Vibration Control of Diamond Nanothreads by Lattice Defect Introduction for Application in Nanomechanical Sensors

Abstract

:1. Introduction

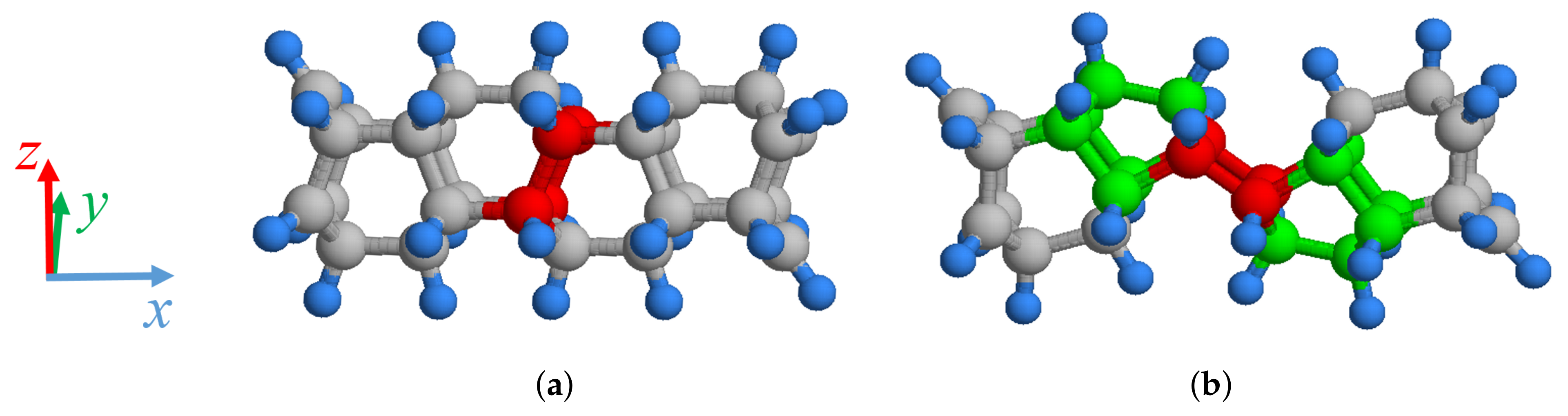

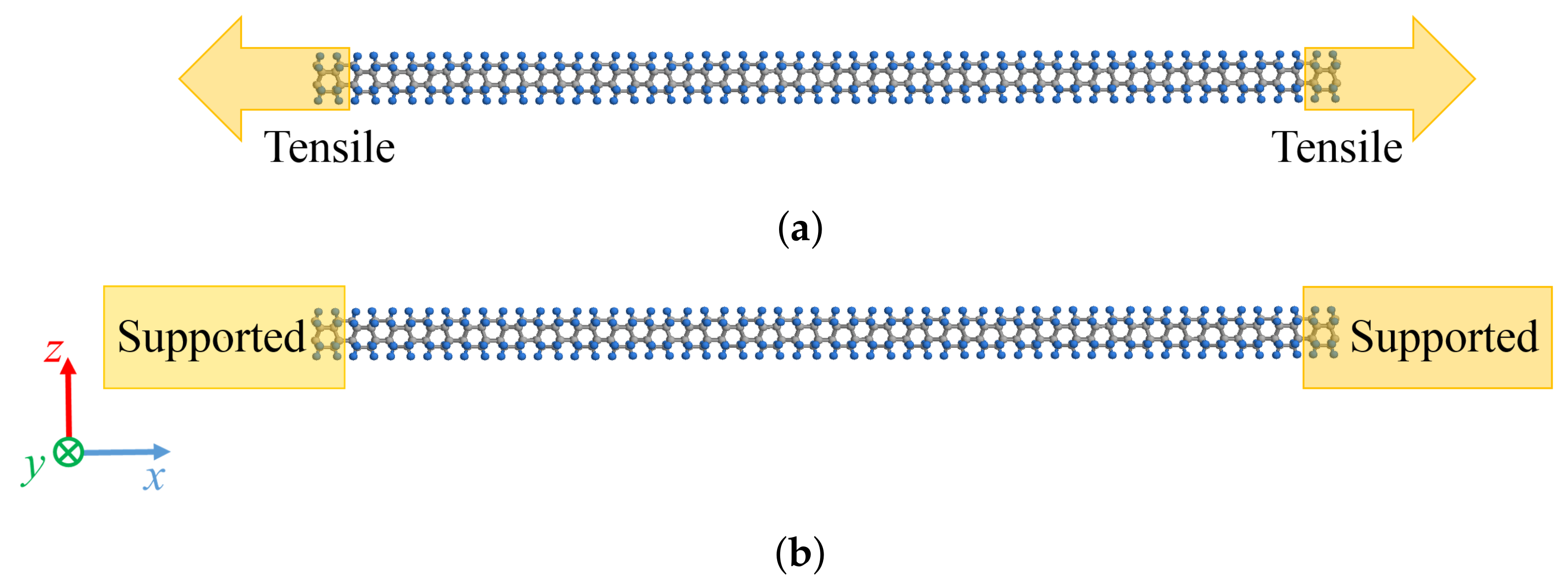

2. Methods

2.1. Molecular Dynamics Simulation

- In the tensile analysis, the tensile speed is 0.01 Å/ps. The system temperature 5 K is stabilized considering an NPT ensemble with 100,000 steps.

- In the vibration analysis, an initial displacement is applied along the z-axis to the six-membered ring at the center in the x-axis direction, and subsequently the constraint is released to achieve free vibration.

- The relaxed structure of the analytical model is obtained, using the conjugate gradient method with accuracy eV.

- The system temperature 5 K is stabilized, considering an NVT ensemble with 100,000 steps.

