1. Introduction

Microwave absorbing coatings were first used in military stealth technology. Stealth technology can effectively improve the survival and penetration ability of weapons and equipment, showing great power in modern war. A stealth fighter is coated with a layer or multi-layer absorbing material in the fuselage for avoiding radar tracking. Microwave absorbing coatings are not only widely used in military fields, but also increasingly important in civil fields such as electromagnetic compatibility and microwave radiation protection. Microwave equipment, communication transmitting stations, power transmission and transformation equipment and mobile phones all have electromagnetic radiation. Electromagnetic interference produced by electromagnetic radiation not only affects the realization of high performance for electronic products, but also causes long-term or short-term harm to the human body. Therefore, it is possible to use microwave absorption coatings for microwave radiation protection. The research and development of MA materials has important application value [

1,

2,

3,

4]. The MA materials are required to absorb electromagnetic waves as high as possible within a given frequency range. Therefore, the materials are required to have a wide absorption bandwidth, strong absorption, light weight, and thin thickness [

5,

6,

7,

8].

According to the loss mechanism, MA materials can be divided into magnetic loss type and dielectric loss type. Magnetic loss materials include ferrite, carbonyl iron, ferromagnetic metal, etc. [

9,

10]. Ferromagnetic metal micro-powder microwave absorbing materials are composed of ferromagnetic metal iron, cobalt, nickel and their alloys, which loses electromagnetic wave through magnetic hysteresis loss, eddy current loss, etc. Compared with ferrite series MA materials, ferromagnetic metal powder has higher permeability and saturation magnetization, better magnetic loss and temperature stability [

11,

12]. However, the application of ferromagnetic micro-powder is limited by its narrow absorbing bandwidth, high density, easy oxidation and poor corrosion resistance. Nowadays, ferromagnetic metal micro-powder materials are modified mainly through coating and doping [

9,

13]. Dielectric loss absorbing materials such as silicon carbide, carbon materials (carbon fiber, carbon nanotubes, porous carbon), etc., whose mechanism is dielectric polarization relaxation loss. Compared with metal materials, carbon materials are widely used in field of MA due to their light weight, high dielectric constant and good chemical stability [

14,

15,

16]. Khurram et al. studied the honeycomb core material filled with 10 wt.% carbon powder and obtained a reflectivity of −7 dB with a bandwidth of 18 GHz [

17]. However, although carbon materials have wide-band and excellent dielectric loss, its weak magnetic property leads to poor magnetic loss.

In recent years, a number of new carbon-based MA nanomaterials (carbon nanotubes, carbon coated metal particles and graphene) have provided a nanoscale MA composite material [

18,

19,

20,

21,

22]. Lu et al. [

20] studied the simulated reflectivity of carbon nanotube composites with shell-core structure up to −47 dB and the bandwidth of −20 dB up to 2.0 GHz; Wan et al. [

23] studied the composite material with Fe–Co alloy particles grown on the surface of carbon fiber. When the thickness was 1.8 mm, they had a minimum reflectivity of −37.7 dB; Huang et al. [

24] studied carbon-coated nickel nanoparticles, when the coating thickness was 3 mm, minimum reflection loss was −39.8 dB and absorbing band width was 8.4 GHz; Zhang et al. [

25] prepared nanocomposite particles with CoFe

2O

4 as the core and carbon nanotubes (CNT) as the shell. They found that the CNT grew on the surface of CoFe

2O

4 microspheres. When the coating thickness was 2 mm, the maximum reflection loss was −32.8 dB, and the absorption bandwidth was 5.7 GHz. Sun et al. [

26] prepared a FeNi/graphene nanocomposite material combining dielectric loss and magnetic loss. When the thickness of the absorbing coating was 1.5 mm, it had a minimum reflect loss of −32 dB at 12.4 GHz and a bandwidth of 3.3 GHz. Liu et al. [

27] obtained a good impedance match on porous carbon coated nickel nano-absorbing material. When the thickness was 2.6 mm, the minimum reflectivity was −51.8 dB. Chan et al. [

16] used carbon nanotube/ferromagnetic metal micro-powder composite absorbing materials in antenna design to eliminate various parasitic signals and improve antenna performance. As one of the most promising new MA materials, nano carbon-based absorbing composite materials will likely obtain high MA performance. In this paper, based on these excellent absorbing materials (such as carbon nanotubes, carbon coated iron nanoparticles, nickel nanoparticles, micron iron powder, etc.), the performance optimization design of micro-nano multilayer composite absorbing materials will be studied.

