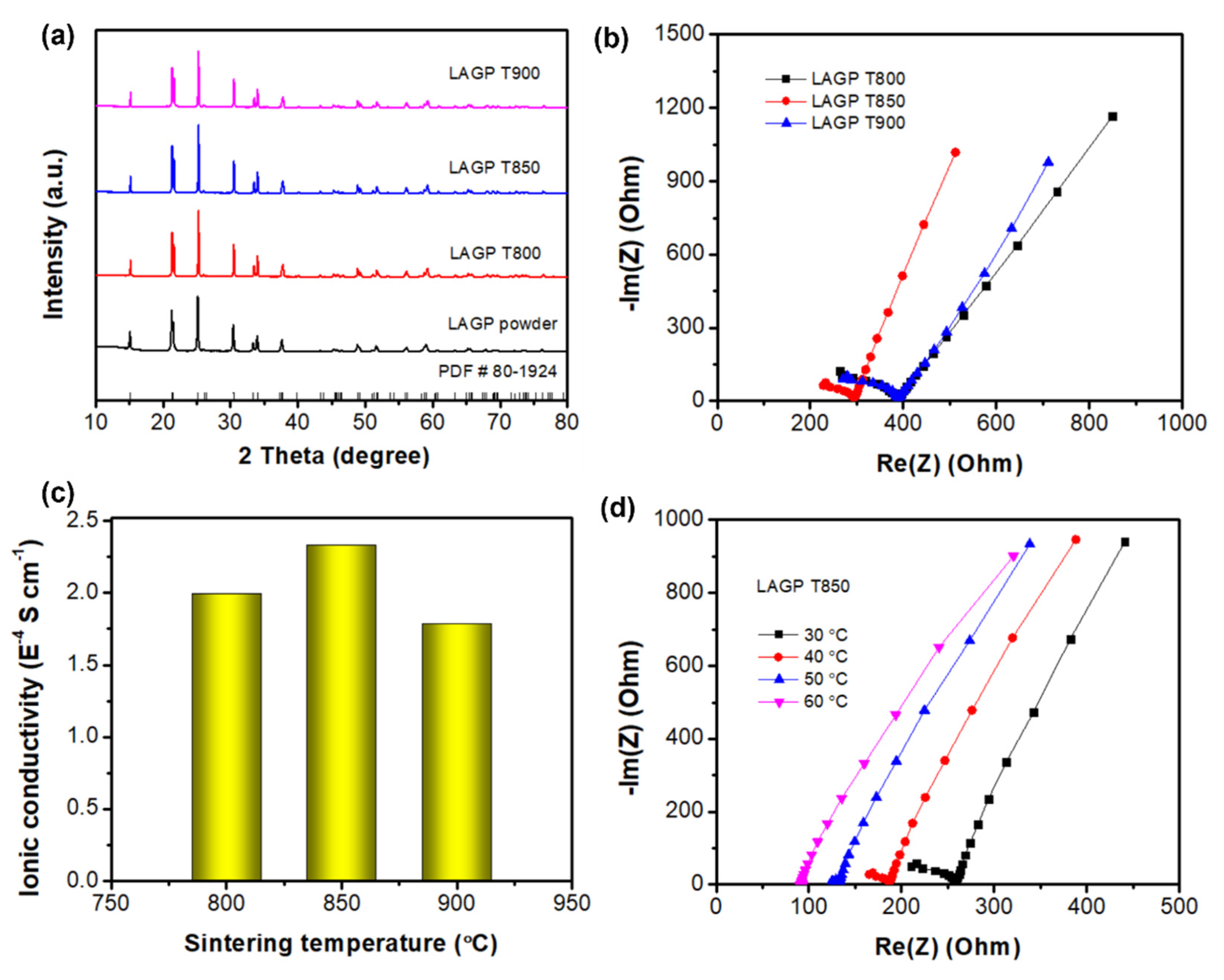

2.2. Preparation of LAGP Pellets

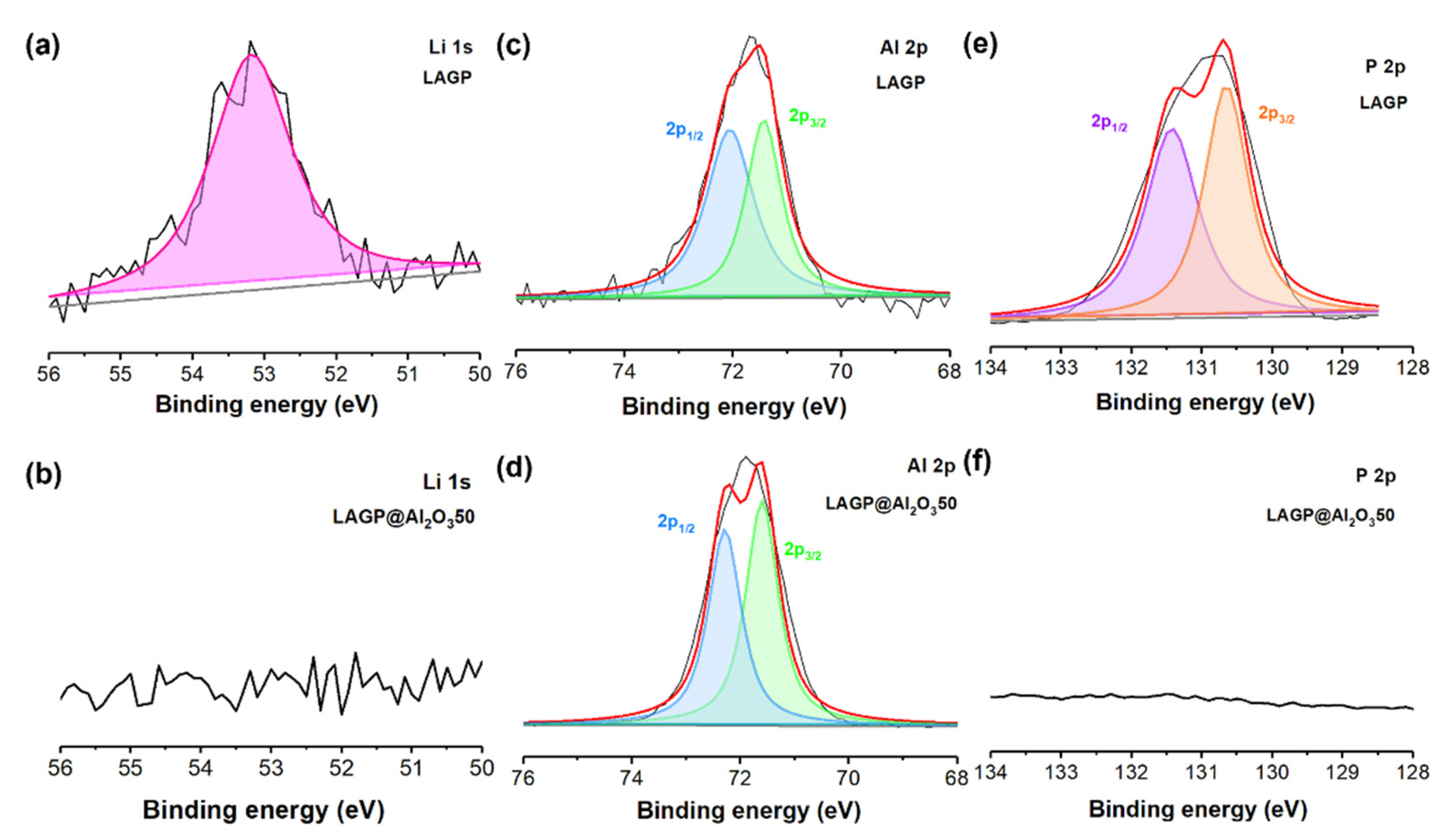

2.3. Atomic Layer Deposition of Al2O3 on LAGP

2.4. Materials Characterizations

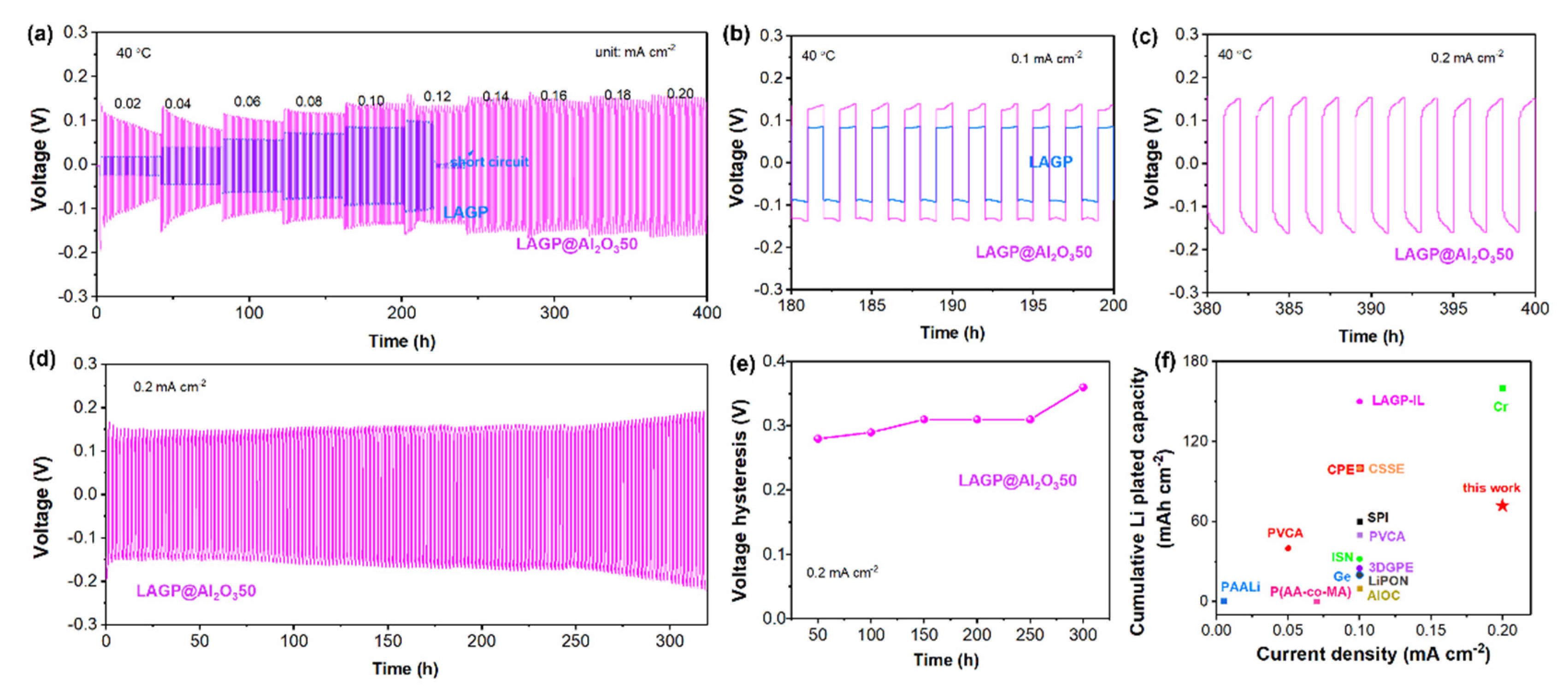

2.5. Electrochemical Measurements

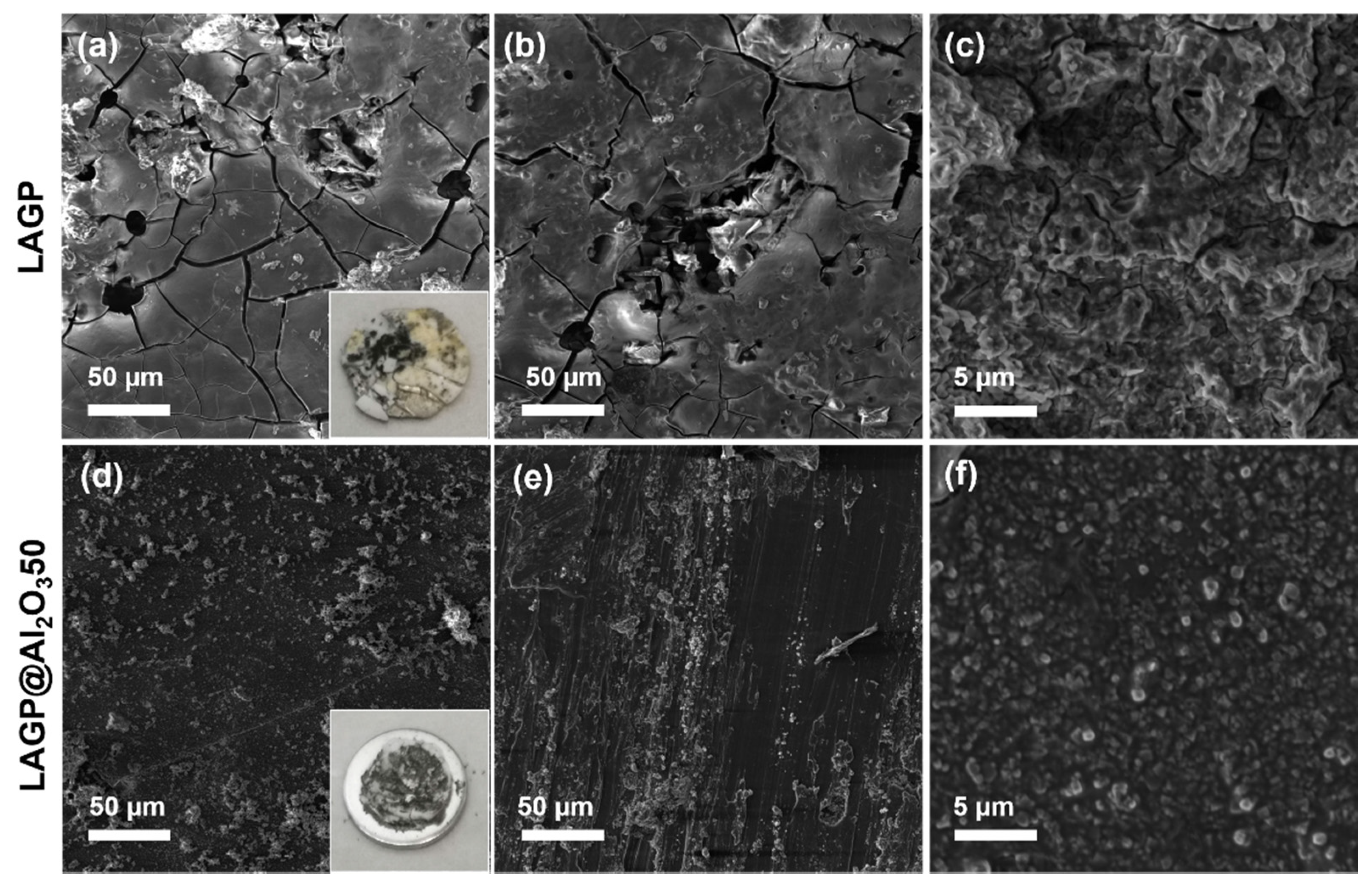

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Z.; Pan, H.; Li, C.; Mu, X.; Du, Y.; Zhang, F.; Zhang, X.; He, P.; Zhou, H. An in situ solidifying strategy enabling high-voltage all-solid-state Li-metal batteries