Tailoring Morphology and Vertical Yield of Self-Catalyzed GaP Nanowires on Template-Free Si Substrates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Oxidation of Si (111) Substrates

2.2. Epitaxial Growth

2.3. Electron Microscopy Characterization

3. Results and Discussion

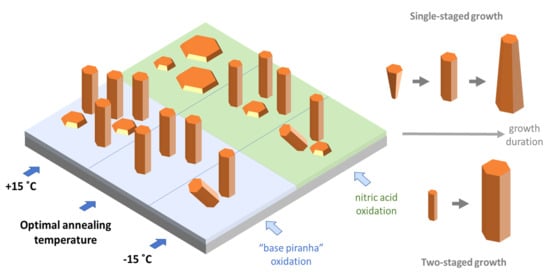

3.1. Role of Silicon Oxide Preparation

3.2. Roles of the Growth Temperature and Flux Rates

3.3. NW Growth Evolution

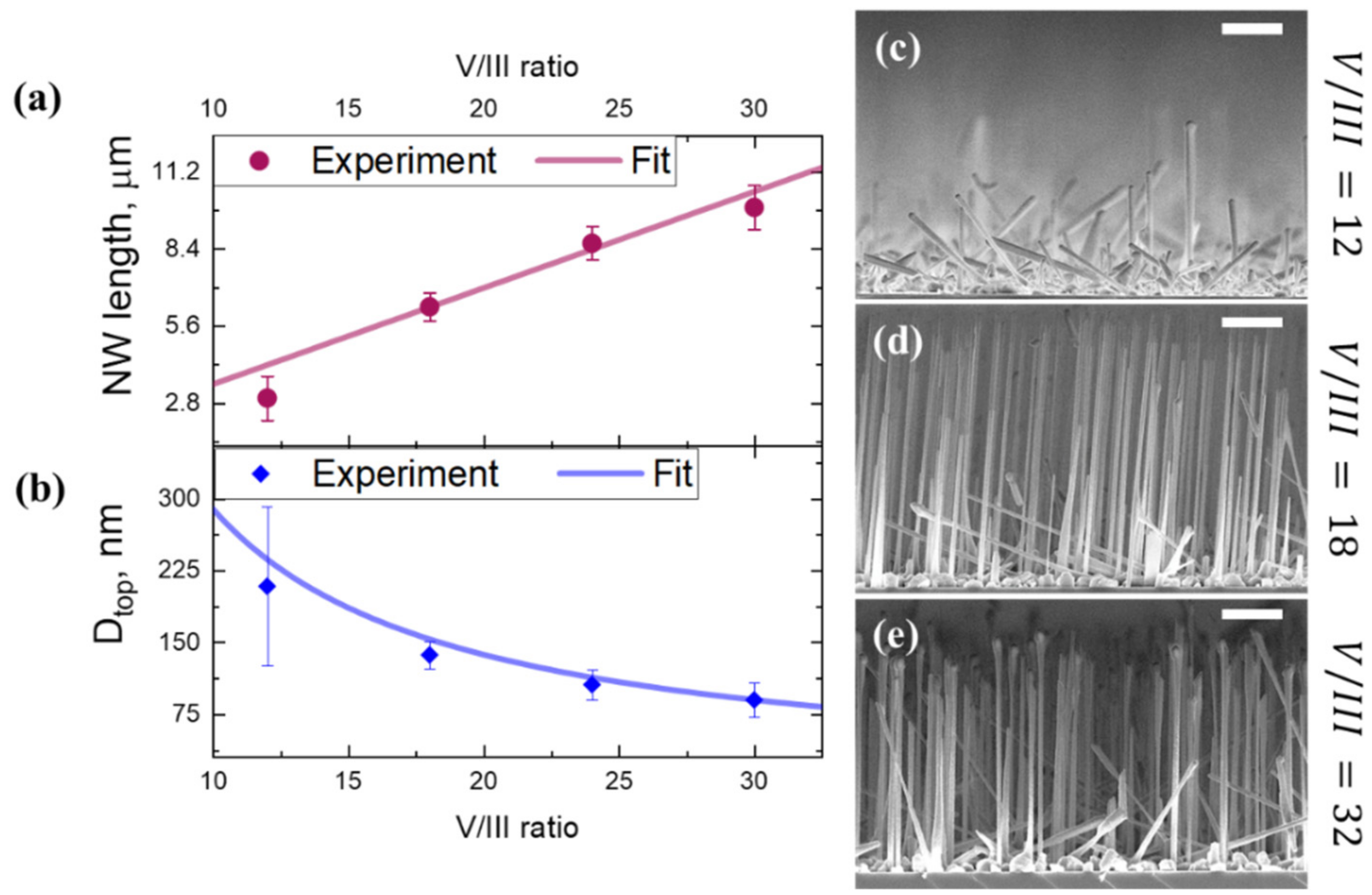

3.4. Role of the V/III Ratio

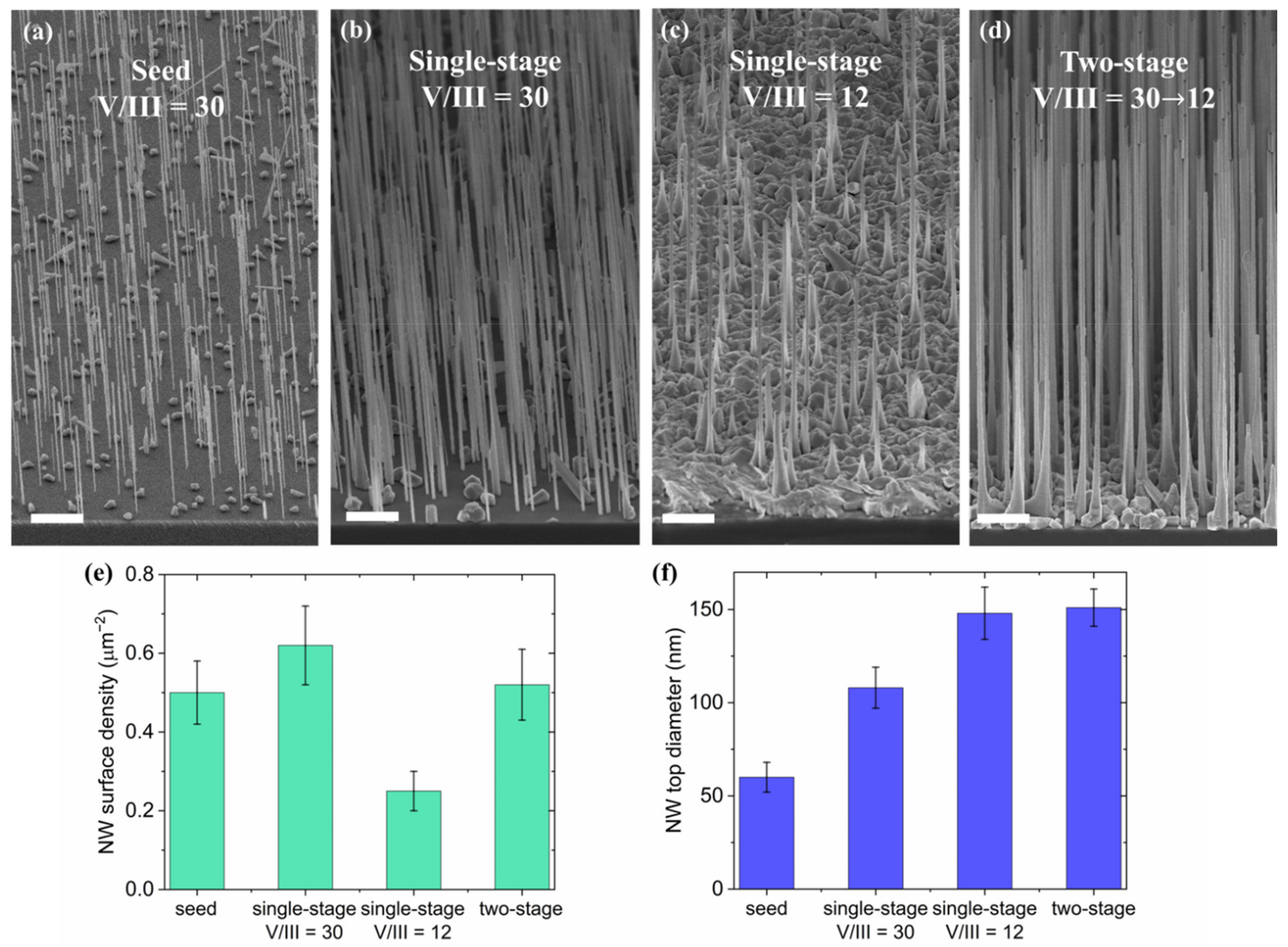

3.5. Two-Staged Growth

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Quan, L.N.; Kang, J.; Ning, C.-Z.; Yang, P. Nanowires for photonics. Chem. Rev. 2019, 119, 9153–9169. [Google Scholar] [CrossRef]

- Goktas, N.I.; Wilson, P.; Ghukasyan, A.; Wagner, D.; McNamee, S.; LaPierre, R. Nanowires for energy: A review. Appl. Phys. Rev. 2018, 5, 041305. [Google Scholar] [CrossRef]