At present, the research of MA materials is mainly toward the direction of low-dimensionality, complexity, and multi-functionality and compatibility. Compatibility requires that the absorbing material has a wide-band absorbing characteristic. The complexity of materials means using composites of multiple materials to meet the comprehensive performance of MA materials. However, these requirements are mutually restricted. For example, it is easy to design a kind of absorbing material with thin thickness, but its absorbing bandwidth and strength are insufficient, we can also easily design a high absorption material within a certain amount of bandwidth, but it is too heavy or too thick to achieve the demand of the application. Therefore, it is very important to combine various materials and design a MA material with good comprehensive performance. To design the MA materials with thin thickness, light weight, wide bandwidth and high absorption performance is a typical optimization problem. Compared with single layer absorbing coating, multi-layer coatings can obtain better performance by adjusting material type and thickness of each layer. Thickness of each layer, electromagnetic parameters of absorbing material and material order will all affect the absorbing properties. Compared with the single-layer absorbing coating, the multi-layer absorbing coating is more beneficial to widen the absorption bandwidth and enhance the reflection loss [

28,

29,

30].

There are many factors influencing the reflectivity of the MA material. The combination of the optimal dielectric materials is mostly empirical at present. When there are many material layers or too many types of materials, the optimization design is time-consuming and laborious using experimental method only, and it needs computer-aided optimization design. When using multiple dielectric materials to match the design of multilayer absorbing materials, the relationship between the combined absorbing performance and their original absorbing performance of each material is not a simple linear relationship, so that the results of the electromagnetic optimization are highly nonlinear, multi-parameter and multi-peak features, and the use of algorithms will greatly improve the efficiency of optimization design.