- The constraint is released after an initial displacement is applied to the six-membered ring centered in the x-axis direction, considering an NVT ensemble with 3,000,000 steps.

- Free vibration is performed in an NVE ensemble with 3,000,000 steps.

- In the vibration analysis of a DNT under an applied strain, the strain is applied immediately after the structure of the system stabilizes, after which an initial displacement is applied.

- In the vibration analysis of a DNT with an additional mass, the atoms at the center in the x-axis direction being set with additional mass are regarded as the equivalent mass atoms. The analysis is performed according to analysis steps with different equivalent mass atoms.

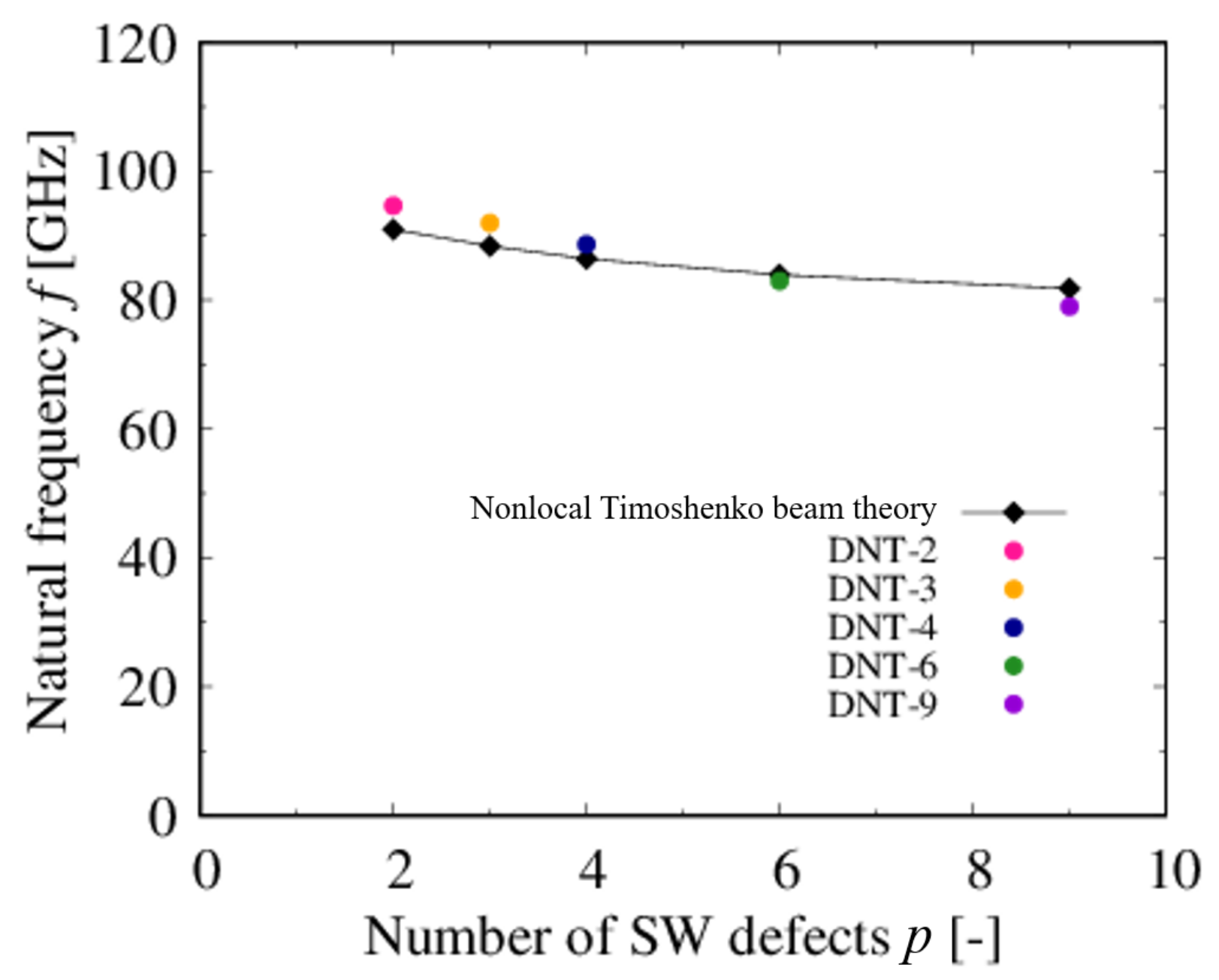

2.2. Nonlocal Timoshenko Beam Theory

3. Results and Discussion

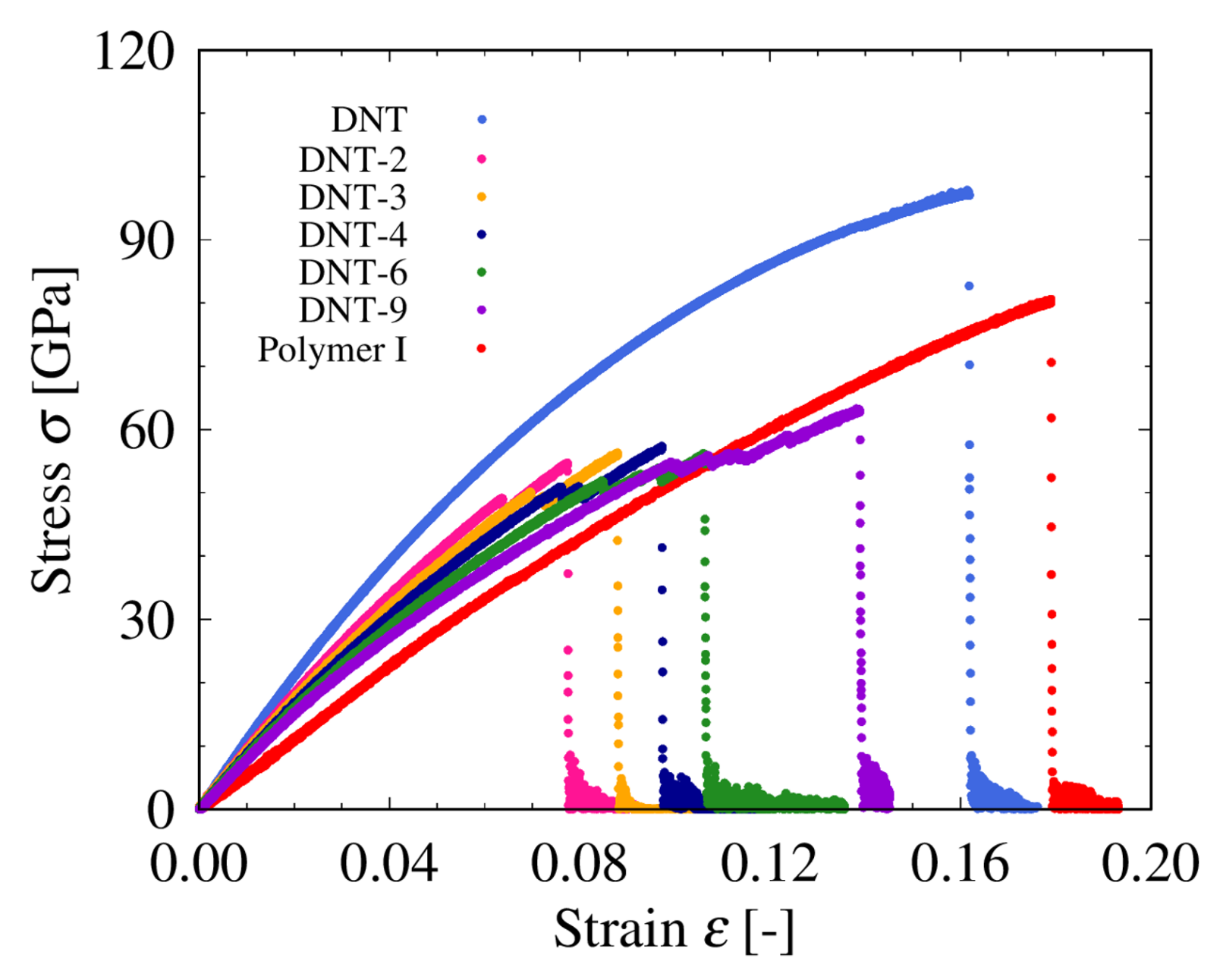

3.1. Determination of Material Properties

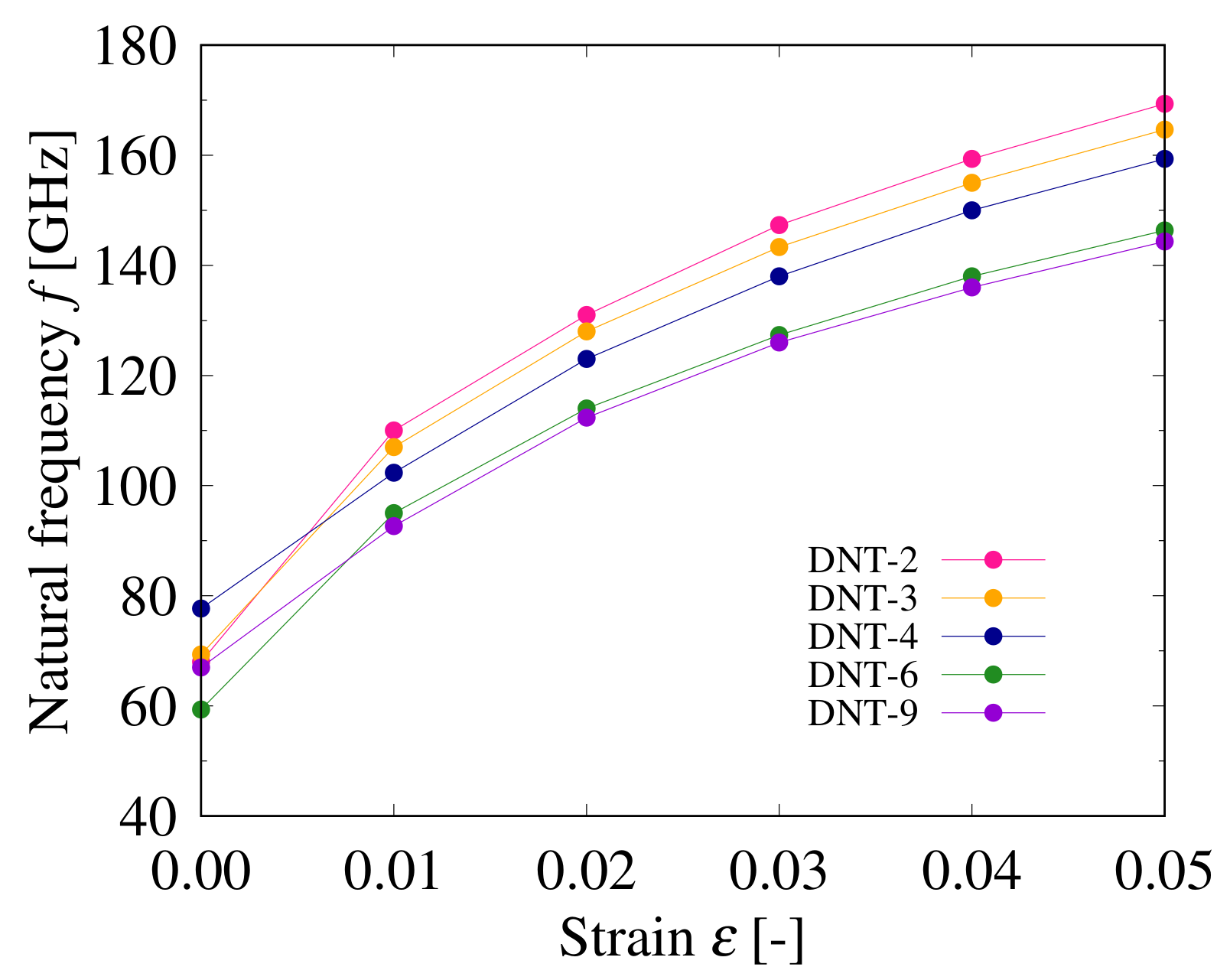

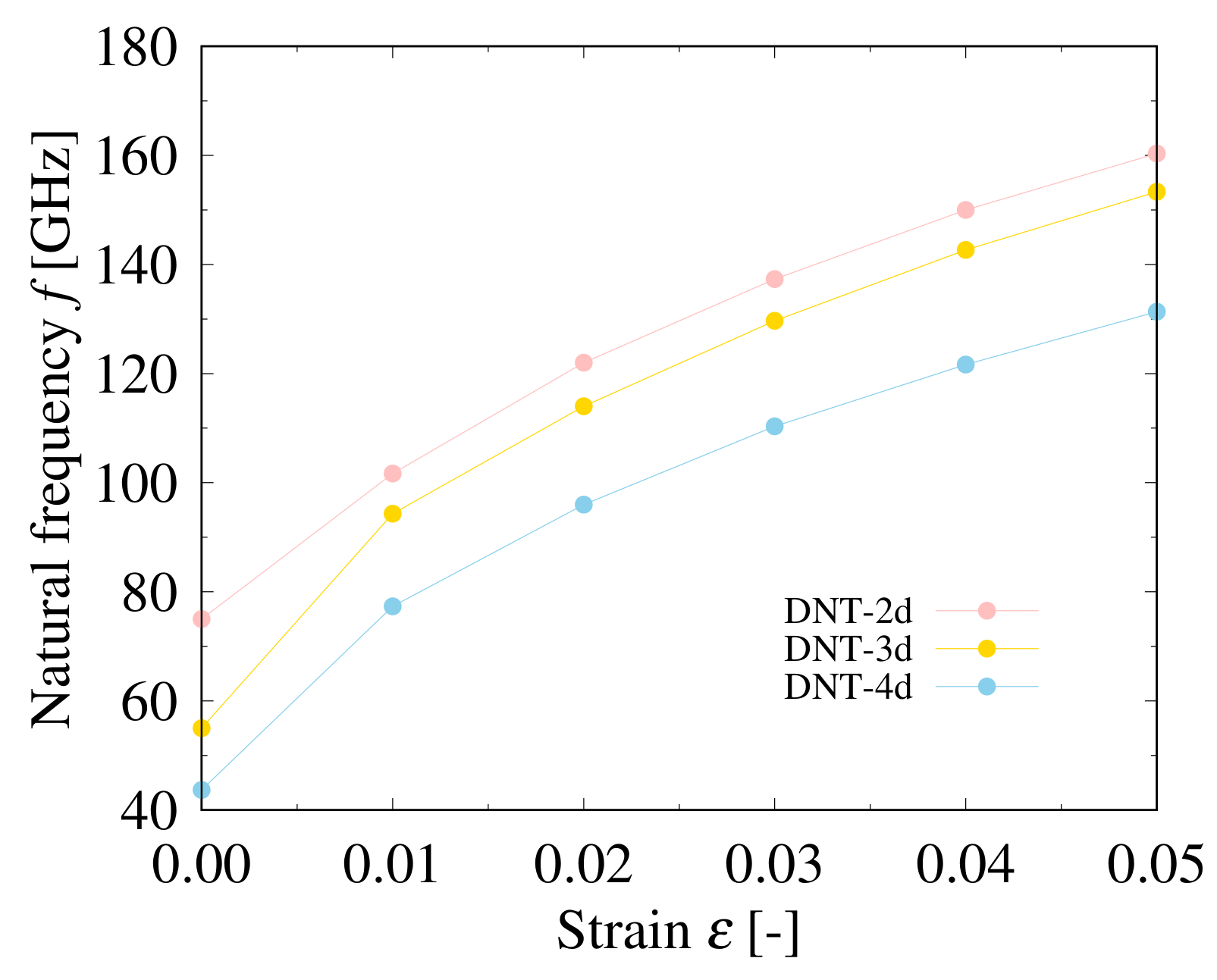