- Bai, M.; Huang, H.; Liu, Z.; Zhan, T.; Xia, S.; Li, X.; Sibirev, N.; Bouravleuv, A.; Dubrovskii, V.G.; Cirlin, G. InAs/InP core/shell nanowire gas sensor: Effects of InP shell on sensitivity and long-term stability. Appl. Surf. Sci. 2019, 498. [Google Scholar] [CrossRef]

- Mårtensson, T.; Svensson, C.P.T.; Wacaser, B.A.; Larsson, M.W.; Seifert, W.; Deppert, K.; Gustafsson, A.; Wallenberg, L.R.; Samuelson, L. Epitaxial III–V nanowires on silicon. Nano Lett. 2004, 4, 1987–1990. [Google Scholar] [CrossRef]

- Dubrovskii, V.G. Understanding the vapor–liquid–solid growth and composition of ternary III–V nanowires and nanowire heterostructures. J. Phys. D Appl. Phys. 2017, 50, 453001. [Google Scholar] [CrossRef]

- Dobrovolsky, A.; Stehr, J.E.; Sukrittanon, S.; Kuang, Y.; Tu, C.W.; Chen, W.M.; Buyanova, I.A. Fabry-perot microcavity modes in Single GaP/GaNP core/shell nanowires. Small 2015, 11, 6331–6337. [Google Scholar] [CrossRef]