operating at room temperature. J. Mater. Chem. A 2020, 8, 25217–25225. [Google Scholar] [CrossRef]

- Han, X.; Chen, J.; Chen, M.; Zhou, W.; Zhou, X.; Wang, G.; Wong, C.P.; Liu, B.; Luo, L.; Chen, S.; et al. Induction of planar Li growth with designed interphases for dendrite-free Li metal anodes. Energy Storage Mater. 2021, 39, 250–258. [Google Scholar] [CrossRef]

- Cortes, F.J.Q.; Lewis, J.A.; Tippens, J.; Marchese, T.S.; McDowell, M.T. How Metallic Protection Layers Extend the Lifetime of NASICON-Based Solid-State Lithium Batteries. J. Electrochem. Soc. 2019, 167, 050502. [Google Scholar] [CrossRef]

- Gao, Z.; Sun, H.; Fu, L.; Ye, F.; Zhang, Y.; Luo, W.; Huang, Y. Promises, Challenges, and Recent Progress of Inorganic Solid-State Electrolytes for All-Solid-State Lithium Batteries. Adv. Mater. 2018, 30, e1705702. [Google Scholar] [CrossRef]

- Manthiram, A.; Yu, X.; Wang, S. Lithium battery chemistries enabled by solid-state electrolytes. Nat. Rev. Mater. 2017, 2, 16103. [Google Scholar] [CrossRef]

- Sun, C.; Liu, J.; Gong, Y.; Wilkinson, D.P.; Zhang, J. Recent advances in all-solid-state rechargeable lithium batteries. Nano Energy 2017, 33, 363–386. [Google Scholar] [CrossRef] [Green Version]

- Zheng, F.; Kotobuki, M.; Song, S.; Lai, M.O.; Lu, L. Review on solid electrolytes for all-solid-state lithium-ion batteries. J. Power Sources 2018, 389, 198–213. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, L.; Yu, Y.; Sun, J. Progress of enhancing the safety of lithium ion battery from the electrolyte aspect. Nano Energy 2019, 55, 93–114. [Google Scholar] [CrossRef]