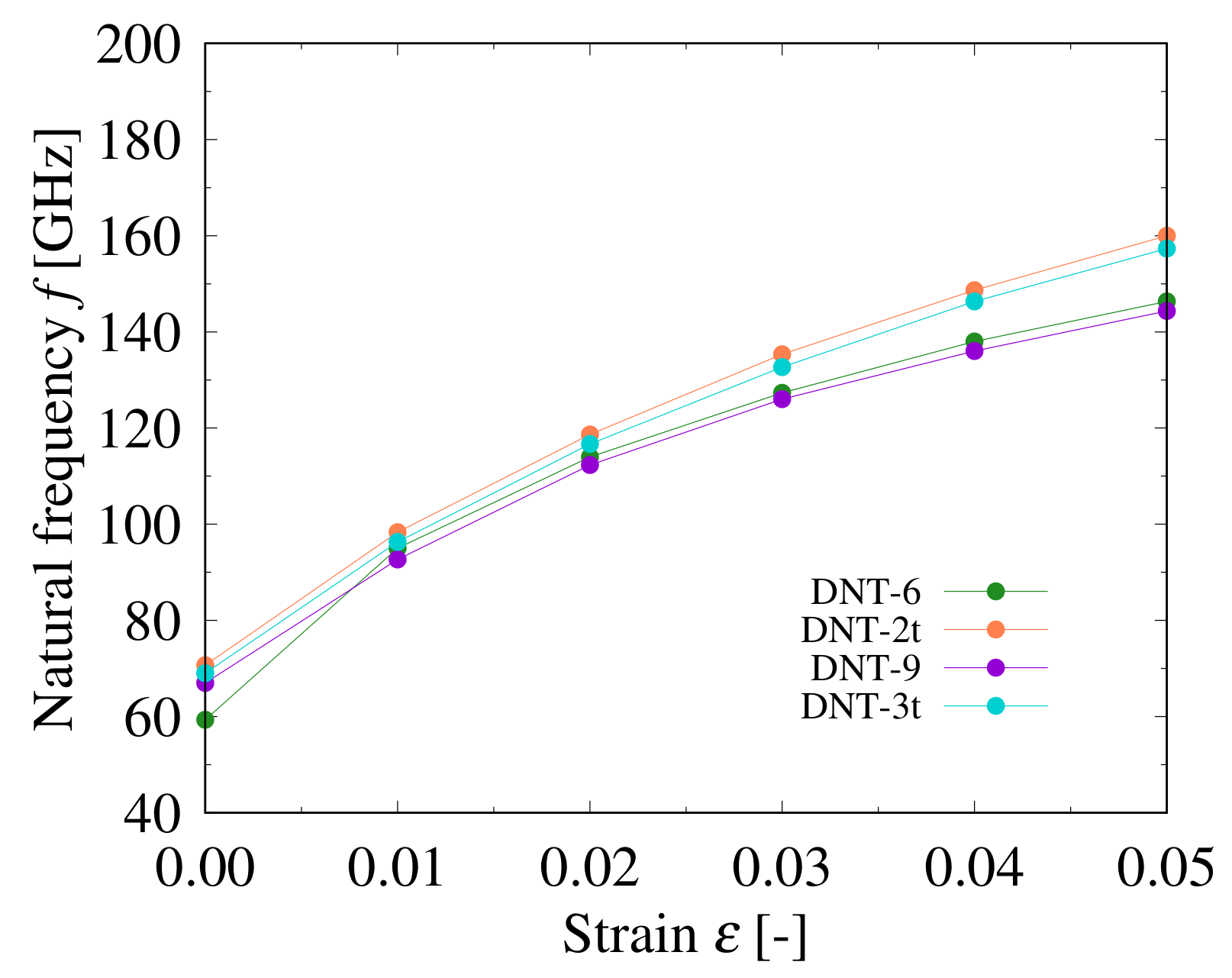

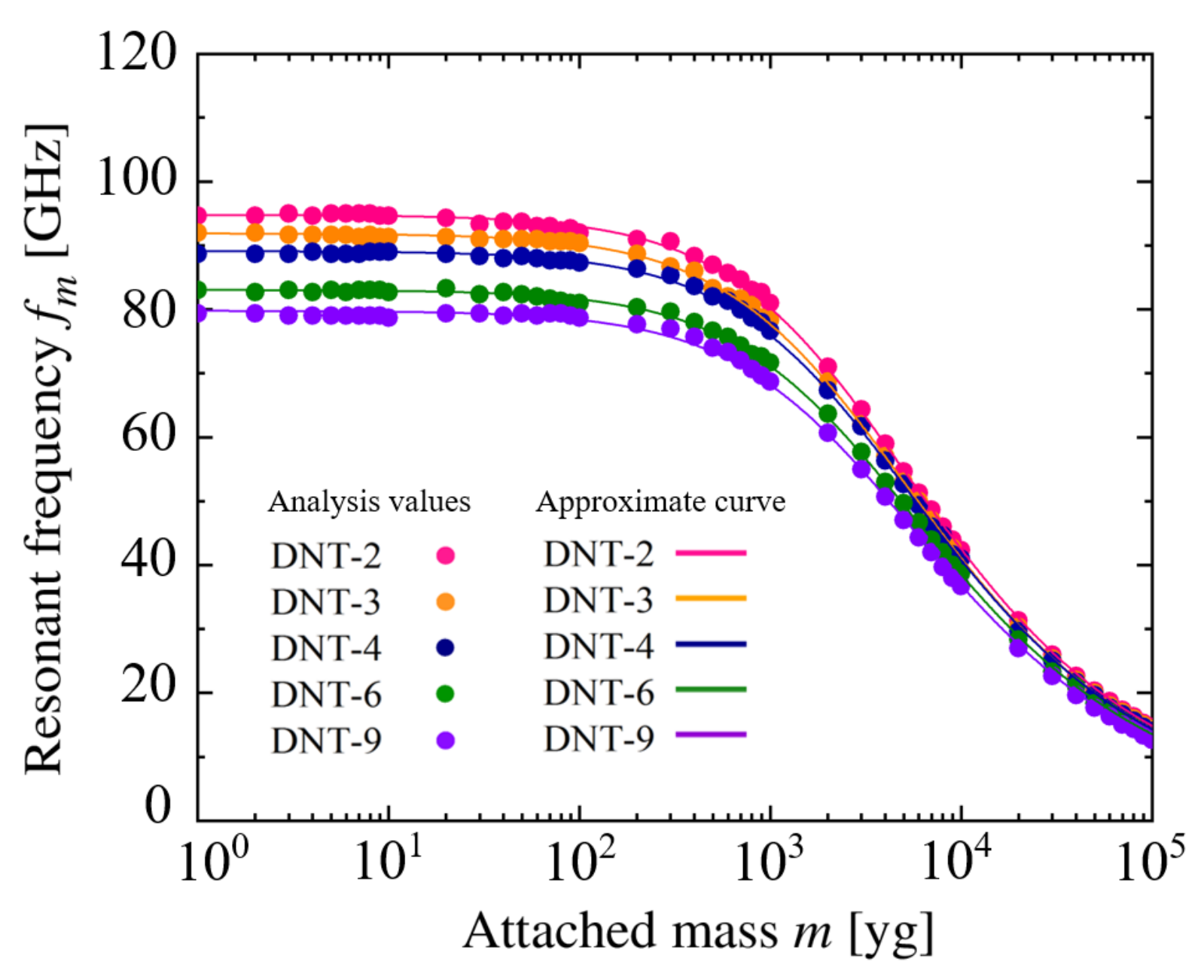

3.2. Vibration Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SW | Stone-Wales |

| GSs | Graphene sheets |

| CNTs | Carbon nanotubes |

| DNTs | Diamond nanothreads |

| MD | Molecular dynamics |

References

- Poncharal, P.; Wang, Z.; Ugarte, D.; De Heer, W.A. Electrostatic deflections and electromechanical resonances of carbon nanotubes. Science 1999, 283, 1513–1516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bunch, J.S.; Van Der Zande, A.M.; Verbridge, S.S.; Frank, I.W.; Tanenbaum, D.M.; Parpia, J.M.; Craighead, H.G.; McEuen, P.L. Electromechanical resonators from graphene sheets. Science 2007, 315, 490–493. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.X.; Liu, Y.; Shimoda, M. Vibration analysis of a carbyne-based resonator in nano-mechanical mass sensors. J. Phys. D Appl. Phys. 2015, 48, 115303. [Google Scholar] [CrossRef]