- Yuan, Q.; Fang, L.; Yang, H.; Gan, X.; Khayrudinov, V.; Lipsanen, H.; Sun, Z.; Zhao, J. Low-power continuous-wave second harmonic generation in semiconductor nanowires. Laser Photon. Rev. 2018, 12, 1800126. [Google Scholar] [CrossRef] [Green Version]

- Roy, P.; Bolshakov, A.D. Ga-GaP nanowire hybrid optical system for enhanced coupling, focusing and steering of light. J. Phys. D Appl. Phys. 2020, 53, 295101. [Google Scholar] [CrossRef]

- Trofimov, P.; Pushkarev, A.P.; Sinev, I.S.; Fedorov, V.V.; Bruyère, S.; Bolshakov, A.; Mukhin, I.S.; Makarov, S.V. Perovskite–gallium phosphide platform for reconfigurable visible-light nanophotonic chip. ACS Nano 2020, 14, 8126–8134. [Google Scholar] [CrossRef]

- Barrigón, E.; Heurlin, M.; Bi, Z.; Monemar, B.; Samuelson, L. Synthesis and applications of III–V nanowires. Chem. Rev. 2019, 119, 9170–9220. [Google Scholar] [CrossRef]

- Tomioka, K.; Tanaka, T.; Hara, S.; Hiruma, K.; Fukui, T. III–V nanowires on Si substrate: Selective-area growth and device applications. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1112–1129. [Google Scholar] [CrossRef]

