Fracture and Embedment Behavior of Brittle Submicrometer Spherical Particles Fabricated by Pulsed Laser Melting in Liquid Using a Scanning Electron Microscope Nanoindenter

Abstract

1. Introduction

2. Materials and Methods

2.1. Particle Fabrication

2.2. Characterization

2.3. Observation of Fracture and Embedment Behavior of SMPs

3. Results and Discussion

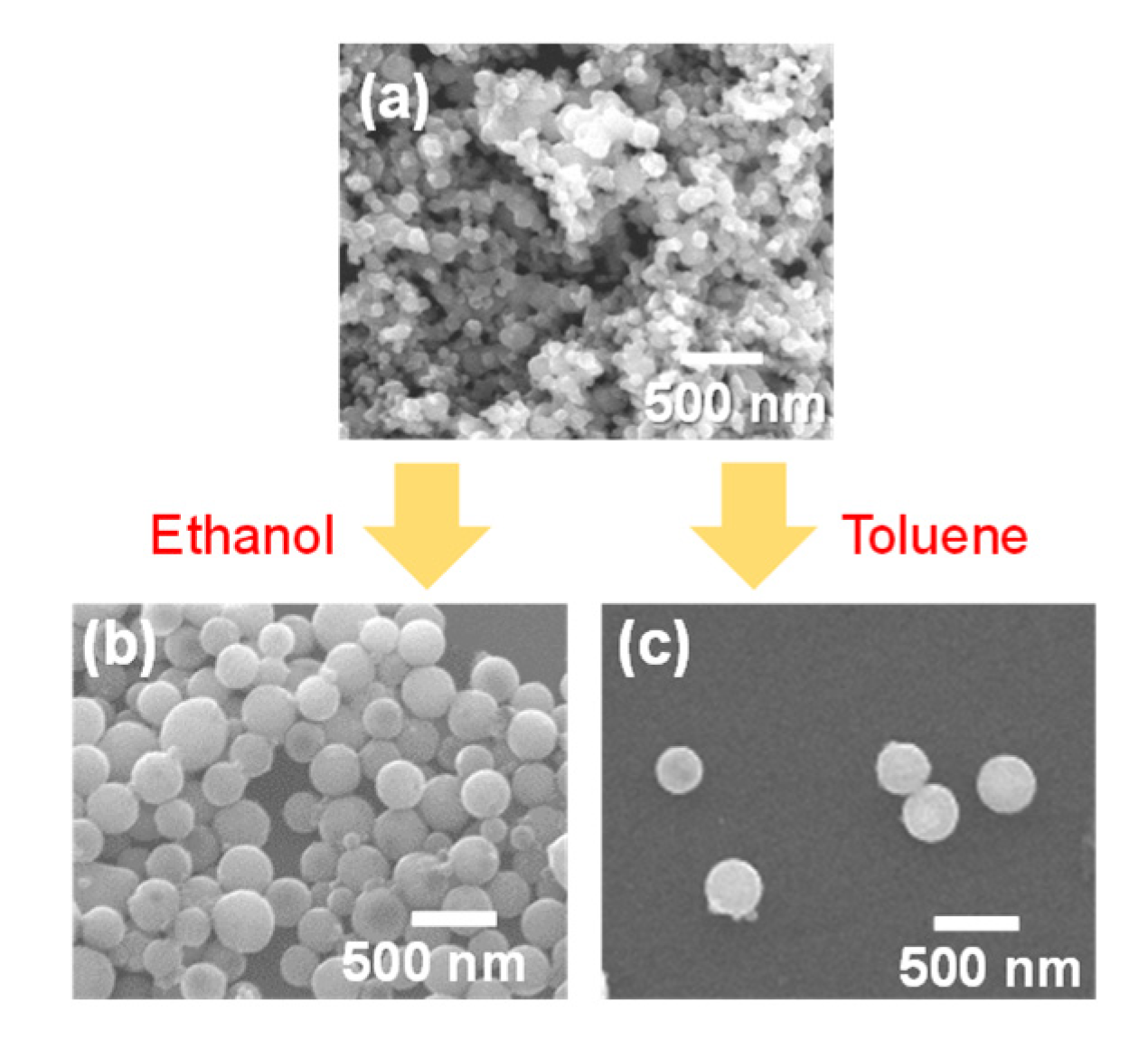

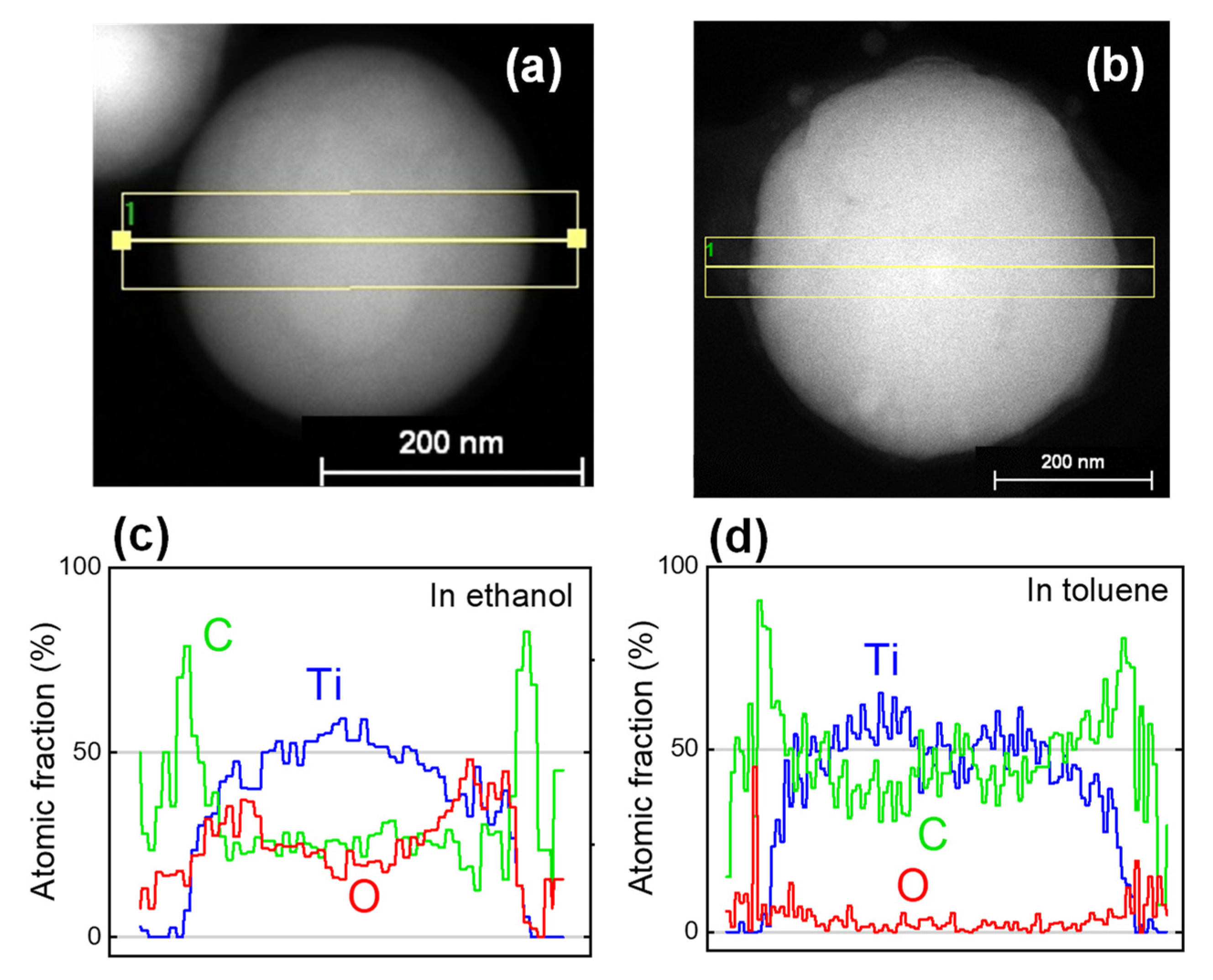

3.1. Fabrication of TiC SMPs by PLML

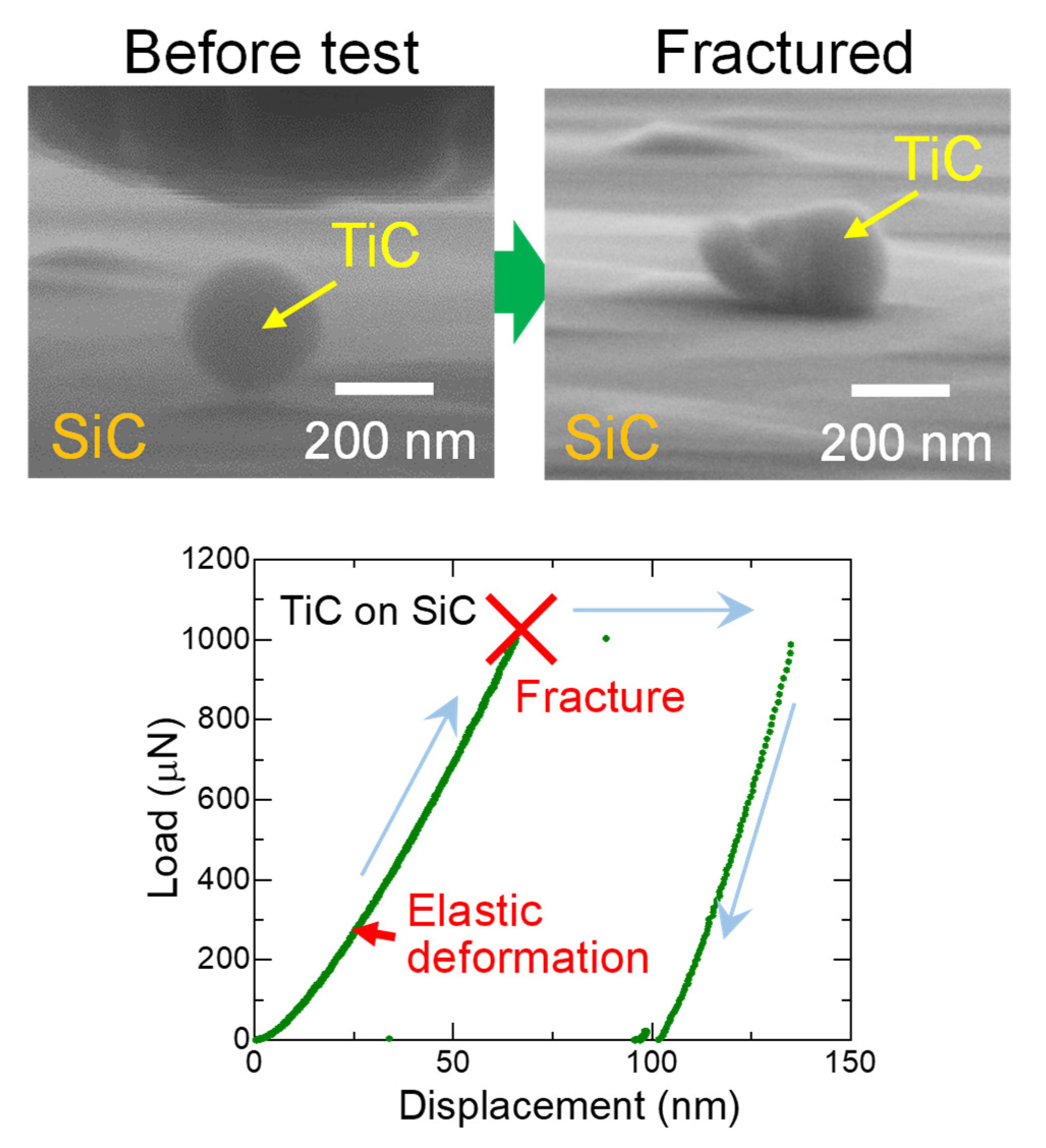

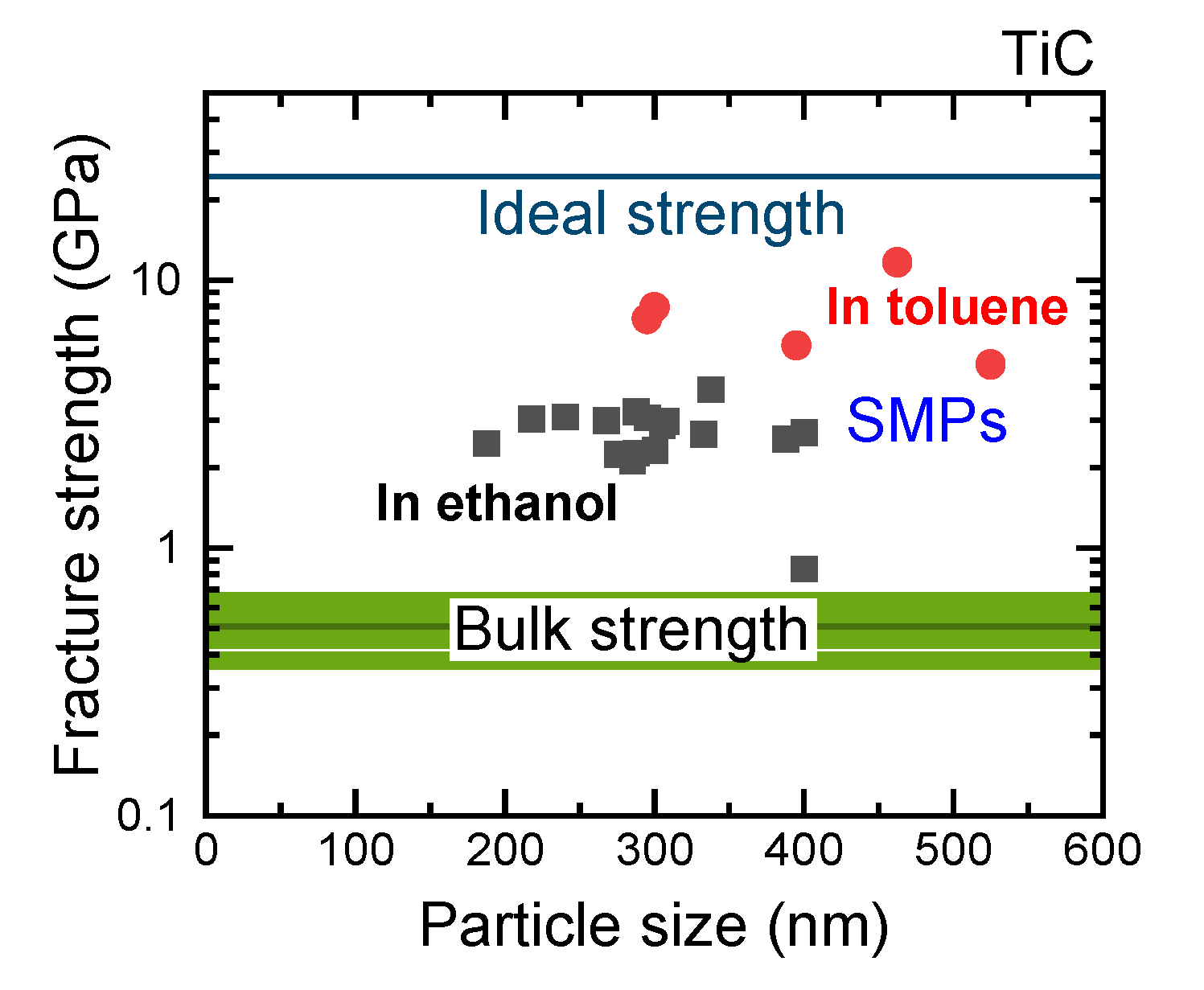

3.2. Fracture Strength of TiC SMPs Prepared by PLML

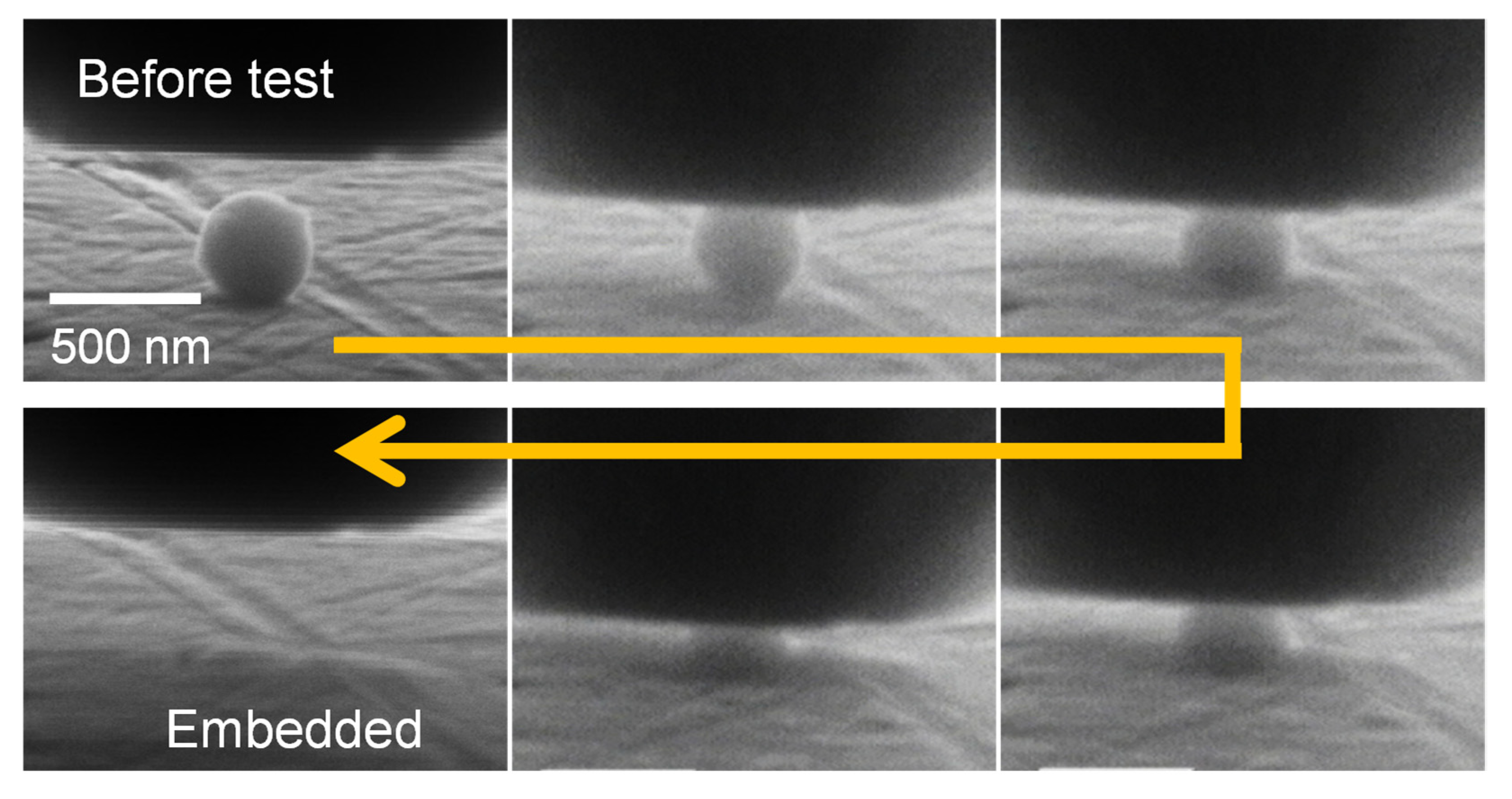

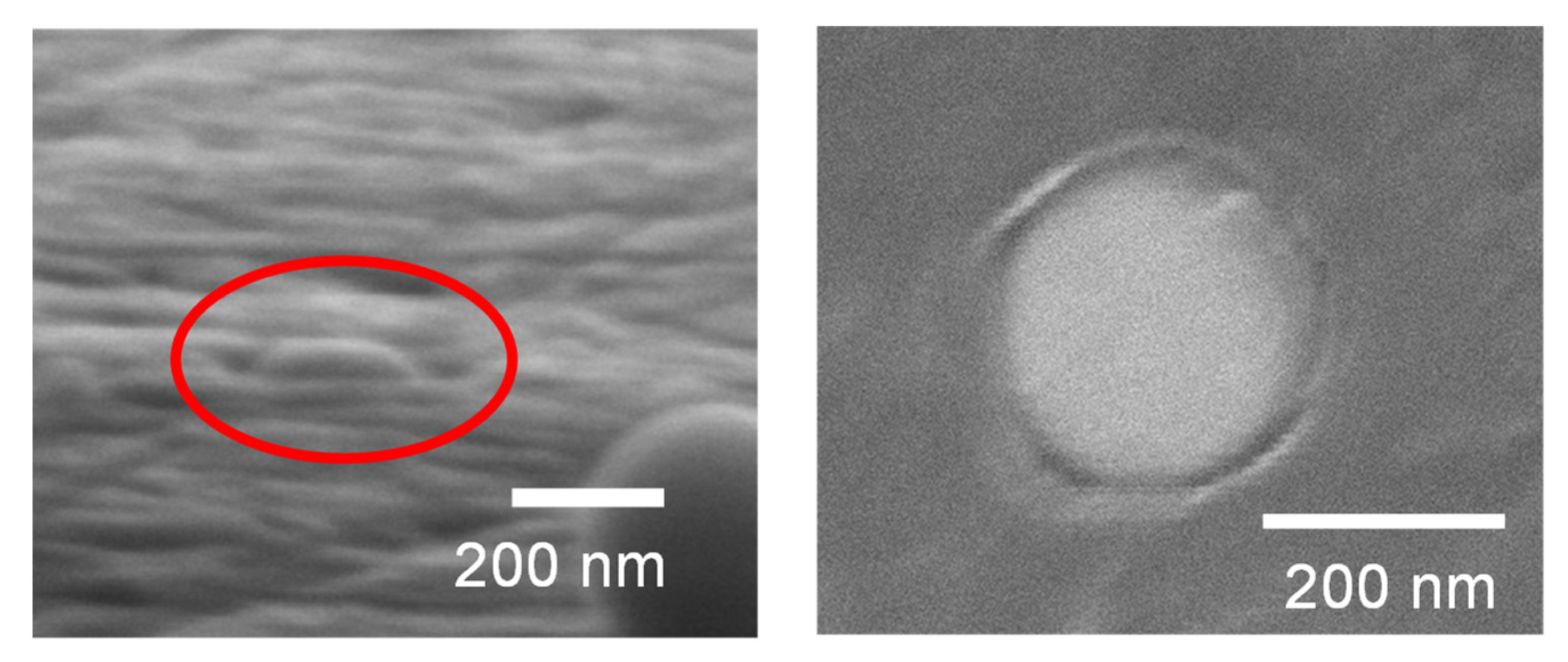