- Shi, J.X.; Lei, X.W.; Natsuki, T. Review on Carbon Nanomaterials-Based Nano-Mass and Nano-Force Sensors by Theoretical Analysis of Vibration Behavior. Sensors 2021, 21, 1907. [Google Scholar] [CrossRef]

- Fitzgibbons, T.C.; Guthrie, M.; Xu, E.S.; Crespi, V.H.; Davidowski, S.K.; Cody, G.D.; Alem, N.; Badding, J.V. Benzene-derived carbon nanothreads. Nat. Mater. 2015, 14, 43–47. [Google Scholar] [CrossRef]

- Roman, R.E.; Kwan, K.; Cranford, S.W. Mechanical properties and defect sensitivity of diamond nanothreads. Nano Lett. 2015, 15, 1585–1590. [Google Scholar] [CrossRef]

- Xu, E.S.; Lammert, P.E.; Crespi, V.H. Systematic enumeration of sp3 nanothreads. Nano Lett. 2015, 15, 5124–5130. [Google Scholar] [CrossRef]

- Zhan, H.; Zhang, G.; Tan, V.; Cheng, Y.; Bell, J.M.; Zhang, Y.W.; Gu, Y. From brittle to ductile: A structure dependent ductility of diamond nanothread. Nanoscale 2016, 8, 11177–11184. [Google Scholar] [CrossRef] [Green Version]