- Wilson, D.P.; LaPierre, R.R. Simulation of optical absorption in conical nanowires. Opt. Express 2021, 29, 9544. [Google Scholar] [CrossRef]

- Mozharov, A.; Bolshakov, A.; Cirlin, G.; Mukhin, I. Numerical modeling of photovoltaic efficiency of n-type GaN nanowires on p-type Si heterojunction. Phys. Status Solidi Rapid Res. Lett. 2015, 9, 507–510. [Google Scholar] [CrossRef]

- Lee, G.J.; Park, K.; Kim, M.S.; Chang, S.; Seok, T.J.; Park, H.; Ju, G.; Kim, K.; Song, Y.M. Selective and sensitive photon sieve based on III–V semiconductor nanowire forest fabricated by lithography-free process. Adv. Opt. Mater. 2020, 8, 2000198. [Google Scholar] [CrossRef]

- Svensson, J.; Dey, A.W.; Jacobsson, D.; Wernersson, L.-E. III–V nanowire complementary metal–oxide semiconductor transistors monolithically integrated on Si. Nano Lett. 2015, 15, 7898–7904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tomioka, K.; Yoshimura, M.; Fukui, T. A III–V nanowire channel on silicon for high-performance vertical transistors. Nature 2012, 488, 189–192. [Google Scholar] [CrossRef]

- Guan, N.; Dai, X.; Julien, F.H.; Eymery, J.; Durant, C.; Tchernycheva, M. Nitride Nanowires for Light Emitting Diodes. In Light-Emitting Diodes; Springer: Cham, Switzerland, 2019; pp. 425–484. [Google Scholar]

- Ren, D.; Meng, X.; Rong, Z.; Cao, M.; Farrell, A.C.; Somasundaram, S.; Azizur-Rahman, K.M.; Williams, B.S.; Huffaker, D.L. Uncooled photodetector at short-wavelength infrared using InAs nanowire photoabsorbers on InP with p-n heterojunctions. Nano Lett. 2018, 18, 7901–7908. [Google Scholar] [CrossRef]

- Bastiman, F.; Küpers, H.; Somaschini, C.; Geelhaar, L. Growth map for Ga-assisted growth of GaAs nanowires on Si (111) substrates by molecular beam epitaxy. Nanotechnology 2016, 27, 095601. [Google Scholar] [CrossRef]

- Küpers, H.; Lewis, R.B.; Tahraoui, A.; Matalla, M.; Krüger, O.; Bastiman, F.; Riechert, H.; Geelhaar, L. Diameter evolution of selective area grown Ga-assisted GaAs nanowires. Nano Res. 2018, 11, 2885–2893. [Google Scholar] [CrossRef] [Green Version]

- Güniat, L.; Caroff, P.; Fontcuberta i Morral, A. Vapor phase growth of semiconductor nanowires: Key developments and open questions. Chem. Rev. 2019, 119, 8958–8971. [Google Scholar] [CrossRef] [Green Version]

- Bar-Sadan, M.; Barthel, J.; Shtrikman, H.; Houben, L. Direct imaging of single Au atoms within GaAs nanowires. Nano Lett. 2012, 12, 2352–2356. [Google Scholar] [CrossRef] [Green Version]

- Du, Y.A.; Sakong, S.; Kratzer, P. As vacancies, Ga antisites, and Au impurities in zinc blende and wurtzite GaAs nanowire segments from first principles. Phys. Rev. B 2013, 87, 075308. [Google Scholar] [CrossRef] [Green Version]

- Assali, S.; Greil, J.; Zardo, I.; Belabbes, A.; de Moor, M.W.A.; Koelling, S.; Koenraad, P.M.; Bechstedt, F.; Bakkers, E.P.A.M.; Haverkort, J.E.M. Optical study of the band structure of wurtzite GaP nanowires. J. Appl. Phys. 2016, 120, 044304. [Google Scholar] [CrossRef] [Green Version]