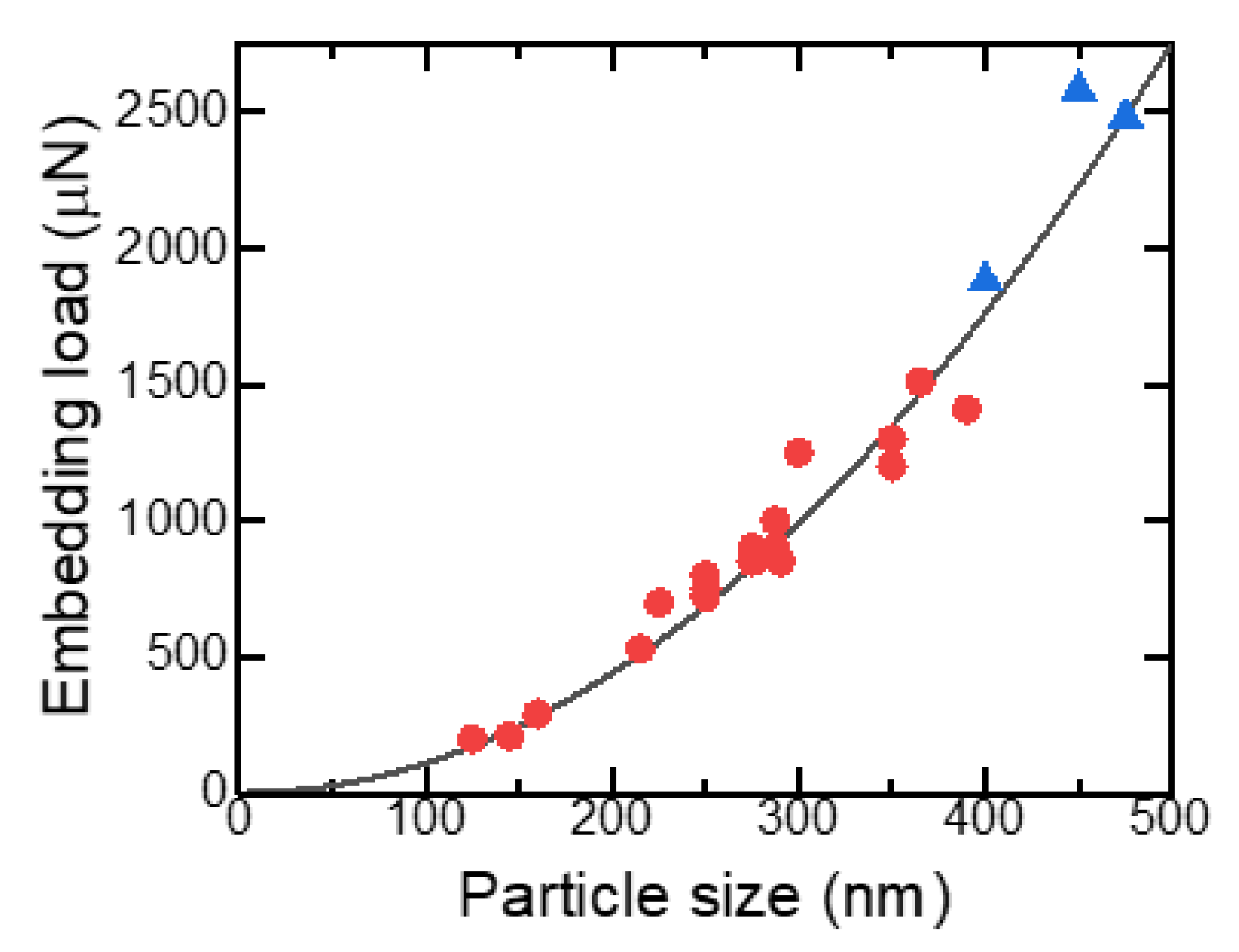

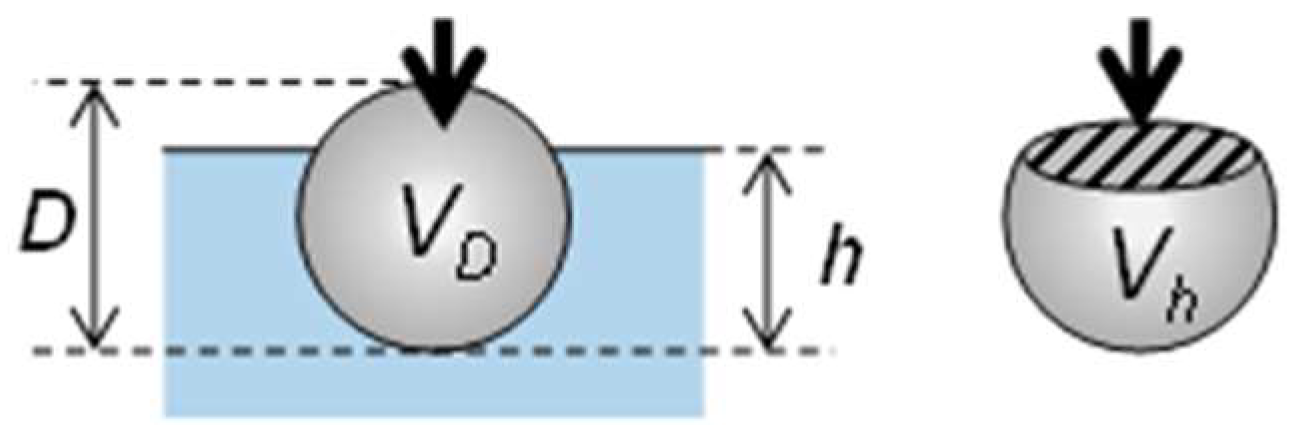

3.3. Embedding Process of SMPs Obtained via PLML

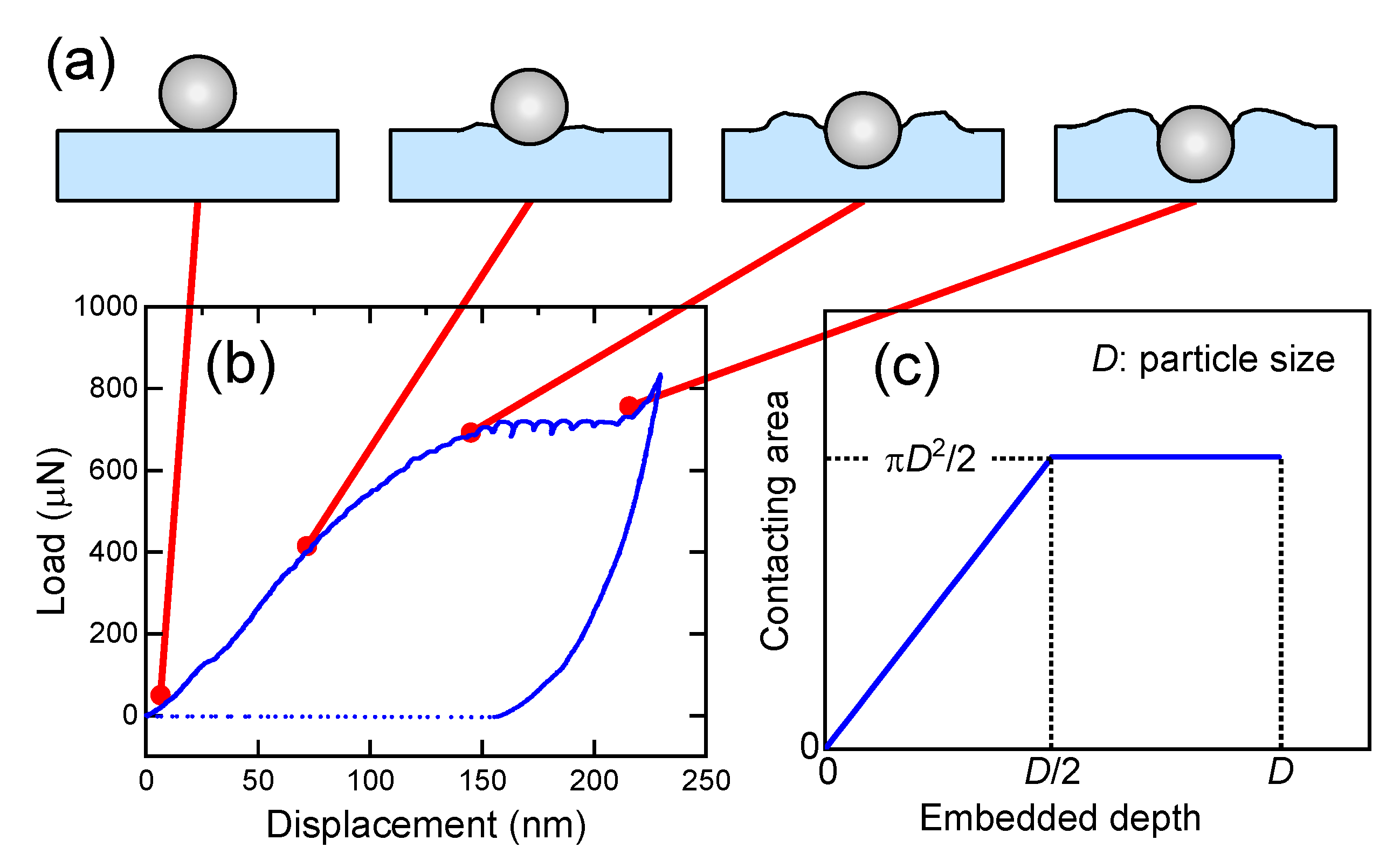

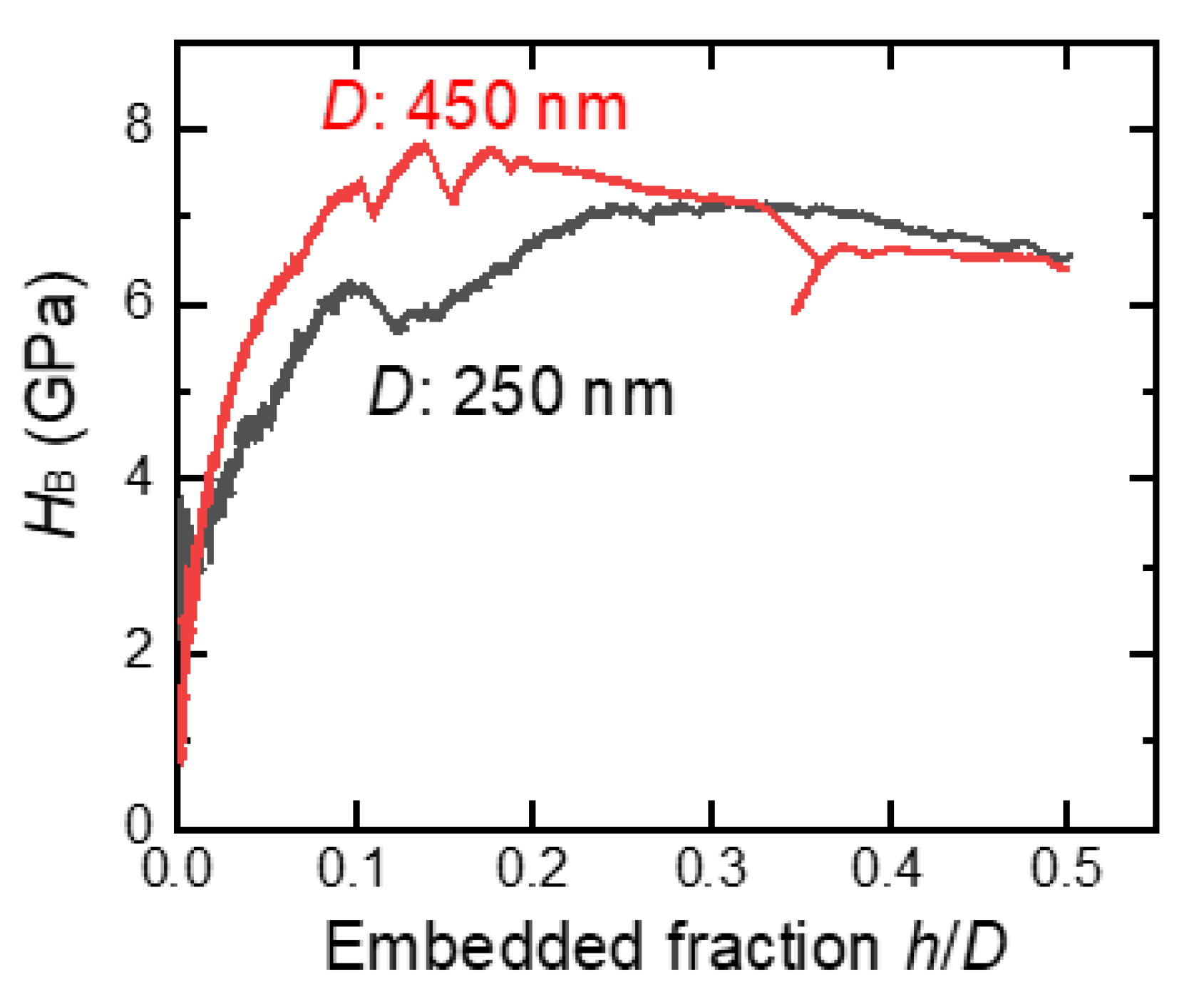

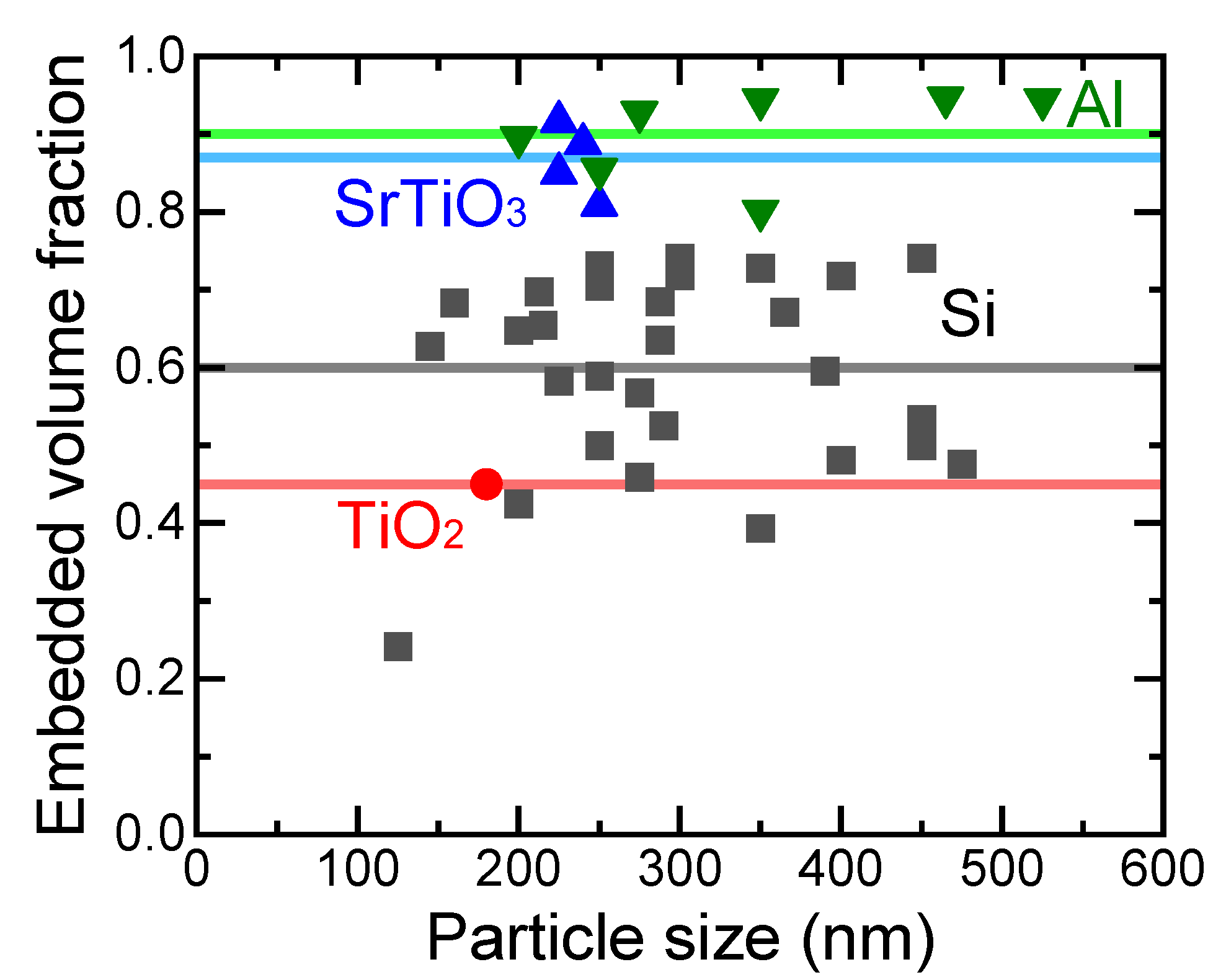

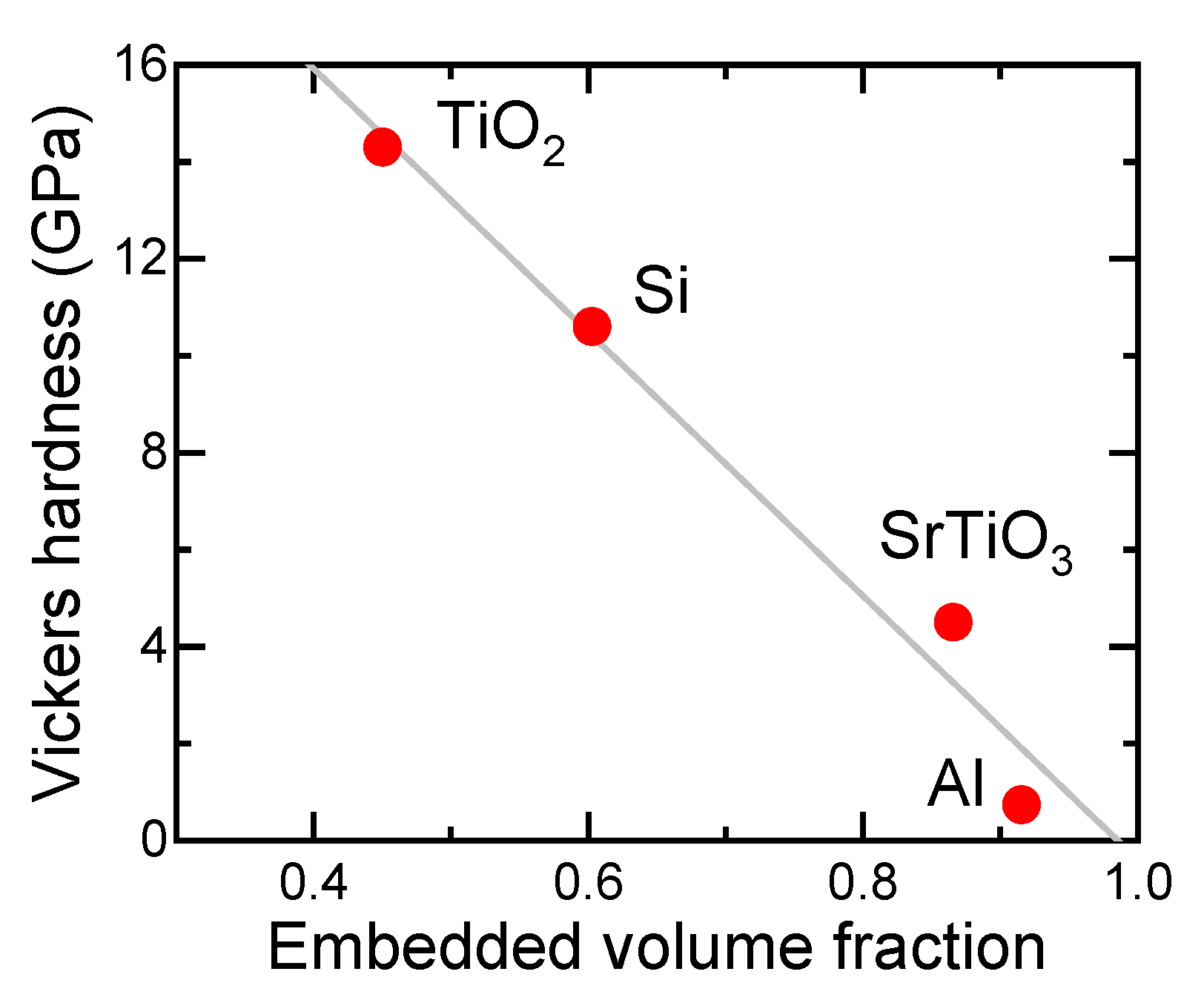

3.4. Hardness Estimation of Substrates via SMP Embedding Process

3.5. Substrate Effects on the SMP Embedding Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, X.; Gong, H.; Wang, Y.; Chen, Q.; Zhang, J.; Zheng, S.; Yang, S.; Cao, B. Laser-induced reshaping of particles aiming at energy-saving applications. J. Mater. Chem. 2012, 22, 15947–15952. [Google Scholar] [CrossRef]