- Feng, C.; Xu, J.; Zhang, Z.; Wu, J. Morphology-and dehydrogenation-controlled mechanical properties in diamond nanothreads. Carbon 2017, 124, 9–22. [Google Scholar] [CrossRef]

- Silveira, J.F.R.V.; Muniz, A.R. First-principles calculation of the mechanical properties of diamond nanothreads. Carbon 2017, 113, 260–265. [Google Scholar] [CrossRef]

- Silveira, J.F.R.V.; Muniz, A.R. Functionalized diamond nanothreads from benzene derivatives. Phys. Chem. Chem. Phys. 2017, 19, 7132–7137. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, G.; Yakobson, B.I.; Zhang, Y.W. Kinetic theory for the formation of diamond nanothreads with desired configurations: A strain–temperature controlled phase diagram. Nanoscale 2018, 10, 9664–9672. [Google Scholar] [CrossRef]

- Tangarife, E.; Gonzalez, R.I.; Cardenas, C.; Bringa, E.M.; Munoz, F. Molecular simulations of carbon allotropes in processes with creation and destruction of chemical bonds. Carbon 2019, 144, 177–184. [Google Scholar] [CrossRef]

- Xiao, J.; Chen, M.M.; Liu, W.J.; He, J.; Pan, C.N.; Long, M.Q. Perfect mechanical and robust electronic properties of new carbon nanothreads: A first principles study. Phys. E Low Dimens. Syst. Nanostruct. 2019, 111, 37–43. [Google Scholar] [CrossRef]

- Duan, K.; Zhang, J.; Li, L.; Hu, Y.; Zhu, W.; Wang, X. Diamond nanothreads as novel nanofillers for cross-linked epoxy nanocomposites. Compos. Sci. Technol. 2019, 174, 84–93. [Google Scholar] [CrossRef]

- Huss, S.; Wu, S.; Chen, B.; Wang, T.; Gerthoffer, M.; Ryan, D.; Smith, S.; Crespi, V.; Badding, J.; Elacqua, E. Scalable Synthesis of Crystalline One-Dimensional Carbon Nanothreads through Modest-Pressure Polymerization of Furan. ACS Nano 2021, 15, 4134–4143. [Google Scholar] [CrossRef]

- Biswas, A.; Ward, M.; Wang, T.; Zhu, L.; Huang, H.T.; Badding, J.; Crespi, V.; Strobel, T. Evidence for Orientational Order in Nanothreads Derived from Thiophene. J. Phys. Chem. Lett. 2019, 10, 7164–7171. [Google Scholar] [CrossRef]