- Karlström, O.; Wacker, A.; Nilsson, K.; Astromskas, G.; Roddaro, S.; Samuelson, L.; Wernersson, L.-E. Analysing the capacitance—Voltage measurements of vertical wrapped-gated nanowires. Nanotechnology 2008, 19, 435201. [Google Scholar] [CrossRef]

- Schunemann, P.G.; Mohnkern, L.; Vera, A.; Yang, X.S.; Lin, A.C.; Harris, J.S.; Tassev, V.; Snure, M. All-epitaxial growth of orientation-patterned gallium phosphide (OPGaP). In Proceedings of the Lasers, Sources, and Related Photonic Devices, San Diego, CA, USA, 1–3 February 2012; OSA: Washington, DC, USA, 2012; p. ITh5B.5. [Google Scholar]

- Parsons, D.F.; Coleman, P.D. Far infrared optical constants of gallium phosphide. Appl. Opt. 1971, 10, 1683_1–1685. [Google Scholar] [CrossRef] [PubMed]

- Fedorov, V.V.; Bolshakov, A.; Sergaeva, O.; Neplokh, V.; Markina, D.; Bruyere, S.; Saerens, G.; Petrov, M.I.; Grange, R.; Timofeeva, M.; et al. Gallium phosphide nanowires in a free-standing, flexible, and semitransparent membrane for large-scale infrared-to-visible light conversion. ACS Nano 2020, 14, 10624–10632. [Google Scholar] [CrossRef] [PubMed]

- Assali, S.; Zardo, I.; Plissard, S.; Kriegner, D.; Verheijen, M.A.; Bauer, G.; Meijerink, A.; Belabbes, A.; Bechstedt, F.; Haverkort, J.E.M.; et al. Direct band gap wurtzite gallium phosphide nanowires. Nano Lett. 2013, 13, 1559–1563. [Google Scholar] [CrossRef]

- Assali, S.; Lähnemann, J.; Vu, T.T.T.; Jöns, K.D.; Gagliano, L.; Verheijen, M.A.; Akopian, N.; Bakkers, E.P.A.M.; Haverkort, J.E.M. Crystal phase quantum well emission with digital control. Nano Lett. 2017, 17, 6062–6068. [Google Scholar] [CrossRef]

- Assali, S.; Gagliano, L.; Oliveira, D.S.; Verheijen, M.A.; Plissard, S.R.; Feiner, L.F.; Bakkers, E.P.A.M. Exploring crystal phase switching in GaP nanowires. Nano Lett. 2015, 15, 8062–8069. [Google Scholar] [CrossRef]

- Sharov, V.; Alekseev, P.; Fedorov, V.; Nestoklon, M.; Ankudinov, A.; Kirilenko, D.; Sapunov, G.; Koval, O.; Cirlin, G.; Bolshakov, A.; et al. Work function tailoring in gallium phosphide nanowires. Appl. Surf. Sci. 2021, 563, 150018. [Google Scholar] [CrossRef]

- Ellis, W.C.; Frosch, C.J.; Zetterstrom, R.B. Morphology of gallium phosphide crystals grown by VLS mechanism with gallium as liquid-forming agent. J. Cryst. Growth 1968, 2, 61–68. [Google Scholar] [CrossRef]

- Zhang, Y.; Aagesen, M.; Holm, J.V.; Jørgensen, H.I.; Wu, J.; Liu, H. Self-catalyzed GaAsP nanowires grown on silicon substrates by solid-source molecular beam epitaxy. Nano Lett. 2013, 13, 3897–3902. [Google Scholar] [CrossRef]

- Kuyanov, P.; Boulanger, J.; LaPierre, R.R. Control of GaP nanowire morphology by group V flux in gas source molecular beam epitaxy. J. Cryst. Growth 2017, 462, 29–34. [Google Scholar] [CrossRef]