- Chen, J.; Wu, J.; Wang, X.; Zhou, A.A.; Yang, Z. Research progress and application prospect of solid-state electrolytes in commercial lithium-ion power batteries. Energy Storage Mater. 2021, 35, 70–87. [Google Scholar] [CrossRef]

- Ye, T.; Li, L.; Zhang, Y. Recent Progress in Solid Electrolytes for Energy Storage Devices. Adv. Funct. Mater. 2020, 30, 2000077. [Google Scholar] [CrossRef]

- Lu, W.; Xue, M.; Zhang, C. Modified Li7La3Zr2O12 (LLZO) and LLZO-polymer composites for solid-state lithium batteries. Energy Storage Mater. 2021, 39, 108–129. [Google Scholar] [CrossRef]

- Chen, S.; Xie, D.; Liu, G.; Mwizerwa, J.P.; Zhang, Q.; Zhao, Y.; Xu, X.; Yao, X. Sulfide solid electrolytes for all-solid-state lithium batteries: Structure, conductivity, stability and application. Energy Storage Mater. 2018, 14, 58–74. [Google Scholar] [CrossRef]

- Hou, M.; Liang, F.; Chen, K.; Dai, Y.; Xue, D. Challenges and perspectives of NASICON-type solid electrolytes for all-solid-state lithium batteries. Nanotechnology 2020, 31, 132003. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; He, P.; Zhou, H. Rechargeable Solid-State Li-Air and Li-S Batteries: Materials, Construction, and Challenges. Adv. Energy Mater. 2018, 8, 1701602. [Google Scholar] [CrossRef]

- Li, L.; Deng, Y.; Chen, G. Status and prospect of garnet/polymer solid composite electrolytes for all-solid-state lithium batteries. J. Energy Chem. 2020, 50, 154–177. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.-Q.; Shen, L.; Liu, Q.; Ma, J.-B.; Lv, W.; He, Y.-B.; Yang, Q.-H. Progress and Perspective of Ceramic/Polymer Composite Solid Electrolytes for Lithium Batteries. Adv. Sci. 2020, 7, 1903088. [Google Scholar] [CrossRef] [Green Version]

- Kuo, P.H.; Du, J. Lithium Ion Diffusion Mechanism and Associated Defect Behaviors in Crystalline Li1+xAlxGe2−x(PO4)3 Solid-State Electrolytes. J. Phys. Chem. C 2019, 123, 27385–27398. [Google Scholar] [CrossRef]

- Yan, B.; Zhu, Y.; Pan, F.; Liu, J.; Lu, L. Li1.5Al0.5Ge1.5(PO4)3 Li-ion conductor prepared by melt-quench and low temperature pressing. Solid State Ion. 2015, 278, 65–68. [Google Scholar] [CrossRef]

- Yang, G.; Safanama, D.; Phuah, K.C.; Adams, S. Enhanced Li1+xAlxGe2−x(PO4)3 Anode-Protecting Membranes for Hybrid Lithium-Air Batteries by Spark Plasma Sintering. ACS Omega 2020, 5, 18205–18212. [Google Scholar] [CrossRef]

- Zhang, M.; Takahashi, K.; Imanishi, N.; Takeda, Y.; Yamamoto, O.; Chi, B.; Pu, J.; Li, J. Preparation and Electrochemical Properties of Li1+xAlxGe2−x(PO4) Synthesized by a Sol-Gel Method. J. Electrochem. Soc. 2012, 159, A1114–A1119. [Google Scholar] [CrossRef]

- Paolella, A.; Zhu, W.; Bertoni, G.; Perea, A.; Demers, H.; Savoie, S.; Girard, G.; Delaporte, N.; Guerfi, A.; Rumpel, M.; et al. Toward an All-Ceramic Cathode–Electrolyte Interface with Low-Temperature Pressed NASICON Li1.5Al0.5Ge1.5(PO4)3 Electrolyte. Adv. Mater. Inter. 2020, 7, 2000164. [Google Scholar] [CrossRef]

- Thokchom, J.S.; Kumar, B. The effects of crystallization parameters on the ionic conductivity of a lithium aluminum germanium phosphate glass–ceramic. J. Power Sources 2010, 195, 2870–2876. [Google Scholar] [CrossRef]