- Nobrega, M.; Teixeira-Neto, E.; Cairns, A.; Temperini, M.; Bini, R. One-dimensional diamondoid polyaniline-like nanothreads from compressed crystal aniline. Chem. Sci. 2018, 9, 254–260. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romi, S.; Fanetti, S.; Alabarse, F.; Mio, A.; Bini, R. Synthesis of double core chromophore-functionalized nanothreads by compressing azobenzene in a diamond anvil cell. Chem. Sci. 2021, 12, 7048–7057. [Google Scholar] [CrossRef]

- Demingos, P.; Muniz, A. Electronic and mechanical properties of partially saturated carbon and carbon nitride nanothreads. J. Phys. Chem. C 2019, 123, 3886–3891. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhan, H.; Nie, Y.; Xu, X.; Gu, Y. Role of nitrogen on the mechanical properties of the novel carbon nitride nanothreads. J. Phys. Chem. C 2019, 123, 28977–28984. [Google Scholar] [CrossRef]

- Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.; Li, J. Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Liu, Y. Detecting both the mass and position of an accreted particle by a micro/nano-mechanical resonator sensor. Sensors 2014, 14, 16296–16310. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhao, Y.P. Mass and force sensing of an adsorbate on a beam resonator sensor. Sensors 2015, 15, 14871–14886. [Google Scholar] [CrossRef] [Green Version]

- Nag, A.; Alahi, M.; Eshrat, E.; Mukhopadhyay, S.C.; Liu, Z. Multi-Walled Carbon Nanotubes-Based Sensors for Strain Sensing Applications. Sensors 2021, 21, 1261. [Google Scholar] [CrossRef]

- Li, C.; Chou, T.W. Mass detection using carbon nanotube-based nanomechanical resonators. Appl. Phys. Lett. 2004, 84, 5246–5248. [Google Scholar] [CrossRef] [Green Version]

- Shen, Z.B.; Tang, G.J.; Zhang, L.; Li, X.F. Vibration of double-walled carbon nanotube based nanomechanical sensor with initial axial stress. Omput. Mater. Sci. 2012, 58, 51–58. [Google Scholar] [CrossRef]

- Eltaher, M.; Agwa, M. Analysis of size-dependent mechanical properties of CNTs mass sensor using energy equivalent model. Sens. Actuators A Phys. 2016, 246, 9–17. [Google Scholar] [CrossRef]

- Lei, X.W.; Natsuki, T.; Shi, J.X.; Ni, Q.Q. An atomic-resolution nanomechanical mass sensor based on circular monolayer graphene sheet: Theoretical analysis of vibrational properties. J. Appl. Phys. 2013, 113, 154313. [Google Scholar] [CrossRef]

- Zhou, S.M.; Sheng, L.P.; Shen, Z.B. Transverse vibration of circular graphene sheet-based mass sensor via nonlocal Kirchhoff plate theory. Comput. Mater. Sci. 2014, 86, 73–78. [Google Scholar] [CrossRef]

- Natsuki, T.; Urakami, K. Analysis of vibration frequency of carbon nanotubes used as nano-force sensors considering clamped boundary condition. Electronics 2019, 8, 1082. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Mielke, S.L.; Khare, R.; Troya, D.; Ruoff, R.S.; Schatz, G.C.; Belytschko, T. Mechanics of defects in carbon nanotubes: Atomistic and multiscale simulations. Phys. Rev. B Condens. Matter 2005, 71, 115403. [Google Scholar] [CrossRef]

- Suenaga, K.; Wakabayashi, H.; Koshino, M.; Sato, Y.; Urita, K.; Iijima, S. Imaging active topological defects in carbon nanotubes. Nat. Nanotechnol. 2007, 2, 358–360. [Google Scholar] [CrossRef]

- Lei, X.W.; Nakatani, A. Local equilibrium configurations and minimum energy path of carbon nanotubes with Stone-Wales defects and their related pentagon-heptagon lattice defects. Comput. Mater. Sci. 2017, 133, 194–199. [Google Scholar] [CrossRef]

- Zhang, T.; Li, X.; Gao, H. Designing graphene structures with controlled distributions of topological defects: A case study of toughness enhancement in graphene ruga. Extrem. Mech. Lett. 2014, 1, 3–8. [Google Scholar] [CrossRef]

- Zhang, T.; Gao, H. Toughening graphene with topological defects: A perspective. ASME J. Appl. Mech. 2015, 82. [Google Scholar] [CrossRef]

- Qin, H.; Sun, Y.; Liu, J.Z.; Li, M.; Liu, Y. Negative Poisson’s ratio in rippled graphene. Nanoscale 2017, 9, 4135–4142. [Google Scholar] [CrossRef]

- Shi, J.X.; Ohmura, K.; Shimoda, M.; Lei, X.W. A consistent methodology for optimal shape design of graphene sheets to maximize their fundamental frequencies considering topological defects. J. Mech. Phys. Solids 2018, 116, 117–134. [Google Scholar] [CrossRef]

- Li, X.; Baldini, M.; Wang, T.; Chen, B.; Xu, E.S.; Vermilyea, B.; Crespi, V.H.; Hoffmann, R.; Molaison, J.J.; Tulk, C.A.; et al. Mechanochemical synthesis of carbon nanothread single crystals. J. Am. Chem. Soc. 2017, 139, 16343–16349. [Google Scholar] [CrossRef]

- Wu, W.; Tai, B.; Guan, S.; Yang, S.A.; Zhang, G. Hybrid structures and strain-tunable electronic properties of carbon nanothreads. J. Phys. Chem. C 2018, 122, 3101–3106. [Google Scholar] [CrossRef] [Green Version]

- Peddieson, J.; Buchanan, G.R.; McNitt, R.P. Application of nonlocal continuum models to nanotechnology. Int. J. Eng. Sci. 2003, 41, 305–312. [Google Scholar] [CrossRef]