- Oehler, F.; Cattoni, A.; Scaccabarozzi, A.; Patriarche, G.; Glas, F.; Harmand, J.C. Measuring and modeling the growth dynamics of self-catalyzed GaP nanowire arrays. Nano Lett. 2018, 18, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Bolshakov, A.D.; Dvoretckaia, L.N.; Fedorov, V.V.; Sapunov, G.A.; Mozharov, A.M.; Shugurov, K.Y.; Shkoldin, V.A.; Mukhin, M.S.; Cirlin, G.E.; Mukhin, I.S. Microlens-enhanced substrate patterning and MBE growth of GaP nanowires. Semiconductors 2018, 52, 2088–2091. [Google Scholar] [CrossRef]

- Koivusalo, E.S.; Hakkarainen, T.; Guina, M. Structural investigation of uniform ensembles of self-catalyzed GaAs nanowires fabricated by a lithography-free technique. Nanoscale Res. Lett. 2017, 12, 192. [Google Scholar] [CrossRef] [Green Version]

- Tauchnitz, T.; Berdnikov, Y.; Dubrovskii, V.G.; Schneider, H.; Helm, M.; Dimakis, E. A simple route to synchronized nucleation of self-catalyzed GaAs nanowires on silicon for sub-Poissonian length distributions. Nanotechnology 2018, 29, 504004. [Google Scholar] [CrossRef]

- Matteini, F.; Tütüncüoglu, G.; Potts, H.; Jabeen, F.; Fontcuberta i Morral, A. Wetting of Ga on SiOx and its impact on GaAs nanowire growth. Cryst. Growth Des. 2015, 15, 3105–3109. [Google Scholar] [CrossRef]

- Matteini, F.; Tütüncüoğlu, G.; Rüffer, D.; Alarcón-Lladó, E.; Fontcuberta i Morral, A. Ga-assisted growth of GaAs nanowires on silicon, comparison of surface SiOx of different nature. J. Cryst. Growth 2014, 404, 246–255. [Google Scholar] [CrossRef] [Green Version]

- Tan, S.L.; Genuist, Y.; den Hertog, M.I.; Bellet-Amalric, E.; Mariette, H.; Pelekanos, N.T. Highly uniform zinc blende GaAs nanowires on Si(111) using a controlled chemical oxide template. Nanotechnology 2017, 28, 255602. [Google Scholar] [CrossRef]

- Madsen, M.H.; Aagesen, M.; Krogstrup, P.; Sørensen, C.; Nygård, J. Influence of the oxide layer for growth of self-assisted InAs nanowires on Si (111). Nanoscale Res. Lett. 2011, 6, 516. [Google Scholar] [CrossRef] [Green Version]

- Okumura, H.; Akane, T.; Tsubo, Y.; Matsumoto, S. Comparison of conventional surface cleaning methods for Si molecular beam epitaxy. J. Electrochem. Soc. 1997, 144, 3765–3768. [Google Scholar] [CrossRef]

- Ishizaka, A.; Shiraki, Y. Low Temperature surface cleaning of silicon and its application to silicon MBE. J. Electrochem. Soc. 1986, 133, 666–671. [Google Scholar] [CrossRef]

- Kern, W. The Evolution of silicon wafer cleaning technology. J. Electrochem. Soc. 1990, 137, 1887–1892. [Google Scholar] [CrossRef]

- Imamura, K.; Takahashi, M.; Asuha; Hirayama, Y.; Imai, S.; Kobayashi, H. Nitric acid oxidation of Si method at 120 °C: HNO3 concentration dependence. J. Appl. Phys. 2010, 107, 054503. [Google Scholar] [CrossRef]

- Deligiannis, D.; Alivizatos, S.; Ingenito, A.; Zhang, D.; van Sebille, M.; van Swaaij, R.A.; Zeman, M. Wet-chemical Treatment for improved surface passivation of textured silicon heterojunction solar cells. Energy Procedia 2014, 55, 197–202. [Google Scholar] [CrossRef] [Green Version]

- Telieps, W.; Bauer, E. The (7 × 7) ↔ (1 × 1) phase transition on Si (111). Surf. Sci. 1985, 162, 163–168. [Google Scholar] [CrossRef]