- Pershina, S.V.; Pankratov, A.A.; Vovkotrub, E.G.; Antonov, B.D. Promising high-conductivity Li1.5Al0.5Ge1.5(PO4)3 solid electrolytes: The effect of crystallization temperature on the microstructure and transport properties. Ionics 2019, 25, 4713–4725. [Google Scholar] [CrossRef]

- Chung, H.; Kang, B. Mechanical and Thermal Failure Induced by Contact between a Li1.5Al0.5Ge1.5(PO4)3 Solid Electrolyte and Li Metal in an All Solid-State Li Cell. Chem. Mater. 2017, 29, 8611–8619. [Google Scholar] [CrossRef]

- He, L.; Sun, Q.; Chen, C.; Oh, J.A.S.; Sun, J.; Li, M.; Tu, W.; Zhou, H.; Zeng, K.; Lu, L. Failure Mechanism and Interface Engineering for NASICON-Structured All-Solid-State Lithium Metal Batteries. ACS Appl. Mater. Interfaces 2019, 11, 20895–20904. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Chen, S.; Yang, J.; Liu, G.; Yao, X.; Cui, P.; Xu, X. Stable cycling of all-solid-state lithium battery with surface amorphized Li1.5Al0.5Ge1.5(PO4)3 electrolyte and lithium anode. Electrochim. Acta 2019, 297, 281–287. [Google Scholar] [CrossRef]

- Liu, Q.; Yu, Q.; Li, S.; Wang, S.; Zhang, L.; Cai, B.; Zhou, D.; Li, B. Safe LAGP-based all solid-state Li metal batteries with plastic super-conductive interlayer enabled by in-situ solidification. Energy Storage Mater. 2020, 25, 613–620. [Google Scholar] [CrossRef]

- Liu, Y.; Li, C.; Li, B.; Song, H.; Cheng, Z.; Chen, M.; He, P.; Zhou, H. Germanium Thin Film Protected Lithium Aluminum Germanium Phosphate for Solid-State Li Batteries. Adv. Energy Mater. 2018, 8, 1702374. [Google Scholar] [CrossRef]

- Xiong, S.; Liu, Y.; Jankowski, P.; Liu, Q.; Nitze, F.; Xie, K.; Song, J.; Matic, A. Design of a Multifunctional Interlayer for NASCION-Based Solid-State Li Metal Batteries. Adv. Funct. Mater. 2020, 30, 2001444. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Sun, Q.; Zhao, Y.; Wang, B.; Kaghazchi, P.; Adair, K.R.; Li, R.; Zhang, C.; Liu, J.; Kuo, L.-Y.; et al. Stabilizing the Interface of NASICON Solid Electrolyte against Li Metal with Atomic Layer Deposition. ACS Appl. Mater. Interfaces 2018, 10, 31240–31248. [Google Scholar] [CrossRef]

- Bosubabu, D.; Sivaraj, J.; Sampathkumar, R.; Ramesha, K. LAGP|Li Interface Modification through a Wetted Polypropylene Interlayer for Solid State Li-Ion and Li–S batteries. ACS Appl. Energy Mater. 2019, 2, 4118–4125. [Google Scholar] [CrossRef]

- He, L.; Chen, C.; Kotobuki, M.; Zheng, F.; Zhou, H.; Lu, L. A new approach for synthesizing bulk-type all-solid-state lithium-ion batteries. J. Mater. Chem. A 2019, 7, 9748–9760. [Google Scholar] [CrossRef]

- Hu, Y.; Zhong, Y.; Qi, L.; Wang, H. Inorganic/polymer hybrid layer stabilizing anode/electrolyte interfaces in solid-state Li metal batteries. Nano Res. 2020, 13, 3230–3234. [Google Scholar] [CrossRef]

- Li, C.; Chen, Y.; Li, Z.; Zhang, Y.; Fang, Z.; Xu, J.; Sun, Y.; Bao, H.; Cheng, H. Construction of sticky ionic conductive buffer layer for inorganic electrolyte toward stable all-solid-state lithium metal batteries. J. Power Sources 2021, 495, 229765. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Z.; Luo, L.; You, R.; Jiao, J.; Huang, W.; Wang, J.; Li, C.; Han, X.; Chen, S. Enhancing the interface stability of Li1.3Al0.3Ti1.7(PO4)3 and lithium metal by amorphous Li1.5Al0.5Ge1.5(PO4)3 modification. Ionics 2020, 26, 3815–3821. [Google Scholar] [CrossRef]