- Eringen, A.C. On differential equations of nonlocal elasticity and solutions of screw dislocation and surface waves. J. Appl. Phys. 1983, 54, 4703–4710. [Google Scholar] [CrossRef]

- Yang, J.; Ke, L.L.; Kitipornchai, S. Nonlinear free vibration of single-walled carbon nanotubes using nonlocal Timoshenko beam theory. Phys. E Low Dimens. Syst. Nanostruct. 2010, 42, 1727–1735. [Google Scholar] [CrossRef]

- Lei, X.W.; Natsuki, T.; Shi, J.X.; Ni, Q.Q. Surface effects on the vibrational frequency of double-walled carbon nanotubes using the nonlocal Timoshenko beam model. Compos. B. Eng. 2012, 43, 64–69. [Google Scholar] [CrossRef]

- Boumia, L.; Zidour, M.; Benzair, A.; Tounsi, A. A Timoshenko beam model for vibration analysis of chiral single-walled carbon nanotubes. Phys. E Low Dimens. Syst. Nanostruct. 2014, 59, 186–191. [Google Scholar] [CrossRef]

- Jiang, L.Y.; Yan, Z. Timoshenko beam model for static bending of nanowires with surface effects. Phys. E Low Dimens. Syst. Nanostruct. 2010, 42, 2274–2279. [Google Scholar] [CrossRef]

- Chiu, M.S.; Chen, T. Bending and resonance behavior of nanowires based on Timoshenko beam theory with high-order surface stress effects. Phys. E Low Dimens. Syst. Nanostruct. 2013, 54, 149–156. [Google Scholar] [CrossRef]

- Murmu, T.; Pradhan, S.C. Buckling analysis of a single-walled carbon nanotube embedded in an elastic medium based on nonlocal elasticity and Timoshenko beam theory and using DQM. Phys. E Low Dimens. Syst. Nanostruct. 2009, 41, 1232–1239. [Google Scholar] [CrossRef]

- Apuzzo, A.; Barretta, R.; Fabbrocino, F.; Faghidian, S.; Luciano, R.; Sciarra, F.M.D. Axial and torsional free vibrations of elastic nano-beams by stress-driven two-phase elasticity. J. Appl. Comput. Mech. 2019, 5, 402–413. [Google Scholar] [CrossRef]

- Pinnola, F.; Faghidian, S.; Barretta, R.; de Sciarra, F.M. Variationally consistent dynamics of nonlocal gradient elastic beams. Int. J. Eng. Sci. 2020, 149, 103220. [Google Scholar] [CrossRef]

- Pinnola, F.; Vaccaro, M.; Barretta, R.; de Sciarra, F.M. Random vibrations of stress-driven nonlocal beams with external damping. Meccanica 2020, 56, 1329–1344. [Google Scholar] [CrossRef]

- Shen, Z.B.; Sheng, L.P.; Li, X.F.; Tang, G.J. Nonlocal Timoshenko beam theory for vibration of carbon nanotube-based biosensor. Phys. E Low Dimens. Syst. Nanostruct. 2012, 44, 1169–1175. [Google Scholar] [CrossRef]

- Giannopoulos, G. Fullerenes as mass sensors: A numerical investigation. Phys. E Low Dimens. Syst. Nanostruct. 2014, 56, 36–42. [Google Scholar] [CrossRef]

- Giannopoulos, G.; Georgantzinos, S. Establishing detection maps for carbon nanotube mass sensors: Molecular versus continuum mechanics. Acta Mech. 2017, 228, 2377–2390. [Google Scholar] [CrossRef]

- Fakher, M.; Rahmanian, S.; Hosseini-Hashemi, S. On the carbon nanotube mass nanosensor by integral form of nonlocal elasticity. Int. J. Mech. Sci. 2019, 150, 445–457. [Google Scholar] [CrossRef]

- Wen, X.D.; Hoffmann, R.; Ashcroft, N. Benzene under high pressure: A story of molecular crystals transforming to saturated networks, with a possible intermediate metallic phase. J. Am. Chem. Soc. 2011, 133, 9023–9035. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Stuart, S.J.; Tutein, A.B.; Harrison, J.A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 2000, 112, 6472–6486. [Google Scholar] [CrossRef] [Green Version]

- Duan, K.; Li, L.; Hu, Y.; Wang, X. Pillared graphene as an ultra-high sensitivity mass sensor. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Duan, K.; Li, Y.; Li, L.; Hu, Y.; Wang, X. Diamond nanothread based resonators: Ultrahigh sensitivity and low dissipation. Nanoscale 2018, 10, 8058–8065. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lei, X.-W.; Bando, K.; Shi, J.-X. Vibration Control of Diamond Nanothreads by Lattice Defect Introduction for Application in Nanomechanical Sensors. Nanomaterials 2021, 11, 2241. https://doi.org/10.3390/nano11092241

Lei X-W, Bando K, Shi J-X. Vibration Control of Diamond Nanothreads by Lattice Defect Introduction for Application in Nanomechanical Sensors. Nanomaterials. 2021; 11(9):2241. https://doi.org/10.3390/nano11092241

Chicago/Turabian StyleLei, Xiao-Wen, Kazuki Bando, and Jin-Xing Shi. 2021. "Vibration Control of Diamond Nanothreads by Lattice Defect Introduction for Application in Nanomechanical Sensors" Nanomaterials 11, no. 9: 2241. https://doi.org/10.3390/nano11092241

APA StyleLei, X.-W., Bando, K., & Shi, J.-X. (2021). Vibration Control of Diamond Nanothreads by Lattice Defect Introduction for Application in Nanomechanical Sensors. Nanomaterials, 11(9), 2241. https://doi.org/10.3390/nano11092241