- Koval, O.Y.; Fedorov, V.V.; Bolshakov, A.D.; Eliseev, I.E.; Fedina, S.V.; Sapunov, G.A.; Udovenko, S.A.; Dvoretckaia, L.N.; Kirilenko, D.A.; Burkovsky, R.G.; et al. XRD evaluation of wurtzite phase in MBE grown self-catalyzed GaP nanowires. Nanomaterials 2021, 11, 960. [Google Scholar] [CrossRef]

- Matteini, F.; Tütüncüoglu, G.; Mikulik, D.; Vukajlovic-Plestina, J.; Potts, H.; Leran, J.-B.; Carter, W.C.; Fontcuberta i Morral, A. Impact of the Ga droplet wetting, morphology, and pinholes on the orientation of GaAs nanowires. Cryst. Growth Des. 2016, 16, 5781–5786. [Google Scholar] [CrossRef]

- Glas, F. Vapor fluxes on the apical droplet during nanowire growth by molecular beam epitaxy. Phys. Status Solidi Basic Res. 2010, 247, 254–258. [Google Scholar] [CrossRef]

- Ramdani, M.R.; Harmand, J.C.; Glas, F.; Patriarche, G.; Travers, L. Arsenic pathways in self-catalyzed growth of GaAs nanowires. Cryst. Growth Des. 2013, 13, 91–96. [Google Scholar] [CrossRef]

- Eaton, S.W.; Fu, A.; Wong, A.B.; Ning, C.-Z.; Yang, P. Semiconductor nanowire lasers. Nat. Rev. Mater. 2016, 1, 16028. [Google Scholar] [CrossRef]

| (min) | L (µm) | |||

|---|---|---|---|---|

| 60 | 80 ± 10 | 54 ± 9 | 4.00 ± 0.36 | 2.15 |

| 120 | 79 ± 10 | 97 ± 15 | 7.33 ± 0.54 | 2.11 |

| 130 | 78 ± 10 | 111 ± 14 | 8.54 ± 0.6 | 2.09 |

| 310 | 82 ± 21 | 216 ± 45 | 25.69 ± 0.6 | 2.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fedorov, V.V.; Berdnikov, Y.; Sibirev, N.V.; Bolshakov, A.D.; Fedina, S.V.; Sapunov, G.A.; Dvoretckaia, L.N.; Cirlin, G.; Kirilenko, D.A.; Tchernycheva, M.; et al. Tailoring Morphology and Vertical Yield of Self-Catalyzed GaP Nanowires on Template-Free Si Substrates. Nanomaterials 2021, 11, 1949. https://doi.org/10.3390/nano11081949

Fedorov VV, Berdnikov Y, Sibirev NV, Bolshakov AD, Fedina SV, Sapunov GA, Dvoretckaia LN, Cirlin G, Kirilenko DA, Tchernycheva M, et al. Tailoring Morphology and Vertical Yield of Self-Catalyzed GaP Nanowires on Template-Free Si Substrates. Nanomaterials. 2021; 11(8):1949. https://doi.org/10.3390/nano11081949

Chicago/Turabian StyleFedorov, Vladimir V., Yury Berdnikov, Nickolay V. Sibirev, Alexey D. Bolshakov, Sergey V. Fedina, Georgiy A. Sapunov, Liliia N. Dvoretckaia, George Cirlin, Demid A. Kirilenko, Maria Tchernycheva, and et al. 2021. "Tailoring Morphology and Vertical Yield of Self-Catalyzed GaP Nanowires on Template-Free Si Substrates" Nanomaterials 11, no. 8: 1949. https://doi.org/10.3390/nano11081949

APA StyleFedorov, V. V., Berdnikov, Y., Sibirev, N. V., Bolshakov, A. D., Fedina, S. V., Sapunov, G. A., Dvoretckaia, L. N., Cirlin, G., Kirilenko, D. A., Tchernycheva, M., & Mukhin, I. S. (2021). Tailoring Morphology and Vertical Yield of Self-Catalyzed GaP Nanowires on Template-Free Si Substrates. Nanomaterials, 11(8), 1949. https://doi.org/10.3390/nano11081949