- Li, W.; Wang, Q.; Jin, J.; Li, Y.; Wu, M.; Wen, Z. Constructing dual interfacial modification by synergetic electronic and ionic conductors: Toward high-performance LAGP-Based Li-S batteries. Energy Storage Mater. 2019, 23, 299–305. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, Z.; Zhai, W.; Hou, G.; Chen, L.; Ci, L. Bifunctional In Situ Polymerized Interface for Stable LAGP-Based Lithium Metal Batteries. Adv. Mater. Inter. 2021, 8, 2100072. [Google Scholar] [CrossRef]

- Kerman, K.; Luntz, A.; Viswanathan, V.; Chiang, Y.-M.; Chen, Z. Review—Practical Challenges Hindering the Development of Solid State Li Ion Batteries. J. Electrochem. Soc. 2017, 164, A1731–A1744. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Lu, L. Influence of crystallization temperature on ionic conductivity of lithium aluminum germanium phosphate glass-ceramic. J. Power Sources 2015, 290, 123–129. [Google Scholar] [CrossRef]

- DeWees, R.; Wang, H. Synthesis and Properties of NaSICON-type LATP and LAGP Solid Electrolytes. ChemSusChem 2019, 12, 3713–3725. [Google Scholar] [CrossRef]

- Mariappan, C.R.; Yada, C.; Rosciano, F.; Roling, B. Correlation between micro-structural properties and ionic conductivity of Li1.5Al0.5Ge1.5(PO4)3 ceramics. J. Power Sources 2011, 196, 6456–6464. [Google Scholar] [CrossRef]

- Kaliyappan, K.; Liu, J.; Xiao, B.; Lushington, A.; Li, R.; Sham, T.-K.; Sun, X. Enhanced Performance of P2-Na0.66(Mn0.54Co0.13Ni0.13)O2 Cathode for Sodium-Ion Batteries by Ultrathin Metal Oxide Coatings via Atomic Layer Deposition. Adv. Funct. Mater. 2017, 27, 1701870. [Google Scholar] [CrossRef]

- Oswald, S.; Thoss, F.; Zier, M.; Hoffmann, M.; Jaumann, T.; Herklotz, M.; Nikolowski, K.; Scheiba, F.; Kohl, M.; Giebeler, L.; et al. Binding Energy Referencing for XPS in Alkali Metal-Based Battery Materials Research (II): Application to Complex Composite Electrodes. Batteries 2018, 4, 36. [Google Scholar] [CrossRef] [Green Version]

- Yu, Q.; Han, D.; Lu, Q.; He, Y.-B.; Li, S.; Liu, Q.; Han, C.; Kang, F.; Li, B. Constructing Effective Interfaces for Li1.5Al0.5Ge1.5(PO4)3 Pellets To Achieve Room-Temperature Hybrid Solid-State Lithium Metal Batteries. ACS Appl. Mater. Interfaces 2019, 11, 9911–9918. [Google Scholar] [CrossRef]

- Zhai, P.; Fu, L.; Yuan, S.; Shi, L.; Zhu, J.; Zhao, Y.; Wang, Z. Ionic Conductive Thermoplastic Polymer Welding Layer for Low Electrode/Solid Electrolyte Interface Resistance. ACS Appl. Energy Mater. 2020, 3, 7011–7019. [Google Scholar] [CrossRef]

- Wang, M.; Huai, L.; Hu, G.; Yang, S.; Ren, F.; Wang, S.; Zhang, Z.; Chen, Z.; Peng, Z.; Shen, C.; et al. Effect of LiFSI Concentrations To Form Thickness- and Modulus-Controlled SEI Layers on Lithium Metal Anodes. J. Phys. Chem. C 2018, 122, 9825–9834. [Google Scholar] [CrossRef]

- Nojabaee, M.; Kuster, K.; Starke, U.; Popovic, J.; Maier, J. Solid Electrolyte Interphase Evolution on Lithium Metal in Contact with Glyme-Based Electrolytes. Small 2020, 16, e2000756. [Google Scholar] [CrossRef]

- Jung, S.C.; Han, Y.-K. How Do Li Atoms Pass through the Al2O3 Coating Layer during Lithiation in Li-ion Batteries? J. Phys. Chem. Lett. 2013, 4, 2681–2685. [Google Scholar] [CrossRef]