- Jendrzej, S.; Gondecki, L.; Debus, J.; Moldenhauer, H.; Tenberge, P.; Barcikowski, S.; Gökce, B. Tribological properties of laser-generated hard ceramic particles in a gear drive contact. Appl. Surf. Sci. 2019, 467–468, 811–818. [Google Scholar] [CrossRef]

- Murugavel, P.; Kalaiselvam, M.; Raju, A.R.; Rao, C.N.R. Sub-micrometre spherical particles of TiO2, ZrO2 and PZT by nebulized spray pyrolysis of metal–organic precursors. J. Mater. Chem. 1997, 7, 1433–1438. [Google Scholar] [CrossRef]

- Kondo, M.; Shishido, N.; Kamiya, S.; Kubo, A.; Umeno, Y.; Ishikawa, Y.; Koshizaki, N. High-Strength Sub-Micrometer Spherical Particles Fabricated by Pulsed Laser Melting in Liquid. Part. Part. Syst. Char. 2018, 35, 1800061. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Shimizu, Y.; Sasaki, T.; Koshizaki, N. Boron carbide spherical particles encapsulated in graphite prepared by pulsed laser irradiation of boron in liquid medium. Appl. Phys. Lett. 2007, 91, 161110. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Feng, Q.; Koshizaki, N. Growth fusion of submicron spherical boron carbide particles by repetitive pulsed laser irradiation in liquid media. Appl. Phys. A 2010, 99, 797–803. [Google Scholar] [CrossRef]

- Wang, H.; Pyatenko, A.; Kawaguchi, K.; Li, X.; Swiatkowska-Warkocka, Z.; Koshizaki, N. Selective pulsed heating for the synthesis of semiconductor and metal submicrometer spheres. Angew. Chem. Int. Ed. Engl. 2010, 49, 6361–6364. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Miyauchi, M.; Ishikawa, Y.; Pyatenko, A.; Koshizaki, N.; Li, Y.; Li, L.; Li, X.; Bando, Y.; Golberg, D. Single-crystalline rutile TiO2 hollow spheres: Room-temperature synthesis, tailored visible-light-extinction, and effective scattering layer for quantum dot-sensitized solar cells. J. Am. Chem. Soc. 2011, 133, 19102–19109. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Koshizaki, N.; Li, L.; Jia, L.; Kawaguchi, K.; Li, X.; Pyatenko, A.; Swiatkowska-Warkocka, Z.; Bando, Y.; Golberg, D. Size-tailored ZnO submicrometer spheres: Bottom-up construction, size-related optical extinction, and selective aniline trapping. Adv. Mater. 2011, 23, 1865–1870. [Google Scholar] [CrossRef] [PubMed]

- Pyatenko, A.; Wang, H.; Koshizaki, N.; Tsuji, T. Mechanism of pulse laser interaction with colloidal nanoparticles. Laser Photonics Rev. 2013, 7, 596–604. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Koshizaki, N.; Pyatenko, A.; Saitoh, N.; Yoshizawa, N.; Shimizu, Y. Nano- and Submicrometer-Sized Spherical Particle Fabrication Using a Submicroscopic Droplet Formed Using Selective Laser Heating. J. Phys. Chem. C 2016, 120, 2439–2446. [Google Scholar] [CrossRef]

- Zhang, D.; Gökce, B.; Barcikowski, S. Laser Synthesis and Processing of Colloids: Fundamentals and Applications. Chem. Rev. 2017, 117, 3990–4103. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Liu, P.; Wang, C.X.; Yang, G.W. External field-assisted laser ablation in liquid: An efficient strategy for nanocrystal synthesis and nanostructure assembly. Prog. Mater Sci. 2017, 87, 140–220. [Google Scholar] [CrossRef]

- Amendola, V.; Amans, D.; Ishikawa, Y.; Koshizaki, N.; Scirè, S.; Compagnini, G.; Reichenberger, S.; Barcikowski, S. Room-Temperature Laser Synthesis in Liquid of Oxide, Metal-Oxide Core-Shells, and Doped Oxide Nanoparticles. Chem. Eur. J. 2020, 26, 9206–9242. [Google Scholar] [CrossRef] [PubMed]

- Sakaki, S.; Ikenoue, H.; Tsuji, T.; Ishikawa, Y.; Koshizaki, N. Pulse-Width Dependence of the Cooling Effect on Sub-Micrometer ZnO Spherical Particle Formation by Pulsed-Laser Melting in a Liquid. ChemPhysChem 2017, 18, 1101–1107. [Google Scholar] [CrossRef] [PubMed]