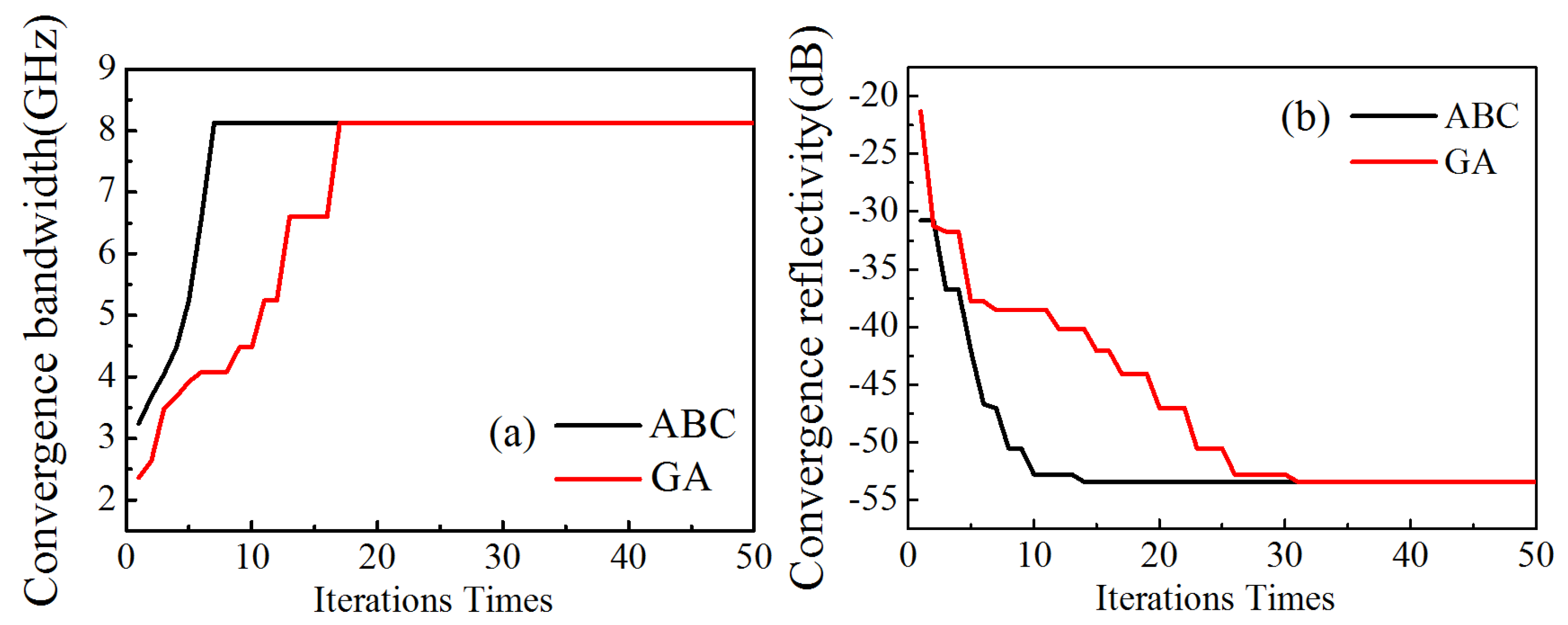

At present, the genetic algorithm (GA) has been used in the optimization design of MA materials. Wang [

31] optimized the performance of absorbing coatings by using GA algorithm, and the reflectivity in the specified frequency interval achieves the best comparing no optimization. The calculation results show that each layer thickness of the material, the type of material and the arrangement order of the materials, the design results are accurate and effective, and the use of GA greatly improves the efficiency of optimization design. Compared with other algorithms, the GA optimization has higher accuracy, but a vast calculating amount. Feng [

32] optimized the reflectivity of the absorbing material with an improved GA. The two obtained layers of absorbing material (inner layer 0.9 mm, outer layer 2.7 mm) can realize the reflectivity less than −15 dB within a wide range of 8–18 GHz. Jiang [

33] presented the application of the NSGA-II for constructing Pareto optimal designs of microwave absorbers. Results indicate that the NSGA-II can work more efficiently than traditional Pareto genetic algorithms. N. Dib [

34] presented the optimal design of multilayer microwave absorbers using differential evolution (DE) with competitive control-parameter setting technique, and a very wideband (0.1–20 GHz), thin (total thickness of 6.8 mm) seven-layer absorber has been designed. Artificial bee colony (ABC) algorithm, as a new swarm intelligence optimization algorithm, has become another important optimization algorithm in the field of biomimetic intelligence computing. Toktas [

35,

36,

37] designed multilayer radar absorbing material by utilizing a predefined material set including electrical variables existing in the literature, and various numbers of layers are optimally determined using artificial bee colony (ABC). They presented a three-dimensional objective space optimization strategy using an enhanced multi-objective artificial bee colony (ABC) algorithm for the design optimization of layered radar absorbing material, and optimized material are picked up from a composite material database with 51specimens from nine previously reported studies. Yigit [

38] optimized the thicknesses, sequence and number of layers of the MRA structures using the materials given in the literature by triple-objective artificial bee colony algorithm optimizations at the frequency ranges of 2–18 GHz for each angle of incidence from 0° to 60°. However, until now, there is no report about the application of ABC algorithm for the optimization design of multilayer new carbon-based MA micro-nano composite materials. In our work, we selected optimizing bandwidth and reflectivity as the objective function for design, and apply ABC and GA algorithm to give the optimal assembling of several new carbon-based absorbing materials, and the purpose of optimizing the absorbing bandwidth and reflectivity performance is achieved. At the same time, we discuss the efficiency of different optimization algorithms for the same problem based on different algorithms mechanisms. According to the theory of electromagnetic wave transmission line, matlab software is used to simulate reflectivity curve after optimization [

21].