- Zhang, B.; Zhong, J.; Pan, F.; Lin, Z. Potential Solid-State Electrolytes with Good Balance between Ionic Conductivity and Electrochemical Stability: Li5-xM1-xMx′O4 (M = Al and Ga and M′ = Si and Ge). ACS Appl. Mater. Interfaces 2021, 13, 61296–61304. [Google Scholar] [CrossRef]

| Cell Configuration | Interface Modification Layer | Cycling Performance | Cumulative Li Plated Capacity (mAh cm−2) | References |

|---|---|---|---|---|

| Li/PP-LAGP-PP/Li * | PP | 500s @0.25 mA | - | [31] |

| Li/SPI-LAGP-SPI/Li * | SPI, by in situ solidification, 10 µm | 600 h @0.1 mA cm−2 | 60 | [1] |

| PAALi/LAGP/PAALi * | PAALi + LAGP | 100 h @0.005 mA cm−2 | 0.5 | [32] |

| Li/P(AA-co-MA)-LAGP- P(AA-co-MA)/Li | P(AA-co-MA), by spray-coating, 1.5 µm | 20,000 s @0.07 mA cm−2 | 0.39 | [25] |

| Li/PVCA-LAGP-PVCA/Li * | LiTFSI/PVCA, | 500 h @0.1 mA cm−2 | 50 | [33] |

| Li/AIOC-LAGP-AIOC/Li | AIOC, by spin coating, 11 µm | 100 h @0.1 mA cm−2 | 10 | [34] |

| Li/CPE-LAGP-CPE/Li | CPE, by spin coating | 1000 h @0.1 mA cm−2 | 100 | [36] |

| Li/lSN-LAGP-lSN/Li * | SN + LLZAO + FEC + LiTFSI, by in situ solidification | 320 h @0.1 mA cm−2 | 32 | [27] |

| Li/Ge-LAGP-Ge/Li | Ge, by puttering, 60 nm | 200 h @0.1 mA cm−2 | 20 | [28] |

| Li/Cr-LAGP-Cr/Li | Cr, by sputtering, 30 nm | 800 h @0.2 mA cm−2 | 160 (overpotential: 1.2 V) | [3] |

| Li/LAGP-IL-LAGP-LAGP-IL/Li | LAGP-IL | 1500 h @0.1 mA cm−2 | 150 | [29] |

| Li/3DGPE-LAGP-3DGPE/Li * | PVDF-HFP + PEGDE + DPPO, 100 µm | 250 h @0.1 mA cm−2 | 25 | [44] |

| Li/CSSE-LAGP-CSSE/Li | PVC + TPU + LiTFSI, 50 µm | 1000 h @0.1 mA cm−2 | 100 | [45] |

| Li/PVCA-LAGP-PVCA/Li | PVCA + FEC | 800 h @0.05 mA cm−2 | 40 | [37] |

| Li/LiPON-LAGP-LiPON/Li | LiPON, by sputtering, 3 µm | 200 h @0.1 mA cm−2 | 20 | [26] |

| Li/Al2O3-LAGP- Al2O3/Li * | Al2O3, by ALD, 5 nm | 360 h @0.2 mA cm−2 | 72 (overpotential: 0.3 V) | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Liu, H.; Xie, Z.; Qu, W.; Liu, J. Improving the Stability of Lithium Aluminum Germanium Phosphate with Lithium Metal by Interface Engineering. Nanomaterials 2022, 12, 1912. https://doi.org/10.3390/nano12111912

Zhang Y, Liu H, Xie Z, Qu W, Liu J. Improving the Stability of Lithium Aluminum Germanium Phosphate with Lithium Metal by Interface Engineering. Nanomaterials. 2022; 12(11):1912. https://doi.org/10.3390/nano12111912

Chicago/Turabian StyleZhang, Yue, Hanshuo Liu, Zhong Xie, Wei Qu, and Jian Liu. 2022. "Improving the Stability of Lithium Aluminum Germanium Phosphate with Lithium Metal by Interface Engineering" Nanomaterials 12, no. 11: 1912. https://doi.org/10.3390/nano12111912

APA StyleZhang, Y., Liu, H., Xie, Z., Qu, W., & Liu, J. (2022). Improving the Stability of Lithium Aluminum Germanium Phosphate with Lithium Metal by Interface Engineering. Nanomaterials, 12(11), 1912. https://doi.org/10.3390/nano12111912