- Suehara, K.; Takai, R.; Ishikawa, Y.; Koshizaki, N.; Omura, K.; Nagata, H.; Yamauchi, Y. Reduction Mechanism of Transition Metal Oxide Particles in Thermally Induced Nanobubbles during Pulsed Laser Melting in Ethanol. ChemPhysChem 2021, 22, 675–683. [Google Scholar] [CrossRef]

- Yoshida, M.; Ogiso, H.; Nakano, S.; Akedo, J. Compression test system for a single submicrometer particle. Rev. Sci. Instrum. 2005, 76, 093905. [Google Scholar] [CrossRef]

- Hiramatsu, Y.; Oka, Y.; Kiyama, H. Rapid Determination of the Tensile Strength of Rocks with Irregular Test Pieces (in Japanese). J. Mining Metall. Inst. Jpn. 1965, 81, 1024–1030. [Google Scholar] [CrossRef]

- Hiramatsu, Y.; Oka, Y. Determination of the tensile strength of rock by a compression test of an irregular test piece. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1966, 3, 89–90. [Google Scholar] [CrossRef]

- Hiramatsu, Y.; Oka, Y.; Kiyama, H. Investigations on the Disc Test, Ring Test and Indentation Test for Rocks (in Japanese). J. Mining Metall. Inst. Jpn. 1969, 85, 8–14. [Google Scholar] [CrossRef][Green Version]

- Fu, Z.; Koc, R. Pressureless sintering of submicron titanium carbide powders. Ceram. Int. 2017, 43, 17233–17237. [Google Scholar] [CrossRef]

- Iseki, T.; Yano, T.; Chung, Y.-S. Wetting and Properties of Reaction Products in Active Metal Brazing of SiC. J. Ceram. Soc. Jpn. 1989, 97, 710–714. [Google Scholar] [CrossRef]

- Ono, T.; Ueki, M.; Shimizu, M. Fabrication and Characterization of Titanium Carbide-Graphite Composite Materials (1st Report), Mechanical Properties and Microstructure of Titanium Carbide and Its Compsoites with Addition of a Small Amount of Graphite (in Japanese). Trans. JSME (A) 1993, 59, 1978–1984. [Google Scholar] [CrossRef][Green Version]

- Tang, B.; Shen, Y.; An, Q. Shear-induced brittle failure of titanium carbide from quantum mechanics simulations. J. Am. Ceram. Soc. 2018, 101, 4184–4192. [Google Scholar] [CrossRef]

- Fuse, H.; Koshizaki, N.; Ishikawa, Y.; Swiatkowska-Warkocka, Z. Determining the Composite Structure of Au-Fe-Based Submicrometre Spherical Particles Fabricated by Pulsed-Laser Melting in Liquid. Nanomaterials 2019, 9, 198. [Google Scholar] [CrossRef]

- Sato, Y.; Shinzato, S.; Ohmura, T.; Hatano, T.; Ogata, S. Unique universal scaling in nanoindentation pop-ins. Nat. Commun. 2020, 11, 4177. [Google Scholar] [CrossRef]

- Liu, M.; Lin, J.-y.; Lu, C.; Tieu, K.A.; Zhou, K.; Koseki, T. Progress in Indentation Study of Materials via Both Experimental and Numerical Methods. Crystals 2017, 7, 258. [Google Scholar] [CrossRef]

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2016, 65, 23. [Google Scholar] [CrossRef]

- Hess, D.R.; Doty, H.W. Brinell hardness testing methods and their applicability. In Proceedings of the AFS 124th Metalcasting Congress, Cleveland, OH, USA, 21–23 April 2020; p. 12. [Google Scholar]

- Pathak, S.; Kalidindi, S.R. Spherical nanoindentation stress–strain curves. Mater. Sci. Eng. R Rep. 2015, 91, 1–36. [Google Scholar] [CrossRef]

- Chudoba, T.; Schwarzer, N.; Richter, F. Determination of elastic properties of thin films by indentation measurements with a spherical indenter. Surf. Coat. Technol. 2000, 127, 9–17. [Google Scholar] [CrossRef]

- Bei, H.; Lu, Z.P.; George, E.P. Theoretical Strength and the Onset of Plasticity in Bulk Metallic Glasses Investigated by Nanoindentation with a Spherical Indenter. Phys. Rev. Lett. 2004, 93, 125504. [Google Scholar] [CrossRef] [PubMed]

- Martinez, R.; Xu, L.R. Comparison of the Young’s moduli of polymers measured from nanoindentation and bending experiments. MRS Commun. 2014, 4, 89–93. [Google Scholar] [CrossRef]

- Kim, M.; Marimuthu, K.P.; Lee, J.H.; Lee, H. Spherical indentation method to evaluate material properties of high-strength materials. Int. J. Mech. Sci. 2016, 106, 117–127. [Google Scholar] [CrossRef]

- Walls, M.G.; Chaudhri, M.M.; Tang, T.B. STM profilometry of low-load Vickers indentations in a silicon crystal. J. Phys. D Appl. Phys. 1992, 25, 500–507. [Google Scholar] [CrossRef]

- Budnitzki, M.; Kuna, M. Experimental and numerical investigations on stress induced phase transitions in silicon. Int. J. Solids Struct. 2017, 106–107, 294–304. [Google Scholar] [CrossRef]

- INSPEC. Properties of Silicon; INSPEC, Institution of Electrical Engineers: New York, NY, USA; London, UK, 1988; Volume 4. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakamura, D.; Koshizaki, N.; Shishido, N.; Kamiya, S.; Ishikawa, Y. Fracture and Embedment Behavior of Brittle Submicrometer Spherical Particles Fabricated by Pulsed Laser Melting in Liquid Using a Scanning Electron Microscope Nanoindenter. Nanomaterials 2021, 11, 2201. https://doi.org/10.3390/nano11092201

Nakamura D, Koshizaki N, Shishido N, Kamiya S, Ishikawa Y. Fracture and Embedment Behavior of Brittle Submicrometer Spherical Particles Fabricated by Pulsed Laser Melting in Liquid Using a Scanning Electron Microscope Nanoindenter. Nanomaterials. 2021; 11(9):2201. https://doi.org/10.3390/nano11092201

Chicago/Turabian StyleNakamura, Daizen, Naoto Koshizaki, Nobuyuki Shishido, Shoji Kamiya, and Yoshie Ishikawa. 2021. "Fracture and Embedment Behavior of Brittle Submicrometer Spherical Particles Fabricated by Pulsed Laser Melting in Liquid Using a Scanning Electron Microscope Nanoindenter" Nanomaterials 11, no. 9: 2201. https://doi.org/10.3390/nano11092201

APA StyleNakamura, D., Koshizaki, N., Shishido, N., Kamiya, S., & Ishikawa, Y. (2021). Fracture and Embedment Behavior of Brittle Submicrometer Spherical Particles Fabricated by Pulsed Laser Melting in Liquid Using a Scanning Electron Microscope Nanoindenter. Nanomaterials, 11(9), 2201. https://doi.org/10.3390/nano11092201